Introduction: Navigating the Global Market for myers 2 hp irrigation pump

In the competitive landscape of agricultural and irrigation solutions, sourcing reliable irrigation equipment like the Myers 2 HP irrigation pump can be a daunting challenge for international B2B buyers. This guide is designed to simplify the procurement process by offering a comprehensive overview of the Myers 2 HP pump, covering its specifications, applications, and advantages. With an emphasis on performance and efficiency, the Myers QP20 pump stands out as a versatile solution for a variety of irrigation needs, from agricultural fields to landscaping projects.

Throughout this guide, we will delve into the different types of Myers pumps available, their suitability for various applications, and essential factors to consider when selecting a supplier. Additionally, we will explore pricing structures, warranty options, and maintenance tips, equipping buyers with the knowledge necessary to make informed purchasing decisions.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Brazil and Nigeria, will find this resource invaluable. By addressing key challenges in sourcing and evaluating irrigation equipment, this guide empowers businesses to enhance their operational efficiency and ensure sustainable agricultural practices. Whether you are seeking to upgrade your existing systems or invest in new technology, understanding the dynamics of the Myers 2 HP irrigation pump market will provide a solid foundation for your purchasing strategy.

Understanding myers 2 hp irrigation pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| QP20 Quick Prime Sprinkler Pump | Self-priming, up to 95 GPM, 116 ft max head, durable cast iron casing | Lawn and garden irrigation, car washes, high-volume cleaning | Pros: Efficient, durable, easy to service. Cons: Not suitable for corrosive liquids. |

| QP15 Self-Priming Sprinkler Pump | Slightly lower capacity than QP20, 60 GPM, same robust construction | Small to medium irrigation systems, residential gardens | Pros: Cost-effective, reliable performance. Cons: Limited flow rate for larger applications. |

| QP30 High Capacity Pump | Higher capacity at 90 GPM, designed for larger irrigation needs | Commercial landscaping, agricultural irrigation | Pros: High flow rate, suitable for extensive applications. Cons: Higher initial investment. |

| Submersible Pumps | Designed for underwater use, varying capacities | Deep well irrigation, water extraction | Pros: Effective for deep water sources. Cons: Installation complexity, requires specialized knowledge. |

| Jet Pumps | Non-self-priming, ideal for shallow wells, compact design | Residential water supply, small-scale irrigation | Pros: Space-saving design, lower cost. Cons: Limited performance in deep well applications. |

What Are the Key Characteristics of the QP20 Quick Prime Sprinkler Pump?

The QP20 Quick Prime Sprinkler Pump is engineered for high-performance irrigation tasks, capable of delivering up to 95 gallons per minute (GPM) with a maximum head of 116 feet. Its self-priming feature allows for easy operation without the need for a priming tank, making it ideal for continuous use in lawn and garden irrigation, as well as in car washes and other cleaning applications. The robust cast iron construction ensures durability, while the energy-efficient motor enhances operational cost-effectiveness. Buyers should consider its suitability for large-scale irrigation versus its limitations with corrosive liquids.

How Does the QP15 Self-Priming Sprinkler Pump Compare?

The QP15 Self-Priming Sprinkler Pump offers a slightly lower capacity of 60 GPM, making it well-suited for small to medium-sized irrigation systems. Its self-priming design simplifies installation and maintenance, making it an attractive option for residential gardens. While it is cost-effective and reliable, its limited flow rate may not meet the demands of larger agricultural applications. Buyers should evaluate their specific irrigation needs to determine if the QP15 provides adequate performance.

Why Choose the QP30 High Capacity Pump?

For businesses requiring higher water delivery rates, the QP30 High Capacity Pump stands out with its ability to handle up to 90 GPM. This pump is designed for commercial landscaping and agricultural irrigation, where extensive water distribution is necessary. Its higher initial investment is justified by its efficiency and capability to support large irrigation systems. Buyers should consider the scale of their operations when deciding if the QP30 is the right fit for their irrigation needs.

What Are the Advantages of Submersible Pumps?

Submersible pumps are specifically designed for underwater applications, making them ideal for deep well irrigation and water extraction. They excel in situations where surface pumps may struggle, particularly in deep water sources. However, their installation can be complex and may require specialized knowledge. Buyers should weigh the benefits of effective deep-water sourcing against the challenges of installation and maintenance.

When to Use Jet Pumps for Irrigation?

Jet pumps are compact, non-self-priming pumps suitable for shallow wells and small-scale irrigation. Their space-saving design makes them a popular choice for residential water supply systems. While they are generally lower in cost, jet pumps may not perform effectively in deep well applications. Buyers should assess their well depth and irrigation requirements to determine if a jet pump is the best solution for their needs.

Key Industrial Applications of myers 2 hp irrigation pump

| Industry/Sector | Specific Application of myers 2 hp irrigation pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation for Crop Production | Enhances crop yield and reduces water wastage | Availability of local suppliers, compatibility with existing systems |

| Landscaping and Gardening | Lawn and Garden Sprinkler Systems | Ensures consistent watering, promoting healthy growth | Durability against harsh weather conditions, ease of maintenance |

| Construction and Heavy Industry | Water Supply for Dust Control in Construction Sites | Minimizes dust, improving site safety and compliance | Power supply requirements, portability for site mobility |

| Car Wash and Maintenance | Water Supply for High-Volume Cleaning | Increases operational efficiency and customer satisfaction | Flow rate capacity, energy efficiency for cost savings |

| Mining and Quarrying | Water Supply for Equipment Cooling and Dust Suppression | Protects machinery from overheating, enhances worker safety | Robustness for continuous operation, resistance to contaminants |

How is the Myers 2 HP Irrigation Pump Used in Agriculture?

In the agriculture sector, the Myers 2 hp irrigation pump is primarily used for irrigation systems to supply water for crop production. This pump’s ability to deliver up to 95 gallons per minute (GPM) allows farmers to irrigate large fields efficiently. It addresses the challenge of inconsistent water supply, especially in regions prone to drought. International buyers, particularly from Africa and South America, should consider the pump’s compatibility with local irrigation systems and its energy consumption to optimize operational costs.

What Role Does the Myers 2 HP Pump Play in Landscaping and Gardening?

For landscaping and gardening applications, the Myers 2 hp pump is vital for maintaining lush lawns and vibrant gardens through automated sprinkler systems. Its self-priming feature simplifies setup, making it ideal for residential and commercial landscaping projects. This pump resolves issues of uneven watering, ensuring that plants receive adequate hydration. Buyers in Europe and the Middle East should focus on the pump’s durability against local weather conditions and its ease of maintenance to ensure long-term performance.

How Does the Myers Pump Benefit Construction and Heavy Industry?

In construction and heavy industry, the Myers 2 hp irrigation pump is utilized for dust control on construction sites. By supplying high volumes of water, it minimizes airborne dust, thus enhancing site safety and regulatory compliance. This application is particularly relevant in regions with stringent environmental regulations. Buyers should evaluate the pump’s portability and power supply requirements to ensure it meets the dynamic needs of construction environments.

In What Ways Does the Myers 2 HP Pump Enhance Car Wash Operations?

The Myers 2 hp pump is an essential component in car wash facilities, providing a reliable water supply for high-volume cleaning operations. Its capacity to maintain consistent water flow improves operational efficiency and enhances customer satisfaction. Car wash operators should consider the pump’s energy efficiency to manage operational costs effectively, especially in regions where energy prices are high.

How is the Myers 2 HP Pump Used in Mining and Quarrying?

In the mining and quarrying sector, the Myers 2 hp pump serves critical functions such as cooling equipment and suppressing dust. Its robust design allows for continuous operation in harsh environments, protecting machinery from overheating and ensuring worker safety. Buyers in this sector must prioritize the pump’s durability and resistance to contaminants, ensuring it can withstand the rigors of mining operations while maintaining performance.

3 Common User Pain Points for ‘myers 2 hp irrigation pump’ & Their Solutions

Scenario 1: Inefficient Water Distribution in Large Agricultural Fields

The Problem:

B2B buyers in regions such as South America and Africa often manage extensive agricultural operations where efficient irrigation is crucial for crop yields. However, many face challenges with inadequate water distribution due to the limitations of their current irrigation systems. This could be caused by insufficient pump capacity, leading to uneven watering across fields. Such inefficiencies can result in wasted resources, increased operational costs, and ultimately, reduced crop production.

The Solution:

To address the issue of inefficient water distribution, B2B buyers should consider the Myers 2 HP irrigation pump, specifically the QP20 model, which boasts a maximum flow rate of 95 GPM. This pump is designed for high-volume applications, ensuring that large areas receive adequate water coverage. It’s crucial for buyers to assess their specific irrigation needs by calculating the total dynamic head (TDH) required for their fields and ensuring that the Myers pump can meet these specifications. Implementing a strategic layout that maximizes the pump’s performance can optimize water flow. Additionally, integrating the pump with an automated irrigation system can enhance efficiency further by ensuring that water is distributed uniformly and only when necessary.

Scenario 2: Frequent Mechanical Failures and Maintenance Costs

The Problem:

In the Middle East, where irrigation systems are often subjected to harsh environmental conditions, B2B buyers frequently encounter mechanical failures in their pumps. These breakdowns not only disrupt operations but also lead to significant maintenance costs and downtime. The challenge is compounded when the pumps used are not built to withstand such conditions or require frequent servicing, which can strain budgets and resources.

The Solution:

Investing in a robust and reliable solution like the Myers 2 HP irrigation pump can significantly mitigate these issues. The QP20 model features a durable cast-iron casing and a brass impeller, engineered for long-lasting performance even under demanding conditions. Buyers should prioritize sourcing pumps that are specifically designed for the environmental challenges they face, ensuring that they can withstand high temperatures and potential debris in the water. Implementing a regular maintenance schedule, including routine checks on seals and mechanical components, can also preemptively address potential issues, thus extending the life of the pump and reducing overall maintenance costs.

Scenario 3: Complicated Installation and Setup Processes

The Problem:

B2B buyers in Europe often encounter difficulties during the installation of irrigation pumps, leading to extended project timelines and increased labor costs. The complexity of connecting pumps to existing irrigation systems or modifying them to fit specific agricultural layouts can create confusion and frustration among teams unfamiliar with the technology.

The Solution:

To streamline the installation process, it is essential for buyers to choose the Myers 2 HP irrigation pump for its user-friendly design and straightforward installation requirements. The QP20 model is pre-wired for 230 volts and can be easily configured for 115 volts, simplifying the electrical setup. Buyers should consult the provided installation manual and consider working with local suppliers who can offer technical support and guidance tailored to their specific needs. Investing in training sessions for staff on the proper installation techniques can also enhance efficiency and reduce errors during setup. Additionally, leveraging local expertise for installation can ensure that the pump is optimally positioned for peak performance in the irrigation system.

Strategic Material Selection Guide for myers 2 hp irrigation pump

When selecting materials for the Myers 2 HP irrigation pump, several factors must be considered, including performance characteristics, durability, cost, and compliance with international standards. This analysis focuses on four common materials used in the construction of the pump: cast iron, brass, Buna-Nitrile elastomers, and stainless steel. Each material’s properties, advantages, disadvantages, and implications for international B2B buyers will be discussed.

What are the Key Properties of Cast Iron in Myers 2 HP Irrigation Pumps?

Cast iron is widely used in the construction of the Myers 2 HP irrigation pump due to its excellent strength and durability. It can withstand high temperatures and pressures, making it suitable for continuous operation. Cast iron also offers good corrosion resistance, particularly when enamel-coated, which enhances its lifespan in various environments.

Pros and Cons: The primary advantage of cast iron is its durability and ability to handle high-stress applications. However, it is relatively heavy, which can complicate shipping and installation. Additionally, cast iron can be more expensive than some alternatives, but its longevity often justifies the initial investment.

Impact on Application: Cast iron is compatible with a variety of water sources, including well water and surface water. However, it is not suitable for corrosive chemicals, which could lead to premature failure.

Considerations for International Buyers: Buyers in regions such as Africa and South America should ensure compliance with local standards regarding material certifications. Cast iron components should meet ASTM standards for durability and performance.

How Does Brass Contribute to the Performance of Myers 2 HP Irrigation Pumps?

Brass is commonly used for the impeller and fittings in the Myers 2 HP irrigation pump due to its excellent corrosion resistance and mechanical properties. It can handle high pressures and temperatures, making it ideal for water applications.

Pros and Cons: The key advantage of brass is its resistance to corrosion and its ability to maintain structural integrity over time. However, brass is more expensive than some other materials and can be subject to dezincification in certain water conditions, which may affect its longevity.

Impact on Application: Brass is suitable for use with potable water and is often preferred in applications where water quality is a concern. Its compatibility with various water types makes it a versatile choice.

Considerations for International Buyers: Compliance with standards such as NSF/ANSI for drinking water is crucial for buyers in Europe and the Middle East. Ensuring that brass components meet these standards can enhance marketability.

What Role Do Buna-Nitrile Elastomers Play in Myers 2 HP Irrigation Pumps?

Buna-Nitrile elastomers are used for seals and gaskets in the Myers 2 HP irrigation pump. This material is known for its excellent resistance to water, oils, and various chemicals, making it ideal for sealing applications.

Pros and Cons: The primary advantage of Buna-Nitrile is its flexibility and ability to maintain a reliable seal under varying temperatures and pressures. However, it may not perform well in extreme temperatures or with certain solvents, which could limit its application.

Impact on Application: Buna-Nitrile is particularly effective in preventing leaks in water applications, ensuring efficient operation of the pump. However, its limitations in chemical resistance must be considered when used in specific environments.

Considerations for International Buyers: Buyers should verify that Buna-Nitrile seals meet relevant international standards for chemical resistance and durability, particularly in regions with diverse environmental conditions.

Why is Stainless Steel Considered for Certain Components of Myers 2 HP Irrigation Pumps?

Stainless steel is often used for components that require high corrosion resistance, such as shafts and fasteners. Its ability to withstand harsh environments makes it a reliable choice for irrigation systems.

Pros and Cons: The key advantage of stainless steel is its exceptional corrosion resistance and strength, which ensures a long service life. However, it is generally more expensive than other materials, which can impact overall costs.

Impact on Application: Stainless steel is suitable for applications involving saline or brackish water, where corrosion is a significant concern. Its robustness makes it ideal for demanding conditions.

Considerations for International Buyers: Buyers should ensure that stainless steel components comply with international standards like ASTM or DIN to guarantee quality and performance, especially in regions with stringent regulations.

Summary Table of Material Selection for Myers 2 HP Irrigation Pump

| Material | Typical Use Case for myers 2 hp irrigation pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Pump casing and motor bracket | High durability and strength | Heavy and can complicate installation | Medium |

| Brass | Impeller and fittings | Excellent corrosion resistance | More expensive and prone to dezincification | High |

| Buna-Nitrile | Seals and gaskets | Flexibility and reliable sealing | Limited performance in extreme temperatures | Medium |

| Stainless Steel | Shafts and fasteners | Exceptional corrosion resistance | Higher cost compared to other materials | High |

This material selection guide provides essential insights for B2B buyers considering the Myers 2 HP irrigation pump. Understanding the properties and implications of each material can lead to informed purchasing decisions that align with operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for myers 2 hp irrigation pump

What Are the Main Stages of Manufacturing for the Myers 2 HP Irrigation Pump?

The manufacturing process of the Myers 2 HP irrigation pump involves several critical stages that ensure each unit meets rigorous quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with selecting high-quality raw materials, primarily cast iron for the pump casing and brass for the impeller. The materials undergo stringent quality checks to ensure they meet required specifications. This step is crucial as the durability and efficiency of the pump heavily depend on the quality of these materials.

Forming: After preparation, the materials are shaped into their respective components. For the cast iron parts, techniques such as sand casting are employed, allowing for precise shaping and structural integrity. The brass impellers are typically formed using die-casting methods, which provide excellent dimensional accuracy and surface finish.

Assembly: The assembly stage brings together all the components, including the motor, pump casing, impeller, and mechanical seals. Each component is meticulously aligned to ensure smooth operation. Advanced techniques, such as automated assembly lines, are often used to enhance efficiency while maintaining quality standards.

Finishing: The final stage of manufacturing involves surface treatments and coatings to enhance corrosion resistance and aesthetic appeal. This may include enamel coating for cast iron parts and polishing of brass components. Additionally, assembly integrity is verified, ensuring that all seals are properly fitted to prevent leaks.

How Is Quality Assurance Implemented in the Manufacturing of Myers Pumps?

Quality assurance (QA) is integral to the manufacturing process of Myers 2 HP irrigation pumps, with multiple checkpoints established to ensure every pump meets international standards.

International Standards Compliance: Myers pumps are manufactured in compliance with ISO 9001, an internationally recognized standard for quality management systems. This certification requires continuous monitoring and improvement of manufacturing processes, ensuring consistent product quality.

Industry-Specific Certifications: Beyond general standards, pumps may also adhere to specific certifications such as CE marking for European markets and API standards for industrial applications. These certifications indicate compliance with safety, health, and environmental protection standards.

Quality Control Checkpoints: The QA process includes several critical checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to catch any deviations from the quality standards early in the production process.

– Final Quality Control (FQC): Once the pumps are fully assembled, they undergo rigorous testing, including performance tests to check flow rate, pressure, and operational efficiency.

What Testing Methods Are Commonly Used for Quality Assurance?

To ensure reliability and performance, various testing methods are employed throughout the manufacturing process of Myers irrigation pumps:

Hydraulic Testing: Pumps are tested under simulated operational conditions to verify their performance metrics such as flow rate and pressure. This helps ensure that the pumps can handle the specified workload.

Leak Testing: Each pump undergoes a leak test to ensure that all seals are functioning correctly. This is crucial to prevent water loss and maintain efficiency during operation.

Vibration and Noise Testing: These tests assess the operational smoothness of the pump and ensure that noise levels remain within acceptable limits, contributing to a better user experience.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure product reliability and compliance with local regulations.

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request detailed reports from these audits to assess compliance with standards.

Quality Control Reports: Suppliers should be able to provide documentation of their quality control processes, including IQC, IPQC, and FQC results. Reviewing these reports can help buyers evaluate the supplier’s commitment to quality.

Third-Party Inspections: Engaging third-party inspection services can provide an objective assessment of the supplier’s quality assurance practices. These inspections often include detailed reports on compliance with relevant standards.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating quality control and certification nuances is crucial for international B2B buyers, particularly those in regions like Brazil and Nigeria, where market conditions and regulatory requirements can vary significantly.

Understanding Local Standards: Buyers should familiarize themselves with local regulations regarding product certifications and safety standards. This knowledge will help them ensure that the products they source meet the necessary legal requirements in their respective markets.

Customs and Import Regulations: International buyers must also be aware of customs regulations that may affect the importation of pumps. Products may require specific certifications to clear customs, which can delay delivery if not properly addressed.

Cultural and Language Barriers: When sourcing from international suppliers, language and cultural differences may pose challenges in communication. Buyers should consider working with local representatives or consultants who understand both the supplier’s and buyer’s markets to facilitate smoother transactions.

By understanding the manufacturing processes and quality assurance measures for the Myers 2 HP irrigation pump, B2B buyers can make informed purchasing decisions that ensure reliability and performance in their irrigation systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘myers 2 hp irrigation pump’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure the Myers 2 HP irrigation pump. Whether you are operating in Africa, South America, the Middle East, or Europe, following these steps will ensure that you make an informed and strategic purchase that meets your operational needs.

Step 1: Define Your Technical Specifications

Before initiating your procurement process, clearly outline the technical requirements for the Myers 2 HP irrigation pump. This includes understanding the pump’s flow rate, maximum head, and compatibility with your existing irrigation system.

- Key specifications to consider:

- Flow rate (up to 95 GPM for the QP20 model).

- Maximum head (up to 116 ft).

- Voltage requirements (typically 230V).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who offer the Myers 2 HP irrigation pump. Look for suppliers with a solid reputation and experience in the irrigation pump market.

- Considerations for supplier selection:

- Supplier reviews and ratings.

- Industry experience and specialization in irrigation solutions.

- Availability of technical support and after-sales service.

Step 3: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and compliance with international standards. This is crucial for ensuring quality and reliability.

- Certifications to look for:

- ISO certifications.

- Compliance with local and international safety standards.

- Product-specific certifications that may be required in your region.

Step 4: Request Detailed Quotations

Once you have narrowed down your supplier list, request detailed quotations. This should include pricing, shipping costs, lead times, and warranty information.

- What to include in your quotation request:

- Specific model (e.g., Myers QP20).

- Quantity and any bulk purchasing discounts.

- Terms of payment and delivery schedules.

Step 5: Evaluate Warranty and Service Agreements

Understanding the warranty and service agreements is essential for long-term satisfaction with your purchase. Ensure that the supplier offers a reasonable warranty period and clear terms for service and support.

- Key aspects to review:

- Length and scope of the warranty.

- Availability of spare parts and repair services.

- Response times for service requests.

Step 6: Conduct Site Compatibility Assessments

Before finalizing your purchase, assess the compatibility of the Myers 2 HP irrigation pump with your site conditions. Consider factors such as installation space, water source, and existing infrastructure.

- Compatibility factors to evaluate:

- Suction lift requirements (up to 25 ft for the QP20).

- Installation location and access for maintenance.

- Potential need for additional equipment or modifications.

Step 7: Finalize Purchase and Arrange Logistics

After selecting your supplier and confirming the details, finalize your purchase. Ensure that you have a clear logistics plan in place for the delivery and installation of the pump.

- Logistics considerations:

- Shipping methods and timelines.

- Import regulations and duties applicable in your region.

- Coordination for installation and commissioning of the pump.

By following this checklist, you can streamline your procurement process and ensure that you select the right Myers 2 HP irrigation pump to meet your agricultural or landscaping needs effectively.

Comprehensive Cost and Pricing Analysis for myers 2 hp irrigation pump Sourcing

What Are the Key Cost Components for Sourcing the Myers 2 HP Irrigation Pump?

When sourcing the Myers 2 HP irrigation pump, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The Myers pump is constructed from durable materials such as cast iron for the casing and brass for the impeller. The quality of these materials directly affects the pump’s performance and longevity, making them a significant portion of the overall cost.

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and testing of the pumps. Skilled labor is essential for ensuring the pumps meet performance standards and specifications.

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs, which can be passed on to buyers.

Tooling: The initial costs associated with the production tools and molds required for manufacturing the pump. Higher-quality tooling may result in better quality and consistency, impacting the final price.

Quality Control (QC): Rigorous testing and inspection processes ensure that each pump meets the required specifications. This can add to the overall cost but is vital for maintaining product reliability, especially in demanding applications.

Logistics: Transportation and storage costs are critical, particularly for international shipments. Factors such as distance, shipping method, and local regulations can influence these costs significantly.

Margin: Suppliers typically add a profit margin to cover operational costs and ensure sustainability. The margin can vary based on the supplier’s market positioning and competitive landscape.

How Do Price Influencers Impact the Cost of the Myers 2 HP Pump?

Several factors can influence the pricing of the Myers 2 HP irrigation pump, including:

Volume/MOQ: Bulk orders often lead to cost reductions. Suppliers may offer discounts for larger quantities, which is beneficial for buyers looking to equip extensive irrigation systems.

Specifications and Customization: Buyers requiring specific features or modifications may incur additional costs. Understanding the balance between customization and standard options is essential for budget management.

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO standards) can increase costs but also provide assurance of quality and reliability, particularly important in markets with strict compliance requirements.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records may charge higher prices, reflecting their quality assurance practices.

Incoterms: The chosen Incoterms (International Commercial Terms) can affect the total landed cost. Terms that place more responsibility on the buyer may lead to lower upfront costs but could increase risks and expenses related to logistics and customs.

What Buyer Tips Can Help Optimize Costs for the Myers 2 HP Pump?

International B2B buyers should consider several strategies to optimize costs when sourcing the Myers 2 HP irrigation pump:

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes from multiple suppliers to negotiate better terms.

Focus on Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes initial purchase price, operating costs, maintenance, and potential downtime. A slightly higher upfront cost may be justified by lower long-term operating expenses.

Understand Pricing Nuances for International Markets: Recognize that currency fluctuations, import duties, and local taxes can significantly affect the total cost. It’s advisable to work with local partners or consultants who understand the regional market dynamics.

Evaluate Warranty and Support: A robust warranty and customer support can mitigate risks associated with equipment failure, potentially saving costs related to repairs and replacements.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and effective buyer strategies can empower B2B buyers to make informed purchasing decisions regarding the Myers 2 HP irrigation pump, ultimately leading to better investment outcomes.

Alternatives Analysis: Comparing myers 2 hp irrigation pump With Other Solutions

Understanding Alternatives for Irrigation Solutions

In the competitive landscape of irrigation systems, selecting the right pump is crucial for optimizing water management. The Myers 2 HP irrigation pump is a reputable choice, known for its efficiency and reliability. However, it’s essential for B2B buyers to consider alternative solutions that may better suit specific operational needs or budget constraints. This section analyzes the Myers pump in comparison to two viable alternatives: a solar-powered irrigation pump and a centrifugal pump system.

Comparison Table

| Comparison Aspect | Myers 2 HP Irrigation Pump | Solar-Powered Irrigation Pump | Centrifugal Pump System |

|---|---|---|---|

| Performance | 69 GPM, max head 116 ft | Varies (up to 30 GPM) | Up to 100 GPM |

| Cost | Approx. $949 | $1,200 – $2,500 | $800 – $2,000 |

| Ease of Implementation | Moderate (requires power) | High (off-grid solution) | Moderate (requires setup) |

| Maintenance | Low (routine checks) | Low (minimal moving parts) | Moderate (periodic maintenance) |

| Best Use Case | Large-scale irrigation | Remote areas with no power | General irrigation needs |

In-Depth Analysis of Alternatives

What are the Benefits and Drawbacks of Solar-Powered Irrigation Pumps?

Solar-powered irrigation pumps harness renewable energy, making them an environmentally friendly choice. They are particularly beneficial in remote areas where traditional power sources are unavailable. However, their performance can be limited by weather conditions and may not deliver the same flow rates as the Myers pump, which operates effectively in high-demand scenarios. Initial setup costs can also be higher, although long-term savings on energy can offset this.

How Do Centrifugal Pump Systems Compare?

Centrifugal pump systems offer flexibility and high efficiency, capable of achieving flow rates that can surpass the Myers pump. They are particularly suitable for varied irrigation applications, from agricultural fields to landscape watering. However, they often require a more complex setup and maintenance can be more intensive, especially in terms of ensuring the pump is primed correctly. Their operational costs can also vary based on the energy source used.

Making the Right Choice for Your Irrigation Needs

When choosing between the Myers 2 HP irrigation pump and its alternatives, consider your specific irrigation requirements, budget, and environmental conditions. The Myers pump is ideal for consistent, high-volume applications and is favored for its reliability and ease of maintenance. In contrast, solar-powered pumps are excellent for sustainable practices in off-grid locations, while centrifugal systems provide versatility for various irrigation tasks. Ultimately, the decision should align with operational goals, available resources, and long-term sustainability considerations, ensuring that the selected solution effectively meets the demands of your irrigation projects.

Essential Technical Properties and Trade Terminology for myers 2 hp irrigation pump

What Are the Key Technical Properties of the Myers 2 HP Irrigation Pump?

The Myers 2 HP irrigation pump, specifically the QP20 model, is designed for high-performance applications, making it essential for B2B buyers to understand its technical specifications. Here are some critical properties:

Material Composition: The pump features a cast iron casing with a brass impeller. This combination ensures durability and resistance to wear, making it suitable for continuous operation in demanding conditions. For B2B buyers, understanding material quality is crucial as it impacts the pump’s lifespan and maintenance needs, thus affecting total cost of ownership.

Flow Rate: The Myers QP20 can deliver a maximum flow rate of up to 95 gallons per minute (GPM). Flow rate is a key performance indicator that determines the pump’s suitability for various applications, from agricultural irrigation to large-scale landscaping projects. Buyers should evaluate their water delivery needs to ensure optimal pump selection.

Maximum Head and Shut-off Pressure: This pump can achieve a maximum head of 116 feet and a shut-off pressure of 50 PSI. These specifications indicate the pump’s ability to lift water to significant heights and maintain pressure, which is vital for efficient irrigation systems. Understanding these parameters helps buyers assess whether the pump can meet their specific operational requirements.

Self-Priming Capability: The Quick Prime technology allows the pump to self-prime without needing additional water for repriming after installation. This feature is particularly advantageous in regions where water supply may be inconsistent, enhancing operational efficiency. B2B buyers should consider how this capability can reduce labor costs and downtime.

Electrical Specifications: The Myers 2 HP pump operates at 230 volts and is designed for single-phase power. This specification is important for buyers to match the pump with their electrical supply and ensure compliance with local regulations. It also influences installation costs and potential energy consumption.

Suction Lift: With a suction lift of up to 25 feet, this pump can effectively draw water from deep wells or cisterns. This property is essential for buyers in areas with limited water sources, ensuring they can access necessary water supplies for irrigation.

What Common Trade Terminology Should B2B Buyers Know When Purchasing a Myers 2 HP Irrigation Pump?

Understanding industry jargon can facilitate smoother transactions and better decision-making for B2B buyers. Here are some common terms related to purchasing the Myers 2 HP irrigation pump:

OEM (Original Equipment Manufacturer): This term refers to companies like Myers that produce parts or equipment that may be marketed by another manufacturer. Knowing the OEM can assure buyers of quality and compatibility, especially when considering replacement parts or warranties.

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ helps in budgeting and inventory management, particularly when planning for large-scale irrigation projects.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and other details for specific products. B2B buyers should utilize RFQs to gather competitive pricing and terms, ensuring they make informed purchasing decisions.

Incoterms: Short for International Commercial Terms, these are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and obligations, which can significantly impact overall project budgets.

TDH (Total Dynamic Head): This term refers to the total height that the pump must lift water, including friction losses in the system. Understanding TDH is essential for buyers to ensure that the pump selected can handle their specific irrigation system requirements.

Warranty: A warranty is a guarantee from the manufacturer regarding the performance and reliability of the pump. B2B buyers should carefully review warranty terms to protect their investment and understand the support available for maintenance and repairs.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when selecting the Myers 2 HP irrigation pump, ultimately optimizing their irrigation solutions for efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the myers 2 hp irrigation pump Sector

What Are the Key Market Dynamics and Trends Influencing the Myers 2 HP Irrigation Pump Sector?

The global market for irrigation pumps, particularly the Myers 2 HP model, is shaped by several critical factors. One of the primary drivers is the increasing demand for efficient irrigation solutions due to the growing agricultural sector and the pressing need for water conservation. Regions such as Africa and South America are experiencing a surge in agricultural investments, necessitating robust irrigation systems to support food security initiatives. In Europe and the Middle East, climate change has prompted a shift towards sustainable farming practices, further driving the need for reliable irrigation technology.

Emerging technologies are also influencing sourcing trends in this sector. The rise of smart irrigation systems, which incorporate IoT devices and real-time data analytics, is becoming increasingly relevant. These systems allow for better water management and can significantly enhance the operational efficiency of Myers pumps. B2B buyers should be aware of these advancements when considering procurement, as they can lead to long-term cost savings and improved productivity.

Furthermore, international buyers should keep an eye on fluctuating supply chains, particularly in light of recent global disruptions. Sourcing strategies may need to adapt to ensure the availability of essential components, especially in regions with limited manufacturing capabilities. Collaborating with reliable suppliers who can guarantee timely deliveries and quality assurance is crucial for maintaining operational continuity.

How Is Sustainability and Ethical Sourcing Impacting the Myers 2 HP Irrigation Pump Market?

Sustainability has become a focal point for B2B buyers in the irrigation pump sector, including those sourcing Myers 2 HP models. The environmental impact of irrigation practices is under scrutiny, with a growing emphasis on reducing carbon footprints and enhancing resource efficiency. Buyers are increasingly seeking products made from sustainable materials and designed for energy efficiency, which can significantly lower operational costs over time.

Ethical sourcing is equally important in the current market landscape. Buyers are encouraged to work with manufacturers that uphold fair labor practices and environmental stewardship. Certifications such as Energy Star or ISO 14001 can serve as indicators of a supplier’s commitment to sustainability. When selecting Myers pumps, international buyers should prioritize vendors that demonstrate transparency in their supply chains and adhere to ethical standards.

The use of green materials in pump manufacturing is also gaining traction. For instance, the Myers 2 HP irrigation pump features components like lead-free brass and corrosion-resistant materials, which not only enhance durability but also minimize environmental impact. This aligns with the growing consumer demand for eco-friendly products, providing a competitive edge for suppliers committed to sustainable practices.

What Is the Historical Context Behind the Myers 2 HP Irrigation Pump?

The evolution of the Myers 2 HP irrigation pump is rooted in the broader development of irrigation technology over the past century. Initially designed for agricultural use, the Myers brand has established a reputation for producing reliable and efficient pumps that meet the demands of various applications. The introduction of self-priming features, such as those found in the Quick Prime series, has revolutionized the ease of use and operational efficiency of irrigation systems.

Historically, as water scarcity became a pressing global issue, the need for more effective irrigation solutions intensified. Myers responded by innovating its product offerings, ensuring that their pumps not only meet current agricultural needs but also adapt to changing environmental conditions. This adaptability and commitment to quality have solidified Myers’ position as a trusted supplier for B2B buyers seeking robust irrigation solutions.

In conclusion, understanding the dynamics of the Myers 2 HP irrigation pump market, alongside the emphasis on sustainability and ethical sourcing, equips international B2B buyers with the insights needed to make informed purchasing decisions. By aligning with suppliers that prioritize innovation and responsible practices, businesses can enhance their operational efficiency while contributing to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of myers 2 hp irrigation pump

How do I ensure the Myers 2 hp irrigation pump is suitable for my specific irrigation needs?

To determine if the Myers 2 hp irrigation pump meets your requirements, consider factors such as flow rate, head pressure, and the type of irrigation system you have. The QP20 model offers a maximum flow rate of 95 GPM and a head capacity of up to 116 feet, making it ideal for large-scale applications. Evaluate your landscape’s specific water needs, including the size of the area to be irrigated and the type of crops or plants involved, to ensure compatibility.What are the key features of the Myers 2 hp irrigation pump that differentiate it from competitors?

The Myers 2 hp irrigation pump, specifically the QP20 model, is designed for high-volume applications with a self-priming feature that allows for quick and easy operation. Its robust cast-iron construction ensures durability, while the lead-free brass impeller enhances performance and longevity. Additionally, the pump’s energy-efficient design minimizes operational costs, making it a reliable choice for B2B buyers focused on long-term investments.What are the typical lead times for purchasing a Myers 2 hp irrigation pump?

Lead times can vary based on factors such as order volume and supplier location. Typically, for international orders, you can expect a lead time of 2-4 weeks, including manufacturing and shipping. It’s advisable to communicate with your supplier about any specific timelines, especially if you’re working on a project with strict deadlines. Ensure that you factor in potential customs delays when planning your purchase.What payment terms should I expect when sourcing Myers irrigation pumps?

Payment terms can vary by supplier and region, but common practices include a 30% deposit upon order confirmation, with the remaining balance due before shipping. Some suppliers may offer net 30 or net 60 terms depending on your creditworthiness. Always discuss and confirm the payment terms upfront to avoid any misunderstandings and to ensure a smooth transaction process.Are there customization options available for the Myers 2 hp irrigation pump?

Yes, many suppliers offer customization options for the Myers 2 hp irrigation pump, such as adjusting voltage specifications, adapting the pump for specific applications, or including additional components like control boxes. It’s essential to discuss your specific requirements with your supplier to determine what options are available and any associated costs or lead times for custom modifications.What quality assurance measures should I expect from suppliers of Myers irrigation pumps?

Reputable suppliers should provide quality assurance through various measures, including product certifications, warranty information, and testing protocols. Inquire about the supplier’s quality control processes, such as inspections at different stages of production and adherence to international standards. A solid warranty, typically around one year for the Myers QP20, also reflects the manufacturer’s confidence in the product’s durability and performance.What logistics considerations should I keep in mind when sourcing Myers pumps internationally?

When sourcing Myers pumps for international delivery, consider shipping methods, costs, and customs regulations in your destination country. Discuss with your supplier the best shipping options to balance cost and delivery speed. Additionally, ensure that you understand any import duties or taxes that may apply to your order, and consider partnering with a logistics provider to streamline the process.How can I vet suppliers for purchasing Myers 2 hp irrigation pumps?

Vetting suppliers involves checking their credentials, including certifications, customer reviews, and references from previous clients. Request information about their experience in the industry, production capacity, and after-sales support. Engaging in direct communication, such as video calls or site visits, can also provide valuable insights into their operations. Utilize platforms like Alibaba or industry-specific trade shows to find reputable suppliers and assess their reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Myers 2 Hp Irrigation Pump Manufacturers & Suppliers List

1. Myers – Self Priming Sprinkler Pumps

Domain: myerspumpsupply.com

Registered: 2005 (20 years)

Introduction: [{‘name’: ‘Myers Self Priming Sprinkler Pump’, ‘model’: ‘QP-15’, ‘flow_rate’: ’60 GPM’, ‘power’: ‘1.5 HP’, ‘voltage’: ‘115/230/1/60’, ‘type’: ‘self-priming sprinkler and irrigation pump’, ‘pipe_size’: ‘1-1/2″ X 1-1/2″‘}, {‘name’: ‘Myers Self Priming Sprinkler Pump’, ‘model’: ‘QP-20’, ‘flow_rate’: ’69 GPM’, ‘power’: ‘2 HP’, ‘voltage’: ‘230/1/60’, ‘type’: ‘self-priming sprinkler and irrigation pump’…

2. Myers – QP20 Self-Priming Centrifugal Pump

Domain: pumpproducts.com

Registered: 2003 (22 years)

Introduction: {“model”:”Myers QP20″,”type”:”Self-Priming Centrifugal Pump”,”horsepower”:”2 HP”,”voltage”:”230 Volts”,”phase”:”1 Phase”,”discharge_size”:”1-1/2 NPT”,”suction_size”:”1-1/2 NPT”,”max_flow_rate”:”95 GPM”,”max_head”:”116 ft”,”shut_off_pressure”:”50 PSI”,”impeller_material”:”Brass”,”body_material”:”Cast Iron”}

3. MYERS – Sprinkler Pumps

Domain: bondsupply.com

Registered: 2000 (25 years)

Introduction: {“products”:[{“name”:”MYERS QP10-01 MYERS 1 HP SPRINKLER PUMP”,”price”:”$611.92″,”availability”:”8 ea”},{“name”:”MYERS QP15-01 MYERS 11/2 HP SPRINKLER PUMP”,”price”:”$638.56″,”availability”:”2 ea”},{“name”:”MYERS QP20 MYERS 2 HP SPRINKLER PUMP”,”price”:”$862.36″,”availability”:”6 ea”}]}

4. Myers – Self-Priming Centrifugal Sprinkler/Irrigation Pump

Domain: plumbing-deals.com

Registered: 2008 (17 years)

Introduction: {“Brand”:”Myers”,”MPN”:”QP20″,”Type”:”Self-Priming Centrifugal Sprinkler/Irrigation Pump”,”Size/Capacity”:”2 HP (≈1.49 kW); up to 95 GPM”,”Material/Finish”:”Cast-iron casing; brass impeller; carbon/ceramic mechanical shaft seal”,”Performance”:”Max head up to 116 ft; shut-off pressure 50 PSI”,”Connections/Fit”:”1-1/2\” NPT suction and 1-1/2\” NPT discharge”,”Suction Lift”:”Up to 25 ft (installation…

5. Myers – Quick Prime Sprinkler Pump 2 HP

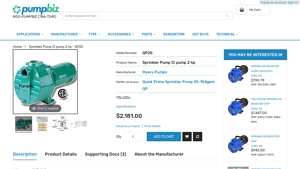

Domain: pumpbiz.com

Registered: 2000 (25 years)

Introduction: {“Model Number”:”QP20″,”Product Name”:”Sprinkler Pump CI pump 2 hp”,”Manufacturer”:”Myers Pumps”,”Series”:”Quick Prime Sprinkler Pump”,”Max Flow (GPM)”:”95″,”Max Flow (GPH)”:”5700″,”TDH Maximum (Ft)”:”116″,”TDH Maximum (PSI)”:”50″,”Horse Power (HP)”:”2″,”Inlet Connection Type”:”FNPT”,”Inlet Size (In.)”:”1.5″,”Outlet Connection Type”:”FNPT”,”Outlet Size (In.)”:”1.5″,”Wetted Materials”:”CI-Brass Ela…

6. Myers – PQP20 Centrifugal/Sprinkler Pump

Domain: rcworst.com

Registered: 2007 (18 years)

Introduction: {“Product Name”: “Myers PQP20 Centrifugal/Sprinkler Pump”, “Horsepower”: “2.0 HP”, “Voltage”: “230V”, “Motor Type”: “Internal Thermal Overload”, “Amp Draw (full load)”: “12”, “Maximum Head”: “up to 128′”, “Maximum Capacity”: “up to 78 GPM”, “Discharge Pipe Size”: “2.0” NPT”, “Suction Size”: “2.0” NPT”, “Impeller Type”: “Polycarbonate”, “Body Construction”: “Fiberglass-Reinforced Polypropylene”, “F…

7. Pentair – Myers QP Quick Prime Pumps

Domain: pentair.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Pentair Myers QP Quick Prime Self-Priming Centrifugal Pumps”, “description”: “Designed for demanding jobs requiring a lot of water over long periods, suitable for lawn and garden sprinkling, car washing, and other large cleaning tasks. Built for continuous high performance service.”, “features”: [“Rugged construction for long, continuous service without motor overload”, “Manufact…

8. Myers – QP Quick Prime Pumps

Domain: store.waterpumpsupply.com

Registered: 2003 (22 years)

Introduction: Myers QP Quick Prime Pumps are self-priming centrifugal pumps designed for sprinkler and irrigation applications. Available in 1-1/2 HP, 2 HP, and 3 HP models, they deliver strong performance for demanding jobs such as lawn and garden sprinkling, irrigation, and large cleaning tasks. The pumps are not suitable for corrosive chemicals or flammable liquids. Key specifications include:

– Model QP-15…

9. Myers – Quick Prime Self Priming Sprinkler Pump

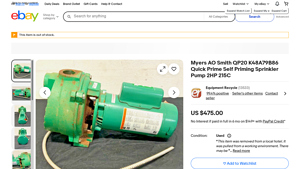

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_name”:”Myers AO Smith QP20 K48A79B86 Quick Prime Self Priming Sprinkler Pump”,”power”:”2HP”,”condition”:”Used”,”item_number”:”157039962513″,”brand”:”Myers”,”type”:”Sprinkler”,”openings”:”1-3/4 inch”,”location”:”215C”,”price”:”$475.00″,”delivery”:”Free 2-4 day delivery or free local pickup from Rosedale, Maryland, United States 21237″,”description”:”An item that has been used previously. The…

Strategic Sourcing Conclusion and Outlook for myers 2 hp irrigation pump

In the realm of irrigation solutions, the Myers 2 HP irrigation pump stands out as a reliable choice for international B2B buyers. Its robust design, featuring a self-priming capability and durable materials, ensures efficient water management across various applications, from agricultural fields to landscaping projects. The pump’s capacity to deliver up to 95 GPM and a maximum head of 116 feet positions it as a versatile solution for high-demand environments.

Strategic sourcing of the Myers 2 HP pump not only enhances operational efficiency but also provides buyers with the opportunity to secure competitive pricing and favorable terms. Engaging with trusted suppliers can lead to long-term partnerships, ensuring consistent access to quality products and technical support.

As global demand for efficient irrigation solutions continues to rise, particularly in regions like Africa, South America, the Middle East, and Europe, now is the time to invest in dependable equipment that meets the challenges of modern agriculture. By prioritizing strategic sourcing, buyers can position themselves for success, capitalizing on the advantages of quality, performance, and reliability. Explore your options today and elevate your irrigation strategy with the Myers 2 HP pump.