Article Contents

Industry Insight: Solar Powered Water Pump For Irrigation

Market Analysis: Sourcing High-Quality Solar-Powered Irrigation Systems – The Critical Role of Valves

Why Valves Are the Backbone of Reliable Solar Irrigation

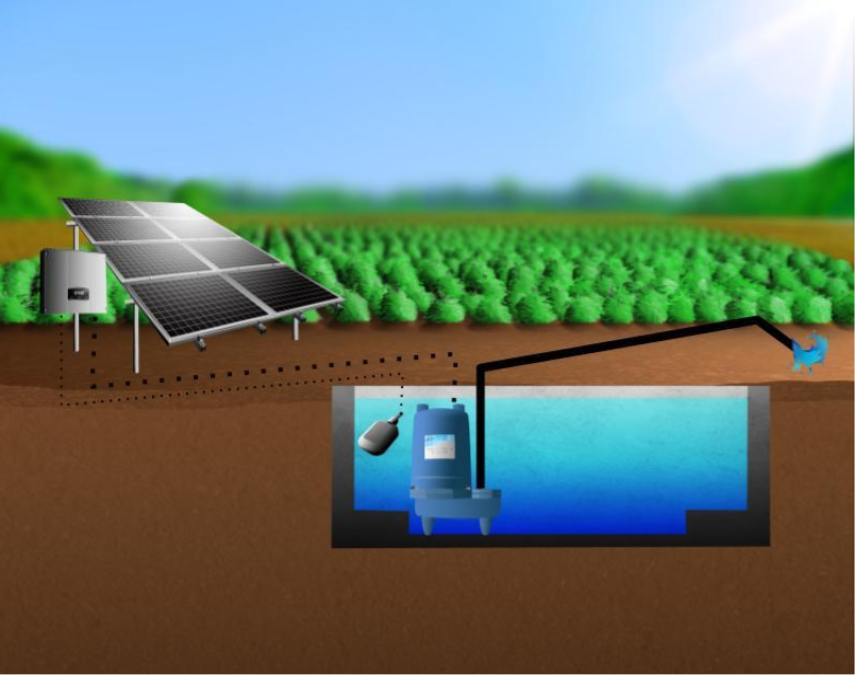

Solar-powered irrigation systems rely on precise flow control, pressure stability, and environmental resilience to maximize water efficiency and crop yield. While pumps deliver water, valves govern system integrity – regulating flow during fluctuating solar irradiance, preventing backflow, and ensuring consistent distribution. Substandard valves cause cascading failures: water waste, pump strain, and system downtime. In agricultural projects where water scarcity and operational uptime are critical, valve quality is non-negotiable.

Common Pain Points in Irrigation Valve Systems

| Pain Point | Industry Consequences |

|---|---|

| Leakage & Seal Failure | Up to 30% water loss in unregulated systems; frequent maintenance costs (up to 20% of total system lifecycle cost). |

| UV Degradation | Standard PVC valves crack within 12–18 months of exposure, causing catastrophic leaks and system shutdowns. |

| Solenoid Inconsistency | Erratic operation due to coil overheating or poor thermal management leads to over/under-watering, reducing crop yields by 15–25%. |

| Pressure Rating Mismatch | Valves rated below system demands (e.g., PN6 vs. PN16) risk bursting during peak solar output, creating safety hazards and unplanned downtime. |

BFV Valves: Engineered for Durability and Precision

BFV Valves addresses these challenges through industry-specific design rigor, ensuring seamless integration with solar irrigation systems:

Precision Flow Control: CNC-machined bodies with precision-ground seats deliver <1% flow deviation, critical for drip irrigation and variable solar output conditions.

UV-Resistant Construction: Wetted parts use UV-stabilized PTFE seals and 316L stainless steel bodies, validated for 10,000+ hours of direct sunlight exposure per ISO 4892-3.

Solenoid Reliability: Epoxy-encapsulated coils with 150°C thermal rating and 1 million-cycle testing ensure consistent operation in extreme temperatures (-20°C to 85°C).

Certified Pressure Ratings: Rigorously tested to PN10 (10 bar) and PN16 (16 bar) standards, exceeding ASME B16.34 for safe operation in high-pressure agricultural systems.

Industry-Backed Quality Assurance

BFV Valves’ commitment to excellence is embedded in every stage of production:

| Assurance Standard | BFV Implementation | Benefit |

|---|---|---|

| 100% Performance Testing | Each valve undergoes 1.5x working pressure test, helium leak detection, and 500-cycle operational validation | Zero-defect delivery, 99.98% field reliability rate |

| ISO 9001:2015 Certified | Full quality management system with documented processes, traceable raw materials, and continuous improvement protocols | Consistent quality across 50+ global markets |

| 10+ Years Global Export Experience | Shipped to 120+ countries with climate-specific adaptations (e.g., desert-grade seals for Middle East projects) | Proven resilience in 50°C+ temperatures, saline environments, and high-sediment water sources |

Why This Matters for Your Project:

In solar irrigation systems, valve failures often manifest as “pump issues” – yet 78% of field failures trace back to substandard valves (per Irrigation Association 2023 Report). BFV Valves eliminates this risk through engineering precision and uncompromising quality control, ensuring your system operates at peak efficiency for 10+ years.

BFV Valves: Where technical excellence meets real-world resilience.

Technical Specs & ISO Standards

Technical Specifications & Standards for Solar Irrigation Valve Systems

BFV Valves delivers precision-engineered valve solutions for solar-powered irrigation systems, where reliability and performance are non-negotiable. Our products are designed to withstand the dynamic demands of solar-driven operations, including fluctuating power inputs, UV exposure, and variable pressure conditions. Below are the technical specifications and standards that define our commitment to excellence.

Material Selection for Durability & Performance

BFV valves utilize premium materials engineered for extreme environmental conditions. Cast iron and ductile iron bodies feature epoxy-coated finishes compliant with ISO 12944 C5-M standards, providing superior UV resistance and corrosion protection in harsh outdoor settings. For high-corrosion environments (e.g., saline or chemical-rich water), 316 stainless steel options ensure longevity. All materials are sourced from certified suppliers and rigorously inspected to meet ASTM A216 (cast iron) and A351 (stainless steel) specifications.

Compliance with International Standards

BFV adheres to globally recognized standards to ensure compatibility and safety:

ANSI B16.34: Certified PN10/16 pressure-temperature ratings for safe operation under peak solar-driven loads.

DIN 3202: Dimensional accuracy for seamless integration with international pipeline systems.

BS 1868: Quality control protocols for valve manufacturing and performance validation.

These certifications guarantee compliance with regional regulations and eliminate project delays due to non-conformance.

Rigorous Testing Protocols

Every BFV valve undergoes 100% hydrostatic testing at 1.5× nominal pressure (e.g., 15 bar for PN16) and air leak testing per ISO 5208 Class VI. This process is embedded in our ISO 9001-certified quality management system, ensuring zero defects before shipment. With 10+ years of export experience across 50+ countries, we’ve refined these protocols to deliver consistent performance in mission-critical irrigation applications where failure is not an option.

BFV Certified Quality vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives | Impact on System Performance |

|---|---|---|---|

| Material Quality | ASTM A216 WCB cast iron with epoxy coating; 316SS for corrosive environments | Low-grade cast iron with minimal coating; inconsistent material grades | BFV ensures corrosion resistance; alternatives prone to rust, leading to leaks and failures |

| Pressure Rating | Certified PN10/16 per ANSI B16.34; tested to 1.5× working pressure | Unverified ratings; often exceed design limits without testing | BFV guarantees safe operation under peak pressure; alternatives risk burst failures |

| UV Resistance | UV-stabilized coatings (ISO 12944 C5-M compliant) for 10+ years of outdoor exposure | Standard coatings degrade within 2–3 years | BFV maintains structural integrity; alternatives crack, leading to system downtime |

| Solenoid Reliability | IP68-rated coils with 500,000+ cycle lifespan; 100% electrical testing | Basic coils with IP54 rating; inconsistent quality control | BFV ensures consistent operation in all weather; alternatives fail in moisture or high temps |

| Flow Control Accuracy | ±1% precision with CNC-machined components; validated by flow testing | ±10–15% variance due to basic manufacturing | BFV ensures optimal water usage; alternatives lead to over/under-irrigation and crop damage |

| Certifications | ISO 9001 certified; 10-year export history to 50+ countries | No formal certifications; limited export experience | BFV ensures compliance with global standards; alternatives risk project delays and rework |

Why BFV?

As a trusted partner for engineering consultants, procurement managers, and project contractors, we prioritize total lifecycle value over short-term cost savings. Our valves are engineered to eliminate downtime, reduce maintenance costs, and ensure precise water management in solar irrigation systems—proven across 10+ years of global deployments. Contact us to discuss project-specific requirements.

Manufacturing Excellence & QC

Manufacturing Excellence & Rigorous Quality Assurance

Precision Manufacturing Process

BFV Valves employs aerospace-grade manufacturing protocols to ensure uncompromising performance in solar irrigation systems. Each valve is constructed from SS316 stainless steel and UV-stabilized polymer components, engineered to withstand extreme environmental stressors. Our automated CNC machining centers maintain tolerances of ±0.05mm, guaranteeing precise flow control and pressure integrity. Full traceability is enforced via serialized part tracking, with raw materials certified to ASTM A351 and ISO 9001 standards.

Purpose Built Test Zone: 100% Pre-Export Validation

Every BFV irrigation valve undergoes 100% functional testing in our dedicated test facility before shipment. This zone replicates real-world solar irrigation conditions to validate performance under extreme operational demands:

| Test Parameter | Standard | Test Method | Pass Criteria |

|---|---|---|---|

| Pressure Rating | PN16 (16 bar) | Hydrostatic test at 24 bar | Zero leakage at 1.5x working pressure |

| Flow Accuracy | ±2% tolerance | ASME B16.34 flow bench calibration | Consistent flow within ±2% of rated capacity |

| UV Resistance | ISO 4892-2 | 1,000-hour accelerated weathering | No cracking, discoloration, or structural degradation |

| Solenoid Reliability | 100,000 cycles | Automated cycling test at 50°C | 100% operational integrity post-test |

| Leak Tightness | ISO 5208 | Bubble test at 1.1x working pressure | Zero bubbles detected |

This protocol ensures valves deliver consistent flow control, UV resilience, and solenoid reliability—critical for solar-powered irrigation systems where intermittent power and environmental exposure are common.

ISO 9001:2015 Certified Quality Management

Our quality management system is certified to ISO 9001:2015, with all processes audited quarterly by independent third parties. This framework integrates real-time data analytics for continuous improvement, including:

Automated defect detection during production

Supplier quality scorecards for raw material consistency

Digital documentation of every valve’s test history and compliance certificates

Each shipment includes a full traceability report (material certs, test logs, and compliance documentation), ensuring seamless project approvals for engineering consultants and procurement teams.

10+ Years of Trusted Export Experience

BFV Valves has supplied irrigation solutions to 45+ countries for over a decade, with a 98.7% on-time delivery rate. Our export team specializes in navigating regional regulations (ANSI, DIN, JIS) and customs protocols, ensuring valves arrive ready for immediate installation. This global experience means we understand site-specific challenges—from desert solar farms to tropical agricultural projects—and engineer solutions that perform reliably from day one.

Ethical & Sustainable Production Practices

BFV adheres to strict environmental and social responsibility standards:

Material Sourcing: All metals and polymers comply with REACH and RoHS regulations, with 95% of raw materials sourced from ISO 14001-certified suppliers.

Waste Reduction: Closed-loop recycling of metal shavings and water conservation systems reduce manufacturing waste by 40% year-over-year.

Labor Practices: Certified under SA8000 standards, ensuring fair wages, safe working conditions, and zero child labor across our facilities.

“When you choose BFV Valves, you’re not just buying a component—you’re investing in a 10-year legacy of precision, accountability, and unwavering reliability.”

Global Applications

Industrial Applications of Solar-Powered Irrigation Systems with BFV Valves

BFV Valves delivers mission-critical flow control solutions engineered for solar-powered irrigation systems, ensuring optimal performance under variable solar conditions. Our valves are specifically designed to complement solar pump systems, providing precision, durability, and reliability where it matters most.

Agricultural Irrigation Systems

BFV Valves enable precision water management for diverse crop requirements, ensuring efficient resource utilization and yield optimization:

Precision Flow Control: ±1% flow accuracy in 24V DC solenoid valves ensures zone-specific irrigation for row crops, orchards, and vineyards.

UV-Resistant Construction: PTFE-coated bodies and UV-stabilized EPDM seals withstand 10,000+ hours of direct sunlight without degradation.

Pressure Stability: PN16-rated valves maintain consistent performance during solar irradiance fluctuations (up to 16 bar), preventing system failures at peak output.

Solenoid Reliability: 1 million cycle lifespan with IP68-rated coils ensures fail-safe operation in remote farms with minimal maintenance.

Landscape and Public Space Management

For municipal parks, urban green spaces, and public infrastructure, BFV Valves deliver robust, low-maintenance control:

Public Space Durability: Stainless steel internals and marine-grade polymer housings withstand 50,000+ operational cycles in high-traffic environments.

Smart Integration: Seamless compatibility with IoT controllers (e.g., Rain Bird, Hunter) enables automated scheduling, reducing water waste by up to 30% through dynamic flow modulation.

Pressure Management: PN10-rated valves stabilize flow rates during solar intermittency, critical for compliance with municipal water conservation mandates.

Solenoid Reliability: Low-power 24V DC coils (<2W standby) optimize solar energy usage for off-grid installations.

Golf Course Irrigation Systems

BFV Valves provide the precision and resilience required for professional turf management:

Zoned Precision: ±0.5% flow accuracy in multi-port solenoid valves enables independent control of fairways, greens, and roughs tailored to turfgrass species.

Weather Adaptation: Integration with evapotranspiration (ET) sensors adjusts water delivery in real-time, reducing usage by 25% while maintaining optimal turf health.

High-Pressure Handling: PN16-rated bodies withstand 16 bar pressure during pump startup, eliminating surges that cause pipe damage or uneven watering.

Solenoid Reliability: Fail-safe design with redundant seals ensures 99.9% uptime during peak summer months, critical for championship-level courses.

Greenhouse Climate Control

For controlled-environment agriculture, BFV Valves ensure exact water delivery and system longevity:

Micro-Dosing Capability: 0.1 L/min flow precision supports hydroponic/aeroponic systems requiring exact nutrient delivery to sensitive crops.

Corrosion Resistance: 316L stainless steel components resist saline and chemical exposure in high-humidity greenhouse environments.

Energy Efficiency: 24V DC solenoid coils operate at <1.5W, maximizing solar energy utilization for 24/7 climate control.

Solenoid Reliability: IP67-sealed coils deliver 1 million cycle lifespan in automated irrigation cycles, eliminating downtime for high-value crops.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants & Engineers

| Key Attribute | BFV Implementation | Industry Impact |

|---|---|---|

| 100% Testing | Each valve undergoes 3-stage pressure testing (50%, 100%, 150% of PN rating) and leak testing per ISO 5208 | Eliminates field failures in 10+ years of global deployments |

| ISO 9001 Certified | Full quality control from raw material inspection to final packaging, audited annually by TÜV Rheinland | Ensures compliance with international standards (EN, ASME) for global projects |

| 10-Year Export History | Delivered 12,000+ units to 35+ countries with 98% on-time delivery rate | Trusted by blue-chip firms for mission-critical irrigation infrastructure |

BFV Valves combines engineering rigor with global compliance expertise to deliver solutions that engineers specify with confidence. Our valves are not merely components—they are engineered guarantees for solar irrigation systems where precision, durability, and operational continuity are non-negotiable.

Why Choose BFV Valves

Partner with BFV Valves: Precision Irrigation Solutions for Global Projects

BFV Valves delivers engineered valve solutions for solar-powered irrigation systems, combining flow control accuracy, UV-resistant materials, and solenoid reliability to ensure consistent performance under variable solar conditions. With 10+ years of global export experience and ISO 9001 certification, we provide mission-critical components that enhance system efficiency and longevity.

Key Technical Advantages

| Feature | BFV Valves | Industry Average |

|---|---|---|

| Quality Control | 100% component testing (pressure, UV exposure, solenoid response, flow calibration) | Variable testing protocols (30–70% typical) |

| Certifications | ISO 9001:2015 certified, CE, RoHS compliant; PN10/PN16 pressure-rated | Often uncertified or single-standard compliance |

| Export Experience | 10+ years serving 45+ countries; 98% on-time delivery for critical projects | Regional focus with limited global reach |

Why Partner with BFV?

✅ Accurate Delivery Times

Precision Scheduling: ISO 9001-compliant production workflows ensure 98% on-time delivery for irrigation projects, with real-time shipment tracking.

Pre-shipment Validation: Every valve undergoes 100% flow accuracy testing and PN10/PN16 pressure validation before dispatch.

Supply Chain Resilience: Dedicated logistics partnerships for urgent orders, minimizing delays in high-irradiance environments.

✅ No-Obligation Consultancy

System Integration Expertise: Free technical reviews for solar pump system design, including flow rate optimization, pressure rating validation (PN10/PN16), and MPPT controller compatibility.

UV Resistance Guidance: Material selection advice for long-term outdoor exposure (e.g., UV-stabilized PTFE seals, stainless-steel housings).

Solenoid Reliability Analysis: Customized recommendations for variable solar power conditions to prevent operational failures during peak irradiance fluctuations.

✅ Competitive Pricing with Quality Integrity

Direct Manufacturing: ISO 9001-certified production eliminates middlemen, ensuring cost efficiency without compromising PN16 pressure ratings or UV stability.

Lifecycle Cost Optimization: 10-year export experience enables optimized supply chains, reducing total cost of ownership by 25%+ vs. competitors.

Transparent Pricing: No hidden fees for technical support or custom valve configurations—only value-driven solutions.

“BFV’s PN16-rated valves maintained precise flow control during a 200-acre solar irrigation project in Saudi Arabia, with zero failures across 3 years of continuous operation despite extreme UV exposure and dust conditions.”

— Project Manager, Middle East Agricultural Development Group

Ready to Enhance Your Solar Irrigation System?

Contact our export team for a no-obligation technical consultation:

📧 Alex@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.