Introduction: Navigating the Global Market for irrigation valve problems

In the ever-evolving landscape of global agriculture, irrigation valve problems present a critical challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. These issues can severely impact water management efficiency and crop yields, leading to increased operational costs and resource wastage. This comprehensive guide addresses the multifaceted nature of irrigation valve problems, offering insights into various types of valves, their applications, and the common issues that arise during operation.

By exploring the intricacies of valve functionality, buyers will gain a deeper understanding of how to identify and troubleshoot issues such as stuck valves, faulty wiring, and water hammer effects. Additionally, the guide provides practical advice on supplier vetting processes, allowing businesses to source high-quality components and services tailored to their unique agricultural needs.

Moreover, we delve into cost considerations and potential solutions that can enhance the longevity and performance of irrigation systems. This resource empowers international B2B buyers with the knowledge needed to make informed purchasing decisions, ensuring that they can effectively manage irrigation systems that are crucial for sustainable agricultural practices. With actionable insights and expert guidance, this guide aims to streamline the procurement process and mitigate the risks associated with irrigation valve problems.

Understanding irrigation valve problems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stuck or Jammed Valves | Valves that fail to open or close due to debris or mechanical failure. | Agriculture, landscaping, municipal irrigation | Pros: Simple fixes often available; Cons: Can lead to water wastage if undetected. |

| Electrical or Wiring Issues | Problems with the electrical connections or control signals. | Commercial irrigation systems, golf courses | Pros: Identifying wiring issues can prevent larger repairs; Cons: Requires electrical expertise. |

| Clogged or Blocked Valves | Debris buildup causing restricted flow or complete blockage. | Industrial irrigation, horticulture | Pros: Regular maintenance can mitigate issues; Cons: May require disassembly for thorough cleaning. |

| Pressure-Related Problems | Valves not functioning due to insufficient or excessive water pressure. | Large-scale agricultural operations | Pros: Proper pressure management improves system efficiency; Cons: Requires monitoring and potential upgrades. |

| Solenoid Malfunctions | Failure of the solenoid to operate the valve correctly. | Residential and commercial irrigation | Pros: Solenoid replacement is generally straightforward; Cons: Frequent failures can indicate larger systemic issues. |

What Are the Characteristics of Stuck or Jammed Valves?

Stuck or jammed valves are often a result of debris accumulation, mechanical failure, or corrosion. These issues can prevent the valve from opening or closing, disrupting the entire irrigation system. In B2B applications, especially in agriculture and landscaping, identifying and rectifying these issues quickly is crucial to avoid water wastage and maintain optimal irrigation schedules. Buyers should consider the ease of access and maintenance requirements when selecting valves to reduce the risk of these problems.

How Do Electrical or Wiring Issues Affect Irrigation Systems?

Electrical or wiring issues can manifest as valves that fail to respond to control signals. These problems can arise from damaged wiring, incorrect voltage, or faulty controllers, significantly impacting commercial irrigation systems and golf courses. For B2B buyers, ensuring that electrical components are robust and suitable for the operational environment is vital. Regular inspections and the use of high-quality wiring can mitigate these risks.

What Causes Clogged or Blocked Valves?

Clogged or blocked valves are typically caused by debris, sediment, or mineral buildup. This condition restricts water flow and can lead to inefficient irrigation, particularly in industrial settings and horticulture. For B2B buyers, investing in filtration systems and regular maintenance schedules can prevent these issues. Understanding the specific environmental conditions, such as water quality, is essential when selecting valves to ensure longevity and performance.

How Do Pressure-Related Problems Impact Irrigation Efficiency?

Pressure-related problems arise when valves do not operate under the correct water pressure, leading to inefficient irrigation practices. This is particularly relevant in large-scale agricultural operations where consistent pressure is necessary for optimal performance. B2B buyers should prioritize valves that can handle varying pressures and consider pressure regulation systems to maintain efficiency. Regular monitoring and adjustments can prevent costly downtime.

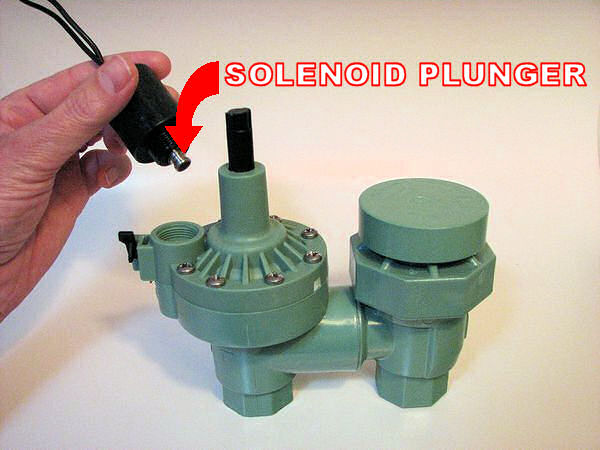

What Are the Implications of Solenoid Malfunctions?

Solenoid malfunctions can prevent valves from operating correctly, leading to irrigation failures. These issues often stem from electrical failures or wear over time. In both residential and commercial applications, quick identification and replacement of faulty solenoids can restore functionality. Buyers should consider the reliability of solenoid components and their compatibility with existing systems to minimize future disruptions.

Key Industrial Applications of irrigation valve problems

| Industry/Sector | Specific Application of Irrigation Valve Problems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Managing Water Distribution in Crop Irrigation | Ensures optimal crop growth and reduces water waste | Durability in harsh climates, compatibility with existing systems |

| Landscaping & Gardening | Efficient Watering Systems for Parks and Gardens | Enhances aesthetic appeal and plant health | Availability of local suppliers, ease of installation and maintenance |

| Municipal Water Supply | Regulating Water Flow in Urban Landscapes | Supports sustainable water management practices | Compliance with local regulations, reliability, and efficiency |

| Mining & Mineral Processing | Dust Suppression and Vegetation Control | Improves safety and operational efficiency | Robustness against abrasive materials, easy access to replacement parts |

| Horticulture | Precise Irrigation for Greenhouses | Maximizes yield and resource conservation | Customization options, ability to handle diverse plant needs |

How Does the Agriculture Sector Benefit from Addressing Irrigation Valve Problems?

In agriculture, irrigation valves are crucial for managing water distribution across vast fields. Problems like stuck valves or faulty wiring can lead to uneven watering, affecting crop yield and quality. By resolving these issues, farmers can ensure efficient water use, which is especially vital in regions facing water scarcity, such as parts of Africa and the Middle East. Buyers should prioritize valves that can withstand local environmental conditions and have a proven track record of reliability.

What Advantages Does the Landscaping Industry Gain from Efficient Irrigation Valve Management?

In landscaping and gardening, irrigation valve problems can significantly impact the health of plants and the overall appearance of green spaces. Issues such as broken or clogged valves can lead to overwatering or underwatering, damaging the landscape. Efficient management of these problems allows for a consistent watering schedule, enhancing aesthetic appeal and maintaining plant health. Buyers in this sector should consider sourcing valves that offer ease of installation and maintenance, as well as local supplier support to minimize downtime.

How Do Municipal Water Supply Systems Utilize Solutions for Irrigation Valve Issues?

Municipal water supply systems depend on reliable irrigation valves to regulate water flow in urban landscapes. Problems like insufficient voltage or clogged solenoid ports can disrupt water distribution, leading to inefficiencies and increased operational costs. Addressing these issues ensures sustainable water management practices, which is critical in densely populated areas. Buyers should focus on valves that comply with local regulations and are designed for high efficiency to meet the demands of urban environments.

What Role Do Irrigation Valves Play in the Mining & Mineral Processing Industry?

In the mining and mineral processing sector, irrigation valves are essential for dust suppression and vegetation control around mining sites. Issues such as valve failures can compromise safety and operational efficiency. By proactively managing these valve problems, companies can enhance safety measures and maintain compliance with environmental regulations. Buyers should seek robust valve solutions that can withstand abrasive materials and provide easy access to replacement parts to ensure continuous operation.

How Is Horticulture Enhanced by Addressing Irrigation Valve Challenges?

Horticulture operations, particularly in greenhouses, require precise irrigation to maximize yield and conserve resources. Irrigation valve problems can lead to inconsistent watering, affecting plant health and growth. By effectively addressing these challenges, horticulturists can optimize water usage and improve productivity. Buyers should look for customizable valve solutions that cater to diverse plant needs and ensure reliable performance in varying environmental conditions.

3 Common User Pain Points for ‘irrigation valve problems’ & Their Solutions

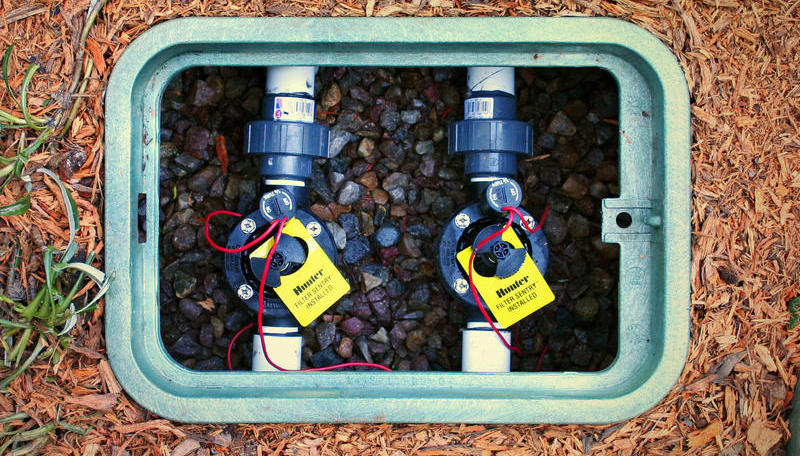

Scenario 1: Inconsistent Water Distribution Across Fields

The Problem: Many agricultural businesses face the challenge of inconsistent water distribution due to faulty irrigation valves. This inconsistency can lead to under-watering certain areas while over-watering others, resulting in crop stress and increased operational costs. For B2B buyers, especially those managing large irrigation systems, identifying and rectifying these issues can be daunting. Over time, sediment and debris can accumulate in valves, causing blockages that prevent them from opening or closing properly, thus disrupting the entire irrigation schedule.

The Solution: To tackle this issue, it’s essential to implement a regular maintenance schedule focused on valve inspection and cleaning. Start by investing in quality filtration systems to prevent debris from entering the irrigation lines. When examining valves, check for any signs of clogging, particularly in the solenoid and exhaust ports. If blockages are detected, disassemble the valve and use a small wire or brush to clear debris. For long-term solutions, consider upgrading to higher-quality valves designed for your specific environmental conditions. Choosing valves made from corrosion-resistant materials can minimize future maintenance needs, ensuring consistent performance across your fields.

Scenario 2: Sprinkler System Not Activating When Needed

The Problem: Irrigation managers often encounter situations where their sprinkler systems fail to activate, leading to potential crop damage and increased water usage. This issue can arise from various factors, including electrical failures, faulty timers, or issues with the valve itself. For B2B buyers, this scenario not only disrupts water supply but also complicates resource management and planning, impacting overall productivity and profitability.

The Solution: A systematic troubleshooting approach is key to resolving this issue. Begin by checking the power supply to the irrigation controller to ensure it is functioning correctly. Use a multimeter to verify that the voltage levels are within the acceptable range (24-28 VAC). If the power supply is intact, inspect the wiring connections leading to the valves for any signs of damage or corrosion. It’s also crucial to manually activate the valve using the solenoid to rule out any mechanical failures. If the valve opens manually but not automatically, replacing the solenoid or upgrading to a more robust controller may be necessary. Additionally, ensuring that all components are compatible and well-suited for the specific irrigation system will enhance reliability.

Scenario 3: High Repair Costs Due to Valve Failures

The Problem: Frequent valve failures can lead to high repair costs and disrupt irrigation schedules, which is a significant pain point for agricultural businesses. B2B buyers may find themselves spending excessively on repairs or replacements, which not only affects their budget but also their ability to maintain consistent water supply for crops. Understanding the root causes of these failures is crucial to mitigating these costs and enhancing system longevity.

The Solution: To reduce repair costs, invest in high-quality, durable valves that are appropriate for your irrigation system’s specific needs and environmental conditions. Conduct a thorough analysis of your existing irrigation infrastructure to identify any systemic weaknesses. Implementing a preventative maintenance program that includes regular inspections and timely replacements of worn components can save significant costs in the long run. Additionally, training staff on proper valve operation and maintenance techniques can prevent misuse that often leads to premature failures. By establishing relationships with reputable suppliers, B2B buyers can also gain access to expert advice and support, ensuring they select the best products for their needs.

Strategic Material Selection Guide for irrigation valve problems

What Are the Key Materials Used in Irrigation Valves?

When selecting materials for irrigation valves, it is crucial to consider their properties, advantages, and limitations. The choice of material can significantly affect the performance, durability, and overall cost of irrigation systems, especially in diverse climates and conditions found in regions like Africa, South America, the Middle East, and Europe.

How Does PVC Perform in Irrigation Valve Applications?

Polyvinyl Chloride (PVC) is a widely used material in irrigation valves due to its excellent chemical resistance and lightweight nature. PVC valves typically have a temperature rating of up to 60°C (140°F) and can handle moderate pressure levels, making them suitable for various irrigation applications.

Pros: PVC is cost-effective, easy to install, and resistant to corrosion, which is vital in areas with high salinity or chemical exposure.

Cons: However, PVC can become brittle over time when exposed to UV light and extreme temperatures, limiting its lifespan in harsh environments.

For international buyers, it is essential to ensure compliance with local standards like ASTM or DIN for quality assurance, particularly in regions with rigorous regulations.

What Are the Benefits of Brass in Irrigation Valves?

Brass is another popular material used in irrigation valves, known for its durability and high strength. It can withstand higher temperatures and pressures compared to PVC, with ratings often exceeding 80°C (176°F) and 10 bar (145 psi).

Pros: Brass valves are resistant to corrosion and can handle a wide range of media, making them suitable for both potable and non-potable water applications.

Cons: The primary drawback is the higher cost compared to PVC and potential for dezincification if not properly alloyed, which can lead to valve failure.

International buyers should consider the additional costs associated with brass but may find it worthwhile for long-term investments in regions where durability is paramount, such as the Middle East.

How Do Stainless Steel Valves Compare for Irrigation Systems?

Stainless steel is often chosen for its exceptional corrosion resistance and strength, making it ideal for challenging environments. These valves can typically handle temperatures up to 200°C (392°F) and high-pressure applications.

Pros: Stainless steel valves are highly durable and require minimal maintenance, making them suitable for long-term use in various irrigation systems.

Cons: The main disadvantage is the cost, as stainless steel valves are significantly more expensive than PVC or brass.

For B2B buyers in regions like Europe, where environmental standards are stringent, stainless steel valves may be a preferred option despite their higher initial investment due to their longevity and reliability.

What Role Does Ductile Iron Play in Irrigation Valves?

Ductile iron is a robust material that offers excellent strength and durability, often used in larger irrigation systems. It can withstand high pressure and is resistant to impact and wear.

Pros: Ductile iron valves are highly durable and can handle extreme conditions, making them ideal for agricultural applications in rugged terrains.

Cons: However, ductile iron is heavier and typically more expensive than other materials, which can increase shipping and installation costs.

International buyers should consider the weight and cost implications, especially in regions with limited access to heavy machinery for installation. Compliance with local standards is also crucial for ensuring product reliability.

Summary Table of Material Selection for Irrigation Valves

| Material | Typical Use Case for irrigation valve problems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Residential and light commercial irrigation | Cost-effective and corrosion-resistant | Brittle under UV exposure and extreme temps | Low |

| Brass | Potable and non-potable water applications | Durable and handles a wide range of media | Higher cost and risk of dezincification | Med |

| Stainless Steel | High-pressure and high-temperature systems | Exceptional durability and low maintenance | High initial cost | High |

| Ductile Iron | Agricultural applications in rugged terrains | Excellent strength and impact resistance | Heavy and higher shipping costs | Med |

This analysis provides a comprehensive overview of material options for irrigation valves, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve problems

What Are the Key Stages in the Manufacturing Process of Irrigation Valves?

The manufacturing of irrigation valves involves several critical stages, each designed to ensure the highest quality and performance. The main stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first step in the manufacturing process is material preparation. Common materials for irrigation valves include brass, PVC, and various alloys that resist corrosion and wear. Suppliers often source these materials based on their durability and compatibility with water and soil conditions typical in agricultural and landscaping applications.

Material preparation involves cutting, machining, and treating these materials to enhance their properties. For instance, brass components may undergo a process to improve their resistance to corrosion, while PVC parts are often treated to withstand UV radiation. This preparation is vital as it directly influences the valve’s longevity and performance in various environmental conditions.

How Are Irrigation Valves Formed During Manufacturing?

The forming stage involves shaping the prepared materials into the desired configurations for valves. This can be achieved through methods such as molding, forging, and machining. For instance, PVC valves are typically manufactured using injection molding, where heated plastic is injected into a mold to create the valve body.

For metal valves, processes such as CNC machining are employed to achieve precise dimensions and tolerances. This precision is crucial for ensuring proper fit and function, particularly in systems where multiple valves are used in conjunction. The forming stage is essential for ensuring that the valves can withstand the pressures and stresses of the irrigation system.

What Steps Are Involved in the Assembly of Irrigation Valves?

Once the individual components are formed, they move to the assembly stage. This involves fitting together various parts, such as the valve body, diaphragm, solenoid, and other mechanisms. Assembly often requires specialized tools and techniques to ensure that seals are tight and that there are no leaks.

During this stage, manufacturers may employ automated assembly lines to increase efficiency and consistency. Manual assembly may also occur for complex valves that require more intricate handling. It is crucial that the assembly process adheres to strict guidelines to prevent any issues that could lead to malfunction.

How Is the Finishing Stage Performed and Why Is It Important?

The finishing stage includes processes such as surface treatment, painting, and quality checks. For metallic components, this might involve galvanizing or applying a protective coating to prevent corrosion. For PVC valves, UV-resistant finishes are often applied to enhance durability.

Finishing is vital as it not only improves the aesthetic appeal of the valves but also extends their lifespan. Properly finished valves can better resist environmental factors, reducing the frequency of replacements and maintenance.

What Are the Quality Assurance Measures in Irrigation Valve Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final products meet both industry standards and customer expectations.

Which International Standards Are Relevant to Irrigation Valve Manufacturing?

Manufacturers of irrigation valves typically adhere to various international quality standards, such as ISO 9001, which outlines the requirements for a quality management system. This certification is crucial for international B2B buyers as it demonstrates a commitment to quality and customer satisfaction.

In addition to ISO standards, specific industry standards such as CE marking (indicating compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) certifications may be relevant, especially for valves used in oil and gas applications. Understanding these standards can guide B2B buyers in assessing the reliability and safety of the products they purchase.

What Are the Key Quality Control Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Regular checks are performed during manufacturing to monitor processes and ensure adherence to quality standards.

- Final Quality Control (FQC): Before the product is shipped, a thorough inspection is conducted to verify that the finished valves function correctly and meet all specifications.

These checkpoints are essential for catching potential defects early in the manufacturing process, thereby reducing the risk of faulty products reaching customers.

What Common Testing Methods Are Used to Ensure Quality in Irrigation Valves?

Manufacturers employ various testing methods to ensure the reliability and functionality of irrigation valves, including:

- Pressure Testing: Valves are subjected to high-pressure conditions to verify that they can withstand operational pressures without leaking.

- Functional Testing: This involves activating the valve to ensure it opens and closes correctly under simulated conditions.

- Environmental Testing: Valves may be exposed to extreme temperatures, humidity, and UV light to assess their durability in diverse environments.

These tests provide critical data that helps manufacturers refine their products and improve quality.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some effective strategies:

What Steps Should Buyers Take to Conduct Supplier Audits?

Buyers should conduct thorough audits of potential suppliers. This can include:

- Site Visits: Visiting the manufacturing facility allows buyers to observe the production process and quality control measures firsthand.

- Document Review: Requesting quality management documentation, including ISO certifications, QC reports, and testing protocols, can provide insights into the supplier’s commitment to quality.

How Can Buyers Utilize Third-Party Inspections for Added Assurance?

Engaging third-party inspection agencies can further enhance the verification process. These agencies can conduct independent assessments of the manufacturing processes and quality control measures, providing unbiased reports that can inform purchasing decisions.

What Unique QC Considerations Exist for International Buyers in Diverse Markets?

International buyers must also be aware of specific quality control nuances that may vary by region. For instance, regulations and standards may differ significantly between countries. Buyers should familiarize themselves with local regulations in their target markets to ensure compliance and avoid potential legal issues.

Additionally, understanding cultural differences in business practices can facilitate smoother negotiations and partnerships with suppliers. This knowledge can lead to better communication and more effective quality assurance throughout the procurement process.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing irrigation valves, ultimately ensuring the reliability and efficiency of their irrigation systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve problems’

Introduction

Navigating the complexities of irrigation valve procurement can be daunting, especially when addressing potential problems. This guide serves as a practical checklist to assist B2B buyers in sourcing irrigation valves effectively, ensuring reliability and performance in their irrigation systems. By following these steps, you can minimize risks and optimize your purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for your irrigation valves is crucial for ensuring compatibility with your existing systems. Consider factors such as valve type (e.g., automatic or manual), pressure ratings, flow rates, and materials. This clarity will help you communicate effectively with suppliers and avoid costly mismatches.

Step 2: Research Potential Suppliers

Before making any commitments, conduct thorough research on potential suppliers. Look for companies with a solid reputation in the industry and experience in your specific market region, whether it be Africa, South America, the Middle East, or Europe. Assess their online presence, client testimonials, and case studies to gauge their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is essential to ensure compliance with international standards and regulations. Look for certifications such as ISO 9001 for quality management and other relevant industry-specific credentials. These certifications provide assurance that the supplier adheres to rigorous quality control processes, which is vital for the longevity and performance of your irrigation valves.

Step 4: Request Samples or Prototypes

Obtaining samples or prototypes of the irrigation valves can significantly influence your purchasing decision. This step allows you to assess the product’s quality and functionality firsthand. Evaluate the materials, construction, and ease of installation to ensure they meet your operational needs before committing to a larger order.

Step 5: Assess After-Sales Support and Warranty Options

A robust after-sales support system is a key indicator of a reliable supplier. Inquire about warranty terms, repair services, and availability of spare parts. Understanding the level of support you can expect post-purchase helps mitigate risks associated with valve malfunction or failure, ensuring your irrigation system remains operational.

Step 6: Check for Local Distribution and Supply Chain Logistics

Consider suppliers that have a local presence or established distribution networks in your region. This can enhance delivery times and reduce shipping costs. Evaluate the supplier’s supply chain logistics to ensure they can meet your demand consistently, especially during peak irrigation seasons.

Step 7: Negotiate Terms and Pricing

Finally, engage in negotiations to secure favorable terms and pricing. Consider factors like bulk purchasing discounts, payment terms, and delivery schedules. Establishing a clear agreement on these elements can lead to a more beneficial long-term relationship, ensuring you get the best value for your investment in irrigation valves.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing irrigation valves, ensuring that they select reliable products that meet their specific needs and operational requirements.

Comprehensive Cost and Pricing Analysis for irrigation valve problems Sourcing

What Are the Key Cost Components for Sourcing Irrigation Valve Solutions?

When sourcing solutions for irrigation valve issues, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The quality and type of materials used in manufacturing irrigation valves significantly impact costs. High-grade materials may elevate the price but will ensure durability and performance, particularly in harsh environments common in regions like Africa and the Middle East.

Labor: Labor costs can vary based on the location of the manufacturing facility. Regions with higher labor costs, such as parts of Europe, may lead to increased pricing for valves. Conversely, sourcing from regions with lower labor costs can reduce expenses but may involve trade-offs in quality.

Manufacturing Overhead: This encompasses expenses related to factory maintenance, utilities, and salaries of non-production staff. Efficient manufacturing processes can minimize overhead and consequently affect pricing.

Tooling: Initial tooling costs can be substantial, especially for customized valve solutions. Buyers should consider whether the tooling investment is justified based on their specific needs and expected order volume.

Quality Control (QC): Rigorous quality assurance processes ensure that valves meet industry standards. While this adds to the cost, it can prevent future issues and reduce maintenance costs.

Logistics: Shipping costs vary based on distance, shipping methods, and Incoterms chosen. International buyers should factor in customs duties and taxes, which can further influence overall pricing.

Margin: Supplier profit margins also play a role in the final price. Understanding the competitive landscape can help buyers negotiate better terms.

How Do Price Influencers Impact the Cost of Irrigation Valves?

Several factors influence the pricing of irrigation valves, and understanding these can aid in making cost-effective decisions:

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often results in discounted rates. Buyers should assess their needs and explore bulk purchasing options to leverage cost savings.

Specifications and Customization: Custom solutions typically incur higher costs due to specialized manufacturing processes. Buyers should weigh the necessity of custom features against the potential cost savings of standard products.

Materials: The choice of materials not only affects durability but also the initial purchase price. Buyers focused on long-term investment should prioritize higher-quality materials that minimize maintenance and replacement costs.

Quality and Certifications: Valves that meet international quality standards may carry a premium price tag. However, investing in certified products can enhance reliability and reduce the risk of failure.

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may charge more but often provide better support and service.

Incoterms: Different shipping terms can alter costs and responsibilities. Understanding Incoterms can help buyers negotiate better shipping arrangements that align with their budgets.

What Are Effective Negotiation Strategies for International B2B Buyers?

For international buyers, particularly in regions like Africa, South America, and the Middle East, navigating pricing nuances is essential:

Total Cost of Ownership (TCO): Buyers should evaluate not just the initial price but the total cost of ownership, including maintenance, potential downtime, and replacement costs. This holistic view can justify higher upfront investments in quality products.

Leverage Long-Term Relationships: Establishing long-term partnerships with suppliers can lead to better pricing and terms. Suppliers often value loyal customers and may offer discounts for repeat business.

Seek Multiple Quotes: Obtaining quotes from multiple suppliers can create a competitive environment that encourages better pricing. Ensure that quotes are for comparable products to facilitate accurate comparisons.

Negotiate Payment Terms: Flexible payment terms can help manage cash flow. Buyers should explore options such as extended payment periods or installment payments to ease financial strain.

Final Thoughts on Sourcing Irrigation Valves

It is essential for B2B buyers to approach the sourcing of irrigation valves with a comprehensive understanding of cost structures and pricing influencers. By leveraging effective negotiation strategies and considering the total cost of ownership, buyers can make informed decisions that balance quality with budget constraints. Remember, prices can vary widely based on many factors, and it is advisable to seek expert guidance or conduct thorough market research to ensure optimal sourcing decisions.

Alternatives Analysis: Comparing irrigation valve problems With Other Solutions

Introduction to Alternative Solutions for Irrigation Issues

When addressing irrigation challenges, particularly those related to valve problems, it’s essential to explore various solutions that can effectively manage water distribution in agricultural or landscaping applications. This analysis provides a comparative overview of traditional irrigation valve issues against alternative technologies, helping B2B buyers make informed decisions based on performance, cost, and maintenance requirements.

Comparison Table

| Comparison Aspect | Irrigation Valve Problems | Smart Irrigation Systems | Drip Irrigation Technology |

|---|---|---|---|

| Performance | Often leads to inconsistent water flow and pressure | Provides real-time data for optimal water usage | Delivers precise water directly to plant roots |

| Cost | Repair costs can accumulate over time | Higher initial investment but reduces long-term costs | Moderate setup cost with low operational costs |

| Ease of Implementation | Requires technical knowledge for installation and maintenance | May need professional installation | Can be installed DIY with proper guidelines |

| Maintenance | Regular checks and repairs needed | Low maintenance with automated adjustments | Minimal maintenance required, mainly filter cleaning |

| Best Use Case | Suitable for large-scale conventional irrigation | Ideal for regions with variable weather conditions | Best for water-scarce areas or specific crop needs |

Detailed Breakdown of Alternatives

Smart Irrigation Systems

Smart irrigation systems utilize sensors and weather data to optimize watering schedules and amounts, significantly improving water efficiency. The primary advantage is the reduction in water waste and the ability to adapt to changing weather conditions in real-time. However, the initial investment can be higher, and while installation may require a professional, the long-term savings on water bills often justify the upfront costs. These systems are particularly beneficial for large agricultural operations or landscaping projects in regions with fluctuating climates.

Drip Irrigation Technology

Drip irrigation is a method that delivers water directly to the roots of plants through a network of tubes and emitters. This technology minimizes evaporation and runoff, making it highly efficient, especially in arid regions. The cost of setup can be moderate, but once installed, operational costs are relatively low. Maintenance typically involves cleaning filters and checking for clogs, which is manageable. Drip irrigation is particularly effective for high-value crops and areas where water conservation is paramount, offering a sustainable solution in water-scarce environments.

Conclusion: Choosing the Right Solution for Your Irrigation Needs

B2B buyers must consider various factors when selecting an irrigation solution. While traditional irrigation valve issues are prevalent, exploring alternatives like smart irrigation systems and drip irrigation technology can lead to enhanced water management, cost savings, and efficiency. Understanding the specific requirements of your operation, such as water availability, crop types, and budget constraints, will guide you in choosing the most suitable solution. Investing in advanced technologies may yield greater long-term benefits, especially in dynamic environments where water conservation is critical.

Essential Technical Properties and Trade Terminology for irrigation valve problems

What Are the Key Technical Properties of Irrigation Valves?

1. Material Grade

The material grade of irrigation valves is crucial for determining their durability and resistance to environmental factors. Common materials include PVC, brass, and stainless steel. Each material has its unique properties; for example, brass is known for its corrosion resistance, while PVC is lightweight and cost-effective. In B2B transactions, understanding material grades helps buyers assess the longevity and maintenance requirements of the valves, ultimately impacting operational costs.

2. Pressure Rating

Pressure rating indicates the maximum pressure a valve can withstand without failure. It is typically measured in pounds per square inch (PSI). For irrigation systems, valves often operate under varying pressures, so selecting a valve with an appropriate pressure rating is vital to prevent leaks or ruptures. Buyers should prioritize valves that meet or exceed the pressure requirements of their specific irrigation setups to ensure reliability and efficiency.

3. Flow Rate

Flow rate, measured in gallons per minute (GPM) or liters per second (L/s), determines how much water can pass through the valve in a given time. A higher flow rate is essential for larger irrigation systems, while smaller systems may require lower flow rates. Understanding flow rate specifications allows B2B buyers to select valves that optimize water usage and meet agricultural or landscaping needs effectively.

4. Tolerance Levels

Tolerance levels refer to the acceptable range of dimensional variations in the valve components. Precision in manufacturing is crucial for ensuring that valves fit properly within the irrigation system and operate efficiently. Tolerance issues can lead to leaks or mechanical failures. For B2B buyers, selecting suppliers who adhere to strict tolerance specifications can reduce the risk of costly replacements and downtime.

5. Solenoid Voltage

The solenoid voltage is a critical specification that affects the operation of electrically activated valves. Most irrigation valves require a voltage of 24-28 VAC to function correctly. Understanding the voltage requirements helps buyers ensure compatibility with their control systems, which is vital for the seamless operation of the irrigation network.

6. Diaphragm Type

The diaphragm type influences how well the valve seals and functions under pressure. Common types include rubber and silicone diaphragms. Each type has its advantages in terms of durability and resistance to wear and tear. Buyers should consider the specific conditions of their irrigation systems, such as chemical exposure and temperature fluctuations, to choose the appropriate diaphragm type.

What Are the Common Trade Terms in the Irrigation Valve Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that may be marketed by another manufacturer. In the irrigation valve sector, OEMs provide specialized parts that meet the quality and performance standards required by irrigation systems. Understanding OEM specifications can help B2B buyers ensure they are sourcing high-quality components that are compatible with their existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is essential for B2B buyers, as it can affect inventory management and cash flow. Knowing the MOQ helps businesses gauge whether a supplier’s offerings align with their purchasing strategies and operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document that potential buyers submit to suppliers to request pricing and terms for specific products or services. In the context of irrigation valves, an RFQ allows buyers to compare costs and terms across multiple suppliers, facilitating informed decision-making. This process is critical for optimizing procurement budgets and ensuring competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is vital for B2B buyers involved in international transactions, as they clarify who is responsible for transportation, insurance, and customs duties. This knowledge helps prevent misunderstandings and additional costs in the supply chain.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. In the irrigation industry, lead times can vary based on the complexity of the order and the supplier’s production capacity. For B2B buyers, knowing the lead time is essential for planning irrigation projects and ensuring that systems are operational when needed.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions that enhance the efficiency and effectiveness of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve problems Sector

What Are the Key Drivers and Trends Influencing the Irrigation Valve Problems Market?

The global irrigation valve market is experiencing transformative dynamics driven by several factors. Rising water scarcity and the need for efficient water management systems are paramount, especially in regions like Africa and the Middle East, where agriculture is vital for economic stability. This urgency has led to an increased focus on advanced irrigation technologies that enhance water conservation, efficiency, and yield.

Moreover, the advent of smart irrigation systems is reshaping sourcing trends. These systems utilize IoT devices and real-time data analytics to monitor and control water flow, minimizing the risk of valve-related issues. As international B2B buyers seek to enhance their agricultural practices, they are increasingly looking for suppliers who offer integrated solutions that combine technology with traditional valve systems.

Emerging market players are also leveraging innovative materials and designs that cater to the unique environmental conditions of different regions. For instance, in South America and Europe, there is a growing demand for valves that can withstand extreme weather conditions and reduce maintenance costs.

Additionally, the integration of e-commerce platforms is revolutionizing how buyers source irrigation valves, enabling them to compare products and suppliers seamlessly. This trend is particularly beneficial for buyers in remote areas, as they can access global suppliers and cutting-edge technologies without geographical limitations.

How Is Sustainability Shaping the Sourcing of Irrigation Valve Solutions?

Sustainability is becoming a critical factor in the procurement process for irrigation valve solutions. Environmental impact assessments are increasingly influencing purchasing decisions, as B2B buyers prioritize suppliers that demonstrate a commitment to sustainable practices. The irrigation sector is under scrutiny for its water usage and potential environmental degradation, leading to a demand for products that minimize these impacts.

Ethical sourcing is also gaining traction, with businesses looking to establish supply chains that prioritize social responsibility and fair labor practices. Buyers are more inclined to partner with manufacturers who possess certifications like ISO 14001 for environmental management or those utilizing recycled materials in their products.

The shift towards ‘green’ certifications is not just about compliance; it’s a strategic move to enhance brand reputation and meet the expectations of environmentally conscious consumers. For irrigation valve manufacturers, investing in sustainable materials and processes can lead to competitive advantages in the marketplace. This includes the development of valves that can utilize reclaimed or recycled water, aligning with global efforts to promote water conservation.

How Has the Irrigation Valve Market Evolved Over Time?

The evolution of the irrigation valve market reflects broader technological advancements and changing agricultural practices. Initially, irrigation systems relied heavily on manual controls and basic mechanical valves, which often led to inefficiencies and significant water waste. Over the decades, the introduction of electric and automated valves transformed the landscape, allowing for more precise control and operation.

In recent years, the integration of smart technologies has marked a significant shift. Modern irrigation valves are now often equipped with sensors and connectivity features that enable real-time monitoring and adjustments based on environmental conditions. This evolution has not only improved the efficiency of irrigation systems but has also reduced the prevalence of common valve issues, such as sticking or electrical failures.

International B2B buyers are now faced with a plethora of options, requiring them to stay informed about the latest innovations and trends to make strategic sourcing decisions. As the market continues to evolve, understanding these historical shifts will be crucial for buyers looking to optimize their irrigation systems effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve problems

How do I solve a stuck irrigation valve issue?

To address a stuck irrigation valve, first, ensure that the water supply is on. If the valve remains unresponsive, inspect the solenoid for clogs or debris. Remove the solenoid and check the diaphragm for obstructions like small rocks. If cleaning does not resolve the issue, the solenoid may need replacement. For complex problems or if the valve is still not functioning, consider consulting a professional to avoid further damage.What is the best irrigation valve for high-salinity water conditions?

For areas with high-salinity water, look for irrigation valves made from corrosion-resistant materials like PVC or stainless steel. Valves with EPDM or Viton seals are preferable, as they offer enhanced durability against saltwater exposure. When sourcing valves, ensure that they meet international quality standards and are specifically designed for saline environments to guarantee longevity and reliability.How can I assess the quality of irrigation valves from suppliers?

To assess the quality of irrigation valves, request product certifications and test reports from potential suppliers. Look for ISO certifications and compliance with international standards like ASTM or ASABE. Additionally, ask for samples to evaluate durability and performance. Consider visiting manufacturing facilities or third-party audits to verify their quality control processes.What customization options should I consider when sourcing irrigation valves?

When sourcing irrigation valves, consider customization options such as size, pressure ratings, and material specifications. Ensure that suppliers can accommodate specific requirements for your irrigation system, such as unique connection types or flow rates. Discuss lead times for custom orders and confirm that the supplier has experience in producing customized solutions for similar projects.What are the typical minimum order quantities (MOQ) for irrigation valves?

Minimum order quantities (MOQ) for irrigation valves can vary significantly among suppliers, typically ranging from 50 to 500 units. Larger manufacturers may offer lower MOQs, while specialized or custom valve providers might require higher quantities. Always clarify the MOQ upfront and explore options for trial orders to test the market before committing to larger purchases.What payment terms should I negotiate with suppliers for irrigation valves?

When negotiating payment terms with suppliers, aim for favorable conditions that protect your cash flow. Common terms include a 30% deposit upfront and the remaining balance upon delivery or after inspection. Consider payment methods that offer buyer protection, such as letters of credit or escrow services, especially when dealing with international suppliers to mitigate risks associated with overseas transactions.How do logistics and shipping impact the sourcing of irrigation valves?

Logistics and shipping play a crucial role in the sourcing process. Assess the supplier’s shipping capabilities, including delivery times and costs to your region. Consider the availability of freight forwarding services and customs clearance support, especially when importing valves from overseas. Ensure that the supplier provides proper documentation and packaging to prevent damage during transit.What steps should I take to ensure proper valve installation and maintenance?

To ensure proper installation and maintenance of irrigation valves, follow the manufacturer’s guidelines closely. Engage trained technicians for installation to avoid issues like leaks or malfunctions. Regularly inspect valves for signs of wear, and perform routine maintenance, including cleaning and testing solenoids. Establish a maintenance schedule to prolong the lifespan of your irrigation system and prevent costly repairs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Irrigation Valve Problems Manufacturers & Suppliers List

1. Hydro-Rain – Pop-Up Rotor 4 in. & K-Rain – MiniPro Rotor 12 in.

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Hydro-Rain Pop-Up Rotor 4 in. | HRX-075, K-Rain MiniPro Rotor 12 in. | 13012

2. Irrigation System – Eight Zone Management

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Irrigation system with eight zones, hardwired timing system, valves with potential busted solenoids, low pressure in zone 7, possible leak in the line, drip leaks in valve to pipe connections.

3. Hills Irrigation – Solenoid Valve Solutions

Domain: hillsirrigation.com.au

Introduction: This company, Hills Irrigation – Solenoid Valve Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Hunter – PGV Irrigation Valves

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: 1″ PGV, PGV Jar-Top, 1½” and 2″ PGV, PGV-ASV, IBV, ICV

5. Simmons Landscape – Irrigation System Valves

Domain: simmonslandscape.com

Registered: 2003 (22 years)

Introduction: Irrigation System Valves: Control water flow, open to hydrate lawns, close to conserve water. Diaphragm: Rubber disk that opens/seals water passage; ensures proper hydration. Solenoid: Responds to electrical signals to open/close the valve; common failure point. Valve Body: Distributes water; important to maintain to prevent mineral buildup.

Strategic Sourcing Conclusion and Outlook for irrigation valve problems

How Can Strategic Sourcing Address Irrigation Valve Challenges?

In navigating the complexities of irrigation valve issues, strategic sourcing emerges as a pivotal solution for international B2B buyers. Understanding common problems such as valve malfunction, wiring faults, and debris accumulation can empower businesses to make informed purchasing decisions. By sourcing high-quality valves and related components, companies can significantly reduce maintenance costs and improve system reliability, ultimately enhancing water efficiency and sustainability.

Investing in robust irrigation systems is not just about immediate repairs; it’s a long-term strategy that ensures operational efficiency across diverse agricultural landscapes in Africa, South America, the Middle East, and Europe. As demand for reliable irrigation grows, particularly in regions facing water scarcity, selecting the right suppliers and products becomes crucial.

Looking ahead, businesses should prioritize partnerships with manufacturers known for their innovation and reliability in valve technology. This proactive approach will not only mitigate current issues but also position companies favorably in an increasingly competitive market. Engage with reputable distributors and invest in quality solutions today to secure a sustainable and efficient irrigation future.