Introduction: Navigating the Global Market for golf course irrigation pumps

In the competitive world of golf course management, selecting the right irrigation pump system is a critical decision that can greatly influence both operational efficiency and course quality. As international buyers navigate the global market for golf course irrigation pumps, they often face the challenge of sourcing reliable, cost-effective solutions that meet their specific needs. This comprehensive guide is designed to empower B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, by providing essential insights into the types, applications, and benefits of various irrigation pump systems.

Within these pages, you will find a detailed exploration of the different pump technologies available, such as vertical turbine, horizontal centrifugal, and submersible turbine pumps, each tailored for specific irrigation scenarios. Additionally, the guide offers critical information on supplier vetting processes, enabling you to identify reputable manufacturers and service providers. Cost considerations, maintenance options, and the latest technological innovations in the field will also be addressed, equipping you with the knowledge needed to make informed purchasing decisions.

By leveraging the insights presented in this guide, B2B buyers can streamline their procurement processes, ensuring that their golf course irrigation systems not only meet regulatory standards but also contribute to sustainable water management practices. Ultimately, this resource is your roadmap to navigating the complexities of sourcing high-quality golf course irrigation pumps in a diverse and evolving marketplace.

Understanding golf course irrigation pumps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical Turbine Pumps | High flow rates, submerged installation, efficient for deep water sources | Large golf courses with deep wells | Pros: High efficiency, durable; Cons: Higher initial cost, complex installation. |

| Horizontal Centrifugal Pumps | Ideal for surface water, compact design, cost-effective | Courses relying on lakes or reservoirs | Pros: Lower cost, easy maintenance; Cons: Limited to surface applications, may require priming. |

| Submersible Pumps | Compact, quiet operation, no priming needed | Smaller courses or areas with limited space | Pros: Space-saving, low noise; Cons: Limited flow rates, potential for debris issues. |

| Booster Pump Stations | Increases water pressure for irrigation systems | Courses needing high pressure for specific areas | Pros: Enhances system efficiency; Cons: Additional energy costs, requires careful integration. |

| Retrofit Pump Panels | Upgrades existing systems with modern technology | Courses with outdated pump stations | Pros: Cost-effective upgrade option; Cons: Compatibility issues with older systems. |

What Are the Key Characteristics of Vertical Turbine Pumps?

Vertical turbine pumps are designed for high flow rates and are typically installed in deep water sources. These pumps feature a submerged design, which allows them to operate efficiently even in challenging conditions. They are particularly suitable for large golf courses that require a consistent and high-volume water supply. B2B buyers should consider the initial investment and installation complexity, as these pumps tend to be more expensive and require specialized setup.

How Do Horizontal Centrifugal Pumps Function?

Horizontal centrifugal pumps are favored for their compact design and cost-effectiveness, making them ideal for golf courses that utilize surface water sources like lakes or reservoirs. They are easier to maintain compared to vertical turbine pumps and do not require priming, which simplifies operation. However, they may have limitations in high-pressure applications and are best suited for courses that do not need extreme pressure.

Why Choose Submersible Pumps for Smaller Golf Courses?

Submersible pumps are compact and operate quietly, making them an excellent choice for smaller golf courses or areas with limited space. They eliminate the need for priming and are generally easier to install. However, their flow rates may not match those of larger systems, and they can be susceptible to debris clogging. Buyers should weigh the benefits of space-saving and noise reduction against the potential for reduced capacity.

What Are the Benefits of Booster Pump Stations?

Booster pump stations are essential for golf courses that require increased water pressure for specific irrigation areas. These systems enhance the efficiency of existing irrigation setups, allowing for better water distribution. While they can improve performance, buyers must consider the additional energy costs and the need for careful integration with existing systems to avoid operational issues.

How Can Retrofit Pump Panels Improve Existing Systems?

Retrofit pump panels provide a modern upgrade for outdated irrigation systems, incorporating advanced technology like variable frequency drives (VFDs) and programmable logic controllers (PLCs). This option is particularly appealing for golf courses looking to enhance efficiency without the cost of a complete system overhaul. However, compatibility with older systems can be a concern, necessitating thorough evaluation before purchase.

Key Industrial Applications of golf course irrigation pumps

| Industry/Sector | Specific Application of Golf Course Irrigation Pumps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Golf Course Management | Automated irrigation systems for maintaining turf quality | Ensures optimal playing conditions, reducing maintenance costs | Reliability, energy efficiency, and compatibility with existing systems |

| Landscape Architecture | Irrigation for golf course landscaping and aesthetics | Enhances visual appeal and environmental sustainability | Customization options and adaptability to diverse environments |

| Agriculture | Water management for golf course-related agricultural projects | Maximizes water efficiency and crop yield in adjacent farmland | Durability in various climates and ease of maintenance |

| Sports Facility Management | Irrigation for multi-sport facilities adjacent to golf courses | Provides consistent water supply for diverse sporting activities | Integration with advanced monitoring and control systems |

| Environmental Management | Sustainable water use practices in golf course operations | Promotes ecological balance and compliance with regulations | Source water quality and environmental impact assessments |

How Are Golf Course Irrigation Pumps Applied in Golf Course Management?

Golf course management relies heavily on automated irrigation systems powered by specialized pumps to maintain turf quality. These pumps ensure that water is distributed evenly across greens, tees, and fairways, optimizing playing conditions. For international buyers, especially in regions like Africa and the Middle East where water scarcity is a concern, selecting energy-efficient pumps that minimize water waste is crucial. Additionally, systems that offer remote monitoring and control can significantly enhance operational efficiency.

What Role Do Golf Course Irrigation Pumps Play in Landscape Architecture?

In landscape architecture, golf course irrigation pumps are used to manage the irrigation of surrounding landscapes, enhancing the visual appeal and sustainability of the course. These pumps help maintain the health of ornamental plants and other landscaping features that contribute to the aesthetic value of the course. Buyers should consider customization options to meet specific environmental conditions and ensure the pumps can adapt to various soil types and plant needs.

How Are Golf Course Irrigation Pumps Used in Agriculture?

Golf courses often coexist with agricultural projects, and irrigation pumps are essential for managing water resources effectively. These pumps facilitate precise water application, which is vital for maximizing crop yield in adjacent farmland. For agricultural applications, buyers must focus on the durability of the pumps in different climates, especially in regions like South America where seasonal variations can be extreme. Pumps that support sustainable water management practices are increasingly sought after.

How Do Golf Course Irrigation Pumps Benefit Sports Facility Management?

In multi-sport facilities that incorporate golf courses, irrigation pumps play a critical role in providing consistent water supply for various sporting activities. This ensures that all areas remain playable and visually appealing. For facility managers, integrating advanced monitoring systems with these pumps can offer real-time data on water usage, allowing for better resource management. Buyers should prioritize pumps that offer easy integration with existing infrastructure and provide reliable service support.

What Environmental Considerations Are Associated with Golf Course Irrigation Pumps?

Environmental management practices are becoming increasingly important in golf course operations. Golf course irrigation pumps contribute to sustainable water use, promoting ecological balance. Buyers need to assess the quality of source water and the potential environmental impacts of their irrigation systems. Selecting pumps that comply with local regulations and support eco-friendly practices is essential, especially in Europe, where environmental standards are stringent.

3 Common User Pain Points for ‘golf course irrigation pumps’ & Their Solutions

Scenario 1: Inconsistent Water Pressure Leading to Uneven Irrigation

The Problem: A common challenge faced by golf course managers is the inconsistency in water pressure delivered by their irrigation pumps. This inconsistency can lead to uneven watering of greens, fairways, and tee boxes, resulting in patchy grass growth, poor playing conditions, and dissatisfied golfers. Factors such as fluctuating water levels in reservoirs or lakes, pump wear and tear, and inadequate pump capacity contribute to this issue. The inability to maintain optimal pressure not only affects the aesthetics of the course but can also lead to increased maintenance costs and labor hours spent on rectifying the damage caused by over or under-watering.

The Solution: To address inconsistent water pressure, golf course managers should consider investing in a variable frequency drive (VFD) system for their irrigation pumps. VFDs allow for real-time adjustments to the pump speed based on current demand, ensuring that water pressure remains consistent across the entire irrigation system. When sourcing a pump station, it’s vital to specify models that are compatible with VFD technology and can accommodate fluctuations in water levels. Furthermore, implementing a robust monitoring system, such as Rain Bird’s MCA (Monitor-Control-Alert), will enable operators to track real-time performance, receive alerts for pressure anomalies, and optimize water usage. Regular maintenance checks and pump station evaluations can also prevent performance issues before they escalate.

Scenario 2: High Energy Costs from Inefficient Pump Operations

The Problem: Energy costs represent a significant portion of the operational budget for golf course irrigation systems. Inefficient pumps can lead to excessive electricity consumption, raising operational costs and impacting profitability. Factors such as outdated pump technology, improper sizing of pumps for specific applications, and lack of energy-efficient design contribute to this challenge. Golf course managers may find themselves paying more than necessary to maintain optimal irrigation levels, which can be particularly burdensome in regions where electricity costs are high.

The Solution: To combat high energy costs, golf course managers should prioritize the selection of energy-efficient pump systems. When evaluating options, look for pumps that utilize advanced technology, such as horizontal centrifugal pumps with high-efficiency motors and VFDs. Additionally, conducting an energy audit of the current irrigation system can help identify inefficiencies and areas for improvement. Implementing a phased replacement strategy for older pumps with newer, more efficient models can lead to substantial long-term savings. Furthermore, establishing a maintenance schedule that includes regular inspections of pump components will ensure that systems operate at peak efficiency, further reducing energy consumption.

Scenario 3: Challenges with Pump Maintenance and Downtime

The Problem: Golf course irrigation systems require consistent maintenance to ensure optimal performance. However, many managers struggle with unplanned downtime due to pump failures, which can lead to inadequate irrigation during critical growing periods. Factors such as lack of access to spare parts, inefficient service support, and the complexity of pump systems can exacerbate maintenance challenges. This can be particularly problematic in remote areas where service providers are not readily available, leading to extended periods without proper irrigation and negatively impacting course conditions.

The Solution: To mitigate maintenance challenges and minimize downtime, golf course managers should establish a comprehensive maintenance plan that includes regular inspections, predictive maintenance practices, and a reliable service support network. Partnering with a reputable pump manufacturer that offers a global service plan can provide access to trained technicians and spare parts, ensuring quick resolution of issues. Additionally, investing in smart technology that allows for remote monitoring and diagnostics can help identify potential problems before they lead to failures. Creating a relationship with local service providers who understand the specific needs of golf course irrigation can also enhance response times and reliability in maintenance support. Regular training for staff on pump operation and maintenance will empower them to handle minor issues proactively, further reducing reliance on external service providers.

Strategic Material Selection Guide for golf course irrigation pumps

What Are the Key Properties of Common Materials Used in Golf Course Irrigation Pumps?

When selecting materials for golf course irrigation pumps, it is essential to consider their properties, durability, and suitability for specific applications. Below are analyses of four common materials used in the construction of these pumps, focusing on their performance characteristics and implications for international buyers.

How Do Stainless Steel and Its Properties Benefit Golf Course Irrigation Pumps?

Stainless steel is renowned for its excellent corrosion resistance and durability, making it a preferred choice for irrigation pumps exposed to various environmental conditions. It typically has a high-temperature rating and can withstand significant pressure, which is crucial for maintaining efficient water flow.

Pros: Stainless steel is highly durable, resistant to rust and corrosion, and requires minimal maintenance. Its strength ensures longevity, which is particularly valuable in regions with harsh climates.

Cons: The initial cost of stainless steel can be high compared to other materials. Additionally, manufacturing complexity may increase due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with both potable and non-potable water applications, making it versatile for different irrigation needs.

Considerations for International Buyers: Compliance with international standards such as ASTM or EN is crucial. Buyers in regions like the Middle East and Africa should ensure that the material meets local corrosion resistance requirements due to high salinity in some water sources.

What Advantages Do Polypropylene and Its Properties Offer for Irrigation Systems?

Polypropylene is a thermoplastic polymer known for its lightweight and excellent chemical resistance. It can handle a range of temperatures and pressures, making it suitable for various irrigation applications.

Pros: Its lower cost compared to metals makes it an attractive option for budget-conscious projects. Polypropylene is also resistant to many chemicals, which is beneficial for irrigation systems that may handle treated or recycled water.

Cons: While it is durable, polypropylene may not withstand high temperatures as effectively as metals, which can limit its application in certain environments.

Impact on Application: Polypropylene is particularly suitable for non-potable water systems and can be used in environments where chemical exposure is a concern.

Considerations for International Buyers: Ensure that the material complies with local regulations regarding chemical resistance and suitability for irrigation applications, especially in regions with stringent water quality standards.

How Do Cast Iron and Its Properties Influence Pump Performance?

Cast iron is a traditional material used in pump construction, known for its strength and ability to absorb vibrations. It is particularly effective in high-pressure applications.

Pros: Cast iron pumps are robust and can handle high flow rates, making them suitable for large golf courses. Their durability means they can last for many years with proper maintenance.

Cons: Cast iron is heavy, which can complicate installation and increase transportation costs. It is also prone to corrosion if not properly coated or maintained.

Impact on Application: Cast iron is best suited for high-flow and high-pressure systems, but its susceptibility to rust means it may not be ideal for all water types.

Considerations for International Buyers: Buyers should look for cast iron products that are coated or treated to enhance corrosion resistance, particularly in humid or coastal regions.

What Role Does PVC Play in Golf Course Irrigation Systems?

PVC (polyvinyl chloride) is widely used in irrigation systems due to its lightweight, affordability, and ease of installation. It is resistant to corrosion and chemicals, making it suitable for various applications.

Pros: PVC is cost-effective and easy to work with, allowing for quick installations. It is also resistant to many chemicals, making it suitable for both potable and non-potable applications.

Cons: PVC has a lower temperature and pressure rating compared to metals, which may limit its use in high-demand situations.

Impact on Application: PVC is ideal for lateral lines and smaller irrigation systems but may not be suitable for mainline applications requiring higher pressure.

Considerations for International Buyers: Ensure compliance with local standards for potable water systems. In regions like South America, where UV exposure can be high, UV-resistant PVC is recommended.

Summary Table of Material Selection for Golf Course Irrigation Pumps

| Material | Typical Use Case for golf course irrigation pumps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Main irrigation lines and high-pressure systems | Excellent corrosion resistance and durability | High initial cost and manufacturing complexity | High |

| Polypropylene | Non-potable water systems | Lightweight and cost-effective | Limited high-temperature performance | Low |

| Cast Iron | High-flow and high-pressure applications | Robust and durable | Heavy and prone to corrosion | Medium |

| PVC | Lateral lines and smaller systems | Cost-effective and easy to install | Lower temperature and pressure ratings | Low |

Selecting the right materials for golf course irrigation pumps is crucial for ensuring reliability and efficiency. By understanding the properties and implications of each material, international buyers can make informed decisions that align with their operational needs and local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for golf course irrigation pumps

What Are the Key Stages in the Manufacturing Process of Golf Course Irrigation Pumps?

The manufacturing process of golf course irrigation pumps involves several critical stages that ensure the final product meets the high standards required for efficient and reliable operation. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with the careful selection of raw materials, which often include high-grade stainless steel, aluminum, and specialized plastics. These materials are chosen for their durability, resistance to corrosion, and ability to withstand varying environmental conditions. Suppliers must ensure that materials comply with international standards to guarantee quality.

Forming: In this stage, the raw materials are shaped into pump components using techniques such as casting, machining, and welding. For example, impellers and casings may be cast from metal alloys, while precision machining ensures that components fit together correctly. Advanced technologies like CNC machining are often employed to enhance accuracy and reduce waste.

Assembly: Once the individual components are formed, they are assembled into pump units. This step involves fitting together the pump casing, motor, impellers, and other critical parts. Skilled technicians conduct this assembly under strict guidelines to ensure that all components function seamlessly. Automated assembly lines may also be utilized to enhance efficiency.

Finishing: The final stage involves surface treatments to enhance durability and aesthetic appeal. This may include powder coating, which provides a robust finish that resists corrosion and wear. Additionally, all systems are thoroughly cleaned to remove any contaminants that could affect performance.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing process of golf course irrigation pumps, ensuring that each unit is reliable and performs as expected. Adhering to international standards such as ISO 9001 and industry-specific certifications like CE and API is crucial for manufacturers aiming to cater to international markets.

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process to monitor quality. These include:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During manufacturing, processes are monitored to detect any deviations from quality standards. This includes real-time inspections of machined parts and assembled units.

– Final Quality Control (FQC): Once the pump is fully assembled, a comprehensive inspection is conducted. This includes testing for leaks, operational efficiency, and overall performance against predefined criteria.Common Testing Methods: Manufacturers employ various testing methods to validate the performance and durability of irrigation pumps. These may include:

– Hydraulic testing to assess flow rates and pressure capabilities.

– Vibration analysis to ensure operational stability.

– Endurance testing to simulate long-term use under different conditions.

What International Standards and Certifications Should B2B Buyers Consider?

For B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding relevant international standards and certifications is essential for ensuring product quality and compliance.

ISO 9001: This standard outlines the criteria for a quality management system and is crucial for manufacturers seeking to demonstrate their commitment to quality and customer satisfaction.

CE Marking: For products sold within the European Economic Area, CE marking indicates that the product meets EU safety, health, and environmental protection requirements.

API Certification: For manufacturers in the oil and gas sector, API certifications ensure that products meet stringent industry standards, which can also apply to irrigation pump components used in these environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive measures to verify the quality control practices of potential suppliers. This can be achieved through several approaches:

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes, quality control systems, and adherence to international standards. This firsthand observation can reveal insights into the supplier’s commitment to quality.

Requesting Quality Reports: Buyers should request detailed quality reports from suppliers, including results from IQC, IPQC, and FQC inspections. These documents provide transparency regarding the quality assurance measures in place.

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies can conduct random checks and provide certification that products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances related to quality control when sourcing golf course irrigation pumps:

Regional Standards Compliance: Different regions may have varying regulations and standards. Buyers must ensure that products meet the specific requirements of their local market, including any additional certifications that may be necessary.

Cultural and Communication Factors: Effective communication is vital when dealing with international suppliers. Understanding cultural differences can facilitate smoother negotiations and ensure that quality expectations are clearly articulated.

Logistical Considerations: Transportation and shipping can impact product integrity. Buyers should consider how pumps are packaged and handled during transit to minimize the risk of damage, which can affect performance upon installation.

By focusing on these critical aspects of the manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing golf course irrigation pumps, ensuring reliability and performance for their projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘golf course irrigation pumps’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for golf course irrigation pumps. As a critical component of maintaining optimal turf conditions, selecting the right pump system involves careful consideration of technical specifications, supplier capabilities, and long-term support. This checklist will help streamline your decision-making process and ensure that you invest in a reliable and efficient irrigation solution.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of selecting the appropriate irrigation pump. Consider factors such as flow rate, pressure requirements, and the type of water source (e.g., lake, well, or municipal supply).

– Flow Rate: Assess the peak demand for water during the hottest months to avoid shortages.

– Pressure Requirements: Ensure the pump can maintain adequate pressure across the entire irrigation system.

Step 2: Assess Environmental Conditions

Understanding the environmental factors that will impact pump performance is crucial. Examine the local climate, soil types, and landscape features of the golf course.

– Soil Type: Different soils have varying water retention capabilities, influencing irrigation needs.

– Climate Conditions: Hotter regions may require more frequent watering, necessitating more robust pump systems.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your needs. Request company profiles, case studies, and references from other golf courses or similar projects.

– Experience: Look for suppliers with a proven track record in providing irrigation solutions specifically for golf courses.

– Customer Support: Evaluate the level of post-purchase support, including warranties, maintenance services, and availability of parts.

Step 4: Request Customized Proposals

Once you have a shortlist of suppliers, request customized proposals that address your specific requirements. This will provide insights into how each supplier plans to meet your needs.

– Design and Engineering: Ensure the proposal includes detailed design plans and engineering specifications that align with your site conditions.

– Cost Breakdown: Analyze the cost structure, including initial investments and long-term maintenance expenses.

Step 5: Inquire About Technology Integration

Modern irrigation systems often incorporate advanced technologies for efficiency and management. Check if the pump systems can integrate with smart irrigation controls or monitoring systems.

– Remote Monitoring: Systems that offer remote access can help optimize water usage and reduce waste.

– Automation Features: Look for pumps that support automation for improved efficiency and ease of use.

Step 6: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications and adhere to industry standards. This is vital for ensuring quality and reliability in pump systems.

– Certifications: Look for ISO certifications or other industry-specific accolades that reflect the supplier’s commitment to quality.

– Compliance: Confirm that the pumps meet local regulations and standards, particularly regarding water usage and energy efficiency.

Step 7: Finalize Contracts with Clear Terms

Once you’ve selected a supplier, finalize contracts with clearly defined terms. Ensure that the agreement includes timelines, delivery schedules, and warranty details.

– Warranties: Review warranty terms to understand coverage for parts and labor.

– Service Agreements: Consider establishing a service agreement for ongoing maintenance and support to prolong the life of your irrigation system.

By following this checklist, B2B buyers can make informed decisions when procuring golf course irrigation pumps, ultimately ensuring efficient water management and optimal playing conditions.

Comprehensive Cost and Pricing Analysis for golf course irrigation pumps Sourcing

What Are the Key Cost Components of Golf Course Irrigation Pumps?

When sourcing golf course irrigation pumps, understanding the cost structure is crucial for international B2B buyers. The main cost components include:

Materials: The choice of materials significantly affects the cost. High-quality materials such as corrosion-resistant steel or advanced polymers can lead to higher upfront costs but may offer better longevity and lower maintenance expenses.

Labor: Labor costs can vary significantly based on the manufacturing location. Regions with lower labor costs, such as parts of South America and Africa, might offer more competitive pricing, but it’s essential to consider the skill level and expertise required for pump assembly and quality assurance.

Manufacturing Overhead: This includes indirect costs related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce these overheads, impacting the final price.

Tooling: Custom tooling for specialized designs or specifications can be a significant cost driver. Buyers should assess whether the tooling costs are justified by the expected performance and efficiency of the irrigation system.

Quality Control (QC): Rigorous QC processes ensure the reliability of irrigation pumps. While additional QC measures increase upfront costs, they can minimize long-term operational issues.

Logistics: Transportation costs can vary widely based on the supplier’s location and the buyer’s destination. Understanding Incoterms can help buyers anticipate these costs and make informed decisions.

Margin: Suppliers typically include a margin to cover risks and profit. This margin can vary based on the supplier’s reputation, market demand, and relationship with the buyer.

How Do Price Influencers Affect Golf Course Irrigation Pump Sourcing?

Several factors can influence the pricing of golf course irrigation pumps:

Volume/MOQ (Minimum Order Quantity): Larger orders often come with discounts. Buyers should evaluate their long-term needs to leverage better pricing.

Specifications and Customization: Custom-designed pumps tailored to specific golf course requirements can increase costs. Buyers should balance customization needs with budget constraints.

Materials and Quality Certifications: Pumps made from high-grade materials that meet international quality standards may command higher prices. Buyers should consider the total cost of ownership, which includes maintenance and operational efficiency over time.

Supplier Factors: Established suppliers with a solid reputation may charge premium prices. However, their products often come with better warranties and support services, which can mitigate risks.

Incoterms: Understanding shipping terms is vital. Different Incoterms can affect the total landed cost, including duties, taxes, and insurance.

What Are Some Effective Buyer Tips for Cost-Efficiency?

B2B buyers can adopt several strategies to optimize costs when sourcing golf course irrigation pumps:

Negotiation: Engage in discussions about pricing, especially for large orders. Suppliers may have flexibility in pricing that could lead to significant savings.

Focus on Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the long-term costs associated with maintenance, energy consumption, and replacement parts. A slightly more expensive pump with lower operating costs may be more economical in the long run.

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of currency fluctuations, import duties, and local regulations that may impact pricing. Building a relationship with suppliers can help mitigate some of these challenges.

Request Multiple Quotes: Gathering quotes from various suppliers can provide a clearer picture of the market and help identify the best value for money.

Consider Local Suppliers: Whenever possible, sourcing from local manufacturers can reduce logistics costs and lead times, offering a more cost-effective solution.

In conclusion, understanding the comprehensive cost structure and pricing influencers for golf course irrigation pumps enables international B2B buyers to make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing golf course irrigation pumps With Other Solutions

Exploring Alternatives to Golf Course Irrigation Pumps

When considering irrigation solutions for golf courses, it is essential to evaluate various technologies that can deliver efficient and reliable water management. While golf course irrigation pumps are a popular choice, alternatives exist that may better suit specific operational needs or budget constraints. This analysis compares golf course irrigation pumps against two viable alternatives: surface water irrigation systems and rainwater harvesting systems.

| Comparison Aspect | Golf Course Irrigation Pumps | Surface Water Irrigation Systems | Rainwater Harvesting Systems |

|---|---|---|---|

| Performance | High efficiency with controlled pressure and flow rates. | Variable performance based on water source and weather conditions. | Dependent on rainfall; can be inconsistent. |

| Cost | Higher initial investment but lower long-term maintenance costs. | Generally lower initial costs, but higher ongoing operational costs. | Moderate initial costs; savings on water bills over time. |

| Ease of Implementation | Requires professional installation and setup. | Easier to set up but may need regular adjustments. | Setup complexity varies; may require filtration systems. |

| Maintenance | Regular maintenance needed; parts can be costly. | Low maintenance but may require frequent checks for blockages. | Minimal maintenance; system longevity depends on quality. |

| Best Use Case | Ideal for large courses requiring consistent water supply. | Suitable for courses near lakes or rivers; good for budget-conscious projects. | Best for environmentally focused courses looking to reduce water costs. |

What are the Benefits and Drawbacks of Surface Water Irrigation Systems?

Surface water irrigation systems utilize nearby water bodies such as lakes or rivers to irrigate golf courses. These systems can be cost-effective, particularly for courses located near abundant water sources. They require less initial investment than pumps and can be adjusted easily based on water availability. However, their performance can be inconsistent, especially during dry spells, and they may not provide the same level of control over water pressure and distribution as pump systems. Maintenance is generally low, but blockages and fluctuations in water quality can pose challenges.

How Does Rainwater Harvesting Offer a Sustainable Irrigation Solution?

Rainwater harvesting systems collect and store rainwater for irrigation purposes. This method promotes sustainability and can significantly reduce dependence on municipal water sources, leading to long-term savings on water bills. The initial setup may require moderate investment, including filtration systems to ensure water quality. However, the performance of these systems is highly dependent on local rainfall patterns, which can lead to inconsistent water availability. Regular maintenance is usually minimal, making it an attractive option for environmentally conscious golf courses aiming to enhance their green credentials.

Making the Right Choice: How Should B2B Buyers Approach Their Decision?

When selecting an irrigation solution, B2B buyers should consider several factors, including the specific needs of the golf course, budget constraints, and environmental goals. Golf course irrigation pumps provide reliable performance and control but come with higher upfront costs. In contrast, surface water systems can be more economical initially, while rainwater harvesting offers sustainability benefits but may not be as reliable during dry periods. Evaluating these factors in the context of the course’s unique conditions will help buyers choose the most suitable irrigation solution to optimize water management and enhance course maintenance.

Essential Technical Properties and Trade Terminology for golf course irrigation pumps

What Are the Critical Technical Properties of Golf Course Irrigation Pumps?

When selecting golf course irrigation pumps, understanding their technical specifications is essential for ensuring optimal performance and longevity. Here are some critical properties to consider:

Material Grade

The materials used in pump construction, such as stainless steel or cast iron, significantly affect durability and resistance to corrosion. For instance, stainless steel pumps are preferable in saline or acidic environments, as they offer superior resistance to rust and wear. Choosing the right material can reduce maintenance costs and extend the pump’s lifespan, which is crucial for budget-conscious golf course managers.Flow Rate (GPM)

Measured in gallons per minute (GPM), the flow rate indicates the volume of water the pump can deliver. Selecting a pump with the appropriate flow rate is vital for meeting the irrigation needs of different areas on the course, such as greens, fairways, and roughs. Insufficient flow can lead to uneven watering, affecting the health of the turf and playing conditions.Pressure Rating (PSI)

The pressure rating, measured in pounds per square inch (PSI), indicates how much pressure the pump can generate. This specification is critical for ensuring that water reaches all areas of the golf course, especially when dealing with elevation changes or extensive piping systems. A pump with a suitable pressure rating ensures efficient water distribution, promoting healthy turf growth.Efficiency Rating

Efficiency is a measure of how much energy the pump consumes relative to its output. High-efficiency pumps reduce operational costs and are environmentally friendly, making them attractive to golf course operators looking to minimize their carbon footprint. Understanding efficiency ratings helps in selecting pumps that not only perform well but also contribute to long-term savings.Tolerance and Compatibility

Tolerance refers to the permissible limits of variation in a physical dimension or property of the pump. Ensuring that the pump’s specifications align with existing infrastructure is critical for seamless integration. Compatibility with other irrigation components, such as valves and controllers, ensures that the entire system operates efficiently.Control System Type

Many modern irrigation pumps come equipped with advanced control systems, such as Variable Frequency Drives (VFDs) and Programmable Logic Controllers (PLCs). These systems enhance operational flexibility and allow for real-time monitoring and adjustments, optimizing water usage and improving overall system performance. Understanding the type of control system can help buyers select pumps that offer the best automation features for their specific needs.

What Are Common Trade Terms Used in Golf Course Irrigation Pump Procurement?

Navigating the procurement process requires familiarity with industry terminology. Here are some common trade terms relevant to golf course irrigation pumps:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM products is crucial for ensuring compatibility and quality when sourcing irrigation pumps, as these manufacturers often provide the components necessary for seamless integration with existing systems.MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning, as purchasing below this threshold can lead to higher per-unit costs or unavailability of the desired product.RFQ (Request for Quotation)

An RFQ is a formal document that solicits price quotes from suppliers for specific products or services. Issuing an RFQ allows buyers to compare prices, terms, and conditions, ensuring they secure the best deal for their irrigation needs.Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping responsibilities, risk management, and cost allocation in the procurement of irrigation pumps.Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for project planning, especially when coordinating irrigation system installations during specific seasons or weather conditions.Warranty Period

The warranty period is the duration for which a manufacturer guarantees the performance of a pump. Knowing the warranty terms helps buyers assess the long-term reliability of their investment and the support they can expect from manufacturers in case of product failures.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring golf course irrigation pumps, ensuring they select products that meet their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the golf course irrigation pumps Sector

What Are the Current Market Dynamics in the Golf Course Irrigation Pumps Sector?

The golf course irrigation pumps market is experiencing significant transformation driven by a combination of technological advancements and global environmental concerns. A surge in demand for sustainable water management practices is prompting golf course operators, particularly in regions like Africa, South America, the Middle East, and Europe, to invest in high-efficiency irrigation systems. These systems not only minimize water wastage but also enhance the quality of turf, leading to improved playing conditions.

Emerging technologies such as smart irrigation systems, which integrate IoT sensors and automated controls, are becoming increasingly popular. These innovations allow for real-time monitoring and data analysis, enabling golf course managers to optimize water usage based on weather patterns and soil moisture levels. Furthermore, there is a growing trend towards prefabricated pump stations, which offer quicker installation times and reduced on-site labor costs compared to traditional systems.

International buyers are also facing the challenge of navigating varying regulatory landscapes and local sourcing requirements. Understanding these dynamics is crucial for making informed purchasing decisions and ensuring compliance with regional standards, particularly in markets with stringent environmental regulations.

How Is Sustainability Shaping Sourcing Trends for Golf Course Irrigation Pumps?

Sustainability is no longer an optional consideration but a fundamental aspect of sourcing strategies in the golf course irrigation pumps sector. The environmental impact of irrigation practices has led to increased scrutiny from both consumers and regulatory bodies. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, which can include the use of energy-efficient pumps and recyclable materials.

Ethical sourcing is also gaining traction, as buyers look to ensure that their suppliers maintain transparent supply chains. Certifications such as ISO 14001 for environmental management and products made from recycled materials are becoming key differentiators in the marketplace. Suppliers that can provide evidence of sustainable practices not only enhance their credibility but also appeal to eco-conscious customers.

Moreover, the integration of advanced materials that reduce corrosion and extend the lifespan of pumps is becoming a standard expectation. By investing in high-quality, sustainable products, golf courses can lower their long-term operational costs and contribute positively to their surrounding environments, aligning with the growing global emphasis on corporate social responsibility.

What Has Been the Evolution of Golf Course Irrigation Pumps?

The evolution of golf course irrigation pumps has been marked by technological advancements and an increasing focus on efficiency. Early systems were primarily mechanical, relying on basic pumps that lacked the automation and precision seen in today’s solutions. As the golf industry grew, so did the demand for more sophisticated irrigation systems that could adapt to varying water sources and soil conditions.

The introduction of electric and solar-powered pumps marked a significant shift, allowing for more sustainable operations. Over the years, the integration of smart technology has revolutionized the sector, enabling remote monitoring and automated irrigation schedules that enhance water conservation efforts. Today, golf course irrigation pumps are not only viewed as essential tools for maintaining turf quality but also as integral components of sustainable water management practices, reflecting the industry’s commitment to environmental stewardship and operational excellence.

Frequently Asked Questions (FAQs) for B2B Buyers of golf course irrigation pumps

How do I solve issues with my existing golf course irrigation pump system?

To address problems with your current irrigation pump system, start by conducting a comprehensive system assessment. Look for common issues such as leaks, pressure drops, and irregular water distribution. Engage with a qualified technician who specializes in irrigation systems for a thorough inspection. Many manufacturers offer free checkups for older pump stations, which can identify inefficiencies and potential failures. Upgrading to modern technology, like Variable Frequency Drives (VFDs) or advanced control panels, can enhance efficiency and reliability.What is the best pump type for golf course irrigation?

The best pump type for your golf course largely depends on water source and specific irrigation needs. Vertical turbine pumps are excellent for deep water sources, providing high flow rates and efficiency. Horizontal centrifugal pumps are suitable for surface water applications and are generally more cost-effective. Consider submersible pumps for compact installations with minimal noise. Consult with a supplier to evaluate your specific requirements, including flow rates, pressure needs, and maintenance considerations.What are the benefits of customizing my golf course irrigation pump system?

Customizing your golf course irrigation pump system allows you to tailor it to your specific needs, ensuring optimal performance and efficiency. Custom solutions can address unique site conditions, such as varying water sources and terrain challenges. By working with manufacturers, you can select specific components that enhance reliability and reduce maintenance costs. Custom systems can also integrate advanced technology for remote monitoring and control, leading to better resource management and reduced water waste.What are the minimum order quantities (MOQ) for golf course irrigation pumps?

Minimum order quantities (MOQ) can vary significantly between suppliers and depend on the type of pump and customization options chosen. Typically, manufacturers may set MOQs based on production runs or to cover shipping costs. For smaller golf courses or initial projects, some suppliers may offer flexible MOQs to accommodate your needs. It’s essential to communicate your requirements with potential suppliers to find the best solution that fits your budget and project timeline.What payment terms should I expect when purchasing irrigation pumps internationally?

Payment terms for international purchases can vary by supplier and region. Common terms include a deposit upfront (usually 20-50%) with the balance due upon shipment or delivery. Some suppliers may offer financing options or letters of credit to facilitate larger transactions. Always clarify payment terms before finalizing your order, and consider the implications of currency exchange rates and international banking fees. Establishing a good relationship with the supplier can also lead to more favorable terms.How can I vet suppliers for golf course irrigation pumps?

To vet suppliers, conduct thorough research on their reputation and experience in the industry. Check for certifications, customer reviews, and case studies that demonstrate their expertise. Request references from previous clients, particularly those in your region, to gauge their reliability and service quality. Engage in direct communication to assess their responsiveness and willingness to provide support. Additionally, consider visiting their manufacturing facility if feasible, or attend industry trade shows to meet suppliers in person.What quality assurance measures should I look for in irrigation pump suppliers?

When evaluating suppliers, inquire about their quality assurance (QA) processes. Look for ISO certifications or similar industry standards that demonstrate commitment to quality. Ask about testing protocols for pump performance, durability, and efficiency. Reputable manufacturers will provide detailed specifications and warranties for their products. Additionally, consider suppliers that offer post-installation support and maintenance services, ensuring long-term reliability of your irrigation system.What logistics considerations should I keep in mind when sourcing irrigation pumps?

Logistics are critical when sourcing irrigation pumps, especially for international buyers. Assess shipping methods, timelines, and costs, as these can significantly impact your project budget and schedule. Determine if the supplier offers freight forwarding services or if you need to arrange your own logistics. Consider import regulations and customs duties in your country, which can affect delivery timelines. Effective communication with your supplier regarding logistics can help avoid delays and ensure a smooth procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Golf Course Irrigation Pumps Manufacturers & Suppliers List

1. Rain Bird – Golf Pumps

Domain: rainbird.com

Registered: 1995 (30 years)

Introduction: The page contains information about Rain Bird’s golf pumps, including various models designed for irrigation systems. Key features include energy efficiency, durability, and advanced technology for optimal performance. The pumps are suitable for different golf course sizes and can handle various water sources. Specific models may include options for variable speed and automatic control systems.

2. Gopps – Golf Irrigation Pump Systems

Domain: gopps.com

Introduction: Golf Irrigation Pump Systems offer reliability and flexibility for golf courses. Key features include: 1. Three pumping system models available to meet various project needs and budgets. 2. Submersible Turbine Pumps: Ideal for surface water applications, compact size, lower cost, silent operation, self-cleaning filter option. 3. Vertical Turbine Pumps: High flow (3,000+ gpm) and pressure (150+ psi…

3. MCI Flowtronex – Irrigation and Pumping Solutions

Domain: flowtronex.com

Registered: 1997 (28 years)

Introduction: MCI Flowtronex offers a range of irrigation and pumping solutions including: Endurance Golf Pump Station, Municipal Pump Station, and Enduroscape Landscape Pump Station. Their products feature single or multi-pump control solutions, custom enclosures, and control panel solutions. They specialize in irrigation pumping systems, municipal water control packages, and waste water solutions with options…

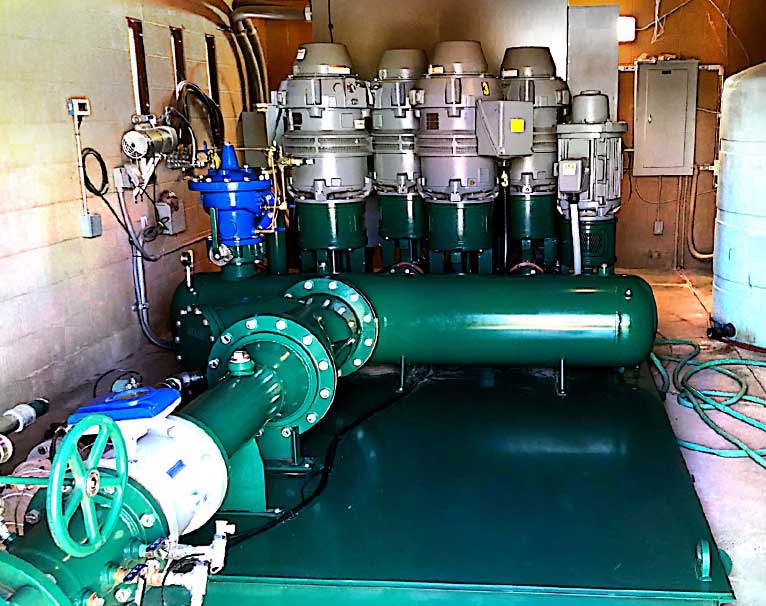

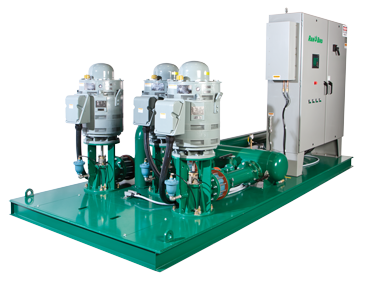

4. Rhino Pumps – RhinoStak™ Irrigation Solutions

Domain: rhinopumps.com

Registered: 2013 (12 years)

Introduction: RhinoStak™ is an all-in-one solution for golf course irrigation, offering prepackaged pump systems engineered for specific flow, pressure, and layout requirements. Each package includes pumps, motors, variable frequency drives, controls, and instrumentation, fully integrated and ready for installation. The systems are optimized for quiet operation, consistent pressure, and long-term reliability. R…

5. PMC – Golf Course Pumping Solutions

Domain: pmc-service.com

Registered: 2010 (15 years)

Introduction: PMC is a manufacturer and service company for golf course pumping stations and pumping equipment, with over 50 years of combined experience. They offer service for any make and model of pumping equipment and controls, in-house design and programming capabilities including variable speed drives, and professional service on pumps and motors. They provide spring startups and services to prepare equip…

6. Greenman Golf & Turf – Professional Irrigation Systems

Domain: greenmangolfturf.com

Registered: 2015 (10 years)

Introduction: Professional Irrigation Systems by Greenman Golf & Turf Solutions are custom designed for golf courses, focusing on efficiency, reliability, and low service costs. Key features include:

– Complete System Monitoring with automatic shutdown for low water levels, overflow, pressure overload, phase faults, and VFD/filter issues.

– Variable Frequency Drive (VFD) for balanced performance and longer mot…

Strategic Sourcing Conclusion and Outlook for golf course irrigation pumps

The strategic sourcing of golf course irrigation pumps is critical for maintaining optimal turf health and ensuring the longevity of irrigation systems. B2B buyers should prioritize suppliers that offer robust, reliable, and energy-efficient solutions tailored to the specific needs of their geographic regions. Key takeaways include the importance of selecting systems that integrate seamlessly with existing infrastructure, the value of warranties and after-sales support, and the benefits of advanced technology in monitoring and controlling water usage.

Investing in quality pump systems not only enhances irrigation efficiency but also reduces long-term operational costs, making it a strategic imperative for golf courses across Africa, South America, the Middle East, and Europe. As climate conditions become increasingly variable, the ability to adapt and innovate in water management will be essential for maintaining the lush greens that golfers expect.

Looking ahead, international B2B buyers are encouraged to engage with leading manufacturers and explore custom solutions that meet the unique demands of their courses. By fostering relationships with reputable suppliers, buyers can ensure their irrigation systems are both effective and sustainable, setting the stage for excellence in golf course management.