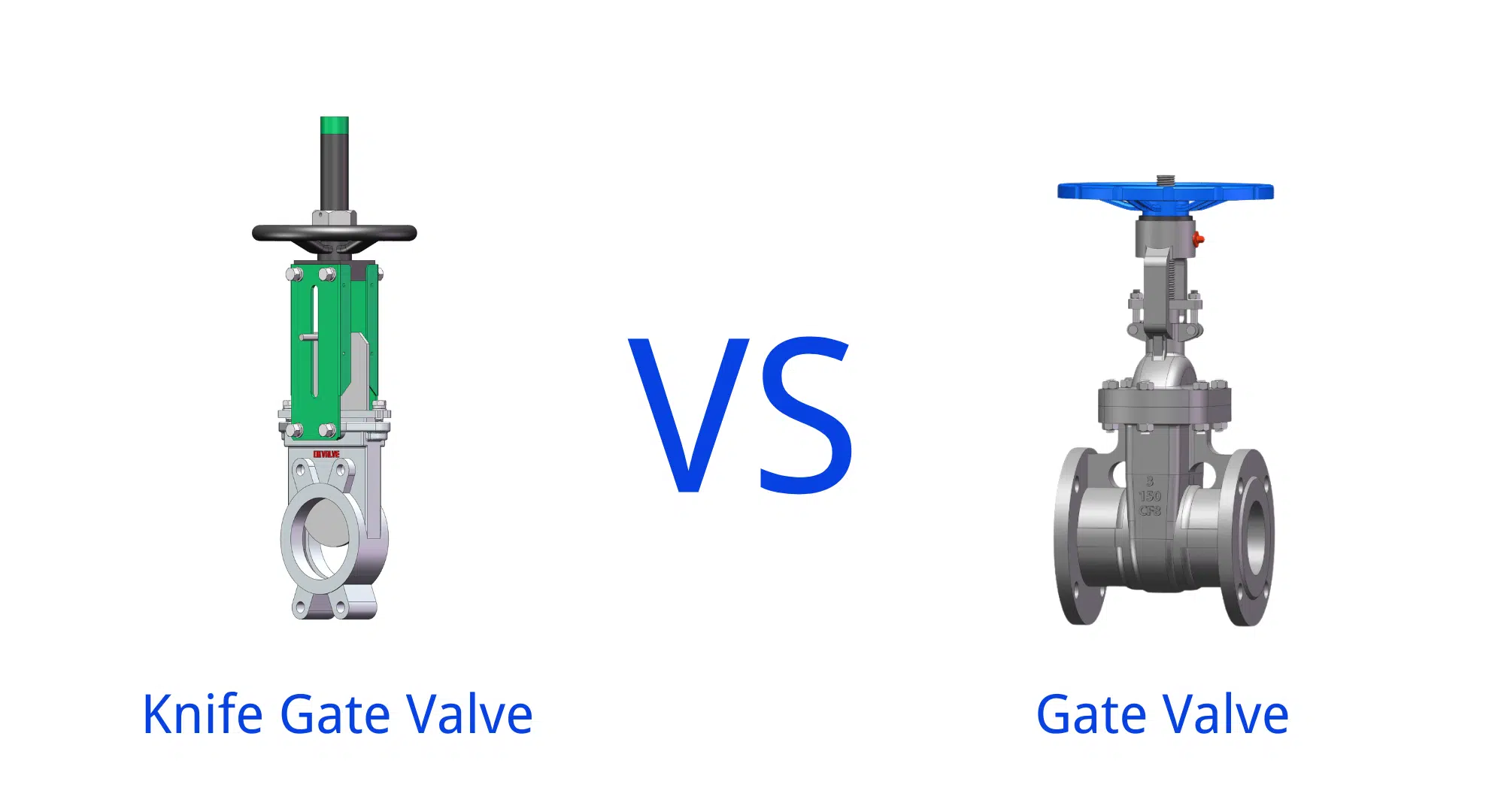

When choosing valves for industrial applications, knife valves and gate valves are two common options. While they may look similar and both provide on/off control, their designs, functions, and ideal applications differ significantly. Understanding the differences between knife valves vs gate valves helps ensure proper selection for your system.

What Is a Knife Valve?

A knife valve (or knife gate valve) is specifically designed for handling slurries, viscous fluids, and solids-laden media. It features a thin, sharp-edged blade (knife) that cuts through thick fluids or soft solids to create a tight seal. Knife valves are commonly used in:

Pulp and paper industry (pulp stock)

Mining and mineral processing (slurry and tailings)

Wastewater treatment

Bulk material handling

Key Characteristics of Knife Valves:

Thin, sharp-edged gate for cutting through materials

Typically designed for low-pressure applications

Compact and lightweight design

Can handle slurries and abrasive media

What Is a Gate Valve?

A gate valve uses a solid, wedge-shaped gate to control the flow of clean liquids or gases. It’s best suited for on/off (isolation) applications where the media is free of debris. Gate valves are widely used in:

Water supply and distribution systems

Oil and gas pipelines

Power plants

General fluid isolation

Key Characteristics of Gate Valves:

Wedge or parallel gate design

Suitable for high-pressure and high-temperature conditions

Provides a tight shut-off for clean media

Not ideal for slurries or abrasive fluids (risk of seat damage)

Knife Valve vs Gate Valve: Main Differences

| Feature | Knife Valve | Gate Valve |

|---|---|---|

| Design | Thin knife-like blade | Solid wedge or parallel gate |

| Best for | Slurries, viscous, or abrasive fluids | Clean liquids and gases |

| Pressure Rating | Low to medium (often below 150 psi) | High (can exceed 300 psi or more) |

| Size & Weight | Compact and lightweight | Larger and heavier |

| Cost | Generally less expensive | Often more expensive |

| Shut-off Quality | Good but not bubble-tight for clean fluids | Excellent for clean fluids |

| Maintenance | Easier to replace gate/seals | Requires more space for servicing |

When to Choose a Knife Valve vs a Gate Valve

Choose a Knife Valve if:

You are handling slurry, wastewater, or abrasive materials.

Space is limited, and a compact valve is needed.

Low pressure and cost-effectiveness are priorities.

Choose a Gate Valve if:

You require tight shut-off in high-pressure or clean liquid systems.

You’re working with potable water, oil, gas, or steam.

Durability and long-term sealing are critical.

Conclusion

Both knife valves and gate valves serve as isolation valves but are built for different conditions. Knife valves excel in handling slurries and solids, while gate valves are preferred for high-pressure, clean-fluid systems. Choosing the correct valve will improve system reliability and reduce maintenance costs.

Looking for industrial-grade knife or gate valves? Contact us for expert recommendations and competitive pricing.