Introduction: Navigating the Global Market for irrigation valve cover rock

In the ever-evolving landscape of global irrigation solutions, sourcing high-quality irrigation valve cover rock presents a unique challenge for B2B buyers. As agricultural and landscaping projects expand across regions such as Africa, South America, the Middle East, and Europe, ensuring both aesthetic appeal and functional protection for vital irrigation components becomes paramount. This guide offers a comprehensive overview of irrigation valve cover rock, detailing various types and materials, applications in diverse environments, and essential supplier vetting strategies.

By examining the intricacies of the market, including cost considerations and regional availability, this resource equips international buyers with the knowledge needed to make informed purchasing decisions. With a focus on durability, weather resistance, and compatibility with leading irrigation systems, the guide addresses common pain points such as product quality and supplier reliability. Whether you are sourcing for large-scale agricultural operations or smaller landscaping projects, understanding the nuances of irrigation valve cover rock will empower you to select the right solutions that meet both your practical needs and aesthetic preferences.

Navigating the global market has never been easier; this guide serves as your roadmap to successful procurement, ensuring that you can enhance the functionality and appearance of your irrigation systems while maximizing your investment.

Understanding irrigation valve cover rock Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Granite Resin Rock Cover | Simulated granite finish, rotomolded resin construction | Landscaping, irrigation systems, plumbing installations | Pros: Aesthetic appeal, durability, lightweight. Cons: May not fit all valve sizes. |

| Sandstone Resin Rock Cover | Sandstone appearance, UV-resistant, hollow interior for equipment | Residential and commercial landscaping | Pros: Natural look, protects from sun damage. Cons: Less color variety than granite. |

| Artificial Rock Well Pump Cover | Larger size options, designed for well pumps and septic systems | Agricultural applications, rural housing developments | Pros: Versatile sizing, weather-resistant. Cons: Heavier, may require more than one person to install. |

| Decorative Valve Box Cover | Customizable colors and designs, lightweight composite materials | Residential gardens, public parks | Pros: High customization, enhances aesthetic value. Cons: Potentially higher cost for custom designs. |

| Heavy-Duty Valve Box Cover | Reinforced material for extreme weather conditions | Industrial applications, high-traffic areas | Pros: Exceptional durability, weather resistance. Cons: Higher weight and cost. |

What Are the Characteristics of Granite Resin Rock Covers?

Granite resin rock covers are popular for their realistic appearance, mimicking natural granite. Made from rotomolded resin, these covers are lightweight yet durable, making them easy to install. They are particularly suitable for irrigation systems and plumbing installations in both residential and commercial settings. B2B buyers should consider the compatibility with existing equipment and the potential need for additional anchoring options due to their lightweight nature.

How Do Sandstone Resin Rock Covers Differ?

Sandstone resin rock covers feature a natural sandstone look and are designed to withstand UV rays, preventing fading over time. The hollow interior allows for ample space for various irrigation and plumbing components. These covers are ideal for landscaping projects where aesthetic appeal is crucial. When purchasing, B2B buyers should evaluate the specific shade and finish that best complements the surrounding environment.

What Makes Artificial Rock Well Pump Covers Ideal for Agricultural Use?

Artificial rock well pump covers are larger and designed specifically for well pumps and septic systems. Their robust construction ensures protection against weather elements, making them suitable for agricultural applications and rural housing developments. Buyers should consider the size and weight of these covers, as they may require additional manpower for installation. Their versatility in sizing can accommodate various project needs.

Why Choose Decorative Valve Box Covers?

Decorative valve box covers offer high customization options in colors and designs, enhancing the visual appeal of gardens and public parks. Made from lightweight composite materials, they are easy to install and can significantly improve the aesthetic value of landscaping projects. B2B buyers should weigh the customization costs against the potential branding benefits, especially in commercial landscaping contracts.

What Are the Advantages of Heavy-Duty Valve Box Covers?

Heavy-duty valve box covers are constructed from reinforced materials designed to withstand extreme weather conditions and high-traffic areas. These covers are ideal for industrial applications where durability is paramount. B2B buyers should consider the higher initial investment against the long-term cost savings associated with reduced replacement frequency due to their robust nature.

Key Industrial Applications of irrigation valve cover rock

| Industry/Sector | Specific Application of irrigation valve cover rock | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Concealing irrigation valves in large-scale farming operations | Protects equipment from environmental damage and enhances aesthetic appeal | Durability against harsh weather, compatibility with local irrigation systems |

| Landscaping & Gardening | Covering sprinkler systems in residential and commercial landscapes | Improves visual appeal while providing necessary protection to valves | Variety of designs to match landscape aesthetics, lightweight for easy installation |

| Water Management | Hiding backflow preventers and pumps in municipal water systems | Ensures compliance with safety regulations and prevents unauthorized access | Sourcing from reputable manufacturers to ensure quality and compliance |

| Construction & Development | Covering plumbing fixtures in new residential or commercial builds | Aids in maintaining a clean site appearance and protects equipment from damage | Custom sizing options for diverse applications, availability of different materials |

| Parks & Recreation | Disguising utility access points in public parks and recreational areas | Enhances visitor experience by blending infrastructure into natural surroundings | Consideration for vandalism resistance, ease of maintenance and access |

How is irrigation valve cover rock utilized in agriculture?

In the agriculture sector, irrigation valve cover rock is primarily used to conceal irrigation valves in large-scale farming operations. This application is crucial as it protects the equipment from environmental elements like UV rays and moisture, which can cause wear and tear. Moreover, these covers enhance the aesthetic appeal of the fields, making them more visually appealing. International buyers, particularly in regions like Africa and South America, should consider sourcing covers that are durable and compatible with local irrigation systems to ensure longevity and effectiveness.

What role does irrigation valve cover rock play in landscaping and gardening?

In landscaping and gardening, irrigation valve cover rock is essential for covering sprinkler systems in both residential and commercial landscapes. These covers not only protect the valves from potential damage but also significantly improve the visual appeal of outdoor spaces. For B2B buyers, particularly in Europe and the Middle East, sourcing a variety of designs that match the landscape aesthetics is crucial. Additionally, the lightweight nature of these covers facilitates easy installation, which is a significant advantage for landscaping businesses.

Why is irrigation valve cover rock important for water management?

In the context of water management, irrigation valve cover rock is utilized to hide backflow preventers and pumps in municipal water systems. This application is vital for ensuring compliance with safety regulations and preventing unauthorized access to essential infrastructure. Businesses in this sector should prioritize sourcing from reputable manufacturers to ensure the quality and compliance of these covers. Furthermore, covers must be designed to withstand local environmental conditions, especially in regions prone to extreme weather.

How does irrigation valve cover rock benefit construction and development projects?

During construction and development, irrigation valve cover rock is used to cover plumbing fixtures, maintaining a clean site appearance and protecting equipment from damage. This application is particularly beneficial in new residential or commercial builds where aesthetics and functionality are equally important. Buyers in this sector should look for custom sizing options to accommodate diverse applications and ensure that the covers are readily available in different materials to suit specific project requirements.

What advantages does irrigation valve cover rock offer in parks and recreation areas?

In parks and recreational areas, irrigation valve cover rock is used to disguise utility access points, enhancing the visitor experience by blending infrastructure into the natural surroundings. This application not only improves the aesthetic quality of public spaces but also helps in maintaining safety by preventing unauthorized access to utility systems. When sourcing these covers, considerations for vandalism resistance and ease of maintenance are essential, especially in high-traffic areas where durability is key.

3 Common User Pain Points for ‘irrigation valve cover rock’ & Their Solutions

Scenario 1: Insufficient Protection Against Environmental Damage

The Problem: Many B2B buyers face the challenge of protecting irrigation valves from harsh environmental conditions. In regions with extreme temperatures, UV exposure, or heavy rainfall, standard valve covers may deteriorate quickly, leading to costly repairs or replacements. Buyers often express frustration when their chosen products fail to provide adequate protection, resulting in operational downtime and increased maintenance costs.

The Solution: To mitigate these issues, it is essential to source irrigation valve cover rocks made from high-quality, weather-resistant materials like rotomolded resin. When specifying products, buyers should prioritize covers that offer UV protection and are designed to withstand extreme weather conditions. Additionally, opting for covers with a realistic, natural look can enhance the aesthetic appeal of landscaping while ensuring functionality. Implementing a regular maintenance schedule to inspect the covers can also help identify any potential damage early, allowing for timely replacements before significant issues arise.

Scenario 2: Incompatibility with Existing Infrastructure

The Problem: A common pain point for B2B buyers is the mismatch between irrigation valve covers and existing valve or plumbing systems. Many buyers report difficulties when trying to fit new covers onto older infrastructure, which can lead to wasted time and resources. This issue is particularly prevalent in regions where infrastructure may not be standardized, causing significant delays in project timelines.

The Solution: To address compatibility issues, buyers should conduct a thorough assessment of their existing infrastructure before purchasing irrigation valve covers. This involves taking accurate measurements of the valves and ensuring that the chosen covers can accommodate them. It is advisable to select covers that are compatible with various brands and models, as this flexibility can ease the integration process. Additionally, working with suppliers who offer customization options can ensure that covers fit seamlessly with existing systems, thereby avoiding installation headaches and project delays.

Scenario 3: Limited Aesthetic Appeal

The Problem: Aesthetic concerns are increasingly important in landscaping and urban planning projects. Buyers often encounter irrigation valve covers that detract from the overall design of the landscape, leading to dissatisfaction among clients or stakeholders. This issue is especially pronounced in regions where landscaping is a critical component of property value and community appeal.

The Solution: To enhance the aesthetic value of irrigation valve covers, buyers should look for options that mimic natural rock formations, such as simulated granite or sandstone. These covers not only conceal unsightly plumbing fixtures but also blend harmoniously with the surrounding environment. When sourcing these products, it is beneficial to select manufacturers that offer a variety of colors and textures, allowing for customization to match specific landscape designs. Additionally, incorporating landscaping elements like plants or decorative stones around the covers can further enhance their visual appeal, creating a seamless integration with the overall landscape design.

By addressing these common pain points with targeted solutions, B2B buyers can ensure they select the right irrigation valve cover rocks that meet both functional and aesthetic needs, ultimately leading to successful project outcomes and satisfied clients.

Strategic Material Selection Guide for irrigation valve cover rock

What Are the Key Materials Used in Irrigation Valve Cover Rock?

When selecting materials for irrigation valve cover rocks, it is essential to consider their properties, advantages, and limitations. This analysis will focus on four common materials: rotomolded resin, fiberglass, concrete, and natural stone. Each material presents unique characteristics that can significantly impact performance and suitability for various applications.

How Does Rotomolded Resin Perform in Irrigation Valve Covers?

Rotomolded resin is a popular choice for irrigation valve covers due to its lightweight nature and durability. This material is resistant to fading, warping, and damage from lawn equipment, making it ideal for outdoor applications. It can withstand a wide range of temperatures and environmental conditions, ensuring longevity.

Pros: Rotomolded resin is cost-effective and easy to install, often requiring no special tools. Its hollow interior allows for ample space for various irrigation components.

Cons: While durable, rotomolded resin may not be as robust as other materials under extreme pressure or heavy impacts.

Impact on Application: This material is compatible with most irrigation systems and provides adequate protection against UV rays and moisture.

Considerations for International Buyers: Buyers should ensure that the resin meets local environmental regulations and standards, such as ASTM or DIN certifications, particularly in regions like Europe and the Middle East.

What Are the Benefits and Drawbacks of Fiberglass for Valve Covers?

Fiberglass is another viable material for irrigation valve covers, known for its strength and resistance to corrosion. It can handle high temperatures and is less prone to cracking compared to other materials.

Pros: Fiberglass is highly durable and can withstand harsh weather conditions. It is also lightweight and easy to transport.

Cons: The manufacturing process for fiberglass can be more complex and costly than for other materials, potentially leading to higher prices for end-users.

Impact on Application: Fiberglass covers are suitable for environments with extreme temperatures, ensuring that irrigation components remain protected.

Considerations for International Buyers: Compliance with international standards is crucial, especially in regions with stringent regulations, like Germany. Buyers should verify that the fiberglass used is free from harmful substances.

Why Choose Concrete for Irrigation Valve Covers?

Concrete is a traditional choice for irrigation valve covers, known for its strength and durability. It can withstand heavy loads and provides excellent protection for the underlying equipment.

Pros: The primary advantage of concrete is its robustness and longevity. It can endure significant pressure and is resistant to various environmental factors.

Cons: Concrete is heavy and may require specialized equipment for installation. It is also prone to cracking if not properly cured.

Impact on Application: Concrete covers are ideal for high-traffic areas where heavy machinery may be present.

Considerations for International Buyers: Buyers should be aware of local construction codes and standards, ensuring that the concrete meets relevant specifications, such as JIS in Japan or ASTM in the U.S.

What Role Does Natural Stone Play in Valve Cover Applications?

Natural stone offers an aesthetically pleasing option for irrigation valve covers, blending seamlessly into landscapes. It is highly durable and can withstand various environmental conditions.

Pros: The natural appearance of stone enhances landscape aesthetics, making it a preferred choice for residential applications. It is also highly durable and resistant to weathering.

Cons: Natural stone can be expensive and may require more labor-intensive installation processes.

Impact on Application: Stone covers are suitable for areas where visual appeal is essential, although they may not be as practical in high-traffic zones.

Considerations for International Buyers: Buyers should consider the availability of local stone and any import regulations that may apply, particularly in regions like Africa and South America, where sourcing may vary.

Summary of Material Selection for Irrigation Valve Covers

| Material | Typical Use Case for irrigation valve cover rock | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rotomolded Resin | Residential irrigation systems | Lightweight and easy to install | Less robust under extreme pressure | Low |

| Fiberglass | Commercial and industrial applications | High durability and corrosion resistance | Higher manufacturing complexity | Medium |

| Concrete | High-traffic areas and heavy machinery zones | Excellent strength and longevity | Heavy and installation requires equipment | Medium |

| Natural Stone | Aesthetic landscaping applications | Visually appealing and durable | Expensive and labor-intensive installation | High |

This guide provides a comprehensive overview of the materials used in irrigation valve covers, helping B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve cover rock

What Are the Key Manufacturing Processes for Irrigation Valve Cover Rock?

The manufacturing of irrigation valve cover rocks involves several critical stages that ensure the final product is durable, aesthetically pleasing, and functional. Understanding these processes can help B2B buyers make informed decisions when sourcing these products.

1. Material Preparation: What Materials Are Used?

Irrigation valve cover rocks are typically made from rotomolded resin, a material known for its resilience against environmental factors. The resin is selected based on its ability to resist fading, warping, and damage from lawn equipment, making it suitable for outdoor use. During the material preparation stage, manufacturers ensure that the resin is free from impurities and mixed to the required specifications to achieve the desired color and texture.

2. Forming: How Is the Product Shaped?

The forming process for irrigation valve covers usually employs rotational molding (rotomolding), a technique that allows for the creation of hollow structures. In this process, the prepared resin is placed in a mold that is heated and rotated. This action evenly distributes the melted resin across the mold’s interior surface, forming a robust and lightweight cover. Key considerations during this stage include temperature control and rotation speed, which directly influence the thickness and strength of the final product.

3. Assembly: Are Additional Components Required?

In many cases, irrigation valve cover rocks may require additional components for optimal functionality. For instance, some designs include pre-drilled holes for landscape stakes to ensure secure anchoring. The assembly stage involves integrating these components, ensuring that all parts fit seamlessly, and that the product meets design specifications.

4. Finishing: What Techniques Are Employed?

The finishing process is crucial for enhancing the visual appeal and durability of the irrigation valve cover rocks. Techniques such as surface texturing, painting, or coating are applied to achieve a natural look, mimicking granite or sandstone. This not only improves aesthetics but also adds an extra layer of protection against the elements. Quality checks during this stage ensure that the finish meets the required standards for color consistency and surface integrity.

What Are the Quality Assurance Standards Relevant to Irrigation Valve Cover Rock?

Quality assurance (QA) is vital in ensuring that irrigation valve cover rocks meet the expectations of B2B buyers, particularly in diverse international markets. Several standards and practices are commonly employed.

International Standards: Which Ones Should Buyers Be Aware Of?

For manufacturers targeting global markets, adhering to international standards such as ISO 9001 is crucial. ISO 9001 outlines the requirements for a quality management system (QMS) that helps organizations ensure consistent quality in their products and services. Additionally, industry-specific certifications like CE marking in Europe and API standards for certain applications may also apply. These certifications assure buyers that the products meet stringent quality and safety requirements.

Key QC Checkpoints: What Should Be Monitored?

Quality control (QC) involves several critical checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the production process. Buyers should ensure that suppliers conduct thorough checks on the resin and other materials used.

In-Process Quality Control (IPQC): Monitoring during the production process is essential to catch any deviations from quality standards early. This includes checking the molding process and ensuring that temperatures and rotation speeds are maintained.

Final Quality Control (FQC): Once the irrigation valve covers are completed, a final inspection is performed to assess the overall quality, including appearance, dimensions, and functionality.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks associated with product quality.

What Are Effective Verification Methods?

Supplier Audits: Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. During an audit, buyers should assess the facilities, equipment, and practices in place.

Quality Reports: Requesting detailed quality reports can help buyers understand how a supplier maintains quality throughout the production process. These reports should outline the results of IQC, IPQC, and FQC.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services can conduct random sampling and testing of products to ensure compliance with relevant standards.

What Are Common Testing Methods for Quality Assurance?

Testing is a crucial aspect of quality assurance for irrigation valve cover rocks. Common methods include:

Physical Testing: This involves assessing the mechanical properties of the resin, such as tensile strength and impact resistance, to ensure durability.

Environmental Testing: Products may be subjected to accelerated weathering tests to evaluate their resistance to UV exposure, moisture, and temperature variations.

Aesthetic Testing: Visual inspections are performed to check for color consistency, surface defects, and overall appearance.

What Should International Buyers Consider Regarding QC and Certification Nuances?

B2B buyers from different regions may encounter varying quality standards and certifications. For example, European buyers may prioritize CE marking, while buyers in the Middle East may focus on local compliance standards. Understanding these nuances can help buyers ensure that the products they source meet local regulations and expectations.

Additionally, cultural factors may influence how quality is perceived and valued. Establishing clear communication with suppliers regarding quality expectations and certifications is vital to ensuring alignment and satisfaction.

In conclusion, understanding the manufacturing processes and quality assurance measures for irrigation valve cover rocks equips B2B buyers with the knowledge to make informed sourcing decisions. By focusing on material preparation, forming, assembly, finishing, and quality control, buyers can ensure they select reliable suppliers who adhere to international standards and deliver high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve cover rock’

When procuring irrigation valve cover rocks, it is essential to follow a structured approach to ensure you select the best products that meet your requirements. This guide provides a step-by-step checklist to help B2B buyers effectively navigate the sourcing process, focusing on quality, compatibility, and supplier reliability.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications of the irrigation valve cover rocks you require. Consider factors such as size, material (e.g., rotomolded resin, granite, sandstone), and design features that complement your landscape aesthetics. Establishing these criteria upfront will streamline the evaluation of potential suppliers and products.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing structures is crucial for making informed purchasing decisions. Conduct a thorough market analysis to identify popular materials and styles in your target regions, such as Africa, South America, the Middle East, and Europe. Pay attention to price ranges from various suppliers to ensure you are not overpaying for your desired products.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct comprehensive evaluations to ensure they meet your quality and service standards. Request detailed company profiles, including their experience in manufacturing irrigation products, and seek references from businesses in similar sectors. Additionally, verify if they have certifications that comply with local and international standards.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request product samples to assess the quality firsthand. Check for durability, aesthetics, and whether the samples match your specified requirements. This step is critical to ensure that the products not only meet functional needs but also align with your landscaping vision.

Step 5: Confirm Compatibility with Existing Equipment

Ensure that the irrigation valve cover rocks are compatible with your existing irrigation and plumbing systems. Verify that the dimensions and design allow for proper installation and accessibility. This compatibility is essential to avoid future complications during installation and maintenance.

Step 6: Review Shipping and Delivery Options

Examine the supplier’s shipping and delivery capabilities, especially if you are sourcing from international markets. Look for suppliers that offer reliable logistics solutions to ensure timely delivery. Additionally, consider any shipping costs that may affect your overall budget.

Step 7: Negotiate Terms and Finalize Purchase

Once you have selected a supplier, engage in negotiations to secure favorable terms. Discuss pricing, payment options, warranties, and return policies to protect your investment. A well-negotiated agreement can lead to long-term partnerships and potential discounts on future orders.

By following this checklist, B2B buyers can navigate the procurement of irrigation valve cover rocks with confidence, ensuring they select high-quality products that enhance their landscaping projects while meeting operational needs.

Comprehensive Cost and Pricing Analysis for irrigation valve cover rock Sourcing

What Are the Key Cost Components for Irrigation Valve Cover Rock Sourcing?

Understanding the cost structure for irrigation valve cover rocks is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Materials: The primary materials used in irrigation valve covers are rotomolded resins, which are durable and weather-resistant. Options like simulated granite and sandstone enhance aesthetic appeal. The choice of material directly impacts pricing, with higher-quality materials typically leading to increased costs.

Labor: Labor costs encompass the workforce involved in production, assembly, and quality assurance. In regions with higher labor costs, such as parts of Europe, the overall cost of the finished product may be elevated. Conversely, sourcing from areas with lower labor costs can reduce expenses but may affect quality.

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Efficient manufacturing processes can minimize overhead costs, which can be crucial for competitive pricing.

Tooling: The initial investment in molds and tools for production is significant. Buyers should consider how these costs are amortized over production volume, as larger orders can dilute tooling expenses per unit.

Quality Control: Ensuring products meet specifications and certifications is vital, particularly in markets with stringent standards. Implementing robust QC processes can increase costs but is necessary for maintaining product integrity.

Logistics: Shipping costs vary based on the distance from the manufacturing site to the buyer, packaging requirements, and transportation mode. International logistics may introduce additional complexities, such as customs duties and import taxes.

Margin: Suppliers typically apply a margin to cover their costs and ensure profitability. This margin can fluctuate based on market conditions and competitive dynamics.

How Do Price Influencers Affect the Cost of Irrigation Valve Covers?

Several factors influence the pricing of irrigation valve covers, including volume, specifications, materials, quality, supplier characteristics, and Incoterms.

Volume/MOQ: Ordering in larger quantities usually allows for better pricing per unit. Buyers should assess their needs carefully and consider potential future demand to negotiate favorable terms.

Specifications and Customization: Custom features, such as specific colors or sizes, can increase production costs. Buyers should weigh the benefits of customization against potential price increases.

Materials and Quality Certifications: The choice of materials affects not only the aesthetic but also the durability and performance of the product. High-quality materials may come at a premium but can lead to lower maintenance costs in the long run.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

Incoterms: Understanding shipping terms is crucial for international transactions. Incoterms dictate who bears the risk and costs at various points during shipping, affecting the total landed cost.

What Buyer Tips Can Help Optimize Cost-Efficiency in Irrigation Valve Cover Purchases?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, several strategies can help optimize costs and ensure a favorable purchasing experience:

Negotiation: Engage in discussions with suppliers to explore discounts for bulk purchases or long-term contracts. Suppliers may be more flexible during negotiations than initially presented.

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, durability, and potential replacement costs over the product’s lifecycle. Investing in higher-quality covers may reduce overall expenses in the long run.

Pricing Nuances: Be aware of regional pricing variations. Factors such as local demand, import tariffs, and currency fluctuations can significantly impact costs. Establishing relationships with multiple suppliers can provide leverage in negotiations.

Market Research: Stay informed about market trends and competitor pricing. Understanding the landscape can help identify the best deals and potential opportunities for cost savings.

Evaluate Supplier Reliability: Look for suppliers with positive reviews and established reputations. Reliability can prevent costly delays and ensure product quality.

Disclaimer on Indicative Prices

Prices for irrigation valve covers can vary widely based on the factors mentioned above. The figures referenced in the context of this analysis are indicative and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing irrigation valve cover rock With Other Solutions

Exploring Alternatives to Irrigation Valve Cover Rock

When it comes to concealing and protecting irrigation systems, various solutions exist beyond the popular irrigation valve cover rock. Each alternative offers distinct advantages and disadvantages, making it crucial for international B2B buyers to assess their specific needs and local conditions before making a decision. Below, we present a comparative analysis of irrigation valve cover rock against two viable alternatives: plastic valve boxes and artificial rock covers.

| Comparison Aspect | Irrigation Valve Cover Rock | Plastic Valve Box | Artificial Rock Cover |

|---|---|---|---|

| Performance | Excellent camouflage; protects against UV damage | Durable but less aesthetically pleasing | Mimics natural stone; protects well |

| Cost | Moderate ($57.29 – $66.99) | Low ($20 – $40) | High ($100 – $150) |

| Ease of Implementation | Lightweight; easy to install | Requires more effort; heavier | Generally easy to install |

| Maintenance | Low; resistant to fading and warping | Low; can become brittle over time | Low; weather-resistant materials |

| Best Use Case | Residential landscapes, gardens | Commercial applications, industrial areas | Residential or high-end landscaping |

An In-Depth Look at Alternative Solutions

Plastic Valve Box

Plastic valve boxes are a widely used alternative due to their affordability and functional design. They are generally lightweight and easy to transport, making them suitable for a variety of applications. However, while they are durable, they lack the aesthetic appeal of rock covers, which can be a significant drawback for residential areas or landscaping projects where visual integration is important. Additionally, plastic can become brittle with age and UV exposure, leading to potential cracking.

Artificial Rock Cover

Artificial rock covers are designed to mimic the appearance of natural stones, offering a more aesthetically pleasing option compared to traditional plastic boxes. These covers provide excellent protection against weather elements and can be installed relatively easily. However, they come at a higher price point, making them less viable for budget-conscious projects. Their weight can also pose installation challenges, particularly in remote or rugged locations.

Making the Right Choice for Your Needs

In conclusion, selecting the right solution for concealing irrigation systems requires careful consideration of various factors, including performance, cost, ease of implementation, maintenance, and specific use cases. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, the decision may hinge on local climatic conditions, aesthetic preferences, and budget constraints.

Ultimately, while irrigation valve cover rock offers a blend of functionality and visual appeal, alternatives like plastic valve boxes and artificial rock covers may better suit certain applications. Evaluating the pros and cons of each option will empower buyers to make informed decisions that align with their operational needs and market demands.

Essential Technical Properties and Trade Terminology for irrigation valve cover rock

What Are the Key Technical Properties of Irrigation Valve Cover Rock?

When considering irrigation valve cover rocks for landscaping and irrigation systems, several technical properties are essential for ensuring durability, functionality, and aesthetics. Here are the critical specifications to keep in mind:

Material Composition

Irrigation valve covers are often made from rotomolded resin or composite materials. These materials are engineered to resist fading, warping, and damage from environmental factors such as UV exposure and moisture. For B2B buyers, selecting high-quality materials ensures longevity and reduces replacement costs.Dimensions and Capacity

The size of the valve cover is crucial. Covers typically come in various dimensions, often measured in inches (e.g., 23 in. W x 30 in. L x 18 in. H). The interior capacity must be sufficient to accommodate the specific plumbing or irrigation components it is designed to protect. Understanding the required dimensions helps buyers choose the right cover for their specific installation needs.Weight and Portability

The weight of the cover affects its installation and handling. A lightweight design allows for easier transportation and installation by a single person. This property is particularly important for B2B buyers looking to minimize labor costs and enhance operational efficiency.Weather Resistance

Covers should exhibit weather-resistant properties to withstand various environmental conditions. This includes being impervious to water infiltration and resistant to extreme temperatures. For businesses operating in regions with harsh climates, selecting weather-resistant products can prevent costly damages and maintenance.Aesthetic Appeal

The simulated natural stone finishes, such as granite or sandstone, provide an aesthetically pleasing appearance that blends with landscaping. The visual quality is important for commercial properties where curb appeal can affect customer perceptions and property values.Installation Features

Features such as pre-drilled holes for landscape stakes enhance stability and security. Understanding these installation features can simplify the setup process, which is beneficial for contractors and landscape professionals.

What Are the Common Trade Terms Related to Irrigation Valve Cover Rock?

Navigating the B2B landscape involves familiarizing oneself with industry-specific terminology. Here are some key terms relevant to irrigation valve cover rocks:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of irrigation valve covers, knowing the OEM can provide insights into the quality and compatibility of products.MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their purchases effectively, ensuring they can meet their project requirements without incurring excess inventory.RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. B2B buyers should utilize RFQs to obtain competitive pricing and ensure they are making informed purchasing decisions.Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance responsibilities, and delivery timelines.Lead Time

This term refers to the time it takes for an order to be processed and delivered. Understanding lead times is critical for project planning, as delays can impact timelines and budgets.Warranty

A warranty is a promise made by the manufacturer regarding the condition of a product. Knowing the warranty terms can provide buyers with peace of mind regarding the longevity and reliability of their investment.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing irrigation valve cover rocks, ensuring they choose the best products for their needs.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve cover rock Sector

What Are the Current Trends Impacting the Irrigation Valve Cover Rock Market?

The irrigation valve cover rock market is experiencing significant growth driven by increasing global emphasis on sustainable landscaping and efficient irrigation solutions. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek environmentally friendly products, manufacturers are innovating with materials that not only mimic natural rock but also meet durability standards. Key trends include the rising popularity of simulated granite and sandstone covers made from rotomolded resin, which offer aesthetics without compromising on functionality.

Emerging technologies are also shaping the sourcing landscape. For instance, advancements in supply chain management software and e-commerce platforms are enabling buyers to access a broader range of products and suppliers. Additionally, the integration of artificial intelligence in inventory management allows for more efficient tracking of stock levels and demand forecasting. International buyers are increasingly prioritizing suppliers that can offer quick shipping and reliable inventory, which is crucial for maintaining project timelines.

The market dynamics indicate a shift towards customization, where buyers are looking for tailored solutions that match specific aesthetic requirements and functional needs. This trend is particularly evident in regions with diverse landscapes, where the cover’s appearance plays a crucial role in integration with the environment. As competition intensifies, suppliers who can provide high-quality, customizable products will have a distinct advantage.

How Is Sustainability Influencing the Sourcing of Irrigation Valve Cover Rocks?

Sustainability is becoming a cornerstone of the irrigation valve cover rock sector, with B2B buyers increasingly concerned about the environmental impact of their sourcing decisions. The demand for ethical sourcing practices is prompting manufacturers to adopt eco-friendly materials and processes. This includes using recycled materials in the production of valve covers and ensuring that their manufacturing processes minimize waste and energy consumption.

Certifications like FSC (Forest Stewardship Council) and other ‘green’ labels are gaining importance among buyers who wish to ensure that their products are sourced responsibly. By choosing suppliers with these certifications, businesses not only contribute to environmental conservation but also enhance their own brand reputation in a market that values sustainability. Moreover, transparent supply chains are essential; buyers are seeking partners who can provide traceability of materials from source to product, ensuring compliance with international sustainability standards.

In addition to environmental concerns, there is a growing recognition of the social implications of sourcing decisions. Companies are increasingly evaluating the labor practices of their suppliers, favoring those that uphold fair labor practices and contribute positively to their local communities. This holistic approach to sustainability is reshaping procurement strategies, making it imperative for suppliers to align with ethical values to attract and retain international B2B clients.

How Has the Irrigation Valve Cover Rock Market Evolved?

The irrigation valve cover rock market has evolved significantly over the past few decades, transitioning from traditional, utilitarian designs to modern, aesthetically pleasing options that blend seamlessly into landscaping. Initially, covers were primarily functional, designed merely to protect irrigation components from weather elements. However, as landscaping aesthetics gained importance, manufacturers began developing products that not only serve a protective purpose but also enhance the visual appeal of outdoor spaces.

This evolution has been accompanied by advancements in materials technology, allowing for the production of lightweight yet durable covers that resist fading, warping, and damage from environmental factors. The introduction of simulated natural materials has further broadened the market, catering to diverse consumer preferences and regional styles. As the industry continues to innovate, the focus is now on creating products that combine functionality with sustainable practices, reflecting the changing priorities of international buyers seeking environmentally responsible solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve cover rock

How do I select the right irrigation valve cover rock for my project?

When selecting an irrigation valve cover rock, consider the size and type of equipment you need to conceal, as well as the aesthetic preferences of your landscape. Look for options with realistic finishes, such as simulated granite or sandstone, that blend well with your environment. Additionally, ensure the cover is made from durable materials like rotomolded resin to withstand weather conditions and resist fading. Finally, verify compatibility with the specific irrigation systems you are using, as some covers may be designed for specific brands or types of equipment.What factors should I consider when sourcing irrigation valve covers internationally?

When sourcing irrigation valve covers internationally, consider factors such as product quality, supplier reliability, and compliance with local regulations. Research potential suppliers thoroughly, checking for certifications and customer reviews. It’s also crucial to assess shipping options, lead times, and costs associated with import duties and taxes. Furthermore, understanding the regional market demand and cultural preferences can help ensure that the products you choose will be well-received in your target market.What are the common minimum order quantities (MOQs) for irrigation valve covers?

Minimum order quantities (MOQs) for irrigation valve covers can vary significantly depending on the supplier and the type of product. Typically, MOQs may range from 50 to 200 units for bulk orders. Always inquire about MOQs when negotiating with suppliers, as some may offer flexibility for first-time buyers or larger contracts. Additionally, consider the cost-effectiveness of ordering in larger quantities, which may reduce the overall cost per unit and lead to better pricing arrangements.How can I ensure the quality of irrigation valve covers from suppliers?

To ensure the quality of irrigation valve covers from suppliers, request samples before placing a bulk order. Evaluate the samples for durability, finish, and compatibility with your existing systems. It’s also advisable to ask for certifications that demonstrate compliance with relevant industry standards. Establishing a good relationship with suppliers can facilitate quality assurance checks and provide insights into their manufacturing processes, allowing you to make informed decisions about your purchases.What payment terms are typically offered by international suppliers?

International suppliers often provide a range of payment terms, including upfront payments, net 30 or net 60 days, and letter of credit options. It’s essential to discuss payment terms early in negotiations to ensure they align with your cash flow and budgeting strategies. Some suppliers may offer discounts for early payments or larger orders. Always ensure that you have a clear understanding of any fees associated with currency exchange and international transactions to avoid unexpected costs.What are the best practices for shipping irrigation valve covers internationally?

When shipping irrigation valve covers internationally, best practices include selecting reliable freight forwarders and understanding the shipping terms (Incoterms) that define the responsibilities of each party involved. Ensure proper packaging to protect the products during transit and consider insurance for high-value shipments. Familiarize yourself with the customs regulations of the destination country, including any documentation required for importation. Lastly, track shipments closely to address any potential delays or issues promptly.Can I customize irrigation valve cover rocks for my brand?

Yes, many suppliers offer customization options for irrigation valve cover rocks, allowing you to incorporate your branding or design preferences. Customization may include specific colors, sizes, or logos. When discussing customization, ensure you communicate your requirements clearly and confirm any minimum order quantities associated with custom products. Keep in mind that customized items may have longer lead times and additional costs, so plan your orders accordingly to meet project timelines.What are the most common applications for irrigation valve cover rocks?

Irrigation valve cover rocks are commonly used to conceal anti-siphon valves, backflow prevention devices, pumps, and well casings in both residential and commercial landscapes. They provide an aesthetically pleasing solution that blends seamlessly with outdoor environments while protecting vital irrigation components from weather damage and UV exposure. Additionally, these covers can enhance the overall appearance of landscaping projects, making them a popular choice among landscape architects and contractors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Irrigation Valve Cover Rock Manufacturers & Suppliers List

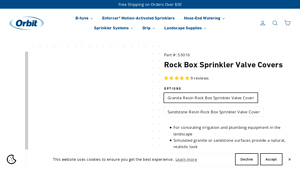

1. Orbit – Rock Box Sprinkler Valve Covers

Domain: orbitonline.com

Registered: 1999 (26 years)

Introduction: {‘name’: ‘Rock Box Sprinkler Valve Covers’, ‘part_number’: ‘53016’, ‘options’: [{‘color’: ‘Granite Resin’, ‘price’: 57.29}, {‘color’: ‘Sandstone Resin’, ‘price’: 68.79}], ‘description’: ‘The rock valve cover is designed to provide an aesthetically pleasing cover for anti-siphon valves, backflow prevention devices, pumps, well casings, and other plumbing fixtures in the landscape. The simulated gra…

2. Reddit – Sprinkler Valve Box Maintenance

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This is the sprinkler valve box for a house, which appears to have been neglected for years, leading to dirt accumulation and potential animal habitation. Users in the comments discuss cleaning methods and preventative measures such as using gravel for drainage.

3. Fake Rock Camo – Backflow and Irrigation Valve Rocks

Domain: fakerockcamo.com

Registered: 2020 (5 years)

Introduction: Backflow and Irrigation Valve Rocks designed to work with Backflow and Irrigation Valve Assemblies. Available models include: Model 102 ($180.00), Model 107 ($82.00), Model 109 ($95.00), Model 110 ($140.00), Model 115 ($120.00), Model 116 ($300.00), Model 125 ($140.00), Model 126 ($140.00). Accessories include Insulated Backflow Pouch Cover ($50.00 – $80.00) and Rock Vents ($4.00 – $17.00).

4. Orbit – Rock Valve Box

Domain: acehardware.com

Registered: 1995 (30 years)

Introduction: Orbit Rock Valve Box, Mfr# 53016, Price: $109.99, Item # 7017711, Free returns on most items within 30 days, Ace Hardware Protection Plan available, includes 100% parts & repair labor coverage for mechanical and electrical defects after manufacturer warranty expires, power surge protection, accidental damage coverage (on select items), prepaid shipping for failed product (both ways), customer serv…

Strategic Sourcing Conclusion and Outlook for irrigation valve cover rock

In the evolving landscape of irrigation solutions, the strategic sourcing of irrigation valve cover rocks offers significant advantages for international B2B buyers. These products not only enhance the aesthetic appeal of outdoor spaces by disguising unsightly plumbing fixtures but also provide practical benefits such as protection from environmental damage and UV exposure. The use of durable materials like rotomolded resin ensures longevity, reducing the need for frequent replacements and thereby lowering overall costs.

For buyers in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the local market dynamics and sourcing options is crucial. Engaging with reliable suppliers who offer a variety of designs and sizes can optimize inventory management and meet specific regional needs.

As the demand for sustainable and visually appealing landscape solutions grows, now is the time to invest in high-quality irrigation valve cover rocks. By prioritizing strategic sourcing, businesses can not only enhance their product offerings but also position themselves as leaders in an increasingly competitive market. Seize this opportunity to elevate your landscape solutions and meet the expectations of your clients.