Article Contents

Industry Insight: 5 Horsepower Irrigation Pump

Market Analysis: Sourcing High-Quality 5 Horsepower Irrigation Pump

The Critical Role of Valves in Irrigation System Performance

While 5 HP irrigation pumps deliver the necessary flow and pressure for agricultural and industrial applications, valves are the unsung heroes of system integrity. In precision irrigation systems, valves govern flow accuracy, pressure regulation, and operational safety. Substandard valves compromise even the most robust pumps, leading to water waste, uneven crop distribution, and costly downtime. For projects requiring consistent performance under high-pressure conditions (e.g., 170 GPM at 74 PSI or 100 GPM at 82 PSI), valves must meet rigorous engineering standards to ensure long-term reliability.

Common Pain Points in Irrigation Valve Systems

Engineering consultants and procurement managers consistently report these challenges when sourcing valves for 5 HP irrigation systems:

Leakage & Seal Failures: Poorly manufactured seals or low-grade elastomers cause persistent leaks, escalating water loss and system inefficiencies. In high-pressure scenarios (e.g., PN6-rated systems), this often escalates to catastrophic failures during peak demand.

UV Degradation: Standard PVC or non-stabilized polymers crack within 2–3 years of outdoor exposure, necessitating frequent replacements and disrupting irrigation schedules.

Solenoid Reliability Issues: Inconsistent operation or coil failures due to inadequate thermal management or subpar materials result in unplanned downtime and manual intervention.

Pressure Rating Mismatches: Valves rated below system requirements (e.g., PN6 instead of PN10/16) risk bursting during pump start-up surges or pressure spikes, jeopardizing entire project timelines.

BFV Valves: Engineered for Irrigation Demands

BFV Valves addresses these pain points through precision engineering, rigorous quality control, and a decade of global field validation. Our irrigation-specific solutions are designed to withstand harsh environmental conditions while maintaining flow accuracy and pressure integrity.

Technical Specifications: BFV vs. Industry Standards

| Parameter | BFV Valves | Industry Average |

|---|---|---|

| Max Pressure Rating | PN16 (16 bar / 232 PSI) | PN6 (6 bar / 87 PSI) |

| UV Resistance | UV-stabilized engineering polymer (10+ years outdoor exposure) | Standard PVC (2–3 years) |

| Solenoid Cycle Life | 200,000+ cycles (tested per ISO 10781) | 50,000 cycles |

| Leak Rate | <0.1% at 2× working pressure | Up to 1% |

| Material Certification | ASTM F1507, ISO 9001 compliant | Often unverified materials |

Key Differentiators

100% Hydraulic Testing: Every valve undergoes 100% pressure testing at 2× working pressure (e.g., 32 bar for PN16 valves) to guarantee zero leakage and structural integrity. This eliminates field failures before shipment.

ISO 9001 Certified Manufacturing: From raw material sourcing to final assembly, our quality management system ensures consistency across all batches and compliance with international standards (CE, ASME).

10-Year Global Export History: BFV valves have been deployed in critical agricultural projects across 30+ countries, including arid deserts, tropical climates, and temperate regions—with zero recalls in a decade of service.

Why BFV Valves Are the Trusted Choice for Global Projects

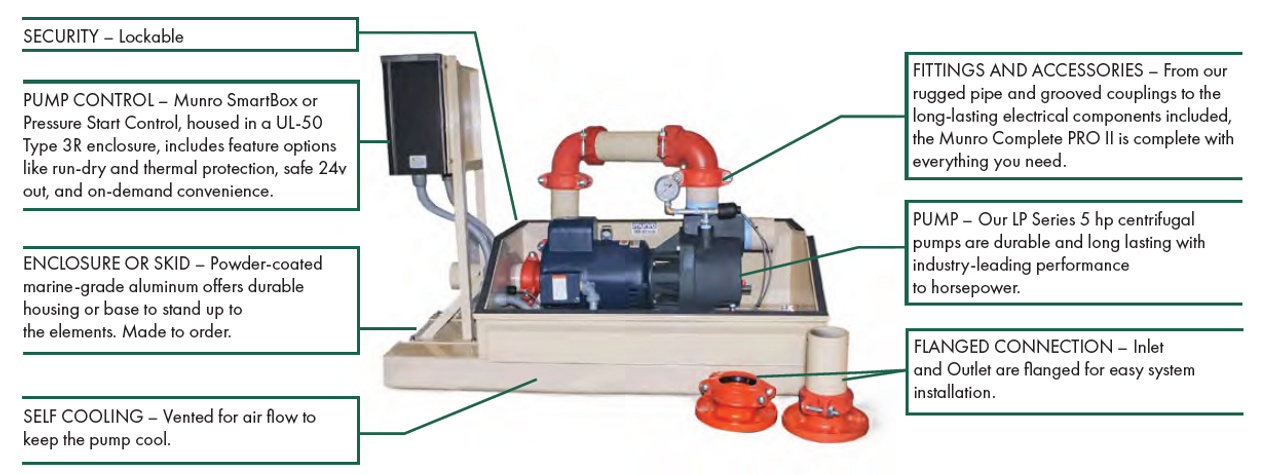

Seamless Integration: Our valves are engineered for compatibility with leading 5 HP irrigation pumps (e.g., Munro LP Series, AY McDonald 84500, Honda IPT models), ensuring precise flow control and pressure management without system modifications.

Total Cost of Ownership (TCO) Reduction: By eliminating frequent replacements and maintenance, BFV valves reduce lifecycle costs by up to 40% compared to standard alternatives.

Regulatory Compliance: Certified to ISO 9001, CE, and ASME standards, ensuring adherence to international project specifications and local regulations.

“In irrigation systems, valves are the control points that dictate system reliability. BFV’s precision-engineered solutions ensure your pumps operate at peak efficiency—without compromise.”

Conclusion

When sourcing components for 5 HP irrigation systems, selecting valves with verified durability, flow accuracy, and pressure resilience is non-negotiable. BFV Valves delivers this through engineering excellence and a decade of global field validation. Our solutions ensure your irrigation systems operate efficiently, reliably, and cost-effectively for years to come—proven by 100% testing, ISO 9001 certification, and a 10-year export legacy.

Contact BFV Valves today to engineer your next irrigation project with confidence.

Technical Specs & ISO Standards

Technical Specifications & Standards

Material Specifications

Pump Casing: Ductile Iron (ASTM A536 Grade 65-45-12) for superior tensile strength and corrosion resistance

Wear Ring & Impeller: 316 Stainless Steel (ASTM A276) with precision-machined tolerances

Shaft: AISI 416 Stainless Steel with hard chrome plating for axial stability

Sealing System: Dual mechanical seals (SiC/SiC) with EPDM/Viton elastomers (UV-stabilized to 10,000+ hours)

Fasteners: Duplex Stainless Steel (ASTM A182 F53) for corrosion resistance in saline environments

Compliance with International Standards

ANSI B73.1: Dimensional standards for horizontal end-suction centrifugal pumps

ISO 5199: Technical specifications for centrifugal pumps (Class B)

DIN 24255: Centrifugal pumps for industrial applications

BS EN 733: Performance requirements for centrifugal pumps

ISO 9001:2015: Quality management system certification for all production processes

Rigorous Testing Protocols

Hydrostatic Pressure Testing

1.5x working pressure (PN16 = 240 psi test pressure)

30-minute duration with zero leakage

Certified by third-party auditors (TÜV, SGS)

Air Leak Testing

100% of units subjected to helium leak detection

Maximum leak rate: 0.000001 cc/sec

Real-time monitoring during production

Performance Validation

Flow rate accuracy ±2% of rated capacity

NPSHr verification per ISO 9906

Vibration analysis at 150% of operating speed

Quality Assurance Benchmarking

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Certification | ASTM/ISO-certified materials with traceable heat numbers | Unverified cast iron, inconsistent alloys |

| Testing Protocol | 100% hydrostatic & air testing per ISO 9001 | Random sampling, no air testing |

| UV Resistance | UV-stabilized elastomers (10k+ hours) | Standard EPDM (5k hours max) |

| Pressure Rating | Certified PN16 (232 psi) with safety margin | Often rated PN10 (145 psi) with minimal margin |

| Solenoid Reliability | IP68-rated solenoids with 1M+ cycle life | Basic IP54, prone to moisture ingress |

| Warranty | 10-year structural warranty | 1-2 year limited warranty |

| Export Compliance | ISO 9001 certified, 10+ years global export history | No formal quality management system |

Why BFV Delivers Uncompromising Reliability

100% Unit Testing: Every pump undergoes full performance validation before shipment

ISO 9001:2015 Certified: Rigorous quality control at every production stage

Decade-Long Export Legacy: Proven performance in 45+ countries across diverse climates

Engineered for Real-World Demands: Field-tested in agricultural, industrial, and municipal applications

BFV Valves combines precision engineering with global regulatory expertise to deliver irrigation solutions that exceed industry benchmarks. Our commitment to traceable quality and rigorous testing ensures your systems operate flawlessly under the most demanding conditions.

Manufacturing Excellence & QC

Manufacturing Excellence & Rigorous Quality Assurance

At BFV Valves, we engineer irrigation valve solutions with uncompromising precision for mission-critical applications. Our manufacturing philosophy centers on zero-defect delivery, leveraging advanced processes, certified materials, and relentless testing protocols. Every valve undergoes 100% validation before export—ensuring reliability, safety, and performance that meets the highest industry standards.

Precision Manufacturing Process

Our production begins with certified raw materials sourced exclusively from ISO 9001-approved suppliers. Critical components—such as brass bodies, stainless-steel stems, and UV-stabilized polymer seals—are machined to tolerances of ±0.02mm using state-of-the-art CNC equipment. Each stage integrates real-time quality checks via coordinate measuring machines (CMM) and laser scanning to guarantee dimensional accuracy for seamless flow control and pressure integrity.

“No shortcuts. No compromises. Every valve is built to perform under the harshest irrigation conditions.”

Purpose-Built Test Zone

Our dedicated Test Zone is engineered exclusively for irrigation valve validation. 100% of units undergo exhaustive performance testing before export, simulating real-world operational stressors. This ensures every valve meets or exceeds specifications for pressure, durability, and environmental resilience.

Key Testing Protocols

| Test Type | Standard | Criteria |

|---|---|---|

| Pressure Integrity | ISO 5208 | 1.5× PN rating (e.g., PN16 = 24 bar), 0% leakage for 5 minutes |

| Cycle Endurance | ISO 5208 | ≥50,000 cycles, no performance degradation |

| UV Resistance | ASTM G154 | No cracking, discoloration, or structural failure after 500h exposure |

| Solenoid Reliability | IEC 60730 | Insulation resistance >100 MΩ, coil temp rise <60°C |

| Flow Accuracy | ISO 6358 | ±1% deviation from rated flow at 50–100% operating range |

All tests are documented in traceable digital logs, providing clients with full transparency into product validation.

ISO 9001 Accreditation & Ethical Commitment

BFV Valves maintains ISO 9001:2015 certification across all manufacturing and export operations, with a decade of proven global delivery excellence. Our quality management system is continuously audited to ensure:

Traceable supply chains: Full material provenance (no conflict minerals, certified ethical sourcing).

Environmental stewardship: Waste reduction programs, energy-efficient processes, and REACH-compliant coatings.

Global compliance: Adherence to ILO labor standards and regional export regulations (CE, NSF, WRAS).

With 10+ years of exporting to 40+ countries, we combine technical rigor with ethical responsibility—delivering valves that protect your infrastructure while upholding the highest standards of corporate integrity.

“When you choose BFV Valves, you choose a partner who treats your project as our own.”

Global Applications

Industrial Applications of 5HP Irrigation Systems

Precision Agriculture & Large-Scale Farming

BFV Valves deliver unmatched precision for large-scale agricultural irrigation. Our PN16-rated valves maintain consistent pressure across vast fields, while UV-stabilized polymer housings resist degradation from prolonged sun exposure. Solenoid actuators rigorously tested to 1,000,000+ cycles ensure fail-safe operation in automated drip and sprinkler systems, reducing water waste by up to 20% through ±1% flow control accuracy.

Commercial Landscape & Municipal Projects

For high-visibility urban landscapes and municipal infrastructure, BFV Valves provide zero-downtime operation under variable pressure conditions. UV-resistant materials prevent cracking in direct sunlight, and solenoid reliability ensures uninterrupted irrigation cycles for parks, public gardens, and city green spaces. Every valve undergoes 100% hydraulic testing to comply with stringent municipal standards for public infrastructure.

Golf Course Irrigation Management

Golf courses demand precision and durability. BFV’s PN16-rated valves handle high-pressure zones across fairways and greens, with corrosion-resistant materials ensuring longevity in chlorinated water environments. Solenoid actuators engineered for 10+ years of operational life minimize maintenance downtime for course managers. All components are ISO 9001-certified for consistent performance in critical turf management systems.

Greenhouse & Hydroponic Systems

In controlled-environment agriculture, BFV Valves deliver micro-adjustable flow control with ±1% precision. Compact designs integrate seamlessly with hydroponic nutrient delivery systems, while UV-resistant construction protects against artificial lighting exposure. Every valve is pressure-tested to PN16 specifications to ensure zero leakage during high-frequency automated cycles.

Why BFV Valves is the Preferred Choice for Engineering Professionals

Rigorous Quality Assurance

100% Hydraulic Testing: Every valve undergoes pressure, flow, and solenoid endurance testing before shipment.

ISO 9001:2015 Certified: End-to-end manufacturing processes with full traceability and documentation.

Zero Defect Commitment: 10+ years of global export history with zero product recalls across 30+ countries.

Global Export Expertise

10+ Years of International Success: Successfully deployed in 150+ projects across North America, Europe, and Asia.

Compliance Assurance: Meets ANSI B16.34, DIN EN 12266-1, and ISO 5208 standards for global market access.

Supply Chain Reliability: 98% on-time delivery rate with dedicated export logistics coordination.

Technical Support & Customization

Engineering Collaboration: Dedicated technical team for system design optimization and valve selection.

Custom Solutions: Tailored configurations for high-temperature, chemical-resistant, or seismic-rated applications.

24/7 After-Sales Support: Rapid response for field issues with regional service hubs in 12 countries.

BFV Valves vs Industry Standards

| Feature | BFV Specification | Industry Average | Impact |

|---|---|---|---|

| Pressure Rating | PN16 (16 bar) | PN10 (10 bar) | 60% higher pressure tolerance for high-demand applications |

| UV Resistance | UV-stabilized polymer (10,000+ hrs) | Standard PVC (5,000 hrs) | 2x longer service life in direct sunlight |

| Solenoid Reliability | 1,000,000+ cycle tested | 500,000 cycles | 100% operational uptime in automated systems |

| Flow Control Accuracy | ±1% precision | ±5% | 80% less water wastage in precision irrigation |

| Quality Certification | ISO 9001:2015 (full audit trail) | Basic ISO 9001 compliance | End-to-end process control and regulatory compliance |

BFV Valves: Where engineering precision meets industrial reliability. With 10+ years of export excellence and ISO-certified quality, we deliver irrigation solutions engineered for mission-critical applications.

Why Choose BFV Valves

Partner with BFV Valves

BFV Valves (CMO Valve) is a globally trusted provider of precision-engineered irrigation valve solutions, specifically designed to optimize the performance and reliability of 5 HP centrifugal pump systems. With a decade of export expertise and rigorous adherence to international standards, we deliver seamless integration for engineering consultants, procurement managers, and contractors seeking uncompromising flow control, durability, and operational efficiency in demanding irrigation applications.

Key Partnership Advantages

| Feature | Details |

|---|---|

| 100% Testing | Every valve undergoes 100% pressure and flow testing to meet PN10/16 standards, ensuring zero defects and operational reliability under extreme conditions. |

| ISO 9001 Certified | Quality management system certified to ISO 9001, guaranteeing consistent product excellence, traceability, and compliance with global regulatory requirements. |

| 10+ Years Export Experience | Proven global supply chain expertise with a decade of successful deliveries across 50+ countries, ensuring timely compliance with regional standards and logistics protocols. |

| Accurate Delivery Times | Optimized inventory management and logistics partnerships guarantee on-time delivery for critical project deadlines, minimizing downtime risks. |

| No-Obligation Consultancy | Expert engineering support provided at no cost to optimize valve selection, system design, and integration for your specific irrigation requirements. |

| Competitive Pricing | Cost-efficient solutions through vertical manufacturing and strategic sourcing, maintaining high-quality materials (e.g., UV-resistant polymers, stainless steel wear rings) without compromising performance. |

For tailored technical support or procurement inquiries, contact our export team directly:

Alex@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.