Introduction: Navigating the Global Market for 12 volt irrigation primer pump

In the quest to enhance irrigation efficiency, sourcing a reliable 12 volt irrigation primer pump presents a significant challenge for international B2B buyers. With varying agricultural needs and environmental conditions across regions such as Africa, South America, the Middle East, and Europe, selecting the right pump is crucial for optimizing water management and ensuring the longevity of irrigation systems. This guide offers a comprehensive exploration of 12 volt irrigation primer pumps, detailing various types, applications, and essential considerations for supplier vetting.

Buyers will gain insights into the operational benefits of these pumps, including their portability, energy efficiency, and ability to function in remote locations powered by 12-volt batteries. Additionally, the guide covers critical aspects such as cost analysis, maintenance requirements, and the potential for integrating renewable energy solutions, making it an invaluable resource for informed purchasing decisions. By addressing the unique challenges faced by different markets, this guide empowers businesses to choose the right equipment tailored to their operational needs, ultimately leading to improved agricultural productivity and sustainability.

Whether you’re looking to enhance irrigation capabilities in arid regions or streamline water transfer processes, this guide will equip you with the knowledge necessary to navigate the global market for 12 volt irrigation primer pumps confidently.

Understanding 12 volt irrigation primer pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable 12 DC Volt Pump Primer | Lightweight aluminum frame; high vacuum capability (24 in. Hg); designed for steep suction pipes. | Priming pumps in agricultural irrigation and chemical spraying. | Pros: Easy to transport; efficient for long suction lines. Cons: Requires a high-amperage battery. |

| 12 Volt Power Primer | High C.F.M. (30 CFM); compact design; can use renewable energy sources. | General irrigation, chemical spraying, and emergency water transfer. | Pros: Versatile and energy-efficient; quick priming. Cons: Initial cost may be higher than manual options. |

| Hand Diaphragm Pump | Manual operation; lightweight; suitable for smaller pumps. | Ideal for smaller irrigation setups and emergency priming. | Pros: Cost-effective; no electricity needed. Cons: Labor-intensive and slower than electric options. |

| Electric Primer Pump | Automatic operation; timer and flow switch features; designed for high suction lifts. | Suitable for large-scale irrigation systems and industrial applications. | Pros: Reduces wear on pumps; efficient for large setups. Cons: Higher upfront investment; may require more maintenance. |

| DC and AC Hybrid Primers | Dual power options (DC and AC); adaptable for various pump types. | Versatile applications in mixed-use environments and diverse farming needs. | Pros: Flexibility in power source; suitable for multiple applications. Cons: Complexity in setup; may require additional components. |

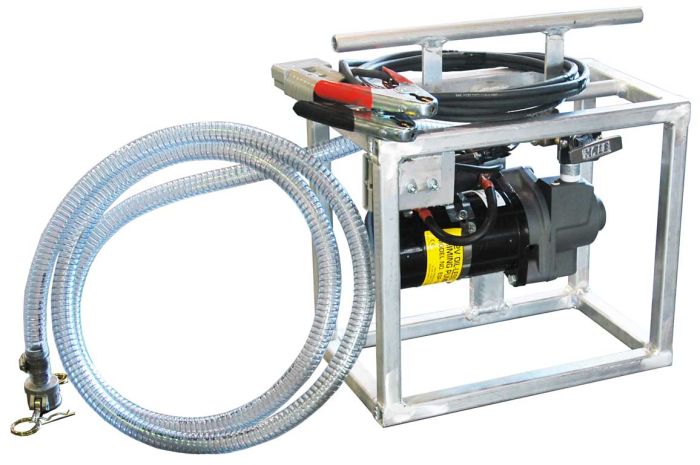

What are the Characteristics of Portable 12 DC Volt Pump Primers?

Portable 12 DC Volt Pump Primers are designed for high efficiency in challenging conditions, particularly where traditional power sources are unavailable. Their lightweight aluminum frames facilitate easy transport, making them ideal for remote agricultural sites. With a maximum vacuum capability of 24 in. Hg, they excel in priming pumps with long or steep suction lines, ensuring reliable operation in various irrigation and chemical applications. Buyers should consider the need for a high-amperage battery, which may add to overall operational costs.

How Does the 12 Volt Power Primer Enhance Efficiency?

The 12 Volt Power Primer is characterized by its ability to deliver a high flow rate of 30 CFM, which makes it suitable for quickly priming irrigation pumps and other applications. Its compact design allows for easy installation and mobility, while compatibility with renewable energy sources adds an eco-friendly dimension. This type is particularly beneficial for B2B buyers looking for versatility and energy efficiency in their irrigation solutions. However, the initial investment may be higher compared to manual alternatives.

Why Choose a Hand Diaphragm Pump for Smaller Applications?

Hand Diaphragm Pumps are manually operated and particularly useful for smaller irrigation setups. They are lightweight and do not require electricity, making them an excellent choice for emergency priming or in regions with limited power access. While they are cost-effective and easy to maintain, their manual operation can be labor-intensive and slower compared to electric options. B2B buyers should weigh the benefits of lower costs against the potential for increased labor requirements.

What Advantages Do Electric Primer Pumps Offer?

Electric Primer Pumps are designed for automatic operation, featuring timers and flow switches that enhance efficiency, particularly in large-scale irrigation systems. They are ideal for high suction lifts and can significantly reduce wear on pumps, making them a smart investment for industrial applications. While the upfront costs may be higher, the efficiency and reduced maintenance needs often justify the investment. B2B buyers should consider their specific irrigation needs and operational scale when evaluating this option.

How Do DC and AC Hybrid Primers Provide Versatility?

DC and AC Hybrid Primers are adaptable solutions that allow users to switch between power sources, making them suitable for various applications in mixed-use environments. Their flexibility enables farmers and businesses to respond to different operational needs efficiently. However, the complexity of setup and potential need for additional components can be a drawback. Buyers should assess their specific requirements and existing infrastructure to determine if a hybrid primer aligns with their operational goals.

Key Industrial Applications of 12 volt irrigation primer pump

| Industry/Sector | Specific Application of 12 volt irrigation primer pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Priming irrigation pumps for crop watering | Ensures consistent water flow, enhancing crop yields | Compatibility with local pump systems and voltage requirements |

| Horticulture | Priming pumps for chemical spraying in nurseries | Improves efficiency in pest and nutrient management | Durability to withstand chemicals and weather conditions |

| Construction | Pumping water for site dewatering or irrigation in landscaping projects | Reduces labor costs and downtime in construction | Portability and ease of setup for remote job sites |

| Mining | Priming pumps for water transfer in mineral processing | Facilitates efficient water management in operations | High suction lift capabilities for deep or steep gradient applications |

| Firefighting | Quick priming of pumps for emergency water supply | Enhances response time in emergencies | Reliability and quick priming capabilities under pressure |

How is the 12 Volt Irrigation Primer Pump Used in Agriculture?

In the agriculture sector, the 12 volt irrigation primer pump is essential for priming irrigation systems that deliver water to crops. It ensures a consistent flow of water, which is critical for maximizing crop yields. By automating the priming process, farmers can reduce manual labor and minimize downtime, particularly in regions with unreliable power sources. International buyers should consider the compatibility of the pump with existing irrigation systems and local voltage requirements to ensure seamless integration.

What Role Does the 12 Volt Primer Pump Play in Horticulture?

In horticulture, the 12 volt irrigation primer pump is used to prime pumps that spray chemicals for pest control and fertilization in nurseries. This application is vital for maintaining plant health and optimizing growth conditions. The efficiency gained from quick priming translates to better resource management and reduced chemical waste. Buyers should prioritize pumps with corrosion-resistant materials to withstand exposure to various chemicals and environmental conditions.

How is the 12 Volt Pump Beneficial for Construction Projects?

For the construction industry, the 12 volt irrigation primer pump is invaluable for dewatering sites and irrigating landscaping projects. It significantly reduces labor costs and project delays by providing a reliable water source. The portability of these pumps allows for easy transport to remote job sites, making them ideal for various construction applications. Buyers should look for features like lightweight design and robust construction to ensure durability in challenging environments.

What is the Importance of the 12 Volt Primer Pump in Mining Operations?

In mining, the 12 volt irrigation primer pump is used to manage water transfer during mineral processing. It helps facilitate efficient water management, which is crucial for operational productivity. The pump’s high suction lift capabilities are particularly advantageous in situations involving deep or steep gradients. International B2B buyers should consider the pump’s performance specifications to ensure it meets the demanding requirements of mining operations.

How Does the 12 Volt Primer Pump Support Firefighting Efforts?

The 12 volt irrigation primer pump is critical in firefighting scenarios, where quick access to water can mean the difference between containment and disaster. It enables firefighters to prime pumps rapidly, ensuring a swift response to emergencies. The reliability and efficiency of these pumps are essential under pressure, making them indispensable for firefighting operations. Buyers should focus on sourcing pumps that offer consistent performance and ease of use in high-stress situations.

3 Common User Pain Points for ’12 volt irrigation primer pump’ & Their Solutions

Scenario 1: Difficulties in Priming Pumps in Remote Locations

The Problem: Many B2B buyers in agriculture and irrigation sectors face the challenge of priming pumps in remote areas where access to electricity is limited. This situation is particularly common in regions of Africa and South America, where farms may be located far from power sources. Hand pumping is often labor-intensive and inefficient, leading to increased downtime and operational costs. Additionally, long suction lines and steep gradients can complicate the priming process, making it even more frustrating for operators who need reliable water flow to sustain their crops.

The Solution: To address this issue, buyers should consider investing in a high-quality 12 volt irrigation primer pump specifically designed for portability and efficiency. These pumps can operate on a standard 12-volt battery, making them ideal for use in remote locations. When sourcing a primer pump, look for models with a robust design that can handle long suction lines and steep gradients, such as those equipped with a powerful DC motor capable of delivering high suction lift. It’s essential to ensure the pump comes with necessary accessories, such as a clear hose and connectors, to facilitate easy installation. Regular maintenance, including checking for air leaks and ensuring the oil reservoir is filled with the correct non-detergent oil, will also enhance the pump’s performance and longevity.

Scenario 2: Inconsistent Priming Performance Leading to Crop Damage

The Problem: Buyers often encounter issues with inconsistent priming performance, which can lead to dry running of pumps. This is a significant concern for B2B buyers in irrigation as it can damage expensive pump equipment and result in reduced crop yields. In regions like the Middle East, where water is scarce, even a brief interruption in irrigation can have devastating effects on crops, making reliable pump operation critical.

The Solution: To mitigate this risk, it is crucial to select a 12 volt irrigation primer pump that offers consistent and reliable performance. Buyers should seek models that provide clear performance metrics such as suction lift capabilities and pumping speed. Implementing a timer switch or flow switch can enhance operational efficiency by automatically shutting off the pump once it is adequately primed. Furthermore, conducting regular maintenance checks, including the inspection of suction lines for leaks and ensuring the pump is free of air pockets, can significantly improve priming efficiency. Training staff on the correct operation of the primer pump will also ensure that they can quickly troubleshoot any issues that arise, maintaining optimal irrigation practices.

Scenario 3: High Operational Costs Due to Inefficient Equipment

The Problem: Another common pain point for B2B buyers is the high operational costs associated with inefficient priming methods and equipment. In many regions, especially in Europe, the focus on sustainability and cost-effectiveness is becoming increasingly important. Businesses often find themselves spending excessive amounts on labor and energy costs due to outdated or poorly functioning pump systems.

The Solution: Transitioning to a modern 12 volt irrigation primer pump can significantly reduce these operational costs. Buyers should look for energy-efficient models that require low power consumption while delivering high performance. Additionally, consider integrating renewable energy sources, such as solar panels, to power the primer pump, which can further cut down on electricity expenses. When evaluating options, it is beneficial to compare the total cost of ownership, including purchase price, energy consumption, and maintenance needs. Opting for a pump with a durable design, built to withstand harsh environmental conditions, will minimize repair costs and downtime, ultimately leading to a more sustainable and cost-effective irrigation solution. Regular training sessions for operators on best practices for using and maintaining the pump can also help in maximizing efficiency and reducing long-term costs.

Strategic Material Selection Guide for 12 volt irrigation primer pump

What Are the Key Materials Used in 12 Volt Irrigation Primer Pumps?

When selecting a 12 volt irrigation primer pump, the choice of materials significantly impacts performance, durability, and application suitability. Below, we analyze four common materials used in the manufacturing of these pumps, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Enhance the Performance of 12 Volt Irrigation Primer Pumps?

Aluminum is widely used in the construction of 12 volt irrigation primer pumps due to its lightweight and corrosion-resistant properties. It typically has a temperature rating of up to 150°C and can handle moderate pressure levels.

Pros: Aluminum’s lightweight nature makes it easy to transport and install. It also has excellent resistance to rust and oxidation, which is beneficial in humid or wet environments.

Cons: While durable, aluminum can be less robust than other metals under extreme pressure, which may limit its use in high-demand applications. Additionally, the cost of aluminum can be higher than some alternatives, impacting overall production costs.

Impact on Application: Aluminum is compatible with various media, including water and non-corrosive chemicals. However, it may not be suitable for highly acidic or alkaline substances.

International Considerations: Buyers from regions such as Africa and South America should ensure that the aluminum used meets local standards for corrosion resistance, particularly in coastal areas where saltwater exposure is a concern.

What Role Does Stainless Steel Play in 12 Volt Irrigation Primer Pumps?

Stainless steel is another popular choice for components in 12 volt irrigation primer pumps, particularly for parts exposed to higher stress or corrosive environments. It can withstand temperatures up to 300°C and offers excellent pressure ratings.

Pros: Stainless steel is known for its strength and durability, making it ideal for high-pressure applications. It also has superior corrosion resistance, which is crucial for pumps operating in harsh conditions.

Cons: The primary drawback is the cost; stainless steel is generally more expensive than aluminum or plastic. Additionally, its weight can make the pump less portable.

Impact on Application: Stainless steel is compatible with a wide range of liquids, including corrosive chemicals. However, its weight may be a disadvantage in applications requiring frequent transport.

International Considerations: Buyers should verify that the stainless steel used complies with international standards like ASTM or DIN, particularly in regions such as Europe where material specifications are stringent.

How Does Plastic Compare for 12 Volt Irrigation Primer Pumps?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is often used in non-structural components of 12 volt irrigation primer pumps. These materials can handle temperatures up to 80°C and moderate pressure.

Pros: Plastic is lightweight and cost-effective, reducing overall manufacturing costs. It also offers good chemical resistance, making it suitable for various applications.

Cons: Plastic is generally less durable than metal and may degrade over time, especially when exposed to UV light or extreme temperatures.

Impact on Application: While plastic is suitable for non-corrosive liquids, it may not be ideal for high-temperature or high-pressure applications.

International Considerations: B2B buyers should ensure that the plastic materials used meet relevant health and safety regulations, especially in agricultural applications where chemical exposure is a concern.

What Advantages Does Brass Provide in 12 Volt Irrigation Primer Pumps?

Brass is commonly used for fittings and valves in 12 volt irrigation primer pumps due to its excellent machinability and resistance to corrosion. It can handle temperatures up to 200°C and moderate pressure levels.

Pros: Brass is durable and offers good resistance to rust, making it suitable for outdoor applications. Its ease of machining allows for precise component fabrication.

Cons: The primary limitation of brass is its cost, which can be higher than plastic and aluminum. Additionally, it may not be suitable for certain aggressive chemicals.

Impact on Application: Brass components are compatible with water and many non-corrosive liquids but may react with acidic substances.

International Considerations: Buyers should check for compliance with international standards, especially in regions with strict regulations on materials used in agricultural applications.

Summary Table of Material Selection for 12 Volt Irrigation Primer Pumps

| Material | Typical Use Case for 12 volt irrigation primer pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components and frames | Lightweight and corrosion-resistant | Less robust under extreme pressure | Medium |

| Stainless Steel | High-pressure applications and corrosive environments | Superior strength and durability | Higher cost and weight | High |

| Plastic | Non-structural components | Cost-effective and lightweight | Less durable and UV sensitive | Low |

| Brass | Fittings and valves | Good machinability and corrosion resistance | Higher cost and potential chemical reactivity | Medium |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in 12 volt irrigation primer pumps, enabling informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 12 volt irrigation primer pump

What Are the Main Stages in the Manufacturing Process of a 12 Volt Irrigation Primer Pump?

The manufacturing process of a 12 volt irrigation primer pump consists of several key stages that ensure the product’s performance, reliability, and compliance with industry standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Manufacturing 12 Volt Irrigation Primer Pumps?

Material preparation begins with sourcing high-quality components that can withstand the rigors of agricultural environments. Common materials include:

- Aluminum: Often used for the frame due to its lightweight and corrosion-resistant properties.

- Plastic: Used for housing and control components, selected for durability and resistance to chemicals.

- Rubber and Seals: Critical for ensuring that the pumps are leak-proof and can handle various fluids.

Suppliers should be vetted for material quality, ensuring they comply with international standards like ISO 9001. This involves obtaining certificates of compliance and material safety data sheets (MSDS) for all components.

What Forming Techniques Are Used in Producing 12 Volt Pumps?

Once materials are prepared, forming techniques are employed to shape the components. Common techniques include:

- CNC Machining: Utilized for precision parts such as pump housings and control valves. CNC machines ensure that components are manufactured to exact specifications, which is vital for performance.

- Injection Molding: Used for plastic components, this technique allows for high-volume production with consistent quality and intricate designs.

- Stamping and Die-Cutting: These methods are employed for metal parts, creating components like brackets and mounting plates.

Each forming technique is carefully selected based on the desired characteristics of the final product, ensuring that the pumps can efficiently handle varying operational demands.

How Are 12 Volt Irrigation Primer Pumps Assembled?

The assembly stage is where all the components come together. It typically involves:

- Sub-Assembly: Individual parts such as the motor, pump casing, and control panel are assembled into sub-units. This allows for easier handling and quality checks.

- Final Assembly: Sub-assemblies are integrated into the final product. Skilled technicians ensure that all components fit perfectly, which is crucial for functionality and safety.

- Wiring and Electrical Connections: Attention to detail is vital in this phase to prevent electrical failures. Each connection is verified to ensure it meets electrical safety standards.

Training for assembly workers is essential, as the quality of assembly directly impacts the pump’s operational reliability.

What Finishing Processes Are Applied to 12 Volt Pumps?

The finishing stage enhances the pump’s durability and aesthetic appeal. This includes:

- Surface Treatment: Anodizing or powder coating aluminum parts to enhance corrosion resistance and prevent wear.

- Quality Inspection: Each pump undergoes a thorough inspection for defects in finish, fit, and function.

- Packaging: Pumps are carefully packaged to prevent damage during transportation, often using eco-friendly materials that align with international shipping standards.

Proper finishing techniques can significantly extend the lifespan of the pump, making them a valuable investment for buyers.

What Quality Assurance Measures Are Implemented for 12 Volt Pumps?

Quality assurance (QA) is critical in the manufacturing process, ensuring that the final product meets performance standards and customer expectations. Several international and industry-specific standards guide these QA practices.

Which International Standards Should Buyers Look For?

International standards like ISO 9001 are foundational for quality management systems across industries. For 12 volt irrigation primer pumps, compliance with CE marking and API standards can also be crucial, especially for buyers in Europe and the Middle East. These certifications indicate that the products meet safety and performance benchmarks.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure compliance with specifications.

- In-Process Quality Control (IPQC): Inspections during the manufacturing stages catch defects early. This may include measuring tolerances and testing the assembly of components.

- Final Quality Control (FQC): A comprehensive assessment is conducted on the finished product, including performance testing under operational conditions.

These checkpoints are critical for maintaining high standards and ensuring that every pump functions as intended.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

B2B buyers should conduct thorough due diligence when selecting suppliers. This can include:

- Supplier Audits: Regular audits of the supplier’s manufacturing facilities can provide insights into their quality assurance processes and adherence to standards.

- Reviewing Quality Reports: Requesting documentation such as quality control reports and compliance certificates can help verify a supplier’s claims.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality practices.

For international buyers, understanding local regulations and quality nuances is crucial. In regions like Africa and South America, varying levels of enforcement and compliance may exist, making it essential to partner with suppliers who demonstrate robust quality practices.

What Testing Methods Are Commonly Used for 12 Volt Irrigation Primer Pumps?

Common testing methods include:

- Performance Testing: Evaluating the pump’s ability to achieve required flow rates and suction capabilities under varying conditions.

- Electrical Testing: Ensuring that all electrical components function correctly and safely.

- Durability Testing: Subjecting pumps to stress tests to simulate real-world operating conditions, assessing their resilience to wear and tear.

These testing methods help ensure that the pumps not only meet but exceed customer expectations, reinforcing the buyer’s investment in quality.

Conclusion: Why Is Quality Assurance Critical for B2B Buyers of 12 Volt Pumps?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing and quality assurance processes behind 12 volt irrigation primer pumps is vital. It directly impacts not only the reliability and efficiency of agricultural operations but also long-term sustainability and cost-effectiveness. By prioritizing suppliers who adhere to rigorous quality standards and practices, buyers can ensure they are making informed decisions that will benefit their operations for years to come.

Practical Sourcing Guide: A Step-by-Step Checklist for ’12 volt irrigation primer pump’

The following guide serves as a comprehensive checklist for B2B buyers looking to procure a 12 volt irrigation primer pump. This step-by-step approach will help ensure that you make informed decisions throughout the sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as the pump’s flow rate, vacuum capability, power consumption, and compatibility with existing systems. Specify the length and type of suction lines to ensure the pump can handle the required tasks effectively.

- Flow Rate: Look for pumps that can deliver the necessary gallons per minute (GPM) for your irrigation needs.

- Vacuum Capability: Ensure the pump can create the required vacuum levels for your specific applications.

Step 2: Research Market Options

Conduct thorough research to identify available products in the market. Compare features, prices, and performance metrics from different manufacturers. Utilize online resources, industry forums, and trade publications to gather insights.

- Manufacturer Reputation: Focus on well-established brands known for quality and durability.

- Product Reviews: Read customer feedback to gauge real-world performance and reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. This step will help you assess their credibility and reliability.

- Certifications: Verify that suppliers comply with international quality standards and certifications relevant to your region.

- Customer Support: Ensure they offer adequate technical support and service options post-purchase.

Step 4: Request Detailed Quotations

Once you’ve narrowed down potential suppliers, request detailed quotations that outline all costs associated with the purchase. This should include the price of the pump, shipping, and any additional fees for installation or maintenance.

- Breakdown of Costs: Ensure the quote provides a clear breakdown of all costs to avoid hidden fees later.

- Bulk Purchase Discounts: Inquire about discounts for bulk purchases, especially if you plan to order multiple units.

Step 5: Assess Warranty and After-Sales Support

A robust warranty and reliable after-sales support can significantly affect the longevity and performance of your investment. Review the warranty terms and conditions to understand what is covered and for how long.

- Coverage Details: Look for warranties that cover parts and labor, as well as any specific conditions that may void the warranty.

- Support Channels: Ensure the supplier has accessible customer service channels for troubleshooting and assistance.

Step 6: Check for Renewable Energy Compatibility

Given the growing focus on sustainability, consider whether the pump can be powered by renewable energy sources, such as solar panels. This can reduce operational costs and enhance your environmental credentials.

- Energy Efficiency: Look for models with low power consumption to further reduce energy costs.

- Compatibility with Solar Systems: Ensure the pump is compatible with existing renewable energy setups if applicable.

Step 7: Finalize Purchase and Confirm Logistics

Once you’ve selected a supplier and agreed on terms, finalize the purchase. Confirm logistics, including shipping timelines and installation requirements, to ensure a smooth delivery and setup process.

- Shipping Arrangements: Clarify shipping methods and expected delivery dates to avoid delays.

- Installation Support: Inquire whether the supplier provides installation support or guidance to help you set up the pump efficiently.

By following these steps, B2B buyers can navigate the procurement process for a 12 volt irrigation primer pump with confidence, ensuring they choose a product that meets their operational needs effectively.

Comprehensive Cost and Pricing Analysis for 12 volt irrigation primer pump Sourcing

What Are the Key Cost Components for Sourcing a 12 Volt Irrigation Primer Pump?

When analyzing the cost structure for sourcing a 12 volt irrigation primer pump, several critical components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The main materials for these pumps include high-grade aluminum and various components like valves, motors, and hoses. The choice of materials can significantly affect the durability and performance of the pump, leading to variations in cost.

Labor: Labor costs will vary based on the region of manufacturing and the complexity of the assembly process. Skilled labor is often required for precise assembly and testing, especially for pumps designed for high suction lifts or specialized applications.

Manufacturing Overhead: This includes costs related to factory operations such as utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help minimize these costs.

Tooling: Initial setup costs for molds and specialized tools can be substantial, particularly for customized pumps. These costs are often amortized over larger production runs, making bulk orders more cost-effective.

Quality Control: Rigorous testing and inspection processes are essential to ensure product reliability, especially given the critical role of irrigation systems in agriculture. QC costs can add up but are necessary to prevent failures in the field.

Logistics: Transportation and shipping costs, influenced by distance and mode of transport, are significant in international sourcing. Buyers must also consider import duties and local taxes.

Margin: Suppliers typically add a profit margin that reflects the risk and investment involved in production. This margin can vary based on competition and market demand.

How Do Pricing Influencers Affect 12 Volt Irrigation Primer Pump Costs?

Several factors can influence the pricing of 12 volt irrigation primer pumps in the B2B market:

Volume/MOQ: Minimum order quantities (MOQ) significantly impact pricing. Larger orders often lead to reduced per-unit costs due to economies of scale, encouraging buyers to negotiate bulk purchases.

Specifications/Customization: Customized pumps with specific features or capabilities will generally cost more than standard models. Buyers should clearly define their requirements to avoid unexpected costs.

Materials: The choice of materials used in the pump construction can lead to price fluctuations. Premium materials may enhance performance but will increase overall costs.

Quality/Certifications: Pumps that meet specific international standards or possess certifications (like ISO) may command higher prices due to the assurance of quality and reliability.

Supplier Factors: Supplier reputation, reliability, and historical performance can affect pricing. Established suppliers may charge a premium, but their reliability can justify the cost.

Incoterms: The chosen shipping terms (like FOB, CIF) can influence final costs. Understanding these terms is essential for budget planning and can impact total landed costs.

What Tips Can Buyers Use to Negotiate Better Prices for 12 Volt Irrigation Primer Pumps?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management can lead to substantial savings:

Leverage Volume Discounts: When possible, consolidate orders to meet minimum order quantities and secure volume discounts.

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and potential downtime. A higher initial investment in a reliable pump can yield savings in the long run.

Negotiate Customization: If customization is required, discuss options that can meet your needs without significantly increasing costs. Sometimes, minor adjustments can make a product fit better without extensive modifications.

Investigate Supplier Options: Compare multiple suppliers to understand market rates. This information can be a powerful tool during negotiations.

Understand Pricing Nuances: Familiarize yourself with local market conditions and currency fluctuations, as these can impact pricing and negotiations.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier agreements, and specific buyer requirements. Always seek quotations from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing 12 volt irrigation primer pump With Other Solutions

When considering irrigation solutions, it’s essential to evaluate various methods that can efficiently achieve the desired outcomes. The 12 volt irrigation primer pump is a popular choice for farmers seeking reliable priming for their irrigation systems. However, understanding how it compares to alternative solutions can help B2B buyers make informed decisions tailored to their specific agricultural needs.

| Comparison Aspect | 12 Volt Irrigation Primer Pump | Alternative 1: Gas-Powered Primer Pump | Alternative 2: Hand Pump Primer |

|---|---|---|---|

| Performance | High suction lift, up to 30 CFM | Strong performance with high suction capabilities | Limited suction, slower operation |

| Cost | Approx. $1,425 | Approx. $2,000 – $3,000 | Approx. $150 – $300 |

| Ease of Implementation | Easy to install and operate with minimal training | Requires more setup time, including fuel management | Manual operation may require physical effort |

| Maintenance | Low maintenance, durable design | Regular maintenance needed for engine | Minimal maintenance, but may require manual upkeep |

| Best Use Case | Ideal for remote areas, quick priming | Suitable for larger farms with high demands | Best for small-scale operations or emergency use |

What Are the Advantages and Disadvantages of Gas-Powered Primer Pumps?

Gas-powered primer pumps are robust machines designed for heavy-duty applications. They deliver high suction capabilities and can handle long suction lines effectively. However, they require fuel, which can lead to additional operational costs and environmental concerns. Maintenance is also more demanding due to engine upkeep, making them less suitable for farmers looking for a low-maintenance solution. Despite these challenges, their performance in high-demand scenarios makes them a viable alternative for larger agricultural operations.

How Do Hand Pump Primers Compare?

Hand pump primers are a cost-effective solution, particularly for small-scale farms or emergency situations. They are lightweight and portable, making them easy to transport. However, their performance is limited when compared to electrical or gas-powered options, often requiring more manual labor and time to prime pumps. While they are lower in cost and maintenance, the reliance on human power can be a disadvantage in larger agricultural settings where efficiency is critical.

How Can B2B Buyers Choose the Right Solution?

When selecting an irrigation priming solution, B2B buyers should evaluate their specific operational needs, including the size of the farm, the distance of water sources, and the availability of power sources. The 12 volt irrigation primer pump is ideal for those needing portability and quick operation without the hassle of fuel or complex setups. In contrast, larger operations with extensive irrigation needs may benefit from gas-powered pumps despite their higher costs and maintenance requirements. Hand pump primers serve well in niche scenarios but may not be suitable for high-demand environments. Ultimately, understanding the unique demands of your agricultural practices will guide you in selecting the most effective priming solution.

Essential Technical Properties and Trade Terminology for 12 volt irrigation primer pump

What Are the Key Technical Properties of a 12 Volt Irrigation Primer Pump?

When considering the purchase of a 12 volt irrigation primer pump, understanding its technical specifications is crucial for ensuring optimal performance and compatibility with existing systems. Below are several key properties that buyers should evaluate:

Pumping Capacity (CFM)

The pumping capacity, typically measured in cubic feet per minute (CFM), indicates the volume of air the pump can move. For instance, a capacity of 30 CFM is common, allowing for quick priming of pumps. This specification is vital as it affects the efficiency of the priming process and the ability to handle various irrigation setups, especially in large-scale operations.Vacuum Pressure (inHg)

Vacuum pressure, measured in inches of mercury (inHg), reflects the pump’s ability to create a vacuum necessary for priming. A pump capable of achieving 24 inHg, for example, is suited for long or steep suction lines. This property is essential for ensuring that the pump can effectively draw water, minimizing the risk of dry running and potential damage.Material Composition

The materials used in the construction of the pump impact its durability and resistance to corrosion. Aluminum frames, often anodized for wear resistance, are favored for their lightweight nature and strength. Understanding the material grade helps buyers assess the pump’s longevity and suitability for harsh agricultural environments, particularly in regions with extreme weather conditions.Power Requirements (Amps)

The amp rating indicates the electrical current the pump requires to operate. Many 12 volt primer pumps operate at around 220 to 300 amps. Buyers should ensure that their power source can meet these requirements, as inadequate power can lead to reduced performance or equipment failure.Control Mechanism

Many modern pumps feature advanced control mechanisms, such as push-pull valves or remote operation capabilities. These controls can enhance user convenience and improve operational efficiency. For B2B buyers, understanding the control options available can lead to better integration with existing systems and reduce the need for manual intervention.

What Common Trade Terms Should B2B Buyers Know When Purchasing a 12 Volt Irrigation Primer Pump?

Navigating the technical specifications is just one part of the procurement process. Familiarity with industry terminology is equally important for making informed purchasing decisions.

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. In the context of irrigation pumps, understanding whether a product is OEM can influence quality expectations and warranty terms, which are critical for long-term investments.MOQ (Minimum Order Quantity)

MOQ refers to the minimum quantity a supplier is willing to sell. This term is crucial for B2B buyers as it impacts the overall cost and inventory management. Understanding the MOQ can help businesses plan their purchases effectively, especially when dealing with large-scale operations.RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. For buyers of irrigation equipment, submitting an RFQ can facilitate competitive pricing and enable better negotiation with multiple suppliers.Incoterms (International Commercial Terms)

Incoterms are predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for international buyers to understand their obligations and risks during shipping, particularly when sourcing from suppliers in different regions.Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times helps buyers plan their operations, especially in agriculture, where timing is critical for planting and irrigation schedules.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing 12 volt irrigation primer pumps, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 12 volt irrigation primer pump Sector

What Are the Key Trends Driving the 12 Volt Irrigation Primer Pump Market?

The 12 volt irrigation primer pump sector is witnessing significant growth driven by several global trends. One of the primary drivers is the increasing demand for efficient irrigation solutions, especially in regions heavily reliant on agriculture, such as Africa, South America, and parts of Europe and the Middle East. With the growing population and the subsequent rise in food demand, farmers are seeking technologies that enhance productivity while minimizing labor costs.

In addition, the trend towards automation in agriculture is influencing the market. Advanced pumping systems equipped with smart technology allow for remote monitoring and management, making it easier for farmers to optimize their irrigation processes. The integration of renewable energy sources, such as solar power, into these systems is also gaining traction, particularly in off-grid areas where traditional power sources are limited.

Furthermore, the market is adapting to the needs of diverse agricultural practices. The versatility of 12 volt irrigation primer pumps enables their use in various applications, from irrigation to chemical spraying, which appeals to a broader customer base. As international B2B buyers seek reliable and efficient solutions, manufacturers are focusing on enhancing product durability, portability, and ease of use, aligning with the increasing need for sustainable farming practices.

How Important Is Sustainability and Ethical Sourcing in the 12 Volt Pump Sector?

Sustainability has become a critical focus for B2B buyers in the 12 volt irrigation primer pump market. The environmental impact of agricultural practices is under scrutiny, making it essential for companies to adopt sustainable production methods. Buyers are increasingly prioritizing products that are made from eco-friendly materials and that minimize energy consumption, particularly in regions where environmental degradation is a pressing concern.

Ethical sourcing is also gaining importance, as companies strive to establish transparent supply chains. Buyers are looking for suppliers who adhere to sustainable practices, including fair labor conditions and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can significantly influence purchasing decisions, as they demonstrate a commitment to sustainability.

Furthermore, the integration of renewable energy sources, such as solar panels, into the design of 12 volt irrigation primer pumps not only enhances their sustainability profile but also aligns with the global shift towards cleaner energy. This not only appeals to environmentally-conscious buyers but also helps in reducing operational costs, making it a win-win for both suppliers and customers.

What Has Been the Evolution of the 12 Volt Irrigation Primer Pump?

The evolution of the 12 volt irrigation primer pump is marked by technological advancements and changing agricultural practices. Initially, manual priming methods dominated, requiring significant labor and time, which proved inefficient for large-scale farming. The introduction of electric and battery-powered pumps revolutionized this process, significantly reducing the time and effort needed for priming.

Over the years, manufacturers have focused on enhancing the efficiency and portability of these pumps. Modern 12 volt primer pumps are designed to be lightweight, easy to transport, and capable of operating in remote areas without electricity, catering to the diverse needs of farmers around the globe. The integration of smart technology and renewable energy options has further propelled the evolution, ensuring that these pumps meet the demands of contemporary agriculture while contributing to sustainable farming practices.

In conclusion, the 12 volt irrigation primer pump market is poised for continued growth, driven by technological innovation, sustainability, and the evolving needs of global agriculture. For international B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of 12 volt irrigation primer pump

1. How do I solve issues with my 12 volt irrigation primer pump not starting?

If your 12 volt irrigation primer pump is not starting, first check the power source. Ensure that the battery is fully charged and properly connected. Inspect the wiring for any damage or loose connections. Additionally, check the control valve to confirm it is functioning correctly. If the pump still fails to start, consult the manufacturer’s troubleshooting guide or contact customer support for further assistance.2. What is the best 12 volt irrigation primer pump for high suction lift applications?

For high suction lift applications, look for a 12 volt irrigation primer pump with a vacuum capability of at least 20-24 inHg and a robust DC motor that provides sufficient power. Models with aluminum frames are preferred for their durability and lightweight nature, making them easier to transport. Ensure that the pump is compatible with your existing irrigation setup and can handle the specific CFM requirements of your system.3. What should I consider when sourcing a 12 volt irrigation primer pump supplier?

When sourcing a supplier for 12 volt irrigation primer pumps, consider their reputation in the market, product quality, and customer service. Verify their experience in your region, especially if you require compliance with local regulations. Request references from other buyers and assess their ability to provide technical support. Additionally, evaluate their logistics capabilities to ensure timely delivery to your location.4. Are there customization options available for 12 volt irrigation primer pumps?

Many manufacturers offer customization options for 12 volt irrigation primer pumps to meet specific operational needs. This can include modifications to the pump’s size, power specifications, or additional features like remote control valves. Discuss your requirements with potential suppliers to determine what customization options are available and any associated costs or lead times.5. What is the minimum order quantity (MOQ) for 12 volt irrigation primer pumps?

The minimum order quantity (MOQ) for 12 volt irrigation primer pumps can vary by supplier. Some manufacturers may require a MOQ of 5 to 10 units, while others might be flexible, especially for first-time buyers or small businesses. It’s essential to communicate your needs directly with suppliers to negotiate terms that work for your purchasing strategy.6. What are the typical payment terms for purchasing 12 volt irrigation primer pumps?

Payment terms for 12 volt irrigation primer pumps can vary significantly among suppliers. Common terms include a 30% deposit upfront with the balance due upon delivery or a net 30 to net 60 payment period. Some suppliers may also accept letters of credit or financing options. Always clarify payment terms before finalizing your order to avoid any misunderstandings.7. How can I ensure quality assurance (QA) for my 12 volt irrigation primer pump?

To ensure quality assurance for your 12 volt irrigation primer pump, request product certifications and quality control documentation from the supplier. Look for suppliers who conduct rigorous testing on their products and have a clear return policy for defective items. Additionally, consider visiting the supplier’s facility if possible, or requesting samples for evaluation before placing a larger order.8. What are the logistics considerations for importing 12 volt irrigation primer pumps?

When importing 12 volt irrigation primer pumps, consider shipping methods, customs duties, and import regulations specific to your country. Work with suppliers who offer reliable logistics support and understand the complexities of international shipping. Ensure you have the necessary documentation for customs clearance and factor in lead times for shipping to avoid delays in your irrigation projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 12 Volt Irrigation Primer Pump Manufacturers & Suppliers List

1. Irrigation Supply – 12 Volt Power Primer

Domain: irrigationsupplyparts.com

Registered: 2011 (14 years)

Introduction: 12 Volt Power Primer

Price: $1,425.00

Pumping Capabilities: 30 C.F.M.

Motor: 3200 RPM DC Motor

Features:

– Easy Operating Panel Mount Valve / 12V Switch

– 3L Oil Reservoir with Mounting Brackets (use 10 or 20 Non-Detergent Oil, Automatic Transmission Oil, or #32 Light Hydraulic Oil)

– Kits come with everything needed to plumb to your existing pump setup

– Easy Installation

– Huge Air Volume

– Hig…

2. ABI – Electric Irrigation Pump Primer

Domain: abi-irrigation.com

Registered: 2000 (25 years)

Introduction: Irrigation Pump Primer – Electric Primer Pump | ABI Irrigation

Key Features:

– Available in DC, AC, and Hand Pump Priming units.

– Ideal for irrigation and slurry pumps, pivots, and various applications.

– Fast, reliable priming for installations with high suction lifts or long suction lines.

– AC or DC units suitable for propane, natural gas, PTO, and diesel-powered irrigation pumps.

– Timer swi…

3. Direct Pivot Parts – 12V DC Self-Priming Pump Primer

Domain: directpivotparts.com

Registered: 2016 (9 years)

Introduction: This company, Direct Pivot Parts – 12V DC Self-Priming Pump Primer, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Protek Specialty – Motorized Power Primer

Domain: protekspecialty.com

Registered: 1999 (26 years)

Introduction: Motorized Power Primer designed for fast and efficient priming in pump installations with high suction lifts or extra suction lines. Available in AC, DC, or gasoline models, ideal for large diesel-powered irrigation pumps. Features include self-lubricating vanes for easier maintenance, dual fan guards meeting OSHA safety requirements, clear plastic water trap housing to indicate priming completion…

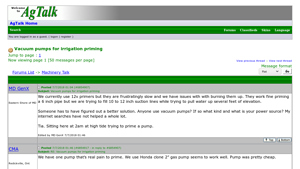

5. NewAgTalk – Vacuum Pumps for Irrigation Priming

Domain: talk.newagtalk.com

Registered: 2000 (25 years)

Introduction: Various vacuum pumps and methods for irrigation priming discussed, including:

– 12v primers (slow and prone to burning out)

– Honda clone 2″ gas pump (affordable and effective)

– Portable vacuum pump used for milking cows with a portable generator

– Vac pump from old liquid manure spreader or vacuum trailer

– Air conditioner system vacuum pump (quick and effective)

– 5hp air compressor setup (can …

6. Rainflo – 6 HP Portable Water Pumps

Domain: rainfloirrigation.com

Registered: 2008 (17 years)

Introduction: Portable Water Pumps include: 6 HP Portable Water Pumps with Honda engine, ideal for sprinklers and drip irrigation, available in high volume-low pressure or high pressure-lower volume. Runs 2.5 hours on a tank of gas, approx. 12 hours with larger tank. Models: 2P5XHR (2″ Pressure Pump) – $865.00, 2S5XHR (2″ Trash Pump) – $895.00, 3S5XHR (3″ Trash Pump) – $960.00. 9 HP Portable Water Pumps with se…

Strategic Sourcing Conclusion and Outlook for 12 volt irrigation primer pump

In conclusion, the strategic sourcing of 12 volt irrigation primer pumps presents a compelling opportunity for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe. These pumps offer a range of advantages including portability, efficiency, and compatibility with renewable energy sources, making them ideal for diverse agricultural applications. The ability to streamline irrigation processes not only enhances productivity but also supports sustainable farming practices.

Investing in high-quality 12 volt primer pumps can significantly reduce labor costs and downtime, while ensuring reliable performance in challenging environments. Buyers should prioritize suppliers who provide comprehensive technical support and robust warranties, ensuring long-term operational success.

As global agricultural demands continue to rise, the need for efficient irrigation solutions will only intensify. We encourage B2B buyers to engage with reputable manufacturers and distributors to explore innovative products that align with their operational needs. By making informed purchasing decisions today, businesses can position themselves for growth and sustainability in the future.