Introduction: Navigating the Global Market for irrigation pump diagram

In the fast-evolving landscape of global agriculture, sourcing the right irrigation pump diagram is paramount for businesses aiming to enhance their productivity and efficiency. International B2B buyers face the challenge of navigating diverse irrigation systems, each with unique specifications and operational demands. This comprehensive guide addresses these complexities by exploring various types of irrigation pump diagrams, their applications, and the critical factors to consider when selecting the right system for specific agricultural needs.

Understanding the intricacies of irrigation pump systems is essential for optimizing water usage, ensuring sustainable practices, and ultimately driving profitability. Buyers will benefit from a thorough examination of supplier vetting processes, enabling them to identify reputable manufacturers that meet local and international standards. Additionally, the guide will delve into cost considerations, helping businesses make informed purchasing decisions that align with their budgetary constraints while maximizing return on investment.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Brazil—this guide empowers stakeholders to confidently select irrigation pump systems tailored to their unique agricultural environments. By providing actionable insights and practical information, we aim to facilitate strategic sourcing decisions that enhance operational efficiency and support sustainable agricultural practices across the globe.

Understanding irrigation pump diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centrifugal Pump Diagram | Utilizes rotational kinetic energy; ideal for high-flow rates | Large-scale agriculture, irrigation systems | Pros: Efficient for large volumes; Cons: Not suitable for high-viscosity fluids. |

| Submersible Pump Diagram | Operates underwater; compact design | Groundwater extraction, deep well irrigation | Pros: Space-saving; Cons: Requires specialized installation. |

| Jet Pump Diagram | Uses a jet of water to create a vacuum; suitable for shallow wells | Residential irrigation, water transfer | Pros: Simple design; Cons: Limited depth capability. |

| Positive Displacement Pump Diagram | Moves fluid by trapping a fixed amount and forcing it through | Precision irrigation, chemical applications | Pros: Consistent flow; Cons: More complex maintenance. |

| Solar-Powered Pump Diagram | Operates using solar energy; eco-friendly | Remote irrigation, sustainable farming | Pros: Reduces energy costs; Cons: Dependent on sunlight availability. |

What are the characteristics and suitability of Centrifugal Pump Diagrams for B2B buyers?

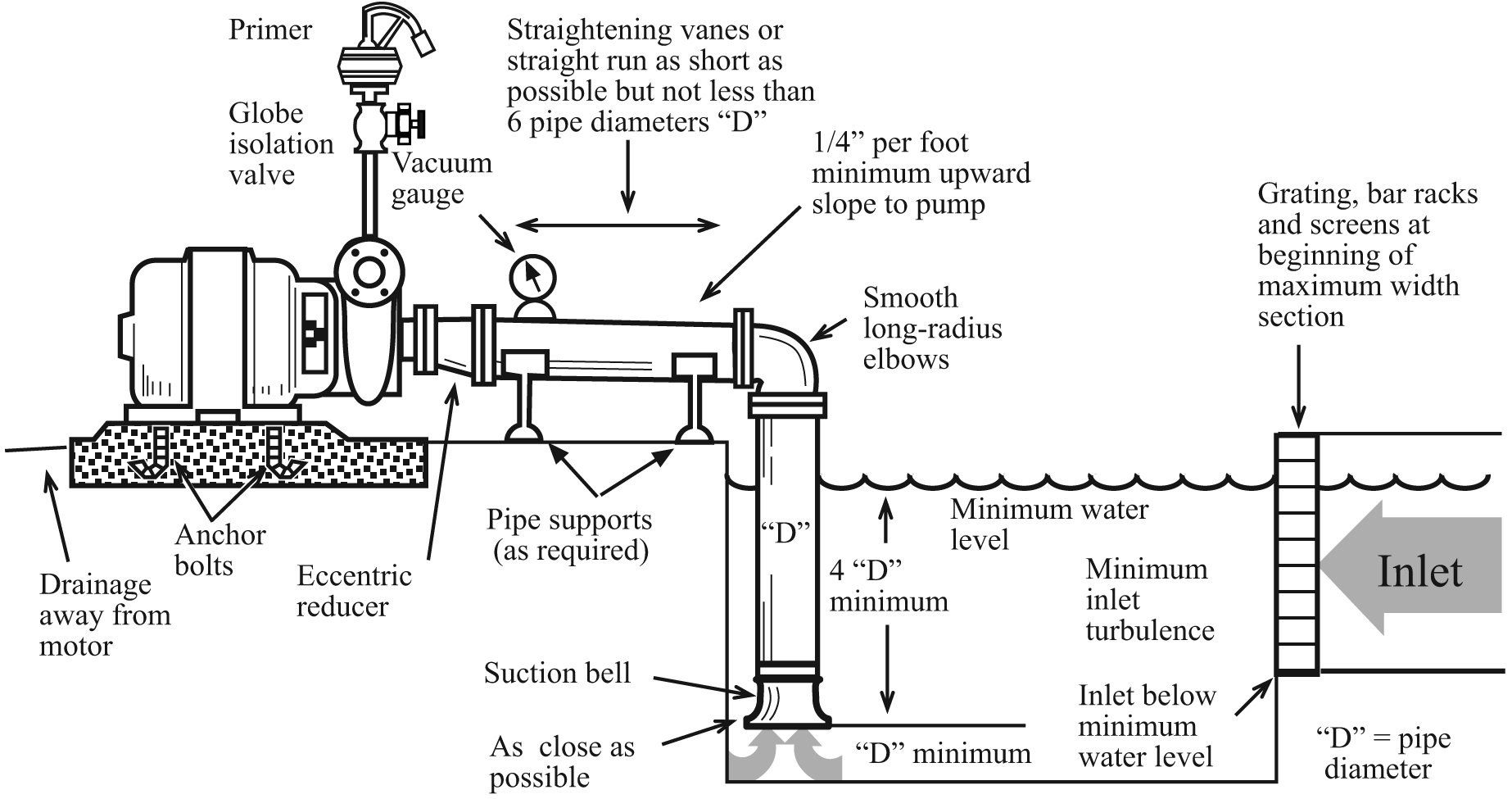

Centrifugal pumps are designed to move fluids through rotational energy, making them highly effective for applications requiring large flow rates. These diagrams typically illustrate the pump’s impeller, casing, and motor assembly. B2B buyers in sectors like agriculture and large-scale irrigation systems benefit from their efficiency and ability to handle a variety of fluids. However, they may not perform well with high-viscosity liquids, which is an essential consideration during purchasing.

How do Submersible Pump Diagrams differ in installation and application?

Submersible pump diagrams depict units designed to operate underwater, often featuring a compact and robust design. They are ideal for applications such as groundwater extraction and deep well irrigation. B2B buyers should consider their space constraints and the need for specialized installation, as these pumps require careful placement in water sources. While submersible pumps are efficient and space-saving, their installation complexity can be a drawback for some buyers.

What makes Jet Pump Diagrams a popular choice for irrigation systems?

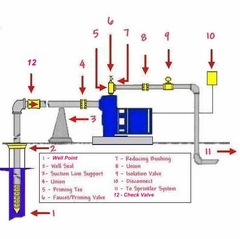

Jet pump diagrams illustrate a system that uses a jet of water to create a vacuum for lifting water, making them suitable for shallow well applications. They are commonly employed in residential irrigation and water transfer systems. B2B buyers appreciate their straightforward design and ease of use. However, their limitation in depth capability is a critical factor to consider, particularly for buyers needing to access deeper water sources.

Why are Positive Displacement Pump Diagrams relevant for precision applications?

Positive displacement pump diagrams show pumps that move fluids by trapping a set volume and forcing it through the discharge. This mechanism allows for consistent flow rates, making them ideal for precision irrigation and chemical applications. B2B buyers should weigh the advantages of reliable flow against the more complex maintenance needs of these systems. Their suitability for high-viscosity fluids can also be a deciding factor in specific industrial applications.

What are the benefits and considerations of Solar-Powered Pump Diagrams?

Solar-powered pump diagrams highlight systems that harness solar energy, making them an eco-friendly choice for irrigation, especially in remote locations. B2B buyers focused on sustainability may find these pumps appealing due to their potential for reduced energy costs. However, the reliance on sunlight availability can be a limitation, making it essential for buyers to assess their geographic and climatic conditions before investing in solar-powered solutions.

Key Industrial Applications of irrigation pump diagram

| Industry/Sector | Specific Application of irrigation pump diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Drip irrigation systems for crop production | Increases yield and water efficiency | Reliability, compatibility with existing systems |

| Horticulture | Greenhouse irrigation systems | Optimizes plant growth and resource management | Energy efficiency, automation capabilities |

| Landscape Management | Irrigation for public parks and recreational areas | Enhances aesthetic appeal and sustainability | Durability, maintenance requirements |

| Aquaculture | Water circulation systems in fish farming | Ensures optimal aquatic environments | Pump capacity, material compatibility |

| Municipal Water Supply | Irrigation for urban landscaping and public gardens | Improves urban livability and environmental health | Compliance with local regulations, energy efficiency |

How is the irrigation pump diagram used in agriculture?

In the agricultural sector, irrigation pump diagrams are essential for designing and implementing drip irrigation systems. These systems deliver water directly to the plant roots, maximizing efficiency and minimizing waste. For international buyers, particularly in regions like Africa and South America, the challenge often lies in the availability of reliable water sources. Thus, selecting pumps that can handle varying water quality and flow rates is crucial. Additionally, understanding the specific requirements for installation and maintenance can prevent costly downtime during the growing season.

What role does the irrigation pump diagram play in horticulture?

Horticulture relies heavily on precise water management, making irrigation pump diagrams vital for greenhouse operations. These diagrams help in setting up systems that maintain optimal moisture levels for various plants, thus enhancing growth and yield. Buyers in Europe and the Middle East should focus on pumps that offer automation features, allowing for programmable watering schedules. This not only saves labor costs but also ensures consistent care for delicate plants, which is essential for high-value crops.

How does irrigation pump diagram benefit landscape management?

In landscape management, irrigation pump diagrams facilitate the design of systems that ensure efficient watering of public parks and recreational areas. Properly designed systems can enhance the aesthetic appeal of these spaces while conserving water. For municipal buyers, particularly in urban areas, it’s essential to consider pumps that are durable and require minimal maintenance. Additionally, energy-efficient options can significantly reduce operational costs, aligning with sustainability goals.

What applications exist for irrigation pump diagrams in aquaculture?

Aquaculture operations depend on consistent water circulation, where irrigation pump diagrams guide the installation of systems that maintain optimal conditions for fish and other aquatic life. Buyers in this sector must consider the specific capacity and flow requirements based on the species being cultivated. Furthermore, selecting pumps made from materials that resist corrosion and biofouling is crucial for maintaining water quality. This is particularly important for international buyers in regions with diverse aquatic environments.

How do municipal water supply systems utilize irrigation pump diagrams?

Municipalities use irrigation pump diagrams to manage water supply for urban landscaping and public gardens. These systems improve the livability of urban areas while promoting environmental health. For international buyers, compliance with local regulations regarding water use is paramount. Additionally, energy-efficient pumps can help municipalities reduce operational costs while meeting the growing demands of urban populations. Understanding the full scope of installation and maintenance needs is key to successful sourcing in this sector.

3 Common User Pain Points for ‘irrigation pump diagram’ & Their Solutions

Scenario 1: Difficulty in Understanding Complex Pump Diagrams

The Problem: B2B buyers often encounter intricate irrigation pump diagrams that can be overwhelming. This complexity can lead to misinterpretation of critical components, resulting in improper installation or selection of pumps. For example, a distributor in South America might struggle to differentiate between the various types of pumps and their corresponding diagrams, which can cause delays in project timelines and increase costs due to potential rework.

The Solution: To alleviate this issue, buyers should seek out simplified, annotated diagrams that clearly highlight key components and their functions. Collaborating with manufacturers who provide detailed, user-friendly diagrams can make a significant difference. Additionally, investing in training sessions for technical staff can enhance their ability to read and interpret these diagrams effectively. Online resources, such as webinars or instructional videos, can also serve as valuable tools for understanding the intricacies of irrigation pump systems. By enhancing diagram literacy, buyers can ensure accurate installations and optimal pump performance.

Scenario 2: Misalignment with Local Regulatory Standards

The Problem: In many regions, especially in Africa and the Middle East, irrigation pump systems must comply with specific local regulations and standards. B2B buyers may find that the diagrams and installation guidelines provided by manufacturers do not align with these local requirements, leading to compliance issues that can result in fines or project delays. For instance, a contractor in the Middle East may face challenges when the specifications in the diagram do not meet the local electrical safety codes.

The Solution: To address this pain point, buyers should engage local experts or consultants who are familiar with regional regulations when sourcing irrigation pump systems. Conducting a thorough review of local codes before finalizing purchases can prevent compliance issues down the line. Manufacturers should also be encouraged to provide regulatory guidance alongside their diagrams, ensuring that buyers are aware of necessary adjustments to meet local standards. By being proactive in regulatory compliance, buyers can avoid costly setbacks and maintain project momentum.

Scenario 3: Inadequate Pump Control Solutions

The Problem: B2B buyers often face challenges when selecting the appropriate pump control methods depicted in irrigation pump diagrams. For example, a buyer in Brazil may struggle to determine whether to use a variable frequency drive (VFD) or a soft starter for their specific application. Inadequate understanding of these control methods can lead to poor pump performance, energy inefficiencies, and increased operational costs.

The Solution: To mitigate this issue, buyers should invest time in understanding the different pump control options available and how they can be effectively implemented. Manufacturers and suppliers should provide comprehensive resources that explain the advantages and disadvantages of each control method, including case studies demonstrating real-world applications. Additionally, buyers can benefit from consulting with technical specialists during the selection process, ensuring that they choose the most suitable control solution for their irrigation system. By making informed decisions about pump control, buyers can enhance system efficiency and reduce operational costs.

Strategic Material Selection Guide for irrigation pump diagram

When selecting materials for irrigation pump diagrams, it is essential to consider the specific properties, advantages, and limitations of each material. This analysis will focus on four common materials: stainless steel, cast iron, plastic (PVC), and bronze. Each material has distinct characteristics that influence its suitability for various applications in irrigation systems.

What Are the Key Properties of Stainless Steel for Irrigation Pumps?

Stainless steel is renowned for its excellent corrosion resistance and high strength, making it suitable for various irrigation environments. It typically handles high-pressure applications and can withstand temperatures ranging from -40°F to 1500°F (-40°C to 815°C). The material’s durability ensures longevity, reducing the need for frequent replacements.

Pros and Cons: While stainless steel offers superior performance and resistance to rust, it is more expensive than other materials. Its manufacturing complexity can also lead to higher production costs. However, its robustness makes it ideal for high-performance applications, especially in regions with harsh environmental conditions.

Impact on Application: Stainless steel is compatible with a wide range of fluids, including potable water, chemicals, and wastewater, making it versatile for different irrigation needs.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Africa and South America should ensure that the stainless steel used meets local regulations regarding water safety.

How Does Cast Iron Compare for Use in Irrigation Pumps?

Cast iron is a traditional material used in pump manufacturing, known for its excellent wear resistance and ability to handle high pressures. It typically has a temperature rating of up to 400°F (204°C) and can withstand significant mechanical stress.

Pros and Cons: The main advantage of cast iron is its durability and ability to absorb vibration, which extends the life of the pump. However, it is prone to corrosion if not properly coated, which can lead to maintenance issues over time. Additionally, cast iron is heavier, which may complicate installation and transportation.

Impact on Application: Cast iron is suitable for pumping water and other non-corrosive fluids. It is less ideal for applications involving aggressive chemicals.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to enhance corrosion resistance, especially in humid or coastal regions. Compliance with local standards is also essential.

What Role Does Plastic (PVC) Play in Irrigation Pump Systems?

Plastic, particularly PVC, is increasingly popular for irrigation systems due to its lightweight nature and resistance to corrosion. PVC pipes can handle pressures up to 150 psi and temperatures up to 140°F (60°C).

Pros and Cons: The primary advantage of PVC is its cost-effectiveness and ease of installation. However, it may not withstand high temperatures or pressures as effectively as metals. Over time, exposure to UV light can degrade PVC, necessitating protective measures.

Impact on Application: PVC is suitable for transporting water and some chemicals but is not recommended for high-pressure applications or extreme temperatures.

Considerations for International Buyers: Buyers should ensure that PVC materials comply with local standards, such as JIS in Japan or ASTM in the U.S. In regions with high UV exposure, selecting UV-resistant PVC is critical.

How Does Bronze Material Benefit Irrigation Pump Applications?

Bronze is a robust material known for its excellent corrosion resistance, particularly in marine environments. It typically handles pressures up to 300 psi and temperatures up to 400°F (204°C).

Pros and Cons: The main advantage of bronze is its durability and resistance to corrosion, making it suitable for various applications. However, it is generally more expensive than cast iron and PVC, which may be a consideration for budget-conscious buyers.

Impact on Application: Bronze is ideal for applications involving seawater or other corrosive environments, making it a preferred choice in coastal areas.

Considerations for International Buyers: Buyers must consider the higher cost of bronze and ensure compliance with relevant standards for marine applications.

Summary Table of Material Selection for Irrigation Pumps

| Material | Typical Use Case for irrigation pump diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure irrigation systems | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Cast Iron | General irrigation applications | Durable and vibration-absorbing | Prone to corrosion without coating | Medium |

| Plastic (PVC) | Low-pressure water transport | Cost-effective and lightweight | Limited temperature/pressure tolerance | Low |

| Bronze | Marine and corrosive environments | Superior corrosion resistance | Higher cost compared to alternatives | High |

This guide provides a comprehensive overview of material selection for irrigation pump diagrams, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation pump diagram

What Are the Key Stages in the Manufacturing Process of Irrigation Pumps?

The manufacturing process for irrigation pumps involves several critical stages, each designed to ensure the final product meets the required standards for efficiency and durability.

Material Preparation

The first stage is material preparation, where raw materials such as cast iron, stainless steel, and thermoplastics are sourced. Quality of materials is paramount, as it directly affects the pump’s lifespan and performance. Suppliers should provide certification for the materials used, ensuring they meet the required mechanical and chemical specifications.

Forming Techniques Used in Pump Manufacturing

Once the materials are prepared, the forming stage begins. Common techniques include casting, machining, and injection molding. For example, the pump casing is often produced through sand casting, which allows for complex shapes and high durability. Precision machining follows to create the impellers and other critical components, ensuring they fit together seamlessly.

How Is Assembly Conducted in Pump Manufacturing?

The assembly process is where all components come together. Typically, a combination of manual assembly and automated systems is used. During this stage, attention to detail is essential to avoid misalignments that could lead to operational inefficiencies. Workers will often use jigs and fixtures to ensure components are accurately positioned before fastening them together.

What Finishing Processes Are Important for Irrigation Pumps?

Finishing processes, such as surface treatment and painting, are the final stages before the pumps are packaged. These treatments not only enhance the aesthetic appeal but also provide corrosion resistance, crucial for outdoor applications. Quality control checks during this stage ensure that all finishing meets environmental and performance standards.

What Quality Assurance Measures Are Essential in Pump Manufacturing?

Quality assurance (QA) is vital in ensuring that irrigation pumps perform reliably over their intended lifespan. Various international standards and industry-specific certifications guide the QA processes.

Which International Standards Should Buyers Consider?

One of the most recognized international standards for quality management is ISO 9001. Compliance with ISO 9001 signifies that a manufacturer has established a quality management system (QMS) that consistently provides products that meet customer and regulatory requirements. Additionally, certifications like CE mark and API standards are crucial for pumps used in specific applications, especially in Europe and the Middle East.

What Are the Key Quality Control Checkpoints in Pump Manufacturing?

Quality control is typically divided into several checkpoints:

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of incoming materials and components. Suppliers must provide certification and quality reports to demonstrate compliance with standards.

In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves routine checks at various stages to ensure that the manufacturing process is adhering to quality standards. This may include dimensional checks, visual inspections, and functional tests.

Final Quality Control (FQC): Once the assembly is complete, FQC ensures that the finished pump meets all specifications and performance criteria. This often involves pressure testing and performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for making informed purchasing decisions.

What Are Effective Ways to Conduct Supplier Audits?

Conducting supplier audits can provide insight into the manufacturing processes and quality assurance measures in place. Buyers should consider asking for:

Detailed Quality Control Reports: These should outline the processes and metrics used in IQC, IPQC, and FQC.

Third-party Inspection Reports: Engaging a third-party inspection agency can provide an unbiased view of the supplier’s quality control measures. This is particularly useful for international buyers who may not have the resources to perform on-site inspections.

What Nuances Should International Buyers Be Aware Of?

International B2B buyers must also consider regional certifications and compliance requirements that may differ from their home country. For instance, pumps sold in the European market must comply with CE directives, while those in the Middle East may need to meet local regulations. Understanding these nuances helps buyers avoid costly compliance issues and ensures that the products they purchase are suitable for their specific market.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance measures associated with irrigation pumps is invaluable for B2B buyers. Understanding each stage of production—from material preparation to finishing—coupled with rigorous quality control standards and verification methods, can significantly impact the performance and reliability of irrigation systems. By prioritizing quality and compliance, buyers can make strategic purchasing decisions that support their operational needs and long-term objectives.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation pump diagram’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure irrigation pump diagrams. Understanding the technical aspects and ensuring compliance with regional requirements are crucial steps in making informed purchasing decisions. This checklist will help you navigate the complexities of sourcing diagrams, ultimately leading to efficient and effective irrigation solutions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes the type of irrigation system (e.g., surface, drip, or sprinkler), the specific pump capacity, and the desired efficiency levels. Having a detailed specification helps in aligning your needs with the appropriate diagrams, ensuring compatibility with existing infrastructure.

- Key Considerations:

- Flow rate and pressure requirements.

- Type of crops or landscapes being irrigated.

Step 2: Identify Regulatory Compliance

Understand the local and international regulations governing irrigation systems in your target markets. Compliance with safety standards and environmental regulations is vital, especially in regions like Africa and South America, where regulations may vary significantly.

- What to Look For:

- Certifications from recognized authorities.

- Compliance with local installation codes.

Step 3: Research Reliable Suppliers

Conduct thorough research to identify suppliers that offer high-quality irrigation pump diagrams. Focus on companies with a strong reputation in the industry and a history of successful projects in your region.

- Evaluation Criteria:

- Customer reviews and testimonials.

- Experience in your specific irrigation application.

Step 4: Request Detailed Diagrams

Once you’ve shortlisted potential suppliers, request detailed diagrams that illustrate the complete installation process. These diagrams should include critical components like pumps, motors, and control systems to ensure clarity and ease of installation.

- Important Aspects:

- Clarity of the diagram and ease of understanding.

- Inclusion of installation instructions and safety warnings.

Step 5: Verify Technical Support and Training

Assess the level of technical support and training that suppliers provide. A supplier that offers comprehensive training on installation and maintenance can significantly reduce operational risks and enhance system efficiency.

- Support Options:

- On-site training sessions.

- Access to online resources and troubleshooting guides.

Step 6: Evaluate Cost vs. Value

While price is a critical factor, it’s essential to weigh cost against the overall value offered by the diagrams and related support services. Cheaper options may lead to higher long-term costs due to inefficiencies or failures.

- Cost Considerations:

- Total cost of ownership, including installation and maintenance.

- Warranty and support terms.

Step 7: Finalize Contracts and Agreements

Before proceeding with a purchase, ensure that all terms and conditions are clearly laid out in a formal agreement. This should include delivery timelines, payment terms, and any post-purchase support.

- Key Elements:

- Clear definition of deliverables.

- Penalties for non-compliance or delays.

By following this checklist, B2B buyers can ensure a systematic approach to sourcing irrigation pump diagrams, facilitating informed decisions that enhance operational effectiveness in agricultural practices.

Comprehensive Cost and Pricing Analysis for irrigation pump diagram Sourcing

What Are the Key Cost Components in Sourcing Irrigation Pump Diagrams?

When analyzing the cost structure for sourcing irrigation pump diagrams, several components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The primary materials involved in creating irrigation pump diagrams often include high-quality paper or digital formats, inks, and other printing resources. The choice of materials can significantly impact costs; for example, digital formats may reduce printing costs but require investment in software.

Labor: Skilled labor is crucial for accurately designing and creating these diagrams. This cost can vary depending on the complexity of the diagrams and the expertise required. International buyers should consider labor costs in their sourcing locations, as they can differ significantly between regions.

Manufacturing Overhead: Overhead costs encompass utilities, rent, and other indirect expenses related to production. Efficient operations can help minimize these costs, but they remain a critical factor in the overall pricing structure.

Tooling: Depending on the complexity of the diagrams, specialized tools may be required for design and production. These tooling costs can be a significant upfront investment, especially for customized diagrams.

Quality Control (QC): Ensuring that diagrams meet quality standards adds to the overall cost. Regular inspections and adherence to industry standards are necessary to maintain the reliability of the diagrams.

Logistics: Shipping costs can vary based on the destination, size, and weight of the diagrams. For international buyers, understanding shipping methods and potential tariffs is crucial for accurate budgeting.

Margin: Finally, suppliers will incorporate a profit margin into their pricing. This margin can vary based on market demand, competition, and supplier reputation.

How Do Price Influencers Affect Irrigation Pump Diagram Costs?

Several factors influence the pricing of irrigation pump diagrams:

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to cost savings. Suppliers may offer discounts for larger orders, making it essential for buyers to assess their needs and negotiate MOQs.

Specifications and Customization: Custom diagrams tailored to specific requirements typically incur higher costs due to additional design work and materials. Buyers should weigh the benefits of customization against budget constraints.

Materials and Quality Certifications: The choice of materials can influence pricing. High-quality, certified materials may cost more but can enhance the longevity and reliability of the diagrams.

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may command higher prices due to their proven track record, while new entrants may offer lower prices to gain market share.

Incoterms: Understanding Incoterms is vital for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the total cost.

What Are the Best Buyer Tips for Negotiating Costs on Irrigation Pump Diagrams?

Negotiate Effectively: Buyers should approach negotiations with a clear understanding of their requirements and budget. Gathering multiple quotes can provide leverage in negotiations.

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, handling, and potential costs associated with quality issues. A slightly higher upfront cost may lead to savings over time if the product is of higher quality.

Understand Pricing Nuances for International Transactions: Different regions have varying pricing structures, influenced by local labor costs, materials, and demand. Buyers from Africa, South America, the Middle East, and Europe should be mindful of these factors when sourcing.

Stay Informed on Market Trends: Keeping abreast of industry trends can help buyers anticipate price fluctuations and make informed purchasing decisions.

Disclaimer for Indicative Prices

Prices for irrigation pump diagrams are subject to change based on market conditions, supplier pricing strategies, and other factors. Buyers are encouraged to conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing irrigation pump diagram With Other Solutions

Exploring Alternative Solutions to Irrigation Pump Diagrams

In the realm of irrigation systems, visual representations such as irrigation pump diagrams serve as critical tools for understanding installation and operational processes. However, several alternative solutions and methods exist that can also facilitate effective irrigation management. This analysis compares irrigation pump diagrams with two viable alternatives: automated irrigation systems and drip irrigation technology. By evaluating these options, B2B buyers can make informed decisions tailored to their specific agricultural needs.

| Comparison Aspect | Irrigation Pump Diagram | Automated Irrigation Systems | Drip Irrigation Technology |

|---|---|---|---|

| Performance | Clear representation of pump setup; requires manual operation. | High efficiency with programmable settings; can optimize water use. | Highly efficient; reduces water wastage; delivers water directly to roots. |

| Cost | Low initial cost; primarily a design tool. | Higher upfront cost; potential savings in water and labor. | Moderate to high initial cost; long-term savings on water usage. |

| Ease of Implementation | Requires technical knowledge for installation; must comply with local regulations. | Can be complex; often requires professional installation. | Straightforward installation; adaptable to various soil types. |

| Maintenance | Minimal ongoing maintenance; dependent on pump upkeep. | Requires periodic system checks and software updates. | Low maintenance; components may need occasional replacement. |

| Best Use Case | Ideal for traditional farming setups and educational purposes. | Best for large-scale operations needing automation and efficiency. | Optimal for arid regions or water-scarce environments; suitable for various crops. |

What are the Advantages and Disadvantages of Automated Irrigation Systems?

Automated irrigation systems offer advanced technology that allows for precise control over water application. These systems can be programmed to operate at specific times, optimizing water usage based on weather conditions and soil moisture levels. The primary advantage is the reduction in labor costs and water waste, leading to increased efficiency. However, the initial investment can be significant, and the complexity of installation may require professional services, which could be a barrier for some B2B buyers.

How Does Drip Irrigation Technology Compare?

Drip irrigation technology focuses on delivering water directly to the plant roots through a network of tubing and emitters. This method is highly efficient and significantly reduces water wastage compared to traditional irrigation methods. Its adaptability to various soil types and crops makes it a versatile choice for many agricultural operations. However, the initial setup cost can be moderate to high, and while maintenance is generally low, components such as emitters may need to be replaced periodically to ensure optimal performance.

Conclusion: Choosing the Right Solution for Your Irrigation Needs

When selecting the most suitable irrigation solution, B2B buyers must carefully consider their specific requirements, including the scale of their operations, budget constraints, and environmental conditions. While irrigation pump diagrams provide a foundational understanding of pump installations, alternatives such as automated irrigation systems and drip irrigation technology may offer enhanced efficiency and water management. Ultimately, understanding the strengths and limitations of each option will empower buyers to make informed decisions that align with their operational goals and sustainability initiatives.

Essential Technical Properties and Trade Terminology for irrigation pump diagram

What Are the Essential Technical Properties of an Irrigation Pump Diagram?

Understanding the technical properties of irrigation pumps is crucial for B2B buyers, especially when selecting equipment that meets specific agricultural and environmental needs. Here are several key specifications that play a significant role in the performance and efficiency of irrigation pumps:

Flow Rate (GPM or LPM)

The flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates the volume of water that the pump can move within a specific time frame. This specification is vital for ensuring that the pump can meet the irrigation needs of a particular area. A higher flow rate is often required for larger agricultural fields, while smaller operations may need pumps with lower flow rates.Total Dynamic Head (TDH)

Total Dynamic Head refers to the total height that water must be lifted by the pump. It includes the vertical lift, friction losses in the system, and any pressure requirements. Understanding TDH is essential for selecting a pump that can efficiently deliver water to the intended location, particularly in hilly or uneven terrains common in many regions, including parts of Africa and South America.Pump Efficiency

Pump efficiency measures how effectively the pump converts electrical energy into hydraulic energy. A higher efficiency rating means lower operational costs and reduced energy consumption, which is crucial for businesses looking to minimize expenses. It also reflects on the environmental impact, making it an important consideration for sustainability-focused organizations.Material Composition

The materials used in constructing the pump components (e.g., stainless steel, plastic, cast iron) affect durability, resistance to corrosion, and overall lifespan. For instance, pumps made from stainless steel may be more suitable for brackish water applications, while plastic pumps might be used in less demanding environments. Buyers should evaluate the material properties based on the water quality and environmental conditions in their operational areas.Operating Temperature and Pressure

Understanding the operating temperature and pressure range of an irrigation pump is essential for ensuring that it can function effectively under specific environmental conditions. This specification helps buyers select pumps that can withstand extreme temperatures or pressures, which is particularly relevant in regions with varying climates.

What Are Common Trade Terminologies Related to Irrigation Pumps?

Navigating the procurement process for irrigation pumps requires familiarity with industry-specific jargon. Here are several terms that are frequently encountered:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is critical for buyers seeking quality assurance, as OEM products often come with guarantees of compatibility and performance.MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is particularly significant for B2B buyers who need to balance cost efficiency with inventory management. Knowing the MOQ helps businesses plan their purchases and manage cash flow effectively.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This process is essential for buyers to compare pricing, terms, and conditions across multiple vendors, ensuring they receive the best value for their investment.Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping, insurance, and delivery obligations, which can significantly affect overall costs and logistics.VFD (Variable Frequency Drive)

A VFD is a type of motor controller that drives an electric motor by varying the frequency and voltage of its power supply. This technology is crucial for optimizing pump performance and energy efficiency, making it an essential consideration for buyers looking to enhance operational efficiency.Pump Curves

Pump curves are graphical representations showing the relationship between flow rate and head for a specific pump. Understanding pump curves is vital for selecting the right pump for an application, ensuring that it operates within its optimal range and meets the required performance criteria.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when purchasing irrigation pumps, ultimately leading to more efficient and cost-effective operations.

Navigating Market Dynamics and Sourcing Trends in the irrigation pump diagram Sector

What Are the Current Market Dynamics and Key Trends Influencing the Irrigation Pump Diagram Sector?

The irrigation pump diagram sector is experiencing significant transformations driven by several global factors. With increasing agricultural demand, particularly in regions like Africa, South America, and Southeast Asia, there is a growing need for efficient irrigation solutions. The rise of precision agriculture technologies is also contributing to this trend, as farmers seek to optimize water usage and enhance crop yields. Consequently, B2B buyers are increasingly looking for sophisticated pump systems that can integrate with smart technologies, such as IoT sensors and automated control systems, to monitor and manage water flow effectively.

Emerging sourcing trends are heavily influenced by the need for cost-effective and reliable solutions. International buyers are focusing on partnerships with manufacturers that offer comprehensive service packages, including installation diagrams and support for local compliance with safety regulations. Additionally, the demand for modular and adaptable systems is on the rise, allowing for easy upgrades as technology evolves. This adaptability is particularly crucial in regions with varying irrigation needs and infrastructure challenges.

Furthermore, sustainability is becoming a cornerstone of purchasing decisions. Buyers are more inclined to source products that demonstrate energy efficiency and reduced environmental impact, aligning with global sustainability goals. This trend is driving innovation in pump design and materials, prompting suppliers to invest in research and development to meet these new demands.

How Does Sustainability and Ethical Sourcing Impact the Irrigation Pump Diagram Market?

Sustainability and ethical sourcing are critical considerations for international B2B buyers in the irrigation pump diagram sector. Environmental concerns are at the forefront, with increasing scrutiny on the ecological impact of agricultural practices. This has led to a heightened focus on sourcing pumps that are designed with energy efficiency in mind, as well as those that utilize sustainable materials. For instance, pumps that minimize water wastage through improved design and control mechanisms are becoming essential.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers that adhere to fair labor practices and maintain transparency throughout their supply chains. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming crucial differentiators in the market. By prioritizing these certifications, buyers can ensure that their procurement processes not only enhance their operational efficiency but also contribute positively to social and environmental outcomes.

Moreover, the trend towards sustainability is encouraging manufacturers to adopt innovative materials that reduce the carbon footprint of their products. For example, the use of recycled components in pump construction is gaining traction. This shift not only appeals to environmentally conscious buyers but also aligns with global initiatives aimed at promoting sustainable agriculture and reducing climate change impacts.

What Is the Evolution of the Irrigation Pump Diagram Sector?

The irrigation pump diagram sector has evolved significantly over the decades, driven by technological advancements and the increasing need for efficient agricultural practices. In the early days, irrigation systems relied heavily on manual labor and simple mechanical pumps. However, as agricultural practices advanced, so too did the technology behind irrigation pumps. The introduction of electric pumps in the mid-20th century marked a pivotal shift, offering enhanced efficiency and reliability.

In recent years, the focus has shifted towards integrating smart technologies into irrigation systems. This evolution reflects a broader trend in agriculture, where data-driven decision-making is becoming standard practice. Modern irrigation pump diagrams now often incorporate sensors and automated controls, allowing for real-time monitoring and adjustments based on environmental conditions. This evolution not only improves water management but also supports sustainable farming practices by optimizing resource use. As the sector continues to grow, B2B buyers can expect further innovations that will enhance efficiency and sustainability in irrigation practices globally.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation pump diagram

How do I solve installation issues with my irrigation pump?

To resolve installation issues, first ensure that the pump is installed by qualified personnel, adhering to local and national codes. Check that the electrical connections are correct, paying attention to wiring configurations. Consult the installation diagram provided by the manufacturer for guidance. If problems persist, consider engaging a local contractor with experience in irrigation systems to ensure compliance and optimal performance.What is the best type of irrigation pump for agricultural applications?

The best type of irrigation pump depends on the specific application, such as the water source, the required flow rate, and the pressure needed. Common options include centrifugal pumps for high flow rates and submersible pumps for deep well applications. Evaluate the pump’s efficiency, energy consumption, and maintenance requirements to choose the best fit for your agricultural needs.How can I verify the reliability of an irrigation pump supplier?

To verify a supplier’s reliability, conduct thorough research by checking their industry reputation, customer reviews, and case studies. Request references from previous clients and assess their experience with similar projects. It’s also advisable to review their certifications and compliance with international standards to ensure product quality and reliability.What customization options are available for irrigation pump diagrams?

Customization options may include specific configurations tailored to your irrigation system’s requirements, such as pump size, type, and operational features. Suppliers often provide customizable diagrams that can incorporate unique local conditions or specific agricultural needs. Discuss your requirements with the supplier to explore available modifications that enhance performance.What is the minimum order quantity (MOQ) for irrigation pumps?

The MOQ for irrigation pumps can vary significantly among suppliers, often depending on the type and size of the pump. Typically, MOQs can range from a single unit for specialized pumps to multiple units for standard models. It’s essential to clarify these terms with the supplier early in negotiations to ensure alignment with your procurement strategy.What payment terms should I expect when purchasing irrigation pumps internationally?

Payment terms can vary widely by supplier and region but typically include options such as upfront payments, letters of credit, or installment plans. It’s crucial to discuss these terms in detail during negotiations and ensure they align with your financial capabilities. Be aware of potential currency exchange risks and consider using escrow services for large transactions to protect your investment.How can I ensure quality assurance (QA) for my irrigation pumps?

To ensure quality assurance, request detailed documentation from suppliers, including certifications, testing results, and compliance with international standards. Establish a QA plan that includes regular inspections and testing upon receipt of products. Additionally, consider suppliers who offer warranties or guarantees, indicating their confidence in product quality.What logistics considerations should I keep in mind when importing irrigation pumps?

When importing irrigation pumps, consider shipping methods, customs regulations, and potential tariffs. Collaborate with logistics experts to determine the most efficient shipping routes and methods. Ensure that all documentation, such as commercial invoices and packing lists, is accurate and complete to avoid delays. Additionally, factor in lead times for production and shipping when planning your procurement schedule.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Irrigation Pump Diagram Manufacturers & Suppliers List

1. Irrigation Solutions – Automated Drip Tape Systems

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user is looking for help designing an irrigation pump setup for a garden measuring 150 x 75 ft, with plants spaced every 18 inches. They are considering either a gasoline pump or an electric sprinkler pump, with a preference for drip tape irrigation. The system should be fully automated, controlled through timers and float switches. They are open to using 275-gallon IBC totes as water storage …

2. C3Controls – Pump Control Products

Domain: c3controls.com

Registered: 2002 (23 years)

Introduction: c3controls offers a range of pump control products including: Contactors, Overload Relays, Direct-On-Line (DOL) Starters, Enclosed Starters, Miniature Circuit Breakers, Terminal Blocks, Terminal Block Relays, and Pilot Devices. These products are designed for various pump control methods such as variable speed drives, soft starters, and direct-on-line starters, catering to applications in water, w…

3. Irrigation Solutions – Pump Start Relay Wiring

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Irrigation Pump Start Relay Wiring Diagram, related interests include Irrigation Pumps, Sprinkler Pump, Irrigation Controller, Water Timer, Rain Bird Sprinkler, Irrigation Digital Timer, Sprinkler System Electrical Wiring.

4. Drip Depot – Y-Strainer & Basket Strainer

Domain: help.dripdepot.com

Registered: 2005 (20 years)

Introduction: Y-Strainer: A screen mesh inline strainer with drain or flush port to prevent large debris from entering the pump. Installed horizontally with the drain port downwards or vertically with flow direction from the top.

Basket Strainer: Used with centrifugal pumps to filter large debris from the suction hose, connecting easily to the submerged end of the suction line. Available in various materials …

5. Myers – HJ100S Irrigation Pump

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Myers HJ100S irrigation pump, 20A/250V three-prong plug, wires: white (neutral), red (hot), black (hot), bare copper (ground).

Strategic Sourcing Conclusion and Outlook for irrigation pump diagram

As the agricultural landscape continues to evolve, the importance of strategic sourcing for irrigation pump systems becomes increasingly evident. By understanding the intricacies of pump diagrams and installation techniques, B2B buyers can enhance operational efficiency while ensuring compliance with local regulations. Key takeaways include the necessity of selecting the right pump control methods, such as variable frequency drives or soft starters, to optimize performance and reduce energy costs.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, investing in high-quality, well-sourced irrigation pump solutions not only supports sustainable agriculture but also positions businesses for long-term success in competitive markets. The ability to adapt to varying environmental conditions and regulatory standards will be crucial for maintaining operational resilience.

Looking ahead, we encourage B2B buyers to leverage this guide as a foundational resource, enabling informed decision-making and fostering partnerships with reputable suppliers. By prioritizing strategic sourcing in irrigation pump systems, organizations can drive innovation, enhance productivity, and contribute to a more sustainable agricultural future.