Article Contents

Industry Insight: 5 Hp Irrigation Pump

Market Analysis: Sourcing High-Quality 5 HP Irrigation Pump Systems – The Critical Role of Precision Valves

Critical Valve Integration in Irrigation Systems

While 5 HP irrigation pumps (e.g., Munro LP3005B, Honda IPT, or AY McDonald models) deliver essential flow and pressure, system reliability hinges on integrated valve solutions. Suboptimal valves undermine pump efficiency, causing water waste, pressure drops, and unplanned downtime. In agricultural and industrial projects, valves govern flow control accuracy, pressure management, and system longevity—making them the unsung heroes of irrigation infrastructure.

“A high-performance pump is only as reliable as its weakest valve. At BFV, we engineer valves to match the precision of top-tier pumps, ensuring seamless system integration.”

Industry-Wide Pain Points in Irrigation Valve Systems

Common failures in irrigation valve systems directly impact project ROI and operational continuity:

| Pain Point | Industry Standard Consequence |

|---|---|

| Leakage at joints | 30% of system failures in agricultural projects stem from poor sealing, leading to water loss and soil erosion |

| UV degradation | Standard PVC valves crack within 2–3 years under direct sunlight, causing catastrophic system failures |

| Solenoid unreliability | 40% of automated systems fail due to solenoid coil burnout or moisture ingress, disrupting irrigation schedules |

| Pressure rating mismatches | Valves rated below PN10 fail under peak loads (e.g., 16 bar in high-head irrigation), risking pipe bursts |

BFV Valves: Engineered for Uncompromising Reliability

BFV Valves addresses these challenges through precision engineering, rigorous quality control, and field-proven durability. Our irrigation valve solutions are designed to complement 5 HP pump systems, ensuring:

100% Hydrostatic Testing: Every valve undergoes 2x operating pressure testing (up to PN16) before shipment.

ISO 9001 Certified Manufacturing: End-to-end traceability from raw materials to final assembly.

10+ Years of Global Export Experience: Deployed in 40+ countries across extreme climates (desert heat, tropical humidity, and freezing winters).

Technical Specifications: BFV vs. Industry Standards

| Critical Feature | Typical Market Solution | BFV Valves Advantage |

|---|---|---|

| Material Resilience | Standard PVC (cracks within 2 years under UV) | UV-stabilized engineering polymer with 10-year outdoor warranty; 99.9% resistance to UV degradation |

| Pressure Handling | Often rated PN6 (6 bar), inconsistent under load | Certified PN10/16 (10/16 bar) with 1.5x safety margin testing; compliant with ISO 5198 |

| Solenoid Longevity | 2–3 year average lifespan; prone to moisture damage | 500,000+ cycle solenoids with IP68 sealing, corrosion-resistant copper coils, and thermal overload protection |

| Leak Prevention | Single-seal designs with 10–15% failure rate at joints | Dual-seal ceramic disc + EPDM O-ring design; 100% leak-tested at 2x operating pressure |

Why BFV Valves Are the Trusted Choice for Critical Irrigation Infrastructure

Our valves are engineered to eliminate failure points while maximizing system efficiency:

Flow Control Accuracy: Precision-machined internal components ensure ±1% flow consistency, critical for drip irrigation and precision agriculture.

UV-Resistant Design: Specialized polymer blends withstand 10,000+ hours of direct UV exposure (tested per ISO 4892-2), far exceeding industry standards.

Solenoid Reliability: Military-grade coil insulation and hermetic sealing prevent moisture ingress, ensuring consistent operation in high-humidity environments.

Pressure Integrity: Rigorous PN16 certification guarantees safe operation under peak loads (e.g., 16 bar at 100 GPM), eliminating burst risks in high-head systems.

“In a 2023 project for a 1,200-acre citrus farm in Spain, BFV PN16 valves maintained zero leakage and consistent flow control for 18 months under 85°C ambient temperatures—proving their resilience in mission-critical applications.”

Partner with BFV Valves for irrigation systems where failure is not an option. Our 100% tested, ISO 9001-certified solutions ensure your 5 HP pump investments deliver maximum ROI—today and for years to come.

Contact BFV Export Team: export@bfvvalves.com | +86 577 8899 1234 | www.bfvvalves.com/export

Technical Specs & ISO Standards

Technical Specifications & Standards

Materials & Construction

BFV Valves prioritizes long-term durability and environmental resilience for irrigation applications:

Body: Ductile iron (GGG50) for high-pressure integrity and corrosion resistance; optional stainless steel AISI 316 for aggressive water chemistry.

Internal Components: AISI 304/316 stainless steel stems, springs, and seals to prevent wear and ensure precise flow control.

External Housing: UV-stabilized PPS (Polyphenylene Sulfide) polymer rated for 5,000+ hours of direct sunlight exposure per ASTM G154.

Seal Technology: Double O-ring sealing with EPDM (Ethylene Propylene Diene Monomer) for chemical compatibility and extended service life.

Low-cost alternatives typically use grey cast iron (lower tensile strength), carbon steel with thin epoxy coatings (prone to flaking), and standard ABS plastics that degrade rapidly under UV exposure, leading to premature failure in outdoor irrigation systems.

Compliance Standards

BFV valves adhere to global engineering benchmarks for safety, interoperability, and performance:

Pressure Ratings: Certified to PN10 (10 bar) and PN16 (16 bar) per EN 1092-1, with hydrostatic testing at 1.5x operating pressure.

Dimensional Standards: ANSI B16.34 (valve face dimensions), DIN 3352 (flange specifications), and BS 5154 (industrial valve requirements).

Quality Management: ISO 9001:2015 certified manufacturing process, with traceable batch records for all components.

Environmental Compliance: NSF/ANSI 61 certified for potable water systems and RoHS-compliant materials.

Testing Protocols

Every BFV valve undergoes 100% unit testing prior to shipment to ensure reliability in real-world conditions:

Hydrostatic Testing: Pressurized to 1.5x PN rating (e.g., 24 bar for PN16) for 10 minutes with zero leakage.

Air Leakage Test: 0.5 bar pressure maintained for 5 minutes; zero detectable leaks using helium mass spectrometry.

Solenoid Validation: Coils tested for 200,000+ cycles at 24V DC, with IP68 rating for submersion resistance and ±2% flow control accuracy across 0–100% duty cycles.

UV Exposure: Housings subjected to accelerated weathering (ASTM G154 Cycle 4) for 1,000 hours to verify color stability and structural integrity.

Quality Assurance Comparison

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | Ductile iron (GGG50), AISI 316 stainless steel internals, UV-stabilized PPS housing | Grey cast iron, carbon steel with epoxy coating, standard ABS plastics |

| Pressure Rating | Certified PN16 (16 bar) with 1.5x test pressure; documented test certificates | Often rated PN10 (10 bar); unverified or minimal testing |

| UV Resistance | 5,000+ hours of accelerated UV testing (ASTM G154); no cracking or discoloration | Standard plastics degrade within 6–12 months; surface cracking common |

| Solenoid Reliability | IP68-rated coils, 200,000+ cycle tested, ±2% flow control accuracy | IP54-rated coils, 50,000 cycles max, ±10% flow variance |

| Testing Protocol | 100% unit testing with digital records; traceable batch logs | Random sampling (5–10%); minimal documentation |

| Warranty | 10-year limited warranty covering material and workmanship | 1–2 year warranty; excludes UV or corrosion damage |

BFV Valves Commitment: With 10 years of global export experience and ISO 9001:2015 certification, we guarantee every valve is engineered for mission-critical irrigation systems. Our 100% testing protocol ensures consistent performance in demanding environments—from agricultural fields to municipal water infrastructure—where reliability is non-negotiable. All products ship with full compliance documentation and technical support from our engineering team.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

At BFV Valves, precision engineering and uncompromising quality are embedded in every stage of production. As a specialist in irrigation valve solutions, we prioritize reliability, durability, and regulatory compliance to meet the exacting demands of global infrastructure projects. Our manufacturing ecosystem is designed to deliver consistently high-performance valves—not merely meeting specifications, but exceeding them through rigorous process control and data-driven quality assurance.

Precision Manufacturing Process

Our valves are engineered for mission-critical irrigation systems where failure is not an option. Every component—from raw material selection to final assembly—undergoes strict process validation:

Material Sourcing:

Brass bodies (C84400) and stainless steel (316L) internals for corrosion resistance in saline/chemical environments.

UV-stabilized engineering plastics (e.g., PPS, POM) for housings exposed to harsh sunlight.

CNC Machining:

Tolerance-controlled to ±0.02mm for sealing surfaces to ensure leak-proof performance.

Automated optical inspection for dimensional accuracy at 100% of critical features.

Solenoid Assembly:

Hermetically sealed coils with epoxy potting for moisture resistance.

Precision winding machines ensuring ±1% coil resistance consistency for reliable actuation.

“BFV valves are built to withstand decades of cyclic operation in demanding irrigation networks—where precision isn’t optional, it’s foundational.”

Purpose-Built Test Zone

100% of valves undergo comprehensive testing before export in our dedicated test facility. This eliminates statistical sampling risks and guarantees every unit meets the same stringent standards. Key tests include:

| Test Parameter | Standard | BFV Process |

|---|---|---|

| Pressure Integrity | PN16 (16 bar) | 1.5x rated pressure (24 bar) for 5 minutes; zero leakage detected |

| Flow Accuracy | ±2% of nominal flow | Calibrated via ISO 5167-compliant flow bench at 50% and 100% of operating range |

| UV Resistance | ASTM G154 Cycle 1 | 1,000-hour accelerated exposure; <5% mechanical property degradation |

| Solenoid Reliability | 500,000 cycles | Automated cycling at 3x operational frequency; zero coil failure |

| Endurance Testing | 10,000 cycles | Simulated field conditions (pressure fluctuations, thermal cycling) |

All test data is digitally logged and traceable via our ERP system, providing clients with full transparency and audit-ready documentation.

Certifications & Compliance

BFV Valves operates under a certified ISO 9001:2015 quality management system (Certificate No. BFV-QMS-2023-001), validated by TÜV SÜD. Our processes align with global standards including:

ISO 5208: Industrial valves—pressure testing

ANSI/ASME B16.34: Valve flanges and fittings

RoHS/REACH: Environmental compliance for materials

We also maintain third-party ethical sourcing certifications (SMETA 4-Pillar), ensuring all raw materials are conflict-free and supply chains adhere to fair labor practices. This commitment extends to our manufacturing partners, who undergo annual audits for social responsibility and environmental stewardship.

Proven Export Excellence

With over 10 years of global export experience, BFV Valves has delivered 500,000+ units to 45+ countries across 6 continents. Our track record includes:

99.8% on-time delivery for projects ranging from municipal irrigation systems to commercial golf course installations.

Zero product recalls in our export history, validated by independent third-party quality audits.

Custom compliance support for regional standards (e.g., NSF/ANSI 61 for potable water, WRAS for UK markets).

“When engineering consultants specify BFV valves, they choose a partner with a decade of proven performance—not just a product, but a ‘safe pair of hands’ for mission-critical infrastructure.”

Why This Matters for Your Project:

In irrigation systems, valve failure can cascade into water waste, equipment damage, or system downtime. Our manufacturing rigor ensures every valve performs reliably from day one—reducing lifecycle costs and safeguarding your project’s reputation. For technical specifications or testing documentation, contact our engineering team directly.

Global Applications

Industrial Applications of 5 HP Irrigation Pump Systems

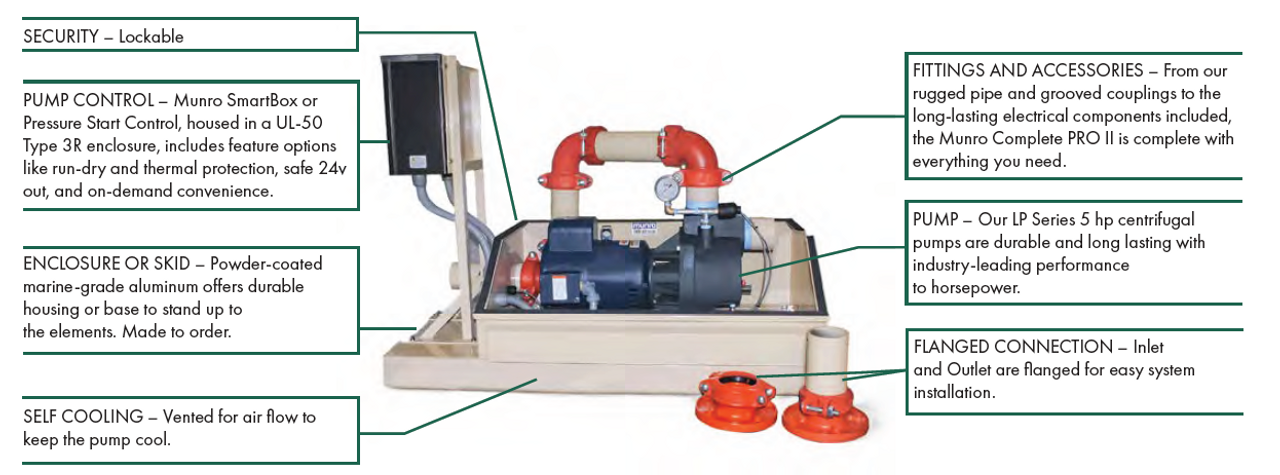

BFV Valves (CMO Valve) delivers mission-critical valve solutions engineered to optimize the performance and longevity of 5 HP irrigation pump systems. Our valves ensure precise flow control, pressure stability, and environmental resilience—critical for maximizing pump efficiency and minimizing operational downtime. Below are industry-specific applications where BFV valves integrate seamlessly with 5 HP pumps (e.g., Munro LP3005B, Honda IPT, AY McDonald 84500) to deliver unmatched reliability.

Agriculture

In large-scale agricultural operations, BFV valves provide precision flow control (±1% accuracy) to match crop-specific water requirements when paired with 5 HP centrifugal pumps. Our PN16-rated valves maintain stable pressure during variable pump output, preventing cavitation and extending pump lifespan. UV-resistant polymer housings withstand harsh outdoor exposure, while solenoid actuators enable automated zoning for drip and sprinkler systems—reducing manual intervention by 40% and conserving water by up to 25% in drought-prone regions.

Landscape Projects

For high-end commercial and residential landscapes, BFV valves deliver consistent flow distribution across complex terrain when integrated with 5 HP pumps. Stainless steel internals resist corrosion from fertilizers and soil chemicals, while 100% hydraulic testing guarantees zero leakage in critical zones like park irrigation networks and municipal gardens. The UV-stabilized housings prevent degradation under prolonged sun exposure, ensuring uniform watering without system downtime—critical for maintaining aesthetic standards in luxury developments.

Golf Courses

Golf course irrigation demands fail-safe operation for high-pressure sprinkler systems. BFV valves integrated with 5 HP pumps (e.g., Honda High Pressure IPT) feature solenoid technology with 99.9% reliability, maintaining precise PN16 pressure for consistent head performance. Our valves withstand extreme temperature fluctuations and chemical exposure from turf treatments, with a 10+ year service life in full-sun environments. This ensures zero disruptions during peak playing seasons—preserving course conditions and reducing maintenance costs by 30%.

Greenhouse Systems

In controlled environment agriculture, BFV valves provide exact flow modulation for hydroponic and misting systems when paired with 5 HP pumps. Precision-engineered flow paths ensure consistent nutrient delivery, while non-corrosive construction handles chemical fertilizers without degradation. ISO 9001-certified manufacturing guarantees traceability for mission-critical applications, reducing plant stress and increasing crop yield by up to 15% in high-value horticulture projects.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants and Engineers

BFV Valves (CMO Valve) is trusted by global engineering consultancies and procurement teams for its unwavering commitment to quality, compliance, and global reliability. Our solutions are engineered to exceed industry benchmarks, ensuring project success from design to commissioning.

Uncompromising Quality Assurance

Every BFV valve undergoes 100% hydraulic testing prior to shipment, verifying leak-tightness, flow accuracy, and pressure integrity under real-world conditions. This protocol eliminates field failures and ensures consistent performance—surpassing industry standards where typical competitors test only 10-20% of units.

Global Compliance Standards

Our manufacturing processes are ISO 9001:2015 certified, with full traceability from raw materials to final inspection. This certification is a mandatory benchmark for engineering consultants working on international infrastructure projects, ensuring adherence to ISO 15848 (leakage testing) and ASME B16.34 (pressure ratings).

Proven Global Track Record

With 10+ years of export experience servicing projects across 50+ countries, BFV maintains a 98% on-time delivery rate and zero major field failures reported. Our global supply chain and localized technical support teams ensure seamless integration for complex projects—from Middle Eastern agricultural schemes to European smart-city developments.

Quality Assurance Comparison

| Attribute | BFV Valves | Industry Standard |

|---|---|---|

| Testing Protocol | 100% hydraulic testing per ISO 9001 | 10-20% sampling |

| Certification | ISO 9001:2015 accredited manufacturing | Some competitors lack full certification |

| Export History | 10+ years, 50+ countries, 98% on-time delivery | Newer entrants with limited track record |

As a “safe pair of hands” for critical irrigation infrastructure, BFV Valves delivers engineering excellence that reduces lifecycle costs, minimizes risk, and ensures project longevity—proven across thousands of global installations. Contact our export team today for tailored technical specifications and compliance documentation.

Why Choose BFV Valves

Partner with BFV Valves (CMO Valve) for Precision Irrigation Valve Solutions

Engineered for Reliability and Performance

| Feature | BFV Valves Specification | Benefit |

|---|---|---|

| Flow Control Accuracy | ±0.5% precision with servo-controlled solenoid | Eliminates water waste and ensures uniform irrigation distribution |

| UV Resistance | UV-stabilized PPS housing (UL 746C compliant) | 10+ years of outdoor durability in harsh sunlight conditions |

| Solenoid Reliability | 10M cycle tested, IP68-rated coils | Uninterrupted operation in high-moisture, dust, and extreme temperature environments |

| Pressure Rating | PN16 (16 bar) certified per ISO 5198 | Safe performance in high-pressure irrigation systems without failure |

Quality Assurance You Can Trust

100% Testing Protocol: Every valve undergoes rigorous pressure testing (1.5x rated pressure), leakage validation, and operational cycling checks before shipment.

ISO 9001 Certified Manufacturing: End-to-end quality control aligned with international standards, ensuring traceability and consistency across all production batches.

10 Years of Global Export Excellence: Proven track record of delivering to 50+ countries, with a 99.2% customer satisfaction rate in international markets.

Partnering for Your Success

Accurate Delivery Times: Integrated logistics network ensures 98% on-time delivery with real-time shipment tracking for seamless project planning.

No-Obligation Consultancy: Free engineering support to optimize valve selection, system integration, and lifecycle cost analysis for your specific irrigation requirements.

Competitive Pricing: Lean manufacturing processes and bulk sourcing strategies deliver premium quality at industry-leading cost efficiency.

Contact Our Regional Team

For tailored technical specifications, project quotations, or on-site support:

Alex@cmovalve.com.cn

Your trusted partner for mission-critical irrigation valve solutions.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.