Introduction: Navigating the Global Market for irrigation valve leak repair

In an increasingly interconnected world, sourcing effective solutions for irrigation valve leak repair poses significant challenges for businesses across various sectors, particularly in regions like Africa, South America, the Middle East, and Europe. With the growing demand for sustainable agriculture and efficient water management, the need for reliable irrigation systems is more crucial than ever. A malfunctioning irrigation valve can lead to substantial water loss, increased operational costs, and ultimately, reduced productivity. This guide addresses these challenges by providing a comprehensive overview of irrigation valve leak repair, covering essential topics such as types of valves, common causes of leaks, troubleshooting techniques, and best practices for maintenance.

International B2B buyers will find invaluable insights on how to evaluate suppliers, assess product quality, and understand cost implications associated with repairs. We delve into the specific applications of various irrigation systems, offering tailored solutions that meet diverse agricultural needs. Additionally, the guide emphasizes the importance of preventative measures and routine maintenance to prolong the lifespan of irrigation components. By equipping decision-makers with actionable knowledge and strategic insights, this guide empowers businesses to make informed purchasing decisions that enhance operational efficiency and sustainability in their irrigation practices. Whether you are a distributor, contractor, or agricultural producer, our guide will serve as a vital resource in navigating the complexities of irrigation valve leak repair.

Understanding irrigation valve leak repair Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Diaphragm Valve Repair | Involves replacing or sealing diaphragm components. | Agricultural irrigation systems | Pros: Cost-effective; Cons: Requires technical skill. |

| Solenoid Valve Replacement | Focuses on electrical components regulating flow. | Commercial landscaping and gardens | Pros: Ensures proper operation; Cons: Can be complex. |

| Vacuum Breaker Repair | Addresses issues with backflow prevention devices. | Municipal water systems | Pros: Prevents contamination; Cons: May require specialized parts. |

| Manual Valve Replacement | Involves replacing manually operated valves. | Residential and small-scale farms | Pros: Simple installation; Cons: Less automation. |

| Electronic Control Repair | Targets issues with automated irrigation controllers. | Large agricultural enterprises | Pros: Enhanced efficiency; Cons: Higher upfront costs. |

What are the characteristics and suitability of Diaphragm Valve Repair?

Diaphragm valve repair is a common solution for irrigation systems experiencing leaks. This type of repair involves either replacing or sealing the diaphragm, a flexible membrane that controls water flow. It is particularly suitable for systems that operate under varying pressure conditions, making it ideal for agricultural irrigation where water conservation is crucial. B2B buyers should consider the availability of replacement parts and the required technical skills for effective repairs, as improper handling can lead to further system complications.

How does Solenoid Valve Replacement impact irrigation systems?

Solenoid valve replacement is essential for maintaining the functionality of automated irrigation systems. These valves are electronically operated and control the water flow based on signals from irrigation controllers. This type of repair is particularly relevant for commercial landscaping and large gardens, where precise water management is vital. Buyers should prioritize sourcing high-quality solenoids to ensure durability and reliability, as well as consider the complexity of installation, which may require specialized knowledge.

Why is Vacuum Breaker Repair critical for irrigation systems?

Vacuum breaker repair addresses leaks within backflow prevention devices, crucial for safeguarding water supplies from contamination. This repair is especially important in municipal water systems where compliance with health regulations is mandatory. B2B buyers in this sector should focus on the reliability of replacement parts and the potential need for specialized technicians, as improper repairs can lead to severe legal and health implications.

What are the benefits of Manual Valve Replacement in irrigation?

Manual valve replacement is a straightforward repair option for irrigation systems that rely on human operation rather than automation. This type of repair is often used in residential and small-scale farming applications, where simplicity and ease of use are priorities. Buyers should consider the ease of installation and maintenance, as well as the potential for lower costs compared to automated systems. However, they should also be aware that manual systems may not offer the same efficiency as automated solutions.

How does Electronic Control Repair enhance irrigation management?

Electronic control repair focuses on fixing issues with automated irrigation controllers, which are essential for optimizing water usage and ensuring efficient irrigation schedules. This type of repair is crucial for large agricultural enterprises that depend on precise water management to maximize crop yields. Buyers should evaluate the initial costs against long-term savings in water usage and labor efficiency, as investing in high-quality electronic controls can significantly enhance overall system performance.

Key Industrial Applications of irrigation valve leak repair

| Industry/Sector | Specific Application of Irrigation Valve Leak Repair | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Repairing irrigation systems in crop production | Reduces water waste and enhances crop yield | Availability of local repair services and parts |

| Landscape Management | Maintaining irrigation systems in public parks and gardens | Ensures healthy landscapes and reduces maintenance costs | Compatibility with existing systems and reliability |

| Horticulture | Repairing valves in greenhouse irrigation systems | Optimizes water usage and supports plant health | Access to specialized components for diverse systems |

| Municipal Water Supply | Managing leaks in municipal irrigation infrastructure | Minimizes water loss and lowers operational costs | Compliance with local regulations and standards |

| Sports Facilities | Maintaining irrigation for athletic fields | Supports optimal playing conditions and turf health | Durability and longevity of repair materials |

How is Irrigation Valve Leak Repair Used in Agriculture?

In the agriculture sector, irrigation valve leak repair is crucial for maintaining efficient water distribution in crop production. Farmers rely heavily on irrigation systems to ensure optimal crop yield, and leaks can lead to significant water loss and increased operational costs. By addressing leaks promptly, agricultural businesses can enhance water conservation efforts, reduce expenses associated with wasted resources, and ultimately improve the profitability of their operations. Buyers in this sector should consider the availability of local repair services and the compatibility of replacement parts with existing systems.

What Role Does Irrigation Valve Leak Repair Play in Landscape Management?

For landscape management, particularly in public parks and gardens, repairing leaking irrigation valves is essential to maintain aesthetic appeal and plant health. Efficient irrigation systems ensure that landscapes receive adequate water without wastage, reducing overall maintenance costs. By preventing leaks, landscape managers can sustain healthy green spaces that attract visitors and enhance community well-being. When sourcing repair solutions, compatibility with existing irrigation systems and the reliability of repair materials are critical considerations for buyers.

Why is Irrigation Valve Leak Repair Important in Horticulture?

In horticulture, particularly within greenhouse environments, effective irrigation is vital for plant growth and health. Repairing leaking valves ensures that water is delivered precisely where needed, optimizing usage and promoting robust plant development. This precision not only conserves water but also reduces the risk of overwatering, which can lead to root diseases. Buyers in the horticulture sector must prioritize access to specialized components that cater to diverse irrigation systems, ensuring that repairs are both effective and sustainable.

How Does Irrigation Valve Leak Repair Impact Municipal Water Supply?

Municipalities managing irrigation infrastructure must prioritize leak repair to minimize water loss and maintain sustainable operations. Leaks in municipal irrigation systems can lead to significant wastage, impacting water supply and increasing operational costs for local governments. By implementing effective repair strategies, municipalities can enhance their water management efforts, comply with regulatory standards, and reduce costs. Buyers in this sector should focus on sourcing materials that meet local regulations and ensure long-lasting solutions.

What Benefits Does Irrigation Valve Leak Repair Offer to Sports Facilities?

Sports facilities rely on well-maintained irrigation systems to ensure optimal playing conditions for athletes. Repairing leaking valves is critical to maintaining healthy turf and preventing water wastage, which can significantly affect the quality of the playing surface. Timely repairs not only support the performance of athletes but also enhance the longevity of the facility’s infrastructure. When sourcing repair solutions, durability and longevity of materials are vital considerations for facility managers looking to uphold high standards in sports maintenance.

3 Common User Pain Points for ‘irrigation valve leak repair’ & Their Solutions

Scenario 1: Frequent Water Loss Due to Valve Malfunctions

The Problem:

B2B buyers often face the challenge of significant water loss caused by malfunctioning irrigation valves. This is particularly pressing in regions where water scarcity is an ongoing concern, such as parts of Africa and the Middle East. A leaking valve not only wastes water but also leads to increased operational costs and potential fines for exceeding water usage limits. Additionally, the urgency of repair can disrupt scheduling for landscaping or agricultural tasks, leading to delays and potential crop damage.

The Solution:

To effectively tackle this issue, it is crucial to establish a regular maintenance schedule that includes inspections of all irrigation components, particularly the valves. Utilize advanced diagnostic tools to monitor water flow and pressure, allowing for the early detection of leaks. When a leak is identified, sourcing high-quality replacement parts is essential. Engage with reliable suppliers who can provide durable valve components that are suited to your specific irrigation system. Implementing a preventive maintenance approach, which includes annual checks and immediate repairs of any identified leaks, will significantly reduce water loss and associated costs.

Scenario 2: Difficulty in Identifying the Source of the Leak

The Problem:

Many buyers struggle with pinpointing the exact source of an irrigation valve leak, which can be frustrating and time-consuming. The complexity of irrigation systems, often buried and interconnected, makes it hard to determine if the issue stems from a valve, a pipe, or a sprinkler head. This uncertainty can lead to unnecessary repairs and increased labor costs, ultimately affecting the bottom line.

The Solution:

Invest in comprehensive training for maintenance staff on the anatomy of the irrigation system. Utilize tools like moisture sensors and pressure gauges to help accurately diagnose leaks. When a leak is suspected, start by isolating sections of the irrigation system to determine which area is affected. Using a process of elimination can help identify whether the issue lies with a specific valve or elsewhere. Additionally, consider leveraging technology, such as leak detection software, which can provide real-time data and enhance accuracy in pinpointing leak locations. This proactive approach will save time, reduce costs, and enhance the overall efficiency of your irrigation system.

Scenario 3: Inadequate Knowledge of Valve Repair Techniques

The Problem:

Another common pain point for B2B buyers is the lack of knowledge regarding proper repair techniques for leaking irrigation valves. Many companies may have staff who are not adequately trained in the technical aspects of valve repairs, leading to improper fixes that result in recurring issues and wasted resources. This gap in knowledge can also lead to reliance on costly external contractors, further straining budgets.

The Solution:

To address this issue, invest in training programs that focus on irrigation system maintenance, particularly valve repair techniques. Collaborate with industry experts to develop workshops that equip your team with the necessary skills to perform effective repairs. Additionally, create a comprehensive resource library that includes manuals, video tutorials, and troubleshooting guides for various valve types. By empowering your team with the right knowledge and tools, you can reduce dependency on external services, enhance repair efficiency, and ultimately prolong the life of your irrigation system components. Consider using quality control checklists during repairs to ensure all steps are followed meticulously, minimizing the risk of future leaks.

Strategic Material Selection Guide for irrigation valve leak repair

When selecting materials for irrigation valve leak repair, it is essential to consider the specific properties and performance requirements of each material. This analysis focuses on four common materials: PVC, brass, rubber, and stainless steel, providing insights into their advantages, disadvantages, and suitability for various applications.

What are the Key Properties of PVC in Irrigation Valve Leak Repair?

PVC (Polyvinyl Chloride) is widely used in irrigation systems due to its excellent resistance to corrosion and chemicals. It can typically withstand pressures up to 150 psi and operates effectively in temperatures ranging from 32°F to 140°F. PVC is lightweight, easy to handle, and can be easily cut and joined using solvent cement.

Pros: PVC is cost-effective and readily available, making it an attractive option for large-scale irrigation projects. Its resistance to corrosion ensures a long lifespan in various environmental conditions.

Cons: However, PVC can become brittle over time, particularly when exposed to UV light, which may lead to cracking. Additionally, it is not suitable for high-temperature applications beyond its rated limits.

Impact on Application: PVC is compatible with most irrigation media, including water and fertilizers. However, it may not be suitable for applications involving high-pressure steam or extreme temperatures.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 is crucial. Buyers from regions like Africa and South America should also consider local availability and the potential need for UV-resistant formulations in sunny climates.

How Does Brass Perform in Irrigation Valve Leak Repair?

Brass is a durable and corrosion-resistant alloy, primarily composed of copper and zinc. It is capable of withstanding high pressures, often exceeding 200 psi, and can operate effectively in temperatures up to 200°F.

Pros: Brass fittings are known for their strength and longevity, making them ideal for high-stress applications. They also provide excellent sealing capabilities, reducing the risk of leaks.

Cons: The primary drawback of brass is its higher cost compared to plastic options like PVC. Additionally, brass can corrode in the presence of certain chemicals, particularly in acidic or saline environments.

Impact on Application: Brass is suitable for potable water applications and can handle a wide range of media, including water and various fertilizers. However, care should be taken to avoid exposure to corrosive substances.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B16 and consider the availability of brass components in their region. In Europe, adherence to EN standards is also critical.

What Role Does Rubber Play in Irrigation Valve Leak Repair?

Rubber is commonly used for seals and gaskets in irrigation valves due to its flexibility and excellent sealing properties. It can withstand moderate pressures, typically up to 100 psi, and operates effectively in temperatures ranging from -20°F to 180°F.

Pros: Rubber provides a reliable seal, preventing leaks and ensuring efficient operation. It is also resistant to wear and tear, making it suitable for dynamic applications.

Cons: However, rubber can degrade over time when exposed to UV light, ozone, and certain chemicals. This degradation can lead to premature failure and the need for frequent replacements.

Impact on Application: Rubber is compatible with water and many fertilizers, but its performance may be compromised in extreme environmental conditions.

Considerations for International Buyers: Buyers should look for rubber products that meet ASTM D2000 or similar standards. In regions with high UV exposure, UV-resistant rubber formulations may be necessary.

Why Choose Stainless Steel for Irrigation Valve Leak Repair?

Stainless steel is renowned for its exceptional strength and corrosion resistance. It can handle high pressures, often exceeding 300 psi, and operates effectively in a wide temperature range, from -100°F to 800°F.

Pros: Stainless steel is incredibly durable and can withstand harsh environmental conditions, making it suitable for long-term applications. Its resistance to corrosion ensures a long lifespan, reducing maintenance costs.

Cons: The primary downside is the higher cost compared to other materials. Additionally, stainless steel can be more challenging to work with due to its weight and the need for specialized tools for cutting and joining.

Impact on Application: Stainless steel is compatible with a wide range of media, including aggressive chemicals and high-temperature fluids. It is often used in industrial applications where reliability is paramount.

Considerations for International Buyers: Compliance with standards such as ASTM A312 is essential. Buyers should also consider the availability of stainless steel components in their local markets, especially in regions with limited access to specialized materials.

Summary Table of Material Selection for Irrigation Valve Leak Repair

| Material | Typical Use Case for irrigation valve leak repair | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General irrigation systems | Cost-effective and lightweight | Brittle over time, UV sensitivity | Low |

| Brass | High-pressure applications | Strong and durable | Higher cost, susceptible to corrosion | Med |

| Rubber | Seals and gaskets | Excellent sealing properties | Degrades under UV and ozone exposure | Low |

| Stainless Steel | Industrial applications | Exceptional strength and durability | Higher cost, challenging to work with | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing materials for irrigation valve leak repair.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve leak repair

What Are the Main Stages of Manufacturing for Irrigation Valve Leak Repair?

The manufacturing process for irrigation valves involved in leak repairs consists of several critical stages, each designed to ensure the final product meets both performance and durability standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

How Is Material Prepared for Irrigation Valve Manufacturing?

The first step in the manufacturing process is material preparation. High-quality materials such as brass, PVC, or thermoplastic elastomers are typically selected for their durability and resistance to corrosion. The material is then cut and shaped into specific dimensions, ensuring that all components will fit together seamlessly during assembly. Rigorous material testing is conducted to verify the integrity and suitability of the materials, including tensile strength and chemical resistance assessments.

What Techniques Are Used in Forming and Assembly of Irrigation Valves?

Once the materials are prepared, forming techniques such as injection molding or CNC machining are employed to create the valve components. Injection molding is often used for plastic parts, allowing for complex shapes and precise tolerances, while CNC machining is utilized for metal parts, ensuring high accuracy and finish quality.

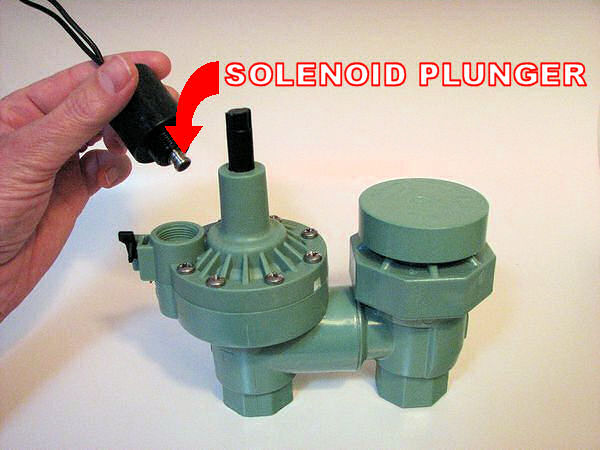

After forming, the assembly process begins. This typically involves fitting the individual components—such as the valve body, diaphragm, and solenoid—together in a controlled environment. Automated assembly lines are increasingly common, as they enhance consistency and speed. During this stage, it’s crucial to ensure that seals and gaskets are correctly positioned to prevent future leaks.

What Are the Finishing Processes for Irrigation Valves?

The finishing stage encompasses several treatments aimed at enhancing the durability and aesthetic appeal of the irrigation valves. Common processes include surface treatment, painting, and coating. For instance, applying a corrosion-resistant coating can significantly extend the lifespan of metal components, while UV-resistant coatings are vital for plastic parts exposed to sunlight.

Once the finishing processes are complete, the valves undergo a visual inspection to check for surface defects and overall appearance. This step is crucial for ensuring that all products meet the visual standards expected by customers.

How Is Quality Assurance Implemented in Irrigation Valve Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for irrigation valves. To ensure that products meet international standards and customer expectations, manufacturers often implement a multi-tiered QA system.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with relevant international standards such as ISO 9001, which outlines a framework for quality management systems. Compliance with these standards signifies that a manufacturer is committed to continuous improvement and customer satisfaction. Additionally, specific certifications like CE marking in Europe and API standards for petroleum equipment can further assure buyers of product quality and safety.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. These typically include:

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Suppliers are often required to provide certificates of analysis to verify material quality.

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC ensures that components are being formed and assembled according to specifications. Random sampling and testing are conducted to ensure consistency.

Final Quality Control (FQC): This final checkpoint involves comprehensive testing of the finished irrigation valves. Common testing methods include pressure testing, leak testing, and functional testing to ensure that the valves operate correctly under specified conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers. One of the most effective methods is conducting audits, which can be either announced or unannounced. During these audits, buyers can assess the manufacturing processes, quality control measures, and overall compliance with international standards.

Additionally, requesting quality reports and documentation can provide insights into a supplier’s QC history. Buyers should also consider third-party inspections, which can serve as an independent verification of a supplier’s claims regarding quality and compliance.

What Are the Nuances of Quality Control for International B2B Buyers?

When dealing with international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of the nuances that may affect quality control. Different regions may have varying standards and regulations, which can impact product quality and compliance.

Furthermore, language barriers and cultural differences can pose challenges in communication, making it essential for buyers to establish clear expectations and protocols. Utilizing local representatives or industry experts can help navigate these complexities effectively.

Conclusion

Understanding the manufacturing processes and quality assurance practices for irrigation valve leak repair is crucial for B2B buyers looking to make informed purchasing decisions. By focusing on material preparation, forming techniques, assembly, finishing processes, and rigorous quality control measures, buyers can ensure they partner with reputable suppliers capable of delivering high-quality products. This knowledge not only aids in selecting the right suppliers but also helps in negotiating terms that align with international standards and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve leak repair’

In the realm of irrigation management, addressing leaks promptly is crucial for maintaining system efficiency and conserving water resources. This guide provides a structured checklist for B2B buyers seeking effective solutions for irrigation valve leak repairs, ensuring that your procurement process is efficient and aligned with best practices.

Step 1: Assess Your Current System’s Requirements

Understanding the specific needs of your irrigation system is the first step in sourcing appropriate repair solutions. Evaluate the type of valves in use, their age, and the common issues you’ve encountered. This information will help you identify the correct parts and services required for effective repairs.

- Identify Valve Types: Different systems may use various valve types (e.g., diaphragm, solenoid). Knowing the specifics can streamline your sourcing.

- Document Issues: Keep a record of past failures or leaks to inform potential suppliers about what improvements or changes are necessary.

Step 2: Define Your Technical Specifications

Create a detailed specification sheet that outlines the technical requirements for the components you need. This will serve as a benchmark for evaluating potential suppliers.

- Material Specifications: Specify materials that are durable and suitable for your environment, such as corrosion-resistant options.

- Compatibility: Ensure that any new parts will be compatible with existing infrastructure to avoid additional costs.

Step 3: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in irrigation components. An informed selection process can lead to better outcomes and partnerships.

- Supplier Reputation: Look for suppliers with positive reviews and a history of reliability in your region.

- Product Range: Ensure they offer a comprehensive range of products to meet your specific needs, including both common and specialized parts.

Step 4: Verify Supplier Certifications

Before making any commitments, ensure that suppliers hold necessary certifications and adhere to industry standards. This step is vital for ensuring quality and compliance.

- ISO Certifications: Check for ISO or other relevant certifications that indicate a commitment to quality management.

- Environmental Compliance: In regions like Europe, adherence to environmental regulations can be a critical factor.

Step 5: Request Samples and Product Documentation

Before finalizing your order, request samples and relevant product documentation to assess quality and compatibility with your system.

- Quality Checks: Inspect samples for durability and functionality, ensuring they meet your specifications.

- Installation Guides: Obtain installation and maintenance guides to facilitate smooth integration into your existing system.

Step 6: Evaluate Warranty and Support Options

Assess the warranty and customer support options provided by potential suppliers. This can significantly affect your long-term satisfaction and operational efficiency.

- Warranty Terms: A robust warranty can safeguard your investment and minimize replacement costs in the event of defects.

- Technical Support: Ensure that suppliers offer accessible technical support for troubleshooting and advice post-purchase.

Step 7: Establish a Relationship for Ongoing Support

Once you’ve selected a supplier, consider establishing a long-term relationship for ongoing support and future needs. This can lead to better pricing and priority service.

- Regular Communication: Maintain open lines of communication for updates on new products or technologies that may benefit your operations.

- Volume Discounts: Discuss potential discounts for bulk purchases or ongoing contracts, which can enhance your procurement strategy.

By following this checklist, B2B buyers can ensure a thorough and effective approach to sourcing irrigation valve leak repair solutions, ultimately leading to enhanced operational efficiency and water conservation.

Comprehensive Cost and Pricing Analysis for irrigation valve leak repair Sourcing

What Are the Key Cost Components for Irrigation Valve Leak Repair?

Understanding the cost structure for irrigation valve leak repair is essential for B2B buyers looking to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials: This includes the cost of replacement parts such as valve diaphragms, solenoids, and gaskets. Depending on the quality and manufacturer, prices can vary significantly. For instance, a high-quality diaphragm may cost more upfront but reduce long-term maintenance costs.

Labor: Skilled labor is required for installation and repair. Labor costs can fluctuate based on regional wage standards and the complexity of the repair. Typically, labor is charged on an hourly basis, with rates varying from $30 to $100 per hour depending on location and expertise.

Manufacturing Overhead: This encompasses indirect costs related to production, such as facility maintenance, utilities, and administrative expenses. These costs are usually calculated as a percentage of total production costs.

Tooling: Specialized tools may be necessary for repairs, adding to the initial investment. This might include diagnostic equipment and specific tools for valve assembly and disassembly.

Quality Control (QC): Ensuring that all parts meet industry standards incurs additional costs. Certifications and testing can increase prices but are crucial for long-term reliability.

Logistics: Transportation costs for parts and labor can also affect the overall price, particularly for international buyers. Factors such as shipping methods, distances, and customs duties must be considered.

Margin: Suppliers typically add a profit margin to cover their operational costs and to ensure sustainability. Margins can range from 10% to 30%, influenced by market competition and demand.

What Price Influencers Should Buyers Be Aware Of?

Several factors influence the pricing of irrigation valve leak repair services and parts, particularly for international B2B buyers.

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often offer better pricing for larger orders, which can be beneficial for companies managing multiple irrigation systems.

Specifications and Customization: Custom parts or specialized valves may incur higher costs due to unique manufacturing processes. Buyers should evaluate whether standard products can meet their needs to avoid unnecessary expenses.

Materials: The choice of materials impacts both durability and cost. Investing in higher-quality materials may result in lower maintenance costs over time.

Quality and Certifications: Products that meet international quality standards often come at a premium. However, these products can provide peace of mind and reduce the risk of future repairs.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer better customer service and quality assurance.

Incoterms: Understanding shipping terms is crucial for international transactions. Different Incoterms can affect the total landed cost of products, including shipping and insurance.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation and cost-efficiency strategies can lead to better pricing outcomes.

Leverage Relationships: Building strong relationships with suppliers can lead to more favorable terms and pricing. Long-term partnerships often yield loyalty discounts.

Total Cost of Ownership (TCO): When evaluating potential purchases, consider not just the upfront costs but also the long-term implications, such as maintenance and operational efficiency.

Research Market Trends: Stay informed about market prices and trends. Understanding the competitive landscape can provide leverage during negotiations.

Be Clear on Specifications: Clearly define your needs to avoid misunderstandings that can lead to higher costs. Providing detailed specifications can help suppliers quote more accurately.

Explore Alternative Suppliers: Do not hesitate to compare multiple suppliers to ensure you are getting the best deal. This also creates competitive pressure that can lead to better pricing.

Disclaimer on Indicative Prices

Prices for irrigation valve leak repair can vary widely based on regional differences, supplier negotiations, and specific project requirements. The figures mentioned should be viewed as indicative, and buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing irrigation valve leak repair With Other Solutions

Introduction: Exploring Alternatives to Irrigation Valve Leak Repair

When dealing with irrigation valve leaks, B2B buyers must consider various solutions beyond traditional repair methods. Understanding alternatives can lead to enhanced operational efficiency, cost savings, and improved water management. This section compares the conventional irrigation valve leak repair with two viable alternatives: replacement with smart irrigation technology and the use of sealant products. Each method offers distinct advantages and drawbacks, depending on specific business needs and operational contexts.

| Comparison Aspect | Irrigation Valve Leak Repair | Smart Irrigation Technology | Sealant Products |

|---|---|---|---|

| Performance | Effective for localized leaks; restores functionality | Automated monitoring and adjustments enhance water efficiency | Quick fix for minor leaks; may not be long-lasting |

| Cost | Moderate; costs include tools, parts, and labor | Higher initial investment; potential long-term savings | Low-cost; minimal investment required |

| Ease of Implementation | Requires some technical knowledge and tools | Installation can be complex; may require professional assistance | Simple application; user-friendly |

| Maintenance | Regular checks needed to prevent future leaks | Minimal maintenance; software updates may be required | Periodic reapplication may be necessary |

| Best Use Case | Ideal for existing systems with manageable leak issues | Best for large-scale operations seeking efficiency | Suitable for temporary fixes in smaller systems |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Smart Irrigation Technology?

Smart irrigation technology uses sensors and automated systems to optimize water use in agricultural and landscaping applications. These systems monitor soil moisture, weather conditions, and plant needs to adjust watering schedules in real-time.

Pros: Smart technology can significantly reduce water waste, lower operational costs over time, and improve crop yields by ensuring plants receive adequate hydration without overwatering.

Cons: The initial investment can be substantial, making it a less attractive option for smaller operations. Additionally, the complexity of installation may require hiring specialists, adding to upfront costs.

How Do Sealant Products Compare as a Quick Solution for Leaks?

Sealant products, such as plumber’s putty or specialized irrigation sealants, offer a straightforward and often inexpensive solution for minor leaks in irrigation systems. These materials can be applied directly to the leak site, providing a temporary fix without the need for extensive repairs.

Pros: The primary advantage is cost-effectiveness and ease of application. Businesses can quickly address minor leaks without significant downtime or investment in tools and parts.

Cons: Sealants are typically not a long-term solution. They may require reapplication over time and do not address underlying issues that could lead to future leaks, potentially resulting in recurring costs.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate solution for irrigation valve leak issues, B2B buyers should assess their specific needs, operational scale, and budget constraints. For businesses with existing systems facing manageable leaks, traditional repair methods may suffice. Conversely, organizations focused on long-term efficiency and water conservation should consider investing in smart irrigation technology. Meanwhile, sealant products can serve as a quick fix for minor leaks, particularly in smaller operations. By carefully weighing the advantages and disadvantages of each option, buyers can make informed decisions that align with their operational goals and sustainability initiatives.

Essential Technical Properties and Trade Terminology for irrigation valve leak repair

What Are the Key Technical Properties Essential for Irrigation Valve Leak Repair?

Understanding the technical specifications of irrigation valve components is crucial for effective leak repair. Here are several essential properties that B2B buyers should prioritize:

Material Grade: The material from which an irrigation valve is made significantly impacts its durability and resistance to environmental factors. Common materials include PVC, brass, and stainless steel. For instance, brass valves offer excellent corrosion resistance and are suitable for high-pressure applications, while PVC is lightweight and cost-effective for low-pressure systems. Selecting the right material can enhance the longevity of the irrigation system, reducing the frequency of repairs.

Pressure Rating: This specification indicates the maximum pressure that a valve can withstand before failure. It is vital to choose a valve that matches or exceeds the pressure levels of the irrigation system to prevent leaks and ensure optimal performance. A mismatch can lead to catastrophic failures, resulting in costly downtime and repairs.

Diaphragm Thickness: The diaphragm is a critical component of a solenoid valve that regulates water flow. A thicker diaphragm typically provides better durability against wear and tear, especially in environments with fluctuating pressures. For B2B buyers, opting for valves with robust diaphragms can minimize maintenance costs and enhance system reliability.

Tolerance Levels: Precision in manufacturing is essential for ensuring that valve components fit together correctly and operate efficiently. Tolerance levels refer to the acceptable range of variation in the dimensions of valve parts. High tolerance levels can lead to better sealing, reducing the likelihood of leaks. For international buyers, understanding tolerance specifications can help ensure compatibility with existing systems.

Flow Rate Capacity: This property defines the volume of water that can pass through the valve over a specific period, usually measured in gallons per minute (GPM). Selecting valves with appropriate flow rate capacities is crucial to maintain efficient irrigation without overloading the system. Miscalculating flow rates can lead to uneven watering, affecting crop yield or landscape health.

Corrosion Resistance: In regions with high salinity or harsh environmental conditions, selecting valves with high corrosion resistance is essential. This property extends the lifespan of the valves and reduces the risk of leaks due to material degradation. B2B buyers should inquire about the corrosion resistance ratings of valves to ensure they are suitable for their specific applications.

What Are Common Trade Terms Used in Irrigation Valve Leak Repair?

Familiarity with industry terminology is vital for effective communication and negotiation. Here are some key terms that B2B buyers should know:

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a valve is an OEM part is essential for ensuring compatibility and quality in irrigation systems.

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers assess budget constraints and inventory needs, particularly in regions with fluctuating demand.

RFQ (Request for Quotation): An RFQ is a standard business process where buyers invite suppliers to bid on specific products or services. It is crucial for B2B buyers to provide detailed specifications when issuing an RFQ to receive accurate pricing and delivery timelines.

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping costs, risk management, and delivery obligations, particularly for international buyers.

Lead Time: This term refers to the time it takes from placing an order until it is delivered. Understanding lead times is critical for planning and managing inventory, ensuring that irrigation projects are executed on schedule.

Warranty Period: This indicates the timeframe during which a manufacturer guarantees the performance of their product. Knowing the warranty period can protect buyers against defects and ensure that they receive quality products, fostering trust and long-term relationships with suppliers.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding irrigation valve leak repair, ensuring efficiency and longevity in their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve leak repair Sector

What Are the Key Market Dynamics and Trends in the Irrigation Valve Leak Repair Sector?

The irrigation valve leak repair sector is influenced by several global drivers that shape its market landscape. Increased awareness of water conservation, particularly in regions such as Africa and the Middle East, has led to a rising demand for efficient irrigation systems. This demand is further bolstered by the growing agricultural sector in South America and parts of Europe, where the need for effective water management is critical. Moreover, advances in technology, such as smart irrigation systems and IoT-enabled monitoring, are emerging trends that international B2B buyers should consider. These technologies not only enhance operational efficiency but also allow for real-time diagnostics, reducing the frequency and cost of repairs.

In addition, there is a notable shift towards digital sourcing platforms, enabling buyers to access a wider range of suppliers and products. This trend is particularly relevant for buyers in regions like Vietnam and Germany, where efficiency in procurement processes is paramount. As the market evolves, businesses are increasingly focusing on supplier relationships, seeking partners that can provide not just products but also expertise in irrigation systems. This emphasis on strategic sourcing is vital for ensuring that repairs are timely and effective, minimizing downtime and resource wastage.

How Does Sustainability Impact the Sourcing of Irrigation Valve Leak Repair Products?

Sustainability has become a cornerstone of sourcing strategies in the irrigation valve leak repair sector. The environmental impact of irrigation practices is under scrutiny, leading to a demand for products that minimize water wastage and promote efficient usage. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through their operations, product offerings, and supply chain practices.

Ethical sourcing is equally critical, as buyers seek materials that are not only high-quality but also sourced responsibly. This includes the use of eco-friendly materials in manufacturing irrigation valves and associated components. Certifications such as ISO 14001 for environmental management and various ‘green’ labels can serve as indicators of a supplier’s commitment to sustainable practices. By choosing partners with these certifications, buyers can align their procurement strategies with global sustainability goals, ultimately contributing to more efficient water management and reduced environmental footprints.

How Has the Irrigation Valve Leak Repair Sector Evolved Over Time?

The irrigation valve leak repair sector has undergone significant evolution over the past few decades, driven by advancements in technology and increasing awareness of water conservation. Initially, repairs were predominantly manual and labor-intensive, relying on traditional methods and basic tools. However, with the advent of new materials and technologies, such as PVC and advanced plastics, the durability and efficiency of irrigation systems have markedly improved.

As the agricultural landscape has changed, so has the approach to irrigation management. The integration of smart technologies, such as automated systems and sensors, has transformed the way leaks are detected and repaired. This evolution not only enhances the efficiency of irrigation systems but also supports sustainable agricultural practices by reducing water wastage. For B2B buyers, understanding this historical context is crucial for making informed decisions about sourcing and investing in modern irrigation solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve leak repair

How do I solve a leaking irrigation valve issue?

To address a leaking irrigation valve, first, shut off the water supply to prevent further leakage. Next, access the valve box and inspect the internal components, including the diaphragm and solenoid. If the diaphragm is damaged, replace it with a new one, ensuring that all seals are tight to prevent future leaks. After reassembling the valve, restore the water supply and test for leaks. Regular maintenance can help mitigate future issues, so consider scheduling routine inspections of your irrigation system.What is the best method for diagnosing sprinkler valve leaks?

The most effective method for diagnosing sprinkler valve leaks involves a systematic inspection of the system. Start by visually checking for signs of water accumulation around the valve area. Next, listen for hissing sounds that may indicate escaping air or water. After shutting off the water supply, disassemble the valve to examine the diaphragm and solenoid for wear or damage. Using a pressure gauge can also help determine if the valve is holding pressure correctly. Documenting these observations will assist in making informed repair decisions.How can I ensure the quality of irrigation valve repair parts?

To ensure the quality of irrigation valve repair parts, source them from reputable suppliers with a proven track record. Verify the supplier’s certifications and request product samples if possible. It’s also beneficial to check customer reviews and feedback on their products. Establishing a long-term relationship with suppliers can lead to better quality control and assurance. Additionally, consider conducting regular audits of suppliers to maintain high standards in your supply chain.What are common minimum order quantities (MOQs) for irrigation valve repair parts?

Minimum order quantities (MOQs) for irrigation valve repair parts can vary significantly based on the supplier and the type of components. Typically, MOQs can range from 50 to 500 units, depending on the item. It’s essential to discuss MOQs upfront with potential suppliers to understand their policies and negotiate terms that suit your business needs. Some suppliers may offer flexible MOQs for first-time buyers or larger orders, so it’s worth exploring these options.What payment terms should I expect when purchasing irrigation valve repair parts internationally?

When purchasing irrigation valve repair parts internationally, payment terms can vary widely. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Letters of credit (LC) are often used in international transactions to provide security for both parties. It’s crucial to negotiate clear payment terms and methods that protect your investment and ensure timely delivery. Be mindful of currency fluctuations and transaction fees that may affect the overall cost.How do I vet potential suppliers for irrigation valve repair parts?

To vet potential suppliers for irrigation valve repair parts, begin by researching their reputation in the industry. Check for certifications, such as ISO standards, and review their product quality history. Request references from previous clients and evaluate their responsiveness to inquiries. Conducting site visits, if feasible, can provide deeper insights into their manufacturing processes and quality control measures. Establishing clear communication channels and understanding their logistics capabilities are also crucial steps in the vetting process.What logistics considerations should I keep in mind for international shipments of irrigation parts?

When planning international shipments of irrigation parts, consider factors such as shipping methods, lead times, and customs regulations. Select a reliable freight forwarder experienced in handling agricultural equipment to ensure timely delivery. Be aware of import duties and taxes that may apply in your destination country, as these can significantly impact overall costs. Additionally, ensure that all necessary documentation, such as invoices and packing lists, is prepared to facilitate smooth customs clearance.How can I customize irrigation valve repair parts for specific needs?

Customizing irrigation valve repair parts to meet specific needs involves collaborating closely with your supplier. Discuss your requirements in detail, including dimensions, materials, and performance specifications. Suppliers with advanced manufacturing capabilities can often accommodate custom orders, but be prepared for longer lead times and potential cost increases. Conducting prototype testing can help ensure that the customized parts meet your operational standards before final production. Always document your specifications and agreements to avoid misunderstandings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Irrigation Valve Leak Repair Manufacturers & Suppliers List

1. Irrigation Solutions – Sprinkler Valve Issues

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Leaking sprinkler valve; issues with valve replacement by irrigation techs; leaks stop when main valve is shut off; potential underground leaks in sprinkler pipes; possible excessive pressure in the system.

2. This Old House – Essential Tools and Parts

Domain: thisoldhouse.com

Registered: 1998 (27 years)

Introduction: Tools needed: garden trowel, Phillips screwdriver, pliers, bucket; Replacement parts: valve diaphragms, waterproof wire connectors, clean stones or gravel, dry rags.

3. Lawn Genie – 150 psi Anti-Siphon Valve with Flow Control

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: Lawn Genie 150 psi Anti-Siphon Valve with Flow Control-L7034

4. Sprinkler Warehouse – Fixing a Broken Sprinkler Valve

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: How to Fix a Broken Sprinkler Valve: Shut off the water to the valve manifold, remove standing water, unscrew the solenoid and set it aside, unscrew the top of the valve and remove it, open the top of the replacement valve, remove internal parts from the defective valve, replace with new pieces, ensure solenoid is wired correctly, activate the zone to confirm repair. Featured Products: Toro Rotor …

5. Hunter – HCV Check Valves

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: The text discusses issues related to valves weeping or leaking when the valve is off. It identifies two main causes: 1) Low Head Drainage, where water drains from the lateral piping out of the sprinkler, which can be resolved by installing check valves (such as the HCV) on sprinklers and lateral lines. 2) Water leaking through the zone valve due to debris obstructing the valve’s diaphragm, which c…

6. Irrigreen – Leak Repair Solutions

Domain: irrigreen.com

Registered: 2013 (12 years)

Introduction: This company, Irrigreen – Leak Repair Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. HWD – Irrigation Valve Replacement Guide

Domain: hwd.com

Registered: 1995 (30 years)

Introduction: Replacing an above ground irrigation valve involves the following key details: 1. Irrigation valves control irrigation zones and are common sources of outdoor leaks. 2. Tools needed include a new valve, adjustable pliers, and plumber’s tape. 3. Steps include turning off the water, relieving pressure, unscrewing fittings, disconnecting valve wires, cleaning pipe threads, applying plumber’s tape, an…

8. Simmons Landscape – Irrigation System Valves

Domain: simmonslandscape.com

Registered: 2003 (22 years)

Introduction: Irrigation System Valves: Key components controlling water flow, including diaphragm (rubber disk for sealing water passage), solenoid (responds to electrical signals to open/close valve), and valve body (distributes water). Common issues include valve not turning on due to electrical issues or solenoid failures, and valve not turning off due to debris or diaphragm damage. Regular inspections and …

9. Angi – Replacement Sprinkler Valves

Domain: angi.com

Registered: 1996 (29 years)

Introduction: Replacement sprinkler valve or part ranges from $13 to $150.

Strategic Sourcing Conclusion and Outlook for irrigation valve leak repair

What Are the Key Takeaways for B2B Buyers in Irrigation Valve Leak Repair?

In the realm of irrigation valve leak repair, strategic sourcing is paramount for international B2B buyers. Understanding the intricate components of sprinkler systems, such as valves, solenoids, and controllers, allows for informed procurement decisions. Buyers should prioritize suppliers that offer high-quality replacement parts, tools, and maintenance materials, ensuring that their irrigation systems operate efficiently and sustainably.

Additionally, embracing preventative maintenance strategies can significantly reduce long-term operational costs and resource wastage, aligning with global sustainability goals. The importance of regular inspections and timely repairs cannot be overstated; they are essential for maximizing system longevity and performance.

How Can International B2B Buyers Prepare for Future Challenges?

As the agricultural landscape evolves, so too will the technologies and solutions available for irrigation systems. Buyers from regions such as Africa, South America, the Middle East, and Europe should remain proactive by fostering relationships with reliable suppliers and investing in training for their maintenance teams. This approach not only enhances immediate repair capabilities but also positions businesses to adapt to future innovations in irrigation technology.

In conclusion, by strategically sourcing high-quality materials and prioritizing effective maintenance, B2B buyers can ensure the resilience and efficiency of their irrigation systems. The time to act is now—commit to sustainable practices that will benefit both your operations and the environment.