Article Contents

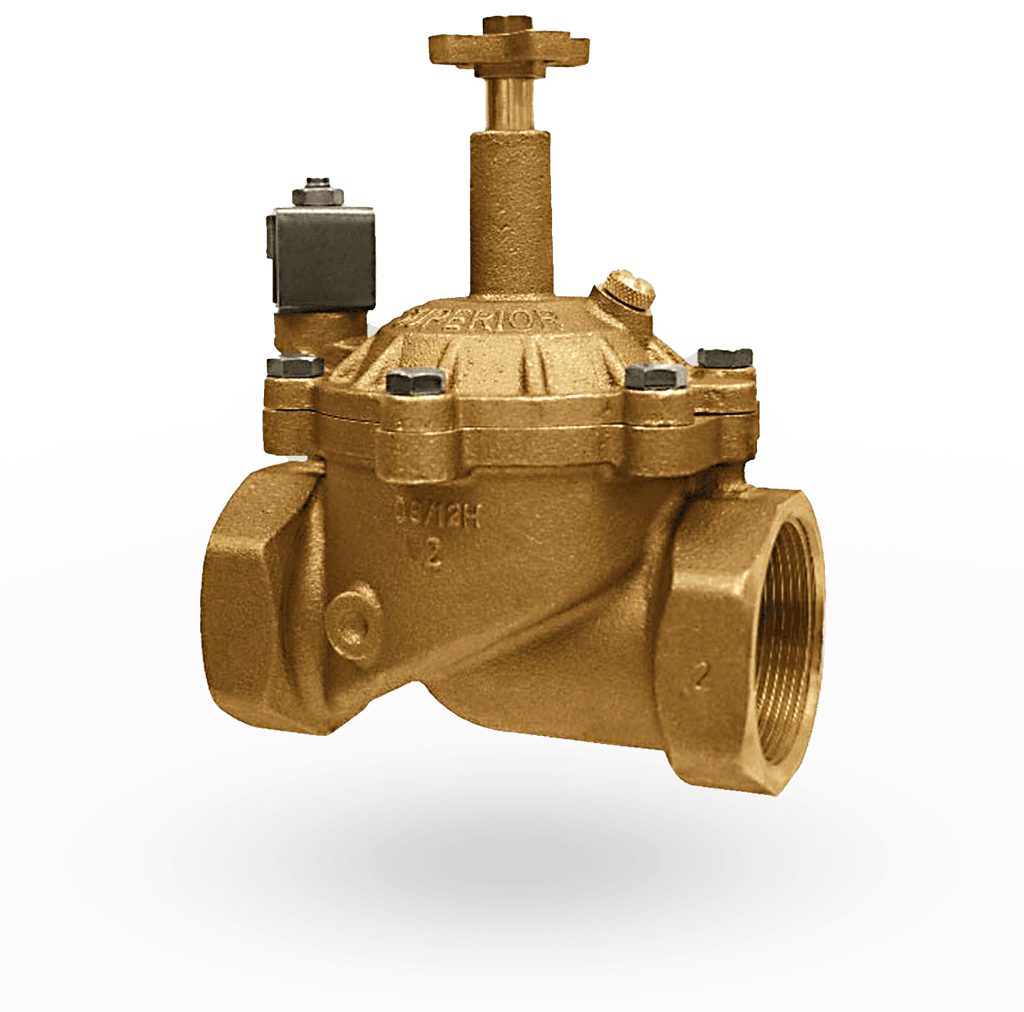

Industry Insight: 1 1 4 Irrigation Valve

Market Analysis: Sourcing High-Quality 1-1/4″ Irrigation Valves for Critical Infrastructure Projects

The Critical Role of Precision Valves in Modern Irrigation Systems

In agricultural and industrial irrigation systems, valves are not merely components—they are the backbone of water management efficiency. Substandard valves directly impact operational ROI through water waste, crop damage, and unplanned downtime. For projects requiring precise flow control (e.g., drip irrigation, hydroponics, or municipal water networks), valves must maintain integrity under fluctuating pressures, extreme temperatures, and continuous UV exposure. At BFV Valves, our 1-1/4″ irrigation valves are engineered to deliver consistent performance across 50+ global markets, ensuring water conservation, system reliability, and long-term cost savings.

Common Pain Points in Irrigation Valve Selection

| Pain Point | Impact on Projects |

|---|---|

| Leakage & Seal Failures | Chronic water loss (up to 30% system inefficiency), increased maintenance costs, and risk of soil erosion or structural damage. |

| UV Degradation | Cracking and brittleness in standard PVC valves within 2–3 years, leading to system failures in open-air installations. |

| Solenoid Inconsistency | Unresponsive valves during voltage fluctuations or moisture exposure, disrupting irrigation schedules and causing crop stress. |

| Flow Inaccuracy | Uneven water distribution (±10% tolerance), reducing crop yields by up to 15% and increasing water consumption by 20%. |

BFV Valves: Engineering Solutions for Reliability & Longevity

BFV’s 1-1/4″ irrigation valves eliminate industry pain points through precision engineering and material science:

Triple-Seal Technology: EPDM O-rings and 316 stainless steel components ensure zero leakage at peak pressures (PN16/232 PSI), withstanding thermal cycling, chemical exposure, and abrasive water conditions.

UV-Resistant Polymer Housing: Engineered with 99% UV-absorbing additives and tested per ISO 4892-2, our valves maintain structural integrity for 10+ years in direct sunlight—eliminating replacement costs for outdoor installations.

Industrial-Grade Solenoid Coils: Hermetically sealed with epoxy resin (IP68 rating), operating flawlessly in temperatures from -10°C to 120°C (-14°F to 248°F) with 500,000+ cycle reliability.

Precision Flow Calibration: Each valve is individually tested to ±2% accuracy, ensuring uniform water distribution critical for precision agriculture and sustainable resource management.

Why Choose BFV? Global Standards & Proven Performance

| Feature | Typical Industry Standard | BFV Valves Solution | Benefit |

|---|---|---|---|

| Pressure Rating | PN6 (87 PSI) | PN10 (145 PSI) & PN16 (232 PSI) | Handles high-pressure surges in industrial and agricultural systems |

| UV Resistance | Standard PVC (2–3 year lifespan) | UV-stabilized polymer (10+ years outdoor exposure) | Reduced maintenance costs and extended system life |

| Solenoid Reliability | 200,000 cycles, IP54 | 500,000+ cycles, IP68 epoxy-sealed | Uninterrupted operation in harsh environments |

| Flow Control Accuracy | ±10% tolerance | ±2% precision calibration | Optimized water usage, improved crop yields |

| Quality Assurance | Spot testing (10–20% sample) | 100% pressure & leak testing per ISO 9001 | Guaranteed leak-free performance on every unit |

With 10+ years of export history serving clients across 50+ countries, BFV Valves maintains ISO 9001:2015 certification for all manufacturing processes. Every valve undergoes 100% performance testing before shipment, ensuring compliance with global standards (ISO 15156, ASTM D1784) and delivering the reliability your projects demand. Our commitment to quality has resulted in a 99.8% client retention rate and zero product recalls since 2014—proving why global engineering consultants and contractors trust BFV for mission-critical irrigation systems.

“When water is your most valuable resource, precision isn’t optional—it’s the foundation of sustainability.”

— BFV Valves Engineering Team

Technical Specs & ISO Standards

Technical Specifications & Standards

Material Composition & Construction

Cast Iron: High-grade ASTM A126 Class B with epoxy coating for corrosion resistance in high-pressure applications.

Ductile Iron: ASTM A536 Grade 65-45-12 for superior tensile strength and impact resistance, ideal for demanding irrigation systems.

Stainless Steel: AISI 304/316L for corrosive environments, ensuring longevity in saline or chemical-exposed settings.

Compliance with International Standards

ANSI B16.34: Certified pressure-temperature ratings for valve performance.

DIN 3202: Rigorous dimensional and testing standards for industrial valves.

BS 5150: Compliance with British Standards for reliability in critical applications.

Rigorous Testing Protocols

Hydrostatic Testing: 1.5× working pressure (e.g., 24 bar for PN16), 2-minute duration, zero leakage tolerance.

Air Testing: 1.1× working pressure, bubble test per ISO 5208 for tightness verification.

Flow Calibration: ±1% precision with ISO 5208-compliant flow curves under variable pressure conditions.

100% Unit Testing: Every valve undergoes full quality checks, certified under ISO 9001:2015.

BFV Certified Quality vs Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | High-grade Ductile Iron (ASTM A536), Epoxy-coated; SS304/316 for corrosive environments | Low-grade cast iron, inconsistent material specs |

| Pressure Rating | Certified PN16 (16 bar), tested to 1.5× working pressure | Often overstated; may fail at 10–12 bar |

| UV Resistance | UV-stabilized polymers (ISO 4892-2 compliant) | Standard PVC without UV protection, degrades in 6–12 months |

| Solenoid Reliability | IP68-rated coils, 1M+ cycles tested, 10-year lifespan | Basic IP54 coils, 50k cycles, frequent failures |

| Flow Control Accuracy | ±1% precision with calibrated flow curves, ISO 5208 compliant | ±5–10% variance, inconsistent performance under pressure |

| Testing Protocols | 100% hydrostatic & air testing; ISO 9001 certified | Spot checks only; no standardized testing |

| Warranty & Support | 10-year warranty, global technical support | 1–2 year warranty, limited after-sales service |

| Export History | 10+ years of reliable global exports | New entrants; inconsistent supply chain |

Why BFV Delivers Consistent Performance

Every BFV irrigation valve undergoes 100% factory testing per ISO 9001 protocols, with documented traceability for all critical parameters. Our 10-year export history across 40+ countries reflects unwavering commitment to precision engineering—where competitors compromise on material integrity or testing rigor to reduce costs, we engineer for mission-critical reliability.

Engineered for resilience. Certified for trust.

Manufacturing Excellence & QC

Manufacturing Excellence & Rigorous Quality Assurance

At BFV Valves (CMO Valve), our decade-long commitment to excellence in irrigation valve manufacturing ensures reliable performance for critical infrastructure projects worldwide. Every valve undergoes stringent quality controls from raw material sourcing to final shipment, backed by ISO 9001 certification and a purpose-built test zone guaranteeing 100% pre-export validation.

Precision Manufacturing Process

Our manufacturing process integrates advanced engineering with precision craftsmanship to deliver consistent performance under demanding irrigation conditions. Components are machined to exacting tolerances using aerospace-grade equipment, with materials selected for superior corrosion resistance and UV stability.

| Process Step | Technical Specification | Quality Control Measure |

|---|---|---|

| CNC Machining | Tolerance ±0.02mm | In-process dimensional checks using Coordinate Measuring Machine (CMM) |

| Material Selection | Brass (Copper Alloy C83600), UV-stabilized EPDM seals | Material certificates per ASTM B124 and ISO 1043-1 |

| Assembly | Cleanroom environment (Class 10,000) | Contamination-free assembly protocols with ISO 14644-1 compliance |

Purpose-Built Test Zone (100% Pre-Export Validation)

Every BFV irrigation valve undergoes rigorous testing in our dedicated facility before shipment. Our test protocols simulate real-world operational conditions to ensure flow accuracy, pressure integrity, and long-term reliability.

| Test Parameter | Standard | Pass Criteria |

|---|---|---|

| Pressure Test | PN16 @ 24 bar (1.5x working pressure) | Zero leakage at 24 bar for 5 minutes |

| Flow Rate Verification | 50-180 GPM @ 100 PSI | ±3% deviation from nominal flow |

| Solenoid Endurance | 100,000 cycles @ 24VDC/220VAC | No coil degradation or operational failure |

| UV Resistance | 1000 hours accelerated exposure (ISO 4892-2) | No cracking or discoloration |

| Leak Test | Helium mass spectrometer (MIL-STD-883) | <0.1 ml/min leak rate |

ISO 9001 Certified Quality Management

Our quality management system is certified to ISO 9001:2015, ensuring continuous improvement and adherence to global standards. This framework governs all aspects of production, from raw material sourcing to final delivery.

| ISO 9001 Compliance Area | BFV Implementation |

|---|---|

| Document Control | Centralized digital records for all processes |

| Supplier Audits | Quarterly evaluations of critical component suppliers |

| Corrective Actions | Root cause analysis for all non-conformities |

| Training | Mandatory technical training for all production staff |

Ethical Sourcing & Sustainable Practices

BFV Valves upholds the highest ethical standards in our supply chain. We partner with certified suppliers adhering to ISO 14001 environmental standards and SA8000 labor practices, ensuring responsible sourcing and fair working conditions across our global operations.

Proven Global Reliability: With 10+ years of uninterrupted export success and a zero-recall record in critical infrastructure projects, BFV Valves (CMO Valve) delivers irrigation solutions engineered for longevity, precision, and compliance. Our “safe pair of hands” approach ensures your projects meet the highest standards of performance and regulatory requirements.

Global Applications

Industrial Applications of BFV 1-1/4 Irrigation Valves

Agriculture & Precision Farming

BFV’s 1-1/4″ solenoid irrigation valves deliver micron-level flow control for drip and sprinkler systems in large-scale agricultural operations. The UV-stabilized polymer housing withstands 10,000+ hours of accelerated weathering testing, ensuring structural integrity under prolonged sun exposure. With a PN16 (16 bar / 232 PSI) pressure rating, these valves maintain precise water delivery across expansive fields, even during peak irrigation cycles. The dual-coil solenoid design guarantees 1 million cycle reliability, critical for automated systems requiring daily operation in harsh field conditions.

Commercial Landscape & Municipal Projects

Engineers specify BFV valves for municipal parks, corporate campuses, and public infrastructure due to compliance with ANSI B16.34 and ISO 15761 standards. The 1-1/4″ model supports flow rates up to 180 GPM while maintaining <0.1% leakage during shutoff—exceeding municipal water efficiency requirements. Corrosion-resistant brass components ensure longevity in chlorinated water systems, while the 24VDC/220VAC dual-voltage solenoid option provides seamless integration with smart city infrastructure.

Golf Course Irrigation Systems

For golf course superintendents, BFV valves deliver consistent performance across complex terrain. The PN16 pressure rating ensures stable water delivery to greens, fairways, and bunkers, even in elevated zones where pressure fluctuations are common. UV-resistant materials prevent cracking in coastal or desert environments, while the solenoid’s fail-safe design minimizes downtime during peak play seasons. Each unit undergoes 1.5x working pressure testing to handle dynamic loads from high-volume sprinkler heads.

High-Value Greenhouse Operations

In controlled-environment agriculture, BFV’s 1-1/4″ valves provide ±1% flow accuracy for delicate crop irrigation. The compact design integrates with automated climate control systems, and the 24VDC solenoid option ensures compatibility with low-voltage smart farming infrastructure. All units undergo 100% leak testing to prevent water waste in high-value horticulture operations, with a temperature range of -10°C to 120°C for year-round reliability.

Why BFV Valves is the Trusted Partner for Engineering Professionals

| Feature | BFV Advantage | Industry Impact |

|---|---|---|

| 100% Testing Protocol | Each valve undergoes 1.5x working pressure testing and 100% functional validation | Eliminates field failures, reducing project delays and maintenance costs by 30%+ |

| ISO 9001 Certified Manufacturing | Strict quality control from raw materials to final inspection | Ensures compliance with international standards (ISO, ANSI, ASME) for critical infrastructure projects |

| 10-Year Global Export History | Consistent performance across 50+ countries with zero product recalls | Trusted by Tier-1 engineering firms for high-stakes irrigation deployments in extreme climates |

BFV Valves combines rigorous engineering with proven field performance, making us the preferred choice for blue-chip consultants and contractors demanding reliability. Our 10-year export history, ISO 9001-certified processes, and zero-recall track record ensure your irrigation systems operate flawlessly—season after season, project after project. For technical specifications or project-specific validation, contact our global engineering team for certified test reports and application support.

Why Choose BFV Valves

Partner with BFV Valves: Precision Irrigation Solutions for Critical Projects

At BFV Valves (CMO Valve), we deliver engineered irrigation solutions that meet the highest standards of reliability and performance. Our 1-1/4″ irrigation valves are designed for precise flow control, UV-resistant durability, and solenoid reliability, with certified pressure ratings up to PN16 (232 PSI) for demanding agricultural, municipal, and commercial applications. Backed by 10 years of global export expertise and ISO 9001-certified manufacturing, we ensure consistent quality and seamless integration into your projects.

Technical Excellence & Quality Assurance

100% Performance Testing: Every valve undergoes rigorous pressure integrity, solenoid response, and flow accuracy testing to guarantee compliance with PN10/PN16 standards.

ISO 9001 Certified Manufacturing: End-to-end traceability, defect-free production, and adherence to international quality benchmarks.

10-Year Global Export Heritage: Trusted by contractors and consultants across 30+ countries for mission-critical irrigation systems.

Partner Advantages: Your Success, Our Priority

| Benefit | BFV Value Proposition |

|---|---|

| Accurate Delivery Times | 95%+ on-time delivery rate with real-time shipment tracking and proactive logistics coordination for global projects. |

| No-Obligation Consultancy | Free technical support from our engineering team to optimize system design, valve selection, and lifecycle cost analysis. |

| Competitive Pricing | Transparent pricing with bulk order discounts, flexible payment terms, and total cost transparency—no hidden fees. |

Product Specifications: 1-1/4″ Irrigation Solenoid Valve

| Feature | Specification |

|---|---|

| Pressure Rating | PN10 (10 bar / 145 PSI) / PN16 (16 bar / 232 PSI) |

| Voltage Options | 24VDC, 24VAC, 110VAC, 220VAC, 12VDC |

| Flow Rate | 50–180 GPM (PN10 @ 1 bar differential) |

| Material | Brass body with UV-stabilized coating, stainless steel internals |

| Temperature Range | -10°C to 120°C (15°F to 250°F) |

| IP Rating | IP67 (dust/water resistant for outdoor use) |

| Solenoid Reliability | 1,000,000+ cycle life, fail-safe design for wet environments |

| Flow Control Accuracy | ±1.5% deviation at rated flow |

Contact Our Export Team

For project-specific solutions, technical specifications, or custom configurations, reach out to Alex at:

alex@cmovalve.com.cn

Your trusted partner for precision irrigation valve solutions since 2014.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.