Introduction: Navigating the Global Market for irrigation valve market market

In an era where water scarcity is becoming a pressing global issue, the irrigation valve market is emerging as a critical sector for businesses seeking to optimize water management in agricultural practices. Sourcing efficient irrigation valves can be challenging, especially for international B2B buyers navigating diverse regional needs and regulatory frameworks. This guide aims to demystify the complexities of the irrigation valve market, offering insights into various types—such as ball, gate, and solenoid valves—and their applications across agriculture, landscaping, and municipal uses.

Within these pages, readers will find comprehensive information on supplier vetting processes, cost considerations, and the latest technological advancements that enhance water conservation efforts. By addressing key challenges such as fluctuating water supplies and the demand for sustainable farming practices, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe—including countries like Vietnam and Saudi Arabia—to make informed purchasing decisions.

Understanding market dynamics, including growth trends and regulatory incentives, will enable businesses to align their operations with global best practices. As the irrigation valve market continues to grow at a robust pace, driven by increasing agricultural demands and government initiatives, this guide serves as a vital resource for companies looking to invest wisely and sustainably in their irrigation systems.

Understanding irrigation valve market market Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ball Valves | Offers quick shut-off and minimal flow resistance. | Agriculture, Landscaping | Pros: Easy maintenance, durable; Cons: Limited flow control. |

| Gate Valves | Provides full flow with minimal pressure drop. | Large-scale irrigation systems | Pros: Efficient for on/off applications; Cons: Slower operation. |

| Butterfly Valves | Compact design with quick operation and low torque. | Industrial applications, Waterworks | Pros: Space-efficient, suitable for large flows; Cons: Less effective for throttling. |

| Solenoid Valves | Automated control using electrical signals. | Precision irrigation, Automation | Pros: Highly efficient, programmable; Cons: Requires electrical supply. |

| Globe Valves | Excellent for flow regulation with throttling capability. | Residential, Commercial | Pros: Good for fine control; Cons: Higher pressure loss. |

What Are Ball Valves and Their B2B Suitability?

Ball valves are among the most popular types in the irrigation valve market, known for their straightforward operation and reliability. They feature a spherical disc that controls flow, allowing for quick shut-off capabilities. This type is particularly suitable for agricultural and landscaping applications where minimal maintenance is required. B2B buyers should consider the ease of installation and low maintenance costs, making ball valves a cost-effective choice for long-term irrigation systems.

How Do Gate Valves Function in Large-Scale Irrigation?

Gate valves are designed to provide a straight-line flow of fluid with minimal pressure loss, making them ideal for large-scale irrigation systems. They operate by lifting a gate out of the path of the fluid, allowing for a full flow when open. B2B purchasers should evaluate their operational speed and efficiency, as gate valves are better suited for applications where a complete shut-off is needed rather than frequent adjustments.

Why Choose Butterfly Valves for Industrial Applications?

Butterfly valves are characterized by their compact design and quick operation, making them suitable for a variety of industrial applications, including waterworks and large-scale irrigation. Their design allows for quick opening and closing, which is essential in systems requiring rapid flow adjustments. B2B buyers should assess their space constraints and the need for high flow rates, as butterfly valves can effectively handle large volumes of water while occupying minimal space.

What Are the Advantages of Solenoid Valves in Precision Irrigation?

Solenoid valves utilize electrical signals to automate water flow, making them ideal for precision irrigation systems. These valves can be programmed to respond to specific conditions, allowing for efficient water management. B2B buyers should consider the initial investment and the need for electrical supply, as solenoid valves can significantly enhance irrigation efficiency, especially in modern agricultural practices.

How Do Globe Valves Enhance Flow Regulation?

Globe valves are designed for flow regulation and throttling, making them an excellent choice for residential and commercial irrigation applications. They provide precise control over water flow, which is crucial in maintaining optimal moisture levels for various plants. B2B buyers should weigh the benefits of effective flow control against the potential for higher pressure loss, as globe valves can be less efficient in large-scale applications compared to other types.

Key Industrial Applications of irrigation valve market market

| Industry/Sector | Specific Application of Irrigation Valve Market Market | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems for crop management | Enhances water efficiency, reduces labor costs | Compatibility with existing systems, durability under local conditions |

| Landscaping | Smart irrigation for residential and commercial spaces | Improves aesthetics, conserves water | Ease of installation, flexibility in design, and automation capabilities |

| Golf Courses | Precision irrigation for greens and fairways | Maintains turf quality, optimizes water usage | Robustness against wear, ease of maintenance, and responsiveness to weather changes |

| Municipal Water Systems | Flow control in public parks and green areas | Ensures sustainable water usage, reduces wastage | Compliance with local regulations, availability of replacement parts |

| Horticulture | Greenhouse irrigation systems | Maximizes plant health, improves yield | Material compatibility with various plants, automation features for monitoring |

How Are Irrigation Valves Used in Agriculture?

In the agricultural sector, irrigation valves play a crucial role in automated irrigation systems that manage water delivery to crops. These systems help farmers optimize water usage, reduce waste, and enhance crop yields. For international buyers, particularly in regions like Africa and South America, the focus should be on valves that can withstand varying climatic conditions and soil types. Buyers should also consider compatibility with existing irrigation setups and the ability to integrate advanced technologies like sensors for real-time monitoring.

What Are the Benefits of Smart Irrigation in Landscaping?

Smart irrigation systems in landscaping utilize irrigation valves to control water flow efficiently, ensuring that gardens and commercial spaces receive the right amount of water. This not only enhances the aesthetic appeal but also conserves water, a critical consideration in regions facing water scarcity, such as the Middle East. When sourcing, buyers should prioritize ease of installation and the ability to integrate with existing landscape designs, as well as the potential for automation to adapt to weather changes.

How Do Golf Courses Benefit from Precision Irrigation?

Golf courses use precision irrigation systems that rely heavily on irrigation valves to maintain optimal turf conditions across greens and fairways. These systems are designed to deliver precise amounts of water, ensuring the health and appearance of the turf while minimizing waste. For golf course operators, particularly in Europe and the Middle East, sourcing durable and low-maintenance valves is essential. Additionally, valves should be responsive to weather conditions, allowing for adjustments based on rainfall and temperature variations.

What Role Do Irrigation Valves Play in Municipal Water Systems?

Municipalities employ irrigation valves in public parks and green areas to manage water flow sustainably. These systems help ensure that water is used efficiently, reducing wastage and promoting healthy green spaces. For international buyers from developing regions, compliance with local water regulations and standards is a critical consideration when sourcing these valves. Furthermore, the availability of replacement parts and maintenance services is essential to ensure long-term functionality.

How Is Horticulture Enhanced by Greenhouse Irrigation Systems?

In horticulture, irrigation valves are integral to greenhouse irrigation systems, where they control water delivery to various plant species. This application maximizes plant health and improves yield, making it vital for commercial growers. Buyers should look for valves made from materials compatible with different plant types and those that offer automation features for monitoring water levels. This is particularly important for international buyers in regions with diverse horticultural practices, such as South America and Europe.

3 Common User Pain Points for ‘irrigation valve market market’ & Their Solutions

Scenario 1: Inefficient Water Management Leading to Crop Loss

The Problem: Many B2B buyers in the agricultural sector face challenges with inefficient water management systems, which can lead to significant crop losses. This inefficiency often stems from outdated or poorly functioning irrigation valves that fail to control water flow effectively. Without precise regulation, crops may receive either too much or too little water, resulting in stunted growth or crop failure. For instance, a buyer managing a large farm may struggle with varying soil moisture levels due to inconsistent valve performance, ultimately impacting yield and profitability.

The Solution: To address this issue, B2B buyers should invest in modern, automated irrigation valves equipped with sensors and smart technology. These valves can automatically adjust the water flow based on real-time soil moisture data, ensuring that crops receive the optimal amount of water. When sourcing these valves, buyers should focus on suppliers that offer integrated solutions, including installation services and ongoing support. Additionally, conducting thorough research on the specific requirements of different crops and soil types will help in selecting the most suitable valve system. Regular maintenance checks and performance evaluations can further enhance efficiency and longevity, ultimately safeguarding crop yields and improving resource management.

Scenario 2: Rising Costs Due to Water Waste and Energy Consumption

The Problem: B2B buyers are increasingly concerned about rising operational costs, particularly due to water waste and high energy consumption associated with traditional irrigation systems. In regions facing water scarcity, inefficient irrigation can lead to exorbitant utility bills and regulatory fines for excessive water usage. A buyer managing multiple agricultural sites may find that outdated valves contribute to significant water loss, driving up costs and complicating budget management.

The Solution: To combat these rising costs, B2B buyers should consider investing in energy-efficient irrigation valves that minimize water usage while optimizing energy consumption. Implementing smart irrigation systems that utilize real-time data analytics can significantly reduce waste. Buyers should seek out suppliers who offer systems with programmable settings that adjust water flow based on weather forecasts and soil moisture levels. Furthermore, training staff on efficient irrigation practices and regularly auditing water usage can help identify inefficiencies. By making these adjustments, buyers can not only reduce their operational costs but also enhance their sustainability efforts, positioning themselves favorably in a market that increasingly values environmental responsibility.

Scenario 3: Limited Product Knowledge Leading to Poor Investment Decisions

The Problem: A common pain point for B2B buyers in the irrigation valve market is the lack of comprehensive product knowledge, which can lead to poor investment decisions. Many buyers are unsure about the types of valves available, their specific applications, and the technologies that could enhance their irrigation systems. This knowledge gap can result in purchasing valves that do not meet the operational needs of their irrigation systems, ultimately wasting time and financial resources.

The Solution: To overcome this challenge, B2B buyers should prioritize education and consultation when exploring options in the irrigation valve market. Engaging with industry experts or attending trade shows can provide valuable insights into the latest technologies and best practices. Buyers should also consider working closely with suppliers who offer educational resources, such as webinars or detailed product guides, to better understand the features and benefits of different valve types. Investing in trial systems or pilot projects can also help buyers assess the performance of new technologies before committing to larger purchases. By enhancing their understanding of the market, buyers can make informed decisions that align with their operational goals, leading to more effective and efficient irrigation solutions.

Strategic Material Selection Guide for irrigation valve market market

What Are the Key Properties of Common Materials Used in Irrigation Valves?

When selecting materials for irrigation valves, it is crucial to consider their properties, performance under various conditions, and compatibility with specific applications. Here, we analyze four common materials: brass, PVC, stainless steel, and polyethylene.

How Does Brass Perform in Irrigation Valves?

Brass is a favored choice for irrigation valves due to its excellent corrosion resistance and durability. It typically has a high-temperature and pressure rating, making it suitable for a range of applications. Brass valves can withstand harsh environmental conditions and are often used in both agricultural and residential settings.

Pros: Brass is known for its strength and longevity, making it a reliable choice for high-pressure systems. Its ease of machining allows for complex designs, which can be beneficial for custom applications.

Cons: The primary drawback of brass is its cost, which can be higher than plastic alternatives. Additionally, brass can be susceptible to dezincification in certain environments, potentially leading to failure.

Impact on Application: Brass is compatible with a wide range of media, including potable water, which is crucial for agricultural applications. However, buyers must ensure that the specific alloy used is suitable for their intended use.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like the Middle East and Europe often prefer brass for its reliability, but they should verify the alloy specifications to avoid dezincification issues.

What Advantages Does PVC Offer for Irrigation Valves?

PVC (Polyvinyl Chloride) is a popular material in the irrigation sector due to its lightweight nature and resistance to corrosion. PVC valves are typically rated for lower pressure applications, making them ideal for residential and small-scale agricultural use.

Pros: PVC is cost-effective and easy to install, significantly reducing labor costs. It also offers excellent chemical resistance, making it suitable for various irrigation fluids.

Cons: The main limitation of PVC is its lower temperature and pressure tolerance compared to metal options. It can become brittle over time when exposed to UV light unless treated.

Impact on Application: PVC is compatible with a variety of irrigation systems, particularly drip and sprinkler systems. However, it is not suitable for high-pressure applications or environments with extreme temperatures.

Considerations for International Buyers: Buyers should ensure that their PVC products meet local standards, such as JIS in Japan or EN in Europe. In regions with high UV exposure, selecting UV-stabilized PVC is crucial.

Why Choose Stainless Steel for Irrigation Valves?

Stainless steel is renowned for its strength and corrosion resistance, making it an excellent choice for high-pressure irrigation systems. It can withstand extreme temperatures and is often used in both agricultural and industrial applications.

Pros: The durability of stainless steel means that it can last significantly longer than plastic options. It is also highly resistant to rust and corrosion, making it suitable for various media.

Cons: The primary disadvantage is its higher cost compared to brass and PVC. Additionally, stainless steel requires more complex manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including aggressive chemicals, making it versatile for various irrigation applications.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM A312 for pipe fittings. In regions like Africa and South America, the initial investment may be higher, but the long-term savings from durability can be significant.

What Role Does Polyethylene Play in Irrigation Valves?

Polyethylene (PE) is another widely used material in irrigation systems, particularly in low-pressure applications. It is lightweight and flexible, making it easy to install and transport.

Pros: Polyethylene is highly resistant to corrosion and chemicals, ensuring longevity in various environments. Its flexibility allows for easy installation in uneven terrains.

Cons: However, polyethylene may not be suitable for high-temperature applications and can become brittle over time, especially in colder climates.

Impact on Application: PE is ideal for drip irrigation systems and is often used in agricultural settings where flexibility is required.

Considerations for International Buyers: Buyers should ensure that the polyethylene used meets local standards for agricultural applications. In regions with varying temperatures, selecting high-density polyethylene (HDPE) can provide added durability.

Summary Table of Material Selection for Irrigation Valves

| Material | Typical Use Case for irrigation valve market market | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-pressure agricultural and residential systems | Excellent durability and corrosion resistance | Higher cost, potential dezincification | High |

| PVC | Residential and small-scale agricultural systems | Cost-effective and easy to install | Lower pressure tolerance, UV sensitivity | Low |

| Stainless Steel | High-pressure and industrial irrigation applications | Long-lasting and versatile | Higher cost, complex manufacturing | High |

| Polyethylene | Drip irrigation and low-pressure systems | Flexible and corrosion-resistant | Not suitable for high temperatures | Medium |

This guide provides a comprehensive overview of material selection for irrigation valves, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve market market

What are the Main Stages of Manufacturing Irrigation Valves?

The manufacturing process for irrigation valves involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets quality and performance standards.

Material Preparation: Selecting the Right Components

The first step in manufacturing irrigation valves is the selection and preparation of materials. Common materials include metals such as brass and stainless steel, as well as high-density plastics like PVC. The choice of material is crucial, as it impacts the valve’s durability and resistance to corrosion. Materials are typically sourced from reputable suppliers and undergo initial quality checks to verify their specifications.

Once the materials are selected, they are cut to size and prepped for forming. This may involve processes like machining or extrusion, depending on the valve design. Proper material handling and storage are essential to prevent contamination or damage before the manufacturing process begins.

How are Irrigation Valves Formed and Assembled?

Forming Techniques: Shaping the Valves

Forming is the next stage in the manufacturing process, where raw materials are transformed into valve components. Various techniques are employed, such as casting, forging, and machining. For instance, ball valves may be machined from solid metal blocks, while plastic valves could be produced using injection molding.

Each technique has its advantages. Casting allows for complex shapes and is cost-effective for large production runs, while machining offers precision and is ideal for custom or low-volume orders. It’s vital to choose the appropriate forming method based on the valve type and production scale.

Assembly: Bringing Components Together

After forming, the individual components are assembled. This stage may involve manual labor or automated processes, depending on the complexity and volume of the production. During assembly, parts such as seals, seats, and actuators are integrated into the valve body. Proper alignment and fitting are critical to ensure optimal performance and prevent leaks.

Quality control measures should be in place during assembly to verify that components meet design specifications. Any discrepancies can lead to issues in the final product, affecting its reliability in the field.

What Finishing Processes are Commonly Used for Irrigation Valves?

Surface Treatment: Ensuring Longevity and Performance

The finishing stage involves applying treatments to enhance the valve’s performance and durability. Common finishing processes include coating, polishing, and surface hardening. Coatings may be applied to improve corrosion resistance, while polishing can enhance aesthetic appeal and reduce friction.

Finishing not only protects the valves but also prepares them for various environmental conditions, which is particularly important for international markets where climatic conditions can vary significantly.

What International Standards and Quality Control Measures Apply?

Understanding Relevant International Standards

Quality assurance in the irrigation valve market is governed by several international standards. ISO 9001 is one of the most recognized quality management standards, ensuring that manufacturers have consistent processes in place to meet customer and regulatory requirements. Other industry-specific certifications may include CE marking for products sold in Europe and API standards for valves used in oil and gas applications.

B2B buyers should look for these certifications when selecting suppliers, as they indicate a commitment to quality and compliance with international safety standards.

Key Quality Control Checkpoints: What to Look For

Quality control (QC) is integral throughout the manufacturing process. Key checkpoints include:

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the production process. Suppliers should provide certifications and documentation to verify material quality.

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that each stage adheres to specified standards. This may involve measuring dimensions, checking tolerances, and testing the functionality of components.

Final Quality Control (FQC): Once the valves are assembled, a final inspection is conducted. This may include pressure testing, leak testing, and performance evaluations to ensure the product meets all specifications before shipping.

How Can B2B Buyers Verify Supplier Quality Control?

Conducting Audits and Reviewing Reports

B2B buyers can ensure the quality of their irrigation valve suppliers through various methods. Conducting supplier audits is an effective way to assess manufacturing practices and quality control systems. These audits can reveal potential weaknesses in processes and help establish a relationship based on transparency and trust.

Additionally, buyers should request quality control reports, which detail inspection results and compliance with relevant standards. These documents provide insights into the supplier’s commitment to quality and can be crucial for long-term partnerships.

Utilizing Third-Party Inspections

For buyers operating in regions like Africa, South America, the Middle East, and Europe, third-party inspections can provide an extra layer of assurance. Engaging independent inspectors to evaluate the manufacturing processes and quality control measures offers an unbiased assessment of the supplier’s capabilities. This is particularly important when dealing with international suppliers, as it helps mitigate risks associated with language barriers and differing regulations.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating Regional Regulations and Standards

International buyers must be aware of the specific regulations and quality standards in their regions. For instance, products sold in Europe must comply with CE marking requirements, while other regions may have different certifications. Understanding these nuances ensures that the irrigation valves meet local market needs and regulatory requirements.

Additionally, cultural differences may affect communication and expectations regarding quality. Establishing clear lines of communication and setting mutual expectations can help bridge these gaps, leading to successful partnerships.

Conclusion: The Importance of Manufacturing and Quality Assurance in the Irrigation Valve Market

In conclusion, understanding the manufacturing processes and quality assurance measures is crucial for B2B buyers in the irrigation valve market. By familiarizing themselves with the stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions and select reliable suppliers. This not only ensures product quality but also enhances operational efficiency, ultimately contributing to successful agricultural practices and sustainable water management.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve market market’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the complexities of procuring irrigation valves. As the demand for efficient irrigation systems grows, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the critical steps in sourcing the right products becomes essential. This checklist will help streamline your procurement process, ensuring you make informed and strategic decisions.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications needed for your irrigation valves. Consider factors such as the type of valve (e.g., ball, gate, solenoid), material (metal or plastic), and pressure ratings. Having precise specifications helps narrow down potential suppliers and ensures that the valves meet the operational requirements of your irrigation system.

Step 2: Research Market Trends and Demand

Stay informed about current trends in the irrigation valves market, particularly regarding sustainability and technological advancements. Understanding the market dynamics—such as the expected growth rates and key drivers—will enable you to anticipate future needs and align your sourcing strategy accordingly. For example, the increasing emphasis on water conservation can influence your choice of products.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Key factors to evaluate include:

– Experience: Look for suppliers with a strong track record in irrigation systems.

– Product Range: Ensure they offer a variety of valve types and materials to meet your specific needs.

Step 4: Verify Supplier Certifications and Compliance

Confirm that potential suppliers hold relevant certifications and comply with industry standards. This step is vital to ensure that the products are safe, reliable, and of high quality. Look for certifications such as ISO 9001 for quality management systems or local regulatory compliance that may affect installation and use in your region.

Step 5: Request Samples and Conduct Testing

Before finalizing your order, request samples of the irrigation valves to test their performance in real-world conditions. This allows you to assess factors such as durability, flow control, and ease of installation. Conducting thorough testing can prevent costly mistakes and ensure the selected valves meet your operational requirements.

Step 6: Negotiate Terms and Conditions

Once you’ve identified suitable suppliers, engage in negotiations to secure favorable terms. Discuss pricing, payment conditions, delivery timelines, and warranty options. A well-negotiated contract can protect your interests and foster a long-term relationship with the supplier.

Step 7: Plan for After-Sales Support and Maintenance

Lastly, inquire about the after-sales support and maintenance services offered by your supplier. Understanding their capabilities in providing ongoing support can significantly impact the longevity and efficiency of your irrigation system. Ensure that your supplier is committed to assisting you with any issues that may arise post-installation.

By following this step-by-step checklist, you will be better equipped to source irrigation valves that meet your needs and contribute to effective water management in your agricultural operations.

Comprehensive Cost and Pricing Analysis for irrigation valve market market Sourcing

What Are the Key Cost Components in the Irrigation Valve Market?

Understanding the cost structure of irrigation valves is essential for B2B buyers aiming to optimize their procurement strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The choice of materials significantly influences costs. Common materials include brass, PVC, and stainless steel, each with different price points and durability. For instance, brass valves may offer superior longevity and resistance to corrosion but come at a higher cost compared to plastic options.

Labor: Labor costs can vary based on the manufacturing location. Countries with lower labor costs may offer cheaper products, but this can sometimes compromise quality. It’s essential to balance labor costs with the expected quality to ensure a viable product.

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs, ultimately impacting the final pricing.

Tooling: Custom tooling can be a significant upfront investment. For customized or specialized valves, the tooling costs will be amortized over the production volume, affecting unit prices.

Quality Control (QC): Rigorous QC processes ensure that the valves meet the necessary standards and certifications. While this may add to the cost, it is crucial for maintaining reliability and safety, especially in agricultural applications.

Logistics: Transportation and shipping costs, especially for international buyers, can substantially impact the total cost. Factors like distance, shipping method, and Incoterms will play a vital role in determining logistics expenses.

Margin: Suppliers typically include a profit margin, which can vary based on market demand, competition, and the perceived value of the product.

What Factors Influence Pricing in the Irrigation Valve Market?

Several price influencers can affect the overall cost of irrigation valves, making it crucial for buyers to be aware of these factors when sourcing.

Volume/MOQ: Minimum order quantities (MOQ) and bulk purchasing often lead to lower per-unit prices. Suppliers may offer significant discounts for larger orders, which can be particularly beneficial for businesses with extensive irrigation needs.

Specifications and Customization: Customized valves that meet specific requirements can incur higher costs. Buyers should clearly define their needs upfront to avoid unexpected expenses later in the process.

Materials: As previously mentioned, the choice of materials affects not only the initial cost but also the long-term value and maintenance expenses. Investing in higher-quality materials can lead to lower total ownership costs.

Quality and Certifications: Valves that comply with international standards or have specific certifications may carry a premium price. However, these certifications can also provide assurance of reliability and performance, which can be essential in critical irrigation applications.

Supplier Factors: The supplier’s reputation, experience, and production capacity can influence pricing. Established suppliers may charge more due to their reliability and service, while emerging suppliers may offer lower prices to gain market share.

Incoterms: Understanding the terms of shipping is crucial for international buyers. Incoterms can define who is responsible for shipping costs, insurance, and liability, thus affecting the total cost of acquisition.

How Can Buyers Optimize Costs in the Irrigation Valve Market?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost efficiency.

Negotiation: Engage in negotiations with suppliers to secure better pricing or terms, especially when placing bulk orders. Building a long-term relationship can also lead to preferential pricing.

Total Cost of Ownership (TCO): Evaluate the total cost of ownership rather than just the purchase price. This includes installation, maintenance, and operational costs over the valve’s lifespan.

Pricing Nuances: Be aware of currency fluctuations and import duties when sourcing internationally. These factors can significantly affect the final cost and should be factored into budgeting.

Research and Compare Suppliers: Conduct thorough research to compare suppliers based on pricing, quality, and service levels. Leveraging this information can lead to more informed purchasing decisions.

Disclaimer

Prices and cost structures provided in this analysis are indicative and may vary based on market conditions, specific supplier quotes, and other situational factors. Always consult with suppliers for precise pricing tailored to your requirements.

Alternatives Analysis: Comparing irrigation valve market market With Other Solutions

Exploring Alternative Solutions to the Irrigation Valve Market

In the quest for effective irrigation management, various solutions exist that can complement or serve as alternatives to traditional irrigation valves. Understanding these alternatives can help B2B buyers make informed decisions that align with their agricultural needs and sustainability goals.

| Comparison Aspect | Irrigation Valve Market Market | Drip Irrigation Systems | Smart Irrigation Technologies |

|---|---|---|---|

| Performance | High precision in water flow control, adaptable to various crops | Delivers water directly to the root zone, minimizing evaporation and runoff | Uses sensors and algorithms for optimal water distribution, based on real-time data |

| Cost | Moderate initial investment, with ongoing maintenance costs | Lower installation cost but requires regular maintenance | Higher upfront costs due to technology, but potential long-term savings |

| Ease of Implementation | Relatively straightforward installation, depending on existing systems | Requires careful planning to ensure proper layout and coverage | Can be complex to install; may require professional assistance |

| Maintenance | Requires periodic checks and replacements, especially in high-use environments | Needs regular inspection and cleaning to prevent clogging | Minimal once set up, but requires software updates and occasional sensor maintenance |

| Best Use Case | Large-scale agriculture needing precise control over water usage | Arid regions or where water conservation is critical | Urban areas and commercial farms where real-time data can enhance efficiency |

Drip Irrigation Systems: Pros and Cons

Drip irrigation systems are designed to deliver water directly to the plants’ root zones, minimizing water loss through evaporation and runoff. They are particularly beneficial in areas with limited water resources. The main advantages include lower water usage and reduced weed growth. However, they do require regular maintenance to prevent clogging, and the initial layout can be labor-intensive, making them less suitable for larger, less structured agricultural operations.

Smart Irrigation Technologies: Pros and Cons

Smart irrigation technologies leverage advanced sensors and data analytics to optimize water usage based on environmental conditions. These systems can significantly reduce water waste and improve crop yields by providing precise irrigation schedules. While the technology can lead to long-term savings and efficiency, the initial investment can be high, and the installation process may require professional expertise. Additionally, ongoing software updates and sensor maintenance can add to operational costs.

Conclusion: How to Choose the Right Irrigation Solution

When selecting the appropriate irrigation solution, B2B buyers should consider their specific agricultural needs, budget constraints, and operational capabilities. The irrigation valve market excels in providing precise control over water flow, making it ideal for larger farming operations. In contrast, drip irrigation systems offer a cost-effective solution for water-scarce regions, while smart irrigation technologies present an innovative approach for those willing to invest in technology for long-term gains. By assessing these factors, buyers can align their irrigation strategy with their sustainability goals and operational efficiency.

Essential Technical Properties and Trade Terminology for irrigation valve market market

What Are the Key Technical Properties of Irrigation Valves That B2B Buyers Should Know?

When selecting irrigation valves, understanding their technical properties is crucial for ensuring efficiency and compatibility with your irrigation system. Here are some essential specifications to consider:

Material Grade

The material used in irrigation valves significantly affects their durability and performance. Common materials include brass, PVC, and stainless steel. Brass valves are known for their strength and resistance to corrosion, making them suitable for high-pressure applications. PVC is lighter and cost-effective, ideal for low-pressure systems. Understanding material grade helps in selecting valves that can withstand environmental conditions specific to regions like Africa or the Middle East, where temperature and humidity can vary significantly.Pressure Rating

This specification indicates the maximum pressure the valve can handle without failure. Irrigation valves typically have pressure ratings ranging from 150 psi to over 300 psi. Selecting a valve with an appropriate pressure rating is essential for ensuring that it can manage the water flow demands of your irrigation system without risk of leaks or bursts, especially in high-pressure agricultural environments.Flow Coefficient (Cv Value)

The Cv value measures the flow capacity of the valve. A higher Cv value indicates the valve can allow more water to pass through at a given pressure drop. This is important for B2B buyers who need to optimize water flow for large agricultural fields, ensuring efficient irrigation without wasting resources. Knowing the Cv value can aid in designing an effective irrigation layout.Temperature Range

Irrigation valves must operate effectively within specific temperature limits. For example, standard PVC valves might only function well at temperatures below 140°F, while metal valves can handle higher temperatures. Understanding the temperature range is vital for applications in regions with extreme weather conditions, ensuring longevity and reliability of the valves.Tolerance Levels

Tolerance refers to the acceptable variation in dimensions and performance characteristics of the valve. This specification is crucial for ensuring that the valve fits properly within the irrigation system and operates as intended. Tighter tolerances often mean better performance and lower leakage rates, which is especially important for precision irrigation systems.

Which Trade Terminology Is Essential for Navigating the Irrigation Valve Market?

Familiarity with industry jargon can streamline communication and negotiations in the irrigation valve market. Here are some common terms that B2B buyers should understand:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the irrigation valve market, knowing whether a valve is produced by an OEM can assure you of its quality and compatibility with your existing systems.MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially for businesses looking to scale their operations without incurring unnecessary costs.RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. It is crucial for B2B transactions, allowing buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal for their irrigation needs.Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping costs, insurance, and delivery locations. Familiarity with these terms is vital for international buyers, particularly in regions like South America and Europe, to avoid misunderstandings during transactions.Smart Irrigation Systems

This term refers to advanced irrigation solutions that utilize technology such as sensors and timers to optimize water usage. Understanding smart irrigation systems is increasingly important for buyers focused on efficiency and sustainability, particularly as global concerns about water conservation grow.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring their irrigation systems are both effective and efficient.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve market market Sector

What Are the Current Trends Shaping the Global Irrigation Valve Market?

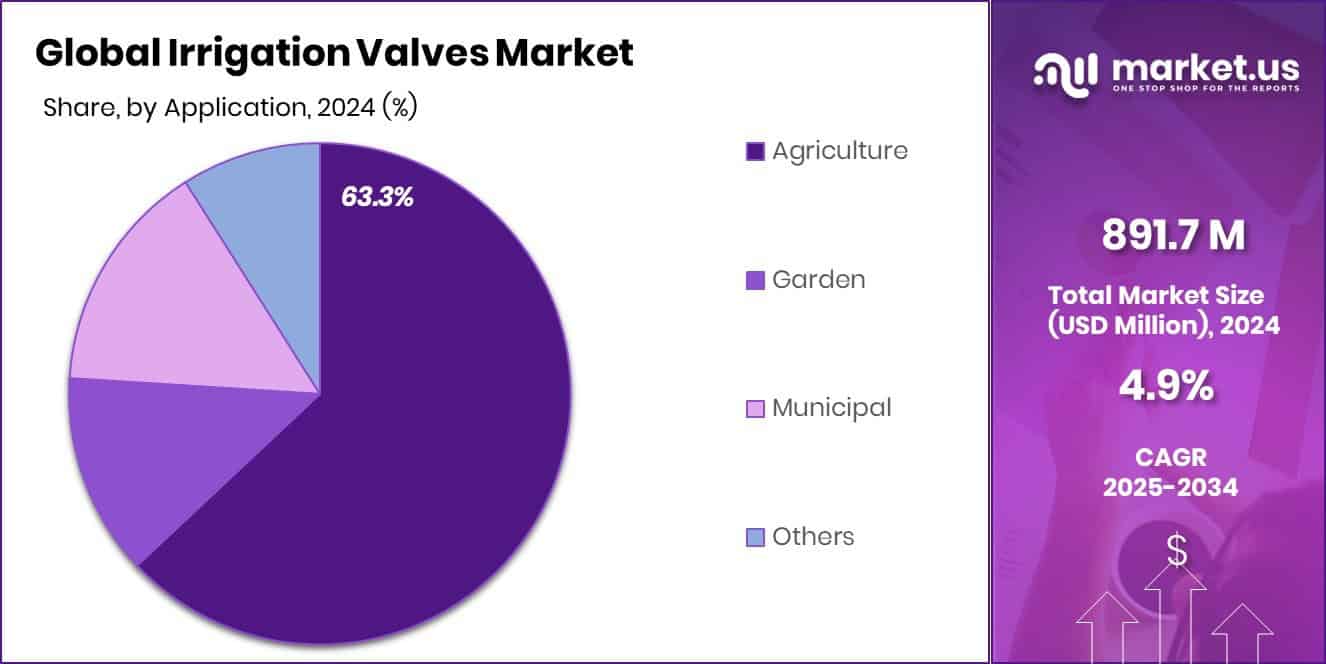

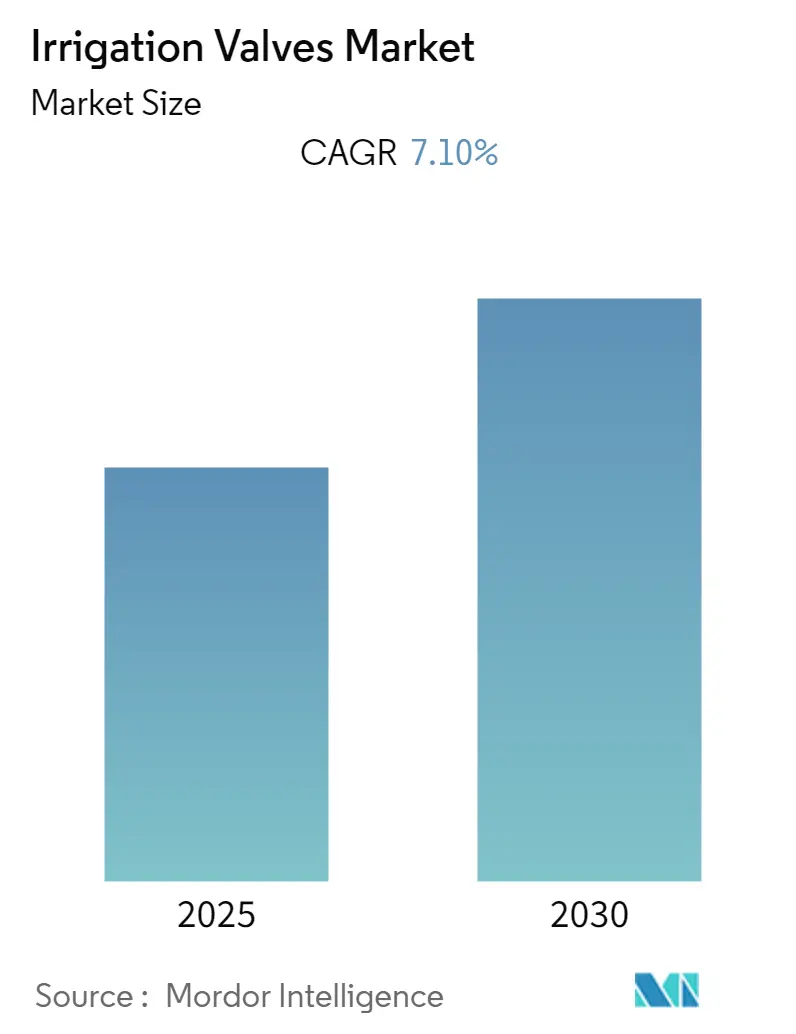

The global irrigation valve market is poised for significant growth, driven by several key factors. A major driver is the increasing demand for efficient water management systems, particularly in regions facing water scarcity, such as parts of Africa and the Middle East. With a projected CAGR of 7.1% from 2025 to 2030, the market is expanding due to rising agricultural activities and government initiatives promoting sustainable irrigation practices. For international B2B buyers, especially from emerging markets like South America and Southeast Asia, the adoption of smart irrigation technologies represents a noteworthy trend. Automation and precision agriculture are gaining traction, allowing farmers to optimize water usage and crop yield through advanced monitoring systems.

Moreover, the trend towards sustainable farming practices is influencing sourcing decisions. Buyers are increasingly looking for irrigation valves that integrate with smart systems, offering features like remote control and data analytics. The growing awareness of climate change impacts has led to an emphasis on technologies that minimize water wastage. Companies that can offer innovative solutions, such as ball valves for precise control and low-maintenance options, are likely to capture significant market share.

How Is Sustainability Reshaping B2B Sourcing in the Irrigation Valve Market?

Sustainability is becoming a cornerstone of sourcing strategies in the irrigation valve market. Environmental concerns over water usage and the carbon footprint of manufacturing processes are prompting buyers to seek suppliers committed to ethical practices. The importance of ethical supply chains is underscored by the growing consumer demand for transparency and sustainability. B2B buyers are increasingly prioritizing suppliers who utilize eco-friendly materials and processes, such as recycled metals or low-impact manufacturing methods.

Certifications like ISO 14001 and adherence to environmental standards are becoming critical criteria in the supplier selection process. Buyers are also looking for products that qualify for ‘green’ certifications, which can enhance their brand reputation and appeal to environmentally conscious consumers. The focus on sustainability extends beyond product selection; it encompasses the entire supply chain, from raw material sourcing to end-of-life product disposal. As a result, suppliers who can demonstrate their commitment to sustainability are likely to stand out in a competitive market.

What Is the Historical Context Behind the Irrigation Valve Market’s Development?

The irrigation valve market has evolved significantly over the past few decades, driven by advancements in agricultural technology and increasing awareness of water conservation. Initially, traditional irrigation methods dominated, relying heavily on manual controls. However, the introduction of automated systems and smart technology has revolutionized the industry, enabling more efficient water usage.

In the 1990s, the focus began shifting towards sustainable agricultural practices, with an emphasis on reducing water waste. This shift was accelerated by global challenges such as climate change and growing populations, which necessitated more efficient farming techniques. As a result, the irrigation valve market began embracing innovations such as solenoid valves and electronic control systems.

Today, the market reflects a blend of traditional practices and cutting-edge technology, catering to a diverse range of agricultural needs. The ongoing evolution of the irrigation valve market continues to shape the agricultural landscape, making it a vital area for B2B buyers looking to enhance operational efficiency and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve market market

How do I select the right irrigation valve for my agricultural needs?

Selecting the right irrigation valve involves assessing your specific agricultural requirements. Consider factors such as the type of crops, the scale of your irrigation system, and the water source. Ball valves are popular for their ease of use and low maintenance, while solenoid valves offer automation for precision irrigation. Additionally, ensure the valve material is suitable for your environment—PVC for lighter applications or brass for durability in harsh conditions. Consulting with suppliers who understand local agricultural practices can further refine your selection.What are the key features to look for in high-quality irrigation valves?

When sourcing irrigation valves, prioritize features such as durability, ease of operation, and maintenance requirements. Look for valves made from corrosion-resistant materials like stainless steel or high-grade plastic. Check for certifications or quality standards that the valves meet, ensuring they can withstand pressure variations and environmental conditions. Additionally, consider valves with built-in technology for automation or smart irrigation capabilities, which can optimize water usage and improve crop yields.What are the typical payment terms for international purchases of irrigation valves?

Payment terms can vary significantly based on the supplier and your negotiation. Common terms include a 30% deposit upon order confirmation, with the remaining balance due before shipment. Some suppliers may offer letters of credit or payment upon delivery for established buyers. It’s essential to clarify payment methods accepted, such as wire transfers or credit terms, and ensure they align with your financial capabilities and risk management strategies.What is the minimum order quantity (MOQ) for irrigation valves?

Minimum order quantities (MOQ) for irrigation valves typically depend on the supplier and the type of valve. Many manufacturers set MOQs to ensure production efficiency, which can range from 50 to several hundred units. However, some suppliers may be flexible, especially for new clients or trial orders. Discussing your specific needs and establishing a good relationship with suppliers can sometimes lead to more favorable terms.How can I ensure the quality of irrigation valves from international suppliers?

To ensure quality, conduct thorough supplier vetting. Request certifications such as ISO or other relevant quality standards. Ask for product samples before placing larger orders to assess material quality and performance. Consider using third-party inspection services to evaluate the valves before shipment. Additionally, seek references or reviews from other buyers in your region to gauge the supplier’s reliability and product durability.What logistics considerations should I keep in mind when importing irrigation valves?

When importing irrigation valves, consider shipping methods, transit times, and customs regulations in your country. Sea freight is often cost-effective for bulk orders, while air freight is faster but more expensive. Ensure you understand the import duties and taxes applicable to your shipment. Collaborating with a reliable logistics provider can help navigate these complexities and ensure timely delivery of your valves.Can I customize irrigation valves to suit specific applications?

Yes, many suppliers offer customization options for irrigation valves to meet specific agricultural or operational needs. Customizations can include valve size, material, and specific features like pressure ratings or built-in automation systems. Discuss your requirements with potential suppliers early in the negotiation process, as custom orders may require longer lead times and could affect pricing.What trends are influencing the irrigation valve market globally?

Global trends impacting the irrigation valve market include the increasing adoption of smart irrigation technologies, driven by the need for efficient water management amid climate change. Growing government initiatives promoting sustainable agriculture are also fueling demand. Additionally, rising awareness of water conservation practices in regions like Africa and South America is boosting the market. Suppliers that innovate and provide advanced solutions, such as automated or remote-controlled valves, are likely to gain a competitive edge in this evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Irrigation Valve Market Market Manufacturers & Suppliers List

1. Mordor Intelligence – Irrigation Valves Market Overview

Domain: mordorintelligence.com

Registered: 2013 (12 years)

Introduction: The Irrigation Valves Market is segmented by Material Type (Metal Valves, Plastic Valves), Valve Type (Ball Valve, Butterfly Valve, Globe Valve, Automatic Valves), and Application (Agricultural, Non-Agricultural). The market is expected to register a CAGR of 7.1% during the forecast period from 2025 to 2030. Key trends include the significant demand for Ball Valves, which are known for their ease …

2. Market.us – Global Irrigation Valves Insights

Domain: market.us

Registered: 2002 (23 years)

Introduction: Global Irrigation Valves Market is expected to be worth around USD 1,438.7 Million by 2034, up from USD 891.7 Million in 2024, and grow at a CAGR of 4.9% from 2025 to 2034. In 2024, metal valves held a dominant 67.9% share in the global irrigation valves market. Ball valves led by type, capturing a 34.8% share of the irrigation valves market demand globally. Agriculture application contributed 63….

3. Verified Market Research – North America Irrigation Valves

Domain: verifiedmarketresearch.com

Registered: 2018 (7 years)

Introduction: This company, Verified Market Research – North America Irrigation Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Sprinkler Valves – Market Growth Insights

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: Sprinkler Valves Market size is estimated to be USD 1.5 Billion in 2024 and is expected to reach USD 2.8 Billion by 2033 at a CAGR of 7.5% from 2026 to 2033. Key highlights include innovative smart solutions driven by IoT and automation, competitive landscape dominated by eco-friendly materials and advanced remote control systems, regulatory challenges leading to demand for low-flow and drought-re…

5. Market Research Future – Irrigation Valve Market Insights

Domain: marketresearchfuture.com

Registered: 2015 (10 years)

Introduction: Irrigation Valve Market Overview: The market size was estimated at 3.15 USD Billion in 2023 and is expected to grow to 5.0 USD Billion by 2035, with a CAGR of 3.93% from 2025 to 2035. Key trends include increasing agricultural demand, the adoption of smart irrigation technologies, government initiatives for sustainable farming, and advancements in materials and design. The market is segmented by t…

6. Irrigation Sprinkler Valves – Global Market Insights 2025-2031

Domain: marketresearchreports.com

Registered: 2001 (24 years)

Introduction: Global Irrigation Sprinkler Valves Market Growth 2025-2031 report published on March 13, 2025, with 91 pages. The report provides information about manufacturers, machinery, and the industry & manufacturing sector. It includes global market data and forecasts, with pricing starting at USD 3,660.00 for a Single User License (PDF). Key players include TORO, Hunter Industries, RAIN BIRD, Netafim, and…

7. Irrigation Solenoid Valve – Market Insights 2025

Domain: reports.valuates.com

Registered: 2003 (22 years)

Introduction: Irrigation Solenoid Valve Market Research Report 2025, Published Date: April 2025, Report Code: QYRE-Auto-15J13685, Pages: 110. The global market for Irrigation Solenoid Valve was valued at US$ million in 2024 and is projected to reach a revised size of US$ million by 2031, growing at a CAGR of % during the forecast period. Major manufacturers include BERMAD, TECNIDRO, Banjo, VYRSA, tayfursu, Arma…

8. Verified Market Reports – Air Valve Market Insights

Domain: verifiedmarketreports.com

Registered: 2018 (7 years)

Introduction: Air Valve Market Size: USD 4.5 Billion in 2024, forecasted to achieve USD 6.8 Billion by 2033, with a CAGR of 5.2% from 2026 to 2033. Key segments include: By Product Type (Solenoid Valves, Pneumatic Control Valves), By Actuation Type (Electronic Actuation, Pneumatic Actuation), By End-Use Industry (Oil & Gas, Water & Wastewater Treatment), By Size and Design (Small Size Valves, Compact Design Val…

9. DataIntelo – Farmland Irrigation Valve Market Insights

Domain: dataintelo.com

Registered: 2019 (6 years)

Introduction: Farmland Irrigation Valve Market Report | Global Forecast From 2025 To 2033. Key segments include Product Type (Electric Valves, Hydraulic Valves, Pneumatic Valves, Mechanical Valves), Application (Agricultural Irrigation, Landscape Irrigation, Greenhouse Irrigation, Others), Material (Plastic, Metal, Composite), Distribution Channel (Online, Offline), and Region (Asia Pacific, North America, Lati…

10. Automatic Irrigation Valve – Market Insights

Domain: sites.google.com

Registered: 1997 (28 years)

Introduction: The global Automatic Irrigation Valve market was valued at approximately $2.5 billion in 2022, with a compound annual growth rate (CAGR) of 8.3% projected from 2023 to 2028. The increasing adoption of smart irrigation solutions, driven by the need for water conservation and efficient resource management, is a key factor propelling market growth. As agricultural and landscaping sectors continue to …

Strategic Sourcing Conclusion and Outlook for irrigation valve market market

How Can Strategic Sourcing Transform Your Approach to the Irrigation Valve Market?

In summary, the irrigation valve market is poised for significant growth, driven by the urgent need for water conservation and efficient agricultural practices. As the market is projected to expand at a CAGR of 4.9% to reach approximately USD 1.4 billion by 2034, it presents an invaluable opportunity for international B2B buyers. Strategic sourcing plays a crucial role in navigating this dynamic landscape, allowing businesses to identify reliable suppliers, optimize procurement processes, and enhance supply chain resilience.

For buyers in Africa, South America, the Middle East, and Europe, the importance of aligning with leading manufacturers cannot be overstated. The adoption of innovative irrigation technologies, including smart systems, will be pivotal in maximizing yield and minimizing water waste. As governments increasingly support sustainable agriculture initiatives, now is the time to invest in high-quality irrigation valves that can adapt to evolving market demands.

To capitalize on these trends, engage with reputable suppliers, assess product offerings critically, and stay informed about emerging technologies. This proactive approach will ensure that your business not only meets current agricultural challenges but also positions itself favorably for future growth in a competitive global market.