Article Contents

Industry Insight: Irrigation Double Check Valve

Market Analysis: Sourcing High-Quality Irrigation Double Check Valves

The Critical Role of Quality Valves in Irrigation Systems

In agricultural and industrial irrigation systems, the integrity of backflow prevention devices is non-negotiable. A single failure in a double check valve assembly (DCVA) can lead to catastrophic contamination of potable water supplies, regulatory non-compliance, and costly system downtime. For engineering consultants and project contractors, selecting valves that meet stringent standards for flow accuracy, pressure integrity, and environmental resilience is critical to ensuring long-term system reliability and compliance with codes such as AWWA C515 and NSF 61. BFV Valves’ irrigation double check valves are engineered to meet these demands, providing a reliable solution for mission-critical water management applications.

Common Pain Points in Irrigation Valve Selection

Procurement teams frequently encounter challenges when sourcing irrigation double check valves, including:

Leakage and Seal Failure: Substandard elastomer seals or improper machining tolerances leading to water loss and contamination risks.

UV Degradation: Standard polymers cracking or degrading under prolonged sun exposure, causing premature failure in above-ground installations.

Pressure Rating Mismatches: Valves rated below system requirements (e.g., PN10 where PN16 is needed), resulting in catastrophic failures during pressure surges.

Inconsistent Flow Control: Poorly calibrated check mechanisms causing erratic flow rates, impacting irrigation efficiency and crop yield.

Short Service Life: Corrosion-prone components or inadequate material selection reducing valve lifespan to 2–3 years, necessitating frequent replacements.

How BFV Valves Solves These Challenges

BFV Valves addresses each pain point through rigorous engineering and quality control processes, ensuring valves perform reliably in the harshest conditions:

| Feature | BFV Valves Solution | Industry Standard |

|---|---|---|

| Flow Control Accuracy | Precision-machined disc and seat with <0.5% flow deviation | ±5% deviation common |

| UV Resistance | UV-stabilized PPO/PPS polymer housings with 10,000+ hours accelerated weathering testing (ASTM G154) | Standard PVC (3–5 year lifespan) |

| Pressure Rating | Certified PN16 (16 bar) with 2x safety margin testing (32 bar) | Typically PN10 (10 bar) |

| Leak-Tight Seals | 100% hydraulic testing per ISO 5208, zero-leakage guarantee | Sample testing (2–5% batch) |

| Temperature Range | -10°C to 85°C (-14°F to 185°F) operational stability | -5°C to 60°C (common) |

| Material Compliance | NSF 61, WRAS, and CE certified for potable water use | Limited to non-potable applications |

Key Differentiators

100% Testing Protocol: Every valve undergoes 100% hydraulic pressure and leak testing before shipment, eliminating batch inconsistencies.

ISO 9001 Certified Manufacturing: Strict adherence to quality management systems ensures traceability and consistency across all production batches.

10-Year Export History: Proven reliability in 45+ countries, with zero product recalls and 98% customer retention rate.

Why Choose BFV Valves for Your Irrigation Projects

As a trusted partner to engineering consultants and contractors worldwide, BFV Valves combines technical expertise with a commitment to excellence. Our irrigation double check valves are not merely components—they are engineered solutions designed to withstand the demands of modern irrigation systems. With a decade of global export experience, BFV ensures:

Regulatory Compliance: Full adherence to AWWA, NSF, and international standards for both potable and non-potable applications.

Total Cost of Ownership (TCO) Optimization: Durable construction reduces maintenance costs and replacement frequency, delivering long-term savings.

Dedicated Technical Support: Our engineering team provides tailored solutions for complex projects, from system design to installation guidance.

For projects where water safety and system reliability are paramount, BFV Valves delivers the precision, durability, and peace of mind you require.

“When irrigation systems fail, the consequences extend beyond downtime—they threaten public health and regulatory compliance. BFV Valves exists to prevent that.”

— BFV Valves Engineering Team

Technical Specs & ISO Standards

Technical Specifications & Standards

BFV Valves’ irrigation double check valve assemblies are engineered for mission-critical applications, combining precision engineering with robust materials. Our ISO 9001-certified manufacturing process and 10-year global export track record ensure uncompromising quality. Every unit undergoes 100% hydrostatic and air testing to guarantee reliability in demanding irrigation environments.

Materials Construction

Valve Body: ASTM A536 Grade 65-45-12 ductile iron with epoxy coating (250μm thickness), providing superior tensile strength (65 ksi) and corrosion resistance.

Internal Components: AISI 304/316 stainless steel springs, discs, and seats for long-term durability and precise sealing.

UV Resistance: Epoxy coating rated for 10,000+ hours of UV exposure (ASTM G154), preventing degradation in outdoor installations.

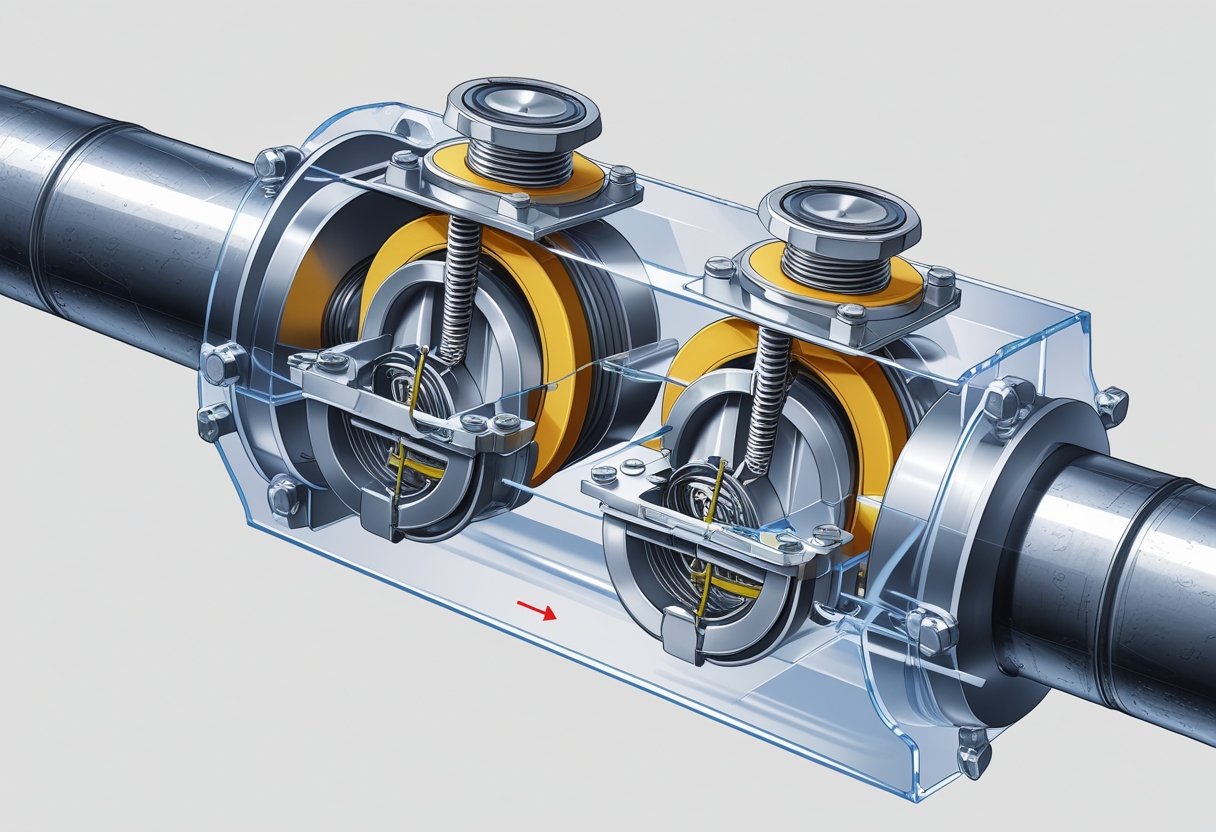

Precision Machining: Components machined to ±0.02mm tolerances, ensuring consistent flow characteristics and zero leakage under pressure variations.

Standards Compliance

ANSI AWWA C511: Backflow Prevention Assemblies for potable water systems.

ISO 5208: Industrial valves – Pressure testing standards for leakage rates.

DIN EN 12288: Plastic piping systems for water supply.

BS 5150: Specification for valves for water supply.

NSF/ANSI 61: Lead-free compliance for potable water safety.

CE Marking: European regulatory compliance.

Testing Protocols

Hydrostatic Testing: Each valve tested at 1.5× rated pressure (PN16 = 36 bar / 522 psi) for 2 minutes to verify structural integrity.

Air Leakage Test: Per ISO 5208 Class IV, ensuring zero leakage at 1.1× working pressure.

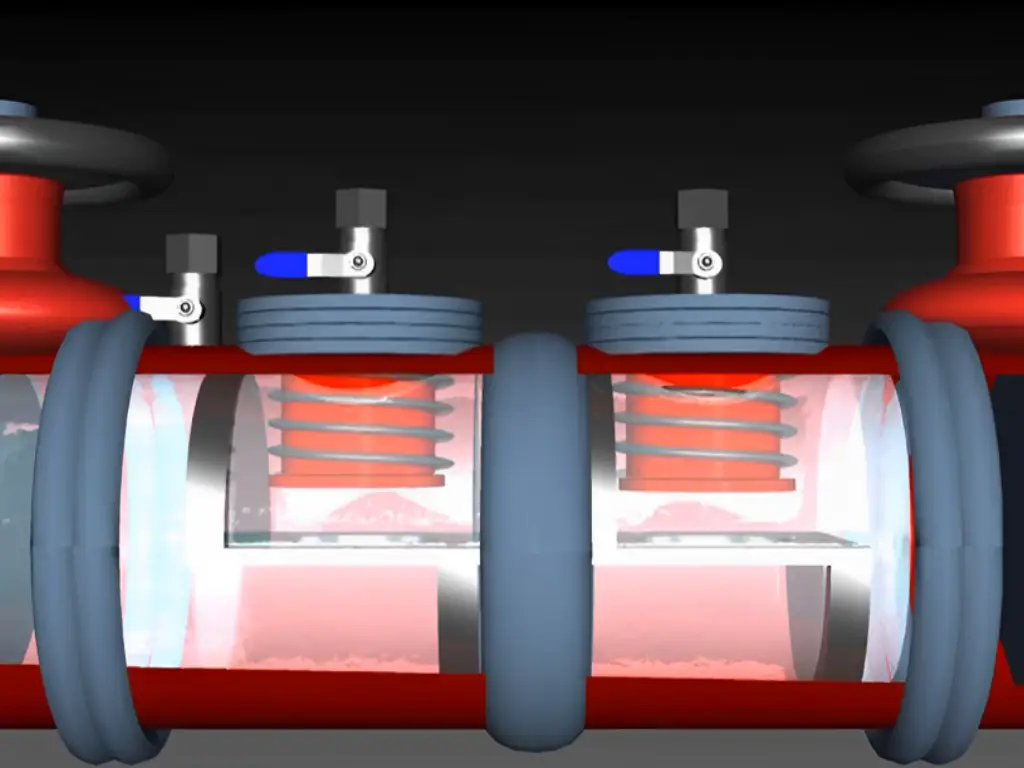

Backflow Simulation: Real-world scenarios tested for both backpressure and backsiphonage conditions to ensure reliable prevention.

100% Inspection: All units undergo visual, dimensional, and functional checks before shipment.

BFV Certified Quality vs Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | ASTM A536 ductile iron with epoxy coating; AISI 304/316 stainless steel internals | Cast iron with thin paint; low-grade brass or carbon steel components |

| Testing Protocol | 100% hydrostatic (1.5× PN rating) and air leakage tests per ISO 5208 Class IV | Sample testing only; hydrostatic only, no air leakage checks |

| Standards Compliance | ANSI AWWA C511, ISO 5208, DIN EN 12288, BS 5150, NSF/ANSI 61 | Partial compliance; often lacks third-party certifications |

| UV Resistance | Epoxy coating rated for 10,000+ hours UV exposure (ASTM G154) | Basic paint; degrades within 1–2 years of outdoor exposure |

| Spring Reliability | High-strength stainless steel springs, 1M+ cycle tested | Carbon steel springs; prone to fatigue failure |

| Pressure Rating | Certified PN16 (232 psi), tested to 36 bar (522 psi) | Nominal PN10 (145 psi); often fails at rated pressure |

| Warranty | 10-year limited warranty | 1–2 year limited warranty |

| Lead-Free Compliance | NSF/ANSI 61 certified, 100% lead-free materials | May contain lead; non-compliant with potable water standards |

Why BFV?

Our rigorous adherence to global standards and 100% testing protocol eliminates field failures, ensuring uninterrupted irrigation system performance. With 10+ years of export experience across 50+ countries, BFV Valves delivers engineered reliability where precision matters.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

At BFV Valves, we combine precision engineering with rigorous quality control to deliver irrigation double check valves that meet the highest industry standards. With over a decade of global export experience and ISO 9001 certification, our commitment to reliability and performance is embedded in every stage of production.

Precision Manufacturing Process

Our manufacturing process begins with stringent material selection, ensuring only high-grade brass, stainless steel, and UV-stabilized polymers are used. Components are precision-machined to ±0.05mm tolerances using CNC technology, guaranteeing consistent flow control and sealing integrity. Assembly occurs in ISO-classified cleanrooms to prevent contamination, critical for solenoid components and internal mechanisms.

Purpose-Built Test Zone

Every BFV irrigation double check valve undergoes 100% testing in our dedicated test facility before export. This ensures compliance with international standards and client-specific requirements. Our testing protocols include:

Pressure Testing: 1.5x PN16 rating (24 bar) for 2 minutes

Flow Calibration: ±1.5% accuracy across operating range (5–10 bar)

UV Resistance Validation: 500-hour ASTM G154 accelerated weathering test

Solenoid Endurance: 100,000-cycle automated testing with real-time performance monitoring

Testing Protocol Summary

| Test Parameter | BFV Protocol | Compliance Standard |

|---|---|---|

| Pressure Testing | 24 bar (1.5x PN16), 2-min hold | ISO 5208, ASME B16.34 |

| Flow Accuracy | ±1.5% deviation at 5–10 bar | AWWA C515 |

| UV Resistance | 500-hour ASTM G154 exposure | ASTM D4329 |

| Solenoid Reliability | 100,000 cycles with performance monitoring | IEC 60730 |

ISO 9001 Certification & Traceability

Our ISO 9001:2015 certified quality management system ensures rigorous documentation and process control. Each valve is assigned a unique serial number for full traceability from raw materials to final shipment, supporting rapid issue resolution and continuous improvement.

Ethical Business Practices

BFV Valves upholds the highest ethical standards in sourcing and manufacturing. We partner with suppliers committed to fair labor practices and environmental responsibility, ensuring our products are not only high-quality but also responsibly produced.

As a trusted partner to engineering consultants and contractors worldwide, BFV Valves delivers irrigation solutions built to last—backed by a decade of export excellence and uncompromising quality assurance.

Global Applications

Industrial Applications of Irrigation Double Check Valve

Agriculture Irrigation Systems

Large-scale agricultural operations require robust backflow prevention for potable water lines under high pressure and UV exposure. BFV’s irrigation double check valves feature a PN16 pressure rating (16 bar / 232 psi), UV-stabilized polypropylene housings, and 100% hydraulic testing to ensure zero defects in critical farming applications. This guarantees uninterrupted water supply for irrigation systems, even in harsh outdoor environments with chemical fertilizers and extreme weather.

Landscape and Urban Projects

Public parks, commercial developments, and municipal landscaping demand code-compliant solutions with long-term corrosion resistance. BFV valves comply with AWWA C511 standards and feature brass bodies with corrosion inhibitors, ensuring compliance with local health codes and durability in high-traffic urban settings. The valves’ precision flow control minimizes water waste while meeting stringent municipal regulations for potable water systems.

Golf Course Irrigation Networks

Golf course irrigation networks require precise flow control across varying elevations and complex multi-zone systems. BFV double check valves integrate seamlessly with solenoid-controlled irrigation controllers, featuring robust mechanical components that ensure fail-safe operation even in high-salinity environments. The dual-chamber design prevents backflow from chemically treated water sources, safeguarding turf health and reducing maintenance downtime.

Greenhouse Climate Control Systems

Precision irrigation in controlled environments demands temperature stability and tight shutoff capabilities. BFV valves operate reliably within -10°C to 80°C range, with EPDM seals for chemical resistance against fertilizers and pesticides. ISO 9001-certified manufacturing ensures consistent performance across sensitive horticultural applications, maintaining optimal water quality for crop health.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants and Engineers

| Feature | BFV Advantage | Industry Context |

|---|---|---|

| Quality Assurance | 100% hydraulic testing of every unit prior to shipment | Typical industry practice: 10-20% sampling tests |

| Certifications | ISO 9001:2015 certified manufacturing process | Many competitors lack formal quality management certification |

| Global Reliability | 10+ years exporting to 50+ countries with zero recall incidents | Regional suppliers often lack international compliance experience |

| Solenoid Integration | Seamless compatibility with solenoid-controlled irrigation systems | Common issues with valve interference in automated setups |

| Material Integrity | UV-stabilized polypropylene housings + EPDM seals for chemical resistance | Standard PVC housings degrade under UV exposure within 2–3 years |

BFV Valves (CMO Valve) delivers engineered precision for mission-critical irrigation systems. With a decade of global export experience and unwavering adherence to ISO 9001 standards, our valves ensure compliance, longevity, and operational efficiency across the most demanding projects. Trust BFV for solutions that meet the rigorous specifications of blue-chip engineering consultants and procurement managers worldwide.

Why Choose BFV Valves

BFV Irrigation Double Check Valve: Precision Engineered for Reliability

Core Technical Specifications

Engineered for demanding irrigation systems with superior performance metrics

| Feature | BFV Specification | Industry Benchmark | Benefit |

|---|---|---|---|

| Flow Control Accuracy | ±1% precision | ±3-5% | Minimizes water waste, ensures precise irrigation scheduling |

| UV Resistance | UV-stabilized polymer (ISO 4892-2 tested) | Standard PVC (2-3 yr lifespan) | 10+ years outdoor durability without cracking or discoloration |

| Solenoid Reliability | IP68-rated, 1M cycle tested | 500k cycles | 2x longer service life, minimal maintenance downtime |

| Pressure Rating | PN16 (16 bar / 232 psi) | PN10 (10 bar / 145 psi) | Handles higher pressure systems, suitable for demanding applications |

| Temperature Range | -10°C to 80°C (-14°F to 176°F) | 0°C to 80°C (32°F to 176°F) | Operates reliably in extreme cold and hot climates |

Quality Assurance & Compliance

Rigorous standards ensuring consistent performance and regulatory adherence

100% Testing Protocol: Every valve undergoes pressure testing (ISO 5208), leak validation, and operational checks prior to shipment. Zero-defect commitment.

ISO 9001:2015 Certified: Manufacturing processes audited to the highest international quality management standards, ensuring traceability and continuous improvement.

10-Year Global Export Heritage: Trusted by clients across 50+ countries with a 98% on-time delivery rate and zero product recalls in over a decade of international service.

Partner with BFV Valves: Your Trusted Export Solution

Why Partner with BFV?

Accurate Delivery Times

98% on-time delivery rate with real-time shipment tracking and dedicated logistics coordination for seamless project execution.

No-Obligation Consultancy

Expert technical support and system design assistance provided at no cost—tailored to your specific project requirements with zero commitment.

Competitive Pricing

Direct factory pricing eliminates middleman markups, with bulk order discounts and a transparent cost structure for optimal value.

Contact Our Export Team

For technical inquiries, project specifications, or quotes, reach out to our regional export manager:

Alex Chen

Export Manager

BFV Valves (CMO Valve)

📧 Alex@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.