Introduction: Navigating the Global Market for irrigation valve wire

In today’s rapidly evolving agricultural landscape, sourcing the right irrigation valve wire is crucial for enhancing operational efficiency and ensuring effective water management. International B2B buyers face the challenge of navigating a diverse market filled with varying specifications, quality standards, and price points, particularly in regions like Africa, South America, the Middle East, and Europe. This guide addresses these complexities by providing comprehensive insights into the different types of irrigation valve wire, their applications, and essential considerations for supplier vetting.

Throughout this guide, we will explore the various forms of irrigation wire, including direct burial options and specialized communication wires for flow sensors. We will also delve into the critical aspects of installation, maintenance, and performance, ensuring that buyers can make informed decisions tailored to their specific needs. Additionally, we will discuss pricing structures and cost-saving strategies, empowering businesses to optimize their procurement processes.

By equipping international buyers with the knowledge and tools necessary to select high-quality irrigation valve wire, this guide aims to facilitate smarter purchasing decisions. Whether you are operating in Vietnam, Nigeria, or any other global market, understanding the nuances of irrigation wire will enhance your ability to maintain robust irrigation systems, ultimately leading to increased productivity and sustainability in your agricultural practices.

Understanding irrigation valve wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Burial Wire | UV-resistant, waterproof, and designed for underground use | Connecting valves to controllers in irrigation systems | Pros: Durable, minimizes damage from moisture. Cons: Higher initial cost compared to non-burial wire. |

| Multi-Conductor Wire | Available in multiple gauges and conductors (e.g., 18/5, 18/7) | Complex irrigation systems requiring multiple zones | Pros: Versatile, supports various applications. Cons: Can be overkill for simple setups. |

| Flow Sensor Communication Wire | Specialized for connecting flow sensors to controllers | Advanced irrigation systems with flow monitoring | Pros: Enhances system efficiency. Cons: More expensive than standard wire. |

| Common Wire | Simple 2 or 3 conductor wire, typically 18 AWG | Basic irrigation systems and simple valve connections | Pros: Cost-effective, easy to install. Cons: Limited functionality for complex systems. |

| Stranded vs. Solid Wire | Stranded wire is flexible; solid wire is more rigid | Choice based on installation environment | Pros: Stranded is easier to work with; solid is more durable. Cons: Stranded can be less resistant to corrosion. |

What Are the Key Characteristics of Direct Burial Wire?

Direct burial wire is engineered specifically for underground installation in irrigation systems. It is designed to withstand exposure to moisture and UV rays, making it ideal for outdoor applications. Typically made with a durable PVC jacket, this wire is essential for connecting solenoid valves to controllers, ensuring reliable operation. When considering B2B purchases, companies should evaluate local soil conditions and moisture levels, as these can affect the longevity and performance of the wire.

How Does Multi-Conductor Wire Benefit Complex Irrigation Systems?

Multi-conductor wire offers flexibility with various gauges and conductor counts, such as 18/5 or 18/7, allowing for the connection of multiple zones and components in sophisticated irrigation systems. This type of wire is particularly useful for businesses managing large agricultural operations or expansive landscaping projects where multiple valves need to be controlled simultaneously. Buyers should assess their specific system requirements, as choosing the right gauge and conductor count can significantly influence system efficiency.

Why Choose Flow Sensor Communication Wire for Advanced Systems?

Flow sensor communication wire is specialized for connecting flow sensors to irrigation controllers, enabling real-time monitoring and management of water distribution. This wire type is crucial for businesses focused on optimizing water usage, especially in regions where water conservation is a priority. While it may come at a higher price point, the enhanced efficiency and potential cost savings in water usage can justify the investment. B2B buyers should consider the long-term benefits of integrating such technology into their irrigation systems.

What Are the Advantages of Common Wire in Basic Applications?

Common wire, usually available as a simple 2 or 3 conductor wire, is an economical choice for basic irrigation setups. Its straightforward design makes it easy to install, making it a popular option for smaller businesses or residential applications. However, its limited functionality means it may not be suitable for more complex systems. When purchasing, buyers should weigh the initial cost savings against the potential need for future upgrades as their irrigation needs evolve.

How Do Stranded and Solid Wire Compare in Durability and Flexibility?

The choice between stranded and solid wire hinges on the installation environment. Stranded wire is more flexible, making it easier to work with in tight spaces or complex layouts, while solid wire is more durable and resistant to corrosion, making it suitable for permanent installations. B2B buyers should consider the specific requirements of their irrigation projects, including installation ease and long-term durability, when deciding between these two options.

Key Industrial Applications of irrigation valve wire

| Industry/Sector | Specific Application of irrigation valve wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Connecting irrigation controllers to solenoid valves | Ensures efficient water distribution, optimizing crop yields | Gauge specifications, UV resistance, and direct burial ratings |

| Landscaping | Wiring for automated landscape irrigation systems | Reduces labor costs and improves water conservation | Length options, compatibility with existing systems |

| Golf Courses and Sports Fields | Linking irrigation systems for turf management | Maintains optimal playing conditions, enhancing user experience | Durability and resistance to environmental factors |

| Municipal Water Management | Integrating irrigation for public parks and gardens | Promotes sustainable water use and enhances community aesthetics | Compliance with local regulations and environmental standards |

| Horticulture | Electrical connections for greenhouse irrigation systems | Supports precise water delivery for optimal plant growth | Temperature and moisture tolerance, and availability of connectors |

How is irrigation valve wire utilized in agriculture, and what benefits does it provide?

In the agriculture sector, irrigation valve wire is crucial for connecting irrigation controllers to solenoid valves, allowing for automated water distribution across crops. This automation enhances efficiency, ensuring that water is delivered precisely when and where it is needed, thus optimizing crop yields. International buyers, particularly in regions with variable climates like Africa and South America, should consider wire gauge specifications and the wire’s UV resistance, as well as direct burial capabilities to withstand harsh environmental conditions.

What role does irrigation valve wire play in landscaping projects?

In landscaping, irrigation valve wire is used to wire automated irrigation systems, facilitating efficient water use while minimizing labor costs. By enabling precise control over watering schedules, businesses can conserve water, which is increasingly important in regions facing water scarcity. Buyers should look for options that match their existing systems in terms of length and gauge, ensuring compatibility and ease of installation.

How is irrigation valve wire essential for golf courses and sports fields?

Golf courses and sports fields utilize irrigation valve wire to link sophisticated irrigation systems that manage turf health. Properly wired systems maintain optimal playing conditions, which is crucial for enhancing user experience and preserving the aesthetic appeal of the grounds. Buyers in this sector should prioritize durability and resistance to environmental factors, as these installations are often exposed to varying weather conditions and heavy foot traffic.

Why is irrigation valve wire important for municipal water management?

Municipal water management departments employ irrigation valve wire to integrate irrigation systems for public parks and gardens. This use promotes sustainable water practices and enhances community aesthetics, contributing to overall urban sustainability. Buyers should ensure that the wire complies with local regulations and environmental standards, which can vary significantly between regions, particularly in the Middle East and Europe.

What are the applications of irrigation valve wire in horticulture?

In horticulture, irrigation valve wire is vital for establishing electrical connections in greenhouse irrigation systems. These systems require precise water delivery to support optimal plant growth, making reliable wiring essential. Buyers should consider the wire’s temperature and moisture tolerance, as well as the availability of compatible connectors, to ensure that their systems operate effectively in diverse climatic conditions.

3 Common User Pain Points for ‘irrigation valve wire’ & Their Solutions

Scenario 1: Struggling with Wire Durability and Weather Resistance

The Problem: B2B buyers in regions with extreme weather conditions often face significant challenges when sourcing irrigation valve wire that can withstand harsh environments. High temperatures, heavy rainfall, and UV exposure can quickly degrade standard wiring, leading to frequent system failures and costly repairs. This issue is particularly pressing in agricultural sectors in Africa and South America, where reliable irrigation is crucial for crop yields.

The Solution: To combat wire durability issues, buyers should prioritize sourcing high-quality, UV-resistant, and waterproof irrigation valve wire specifically designed for direct burial. Look for products that have a robust PVC jacket to protect against moisture and environmental stressors. For example, opting for 18-gauge wire with a solid copper core will not only ensure better conductivity but also longer-lasting performance. Always verify product specifications and seek out suppliers that provide detailed information on environmental resistance to ensure you make a well-informed purchase.

Scenario 2: Difficulty in Identifying the Correct Wire Gauge and Conductor Count

The Problem: Many B2B buyers struggle with selecting the appropriate wire gauge and conductor count for their irrigation systems, leading to underperformance or system failures. This is particularly common among contractors who may not be fully versed in the technical requirements of different irrigation setups. An incorrect choice can result in insufficient power supply to valves, causing inconsistent water distribution and affecting overall irrigation efficiency.

The Solution: To avoid these pitfalls, it’s essential to conduct a thorough assessment of the irrigation system requirements before purchasing wire. Start by calculating the total length of wire needed and the number of zones being powered. Generally, for systems requiring moderate power, 18-gauge wire is suitable, while more extensive setups may benefit from 16-gauge wire. When in doubt, consult with manufacturers or technical experts who can provide guidance based on the specific needs of your system, ensuring that you have the right conductor count for optimal performance.

Scenario 3: Challenges with Installation and Connectivity

The Problem: Even with the right irrigation valve wire, B2B buyers often encounter difficulties during installation, particularly with ensuring secure and reliable connections between the wire and the solenoid valves. Poor connections can lead to electrical faults, which not only compromise irrigation efficiency but also create safety hazards. This is especially critical in commercial farming operations where operational downtime can lead to significant financial losses.

The Solution: To facilitate a smooth installation process, it’s important to invest in high-quality waterproof wire connectors and follow best practices for making connections. Begin by stripping the wire ends carefully to avoid damage and ensure a clean connection. Use crimp connectors or soldering techniques to secure the connections, and always apply waterproofing measures such as electrical tape or heat shrink tubing to protect against moisture ingress. Additionally, consider using a multimeter to test the connections before sealing the system to guarantee that everything is functioning correctly. By prioritizing installation quality, you can enhance the reliability of your irrigation system and reduce the likelihood of future issues.

Strategic Material Selection Guide for irrigation valve wire

What Are the Key Materials Used in Irrigation Valve Wire?

When selecting irrigation valve wire, the choice of material is crucial for ensuring long-lasting performance and reliability in various environmental conditions. Here, we analyze four common materials used in irrigation valve wire, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Copper

Key Properties: Copper is highly conductive, allowing for efficient electrical transmission. It has a melting point of approximately 1,984°F (1,085°C) and exhibits good corrosion resistance, especially when insulated.

Pros & Cons: Copper wires are durable and flexible, making them easy to install. However, they are more expensive than alternatives like aluminum and can be prone to corrosion in acidic or saline environments.

Impact on Application: Copper is suitable for direct burial applications and can handle various media, including water and fertilizers, without degrading. Its conductivity makes it ideal for systems requiring consistent power supply to solenoid valves.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM for the U.S. or DIN for Europe. Copper wire is widely accepted globally, but fluctuations in copper prices can affect procurement budgets.

2. Aluminum

Key Properties: Aluminum is lightweight and has a melting point of around 1,221°F (660.3°C). It is less conductive than copper, with about 60% of the conductivity of copper.

Pros & Cons: The primary advantage of aluminum is its lower cost and lighter weight, which can reduce shipping expenses. However, it is more susceptible to corrosion, particularly in moist environments, and requires thicker gauges to match copper’s conductivity.

Impact on Application: Aluminum wire is often used in larger installations where weight is a concern. However, its susceptibility to corrosion limits its use in areas with high moisture or salinity.

Considerations for International Buyers: Buyers should be aware of the specific corrosion resistance requirements in their regions. Compliance with international standards is essential, particularly in regions with strict environmental regulations.

3. PVC (Polyvinyl Chloride) Coated Wire

Key Properties: PVC-coated wire provides excellent insulation and protection against moisture, UV light, and abrasion. It can withstand temperatures ranging from -40°F to 140°F (-40°C to 60°C).

Pros & Cons: The insulation enhances durability and extends the lifespan of the wire. However, the coating can add to the overall cost, and improper installation may lead to damage.

Impact on Application: PVC-coated wire is ideal for direct burial applications, providing a barrier against corrosive elements in the soil. It is compatible with various irrigation systems, including those using chemical fertilizers.

Considerations for International Buyers: Ensure that the PVC material meets local environmental regulations regarding plastic use. Compliance with standards such as JIS in Japan or ASTM in the U.S. is also necessary.

4. Direct Burial Wire

Key Properties: This wire is specifically designed for underground installation, featuring robust insulation that can withstand moisture and soil pressure. It is often rated for temperatures up to 90°C (194°F).

Pros & Cons: Direct burial wire is easy to install and does not require additional conduit, reducing installation costs. However, it may have a shorter lifespan in highly acidic or alkaline soils.

Impact on Application: This type of wire is essential for connecting solenoid valves to controllers in irrigation systems, ensuring reliable operation even under challenging conditions.

Considerations for International Buyers: Buyers should verify that the wire meets local standards for direct burial applications. Understanding soil conditions in the installation area is crucial for selecting the right type of direct burial wire.

Summary Table

| Material | Typical Use Case for irrigation valve wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Direct burial, solenoid valve connections | Excellent conductivity and flexibility | Higher cost, prone to corrosion | High |

| Aluminum | Larger installations, cost-sensitive projects | Lightweight and lower cost | Less conductive, susceptible to corrosion | Medium |

| PVC Coated Wire | Underground installations, chemical resistance | Durable insulation against moisture | Higher cost, potential installation issues | Medium |

| Direct Burial Wire | Connecting valves to controllers underground | Easy installation, no additional conduit | Shorter lifespan in harsh soils | Low |

This guide serves as a strategic reference for B2B buyers in selecting the appropriate irrigation valve wire material, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve wire

What Are the Key Stages in the Manufacturing Process of Irrigation Valve Wire?

Manufacturing irrigation valve wire involves several critical stages, each designed to ensure the final product meets the required standards for performance and durability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with selecting high-quality raw materials, typically copper or aluminum, which are favored for their excellent conductivity. The selected wire is then drawn to the appropriate gauge, which can range from 14 to 18 AWG, depending on the application. This stage may also involve applying insulating materials, such as PVC or polyethylene, which provide both protection and flexibility.

Forming: The wire is shaped into the desired configuration. This may include twisting multiple conductors together to enhance strength and conductivity. Advanced techniques like multi-stranding are often employed to improve flexibility, making installation easier in various irrigation setups.

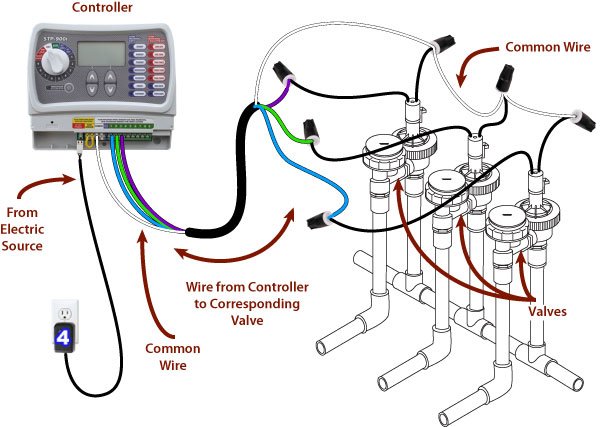

Assembly: At this stage, components such as connectors, terminals, and protective jackets are assembled with the wire. Automated machines often handle this process to ensure consistent quality and reduce human error. The assembly might also include features like color coding for easy identification and installation.

Finishing: The final stage includes applying any additional coatings or treatments, such as UV protection or water resistance, to enhance the wire’s longevity, especially for underground applications. The wires are then cut to length and packaged for shipment, ensuring they remain undamaged during transit.

How Is Quality Assurance Implemented in the Production of Irrigation Valve Wire?

Quality assurance is a fundamental aspect of the manufacturing process, ensuring that the final product adheres to international standards and industry-specific regulations.

International and Industry-Specific Standards: Many manufacturers comply with ISO 9001 standards, which focus on quality management systems. Additionally, products may need to meet CE certification for safety and environmental regulations, particularly when sold in European markets. For specific applications, adherence to standards set by organizations like the American Petroleum Institute (API) may also be essential.

Quality Control Checkpoints: The manufacturing process typically includes several quality control checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): During manufacturing, random samples of wire are tested for gauge, conductivity, and insulation integrity.

– Final Quality Control (FQC): Before packaging, the finished products undergo rigorous testing, including electrical resistance tests and insulation tests, to verify their performance.Common Testing Methods: Various testing methods are employed, including:

– Electrical Testing: Measures conductivity and insulation resistance to ensure the wire will function effectively in irrigation systems.

– Mechanical Testing: Assesses the wire’s tensile strength and flexibility, crucial for installation in challenging environments.

– Environmental Testing: Evaluates the wire’s resistance to UV exposure, moisture, and temperature extremes.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must ensure that their suppliers maintain rigorous quality control processes. Here are several strategies to verify supplier QC:

Conducting Audits: Regular audits of the manufacturing facility can provide insights into the operational processes and quality assurance measures in place. Buyers should request access to audit reports and any corrective actions taken in response to past issues.

Reviewing Quality Assurance Documentation: Suppliers should provide documentation regarding their quality management systems, including certifications and compliance with international standards. This may include ISO certifications and details of quality control processes.

Third-Party Inspections: Engaging third-party inspection agencies can help validate the quality of products before shipment. These agencies conduct independent assessments to ensure that the products meet the specified requirements.

Requesting Product Samples: Before committing to a large order, buyers should request samples of the irrigation valve wire. This allows them to evaluate the product’s quality firsthand and test its performance in real-world applications.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Here are some considerations:

Regional Standards Compliance: Different regions may have specific quality and safety standards. Buyers should ensure that their suppliers are familiar with and compliant with local regulations, such as those set by the African Standards Organization (ASO) or the European Committee for Standardization (CEN).

Supply Chain Transparency: Understanding the supply chain’s transparency is critical, especially when sourcing materials from different countries. Buyers should inquire about the origin of raw materials and the traceability of the manufacturing process.

Cultural and Language Barriers: Effective communication is essential in international transactions. Buyers should ensure that their suppliers can provide clear documentation and support in a language that is mutually understood.

Logistical Challenges: International shipping can introduce additional quality control issues, such as damage during transit. Buyers should establish clear agreements regarding packaging and handling to minimize the risk of product damage.

Conclusion

Manufacturing irrigation valve wire involves a meticulous process that emphasizes quality assurance at every stage. By understanding the manufacturing processes and quality control measures, B2B buyers can make informed decisions, ensuring they source reliable and compliant products for their irrigation systems. Establishing strong relationships with manufacturers who prioritize quality will ultimately lead to enhanced performance and longevity of irrigation solutions in diverse agricultural environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve wire’

In order to successfully source irrigation valve wire, international B2B buyers must follow a systematic approach. This guide offers a checklist designed to ensure that your procurement process is efficient, cost-effective, and meets the technical requirements of your irrigation projects.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right irrigation valve wire for your projects. Consider factors such as wire gauge (e.g., 16 AWG or 18 AWG), number of conductors (e.g., 2, 4, or 7), and whether the wire needs to be direct burial rated. These specifications will guide your selection and help in communicating your needs to potential suppliers.

Step 2: Identify Your Application Needs

Understanding the specific application of the irrigation valve wire is essential. Different projects may require different types of wire, such as low-voltage sprinkler wire or communication wire for flow sensors. Assess the environment—whether it’s residential, agricultural, or commercial—as this will influence the type of wire you need.

Step 3: Research and Compare Suppliers

Conduct thorough research to identify potential suppliers who specialize in irrigation components. Look for companies that have a solid reputation in the industry, particularly those who can provide local support in your target regions like Africa, South America, or Europe. Use online platforms, industry forums, and trade shows to gather information and reviews.

Step 4: Verify Supplier Certifications

Before making a commitment, ensure that your chosen suppliers have the necessary certifications and compliance with international standards. This may include ISO certifications, UL listings, or regional certifications that confirm the wire meets safety and quality standards. Proper certifications can prevent future liabilities and ensure product reliability.

Step 5: Request Samples and Test Quality

Always request samples of the wire before finalizing your order. Testing samples for durability, flexibility, and resistance to environmental factors (like UV exposure and moisture) will provide insights into the product’s performance. This step is vital to ensure that the wire meets your project’s longevity and reliability requirements.

Step 6: Evaluate Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare pricing structures and payment terms. Consider not only the upfront costs but also shipping fees, bulk discounts, and payment flexibility. A clear understanding of costs will help in budgeting and can lead to more favorable negotiation outcomes.

Step 7: Establish Communication and Support Channels

Effective communication with your supplier is key to a successful procurement process. Ensure that the supplier provides reliable customer service and technical support. Establishing a clear line of communication will help in resolving any issues that may arise during procurement or installation.

By following these steps, B2B buyers can ensure that they source the right irrigation valve wire that meets their technical requirements while also fostering strong supplier relationships. This comprehensive approach will ultimately lead to successful irrigation projects and satisfied end-users.

Comprehensive Cost and Pricing Analysis for irrigation valve wire Sourcing

What Are the Key Cost Components in Sourcing Irrigation Valve Wire?

When sourcing irrigation valve wire, understanding the cost structure is essential for effective budgeting and negotiation. The main cost components include:

Materials: The choice of materials significantly impacts pricing. Common materials for irrigation wire include copper and aluminum, with copper being more expensive but offering better conductivity and durability. The gauge of wire also plays a role; thicker wires (lower gauge numbers) are typically more costly.

Labor: Labor costs encompass the workforce involved in manufacturing the wire. Factors such as local wage rates, skill levels, and production efficiency can influence these costs.

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Higher overhead costs can lead to increased pricing for buyers.

Tooling: Custom tooling for specific wire configurations can add to the initial investment. Buyers should consider whether they require bespoke solutions or can work with standard products.

Quality Control (QC): Rigorous testing and quality assurance processes ensure the wire meets industry standards. Higher QC costs can justify higher prices if they lead to better performance and reliability.

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and import duties can significantly affect total expenses.

Margin: Suppliers include their profit margin in the final pricing. Understanding the typical margins in the industry can provide insight during negotiations.

What Price Influencers Should B2B Buyers Consider?

Several factors can influence the price of irrigation valve wire:

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to discounts. Understanding the MOQ set by suppliers can help buyers negotiate better pricing based on anticipated needs.

Specifications and Customization: Custom features or specific certifications may increase costs. Buyers should weigh the necessity of these specifications against their budget constraints.

Material Quality and Certifications: Higher quality materials and certifications (like UL or CE) typically command higher prices but can offer long-term savings through durability and reliability.

Supplier Factors: The supplier’s reputation, location, and production capabilities can impact pricing. Established suppliers may charge more but provide greater reliability and support.

Incoterms: The terms of shipping (e.g., FOB, CIF) affect the overall cost. Understanding these terms can help buyers manage logistics costs more effectively.

What Are the Best Negotiation Tips for International B2B Buyers?

Negotiating effectively is crucial for securing the best deals:

Research Market Prices: Understanding the market rate for irrigation valve wire can empower buyers during negotiations. Utilize multiple suppliers to gauge competitive pricing.

Leverage Volume Discounts: If planning to purchase in bulk, communicate this to suppliers. They may offer favorable terms to secure large orders.

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the wire, including installation and maintenance. A lower upfront cost may not always equate to better value.

Build Relationships: Establishing rapport with suppliers can lead to better terms and pricing over time. Consider long-term partnerships rather than one-off transactions.

Understand Pricing Nuances for Different Regions: International buyers should be aware of regional pricing variations due to local demand, currency fluctuations, and shipping costs.

Conclusion

While indicative prices for irrigation valve wire can vary significantly, understanding the underlying cost components, price influencers, and effective negotiation strategies can help international B2B buyers optimize their sourcing decisions. Always request detailed quotes and be prepared to discuss all aspects of pricing to secure the best possible deal.

Alternatives Analysis: Comparing irrigation valve wire With Other Solutions

Exploring Alternatives to Irrigation Valve Wire: A Comparative Analysis

In the realm of irrigation systems, selecting the right components is crucial for optimal performance and efficiency. While irrigation valve wire is a popular choice for connecting solenoid valves to controllers, it’s essential to consider alternative solutions that might better suit specific needs or contexts. This analysis compares irrigation valve wire with two viable alternatives: Wireless Irrigation Controllers and Low-Voltage Direct Burial Cables.

Comparison Table

| Comparison Aspect | Irrigation Valve Wire | Wireless Irrigation Controllers | Low-Voltage Direct Burial Cables |

|---|---|---|---|

| Performance | Reliable connection; requires physical wiring for signal transmission. | Flexible control; depends on signal strength and battery life. | Highly reliable; designed for underground use, preventing damage. |

| Cost | Moderate; typically ranges from $0.40 to $1.00 per foot. | Higher initial investment; often includes smart features. | Competitive; ranges from $0.30 to $0.80 per foot based on gauge and length. |

| Ease of Implementation | Requires manual installation and physical connections. | Quick setup; minimal wiring needed, often plug-and-play. | Straightforward installation; requires knowledge of electrical connections. |

| Maintenance | Periodic checks for wear and tear; prone to corrosion. | Low maintenance; software updates may be needed. | Requires minimal maintenance; durable against environmental factors. |

| Best Use Case | Ideal for traditional irrigation systems needing direct control. | Best for remote monitoring and control, particularly in large or complex systems. | Suitable for projects requiring direct burial with reliable connectivity in harsh conditions. |

Detailed Breakdown of Alternatives

Wireless Irrigation Controllers

Wireless irrigation controllers provide a modern solution for managing irrigation systems without the need for extensive wiring. These systems use radio signals to communicate between the controller and the valves, allowing for remote adjustments and monitoring through mobile apps. The primary advantage is flexibility; they are easy to install and can be relocated as needed. However, reliance on battery power and signal strength can lead to performance issues in areas with poor connectivity. This solution is best suited for large-scale agricultural operations or landscapes where traditional wiring is impractical.

Low-Voltage Direct Burial Cables

Low-voltage direct burial cables are designed for underground installation, offering a robust alternative to traditional irrigation valve wire. These cables are typically insulated to withstand moisture and soil conditions, making them ideal for permanent irrigation setups. They are generally easier to install than traditional wiring systems since they require fewer components. However, they may not provide the same level of flexibility as wireless solutions, and any modifications to the system can necessitate digging up the cables. This option works well for businesses that need a durable, long-lasting solution in a fixed location.

Conclusion: Choosing the Right Solution for Your Irrigation Needs

When selecting an irrigation solution, B2B buyers must consider the specific requirements of their operations. Irrigation valve wire remains a strong choice for conventional setups, providing reliable performance in direct connections. However, for those looking for flexibility and modern features, wireless irrigation controllers offer innovative control options. Meanwhile, low-voltage direct burial cables provide a robust alternative for projects requiring durability in challenging environments. Ultimately, the decision should be based on factors such as cost, ease of implementation, and the specific irrigation goals of the buyer’s operation.

Essential Technical Properties and Trade Terminology for irrigation valve wire

What Are the Key Technical Properties of Irrigation Valve Wire?

When considering irrigation valve wire, several technical specifications are crucial for ensuring optimal performance and durability in agricultural and landscaping applications. Understanding these properties can help B2B buyers make informed purchasing decisions.

1. Gauge (AWG)

The American Wire Gauge (AWG) system defines the wire’s diameter, which directly influences its current-carrying capacity and resistance. Common gauges for irrigation valve wire include 14, 16, and 18 AWG. A lower gauge number indicates a thicker wire that can handle more current, making it suitable for larger installations or systems with high power demands. Selecting the appropriate gauge is vital to prevent overheating and ensure efficient operation.

2. Conductor Material

Irrigation valve wires are typically made from copper or aluminum. Copper is favored for its excellent conductivity and resistance to corrosion, making it ideal for underground applications where moisture is a concern. Aluminum, while lighter and less expensive, has lower conductivity and may require larger gauges to achieve the same performance. Understanding the material properties is essential for ensuring longevity and reliability in irrigation systems.

3. Insulation Type

The insulation protects the wire from environmental factors such as moisture, UV rays, and physical abrasion. Common insulation materials include PVC and polyethylene, with UV-resistant options available for outdoor applications. Choosing the right insulation type is critical to prevent short circuits and wire degradation, which can lead to system failures and increased maintenance costs.

4. Direct Burial Rating

Direct burial wire is specifically designed for underground installation, eliminating the need for conduit. These wires are rated for direct burial, meaning they can withstand soil moisture and pressure without deteriorating. This property is particularly important for reducing installation complexity and ensuring the long-term reliability of the irrigation system.

5. Voltage Rating

Voltage ratings indicate the maximum voltage the wire can safely carry. Most irrigation systems operate at low voltage (24V), but understanding the wire’s voltage capacity is essential for ensuring compatibility with controllers and solenoid valves. Selecting a wire with an appropriate voltage rating prevents electrical hazards and system malfunctions.

6. Length and Number of Conductors

The length of the wire and the number of conductors (e.g., 2, 4, 5, or more) determine the wire’s application in the irrigation system. More conductors allow for complex systems with multiple zones or additional features like sensors. Buyers should consider both the layout of their irrigation systems and future scalability when choosing wire length and conductor count.

What Are Common Trade Terms Related to Irrigation Valve Wire?

Navigating the B2B landscape requires familiarity with industry jargon. Here are some key terms relevant to irrigation valve wire procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications can help buyers ensure compatibility with existing systems and identify high-quality components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and cash flow. Knowing the MOQ can help businesses plan their purchases according to project needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers. It typically includes specifications, quantities, and other requirements. Using an RFQ is essential for obtaining competitive pricing and ensuring that suppliers understand the exact needs of the project.

4. Incoterms

International Commercial Terms (Incoterms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage shipping costs, insurance, and delivery timelines effectively.

5. Direct Burial

As mentioned earlier, direct burial refers to wires that can be installed underground without additional protective conduits. This term is vital for buyers to ensure they select the right wire for their installation environment.

6. Conductor Count

The conductor count specifies how many individual wires are within a single cable. This is important for determining the wire’s application in complex irrigation systems, allowing for efficient control and communication between components.

By understanding these properties and terms, B2B buyers can make well-informed decisions that enhance the effectiveness and reliability of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve wire Sector

What Are the Current Market Dynamics and Key Trends in the Irrigation Valve Wire Sector?

The global irrigation valve wire market is experiencing significant transformation driven by factors such as the increasing demand for efficient water management, advancements in irrigation technologies, and growing agricultural activities in emerging economies. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are particularly focused on sourcing high-quality irrigation wire solutions that can withstand local environmental conditions.

Emerging trends include the integration of smart technologies into irrigation systems, facilitating automated water management and enhancing efficiency. The rise of IoT-enabled irrigation solutions allows for real-time monitoring and control, making it essential for irrigation valve wire to support these advanced functionalities. Additionally, there is a noticeable shift towards using multi-conductor wires that can support various components in irrigation systems, such as sensors, solenoids, and controllers, ensuring streamlined operations.

Another critical market dynamic is the emphasis on cost-effectiveness and reliability. Buyers are increasingly seeking suppliers that offer competitive pricing without compromising on quality. As logistics and supply chain efficiencies improve, B2B buyers are also exploring direct purchasing options from manufacturers to reduce costs and enhance procurement processes. Understanding these dynamics will empower international buyers to make informed decisions that align with their operational requirements and budget constraints.

How Is Sustainability and Ethical Sourcing Addressed in the Irrigation Valve Wire Sector?

Sustainability is a pressing concern in the irrigation valve wire sector, particularly as environmental regulations tighten globally. The production and disposal of electrical wires can have significant environmental impacts, including resource depletion and pollution. Thus, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices.

Ethical sourcing is gaining traction as companies recognize the importance of maintaining transparent supply chains. Buyers are encouraged to seek out manufacturers that use eco-friendly materials, such as recyclable copper and biodegradable insulation, as well as those who hold certifications like RoHS (Restriction of Hazardous Substances) and ISO 14001 for environmental management. These certifications not only assure buyers of compliance with environmental standards but also enhance their brand reputation in an increasingly eco-conscious market.

Moreover, the trend towards sustainability is prompting innovations in product design. Manufacturers are exploring the use of UV-resistant and direct burial wires that minimize environmental disruption during installation and operation. For international buyers, aligning procurement strategies with sustainability goals can yield long-term cost savings and create positive impacts on local ecosystems.

What Is the Brief Evolution and History of the Irrigation Valve Wire Market?

The irrigation valve wire market has evolved significantly over the last few decades, transitioning from basic copper wires to more specialized solutions tailored for modern irrigation systems. Initially, irrigation systems utilized simple two-wire configurations for solenoid operation. However, as the need for more complex irrigation solutions grew, so did the innovation in wire technologies.

With the advent of advanced irrigation techniques, such as drip and automated systems, the demand for multi-conductor and UV-resistant wires surged. This evolution was further accelerated by the adoption of smart technologies and automation in agriculture. Today, international buyers are looking for sophisticated wiring solutions that not only enhance system performance but also ensure durability and reliability in diverse environmental conditions. This historical context underscores the importance of understanding technological advancements and market trends in making informed sourcing decisions in the irrigation valve wire sector.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve wire

How do I solve issues with irrigation valve wire connections?

To address problems with irrigation valve wire connections, first, check for physical damage or corrosion at connection points. Ensure that all wire connectors are properly sealed and waterproof to prevent moisture ingress. If the system is not functioning, use a multimeter to test for continuity along the wire. Additionally, verify that the wire gauge is appropriate for the distance and load requirements of your system. If issues persist, consider consulting with a qualified irrigation technician for troubleshooting and repair.What is the best wire gauge for irrigation valve systems?

The ideal wire gauge for irrigation valve systems typically ranges from 16 AWG to 18 AWG, depending on the distance between the controller and valves. For shorter runs (up to 100 feet), 18 AWG is often sufficient. However, for longer distances or systems with multiple valves, 16 AWG is recommended to minimize voltage drop. Always consider the specific requirements of your irrigation system, including the number of solenoids and power needs, to ensure optimal performance.What customization options are available for irrigation valve wire?

Many suppliers offer customization options for irrigation valve wire, including variations in gauge, conductor count, and insulation types. You can request specific lengths, colors, or even UV-resistant and direct burial options tailored to your project needs. Some manufacturers may also provide branding or labeling on the wires for easier identification. When inquiring about customization, ensure to communicate your specifications clearly to avoid delays in production and shipping.What are typical minimum order quantities (MOQs) for irrigation valve wire?

Minimum order quantities for irrigation valve wire can vary significantly among suppliers, ranging from 100 feet to several thousand feet, depending on the product type and manufacturer. For bulk orders, some suppliers may offer lower MOQs or flexible options to accommodate project sizes. When sourcing internationally, consider negotiating MOQs with suppliers to align with your project requirements while ensuring cost-effectiveness.How can I vet suppliers for irrigation valve wire?

To effectively vet suppliers for irrigation valve wire, start by checking their industry reputation through customer reviews and testimonials. Assess their certifications and compliance with international standards for quality and safety. Request samples to evaluate product quality firsthand, and inquire about their manufacturing processes and sourcing materials. Establish communication to gauge their responsiveness and willingness to meet your specific needs, which can indicate their reliability as a partner.What payment terms should I expect when purchasing irrigation valve wire internationally?

Payment terms can vary among international suppliers, but common practices include advance payment, partial upfront deposits, and payment upon delivery. Letter of credit is another option that provides security for both parties. Before finalizing any transaction, clarify the payment structure, currency, and any additional fees related to customs or banking. Establishing clear payment terms helps to mitigate risks and fosters a transparent relationship with your supplier.What quality assurance measures should I look for in irrigation valve wire?

When sourcing irrigation valve wire, look for suppliers that implement stringent quality assurance measures, such as ISO certifications and adherence to industry standards. Inquire about testing protocols for wire durability, insulation resistance, and overall performance. Request documentation of quality inspections and consider suppliers that offer warranties or guarantees on their products. This ensures that you are purchasing reliable, high-quality wire suitable for your irrigation systems.What logistics considerations should I keep in mind for international shipping of irrigation valve wire?

When planning for international shipping of irrigation valve wire, consider the lead times for production and delivery, as these can vary widely by region. Assess the shipping methods available (air, sea, or land) and their respective costs and transit times. Ensure that your supplier provides necessary documentation for customs clearance, including invoices and certificates of origin. Additionally, factor in potential duties and taxes that may apply to your shipment, which can impact overall costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Irrigation Valve Wire Manufacturers & Suppliers List

1. Hunter – 18 AWG Sprinkler Wire Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Sprinkler Wire options discussed include 16 AWG Single Conductor and 18 AWG Multi-Conductor. The user is considering using 18/13 gauge wire. The context involves installing a sprinkler system with 10 valves within 20 feet of the controller (Hunter Pro-HC 12 Station). Recommendations suggest that 18 gauge is adequate for 24 volts max and under 0.5 amps, with a maximum amp capacity well over 4x that…

2. Sprinkler Warehouse – Wiring Supplies

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Wiring supplies needed: bundle of wires (16-gauge and 18-gauge), waterproof connectors filled with silicone, color-coded wires for solenoids, common white wire. Important notes: waterproof connectors protect against water damage, wires must be buried at least 6″ deep, and secured with plastic electrical staples when running up a structure. Recommended products: LV 9000 wire connector, LV 9500 wire…

3. DripWorks – 5 Strand Wire

Domain: dripworks.com

Registered: 1998 (27 years)

Introduction: Product Name: 5 Strand Wire (up to 4 Valves)

Price Range: $54.95 – $165.95

SKU: Q_TDB5

UPC: Not specified

Description: Use this five strand direct burial wire to connect up to four valves to a timer. The fifth wire is the common.

Available Lengths: 100′, 250′, 500′

4. Paige Electric – Irrigation Wire

Domain: cheapsprinklers.com

Registered: 2014 (11 years)

Introduction: Paige Irrigation Wire is designed for irrigation and water-related applications, as well as professional low-voltage lighting and industrial uses. It is manufactured by Paige Electric, which specializes in providing wire, cables, cable assemblies, and electrical accessories. The product is suitable for landscape irrigation, golf courses, and low-voltage lighting industries.

Strategic Sourcing Conclusion and Outlook for irrigation valve wire

What Are the Key Insights for B2B Buyers of Irrigation Valve Wire?

In today’s competitive landscape, strategic sourcing of irrigation valve wire is essential for optimizing operational efficiency and ensuring the longevity of irrigation systems. Buyers from Africa, South America, the Middle East, and Europe must prioritize quality and reliability when selecting suppliers. Understanding specifications such as wire gauge, conductor count, and burial suitability can significantly impact system performance and maintenance costs.

Furthermore, leveraging a diverse supplier base can mitigate risks associated with supply chain disruptions, particularly in regions experiencing rapid agricultural growth. As climate changes influence water availability, investing in advanced irrigation solutions is not just beneficial; it’s imperative for sustainability and productivity.

How Can International Buyers Position Themselves for Future Success?

Looking ahead, international B2B buyers should focus on building strong partnerships with manufacturers who offer innovative products tailored to regional needs. Emphasizing local sourcing when feasible can reduce lead times and enhance responsiveness to market demands.

Engage with suppliers who provide comprehensive support, including installation guidance and troubleshooting resources. By adopting a proactive approach to sourcing, businesses can ensure they are well-equipped to meet future irrigation challenges. Take action now to secure your supply chain and invest in high-quality irrigation valve wire solutions that will support your agricultural initiatives for years to come.