Introduction: Navigating the Global Market for dss knife gate valve

In the competitive landscape of industrial valve solutions, sourcing a reliable DSS knife gate valve can pose significant challenges for international B2B buyers. Industries such as oil and gas, mining, and wastewater management demand valves that can withstand extreme conditions while ensuring zero leakage and optimal performance. This guide addresses these challenges by providing a comprehensive overview of the various types of DSS knife gate valves, their specific applications, and the critical features that differentiate them in the market.

Throughout this guide, we will delve into the intricacies of selecting the right DSS knife gate valve, including essential criteria for supplier vetting, cost considerations, and maintenance practices. We will also explore the global market dynamics, highlighting key players and trends that impact sourcing decisions. For buyers in regions such as Africa, South America, the Middle East, and Europe—including countries like Brazil and Vietnam—this resource is designed to empower you with the knowledge necessary to make informed purchasing decisions.

By equipping you with insights into valve specifications, performance standards, and industry compliance, this guide aims to facilitate a seamless procurement process. Ultimately, our goal is to help you navigate the complexities of the global market, ensuring that your operations are supported by high-quality, durable, and efficient valve solutions that enhance productivity and minimize downtime.

Understanding dss knife gate valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Severe Service Knife Gate Valve | Bidirectional zero-leakage design, guided shear gate | Mining, Oil & Gas, Chemical Processing | Pros: High durability, excellent sealing; Cons: Higher initial cost. |

| General Service Knife Gate Valve | Standard design, suitable for less harsh environments | Water Treatment, Pulp & Paper | Pros: Cost-effective, versatile; Cons: Limited in extreme conditions. |

| Double Block and Bleed Valve | Two isolation points, integrated bleed system | Oil & Gas, Power Generation | Pros: Enhanced safety, reliable isolation; Cons: More complex installation. |

| Pinch Valve | Flexible sleeve, ideal for slurries and viscous materials | Wastewater, Food Processing | Pros: Excellent for abrasive materials; Cons: Maintenance can be challenging. |

| Control Valve | Adjustable flow control, often integrated with automation systems | Chemical Processing, Power Plants | Pros: Precision control; Cons: Requires additional components for automation. |

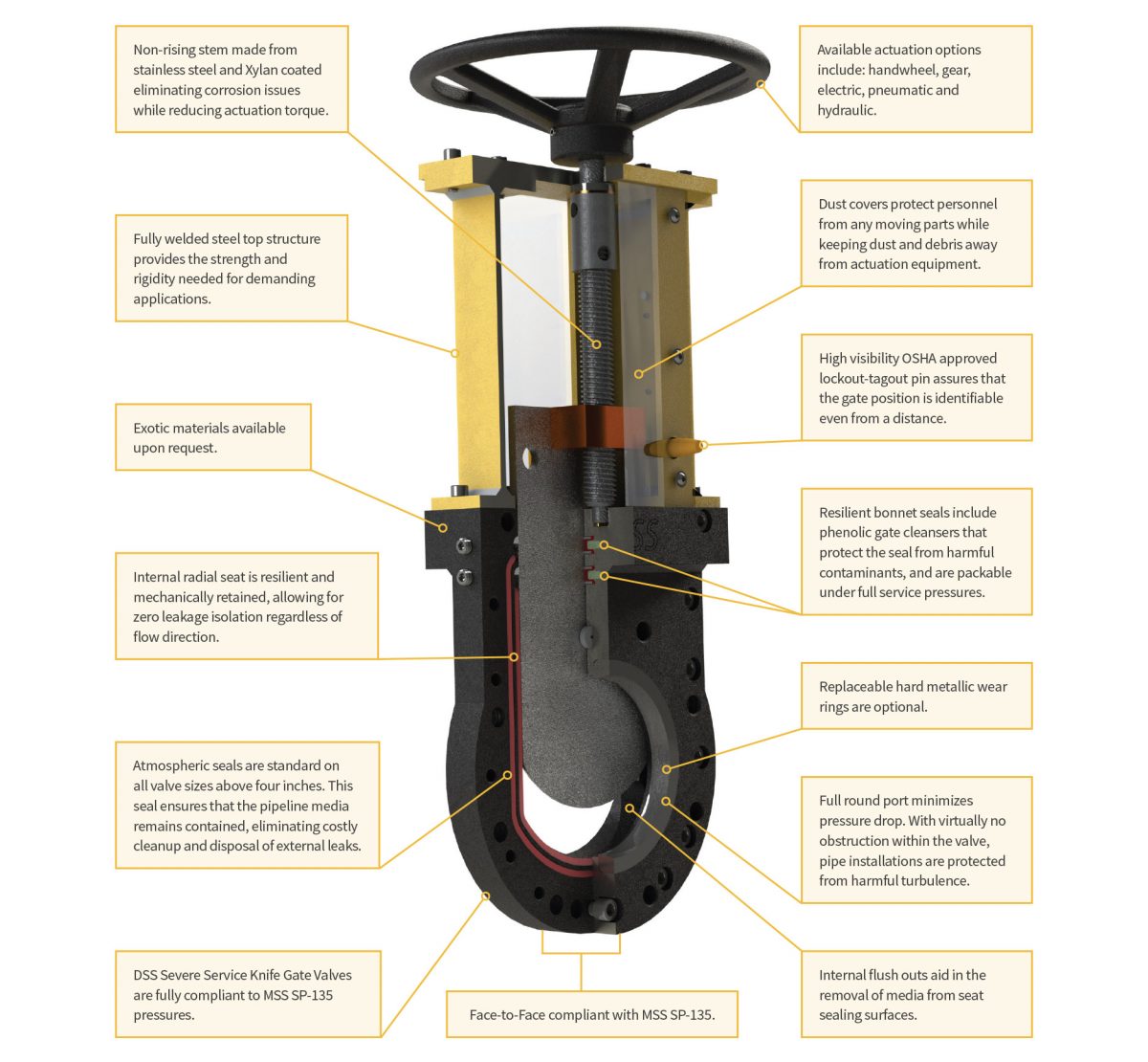

What Are the Key Characteristics of Severe Service Knife Gate Valves?

The Severe Service Knife Gate Valve (SSKGV) is engineered for extreme conditions, featuring a bidirectional zero-leakage design and a guided shear gate. This design allows the valve to cut through various media, including solids and fibrous materials, making it ideal for industries like mining and chemical processing. Buyers should consider the valve’s ability to handle high pressures and its compliance with stringent industry standards, which ensures reliability in critical applications.

How Do General Service Knife Gate Valves Differ in Application?

General Service Knife Gate Valves are designed for less demanding environments, providing a cost-effective solution for applications such as water treatment and pulp and paper. They offer versatility and ease of maintenance but may not withstand the same harsh conditions as their severe service counterparts. B2B buyers should evaluate their operational environment to determine if a general service valve meets their needs without compromising safety and efficiency.

What Advantages Do Double Block and Bleed Valves Offer?

Double Block and Bleed Valves feature two isolation points and an integrated bleed system, enhancing safety in applications like oil and gas. This design allows for effective maintenance while minimizing the risk of leaks. Buyers looking for reliable isolation in critical processes should consider these valves, keeping in mind that the complexity of installation may require additional planning and resources.

When Should You Consider Pinch Valves?

Pinch Valves are particularly effective for handling slurries and viscous materials due to their flexible sleeve design. They excel in applications within wastewater and food processing industries. While they offer significant benefits for abrasive materials, B2B buyers should be aware of the maintenance challenges associated with these valves, which may require more frequent inspections and replacements.

How Do Control Valves Enhance Operational Efficiency?

Control Valves are designed for precise flow regulation and are often integrated with automation systems. They are essential in industries like chemical processing and power generation where flow control is critical. Buyers should consider the additional components required for automation and the potential for enhanced operational efficiency, which can lead to significant cost savings over time.

Key Industrial Applications of dss knife gate valve

| Industry/Sector | Specific Application of dss knife gate valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Isolation of slurries and tailings | Ensures zero-leakage, reducing environmental risk and operational costs | Need for high durability and resistance to abrasive materials |

| Oil and Gas | Control of crude oil and gas flow | Provides reliable isolation and safety in high-pressure environments | Compliance with API and ASME standards for safety |

| Pulp and Paper | Handling of fibrous slurries | Minimizes downtime and maintenance costs due to robust design | Requirement for corrosion resistance and customization options |

| Wastewater Treatment | Regulation of sewage and industrial effluents | Enhances operational efficiency and environmental compliance | Consideration for materials that withstand corrosive substances |

| Chemical Processing | Isolation in chemical transfer and storage | Reduces leakage and contamination risks in hazardous environments | Need for compliance with international safety standards |

How is the dss knife gate valve utilized in the mining industry?

In the mining sector, the dss knife gate valve plays a crucial role in the isolation of slurries and tailings during processing. These valves are designed to handle abrasive materials and provide zero-leakage performance, which is essential for minimizing environmental risks and operational costs. Buyers in this sector must consider the valve’s durability and resistance to wear, ensuring it can withstand harsh conditions often found in mining operations.

What is the role of dss knife gate valves in the oil and gas industry?

In the oil and gas industry, dss knife gate valves are used for controlling the flow of crude oil and natural gas. Their ability to provide reliable isolation in high-pressure environments is vital for safety and operational integrity. International buyers should ensure that the valves comply with API and ASME standards, which are critical for maintaining safety and efficiency in oil and gas applications, especially in regions with stringent regulations.

How does the dss knife gate valve benefit the pulp and paper industry?

The pulp and paper industry benefits from the use of dss knife gate valves in handling fibrous slurries during production. These valves minimize downtime and maintenance costs due to their robust design, which can withstand the unique challenges posed by fibrous materials. Buyers should focus on corrosion resistance and the availability of customized options to meet specific operational needs, ensuring longevity and reliability in their processes.

Why are dss knife gate valves important for wastewater treatment?

In wastewater treatment, dss knife gate valves are crucial for regulating the flow of sewage and industrial effluents. These valves enhance operational efficiency while ensuring compliance with environmental regulations. For international buyers, it is essential to consider materials that can resist corrosive substances typically found in wastewater, as well as the valve’s ability to maintain performance under varying pressure conditions.

How are dss knife gate valves utilized in chemical processing?

Dss knife gate valves are vital in chemical processing for isolating chemical transfer and storage systems. Their design reduces the risk of leakage and contamination, which is particularly important in hazardous environments. Buyers in this sector must ensure that the valves meet international safety standards and are made from materials capable of withstanding the aggressive chemicals they will encounter, thus ensuring safety and reliability in their operations.

3 Common User Pain Points for ‘dss knife gate valve’ & Their Solutions

Scenario 1: Complications with High-Pressure Applications

The Problem: B2B buyers often face challenges when sourcing valves that must operate under high-pressure conditions, particularly in industries such as oil and gas or chemical processing. Many standard knife gate valves fail to provide the necessary reliability and safety, leading to potential operational disruptions, costly leaks, or even catastrophic failures. This creates anxiety among buyers who must ensure that their equipment not only meets specifications but also performs reliably over time.

The Solution: To address this issue, buyers should prioritize sourcing DSS Severe Service Knife Gate Valves, specifically designed to handle extreme pressures up to ASME Class 1500/PN 250 (3750 psig/250 barg). When specifying these valves, it’s crucial to detail the exact operating conditions, including pressure, temperature, and the type of media being handled. Engaging with DSS’s engineering team can provide tailored solutions that meet specific operational needs. Buyers should also consider regular maintenance schedules and training for personnel on proper valve operation, ensuring that the equipment is not only installed correctly but also maintained to function optimally under high-pressure scenarios.

Scenario 2: Addressing Leakage Issues in Harsh Environments

The Problem: In industries such as mining and wastewater treatment, the risk of leakage from valves can lead to environmental hazards and regulatory non-compliance. Buyers often grapple with the issue of ensuring zero leakage in their valve systems, particularly when dealing with corrosive materials and challenging operational environments. Traditional valves may not provide the needed isolation, leading to costly repairs and potential environmental damage.

The Solution: Buyers should look to the bidirectional zero-leakage design of the DSS Severe Service Knife Gate Valve, which is specifically engineered to prevent leaks even in the harshest conditions. When evaluating potential purchases, it’s essential to request detailed performance specifications and certifications that demonstrate compliance with relevant industry standards, such as MSS SP-135. Additionally, conducting a thorough installation review and ensuring that the valves are fitted with dual transverse seals can significantly enhance their performance in preventing leaks. Buyers should also consider establishing a comprehensive monitoring system to detect any signs of leakage early, allowing for prompt intervention before issues escalate.

Scenario 3: Overcoming Maintenance and Downtime Challenges

The Problem: Unplanned maintenance and downtime can severely impact productivity and profitability in industrial settings. B2B buyers often experience frustration when their knife gate valves require frequent repairs or replacements, particularly in applications involving abrasive materials. This not only affects operational efficiency but also increases overall costs associated with labor and equipment downtime.

The Solution: To mitigate maintenance challenges, investing in DSS Severe Service Knife Gate Valves can provide long-term benefits. These valves are designed to withstand erosion and wear due to their robust construction and guided shear gate design, which allows them to cut through solids and other challenging media effectively. Buyers should ensure they select the appropriate materials based on the specific application, considering options such as exotic materials for corrosive environments. Additionally, implementing a proactive maintenance program, including regular inspections and performance assessments, can help identify potential issues before they lead to valve failure. Collaborating with DSS for training and resources can also empower maintenance teams to effectively handle these valves, further reducing unplanned downtime.

Strategic Material Selection Guide for dss knife gate valve

What Are the Key Materials Used in DSS Knife Gate Valves?

When selecting a knife gate valve for severe service applications, the choice of material is critical. The right material not only affects the valve’s performance but also its longevity and suitability for specific environments. Below, we analyze four common materials used in DSS knife gate valves, highlighting their properties, advantages, disadvantages, and considerations for international buyers.

How Does Stainless Steel Perform in DSS Knife Gate Valves?

Key Properties: Stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, typically rated up to 1500°F (815°C). It can withstand high pressures, making it suitable for severe service applications.

Pros & Cons: The durability of stainless steel is a significant advantage, as it resists rust and oxidation. However, it can be more expensive than other materials and may require complex manufacturing processes, particularly for custom designs.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it ideal for chemical processing industries.

Considerations for International Buyers: Buyers in regions with stringent compliance requirements, such as Europe and North America, should ensure that the stainless steel used meets ASTM standards. In Africa and South America, local sourcing may affect availability and cost.

Why Choose Carbon Steel for DSS Knife Gate Valves?

Key Properties: Carbon steel is robust and can handle high pressures and temperatures, typically rated up to 800°F (427°C). It is less resistant to corrosion compared to stainless steel but can be treated with coatings to enhance its durability.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious projects. However, its susceptibility to rust and corrosion can limit its application in harsh environments without additional protective measures.

Impact on Application: Carbon steel is suitable for applications involving water, slurries, and non-corrosive materials but may not be ideal for highly corrosive environments.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of carbon steel, especially in regions like the Middle East, where humidity can accelerate corrosion. Compliance with local standards, such as DIN or JIS, is also crucial.

What Role Do Exotic Alloys Play in DSS Knife Gate Valves?

Key Properties: Exotic alloys, such as Hastelloy or Inconel, offer exceptional resistance to extreme temperatures and corrosive environments. These materials can withstand pressures exceeding 2500 psi (172 bar) and are often used in specialized applications.

Pros & Cons: The primary advantage of exotic alloys is their unmatched performance in severe service conditions. However, they are significantly more expensive and may require specialized manufacturing techniques.

Impact on Application: Exotic alloys are ideal for the oil and gas industry, where exposure to corrosive chemicals and extreme temperatures is common.

Considerations for International Buyers: Buyers should consider the availability of these materials in their region, as they may not be as readily accessible in Africa or South America. Compliance with international standards is also critical for ensuring safety and reliability.

How Does PVC Compare for DSS Knife Gate Valves?

Key Properties: PVC (Polyvinyl Chloride) is lightweight and offers good chemical resistance, particularly against acids and bases. However, its temperature tolerance is limited, typically around 140°F (60°C) at high pressures.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it suitable for less demanding applications. However, its limitations in pressure and temperature resistance can restrict its use in severe service environments.

Impact on Application: PVC is often used in water treatment and wastewater applications but may not be suitable for high-pressure or high-temperature scenarios.

Considerations for International Buyers: Buyers in regions with less demanding applications may prefer PVC for its affordability. However, they should ensure that the material meets local standards and regulations.

Summary Table of Material Selection for DSS Knife Gate Valves

| Material | Typical Use Case for dss knife gate valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, oil and gas | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Carbon Steel | Water, slurries | Cost-effective | Susceptible to corrosion | Medium |

| Exotic Alloys | Oil and gas, extreme environments | Unmatched performance | Very high cost, specialized mfg | High |

| PVC | Water treatment, wastewater | Affordable and easy to manufacture | Limited pressure/temperature range | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing DSS knife gate valves tailored to their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dss knife gate valve

What Are the Main Stages in the Manufacturing Process of DSS Knife Gate Valves?

The manufacturing process of DSS Knife Gate Valves, particularly the Severe Service Knife Gate Valve (SSKGV), involves several critical stages designed to ensure high-quality performance and reliability in severe service conditions. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material selection and preparation. DSS Valves utilizes high-grade materials specifically engineered to withstand harsh environments, including corrosive substances and extreme temperatures. Materials are sourced primarily from U.S.-based vendors, ensuring compliance with the American Iron and Steel (AIS) Requirement and the Buy American Act (BAA). The preparation phase also involves cutting, machining, and treating these materials to enhance their properties, such as strength and corrosion resistance.

Forming Techniques Used in Knife Gate Valve Production

Once the materials are prepared, they undergo various forming techniques. These may include forging, casting, or machining, depending on the component being produced. For the SSKGV, machining plays a significant role in achieving precise tolerances and surface finishes. Advanced CNC (Computer Numerical Control) machines are employed to ensure uniformity and accuracy across all valve components, particularly the shearing tip and internal gate guides that are crucial for the valve’s performance in cutting through solids, scale, and paste.

Assembly of DSS Knife Gate Valves

Following the forming stage, the assembly process begins. This stage involves the integration of multiple components, including the valve body, gate, seals, and actuation mechanisms. Each assembly is carefully executed to maintain the integrity of the design, particularly the guided shear gate mechanism that is unique to DSS valves. This design feature ensures true isolation and zero leakage, critical for severe service applications. Skilled technicians oversee this process, employing best practices to prevent contamination and ensure that all parts function harmoniously.

Finishing Processes for Enhanced Performance

The final stage of manufacturing is finishing, which includes surface treatments and quality checks. This may involve processes such as polishing, coating, or painting to enhance the valve’s durability and resistance to environmental factors. Finishing not only improves aesthetics but also contributes to the operational lifespan of the valve in demanding applications.

How Is Quality Assurance Integrated into DSS Knife Gate Valve Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process at DSS Valves, ensuring that each knife gate valve meets rigorous performance standards. The company adheres to several international and industry-specific standards, including ISO 9001:2015, CE Certification, and API standards.

What Are the Key Quality Control Standards for Knife Gate Valves?

The ISO 9001:2015 certification signifies that DSS Valves has implemented a robust quality management system that fosters continual improvement and customer satisfaction. The CE certification indicates compliance with EU regulations, while API standards ensure that the valves can withstand the pressures and conditions specific to the oil and gas industry.

What QC Checkpoints Are Involved in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process. These include:

Incoming Quality Control (IQC): This initial checkpoint ensures that all incoming materials meet specified requirements before they enter the manufacturing process.

In-Process Quality Control (IPQC): Throughout the manufacturing phases, IPQC checks are performed to monitor and validate the quality of ongoing work. This includes verifying dimensions and ensuring that machining processes are executed correctly.

Final Quality Control (FQC): After assembly, each valve undergoes rigorous testing to confirm its functionality and reliability. This may involve pressure testing, leakage testing, and performance evaluations under simulated operating conditions.

Which Testing Methods Are Commonly Used in Quality Control?

DSS Valves employs various testing methods to ensure each knife gate valve meets the required specifications. Common methods include:

Hydrostatic Testing: This involves filling the valve with water and applying pressure to identify any leaks or weaknesses in the structure.

Pneumatic Testing: Similar to hydrostatic testing, this method uses air pressure to test the valve’s integrity.

Performance Testing: Valves are subjected to operational simulations to evaluate their performance under expected service conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are several strategies to ensure your supplier maintains high standards:

Supplier Audits: Conducting regular audits of your suppliers’ facilities can provide insights into their manufacturing processes and quality assurance practices. This helps in assessing compliance with industry standards and your specific requirements.

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their testing methods, results, and compliance with international standards. These reports can help buyers understand the level of quality assurance in place.

Engaging Third-Party Inspectors: For added assurance, consider hiring third-party inspection services to evaluate the manufacturing processes and the quality of the products before shipment. This independent verification can help mitigate risks associated with sourcing.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various regulations and standards that may differ from their home countries. Understanding these nuances is vital for ensuring compliance and maintaining product quality. For example:

Regional Standards Compliance: Familiarize yourself with the specific standards and certifications required in your target market. This may include local regulations regarding safety, environmental impact, and performance.

Documentation and Traceability: Ensure that suppliers provide thorough documentation, including certificates of compliance, test reports, and material traceability records. This information is essential for audits and regulatory compliance in your region.

By focusing on these critical aspects of the manufacturing process and quality assurance, international B2B buyers can make informed decisions when sourcing DSS Knife Gate Valves, ensuring they receive reliable, high-performance products suited for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dss knife gate valve’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure DSS Knife Gate Valves, specifically the Severe Service Knife Gate Valve (SSKGV). The procurement of such specialized valves requires a thorough understanding of technical specifications, supplier capabilities, and industry standards. Following this checklist will help ensure you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes pressure ratings, material compatibility, and operational conditions such as temperature and media type.

– Key Considerations: Ensure that the valve can handle the specific challenges of your application, such as corrosive substances or high differential pressure scenarios.

Step 2: Research Industry Standards and Certifications

Understanding relevant industry standards is crucial for compliance and safety. Familiarize yourself with certifications such as API, ASME, and MSS specifications that the valve must meet.

– Why It Matters: Compliance ensures that the valve will perform reliably in severe service conditions and minimizes the risk of operational failures.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation of their capabilities and reputation. Request company profiles, case studies, and references from existing customers in your industry.

– Assessment Criteria: Look for suppliers with a proven track record in manufacturing severe service valves, particularly those that have been operational in similar environments.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold the necessary certifications for quality assurance and regulatory compliance. This includes ISO 9001:2015 for quality management and CE certification for European markets.

– Importance: Certifications not only validate the quality of the product but also indicate the supplier’s commitment to maintaining high manufacturing standards.

Step 5: Request Detailed Product Information

Engage with suppliers to obtain detailed product specifications and performance data for the DSS Knife Gate Valve. This includes information on actuation options, maintenance requirements, and warranty policies.

– What to Look For: Assess the valve’s design features, such as bidirectional zero-leakage isolation, to ensure it aligns with your operational demands.

Step 6: Conduct Cost-Benefit Analysis

Analyze the total cost of ownership (TCO) including initial purchase price, installation, and maintenance costs. A higher upfront investment in a quality valve can lead to lower long-term costs due to reduced downtime and maintenance needs.

– Calculating TCO: Consider factors such as the expected lifespan of the valve and the operational savings associated with reduced failures.

Step 7: Finalize and Document Purchase Agreements

Once you’ve selected a supplier, ensure that all terms are clearly documented in a purchase agreement. This should include delivery timelines, payment terms, and after-sales support.

– Documentation Importance: A well-documented agreement protects both parties and provides clarity on expectations, ensuring a smoother procurement process.

By following this checklist, B2B buyers can effectively navigate the sourcing process for DSS Knife Gate Valves, ensuring that they meet their operational requirements while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for dss knife gate valve Sourcing

What Are the Key Cost Components in Sourcing DSS Knife Gate Valves?

When evaluating the cost structure for sourcing DSS knife gate valves, various components come into play. The primary cost components include:

Materials: High-quality materials are essential for the durability and performance of knife gate valves, especially in severe service conditions. Common materials include stainless steel, carbon steel, and specialized alloys designed to resist corrosion and wear. The cost of raw materials can fluctuate based on market conditions, impacting overall pricing.

Labor: Skilled labor is necessary for the manufacturing and assembly of knife gate valves. Labor costs can vary significantly depending on the region, with countries in Africa, South America, and parts of Europe experiencing different wage structures.

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as facility costs, utilities, and administrative expenses. Overhead can vary based on the scale of operations and the efficiency of the manufacturing processes.

Tooling: Custom tooling may be required for specialized valve designs or modifications. The upfront investment in tooling can influence the overall cost, particularly for low-volume orders.

Quality Control (QC): Ensuring the valves meet stringent quality standards incurs additional costs. This includes testing, inspection, and certification processes, which are critical for valves used in high-pressure and hazardous environments.

Logistics: Shipping costs can significantly affect the total price, especially for international buyers. Factors like distance, shipping methods, and import duties must be considered.

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on competition and perceived value in the market.

How Do Price Influencers Impact the Cost of DSS Knife Gate Valves?

Several factors influence the pricing of DSS knife gate valves:

Volume/MOQ: Minimum order quantities (MOQs) and volume purchases often lead to discounts. Larger orders can reduce per-unit costs, making it advantageous for buyers to consolidate purchases.

Specifications and Customization: Custom features, such as specific actuation options or material specifications, can increase the price. Buyers should clearly define their requirements to avoid unexpected costs.

Materials: The choice of materials directly affects pricing. Higher-grade materials designed for extreme conditions may incur additional costs but offer longer service life and reduced maintenance.

Quality and Certifications: Products that meet international quality standards and certifications (such as ISO or CE) may carry a premium price. However, these certifications often justify the investment through enhanced reliability and safety.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their experience and proven track record, but they often provide better service and product quality.

Incoterms: Understanding Incoterms is crucial for international buyers, as they dictate the responsibilities for shipping costs, insurance, and risk. Selecting the right Incoterm can influence overall pricing and delivery times.

What Are Some Negotiation and Cost-Efficiency Tips for International Buyers?

International buyers should consider several strategies to enhance cost-efficiency when sourcing DSS knife gate valves:

Leverage Volume Discounts: Consolidate orders to meet MOQs and negotiate better pricing based on higher volume purchases. This approach can significantly reduce costs per unit.

Engage in Open Negotiation: Establish transparent communication with suppliers to discuss pricing structures, potential discounts, and flexible payment terms. A collaborative approach can lead to mutually beneficial agreements.

Evaluate Total Cost of Ownership (TCO): Consider the long-term costs associated with valve performance, including maintenance, downtime, and replacement. Investing in higher-quality valves may have a higher upfront cost but result in lower TCO.

Research and Compare Suppliers: Take the time to compare multiple suppliers based on quality, price, and service. Ensure that the chosen supplier meets the required standards and can provide reliable delivery timelines.

Stay Informed on Market Trends: Monitor global material costs and trends in valve technology to make informed purchasing decisions. Being aware of market conditions can provide leverage during negotiations.

Disclaimer on Indicative Prices

It’s important to note that pricing for DSS knife gate valves can vary significantly based on the aforementioned factors. Prospective buyers are encouraged to obtain detailed quotes from suppliers to understand the specific costs associated with their requirements.

Alternatives Analysis: Comparing dss knife gate valve With Other Solutions

Introduction to Alternative Solutions for Knife Gate Valves

When selecting a valve for industrial applications, especially in severe service environments, it is essential to consider various options available in the market. The DSS Knife Gate Valve is renowned for its robust design and capability to handle challenging conditions. However, there are alternative solutions that may also meet specific operational needs. This analysis compares the DSS Knife Gate Valve against two viable alternatives: the Slide Gate Valve and the Butterfly Valve, evaluating their performance, cost, ease of implementation, maintenance, and best-use cases.

Comparison Table

| Comparison Aspect | Dss Knife Gate Valve | Slide Gate Valve | Butterfly Valve |

|---|---|---|---|

| Performance | Excellent for severe service; zero-leakage design | Good for bulk material handling; moderate leakage | Fast operation; limited sealing capability |

| Cost | Higher initial investment; lower TCO due to durability | Moderate cost; depends on size and material | Generally lower cost; cost-effective for large volumes |

| Ease of Implementation | Requires precise installation; can be complex | Relatively easy to install; straightforward design | Simple installation; minimal space requirements |

| Maintenance | Low maintenance; durable materials | Moderate maintenance; wear on seals | Requires more frequent maintenance; seals may degrade |

| Best Use Case | Mining, chemical processing, wastewater management | Bulk material handling in mining and agriculture | Water distribution, HVAC systems, and general industrial use |

Detailed Breakdown of Alternatives

Slide Gate Valve

The Slide Gate Valve is commonly used for controlling the flow of bulk materials. It consists of a flat plate that slides within the valve body to open or close the flow path. One of its primary advantages is its straightforward installation process, making it an attractive option for many operations. However, it can experience moderate leakage, which may not be suitable for applications requiring absolute isolation. While the initial investment is generally moderate, the valve may require regular maintenance to ensure the seals do not wear down over time.

Butterfly Valve

The Butterfly Valve is known for its simple structure and fast operation, making it ideal for applications where quick flow control is necessary. It features a rotating disc that opens or closes the flow path. This valve is typically more cost-effective than the DSS Knife Gate Valve, especially for large volume applications. However, it does not provide the same level of sealing capability, which may result in leakage, particularly in high-pressure systems. Maintenance can be more frequent due to wear on the seals, and it is best suited for less severe service environments.

Conclusion: Choosing the Right Valve Solution

In selecting the appropriate valve for your application, B2B buyers should carefully assess their specific operational requirements. The DSS Knife Gate Valve excels in severe environments, offering robust performance and low maintenance, albeit at a higher initial cost. In contrast, the Slide Gate Valve and Butterfly Valve present viable alternatives with varying advantages and limitations, particularly in terms of cost and ease of use. Ultimately, the decision should align with the operational demands, budget constraints, and desired performance outcomes of the specific industry application. By understanding these alternatives, buyers can make informed decisions that enhance efficiency and reliability in their operations.

Essential Technical Properties and Trade Terminology for dss knife gate valve

What Are the Key Technical Properties of DSS Knife Gate Valves?

Understanding the technical specifications of DSS Knife Gate Valves is crucial for B2B buyers, especially when selecting valves for severe service applications. Below are essential properties that define their performance and reliability:

1. Material Grade

DSS Knife Gate Valves are typically constructed from high-grade materials such as stainless steel, carbon steel, or exotic alloys. The material choice affects the valve’s resistance to corrosion, temperature fluctuations, and mechanical wear. For industries like oil and gas or chemical processing, selecting the appropriate material ensures durability and reduces maintenance costs.

2. Pressure Rating

The valves are designed to handle a wide range of pressures, often rated up to ASME Class 1500 (3750 psig) or PN 250 (250 barg). This specification is critical for applications involving high differential pressures, ensuring that the valve can operate safely without risk of failure or leakage.

3. Leakage Rate

DSS Knife Gate Valves feature a bidirectional zero-leakage design, which is vital for preventing fluid loss and environmental contamination. This property is especially important in industries where safety and compliance with environmental regulations are paramount, as it protects both the facility and the surrounding area.

4. Actuation Options

These valves can be equipped with various actuation methods, including pneumatic, hydraulic, electric, or electro-hydraulic systems. The flexibility in actuation allows businesses to tailor the valve operation to specific application needs, enhancing efficiency and control in critical processes.

5. Size and Port Configuration

The valves come in various sizes and configurations, typically featuring a full round port. This design minimizes flow resistance and turbulence, making them ideal for handling viscous fluids or solids. Understanding the right size and configuration is essential for achieving optimal performance in any piping system.

What Are Common Trade Terms Related to DSS Knife Gate Valves?

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are key terms often encountered in the context of DSS Knife Gate Valves:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. When sourcing DSS Knife Gate Valves, buyers may deal directly with the OEM to ensure they receive quality products that meet specific requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding the MOQ is essential for buyers, as it can impact inventory management and cash flow. For large projects, negotiating the MOQ may lead to cost savings.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a price quote for specific products or services. This process is crucial for B2B buyers to compare offers and negotiate better pricing for DSS Knife Gate Valves.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in global trade. Familiarity with these terms helps B2B buyers understand shipping costs, risk transfer, and delivery responsibilities, which are critical when importing DSS Knife Gate Valves from international suppliers.

5. SIL (Safety Integrity Level)

SIL is a measure of safety system performance related to the reliability of safety functions. DSS Knife Gate Valves may be SIL-certified, indicating they meet strict safety standards, which is essential for industries where operational safety is non-negotiable.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when procuring DSS Knife Gate Valves, ensuring they choose the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the dss knife gate valve Sector

What Are the Key Market Drivers and Trends Influencing the DSS Knife Gate Valve Sector?

The global market for DSS knife gate valves is witnessing significant growth, driven by an increasing demand for reliable and efficient fluid control solutions across various industries, including oil and gas, mining, and wastewater management. One of the primary drivers is the rising need for zero-leakage technologies, as industries strive to enhance safety and environmental compliance. This trend is particularly prevalent in regions such as Africa and South America, where infrastructure development and resource extraction are on the rise, necessitating advanced valve technologies that can withstand severe service conditions.

Moreover, the advent of Industry 4.0 is reshaping sourcing strategies. Digitalization and automation are enabling real-time monitoring and predictive maintenance, allowing companies to optimize their supply chains. B2B buyers are increasingly looking for suppliers who provide not only high-quality products but also integrated solutions that include IoT capabilities for enhanced operational efficiency. In regions like the Middle East and Europe, there is a growing emphasis on sourcing valves that comply with stringent international standards, including ISO and CE certifications, to ensure reliability and performance.

Another emerging trend is the customization of valve solutions to meet specific application needs. Suppliers are adapting their product offerings to provide tailored solutions, such as specialized actuation options for different industrial environments. This shift is crucial for international buyers who require products that can seamlessly integrate into their existing systems.

How Is Sustainability and Ethical Sourcing Shaping the DSS Knife Gate Valve Market?

Sustainability is becoming a cornerstone of sourcing strategies in the DSS knife gate valve sector. As environmental regulations tighten globally, B2B buyers are increasingly concerned about the ecological impact of their procurement decisions. The production of knife gate valves often involves materials and processes that can be detrimental to the environment; thus, buyers are seeking suppliers who prioritize sustainable practices.

Ethical sourcing has gained traction as companies look to establish transparent supply chains that minimize environmental footprints. This includes sourcing materials from responsible vendors and ensuring that manufacturing processes adhere to environmental standards. Certifications such as ISO 14001 for environmental management and the use of recyclable materials are increasingly sought after by buyers looking to align their purchasing with their corporate sustainability goals.

Moreover, as consumers demand more environmentally friendly products, the demand for ‘green’ certifications is on the rise. Suppliers that offer products with eco-friendly materials or those that comply with international sustainability standards are likely to gain a competitive edge. This trend is particularly relevant for international buyers from Africa and South America, where the push for sustainable development is becoming more pronounced.

How Has the DSS Knife Gate Valve Sector Evolved Over Time?

The evolution of the DSS knife gate valve sector is marked by significant advancements in design and technology. Initially, knife gate valves were primarily used in simpler applications, but as industries evolved, so did the demands placed on these valves. The introduction of severe service knife gate valves (SSKGV) has transformed the landscape, allowing for applications in harsh environments such as mining and chemical processing.

Over the decades, manufacturers have focused on improving the durability and performance of these valves, leading to innovations such as the guided shear gate design, which enhances cutting capabilities through solids and viscous materials. These advancements not only improve operational efficiency but also align with the growing emphasis on zero-leakage performance, making DSS knife gate valves a critical component in modern industrial applications. As industries continue to innovate and expand, the DSS knife gate valve sector is poised for ongoing growth and transformation.

Frequently Asked Questions (FAQs) for B2B Buyers of dss knife gate valve

How do I solve issues with valve leakage in severe service applications?

To address valve leakage in severe service applications, consider investing in the DSS Severe Service Knife Gate Valve (SSKGV), known for its bidirectional zero-leakage design. This valve is engineered with dual transverse seals and a guided shear gate, enabling it to handle solids, corrosive materials, and extreme pressures without compromising integrity. Regular maintenance and proper installation are also crucial; ensure the valve is compatible with your specific application and operating conditions to minimize leakage risks.What is the best valve for handling corrosive materials in industrial applications?

The DSS Severe Service Knife Gate Valve is an excellent choice for applications involving corrosive materials. Its robust construction and ability to handle extreme pressures make it suitable for industries like chemical processing and wastewater management. Additionally, DSS offers exotic materials upon request, providing further customization to enhance resistance against specific corrosive agents. Always assess the material compatibility with your process fluids to ensure optimal performance.How can I ensure the quality and reliability of my valve supplier?

When vetting a valve supplier, prioritize those with certifications such as ISO 9001:2015 and compliance with industry standards like MSS SP-135. Check for their experience in severe service applications and their ability to provide detailed product documentation, including installation and operation manuals. Customer reviews, case studies, and references from similar industries can also provide insights into their reliability. Engaging directly with the supplier for a factory visit or virtual tour can further validate their capabilities.What are the typical minimum order quantities (MOQs) for DSS knife gate valves?

Minimum order quantities for DSS knife gate valves may vary based on the model and customization requirements. Generally, MOQs can range from a few units for standard products to larger quantities for customized solutions. It’s advisable to discuss your specific needs with the supplier to understand their MOQ policies, as many manufacturers are willing to accommodate smaller orders, especially for first-time buyers or trial runs.What payment terms should I expect when sourcing valves internationally?

Payment terms for international valve sourcing can vary widely among suppliers. Common options include payment in advance, a letter of credit, or net 30/60 terms after delivery. Some suppliers may offer flexible terms based on the buyer’s creditworthiness and order size. It’s essential to negotiate these terms upfront to avoid misunderstandings and ensure a smooth transaction process.How do I handle logistics and shipping for international valve orders?

To manage logistics effectively, collaborate closely with your supplier to determine the best shipping methods and timelines. Consider factors such as shipping costs, customs clearance, and delivery times. Ensure that your supplier provides all necessary documentation, including bills of lading and customs declarations, to facilitate smooth transport. Engaging a reliable freight forwarder can also help streamline the process and mitigate potential delays.Can DSS knife gate valves be customized for specific applications?

Yes, DSS knife gate valves can be tailored to meet specific application requirements. Options include modifications to the valve size, material selection, actuation types, and additional features such as extended stems or special coatings for enhanced durability. Discuss your unique needs with the supplier to explore customization possibilities that align with your operational demands and environmental conditions.What are the key industries that utilize DSS knife gate valves?

DSS knife gate valves are utilized across various industries, including mining, oil and gas, power generation, chemical processing, and wastewater management. Their robust design allows them to thrive in severe service environments, handling challenging materials and high pressures. Understanding the specific needs of your industry can help in selecting the right valve, ensuring optimal performance and longevity in demanding applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Dss Knife Gate Valve Manufacturers & Suppliers List

1. DSS Valves – Severe Service Knife Gate Valve

Domain: dssvalves.com

Registered: 2016 (9 years)

Introduction: Product Name: Severe Service Knife Gate Valve (SSKGV)\nKey Features: 1. Bidirectional zero-leakage design exceeding API, ASME, and MSS specifications up to ASME Class 1500/PN 250 (3750 psig/250 barg). 2. Guided Shear Gate design with a shearing tip and internal gate guides for cutting through all media including solids, scale, fiber, and paste. 3. Designed to perform in harsh conditions, overcomin…

2. DSS VALVES – Knife Gate Valve with Actuator

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “DSS VALVES Knife Gate Valve with Actuator”, “Size”: “3 inch”, “Pressure Rating”: “150 psi”, “Material”: “Stainless Steel (SST)”, “Condition”: “New – Open box”, “Seller”: “JLB The Farm”, “Price”: “$2,750.00 or Best Offer”, “Location”: “Broussard, Louisiana, United States”, “Shipping”: “May not ship to United Kingdom”, “Returns”: “Seller does not accept returns”, “eBay Item Number”…

3. DSS Valves – Severe Service Knife Gate Valves

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, DSS Valves – Severe Service Knife Gate Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. DSS Valves – Severe Service Knife Gate Valves

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, DSS Valves – Severe Service Knife Gate Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Zoro – DSS Manual 150 Stainless Flanged Knife Gate Valve

Domain: zoro.com

Registered: 1995 (30 years)

Introduction: DSS Manual 150 Stainless Flanged 6in Knife Gate Valve, Model: SV1S06-NI-SS-AF1-HW-S19

6. DSS Valves – Severe Service Knife Gate Valves

Domain: flow-fusion.com

Registered: 2018 (7 years)

Introduction: DSS Valves brand the Severe Service Knife Gate Valves. Key products include M81 Knife Gate Valve, Double Block and Bleed Valve, and Check Valves (SSCKV). The company focuses on various industries such as petrochemical, oil & gas, chemical, food & beverage, power, industrial gas, pulp & paper, cement, and waste water. Additional resources include product brochures and technical documentation on ele…

Strategic Sourcing Conclusion and Outlook for dss knife gate valve

In navigating the complexities of industrial operations, the DSS Severe Service Knife Gate Valve (SSKGV) stands out as a vital asset for sectors such as mining, oil and gas, and wastewater management. Its robust design, featuring bidirectional zero-leakage isolation and guided shear technology, ensures reliable performance even under the most challenging conditions. This not only enhances operational efficiency but also significantly reduces the risk of costly downtimes.

Strategic sourcing of the DSS SSKGV can yield substantial long-term benefits. By investing in high-quality valves tailored for severe service, businesses can optimize their processes, enhance safety, and improve overall cost-effectiveness. The durability and reliability of DSS products translate into lower maintenance costs and extended service life, making them an attractive choice for discerning international buyers.

As global industries continue to evolve, now is the time to consider integrating these advanced valve solutions into your operations. For companies in Africa, South America, the Middle East, and Europe, the opportunity to partner with a trusted supplier like DSS Valves can lead to significant competitive advantages. Embrace the future of industrial efficiency by reaching out for a consultation or quote today.