Introduction: Navigating the Global Market for how to shut off irrigation valve

In the dynamic landscape of global agriculture, effectively managing irrigation systems is crucial for optimizing water usage and ensuring crop health. One of the fundamental skills in this area is knowing how to shut off irrigation valves properly. Whether you’re sourcing equipment for expansive farms in Brazil or managing irrigation in arid regions of Saudi Arabia, understanding the intricacies of valve operation is essential. This comprehensive guide delves into the various types of irrigation valves, their specific applications, and crucial maintenance practices, empowering B2B buyers to make informed purchasing decisions.

As international buyers navigate the complexities of irrigation solutions, this guide will also address key considerations such as supplier vetting, cost analysis, and the integration of technology for enhanced efficiency. With a focus on practical insights tailored to the unique challenges faced in regions like Africa, South America, the Middle East, and Europe, this resource serves as a vital tool for professionals seeking to optimize their irrigation systems. By providing detailed instructions and expert recommendations, this guide ensures that businesses can minimize operational disruptions, enhance sustainability, and ultimately improve their bottom line in an increasingly competitive market.

Understanding how to shut off irrigation valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Shut-off Valve | Operated manually with a handle; typically a ball valve | Small to medium-sized irrigation systems | Pros: Simple to operate; low maintenance. Cons: Labor-intensive for larger systems. |

| Electric Solenoid Valve | Automated control via electrical signals; remote operation | Large agricultural and commercial irrigation | Pros: Efficient and precise; integrates with smart systems. Cons: Higher initial cost; requires electrical setup. |

| Backflow Preventer Shut-off | Features built-in backflow prevention; often installed outdoors | Residential and commercial properties | Pros: Protects water supply; essential for compliance. Cons: Can be complex to install; regular maintenance needed. |

| Inline Valve | Installed within the irrigation line; can be manual or automatic | Specialized irrigation systems like drip irrigation | Pros: Space-saving; minimizes water loss. Cons: Difficult to access for repairs; may require specialized tools. |

| Zone Control Valve | Controls water flow to specific zones; can be manual or automated | Large landscaping projects and agricultural fields | Pros: Customizable irrigation; optimizes water usage. Cons: More components increase the potential for failure. |

What Are the Characteristics of Manual Shut-off Valves?

Manual shut-off valves are typically ball valves that require physical operation to control water flow. They are straightforward to use and commonly found in small to medium-sized irrigation systems. B2B buyers should consider their ease of installation and low maintenance requirements, making them ideal for businesses with limited resources or those seeking cost-effective solutions. However, manual operation can become labor-intensive in larger systems, potentially increasing operational costs.

How Do Electric Solenoid Valves Enhance Irrigation Systems?

Electric solenoid valves offer automated control, allowing for remote operation through electrical signals. This feature is particularly beneficial for large agricultural and commercial irrigation systems, where precise control over water flow is essential. B2B purchasers should evaluate the integration capabilities with existing smart irrigation systems. While they provide efficiency and convenience, the initial investment is higher, and proper electrical setup is necessary, which may complicate installation.

Why Are Backflow Preventer Shut-offs Important?

Backflow preventer shut-offs are crucial for protecting the potable water supply from contamination. These valves are often installed outdoors and are essential for compliance with local regulations. They are suitable for both residential and commercial applications. Buyers must consider the need for regular maintenance and potential complexity during installation. While they offer significant protection, the upfront costs and maintenance requirements can be a consideration for budget-conscious businesses.

What Are the Advantages of Using Inline Valves?

Inline valves are installed directly within the irrigation line, allowing for either manual or automatic operation. Their design saves space and reduces water loss, making them ideal for specialized systems like drip irrigation. B2B buyers should assess their accessibility for repairs, as inline valves can be challenging to reach. While they are efficient, the complexity of maintenance may necessitate specialized tools, which could add to overall operational costs.

How Do Zone Control Valves Optimize Water Usage?

Zone control valves manage water flow to specific areas of an irrigation system, allowing for customizable irrigation practices. This capability is particularly beneficial in large landscaping projects and agricultural fields, where different zones may have varying water requirements. Buyers should consider the increased component complexity and potential for failure, which may lead to higher maintenance needs. However, the ability to optimize water usage can significantly reduce costs and improve sustainability, making them an attractive option for large-scale operations.

Key Industrial Applications of how to shut off irrigation valve

| Industry/Sector | Specific Application of how to shut off irrigation valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Seasonal irrigation management to prevent water wastage | Enhances crop yield and conserves water resources | Availability of durable valves suited for varying climates |

| Landscaping | Maintenance of irrigation systems in commercial properties | Reduces operational costs and improves aesthetics | Compatibility with existing systems and ease of installation |

| Municipal Services | Emergency water management during drought or flooding | Ensures public safety and resource allocation | Compliance with local regulations and standards |

| Golf Course Management | Controlled irrigation for greens and fairways | Improves turf quality and reduces maintenance costs | Precision in valve functionality and reliability under pressure |

| Horticulture | Managing water supply for nurseries and greenhouses | Optimizes plant growth and reduces excess runoff | Adaptability to different plant types and environmental conditions |

How is ‘how to shut off irrigation valve’ applied in Agriculture?

In agriculture, knowing how to shut off irrigation valves is critical for seasonal water management. Farmers can prevent water wastage during dry seasons or when rainfall is sufficient. This practice enhances crop yields while conserving essential water resources, especially in regions facing water scarcity, such as parts of Africa and the Middle East. Buyers in this sector should consider sourcing durable valves that can withstand varying climatic conditions, ensuring longevity and efficiency.

What role does shutting off irrigation valves play in Landscaping?

In the landscaping sector, shutting off irrigation valves is vital for the maintenance of irrigation systems in commercial properties. Proper management reduces operational costs and enhances the aesthetic appeal of landscapes. Businesses benefit from improved resource allocation and reduced water bills. Buyers should look for valves that are compatible with existing systems and easy to install, ensuring minimal disruption during maintenance.

How does municipal services utilize irrigation valve shut-off procedures?

Municipal services rely on the ability to shut off irrigation valves for emergency water management, particularly during droughts or flooding. This capability ensures public safety and effective allocation of water resources. It is crucial for municipalities to comply with local regulations and standards when sourcing irrigation valves. They should prioritize suppliers who offer reliable products that meet these requirements.

Why is irrigation valve management essential for Golf Course Management?

In golf course management, controlling irrigation through valve shut-off is essential for maintaining the quality of greens and fairways. This practice not only enhances turf quality but also reduces long-term maintenance costs. Golf course operators should focus on sourcing valves that provide precision functionality and reliability under pressure, ensuring optimal water distribution across the course.

How is irrigation valve shut-off relevant to Horticulture?

In horticulture, effectively managing water supply through valve shut-off procedures is critical for nurseries and greenhouses. This management optimizes plant growth and minimizes excess runoff, which is particularly important in regions like South America where water resources can be limited. Buyers in this sector should seek valves that adapt well to different plant types and environmental conditions, ensuring the health and viability of their crops.

3 Common User Pain Points for ‘how to shut off irrigation valve’ & Their Solutions

Scenario 1: Confusion Over Valve Location Can Lead to System Damage

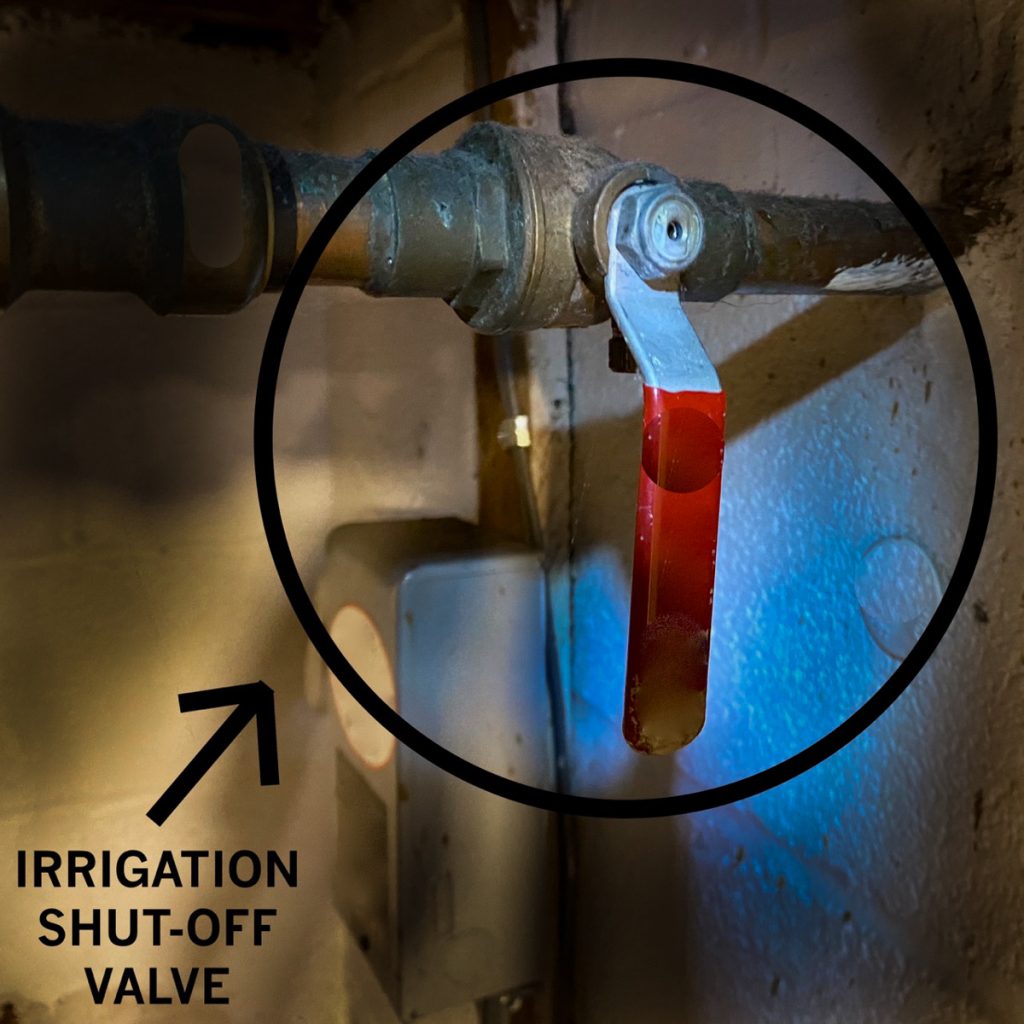

The Problem: B2B buyers often face uncertainty regarding the location of the irrigation shut-off valve, particularly in large agricultural or commercial landscapes. This confusion can lead to prolonged watering, resulting in waterlogging, crop damage, or increased operational costs. Moreover, with different valve designs and placements, such as in basements or utility rooms, the potential for misidentification of the shut-off valve increases, putting the entire irrigation system at risk.

The Solution: To mitigate this risk, buyers should invest in clear, detailed mapping of their irrigation system that includes the exact locations of all shut-off valves. This mapping should be integrated into the system’s maintenance manual and easily accessible to all operational staff. Additionally, conducting training sessions for the team can enhance their understanding of the system layout and the importance of timely shut-off procedures. For companies managing multiple sites, consider implementing a digital management tool that allows for real-time updates and alerts related to valve operations. This proactive approach not only prevents system damage but also optimizes resource allocation and reduces water waste.

Scenario 2: The Challenge of Malfunctioning Valves

The Problem: A common issue that B2B buyers encounter is the malfunctioning of irrigation valves, which can prevent proper shut-off when needed. This is particularly problematic in regions with harsh climates where systems need to be shut off to prevent damage from freezing temperatures. Buyers may find themselves in a scenario where they are unable to effectively manage their irrigation systems due to valve failure, resulting in water wastage and increased costs associated with repairs and replacements.

The Solution: To address this pain point, it’s essential for B2B buyers to implement a regular maintenance schedule that includes inspections and testing of all irrigation valves. Utilizing high-quality, durable valves designed for specific environmental conditions can also minimize the risk of malfunction. In case of a breakdown, having a reliable supplier for replacement parts is crucial. Buyers should establish relationships with local suppliers or manufacturers who can provide prompt service and technical support. Additionally, investing in smart irrigation technology that includes automated shut-off features can provide a safeguard against valve failure, ensuring that systems can be managed efficiently even when manual intervention is required.

Scenario 3: Complications During Seasonal Shut-Downs

The Problem: As seasons change, many B2B buyers need to shut down their irrigation systems to prepare for winter or dry periods. This process can be complicated and time-consuming, particularly for businesses operating in diverse climates across regions like Africa and South America. Mismanagement during seasonal shut-downs can lead to water freezing in pipes, damaging the system and incurring costly repairs, thus creating a significant operational headache.

The Solution: To streamline the seasonal shut-down process, buyers should develop a standardized shut-down protocol that is well-documented and shared with all relevant personnel. This protocol should include step-by-step instructions on how to effectively shut off the irrigation valve, drain the system, and winterize the components. Implementing a checklist can help ensure that no steps are overlooked during the process. Additionally, scheduling shut-downs during optimal weather conditions can reduce risks. For regions with extreme climates, consider collaborating with local irrigation experts who can offer training or support during these critical periods. This strategic approach can minimize downtime and protect the investment in irrigation systems, ultimately leading to cost savings and enhanced operational efficiency.

Strategic Material Selection Guide for how to shut off irrigation valve

What Are the Key Materials for Shutting Off Irrigation Valves?

When selecting materials for irrigation valves, it’s crucial to consider their properties, advantages, and limitations. This analysis will focus on four common materials: brass, PVC, stainless steel, and polyethylene. Each material has unique characteristics that can significantly impact the performance and longevity of irrigation systems.

How Does Brass Perform in Irrigation Valve Applications?

Brass is a popular choice for irrigation valves due to its excellent corrosion resistance and strength. It typically has a high-temperature rating, making it suitable for various climates. Brass valves can withstand pressures up to 600 psi, ensuring durability under high-stress conditions.

Pros: Brass is highly durable and resistant to corrosion, which extends the lifespan of the valve. It also offers good thermal conductivity, making it effective in temperature regulation.

Cons: The primary drawback is its cost, as brass is more expensive than other materials. Additionally, it may require more complex manufacturing processes, which can lead to longer lead times.

Impact on Application: Brass valves are compatible with a wide range of media, including water and various fertilizers, making them versatile for agricultural applications.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential, especially in regions like Europe and the Middle East. Buyers should also consider the availability of brass components in local markets, as sourcing can affect project timelines.

What Are the Benefits of PVC for Irrigation Valves?

PVC (polyvinyl chloride) is widely used in irrigation systems due to its lightweight nature and resistance to chemicals. PVC valves typically operate effectively in temperatures up to 140°F and can handle pressures up to 150 psi.

Pros: PVC is cost-effective and easy to install, making it ideal for large-scale projects. Its resistance to corrosion and chemicals ensures longevity in various environmental conditions.

Cons: While PVC is durable, it can become brittle over time when exposed to UV light, leading to potential failures in outdoor applications. Additionally, its pressure rating is lower than that of brass or stainless steel, which may limit its use in high-pressure systems.

Impact on Application: PVC valves are suitable for water and nutrient solutions, but care should be taken with certain solvents that may degrade the material.

Considerations for International Buyers: In regions like South America and Africa, where UV exposure is high, buyers should consider UV-resistant coatings or alternatives. Compliance with local standards is also crucial to ensure product reliability.

How Does Stainless Steel Compare in Terms of Performance?

Stainless steel is known for its exceptional strength and corrosion resistance, making it ideal for harsh environments. It can handle high pressures, often exceeding 300 psi, and operates effectively in a wide temperature range.

Pros: The durability of stainless steel is unmatched, providing a long service life even in challenging conditions. It is also resistant to rust and staining, ensuring aesthetic appeal.

Cons: The primary limitation is its cost, which can be significantly higher than other materials. Additionally, stainless steel can be more challenging to machine, leading to increased manufacturing complexity.

Impact on Application: Stainless steel valves are suitable for a broad range of media, including potable water and aggressive chemicals, making them versatile for various agricultural and industrial applications.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure compliance with standards like JIS and ASTM. The availability of stainless steel components can vary, impacting project timelines.

Why Choose Polyethylene for Irrigation Valves?

Polyethylene is a flexible and lightweight material commonly used in irrigation systems. It can withstand temperatures up to 120°F and pressures around 100 psi.

Pros: Polyethylene is highly resistant to chemicals and UV light, making it suitable for outdoor applications. Its flexibility allows for easy installation in various terrains.

Cons: However, polyethylene may not be as durable as metal options and can be prone to cracking under extreme conditions. Its lower pressure rating also limits its use in high-pressure systems.

Impact on Application: Polyethylene valves are ideal for low-pressure irrigation systems and are compatible with water and fertilizers.

Considerations for International Buyers: In regions with harsh climates, such as Africa, buyers should ensure that the polyethylene used is UV-stabilized. Compliance with local standards is essential for ensuring product performance.

Summary of Material Selection for Irrigation Valves

| Material | Typical Use Case for how to shut off irrigation valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-pressure irrigation systems | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| PVC | Residential and commercial irrigation | Cost-effective and easy to install | Brittle over time with UV exposure | Low |

| Stainless Steel | Industrial applications and harsh environments | Exceptional strength and longevity | High cost and machining complexity | High |

| Polyethylene | Low-pressure irrigation systems | Flexible and UV resistant | Lower durability and pressure rating | Medium |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding the materials used for shutting off irrigation valves, ensuring optimal performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to shut off irrigation valve

What Are the Main Stages in the Manufacturing Process of Irrigation Valves?

The manufacturing of irrigation valves involves several critical stages designed to ensure durability, reliability, and efficiency. Understanding these stages is essential for B2B buyers looking to source high-quality irrigation valves.

Material Preparation: The first stage involves selecting the right materials, which typically include brass, PVC, or stainless steel. Each material is chosen based on its intended application and environmental conditions. For instance, PVC is lightweight and resistant to corrosion, making it ideal for certain irrigation systems. The materials are then cut and shaped to meet precise specifications.

Forming: In this stage, the materials undergo processes such as molding or machining. For example, brass valves may be cast in molds to achieve the desired shape and size, while PVC components are often produced through extrusion. This stage is crucial as it directly influences the valve’s performance and longevity.

Assembly: After forming, the various components of the irrigation valve are assembled. This includes attaching the actuator, seals, and any other integral parts. Automation is increasingly used in assembly to enhance precision and reduce human error. Proper assembly ensures that the valve operates smoothly and meets flow requirements.

Finishing: The final stage involves surface treatments such as coating or polishing to enhance corrosion resistance and aesthetic appeal. For instance, metal valves may receive a protective coating to prevent rusting, while PVC components may be treated to withstand UV exposure. This stage is vital for extending the lifespan of the product.

What Quality Control (QC) Measures Are Essential for Irrigation Valves?

Quality assurance is paramount in the manufacturing process of irrigation valves, especially for international B2B buyers. Implementing stringent QC measures ensures that the valves meet specific standards and function reliably under various conditions.

International Standards: Adhering to internationally recognized standards such as ISO 9001 ensures that manufacturers implement effective quality management systems. This certification indicates a commitment to quality, customer satisfaction, and continuous improvement.

Industry-Specific Certifications: Depending on the target market, additional certifications may be required. For example, CE marking is essential for products sold in the European Economic Area, while API standards may apply for valves used in oil and gas applications. These certifications assure buyers that the product meets specific safety and performance criteria.

Quality Control Checkpoints: Quality control is divided into several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined quality standards.

– In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to ensure that components are manufactured according to specifications.

– Final Quality Control (FQC): After assembly, a comprehensive inspection is performed to verify the functionality, safety, and reliability of the finished product.Common Testing Methods: Various testing methods are employed to ensure the valves’ integrity and performance:

– Hydrostatic Testing: This method checks for leaks and ensures that the valve can withstand high-pressure environments.

– Functional Testing: Each valve is tested to ensure it operates correctly under simulated conditions.

– Environmental Testing: Valves may be subjected to extreme temperatures or corrosive environments to assess their durability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability and compliance with local regulations.

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational capabilities of the supplier. This firsthand evaluation can reveal potential risks and areas for improvement.

Quality Reports: Requesting detailed quality reports from the supplier can provide insights into their QC processes. These reports should include information on inspection results, testing methodologies, and any corrective actions taken for non-compliance issues.

Third-Party Inspections: Engaging independent third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control practices. These agencies can conduct random inspections and testing, providing additional assurance of product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating quality control and certification requirements can be complex for international buyers. Here are some nuances to consider:

Understanding Regional Standards: Different regions may have varying standards and regulations governing irrigation valves. For example, CE marking is essential in Europe, while ANSI standards may apply in North America. Familiarizing yourself with these regional requirements can prevent compliance issues.

Language Barriers: Communication with suppliers may pose challenges due to language differences. It is advisable to work with suppliers who can provide documentation and support in your preferred language to ensure clarity in specifications and quality standards.

Cultural Considerations: Business practices and expectations may vary across cultures. Understanding these differences can facilitate smoother negotiations and foster stronger supplier relationships.

Local Regulations: Buyers must also be aware of local regulations that may impact the installation and operation of irrigation systems. Compliance with these regulations is essential for avoiding legal and operational issues.

By understanding the manufacturing processes, quality assurance measures, and nuances of sourcing irrigation valves, B2B buyers can make informed decisions that align with their operational needs and regional requirements. This knowledge not only mitigates risks but also enhances the overall efficiency of irrigation systems in various agricultural and landscaping applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to shut off irrigation valve’

The following guide provides a step-by-step checklist for B2B buyers looking to effectively procure the necessary components and knowledge for shutting off irrigation valves. This is critical for maintenance, particularly in regions with varying climates that may impact irrigation systems.

Step 1: Assess Your Irrigation System Type

Understanding the specific type of irrigation system you have is essential before shutting off any valves. Different systems—such as drip, sprinkler, or soaker hoses—may have unique shut-off procedures. Identify the components involved, including valve types and their locations, to ensure proper management.

Step 2: Identify the Shut-off Valve Location

Locate the main shut-off valve for your irrigation system. This valve is typically found in areas such as basements, utility rooms, or near the backflow preventer outside. Knowing its location allows for quick access during emergencies or routine maintenance, preventing damage from unexpected weather changes.

Step 3: Understand Valve Mechanisms

Familiarize yourself with the types of valves in your system—whether they are ball valves, gate valves, or solenoid-operated valves. Each type has a different mechanism for shutting off water flow, which is crucial for effective operation. Look for visual guides or videos that illustrate the specific actions needed for each valve type.

Step 4: Develop a Drainage Strategy

Plan how to drain the irrigation system after shutting off the water. Depending on your setup, this may involve opening drain valves or using a hose to remove excess water. Proper drainage is vital to prevent freezing and potential damage, especially in regions susceptible to cold weather.

Step 5: Schedule Regular Maintenance Checks

Establish a routine maintenance schedule to check the functionality of shut-off valves and other system components. Regular inspections help identify wear and tear, ensuring that your irrigation system operates efficiently and effectively. Document any issues found during inspections for reference during future maintenance.

Step 6: Train Your Staff on Shutdown Procedures

Ensure that all relevant personnel are trained in the proper procedures for shutting off the irrigation system. This training should cover identifying the shut-off valve, the mechanism for shutting it off, and the drainage process. Well-informed staff can act quickly during emergencies, mitigating potential damage.

Step 7: Source Quality Replacement Parts

Invest in high-quality replacement parts for your irrigation system. If valves or other components need to be replaced, ensure that you procure parts that meet the necessary specifications for durability and compatibility with your existing system. Evaluate suppliers based on their product quality, warranty policies, and customer service to ensure a reliable supply chain.

By following this checklist, B2B buyers can effectively manage their irrigation systems, ensuring longevity and functionality while preventing costly damages. Each step is designed to streamline the procurement process and enhance operational efficiency.

Comprehensive Cost and Pricing Analysis for how to shut off irrigation valve Sourcing

What Are the Key Cost Components for Shutting Off an Irrigation Valve?

When evaluating the costs associated with shutting off an irrigation valve, it’s essential to break down the components that contribute to the overall expenditure. The primary cost components include:

Materials: This encompasses the cost of the valve itself, pipes, fittings, and any additional components necessary for the shutdown process. High-quality materials may carry a higher upfront cost but can lead to reduced maintenance and replacement expenses in the long run.

Labor: Labor costs can vary significantly based on the complexity of the irrigation system and the local labor market. Hiring skilled technicians can ensure the job is done efficiently, which may justify higher labor costs.

Manufacturing Overhead: This refers to the indirect costs associated with producing the components required for the irrigation system. These costs may include utilities, rent, and administrative expenses that can be distributed across the products.

Tooling: The tools required for installation or maintenance, such as wrenches, screwdrivers, and testing equipment, represent another cost factor. Investment in durable, high-quality tools may incur higher initial costs but can enhance efficiency and longevity.

Quality Control (QC): Ensuring that the components meet specific standards and certifications can add to the overall cost. However, investing in quality control can prevent future issues and reduce the total cost of ownership.

Logistics: Transportation costs for shipping materials and components, especially in international trade, can significantly affect pricing. Factors like distance, shipping method, and tariffs can all influence logistics costs.

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the margin applied by different suppliers can help buyers negotiate better prices.

What Influences Pricing for Irrigation Valve Shutdown Services?

Various factors can influence the pricing of services related to shutting off irrigation valves. Key influencers include:

Volume/MOQ: Bulk purchasing can lead to discounts. Buyers should consider negotiating for better pricing based on their anticipated volume of purchases.

Specifications/Customization: Custom solutions tailored to specific irrigation systems may incur additional costs. Buyers should evaluate whether standard options suffice or if customization is necessary.

Materials: The choice between different materials (e.g., plastic vs. metal valves) can affect pricing. While metal might be more durable, it can also be more expensive.

Quality/Certifications: Products that meet specific industry standards or certifications may carry a premium price. However, these can also assure buyers of reliability and performance.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with proven track records may charge more but offer better service and product quality.

Incoterms: Understanding the terms of shipping (such as FOB, CIF, etc.) can affect the total cost. Buyers should be aware of who bears the shipping costs and responsibilities.

What Are Effective Buyer Tips for Cost-Efficiency in Irrigation Valve Shutdown?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negotiation: Engage in discussions with suppliers to understand their pricing structures and explore potential discounts, especially for larger orders.

Total Cost of Ownership (TCO): Consider not only the upfront costs but also long-term savings associated with quality and durability. Investing in higher-quality valves may result in lower maintenance costs.

Pricing Nuances: Be aware of regional pricing differences influenced by local market conditions, tariffs, and supply chain logistics. Conducting thorough market research can lead to more informed purchasing decisions.

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming trends or product releases.

Disclaimer on Indicative Prices

Prices for irrigation valve shutdown services can vary widely based on the factors mentioned above. Buyers should conduct their own research and obtain multiple quotes to ensure they are receiving competitive pricing tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing how to shut off irrigation valve With Other Solutions

Exploring Alternative Solutions for Shutting Off Irrigation Valves

In the realm of irrigation management, knowing how to effectively shut off irrigation valves is crucial. However, several alternative methods and technologies can achieve similar results, offering varying benefits depending on the specific needs of the operation. Below, we compare the traditional method of manually shutting off irrigation valves with two other viable alternatives: automated irrigation systems and remote valve control technologies.

| Comparison Aspect | How To Shut Off Irrigation Valve | Automated Irrigation Systems | Remote Valve Control Technologies |

|---|---|---|---|

| Performance | Reliable but requires manual effort | High efficiency, programmed schedules | Flexible and can be controlled remotely |

| Cost | Low initial investment, labor costs for manual shut-off | Higher upfront cost, potential savings on water | Moderate investment, potential savings on labor |

| Ease of Implementation | Straightforward, requires basic knowledge | Requires installation and programming | Requires setup and connectivity to a network |

| Maintenance | Minimal, mainly periodic checks | Moderate, requires regular updates and checks | Moderate, dependent on technology stability |

| Best Use Case | Small to medium-scale operations | Large-scale, high-usage operations | Operations needing flexibility and remote management |

What Are the Advantages and Disadvantages of Automated Irrigation Systems?

Automated irrigation systems provide a sophisticated approach to managing water usage. These systems can be programmed to shut off valves based on weather conditions, moisture levels, or specific schedules, leading to optimized water use and reduced waste. However, the initial investment can be significant, particularly for small businesses or operations with limited budgets. Additionally, these systems require periodic maintenance and updates to ensure they function correctly, which can add to operational costs.

How Do Remote Valve Control Technologies Compare?

Remote valve control technologies offer the flexibility of managing irrigation systems from a distance, often through smartphone applications or centralized control systems. This method is particularly beneficial for large agricultural operations or landscapes where managing multiple zones is crucial. The ability to control valves remotely enhances responsiveness to changing conditions, such as rain or drought. However, the technology requires a moderate investment and relies on stable internet connectivity, which may be a limitation in certain regions.

Conclusion: How to Choose the Right Solution for Your Irrigation Needs

When selecting the appropriate method for shutting off irrigation valves, B2B buyers must consider their specific operational requirements, budget constraints, and the scale of their irrigation needs. Manual shut-off is ideal for smaller operations with straightforward requirements, while automated systems or remote controls offer advanced features for larger, more complex setups. Ultimately, the right choice will depend on balancing initial investment against long-term efficiency and water management goals. Understanding these alternatives empowers buyers to make informed decisions that align with their operational strategies.

Essential Technical Properties and Trade Terminology for how to shut off irrigation valve

What Are the Key Technical Properties for Shutting Off an Irrigation Valve?

Material Grade

The material grade of an irrigation valve is crucial for ensuring durability and resistance to environmental factors. Common materials include PVC, brass, and stainless steel. For example, brass valves are often preferred for their corrosion resistance, especially in regions with high salinity or extreme temperatures. Selecting the appropriate material can extend the lifespan of the valve and reduce maintenance costs, making it a vital consideration for B2B buyers.Pressure Rating

The pressure rating, usually expressed in pounds per square inch (PSI), indicates the maximum pressure the valve can withstand. This specification is critical for ensuring the valve operates effectively under the pressure conditions of the irrigation system. A valve that is not rated for the required pressure may fail, leading to leaks or system breakdowns, which can incur significant repair costs.Flow Rate

Measured in gallons per minute (GPM), the flow rate indicates how much water can pass through the valve at a given time. Understanding the required flow rate for the specific irrigation application is essential for selecting the right valve. Incorrect flow rates can lead to inefficient irrigation or water wastage, impacting operational costs and resource management.Size and Compatibility

The size of the valve, typically measured in inches, must match the piping system to ensure a proper fit and optimal performance. Compatibility with existing irrigation components is crucial, particularly when integrating new valves into established systems. This helps avoid additional costs related to system modifications or replacements.Installation Type

Valves can be categorized based on their installation type, such as inline, angle, or manifold valves. The installation type affects the complexity of the shut-off process and overall system efficiency. Understanding the installation requirements can facilitate easier maintenance and repairs, which is a significant consideration for businesses looking to minimize downtime.

What Common Trade Terms Should B2B Buyers Know When Dealing with Irrigation Valves?

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of irrigation systems, sourcing valves from OEMs can ensure quality and compatibility with existing systems. B2B buyers should evaluate OEM certifications to guarantee reliability and performance.MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for budgeting and inventory management, especially for businesses aiming to maintain a steady supply of irrigation valves without overstocking.RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. When seeking irrigation valves, submitting an RFQ can help businesses compare costs, specifications, and delivery times, enabling informed purchasing decisions.Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers involved in cross-border purchases of irrigation valves, as they dictate shipping responsibilities, risk, and costs.Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For irrigation projects, understanding lead times is crucial for planning and ensuring that systems are operational when needed, especially in seasonal markets where timing can be critical.Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the product. Understanding the warranty terms for irrigation valves can help B2B buyers assess the risk of product failure and the potential costs associated with repairs or replacements.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance their irrigation systems’ efficiency and reliability.

Navigating Market Dynamics and Sourcing Trends in the how to shut off irrigation valve Sector

What Are the Current Market Dynamics in the Irrigation Valve Sector?

The global irrigation valve market is witnessing significant shifts driven by technological advancements, climate change, and increasing agricultural demands. The need for efficient water management systems has become paramount, particularly in regions like Africa and the Middle East, where water scarcity is a pressing issue. As a result, B2B buyers are increasingly seeking innovative solutions that not only conserve water but also enhance the efficiency of irrigation systems.

Emerging technologies such as smart irrigation systems, which utilize IoT devices for real-time monitoring and control, are gaining traction. This trend is particularly relevant for international buyers in South America and Europe, where precision agriculture is on the rise. The integration of automation and remote control features in irrigation valves allows for more precise water usage, reducing wastage and improving crop yields.

Moreover, the demand for durable and reliable irrigation valves is influenced by the varying climatic conditions across regions. Buyers are prioritizing products that can withstand extreme temperatures and weather events, which are becoming more frequent due to climate change. This creates an opportunity for suppliers to market valves with enhanced durability and performance, thereby attracting international buyers looking for long-term solutions.

How Is Sustainability Influencing Sourcing Trends in the Irrigation Valve Market?

Sustainability is becoming a core consideration for B2B buyers in the irrigation valve sector. The environmental impact of agricultural practices is under scrutiny, and companies are increasingly held accountable for their supply chains. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using eco-friendly materials and minimizing waste.

Ethical sourcing is not just a regulatory requirement but a competitive advantage. Buyers are looking for manufacturers that can provide certifications indicating their commitment to sustainability, such as ISO 14001 for environmental management or certifications for recycled materials. The use of ‘green’ materials in irrigation valves—such as plastics derived from recycled sources—can significantly reduce the carbon footprint of agricultural operations.

Furthermore, as consumers become more environmentally conscious, businesses are recognizing that adopting sustainable practices can enhance brand reputation. By sourcing irrigation valves that align with sustainability goals, companies can appeal to a growing market segment that prioritizes eco-friendly products, thereby driving sales and fostering customer loyalty.

What Is the Historical Context of Irrigation Valve Technology?

The evolution of irrigation valve technology dates back to ancient agricultural practices, where simple gates and channels were used to manage water flow. Over the years, advancements in materials and engineering have transformed these basic systems into sophisticated mechanisms that optimize water use. The introduction of automatic and electronic valves in the late 20th century marked a significant turning point, allowing for more precise control over irrigation schedules and amounts.

Today, modern irrigation valves are equipped with features such as backflow prevention and remote monitoring capabilities, reflecting the increasing complexity and demands of contemporary agriculture. This historical progression underscores the importance of innovation in the sector, as suppliers strive to meet the evolving needs of international buyers seeking efficiency, reliability, and sustainability in their irrigation systems.

Frequently Asked Questions (FAQs) for B2B Buyers of how to shut off irrigation valve

1. How do I shut off the irrigation valve in my system?

To shut off your irrigation valve, locate the main shut-off valve, typically found in your basement, utility room, or near the main water supply. Most valves are ball valves; if the handle is parallel to the pipe, the water is on. Turn the handle 90 degrees until it stops to shut the water off. Ensure you do not close the main water supply for your entire property—only the irrigation system. If you are unsure, consult your system’s manual or a professional.2. What tools do I need to manually shut off the irrigation valve?

You generally won’t need specialized tools to shut off your irrigation valve, but having a flat-head screwdriver can be helpful, especially for adjusting backflow preventers or opening drain ports. It’s advisable to have a bucket on hand to catch any residual water when draining the system. Ensure that you also have access to any manuals or instructional videos specific to your irrigation system for guidance.3. How can I prevent damage to my irrigation system during winter?

To prevent damage during winter, ensure you shut off the water supply and drain the system completely. Open any drain valves to allow residual water to escape. For added protection, consider hiring a professional to blow out the lines with an air compressor. This process ensures that all water is expelled, reducing the risk of freezing and breaking pipes.4. What should I consider when sourcing irrigation valves internationally?

When sourcing irrigation valves from international suppliers, consider factors such as quality certifications, compliance with local regulations, and the supplier’s reputation. It’s important to assess their manufacturing capabilities, lead times, and shipping logistics to ensure timely delivery. Additionally, inquire about after-sales support and warranty policies to safeguard your investment.5. How can I vet suppliers for irrigation valves effectively?

To vet suppliers, research their history, customer reviews, and certifications. Request samples to assess the quality of their products before committing to a larger order. It’s also beneficial to communicate directly with the supplier to gauge their responsiveness and willingness to address your concerns. Consider visiting their facilities if possible or utilizing third-party inspection services to ensure compliance with your standards.6. What are typical minimum order quantities (MOQs) for irrigation valves?

Minimum order quantities (MOQs) for irrigation valves can vary widely depending on the supplier and the specific product. Generally, MOQs can range from 50 to 500 units. It’s crucial to discuss your needs with potential suppliers, as some may be flexible with MOQs, especially for first-time buyers or if you are willing to pay a premium for lower quantities.7. What payment terms should I expect when purchasing from international suppliers?

Payment terms can differ greatly between suppliers. Common terms include upfront payment, partial payment upon order confirmation, and the balance before shipping. Some suppliers may offer credit terms for established relationships. Always clarify terms before finalizing an order to avoid misunderstandings, and consider using secure payment methods to protect your transaction.8. How do I ensure quality assurance when buying irrigation valves?

To ensure quality assurance, request product specifications and certifications from your suppliers. Conduct pre-shipment inspections to verify that the valves meet your quality standards before they are shipped. Establish clear quality criteria and communicate these to your supplier. Building a long-term relationship with a reliable supplier can also facilitate better quality control practices and oversight.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 How To Shut Off Irrigation Valve Manufacturers & Suppliers List

1. Hunter – PGV Sprinkler Valve

2. Quality Irrigation – Emergency Sprinkler & Lawn Care Services

Domain: quality-irrigation.com

Registered: 2004 (21 years)

Introduction: Emergency Sprinkler System Shutdown Instructions, Professional Shutdown & Winterization, Backflow Preventer Testing, Lawn Care Services, Fertilization, Aeration/Overseeding, Yard Drainage, Fungicide, Perimeter Pest Control, Residential Sprinkler Systems, Commercial Outdoor Lighting Systems, Drainage Solutions, WiFi Controlled Lawn Sprinkler Systems, Affordable Financing Options, Service Area: Omah…

3. Toro – Check Valve Rotor

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Featured Products: Buy now at Toro Rotor with Check Valve 1 in. | T7P-02, Buy Now Irritrol Rotor 5 in. | 550R

4. Rain Bird – Inline Sprinkler Valves

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: Old Rain Bird inline sprinkler valves, 1″ sprinkler lines, buried 18″ in the ground.

5. Grasseaters – Sprinkler System Services

Domain: grasseaters.com

Registered: 2002 (23 years)

Introduction: Grasseaters, Inc offers sprinkler system services including installation and repair. They provide guidance on how to manually turn off a home sprinkler system using three methods: the Gate Valve (turn 90 degrees clockwise), the Double Check Valve (turn one handle 90 degrees clockwise), and the Meter Box (turn 180 degrees to stop all water flow). The company serves Tarrant County, Johnson County, P…

6. DIY – Sprinkler System Essentials

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: 1. Sprinkler System: Consumer level, typically includes a pump, timing unit (24V), solenoids, and irrigation hardware. 2. Master Valve: Most systems have a master valve on the main line, but it may not be present in all systems. 3. Well Water Source: The system is connected to a well, which may not provide constant pressure. 4. PVC Pipes: The leak is in the yard, off of one of the in-ground PVC pi…

7. JustAnswer – Sprinkler System Valve Box

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Valve box for sprinkler system; no knobs or handles present; individual valves with threading; requires a key to turn off valves; valves may be covered with dirt; manifold pipe connects to individual valves; water can be turned off at street meter or well; valves have a knob about 1/2 inch in diameter for on/off control; turn clockwise to turn off, counterclockwise to turn on.

8. Hunter – Pro-C Sprinkler System

Domain: lawnsite.com

Registered: 2000 (25 years)

Introduction: Hunter Pro-C sprinkler system; features 5 solenoid valves; valves have 1/4 turn mechanism for manual operation; main brass valve connected to water line.

9. Angi – Irrigation Shut-Off Valve

Domain: angi.com

Registered: 1996 (29 years)

Introduction: The irrigation shut-off valve is commonly located near the corners of the house or main building, just downstream of the backflow preventer. It can be found either above-ground (inside a garage, utility closet, or outside in a protective box) or below-ground (in a valve box with a green lid). The shut-off valve typically has a ball valve with a lever handle, which should be perpendicular to the pi…

Strategic Sourcing Conclusion and Outlook for how to shut off irrigation valve

In conclusion, effectively shutting off irrigation valves is a vital operation that safeguards infrastructure and optimizes resource management, especially in regions prone to extreme weather conditions. By understanding the critical steps—from locating the shut-off valve to draining the system—you can mitigate risks associated with freezing temperatures and system malfunctions. This knowledge not only protects your investment but also enhances operational efficiency.

Strategic sourcing plays a crucial role in acquiring high-quality irrigation components and services. By partnering with reputable suppliers who understand the unique challenges faced in diverse markets like Africa, South America, the Middle East, and Europe, businesses can ensure the reliability of their irrigation systems. Consider engaging with local vendors who offer tailored solutions, ensuring that your operations remain sustainable and cost-effective.

Looking ahead, we encourage international B2B buyers to prioritize proactive irrigation management. Investing in quality components and expert services will not only safeguard your infrastructure but also contribute to the long-term sustainability of agricultural practices across varied climates. Take the next step—evaluate your current systems and suppliers to enhance your irrigation strategies today.