Introduction: Navigating the Global Market for lawn irrigation valve

In today’s rapidly evolving agricultural landscape, sourcing reliable lawn irrigation valves poses a significant challenge for B2B buyers across the globe. As water scarcity becomes increasingly prevalent, the demand for efficient irrigation solutions is paramount. This guide aims to equip international buyers, particularly those in Africa, South America, the Middle East, and Europe, with the knowledge necessary to navigate the complex market for lawn irrigation valves. Understanding the various types of valves—such as automatic, anti-siphon, and solenoid-operated options—alongside their specific applications in residential, commercial, and agricultural settings, is essential for making informed purchasing decisions.

This comprehensive resource delves into critical aspects of the lawn irrigation valve market, including supplier vetting processes, cost considerations, and the latest technological advancements. By exploring the nuances of valve specifications, performance metrics, and installation requirements, buyers will be empowered to select the most suitable products for their unique needs. Additionally, we will provide actionable insights into the maintenance and longevity of these systems, ensuring that investments yield optimal returns.

Whether you are based in bustling urban centers or rural landscapes, this guide serves as your essential companion for navigating the intricacies of the lawn irrigation valve market, ultimately helping you to make strategic purchasing decisions that enhance operational efficiency and sustainability.

Understanding lawn irrigation valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Solenoid Valve | Operated via a 24V electric current; diaphragm-based | Residential and commercial irrigation | Pros: Efficient, remote operation; Cons: Requires electrical setup. |

| Anti-Siphon Valve | Prevents backflow; typically has an integrated vacuum breaker | Municipal and landscape irrigation | Pros: Protects water quality; Cons: Slightly higher cost. |

| Manual Valve | Requires manual operation; simple design | Small-scale farms and gardens | Pros: Low maintenance; Cons: Labor-intensive operation. |

| Globe Valve | Features a spherical body; allows for precise flow control | Golf courses and large estates | Pros: Durable, excellent flow regulation; Cons: Bulkier installation. |

| Angle Valve | Designed for corner installations; space-efficient | Tight spaces in commercial settings | Pros: Versatile for layout; Cons: May have limited flow rates. |

What Are Electric Solenoid Valves and Their Key Benefits?

Electric solenoid valves are widely used in both residential and commercial irrigation systems. They function by using a 24V electric current to open and close the valve, allowing for automated watering schedules. These valves are ideal for larger properties where efficient remote operation is essential. When considering these valves, buyers should evaluate their electrical infrastructure, as installation requires a reliable power source and appropriate wiring.

How Do Anti-Siphon Valves Protect Water Quality?

Anti-siphon valves are critical for preventing backflow, which can contaminate the water supply. They are commonly used in municipal and landscape irrigation applications where water quality is paramount. This type of valve usually integrates a vacuum breaker to ensure that water flows in only one direction. While they are slightly more expensive than standard valves, the investment is justified by the added protection against pollution.

Why Choose Manual Valves for Small-Scale Operations?

Manual valves are a straightforward option for small-scale farms and gardens. Their simple design requires users to operate them manually, making them low-maintenance and cost-effective. However, this type of valve can be labor-intensive, particularly in larger setups where frequent adjustments are needed. Buyers should consider their operational capacity and whether the labor involved aligns with their irrigation needs.

What Advantages Do Globe Valves Offer for Flow Regulation?

Globe valves are recognized for their ability to provide precise flow control. Their spherical body design allows for a more controlled water flow, making them suitable for golf courses and expansive estates. While globe valves are durable and offer excellent regulation, their installation can be bulkier compared to other types. B2B buyers should weigh the benefits of flow precision against the installation requirements.

How Do Angle Valves Optimize Space in Irrigation Systems?

Angle valves are specifically designed for installations in tight spaces, making them a versatile choice for commercial settings. Their unique design allows for efficient corner placements, maximizing the use of available space. While angle valves may have limited flow rates compared to other types, their adaptability can be a significant advantage in complex irrigation layouts. Buyers should assess the specific layout of their irrigation systems to determine if angle valves are the best fit.

Key Industrial Applications of lawn irrigation valve

| Industry/Sector | Specific Application of Lawn Irrigation Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems for crop fields | Enhances water efficiency, reduces labor costs | Compatibility with existing systems, durability, and cost-effectiveness |

| Landscaping | Watering solutions for commercial landscaping projects | Improves plant health and aesthetic appeal, saves time | Customization options, weather resistance, and maintenance support |

| Sports Facilities | Irrigation for golf courses and sports fields | Ensures optimal playing conditions, conserves water usage | Heavy-duty materials, pressure regulation features, and local climate adaptability |

| Municipal Parks | Irrigation systems in public parks and gardens | Promotes sustainability and beautification of urban areas | Compliance with local regulations, ease of installation, and scalability |

| Greenhouses | Controlled irrigation for horticultural production | Maximizes yield and resource efficiency | Precision control features, compatibility with automated systems, and energy efficiency |

How Are Lawn Irrigation Valves Used in Agriculture?

In agriculture, lawn irrigation valves are integral to automated irrigation systems that manage water supply to crop fields. They facilitate precise control over water flow, ensuring that crops receive the optimal amount of moisture. This application not only enhances water efficiency but also reduces labor costs by automating irrigation schedules. For international buyers in regions like Africa and South America, sourcing durable valves that can withstand harsh weather conditions and varying soil types is crucial. Additionally, compatibility with existing irrigation systems is a significant consideration.

What Role Do Lawn Irrigation Valves Play in Landscaping?

In the landscaping sector, lawn irrigation valves are essential for maintaining lush, healthy gardens and commercial landscapes. They are used in various watering solutions that cater to different plant types and layouts. By automating irrigation processes, these valves save time and labor while improving plant health and aesthetic appeal. Buyers from Europe and the Middle East should focus on customizable options that fit specific landscape designs and consider weather-resistant materials to ensure longevity in diverse climates.

Why Are Lawn Irrigation Valves Important for Sports Facilities?

Sports facilities utilize lawn irrigation valves to maintain golf courses and athletic fields, ensuring optimal playing conditions. These valves help regulate water distribution, promoting healthy turf growth while conserving water resources. For B2B buyers in this sector, sourcing heavy-duty valves that can handle high-pressure systems is vital. Additionally, features that allow for precise pressure regulation are important to accommodate the specific needs of various sports surfaces, particularly in regions with fluctuating weather patterns.

How Do Municipal Parks Benefit from Lawn Irrigation Valves?

Municipal parks employ lawn irrigation valves to create and sustain green spaces in urban environments. By automating irrigation systems, these valves contribute to sustainability efforts and enhance the aesthetic appeal of public areas. For municipal buyers, compliance with local regulations regarding water usage is critical, as is the need for easy installation and scalability to accommodate future expansions. Sourcing valves that are robust and require minimal maintenance will also add value to municipal projects.

What Advantages Do Lawn Irrigation Valves Provide in Greenhouses?

In greenhouse operations, lawn irrigation valves are vital for controlled irrigation, allowing for precise moisture management tailored to various horticultural needs. This application maximizes crop yield and resource efficiency, essential for competitive agricultural markets. Buyers in this sector, particularly from emerging markets, should prioritize valves with precision control features that integrate seamlessly with automated systems. Energy efficiency is another key consideration, as it impacts overall operational costs and sustainability.

3 Common User Pain Points for ‘lawn irrigation valve’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Type of Valve for Specific Conditions

The Problem: Many B2B buyers face challenges when selecting the appropriate lawn irrigation valve suitable for their specific environmental conditions. Factors such as soil type, plant requirements, and climate can significantly influence the performance of irrigation systems. For instance, buyers in arid regions may struggle with valves that can’t handle low water pressure effectively, while those in humid climates may need valves with anti-siphon capabilities to prevent backflow and contamination. This lack of clarity can lead to improper installations, increased costs, and underperforming irrigation systems.

The Solution: To ensure the right selection of lawn irrigation valves, buyers should conduct a comprehensive site analysis before purchasing. This involves assessing the local soil type, plant species, and climate conditions. Based on this analysis, opt for valves that are specifically designed for those environmental conditions. For example, in areas with fluctuating water pressure, consider using pressure-regulating valves to maintain consistent flow. Additionally, it is beneficial to source valves from reputable manufacturers who provide detailed specifications and guidance on product compatibility with various environmental factors. Engaging with suppliers who offer technical support can also aid in making informed decisions, ensuring that the selected valves will meet the unique demands of the irrigation system.

Scenario 2: High Maintenance and Repair Costs Due to Valve Failures

The Problem: A frequent concern among B2B buyers is the high maintenance and repair costs associated with lawn irrigation valves. Many valves fail prematurely due to factors such as poor quality materials, improper installation, or lack of regular maintenance. This can lead to system inefficiencies, unexpected water wastage, and costly repairs that affect overall operational budgets. Buyers may find themselves caught in a cycle of replacing valves, which not only disrupts service but also strains financial resources.

The Solution: To mitigate these costs, buyers should prioritize the selection of high-quality, durable valves that are suitable for their specific applications. Investing in valves made from corrosion-resistant materials, such as brass or high-grade plastic, can significantly enhance longevity and reduce the frequency of replacements. Additionally, implementing a regular maintenance schedule is crucial. This includes periodic inspections to check for leaks, ensuring proper function of the solenoids, and cleaning filters to prevent clogs. Buyers should also consider investing in smart irrigation systems that provide real-time monitoring and diagnostics, allowing for proactive maintenance. By choosing reliable products and establishing robust maintenance practices, businesses can substantially lower their long-term costs associated with lawn irrigation valves.

Scenario 3: Incompatibility with Existing Irrigation Systems

The Problem: B2B buyers often encounter issues with valve compatibility when integrating new irrigation components into existing systems. This can lead to inefficiencies, system malfunctions, or even complete failure of the irrigation network. For instance, a buyer may purchase a new valve that does not match the existing pipe diameter or fails to work with the current control system, causing delays in project timelines and increased labor costs for retrofitting.

The Solution: To avoid compatibility issues, it is essential for buyers to thoroughly document and understand their current irrigation system specifications before purchasing new valves. This includes pipe sizes, flow rates, and existing control mechanisms. When sourcing new valves, prioritize products that offer flexible installation options, such as adjustable fittings or various connection types. Suppliers should provide detailed compatibility information and support to guide buyers through the selection process. Moreover, consider opting for modular systems that allow for easier upgrades and replacements in the future. Utilizing a standardized approach to system components can also minimize compatibility issues, ensuring that all parts work seamlessly together and enhancing the overall efficiency of the irrigation network.

Strategic Material Selection Guide for lawn irrigation valve

What are the Key Properties of Common Materials Used in Lawn Irrigation Valves?

When selecting materials for lawn irrigation valves, several common options stand out: plastic, brass, stainless steel, and aluminum. Each material has distinct properties that influence performance, durability, and suitability for various applications.

Plastic: Versatile and Cost-Effective

Plastic is the most widely used material for lawn irrigation valves, particularly in residential and light commercial applications. Key properties include resistance to corrosion and a lightweight nature, making installation easier. Plastic valves typically operate well under temperatures up to 60°C and pressure ratings around 150 psi.

Pros: Plastic valves are affordable, lightweight, and resistant to corrosion, making them ideal for various environments. They are also easy to install and maintain.

Cons: However, they can be less durable than metal options, particularly in high-pressure applications or extreme temperatures. Over time, exposure to UV light can degrade plastic, necessitating replacement.

Impact on Application: Plastic valves are suitable for fresh water and non-corrosive media but may not withstand harsh chemicals or high-pressure systems.

International Considerations: Buyers should ensure compliance with local standards, such as ASTM for the U.S. or DIN for Europe, and consider the availability of replacement parts.

Brass: Durable and Reliable

Brass is a popular choice for heavy-duty applications, including commercial and municipal irrigation systems. It offers excellent corrosion resistance and can handle higher temperatures and pressures, often exceeding 200 psi.

Pros: Brass valves are durable, have a long lifespan, and can withstand harsh conditions. They are also less prone to damage from UV exposure compared to plastic.

Cons: The primary drawback is the higher cost compared to plastic options. Brass is also heavier, which can complicate installation and increase shipping costs.

Impact on Application: Brass valves are compatible with a wide range of media, including potable water, making them suitable for municipal applications.

International Considerations: Compliance with standards like JIS in Japan or EN in Europe is crucial. Buyers should also consider the implications of brass’s higher cost in budget-sensitive markets.

Stainless Steel: High Performance in Extreme Conditions

Stainless steel valves are known for their exceptional strength and corrosion resistance, making them suitable for industrial applications and environments with aggressive media.

Pros: They can handle extreme temperatures and pressures, often exceeding 300 psi. Stainless steel is also resistant to rust and corrosion, ensuring longevity.

Cons: The main disadvantage is the high cost and weight, which can make installation more challenging. Additionally, they may require more complex manufacturing processes.

Impact on Application: Stainless steel valves are ideal for corrosive environments, including saline or acidic media, but may not be necessary for standard irrigation applications.

International Considerations: Buyers should verify compliance with international standards, such as ASTM and ISO, to ensure quality and safety.

Aluminum: Lightweight with Good Corrosion Resistance

Aluminum valves are less common but offer a balance between weight and durability. They are resistant to corrosion and can handle moderate pressures, typically around 150 psi.

Pros: Aluminum is lightweight, making it easy to transport and install. It also offers decent resistance to corrosion, particularly with protective coatings.

Cons: However, aluminum valves can be more expensive than plastic and may not be suitable for high-pressure applications. They can also be less durable than brass or stainless steel.

Impact on Application: Aluminum valves are suitable for applications where weight is a concern, but they may not perform well in extreme conditions.

International Considerations: Compliance with local standards is essential, and buyers should consider the availability of compatible components.

Summary Table of Material Selection for Lawn Irrigation Valves

| Material | Typical Use Case for lawn irrigation valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Residential and light commercial | Cost-effective and lightweight | Less durable under high pressure | Low |

| Brass | Heavy-duty and municipal applications | Durable and long-lasting | Higher cost and weight | High |

| Stainless Steel | Industrial and corrosive environments | Exceptional strength and corrosion resistance | High cost and complex manufacturing | High |

| Aluminum | Moderate pressure applications | Lightweight and good corrosion resistance | More expensive than plastic | Medium |

This guide provides a comprehensive overview of the materials commonly used in lawn irrigation valves, helping B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for lawn irrigation valve

What Are the Key Stages in the Manufacturing Process of Lawn Irrigation Valves?

The manufacturing process for lawn irrigation valves consists of several critical stages, each designed to ensure that the final product meets the necessary performance and durability standards.

1. Material Preparation

The first stage involves selecting and preparing the appropriate materials. Lawn irrigation valves are typically made from high-grade plastics or metals, depending on the intended application. For residential and light commercial use, durable plastics like PVC or ABS are common, while heavy-duty applications may require brass or stainless steel. Materials are sourced based on their resistance to corrosion, UV exposure, and pressure tolerance.

Before manufacturing, materials undergo quality checks to ensure they meet specifications. This includes verifying physical properties such as tensile strength and flexibility. Suppliers often provide Material Safety Data Sheets (MSDS) to confirm compliance with international standards.

2. Forming Processes: How Are Lawn Irrigation Valves Shaped?

Once the materials are prepared, the next step is forming them into the required shapes. This can involve various techniques:

Injection Molding: For plastic valves, this technique is prevalent. It involves melting plastic pellets and injecting them into a mold to form the valve body. This process allows for high precision and repeatability, which is essential for creating components that fit together seamlessly.

Casting: For metal valves, casting techniques like sand casting or die casting are often used. This involves pouring molten metal into a mold to create the valve’s shape. This method is suitable for producing complex geometries and larger components.

Machining: After forming, components may be machined to achieve tighter tolerances and finer finishes. CNC (Computer Numerical Control) machines are commonly employed to ensure precision in critical areas like threads and seat surfaces.

3. Assembly: How Are Different Components Joined Together?

The assembly stage involves putting together various components of the valve, including the body, diaphragm, solenoid, and any additional features such as flow control mechanisms.

Diaphragm Installation: The diaphragm is crucial for regulating water flow and pressure. It is typically installed in a manner that allows for effective sealing and operation when the solenoid is energized.

Electrical Connections: For electrically operated valves, solenoids must be connected to the power supply. This requires careful handling to ensure that connections are secure and insulated to prevent failures.

Final Assembly: After individual components are assembled, the entire valve is put together, ensuring that each part functions correctly and aligns with design specifications.

4. Finishing: What Treatments Are Applied for Durability?

The finishing stage involves applying treatments that enhance the valve’s durability and performance. This can include:

Surface Treatments: For metal valves, processes such as anodizing or galvanizing may be used to protect against corrosion. Plastic valves may undergo UV stabilization to prevent degradation from sunlight exposure.

Quality Checks: After finishing, the valves are subjected to final inspections to ensure they meet aesthetic and functional standards. This may include visual inspections and measurements of critical dimensions.

What Quality Assurance Standards Are Essential for Lawn Irrigation Valves?

Quality assurance is paramount in the manufacturing of lawn irrigation valves. Adhering to international and industry-specific standards ensures reliability and safety for end-users.

1. What International Standards Should B2B Buyers Be Aware Of?

ISO 9001: This is a widely recognized quality management standard that outlines requirements for an organization’s quality management system. Compliance indicates that the manufacturer has processes in place to ensure consistent quality in their products.

CE Marking: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards. This is crucial for B2B buyers in Europe who are sourcing products.

API Standards: For valves used in heavy-duty applications, adherence to American Petroleum Institute (API) standards may be necessary, particularly if the valves are used in oil and gas applications.

2. What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process:

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production quality. This includes checking dimensional tolerances and ensuring the correct assembly of components.

Final Quality Control (FQC): After assembly and finishing, a final inspection is performed. This may involve functional testing, pressure testing, and visual inspections to confirm that the product meets all specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure the reliability of the products being sourced.

1. What Steps Can Buyers Take?

Supplier Audits: Conducting audits of the supplier’s manufacturing facilities can provide insights into their quality control processes. This includes reviewing their quality management systems and manufacturing practices.

Requesting Quality Reports: Buyers should request documentation that outlines the supplier’s quality control processes, including testing protocols, inspection reports, and certifications. This can help assess the reliability of the supplier.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These inspections can cover various aspects, from material quality to finished product testing.

2. What Are the Quality Control Nuances for International Buyers?

International buyers need to be aware of specific nuances when it comes to quality assurance:

Regulatory Compliance: Different regions have varying regulations regarding materials and product safety. Understanding these regulations is essential for avoiding compliance issues.

Cultural Considerations: Communication styles and business practices can differ significantly across regions. Establishing clear expectations regarding quality and delivery can help mitigate misunderstandings.

Logistics and Supply Chain: Factors such as shipping times, customs regulations, and local market conditions can affect product availability and quality. Building strong relationships with suppliers can help navigate these challenges.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance standards for lawn irrigation valves is crucial for B2B buyers looking to source reliable products. By focusing on these key areas, buyers can make informed decisions that enhance their procurement strategies and ultimately lead to successful business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lawn irrigation valve’

In the competitive landscape of lawn irrigation systems, procuring the right irrigation valves is crucial for ensuring efficiency and reliability. This guide provides a systematic approach to sourcing lawn irrigation valves, tailored for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure the selected valves meet your operational needs. Consider factors such as flow rate, pressure ratings, and compatibility with existing systems. Additionally, identify whether you require automatic or manual valves, and take note of the material preferences (plastic for general use or metal for heavy-duty applications).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in lawn irrigation valves. Utilize online platforms, industry directories, and trade shows to gather a list of reputable manufacturers. Pay attention to their experience in the market and their reputation among other B2B buyers.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international quality standards. Look for ISO certifications or other relevant industry credentials that indicate adherence to safety and quality benchmarks. This step ensures that the valves you procure will be reliable and meet regulatory requirements in your region.

Step 4: Assess Product Range and Availability

Review the supplier’s product range to ensure they offer various valve types and sizes to meet your project requirements. Check for the availability of both standard and specialized valves, as well as any accessories needed for installation. A diverse product line can save you time and effort in sourcing multiple components from different suppliers.

Step 5: Request Samples and Conduct Testing

Once you have narrowed down your suppliers, request samples of the valves for testing. Evaluate their performance under real operating conditions to assess durability, efficiency, and compatibility with your irrigation systems. Testing samples before bulk purchasing can prevent costly mistakes.

Step 6: Negotiate Pricing and Terms

After confirming the quality of the products, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget constraints and the quantities you intend to order. Establishing favorable terms can enhance your profit margins and ensure timely delivery.

Step 7: Confirm After-Sales Support and Warranty

Finally, inquire about after-sales support and warranty terms. A reliable supplier should provide comprehensive support, including installation guidance and troubleshooting assistance. Understanding warranty coverage can also protect your investment and ensure long-term operational success.

By following this checklist, B2B buyers can strategically navigate the procurement process for lawn irrigation valves, ensuring they select high-quality products from reputable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for lawn irrigation valve Sourcing

What Are the Key Cost Components Involved in Sourcing Lawn Irrigation Valves?

When sourcing lawn irrigation valves, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

Materials: The choice of materials significantly affects the overall cost. Common materials include plastic for residential applications and metal for commercial use, such as brass or stainless steel. Higher quality materials typically yield longer-lasting products but come at a premium.

Labor: Labor costs encompass the wages paid to workers involved in manufacturing, assembling, and testing the valves. These costs can vary based on the region and the complexity of the production process.

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory management. A well-optimized manufacturing process can reduce overhead costs, making sourcing more cost-effective.

Tooling: Initial tooling costs for creating molds and dies can be substantial but are often amortized over large production runs. Custom tooling for specialized valve designs will increase upfront costs.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall costs. Investing in quality can prevent costly returns and enhance customer satisfaction.

Logistics: Shipping and handling are critical components, especially for international buyers. Factors such as distance, mode of transportation, and customs duties influence logistics costs.

Margin: Suppliers typically add a margin to cover their operational costs and profit expectations. Understanding the margin structure can aid in negotiations.

How Do Price Influencers Affect Lawn Irrigation Valve Sourcing?

Several factors can influence the pricing of lawn irrigation valves:

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders often lead to volume discounts, making it more economical for buyers.

Specifications and Customization: Customized valves or those with specific features (e.g., anti-siphon, flow control) may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materials: The choice of materials directly impacts pricing. Premium materials increase costs, but they may offer better durability and performance, leading to a lower total cost of ownership (TCO) over time.

Quality and Certifications: Valves that meet industry standards or possess certifications (like ISO or CE) may come at a higher price but provide assurance of quality and reliability.

Supplier Factors: The supplier’s reputation, experience, and production capabilities can also influence prices. Established suppliers may charge more but offer better service and reliability.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define responsibilities regarding shipping, insurance, and tariffs, which can affect the overall cost.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing lawn irrigation valves, international buyers should consider the following tips:

Negotiation: Engage in negotiations with suppliers to secure better pricing or additional services. Being informed about market prices and cost structures can enhance negotiation leverage.

Total Cost of Ownership (TCO): Assess not just the initial purchase price but also maintenance, operation, and disposal costs over the valve’s lifespan. Investing in higher-quality valves may result in lower TCO.

Understand Pricing Nuances: Different regions may have varying pricing structures due to local demand, availability, and competition. For instance, sourcing from regions with lower production costs can yield significant savings.

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, improved service, and access to exclusive deals or innovations.

Market Research: Conduct thorough market research to understand the competitive landscape and identify potential suppliers. This knowledge can inform your sourcing strategy and help avoid overpaying.

Disclaimer on Indicative Prices

Prices for lawn irrigation valves can vary widely based on the factors discussed above. The information provided is indicative and should be verified with suppliers for the most accurate and current pricing. Buyers are encouraged to conduct their due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing lawn irrigation valve With Other Solutions

Understanding Alternatives to Lawn Irrigation Valves

When it comes to managing water resources efficiently for landscape irrigation, lawn irrigation valves are a common solution. However, buyers should consider various alternatives that may offer distinct advantages depending on specific needs and circumstances. This section compares lawn irrigation valves to two viable alternatives: drip irrigation systems and rainwater harvesting systems.

| Comparison Aspect | Lawn Irrigation Valve | Drip Irrigation System | Rainwater Harvesting System |

|---|---|---|---|

| Performance | Efficient for large areas with high water needs | Highly efficient, minimizes water waste | Variable, depends on rainfall and storage capacity |

| Cost | Moderate initial cost, low operating costs | Higher initial setup costs, low maintenance | Initial costs vary, potential long-term savings |

| Ease of Implementation | Relatively easy to install; requires plumbing knowledge | More complex installation; often requires professional help | Installation can be complex; requires space for tanks |

| Maintenance | Low; occasional valve checks needed | Low; regular filter cleaning required | Moderate; requires tank cleaning and maintenance |

| Best Use Case | Large lawns, commercial landscapes | Gardens, agricultural settings, areas with water scarcity | Urban environments, areas with seasonal rainfall |

What Are the Advantages and Disadvantages of Drip Irrigation Systems?

Drip irrigation systems are designed to deliver water directly to the plant roots through a network of tubing and emitters. This method is highly efficient and reduces water waste significantly compared to traditional methods. The primary advantage is its ability to minimize evaporation and runoff, making it particularly suitable for arid regions or water-scarce areas. However, the initial setup can be more complex and costly than installing lawn irrigation valves, and it often requires professional installation to ensure proper functioning.

How Does Rainwater Harvesting Compare?

Rainwater harvesting systems collect and store rainwater from rooftops or other surfaces for later use in irrigation. This method can provide significant cost savings over time, especially in regions where municipal water is expensive. The main advantage is sustainability, as it utilizes a renewable resource. However, the effectiveness of this system is heavily dependent on local rainfall patterns, and the need for maintenance of storage tanks can add complexity. Additionally, the initial investment can vary widely based on the size and capacity of the system.

How to Choose the Right Solution for Your Irrigation Needs?

When selecting the best irrigation solution, B2B buyers should assess their specific needs against the options available. Consider factors such as the size of the area to be irrigated, local water availability, budget constraints, and long-term sustainability goals. Lawn irrigation valves are ideal for large, open areas needing efficient water distribution. Drip irrigation systems are best suited for targeted watering in gardens or agricultural settings, while rainwater harvesting can be a sustainable choice for urban areas with adequate rainfall. Ultimately, the right choice will depend on a combination of performance requirements, cost-effectiveness, and ease of implementation tailored to the unique environmental conditions of the buyer’s location.

Essential Technical Properties and Trade Terminology for lawn irrigation valve

What Are the Essential Technical Properties of Lawn Irrigation Valves?

Lawn irrigation valves are critical components in maintaining efficient watering systems. Understanding their technical specifications can help B2B buyers make informed purchasing decisions.

What Are the Key Specifications of Lawn Irrigation Valves?

Material Composition

Lawn irrigation valves are typically made from plastic or metal. Plastic valves are lightweight and suitable for residential applications, while metal valves offer durability for commercial and industrial use. The choice of material affects the valve’s longevity, resistance to corrosion, and overall performance under varying environmental conditions.Pressure Rating

This specification indicates the maximum pressure the valve can withstand, usually measured in pounds per square inch (psi). Common ratings range from 10 psi to 150 psi. Understanding pressure ratings is crucial for ensuring compatibility with the irrigation system and preventing leaks or failures during operation.Flow Rate

Measured in gallons per minute (GPM), the flow rate indicates how much water can pass through the valve. Knowing the required flow rate for a specific application ensures efficient watering without over-pressurizing the system. This is particularly important for large agricultural or commercial projects where water conservation is essential.Voltage Requirement

Most modern irrigation valves operate on 24 volts AC or DC. This specification determines the electrical compatibility with existing irrigation controllers. Ensuring the correct voltage can help prevent electrical failures and maintain the efficient operation of the irrigation system.Diaphragm Type

Valves may utilize different diaphragm designs, such as double-beaded or single-beaded diaphragms. The type of diaphragm affects the valve’s reliability and performance, especially in controlling water flow. A high-quality diaphragm can enhance longevity and reduce the need for frequent repairs.Installation Configuration

Lawn irrigation valves can be configured for above-ground or below-ground installation. The choice of configuration impacts ease of access for maintenance and the overall aesthetic of the landscape. B2B buyers should consider installation requirements based on the specific environment and project needs.

What Are Common Trade Terms Used in Lawn Irrigation Valves?

Understanding industry jargon can facilitate smoother transactions and negotiations between buyers and suppliers.

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are then sold under another company’s brand. Knowing the OEM can help buyers assess quality and compatibility with existing systems, as well as establish trust in product performance.MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for budget planning and inventory management, especially for companies looking to stock up on essential parts without over-committing financially.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process allows buyers to compare costs and features across multiple suppliers, enabling better decision-making based on budget and project requirements.Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers understand their obligations and rights, minimizing the risk of disputes during transactions.Backflow Preventer

This device is crucial in irrigation systems to prevent contaminated water from flowing back into the main supply. Knowing about backflow preventers is essential for compliance with local regulations and maintaining water quality.Flow Control Valve

A flow control valve regulates the amount of water flowing through the irrigation system, allowing for efficient water management. Understanding this terminology can help buyers select the appropriate valve for their specific irrigation needs.

Incorporating these technical properties and trade terms into purchasing strategies can empower B2B buyers to make informed decisions that enhance the efficiency and effectiveness of lawn irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the lawn irrigation valve Sector

What Are the Key Drivers and Trends in the Lawn Irrigation Valve Market?

The global lawn irrigation valve market is experiencing significant growth driven by several factors. Increasing urbanization, particularly in emerging markets in Africa, South America, and the Middle East, is leading to a heightened demand for efficient water management systems. Furthermore, advancements in irrigation technology, including smart valves that integrate with IoT systems, are emerging as a pivotal trend. These innovations not only enhance water conservation but also improve operational efficiency, appealing to international B2B buyers focused on sustainability and cost-effectiveness.

Another key trend is the rising awareness of environmental sustainability among consumers and businesses alike. This shift is pushing manufacturers to develop products that minimize water wastage and energy consumption. The introduction of automation in irrigation systems is also becoming more prevalent, allowing for precise water application based on weather forecasts and soil moisture levels. International buyers, particularly from regions like Europe and the Middle East, are increasingly looking for suppliers that can provide advanced, automated solutions.

Lastly, the fluctuating prices of raw materials, along with supply chain disruptions, are influencing sourcing strategies. B2B buyers need to stay informed about market dynamics to negotiate better terms and ensure a steady supply of irrigation valves. Emphasizing long-term partnerships with reliable manufacturers can mitigate risks associated with market volatility.

How Important Is Sustainability and Ethical Sourcing in the Lawn Irrigation Valve Sector?

Sustainability is becoming a critical consideration in the lawn irrigation valve sector. The environmental impact of traditional irrigation practices has prompted international buyers to seek out products that contribute to water conservation and reduced chemical runoff. Ethical sourcing is equally important, as it ensures that the materials used in the manufacturing process are acquired responsibly and with minimal environmental degradation.

B2B buyers should prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or adopting energy-efficient manufacturing processes. Certifications like ISO 14001 for environmental management and WaterSense for water-efficient products can serve as indicators of a supplier’s dedication to sustainability. Furthermore, transparency in the supply chain, including the sourcing of materials, is crucial for establishing trust and credibility with customers.

The push for “green” certifications is also influencing purchasing decisions. Buyers are increasingly inclined to choose products that not only meet their technical requirements but also align with their sustainability goals. By focusing on suppliers with ethical sourcing practices and environmentally friendly products, businesses can enhance their brand reputation while contributing positively to the environment.

How Has the Lawn Irrigation Valve Sector Evolved Over Time?

The lawn irrigation valve sector has undergone significant evolution over the past few decades. Initially, traditional manual valves dominated the market, requiring manual operation and oversight. However, with the advent of technology, the industry has shifted towards automated solutions that offer enhanced efficiency and convenience. The introduction of electric solenoid valves revolutionized the sector, allowing for remote operation and precise control over irrigation schedules.

As environmental concerns gained prominence, manufacturers began to innovate further, focusing on water-saving technologies and smart irrigation systems. Today, the market is characterized by a diverse range of products, including anti-siphon valves, pressure-regulating valves, and integrated smart systems that respond to real-time data. This evolution not only reflects advancements in technology but also a growing commitment to sustainability in the industry, catering to the needs of modern consumers and businesses alike.

Frequently Asked Questions (FAQs) for B2B Buyers of lawn irrigation valve

How do I choose the right lawn irrigation valve for my project?

Selecting the appropriate lawn irrigation valve involves considering several factors, including the type of irrigation system (e.g., drip or sprinkler), the required flow rate, and the pressure specifications. Additionally, assess the materials used in the valve—plastic valves are suitable for residential applications, while metal valves are preferred for commercial or heavy-duty environments. It’s also important to evaluate whether you need features like anti-siphon capabilities or flow control options. Consulting with suppliers about your specific needs can help narrow down the best choices.What are the key features to look for in a lawn irrigation valve?

When sourcing lawn irrigation valves, focus on features that enhance performance and durability. Look for valves with adjustable flow control to manage water usage effectively. Diaphragm-based designs are common for their reliability and low maintenance. Additionally, consider valves with built-in backflow prevention to protect your water supply. Ensure the valve can operate under your local water pressure and temperature conditions, as this will affect its longevity and efficiency.What are the minimum order quantities (MOQs) for lawn irrigation valves?

Minimum order quantities (MOQs) for lawn irrigation valves vary by supplier and are often influenced by the type of valve and materials used. Typically, MOQs can range from 50 to 500 units. It’s advisable to discuss your project requirements with potential suppliers to negotiate favorable terms, especially if you are a smaller buyer. Many manufacturers are willing to accommodate lower MOQs for repeat customers or larger contracts, so establishing a long-term relationship can be beneficial.How can I ensure quality control when sourcing lawn irrigation valves?

To ensure quality control, request samples before placing a large order. This allows you to assess the materials and functionality of the valves firsthand. It’s also important to verify the supplier’s certifications and quality management processes, such as ISO certifications. Consider conducting factory audits or using third-party inspection services to evaluate the production processes and ensure compliance with international standards. Establishing clear quality expectations in your contract can further protect your investment.What payment terms are common in international B2B transactions for irrigation valves?

Payment terms in international B2B transactions typically vary by supplier and can include options like Letter of Credit (LC), advance payment, or payment on delivery. It’s common to negotiate a partial upfront payment (e.g., 30-50%) with the balance due upon shipment or delivery. Discussing payment terms early in the negotiation process is critical, as it helps build trust and ensures that both parties are aligned on financial expectations.What logistics considerations should I keep in mind when importing lawn irrigation valves?

When importing lawn irrigation valves, consider shipping methods, lead times, and customs regulations in your country. Sea freight is often more economical for larger orders, but air freight may be necessary for urgent deliveries. Be aware of any import duties and taxes that could affect your overall costs. Collaborating with a logistics provider familiar with your region can streamline the process and help you navigate potential challenges, ensuring timely delivery of your products.Are there customization options available for lawn irrigation valves?

Many suppliers offer customization options for lawn irrigation valves, allowing you to specify features such as size, material, and additional functionalities like flow control or solenoid types. Customization may also extend to branding, such as incorporating your logo or specific packaging requirements. Be prepared to discuss your specific needs and verify any additional costs or lead times associated with custom orders to ensure they align with your project timeline.How do I vet potential suppliers for lawn irrigation valves?

Vetting suppliers is crucial for ensuring reliable partnerships. Start by researching their reputation through online reviews and industry references. Request information on their manufacturing capabilities, certifications, and compliance with international standards. Engaging in direct communication can provide insights into their responsiveness and customer service. If possible, visit their facilities or attend trade shows where they exhibit to evaluate their operations and product quality firsthand.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Lawn Irrigation Valve Manufacturers & Suppliers List

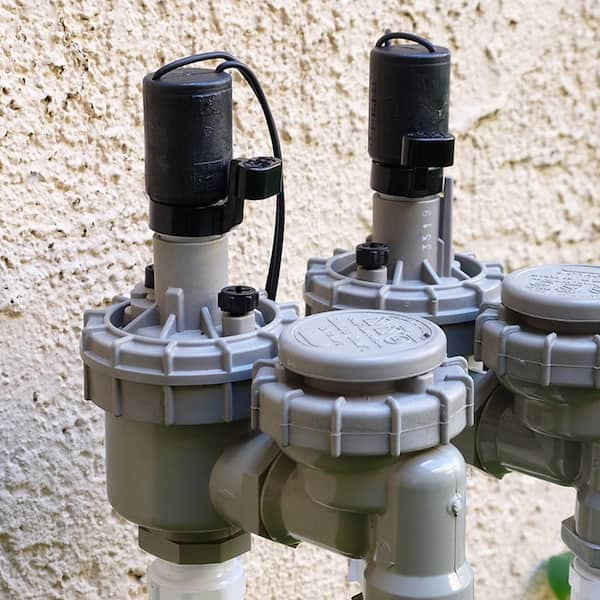

1. Sprinkler Supply Store – Automatic Irrigation Valves

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: Sprinkler valves are automatic irrigation valves that can be globe or angle (straight or bent) and utilize a diaphragm and an electric solenoid to open and close. They are generally made of plastic for residential and most commercial applications, while metal is used for heavy-duty sites such as golf courses and municipal pumping stations.

2. Orbit – Top Underground Valves

Domain: orbitonline.com

Registered: 1999 (26 years)

Introduction: Top Underground Valves for Sprinkler and Drip Systems

3. Lawn Genie – Professional-Quality Irrigation Products

Domain: lawngenie.com

Registered: 1995 (30 years)

Introduction: Lawn Genie offers maintenance-free, easy-to-install, professional-quality irrigation products designed for do-it-yourself homeowners. The product line includes residential irrigation valves and accessories that are adapted from professional-grade equipment. These products are aimed at conserving water and satisfying home watering needs, allowing homeowners to enjoy their landscaping without the ha…

4. Cheap Sprinklers – Irrigation Valves

Domain: cheapsprinklers.com

Registered: 2014 (11 years)

Introduction: Cheap Sprinklers offers a wide range of irrigation valves including residential and commercial options. The selection features electronic solenoid valves, indexing valves, clean water and dirty water valves, low-pressure and high-pressure valves, foot valves, and flow sensor valves. Brands available include K-Rain, Hunter, Rain Bird, and Weathermatic.

5. Irritrol – Long-Term Reliability

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Preferred brands: RainBird, Hunter, Irritrol, Toro. Pressure: 60 psi. Hunter’s PGVs noted for universal solenoids and easy disassembly. 1″ and 1 1/2″ sizes mentioned. Long-term reliability of Irritrol and Rainbird valves highlighted. Issues with solenoid o-rings on Rain Bird valves noted.

6. Rain Bird – CP075 Irrigation Valve

Domain: outdoorsupplyhardware.com

Registered: 2019 (6 years)

Introduction: Lawn & Garden | Watering & Irrigation Valves | Key Products: 1. Rain Bird CP075 Irrigation Valve with Flow Control, Plastic Body, Model Number: CP075 2. Orbit 57281 Inline Sprinkler Valve, 1 in, Model Number: 57281 3. Orbit 51022P Anti-Siphon Control Valve, 3/4 in, FNPT, 70 to 150 psi Pressure, 24 V, Model Number: 51022P 4. Orbit 57029P Automatic Converter, 3/4 in, Model Number: 57029P 5. Lawn Gen…

Strategic Sourcing Conclusion and Outlook for lawn irrigation valve

Why is Strategic Sourcing Essential for Lawn Irrigation Valves?

In the rapidly evolving market for lawn irrigation valves, strategic sourcing emerges as a critical component for international B2B buyers. By leveraging insights into product specifications, supplier capabilities, and regional market dynamics, companies can optimize their procurement processes. Understanding the diverse needs of different geographical markets—such as those in Africa, South America, the Middle East, and Europe—enables buyers to select valves that not only meet technical requirements but also align with local conditions and regulations.

What Are the Key Takeaways for B2B Buyers?

Investing in high-quality valves from reputable manufacturers like Hunter, Rain Bird, and Toro can significantly enhance irrigation efficiency and sustainability. Additionally, prioritizing features such as anti-siphon capabilities, energy efficiency, and ease of installation will lead to long-term savings and operational reliability. Building strong relationships with suppliers can also facilitate better pricing, timely deliveries, and access to innovative products.

How Can You Prepare for Future Trends in Lawn Irrigation?

As global demand for efficient water management solutions continues to rise, B2B buyers should remain vigilant and adaptable. Embrace technology and innovations that promise enhanced performance and sustainability. Engage with suppliers who prioritize eco-friendly practices and smart irrigation technologies. By doing so, businesses can position themselves to not only meet current market demands but also anticipate future trends, ensuring they remain competitive in an increasingly complex landscape.

In conclusion, the strategic sourcing of lawn irrigation valves is not merely a procurement function but a vital strategy that can drive operational success. International buyers are encouraged to explore their options, engage in meaningful supplier partnerships, and stay ahead of industry developments to maximize their return on investment.