Introduction: Navigating the Global Market for irrigation flush valve

In today’s global agricultural landscape, sourcing high-quality irrigation flush valves is crucial for maintaining efficient and sustainable water management systems. These essential components not only help prevent sediment buildup and clogging in irrigation lines but also ensure optimal performance, particularly in regions facing water scarcity challenges like parts of Africa and South America. As international B2B buyers, understanding the nuances of flush valve technologies can significantly impact the success of your irrigation projects, ultimately driving productivity and profitability.

This comprehensive guide delves into various types of irrigation flush valves, including automatic and manual options, and their specific applications across different environments. We will explore critical factors such as supplier vetting, cost considerations, and best practices for installation and maintenance. Whether you are based in Nigeria, Germany, or the Middle East, this resource aims to empower your purchasing decisions by providing actionable insights and expert recommendations tailored to your unique market needs.

By navigating the complexities of the irrigation flush valve market with this guide, you can make informed choices that enhance the efficiency of your agricultural operations while mitigating potential risks associated with subpar products. Equip yourself with the knowledge necessary to select the right flush valves and ensure the longevity and reliability of your irrigation systems.

Understanding irrigation flush valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Flush Valve | Operated manually; simple design; low-cost solution. | Small farms, gardens, and low-tech setups. | Pros: Affordable, easy to install. Cons: Labor-intensive, requires regular manual intervention. |

| Automatic Flush Valve | Automatically flushes debris; operates on flow, not pressure. | Large-scale agricultural systems, commercial landscaping. | Pros: Reduces maintenance, improves efficiency. Cons: Higher initial investment, may require specific installation knowledge. |

| Two-Piece Flush Valve | Comprises separate inlet and outlet; versatile connections. | Residential irrigation, DIY projects. | Pros: Flexible installation options, easy to replace parts. Cons: Potential for leaks if not installed properly. |

| Pressure-Activated Flush Valve | Activates based on specific pressure thresholds; durable materials. | Industrial applications, high-pressure systems. | Pros: Reliable performance under varying conditions. Cons: More complex, may be overkill for smaller systems. |

| Inline Flush Valve | Integrated into the irrigation line; minimal space requirement. | Drip irrigation systems, compact setups. | Pros: Space-efficient, unobtrusive. Cons: Difficult to access for maintenance, may require specialized fittings. |

What Are the Key Characteristics of Manual Flush Valves?

Manual flush valves are straightforward devices that require human operation to clear the irrigation lines. Typically low-cost, they are ideal for small farms, gardens, or low-tech setups where automated systems may not be feasible. Buyers should consider the labor involved in regular maintenance, as these valves necessitate manual flushing to prevent clogging. Their simplicity can be a double-edged sword, offering ease of installation but demanding more time from users.

How Do Automatic Flush Valves Enhance Irrigation Efficiency?

Automatic flush valves are designed to flush debris from irrigation lines without manual intervention. They operate based on water flow rather than pressure, ensuring optimal performance in large-scale agricultural systems and commercial landscaping. When considering an automatic flush valve, buyers should assess the initial investment against the long-term savings in maintenance and efficiency. These valves are particularly beneficial for operations that prioritize labor-saving technologies.

What Advantages Do Two-Piece Flush Valves Offer?

Two-piece flush valves consist of separate inlet and outlet components, allowing for versatile installation in various irrigation setups. Their adaptability makes them suitable for residential irrigation and DIY projects. Buyers should note that while these valves are easy to install and replace, improper installation can lead to leaks. This option is ideal for those seeking flexibility in their irrigation system design.

In What Scenarios Are Pressure-Activated Flush Valves Most Beneficial?

Pressure-activated flush valves are engineered to operate based on specific pressure thresholds, making them suitable for industrial applications and high-pressure systems. Their durable materials ensure reliable performance even in challenging conditions. Buyers must consider the complexity of installation and whether the additional features justify the higher cost for their specific irrigation needs. These valves are ideal for larger operations requiring dependable, robust solutions.

Why Choose Inline Flush Valves for Compact Irrigation Systems?

Inline flush valves are integrated directly into the irrigation line, making them a space-efficient solution for drip irrigation systems and compact setups. They are particularly advantageous in areas where space is limited, as they do not protrude significantly from the line. However, buyers should be aware that accessing these valves for maintenance can be challenging and may require specialized fittings. This type is suitable for operations that prioritize discreet and efficient irrigation management.

Key Industrial Applications of irrigation flush valve

| Industry/Sector | Specific Application of irrigation flush valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated flushing in drip irrigation systems | Reduces labor costs and improves water efficiency | Compatibility with existing systems and local water quality |

| Landscape & Turf Management | Regular cleaning of irrigation lines in landscaped areas | Enhances plant health and aesthetic appeal | Durability under varying climate conditions |

| Greenhouse Operations | Flushing to prevent clogging in nutrient delivery systems | Optimizes growth conditions and resource utilization | Size and pressure ratings to match system specifications |

| Municipal Water Management | Flushing of municipal irrigation systems to maintain flow | Prevents sediment buildup and extends system lifespan | Compliance with local regulations and standards |

| Industrial Facilities | Maintaining consistent water flow in cooling towers | Reduces downtime and increases operational efficiency | Adaptability to different pipe sizes and materials |

How Are Irrigation Flush Valves Used in Agriculture?

In agriculture, irrigation flush valves play a crucial role in automated drip irrigation systems. They help maintain optimal water flow by automatically flushing out debris and sediments that can clog the system. This functionality not only reduces the need for manual labor but also enhances water efficiency, which is vital in regions with limited water resources. For international buyers, especially in Africa and South America, understanding local water quality and ensuring compatibility with existing systems is essential to maximize the benefits of these valves.

What Benefits Do Irrigation Flush Valves Provide in Landscape & Turf Management?

In landscape and turf management, irrigation flush valves are employed to maintain clean irrigation lines, ensuring that water reaches plants without obstruction. By automating the flushing process, these valves enhance the health and aesthetics of landscaped areas, which is particularly important for commercial properties and public parks. Buyers from Europe and the Middle East should consider the durability of valves under varying climate conditions, as this impacts long-term performance and maintenance costs.

How Do Irrigation Flush Valves Optimize Greenhouse Operations?

In greenhouse operations, irrigation flush valves are vital for maintaining nutrient delivery systems. These valves flush out potential clogs, ensuring that plants receive the right nutrients consistently. This optimization contributes to healthier growth conditions and better resource utilization. International buyers should focus on the size and pressure ratings of flush valves to ensure they meet the specific requirements of their greenhouse systems, especially in regions with diverse agricultural practices.

Why Are Irrigation Flush Valves Important for Municipal Water Management?

Municipal water management systems utilize irrigation flush valves to prevent sediment buildup in irrigation lines. By facilitating regular flushing, these valves help maintain consistent water flow, which is essential for public parks and recreational areas. For buyers in the municipal sector, compliance with local regulations and standards is a significant consideration, as it ensures that the systems operate effectively and sustainably.

How Do Industrial Facilities Benefit from Irrigation Flush Valves?

In industrial facilities, irrigation flush valves are used to maintain consistent water flow in cooling towers and other water-dependent systems. By preventing clogging and sediment accumulation, these valves reduce downtime and enhance operational efficiency. Buyers should consider the adaptability of flush valves to different pipe sizes and materials, ensuring seamless integration with existing infrastructure. This is particularly relevant for industries operating in diverse environments across various regions.

3 Common User Pain Points for ‘irrigation flush valve’ & Their Solutions

Scenario 1: Inefficient System Performance Due to Clogging

The Problem: Many B2B buyers, especially those managing large agricultural operations or landscaping projects, face the ongoing issue of clogged irrigation systems. This problem often arises from sediment and debris accumulating within the lines. When flush valves do not perform effectively, it leads to decreased water flow, uneven irrigation, and ultimately, crop or landscape damage. Buyers may find themselves dealing with frequent maintenance and system downtime, which can significantly impact productivity and profits.

The Solution: To combat clogging, it is essential to invest in high-quality automatic flush valves. These valves operate by automatically expelling debris and sediment at the start and end of each irrigation cycle, ensuring that the system remains clean and efficient. When sourcing flush valves, consider models that feature self-cleaning mechanisms and have specifications tailored to your system’s pressure and flow requirements. For example, select flush valves with a minimum pressure threshold that matches your system to ensure optimal performance. Additionally, implementing a regular inspection schedule for your irrigation system can help catch potential issues early, allowing for timely maintenance that minimizes downtime.

Scenario 2: Increased Maintenance Costs from Manual Flushing

The Problem: B2B buyers managing irrigation systems often struggle with the high costs associated with manual flushing of their systems. Manual flushing can be labor-intensive and time-consuming, requiring skilled labor to ensure thorough cleaning. This not only increases operational costs but also takes away valuable time that could be spent on other critical tasks. Moreover, the inconsistency of manual flushing can lead to unexpected failures and inefficiencies.

The Solution: To reduce maintenance costs, consider transitioning to automatic flush valves that require minimal manual intervention. These valves can be programmed to flush the system at predetermined intervals, thereby automating a typically labor-intensive process. When selecting flush valves, look for models that are easy to integrate into existing systems and offer adjustable flushing cycles. It’s also beneficial to partner with suppliers who provide comprehensive product support, ensuring that you can quickly resolve any issues that may arise. By investing in automated solutions, businesses can streamline operations, reduce labor costs, and enhance overall system reliability.

Scenario 3: Incompatibility with Existing Infrastructure

The Problem: International buyers often encounter challenges related to the compatibility of flush valves with their existing irrigation infrastructure. Different regions may have varying standards for pipe sizes and connection types, which can lead to significant installation issues if the wrong flush valve is selected. This can result in costly modifications, delays in project timelines, and frustration for both the buyers and their clients.

The Solution: To avoid compatibility issues, it is crucial to conduct thorough assessments of your existing irrigation system before sourcing flush valves. Buyers should take precise measurements of pipe sizes and types, as well as pressure requirements, to ensure that the selected flush valves will fit seamlessly into their systems. Working with reputable manufacturers who offer a range of models with various connection options—such as female hose threads or pipe threads—can greatly enhance compatibility. Additionally, consider consulting with industry experts or suppliers who can provide insights into the best products for your specific regional standards. This proactive approach will not only save time and money but will also enhance the performance and longevity of your irrigation systems.

Strategic Material Selection Guide for irrigation flush valve

What Are the Key Materials Used in Irrigation Flush Valves?

When selecting materials for irrigation flush valves, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. The choice of material directly impacts the valve’s performance, durability, and overall efficiency in irrigation systems. Below, we analyze four common materials used in the manufacturing of irrigation flush valves.

How Does PVC Perform in Irrigation Flush Valves?

Polyvinyl Chloride (PVC) is a widely used material for irrigation flush valves due to its favorable properties. It boasts excellent chemical resistance, making it suitable for various water conditions, including those with high salinity or chemical additives. PVC can handle temperatures up to 140°F (60°C) and pressures of around 150 PSI, ensuring reliable performance in many irrigation systems.

Pros: PVC is lightweight, cost-effective, and easy to install, which reduces labor costs. It is also resistant to corrosion and UV degradation, making it ideal for outdoor applications.

Cons: However, PVC can become brittle over time when exposed to extreme temperatures, and it may not perform well in freezing conditions. Additionally, its lower pressure rating compared to some metals can limit its use in high-pressure systems.

Impact on Application: PVC is compatible with clean water systems and is often used in drip irrigation setups. However, it may not be suitable for systems that handle high-temperature fluids or abrasive materials.

Considerations for International Buyers: Compliance with ASTM standards is common for PVC products. Buyers in regions like Europe and South America should ensure that the PVC used meets local regulations regarding chemical safety and environmental impact.

What Role Does Brass Play in Irrigation Flush Valves?

Brass is another popular material for irrigation flush valves, known for its strength and durability. It can withstand high pressures (up to 300 PSI) and temperatures (up to 200°F or 93°C), making it suitable for a wide range of applications.

Pros: Brass offers excellent corrosion resistance, particularly against chlorinated water, and has a long lifespan. Its sturdiness makes it ideal for high-demand environments.

Cons: The primary drawback of brass is its higher cost compared to plastic materials. Additionally, it can be susceptible to dezincification in certain water conditions, which may compromise its integrity over time.

Impact on Application: Brass valves are suitable for both clean and slightly contaminated water systems. They are often preferred in commercial agricultural applications where durability is crucial.

Considerations for International Buyers: Brass products must comply with various international standards, including DIN and JIS. Buyers should verify that the brass used is lead-free, particularly in regions with strict regulations on drinking water safety.

How Do Stainless Steel Irrigation Flush Valves Compare?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it an excellent choice for irrigation flush valves. It can handle extreme temperatures (up to 400°F or 204°C) and pressures (up to 500 PSI), making it suitable for demanding applications.

Pros: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, ensuring a long service life even in harsh environments.

Cons: However, stainless steel is significantly more expensive than both PVC and brass. Its weight can also complicate installation and increase shipping costs.

Impact on Application: Stainless steel valves are ideal for systems that require high durability, such as industrial or municipal irrigation systems. They are compatible with a variety of media, including potable water.

Considerations for International Buyers: Buyers should ensure compliance with international standards for stainless steel, such as ASTM A312 or A276. In regions like Africa and the Middle East, where corrosion from saline environments is a concern, selecting the right grade of stainless steel is critical.

What Advantages Do Composite Materials Offer in Irrigation Flush Valves?

Composite materials, often a blend of plastics and metals, are increasingly being used in irrigation flush valves due to their unique properties. These materials can provide a balance of strength, weight, and corrosion resistance.

Pros: Composites are lightweight, resistant to corrosion, and can be engineered to meet specific performance requirements. They often offer good pressure ratings and temperature resistance.

Cons: The manufacturing complexity of composite materials can lead to higher costs. Additionally, their long-term durability may not match that of metals like brass or stainless steel.

Impact on Application: Composite valves are suitable for various irrigation applications, especially where weight is a concern, such as in portable systems.

Considerations for International Buyers: Buyers should look for compliance with relevant international standards and certifications to ensure quality and performance.

Summary Table of Material Selection for Irrigation Flush Valves

| Material | Typical Use Case for irrigation flush valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Drip irrigation systems | Lightweight and cost-effective | Brittle in extreme temperatures | Low |

| Brass | Commercial agricultural applications | High durability and corrosion resistance | Higher cost and potential dezincification | Medium |

| Stainless Steel | Industrial and municipal systems | Exceptional strength and corrosion resistance | High cost and heavier weight | High |

| Composite | Portable and lightweight irrigation systems | Balanced properties and lightweight | Higher manufacturing complexity | Medium |

This strategic material selection guide provides B2B buyers with insights into the performance characteristics and suitability of various materials for irrigation flush valves, enabling informed decision-making tailored to their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation flush valve

What Are the Main Stages of Manufacturing Irrigation Flush Valves?

The manufacturing process for irrigation flush valves typically involves several key stages: material preparation, forming, assembly, and finishing. Each of these stages plays a crucial role in ensuring that the final product meets the performance and durability standards required by international markets.

How Is Material Prepared for Flush Valve Manufacturing?

Material preparation starts with the selection of high-quality raw materials. Common materials include durable plastics, brass, and stainless steel, each chosen for their resistance to corrosion and ability to withstand varying pressure levels. Before manufacturing, materials undergo testing to ensure they meet the required specifications. This includes checking for tensile strength and compatibility with different water types, especially important in regions with diverse water quality, like Africa and the Middle East.

What Forming Techniques Are Used in Flush Valve Production?

Once the materials are prepared, forming techniques come into play. Common methods include injection molding for plastic components and machining for metal parts. Injection molding allows for precise shaping of complex designs, which is essential for the intricate parts of flush valves. Machining, on the other hand, is typically used for metal parts that require high precision, such as threads and fittings. Advanced techniques like 3D printing are also emerging, allowing for rapid prototyping and customization, which can be particularly beneficial for B2B buyers looking for tailored solutions.

How Is the Assembly of Irrigation Flush Valves Conducted?

The assembly stage involves bringing together the formed components into a complete flush valve. This process can vary depending on the type of valve being produced. For instance, automatic flush valves may require additional components such as sensors or electronic controls. Skilled technicians usually oversee this process to ensure each part fits correctly and functions as intended.

During assembly, it’s critical to implement standardized procedures to minimize the risk of errors. Employing techniques like lean manufacturing can optimize assembly line efficiency, reducing waste and ensuring that the final product is both cost-effective and high-quality.

What Finishing Processes Are Common for Flush Valves?

Finishing processes include surface treatment, painting, and quality checks. Surface treatments, such as anodizing for aluminum parts or coating for plastics, enhance durability and resistance to environmental factors, which is particularly important in regions with harsh climates. Painting not only provides a protective layer but can also be used for branding purposes.

Finally, final inspections are conducted to ensure the flush valves meet all specifications before packaging. This is an important stage that ensures that any cosmetic or functional flaws are identified and rectified before the product reaches the market.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is paramount in the manufacturing of irrigation flush valves. International standards such as ISO 9001 ensure that manufacturing processes meet quality management principles. Buyers should look for suppliers that are certified under these standards, as this indicates a commitment to consistent quality.

In addition to ISO certifications, industry-specific certifications like CE marking (for European markets) and API standards (for the oil and gas industry) may also apply. These certifications demonstrate compliance with relevant regulatory requirements and industry best practices.

What Are the Key Quality Control Checkpoints in Flush Valve Manufacturing?

Quality control (QC) checkpoints are critical throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This is the first stage of QC, where raw materials are inspected for quality and compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): This stage involves monitoring the manufacturing process itself, ensuring that all operations conform to established parameters. Regular checks during this phase help catch issues before they escalate.

- Final Quality Control (FQC): Once the flush valves are assembled, they undergo final inspections to ensure functionality and adherence to specifications. This often includes pressure testing and performance checks.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify a supplier’s QC processes:

- Request Documentation: Buyers should ask for quality assurance documentation, including certificates and reports from previous audits.

- Conduct Audits: On-site audits allow buyers to assess a supplier’s manufacturing and QC processes firsthand. This can be particularly useful for establishing long-term partnerships.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing quality and compliance with international standards.

What Are the QC and Certification Nuances for International Buyers?

For international buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential. Different countries may have varying regulatory requirements, which can affect the importation of flush valves.

Buyers should familiarize themselves with local regulations and ensure that their suppliers can provide the necessary certifications for their specific market. Additionally, language barriers and cultural differences can pose challenges in communication regarding quality expectations. Therefore, establishing clear communication channels and expectations upfront can help mitigate potential misunderstandings.

Conclusion

In summary, the manufacturing and quality assurance processes for irrigation flush valves are complex and multifaceted. By understanding the key stages of production and the importance of stringent quality control measures, B2B buyers can make informed decisions when selecting suppliers. Ensuring that suppliers adhere to international standards and are transparent about their QC processes will help mitigate risks and enhance the reliability of irrigation systems in diverse agricultural environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation flush valve’

Introduction

When sourcing irrigation flush valves, particularly in diverse markets such as Africa, South America, the Middle East, and Europe, it’s essential to follow a structured approach. This guide outlines a step-by-step checklist to help B2B buyers ensure they select the right flush valves that meet their operational requirements, comply with local regulations, and provide long-term reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental for selecting the right flush valve. Consider factors such as the type of irrigation system (drip, sprinkler), pressure requirements, and the maximum flow rate.

– Key Metrics: Minimum and maximum operating pressure (e.g., 1.5 to 60 PSI) and flow rates (e.g., 15 GPM) are crucial for optimal performance.

Step 2: Assess Environmental Conditions

Evaluate the environmental conditions where the irrigation system will operate. Different climates and soil types can affect the choice of flush valve.

– Considerations: For example, in regions prone to freezing, select valves designed to prevent freeze damage and mineral buildup.

Step 3: Identify Suitable Valve Types

Understand the various types of flush valves available, such as automatic and manual options. Automatic flush valves can reduce maintenance and enhance efficiency, while manual valves may offer cost savings.

– Options to Explore: Look for features like disassembly for winterization and compatibility with different pipe sizes (e.g., ½” MPT, ¾” FNPT).

Step 4: Evaluate Potential Suppliers

Before making a purchase, it’s crucial to thoroughly vet potential suppliers. Request detailed company profiles, product specifications, and case studies from similar industries.

– Supplier Insights: Look for references from buyers in your region to gauge reliability and service quality. Ensure they can provide technical support as needed.

Step 5: Verify Compliance and Certifications

Ensure that the flush valves comply with local regulations and industry standards. Certifications can provide assurance of quality and safety.

– Important Certifications: Look for ISO certifications or any local certifications relevant to irrigation equipment. This can also affect import regulations in certain regions.

Step 6: Request Samples or Prototypes

If possible, request samples or prototypes to test the performance of the flush valves in your specific environment. This hands-on evaluation can prevent costly mistakes.

– Testing Parameters: Evaluate the valve’s performance under your operating conditions, focusing on flow rates, pressure tolerance, and ease of installation.

Step 7: Negotiate Terms and Pricing

Once you have selected a supplier, negotiate the terms of the contract, including pricing, delivery timelines, and warranty conditions.

– Key Negotiation Points: Discuss bulk purchase discounts and after-sales support to ensure a mutually beneficial agreement.

By following this structured checklist, B2B buyers can confidently source irrigation flush valves that meet their operational needs while ensuring compliance and reliability.

Comprehensive Cost and Pricing Analysis for irrigation flush valve Sourcing

What Are the Key Cost Components in Sourcing Irrigation Flush Valves?

When sourcing irrigation flush valves, understanding the detailed cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The choice of materials significantly impacts the overall cost. High-quality plastics and metals used for manufacturing flush valves can vary widely in price. For instance, valves made from durable, corrosion-resistant materials may cost more initially but offer greater longevity and reduced maintenance.

Labor: Labor costs can fluctuate based on the region of production. In countries with higher wage standards, such as Germany, labor costs may constitute a larger portion of the total price compared to regions with lower wage expectations, like Nigeria or South America.

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and equipment depreciation. The scale of production can affect overhead; larger orders often lead to a lower overhead cost per unit.

Tooling: Custom tooling for specific valve designs can be a significant upfront investment. This cost is particularly relevant for buyers seeking customized flush valves tailored to unique specifications.

Quality Control (QC): Implementing stringent QC processes ensures that the valves meet required standards and specifications. However, this adds to the cost structure, as additional testing and inspection may be necessary.

Logistics: Transportation costs can vary significantly depending on the destination. For international buyers, understanding shipping options, customs duties, and potential delays is essential for accurate cost forecasting.

Margin: Supplier profit margins will vary based on market demand, competition, and the supplier’s operational efficiency. Buyers should be aware that margins can significantly influence the final price.

How Do Price Influencers Affect the Cost of Irrigation Flush Valves?

Several factors can influence the pricing of irrigation flush valves, impacting the total cost for buyers:

Volume and Minimum Order Quantity (MOQ): Suppliers often provide price breaks for larger orders. Buyers should consider their long-term needs to negotiate better pricing based on volume.

Specifications and Customization: Custom features or specifications can increase the cost. Buyers should clearly define their requirements to avoid unexpected expenses.

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, NSF) can lead to increased costs but may also provide assurance of product performance and durability.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge higher prices but offer greater assurance of quality and service.

Incoterms: Understanding the Incoterms (International Commercial Terms) used in the transaction can affect the overall cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) determine who bears the cost and risk at various stages of shipping.

What Are the Best Buyer Tips for Negotiating Prices on Irrigation Flush Valves?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic sourcing can yield significant savings:

Negotiate Based on Total Cost of Ownership (TCO): While the upfront price is important, consider the long-term costs associated with maintenance and replacement. A higher initial investment in durable valves may result in lower TCO.

Understand Pricing Nuances: Each market may have unique pricing structures influenced by local economic conditions. Engage with multiple suppliers to gather insights on price variances and negotiate effectively.

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs that can unlock bulk pricing advantages. This is particularly effective when working with multiple projects or in collaboration with other buyers.

Stay Informed on Market Trends: Keeping abreast of industry trends and supplier innovations can provide leverage in negotiations. Being knowledgeable about new materials or technologies may enable buyers to advocate for better pricing based on improved performance metrics.

Build Strong Relationships with Suppliers: Establishing a good rapport with suppliers can lead to better service, priority in fulfillment, and potentially lower prices over time. Long-term partnerships often yield favorable terms.

By understanding these cost components, price influencers, and negotiation strategies, B2B buyers can make more informed purchasing decisions regarding irrigation flush valves, ensuring they achieve the best value for their investment.

Alternatives Analysis: Comparing irrigation flush valve With Other Solutions

Exploring Alternatives to Irrigation Flush Valves

In the realm of irrigation systems, selecting the right components is crucial for achieving efficiency and longevity. While irrigation flush valves serve an essential role in maintaining system performance, various alternatives can also achieve similar objectives. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | Irrigation Flush Valve | Automatic Flush Valve | Manual Flushing System |

|---|---|---|---|

| Performance | Effective in preventing clogging by draining lines when pressure drops | Automatically flushes debris at the start/end of cycles | Relies on human intervention, can be less consistent |

| Cost | Low to moderate ($1.29 – $31.05) | Moderate to high (varies by model) | Low (cost of labor and time) |

| Ease of Implementation | Simple installation with various fitting options | Requires careful installation and calibration | Simple but labor-intensive |

| Maintenance | Low maintenance; occasional checks required | Low maintenance; self-cleaning | High; requires regular manual checks |

| Best Use Case | Ideal for small to medium systems needing basic clog prevention | Best for larger, automated systems needing consistent performance | Suitable for small, manual systems without automation |

Detailed Breakdown of Alternatives

Automatic Flush Valve

Automatic flush valves offer a sophisticated approach to irrigation management. They are designed to flush debris automatically at the beginning and end of each irrigation cycle, which helps maintain optimal system performance. The major advantage of this solution is its hands-free operation, significantly reducing the need for manual intervention. However, the initial investment can be higher than standard flush valves, and installation requires more precise calibration to ensure proper function. This makes them more suitable for larger, automated irrigation systems where consistent performance is critical.

Manual Flushing System

A manual flushing system is a traditional method where operators periodically flush the irrigation lines to remove debris. This approach is cost-effective in terms of equipment, as it primarily relies on human labor and basic tools. However, it can be inconsistent; the effectiveness depends on the operator’s diligence and understanding of system needs. Manual systems are best suited for smaller operations where automation is not feasible, but the labor-intensive nature can lead to inefficiencies in larger setups.

Conclusion: How to Choose the Right Irrigation Solution

When selecting an irrigation system solution, B2B buyers should assess their specific operational requirements, including system size, maintenance capabilities, and budget constraints. An irrigation flush valve is often the best choice for smaller systems requiring basic clog prevention with minimal maintenance. In contrast, automatic flush valves cater to larger, more complex systems needing automated solutions for consistent performance. Lastly, manual flushing systems may serve smaller operations where labor costs are less of a concern. By weighing these options against their unique needs, buyers can optimize their irrigation strategy for improved efficiency and effectiveness.

Essential Technical Properties and Trade Terminology for irrigation flush valve

What Are the Key Technical Properties of an Irrigation Flush Valve?

When selecting irrigation flush valves, understanding their technical specifications is crucial for ensuring optimal performance and longevity. Here are some essential properties to consider:

Material Grade

The material used for flush valves typically includes high-density polyethylene (HDPE), PVC, or brass. Each material offers different benefits, such as corrosion resistance, durability, and cost-effectiveness. For instance, brass valves are favored in high-pressure environments, while HDPE is lightweight and resistant to chemicals, making it suitable for various irrigation applications.Pressure Rating

Flush valves have specific pressure ratings, usually ranging from 1.5 to 60 PSI. This indicates the maximum pressure the valve can withstand without failure. Understanding this specification is critical for buyers to ensure compatibility with their irrigation systems and prevent leaks or malfunctions.Flow Rate

Flow rate, typically measured in gallons per minute (GPM), indicates the volume of water that can pass through the valve during flushing. Choosing a valve with an appropriate flow rate is essential for maintaining system efficiency, especially in large-scale agricultural setups where water distribution needs to be managed effectively.Connection Types

Flush valves come with various connection types, such as female pipe threads (FPT), male pipe threads (MPT), and barbed connections. Knowing the type of connection required for your irrigation system is vital for seamless installation and ensuring that the valve integrates well with existing components.Automatic vs. Manual Operation

Some flush valves operate automatically, triggering a flush cycle at specified intervals or when the system starts up. Others require manual activation. For B2B buyers, choosing between these options can significantly impact maintenance routines and operational efficiency, particularly in regions with limited resources for routine maintenance.Temperature Tolerance

Depending on the environment, flush valves must be able to operate effectively within specific temperature ranges. This is especially important in areas with extreme weather conditions, as valves that cannot withstand temperature fluctuations may fail, leading to costly repairs or replacements.

What Are Common Trade Terms Related to Irrigation Flush Valves?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of flush valves, knowing whether a product is OEM can assure buyers of its quality and compatibility with their existing systems.MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For irrigation flush valves, understanding the MOQ is important for budgeting and ensuring that purchasing agreements align with project needs, especially for large-scale operations.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. When sourcing flush valves, submitting an RFQ can help buyers compare costs and terms from various manufacturers, facilitating informed purchasing decisions.Incoterms (International Commercial Terms)

These are international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is crucial for B2B buyers engaged in international trade, as they determine who bears the costs and risks associated with shipping flush valves.Lead Time

This term refers to the time taken from placing an order to the delivery of the product. Understanding lead times for flush valves is essential for planning irrigation projects, as delays can impact agricultural schedules or construction timelines.Warranty Period

The warranty period indicates the duration for which the manufacturer guarantees the product against defects or failures. Knowing the warranty terms for flush valves can provide buyers with peace of mind regarding their investment and the expected lifespan of the product.

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions when sourcing irrigation flush valves, ensuring they choose the right products for their specific needs and operational contexts.

Navigating Market Dynamics and Sourcing Trends in the irrigation flush valve Sector

What Are the Current Market Dynamics and Key Trends in the Irrigation Flush Valve Sector?

The irrigation flush valve market is witnessing notable growth driven by several global factors. Increased awareness of water conservation, particularly in water-scarce regions of Africa and the Middle East, has led to a surge in demand for efficient irrigation systems. Additionally, the agricultural sector’s shift towards sustainable practices is prompting B2B buyers to seek solutions that minimize waste and enhance system longevity.

Emerging technologies such as automatic flush valves are gaining traction as they offer significant operational advantages. These devices not only reduce manual maintenance but also ensure optimal performance by flushing out debris and sediment, thus preventing clogging. The rise of smart irrigation solutions, equipped with IoT capabilities, is also influencing sourcing decisions, as businesses look for systems that provide real-time monitoring and data analytics.

For international B2B buyers, understanding regional market dynamics is crucial. In Europe, for instance, the trend is towards high-quality, durable products that comply with stringent environmental regulations. Conversely, in regions like South America and Africa, affordability and ease of installation are often prioritized. As a result, buyers must navigate a complex landscape of suppliers and products, balancing cost with quality and technological advancements.

How Can Sustainability and Ethical Sourcing Impact the Irrigation Flush Valve Market?

The environmental impact of irrigation practices is becoming increasingly important to B2B buyers in the flush valve sector. Flush valves play a critical role in reducing water waste and managing sediment build-up, making them essential for sustainable irrigation systems. As climate change intensifies, the demand for eco-friendly solutions is expected to rise, prompting manufacturers to innovate with sustainable materials and designs.

Ethical sourcing is equally vital in today’s market. B2B buyers are increasingly seeking suppliers who adhere to responsible labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and fair trade certifications can significantly influence purchasing decisions. Buyers should prioritize suppliers who demonstrate transparency in their supply chains, as this not only aligns with corporate social responsibility goals but also enhances brand reputation.

Moreover, the use of ‘green’ materials in the production of irrigation flush valves can be a selling point. Manufacturers that incorporate recycled materials or those that minimize energy consumption during production can appeal to environmentally conscious buyers, thereby gaining a competitive edge in the marketplace.

How Has the Irrigation Flush Valve Sector Evolved Over Time?

The evolution of the irrigation flush valve sector can be traced back to traditional irrigation practices, where manual flushing was the norm. Early designs were rudimentary, lacking efficiency and often leading to excessive water wastage. Over the decades, advancements in materials and technology have transformed flush valves into sophisticated devices that enhance the performance and longevity of irrigation systems.

The introduction of automatic flush valves marked a significant turning point, allowing for self-cleaning mechanisms that dramatically reduce maintenance efforts. Today, these valves are equipped with features such as pressure sensitivity and remote monitoring capabilities, further integrating into the broader landscape of smart irrigation technologies. This evolution reflects a broader trend towards automation and efficiency in the agricultural sector, catering to the needs of modern-day B2B buyers who seek reliable and sustainable solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation flush valve

How do I solve common clogging issues in my irrigation system?

Clogging is a frequent issue in irrigation systems, often caused by sediment or debris accumulation. To mitigate this, consider installing automatic flush valves that regularly clear out particles at system startup. Additionally, ensure proper maintenance schedules are in place to check for clogs in the filter systems. Regularly flushing the lines will help maintain optimal flow and pressure, extending the life of your irrigation infrastructure.What is the best type of flush valve for drip irrigation systems?

The best flush valve for drip irrigation systems typically includes automatic models that flush debris at the start and end of each cycle. Automatic flush valves, like those from reputable brands, help reduce manual labor and ensure consistent system performance. Look for options with low minimum pressure requirements and robust build quality to withstand various environmental conditions, particularly if you operate in regions with extreme climates.What are the typical minimum order quantities (MOQs) for flush valves from suppliers?

Minimum order quantities can vary significantly between suppliers. Generally, MOQs for flush valves range from 50 to 500 units, depending on the manufacturer and the specific model. When sourcing, inquire about bulk purchasing discounts, as larger orders often yield better pricing. Be sure to confirm with suppliers about their flexibility in MOQs, especially if you are testing new products or entering a new market.How can I evaluate and vet suppliers for irrigation flush valves?

Evaluating suppliers involves several steps: check their industry reputation through reviews and testimonials, request product samples to assess quality, and verify their compliance with international standards. It’s also beneficial to ask about their production capacity and lead times. Engaging with suppliers through trade shows or industry conferences can provide additional insights into their reliability and product offerings.What payment terms should I expect when sourcing irrigation flush valves?

Payment terms can vary, but common practices include 30% upfront payment with the balance due before shipment or upon delivery. Some suppliers may offer net 30 or net 60 terms for established relationships. Always clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Ensure that any terms are documented in your contract to avoid misunderstandings.What quality assurance processes should I expect from flush valve manufacturers?

Reputable manufacturers should have rigorous quality assurance processes in place, including material inspections, performance testing, and compliance with industry standards. Ask about their certifications, such as ISO or CE marks, which indicate adherence to quality management systems. Requesting documentation of testing results and warranty information can further assure you of the product’s reliability and durability.How do logistics and shipping impact the cost of sourcing flush valves internationally?

Logistics and shipping can significantly influence the total cost of procurement. Factors such as shipping method, distance, and customs duties should be considered. Air freight is faster but more expensive, while sea freight is more economical for larger orders but takes longer. It’s advisable to work with a logistics provider experienced in international shipping to navigate customs and ensure timely delivery while managing costs effectively.What are the key features to look for in an automatic flush valve?

When selecting an automatic flush valve, consider features like the operational pressure range, flushing volume, and ease of maintenance. A good flush valve should automatically clear debris without manual intervention and have a design that accommodates varying water conditions. Look for models with removable components for easy cleaning and winterization, especially if operating in regions with seasonal temperature fluctuations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Irrigation Flush Valve Manufacturers & Suppliers List

1. DripWorks – Flush Valves

Domain: dripworks.com

Registered: 1998 (27 years)

Introduction: Flush Valves – Price Range: $1.29 – $31.05. SKU: Q_VF. Available Configurations: Flush Valve – FHT (VFH), Flush Valve – 3/4″ FPT (VFP). Description: Small, simple, and economical flush valves that open when water pressure drops below 2.5 PSI, draining the line to prevent prolonged dripping, mineral build-up, and freeze damage. Installation: VFH can connect to 1/2″ mainline using Easy Loc Tee (ELMT…

2. Netafim – A600 Flush Valve

Domain: dripirrigation.com

Registered: 1997 (28 years)

Introduction: Netafim Flush Valve with 1/2″ MPT connection used for drip irrigation systems. Model # A600, SKU: as configured, Manufacturer: Netafim, Manufacturer #: TL050MFV-1. Regular Price: $15.00. This flush valve automatically flushes the lines of a drip system at the start of each irrigation cycle, releasing approximately one gallon of water each time the zone is turned on. It eliminates the need for peri…

3. Rain Bird – Two Piece Flush Valve

Domain: rainbird.com

Registered: 1995 (30 years)

Introduction: Two Piece Flush Valve, Part Numbers: MDCF-COUP & MDCF-CAP, Product URL: https://www.rainbird.com/products/easy-fit-compression-fitting-system

4. Netafim – Automatic Flush Valves

Domain: netafimusa.com

Registered: 2000 (25 years)

Introduction: Automatic Flush Valves help reduce maintenance to your irrigation system and increase dripline performance. They facilitate periodic flushing of your irrigation system at the start and end of each irrigation cycle, allowing a small amount of water to pass through to flush debris that may have accumulated in the system, ensuring optimum operation and performance.

Product Advantages:

– Flushing re…

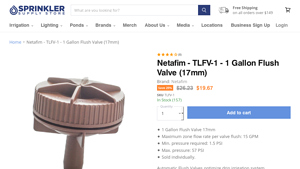

5. Netafim – TLFV-1 Flush Valve

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: {‘name’: ‘Netafim TLFV-1 – 1 Gallon Flush Valve’, ‘brand’: ‘Netafim’, ‘sku’: ‘TLFV-1’, ‘price’: {‘original’: ‘$26.23’, ‘current’: ‘$19.67’}, ‘availability’: ‘In Stock (157)’, ‘specifications’: {‘size’: ’17mm’, ‘maximum_zone_flow_rate’: ’15 GPM’, ‘minimum_pressure_required’: ‘1.5 PSI’, ‘maximum_pressure’: ’57 PSI’}, ‘features’: ‘Automatic Flush Valves optimize drip irrigation system performance by …

6. Drip Depot – Check Valves

Domain: help.dripdepot.com

Registered: 2005 (20 years)

Introduction: Check Valves: One-way valves allowing flow in one direction, used to protect equipment from backflow damage, stop low head drainage, prevent contamination from back siphoning, and provide pressure relief. Common in irrigation systems, they open under positive pressure and close when pressure drops. PVC Inline Check Valves and Hunter HCV Check Valve are examples.

Flush Valves: Devices used at the …

Strategic Sourcing Conclusion and Outlook for irrigation flush valve

What Are the Key Takeaways for B2B Buyers of Irrigation Flush Valves?

In conclusion, strategic sourcing of irrigation flush valves presents significant advantages for international B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe. By investing in high-quality flush valves, buyers can enhance the efficiency of their irrigation systems, reduce maintenance costs, and prevent operational disruptions caused by sediment build-up and clogging. The availability of various models, such as automatic flush valves, allows for tailored solutions that meet specific irrigation needs, ensuring optimal performance across different environmental conditions.

How Can Buyers Leverage Strategic Sourcing for Future Growth?

As water scarcity becomes a pressing concern globally, the demand for efficient irrigation solutions will only increase. International buyers are encouraged to prioritize strategic sourcing partnerships that not only provide high-quality products but also offer ongoing support and expertise. This proactive approach will empower businesses to stay ahead in a competitive landscape, fostering sustainability and resilience in agricultural practices.

In this dynamic market, take the next step by evaluating your current irrigation systems and exploring how strategic sourcing of flush valves can drive your operational efficiency forward. Engage with suppliers who understand your local context and can offer customized solutions that align with your long-term goals.