Introduction: Navigating the Global Market for slurry knife gate valve

In the dynamic landscape of global industrial operations, sourcing the right slurry knife gate valve can be a critical challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. These valves play a pivotal role in various demanding applications, including mining, wastewater treatment, and chemical processing, where reliable isolation and flow control are paramount. The need for effective solutions that can withstand harsh conditions while ensuring minimal maintenance is increasingly pressing.

This comprehensive guide delves into the intricacies of slurry knife gate valves, exploring various types, their specific applications, and the latest innovations in design and functionality. We will also provide insights on supplier vetting processes, cost considerations, and best practices for installation and maintenance. By addressing key questions and challenges faced by international buyers, this guide aims to empower stakeholders with the knowledge needed to make informed purchasing decisions.

Whether you are operating in Brazil’s bustling mining sector or Germany’s advanced wastewater management systems, understanding the nuances of slurry knife gate valves will enhance your operational efficiency and reliability. With this resource, you will be equipped to navigate the complexities of sourcing these essential components, ensuring your projects run smoothly and successfully in a competitive global market.

Understanding slurry knife gate valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wafer Style Knife Gate Valve | Compact design with low weight; bi-directional flow; no seat cavity. | Mining, wastewater treatment, pulp and paper | Pros: Space-efficient, reliable sealing. Cons: Limited to certain pressure ratings. |

| Flanged Knife Gate Valve | Robust construction with flanged ends for secure connections. | Chemical processing, oil and gas, heavy industry | Pros: High durability, easy installation. Cons: Bulkier than wafer style. |

| Bi-directional Knife Gate Valve | Features dual seating for flow from either direction; enhanced sealing. | Slurry handling, thickener feed lines | Pros: Versatile operation, effective isolation. Cons: More complex maintenance. |

| Elastomer Sleeve Knife Gate Valve | Utilizes elastomer technology for tight shut-off; minimal wear. | Slurry transport, mining applications | Pros: Excellent sealing, low maintenance. Cons: Limited temperature and pressure tolerance. |

| Actuated Knife Gate Valve | Equipped with pneumatic or electric actuators for remote operation. | Automated systems, large-scale operations | Pros: Increased efficiency, reduced manual labor. Cons: Higher initial investment. |

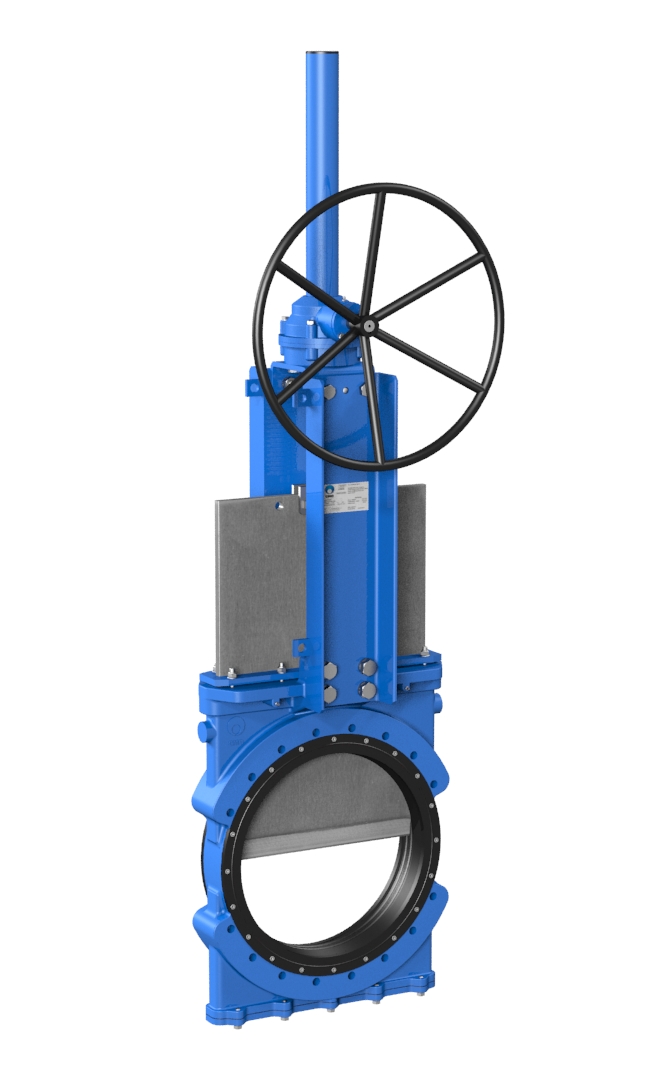

What are the Characteristics of Wafer Style Knife Gate Valves?

Wafer style knife gate valves are designed for compactness, making them ideal for applications where space is a constraint. Their bi-directional flow capability and absence of seat cavities help prevent solids accumulation, ensuring reliable sealing and smooth operation. These valves are commonly used in industries such as mining, wastewater treatment, and pulp and paper. Buyers should consider their specific pressure requirements, as wafer style valves may not handle as high pressures as other types.

How Do Flanged Knife Gate Valves Stand Out?

Flanged knife gate valves are characterized by their robust construction with flanged ends that facilitate secure connections, making them particularly suitable for heavy-duty applications. They are widely employed in chemical processing, oil and gas, and various heavy industries. The main advantages include their high durability and ease of installation; however, their larger size may be a drawback in space-limited environments. Buyers should evaluate their installation settings to ensure compatibility.

What Makes Bi-directional Knife Gate Valves Unique?

Bi-directional knife gate valves are designed with dual seating, allowing flow from either direction while providing enhanced sealing capabilities. These valves are ideal for slurry handling and thickener feed lines in various industries. They offer versatility and effective isolation, but their complexity can lead to increased maintenance demands. Buyers should weigh the benefits of operational flexibility against the potential need for more frequent servicing.

Why Choose Elastomer Sleeve Knife Gate Valves?

Elastomer sleeve knife gate valves leverage advanced elastomer technology to achieve tight shut-off and minimal wear, making them suitable for demanding slurry transport applications, particularly in mining. Their low maintenance requirements and effective sealing are significant advantages. However, buyers should note that these valves may have limitations regarding temperature and pressure tolerance, which should align with the operational conditions of their applications.

What are the Advantages of Actuated Knife Gate Valves?

Actuated knife gate valves come equipped with pneumatic or electric actuators, enabling remote operation and automation in large-scale operations. This feature enhances efficiency and reduces the need for manual labor, making them suitable for automated systems. While the initial investment may be higher, the long-term operational benefits often justify the cost. Buyers should assess their automation needs and operational scale to determine the suitability of these valves.

Key Industrial Applications of slurry knife gate valve

| Industry/Sector | Specific Application of slurry knife gate valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Tailings Management | Efficient isolation of slurry, reducing environmental risks and operational downtime. | Durability under high pressure, resistance to wear, and ease of maintenance. |

| Wastewater Treatment | Sludge Handling | Reliable control of thick sludge flow, ensuring effective treatment processes. | Compatibility with varying sludge compositions and temperature ratings. |

| Pulp and Paper | Pulp Stock Processing | Precise flow control during pulp processing, minimizing waste and enhancing production efficiency. | Resistance to corrosive chemicals and solid content handling capabilities. |

| Oil and Gas | Hydrocarbon Slurry Isolation | Prevents leaks and ensures safe operation in high-pressure environments. | High-pressure ratings, bi-directional flow capabilities, and zero leakage features. |

| Chemical Processing | Chemical Slurry Transfer | Safe and efficient transfer of aggressive slurries, reducing potential hazards. | Chemical compatibility, ease of maintenance, and robust sealing mechanisms. |

How are Slurry Knife Gate Valves Used in Mining Applications?

In the mining sector, slurry knife gate valves are crucial for managing tailings, which are the waste materials left over after the extraction of minerals. These valves provide reliable isolation of thick slurries, preventing environmental contamination and operational interruptions. They are designed to withstand high pressure and abrasive materials, making them ideal for harsh mining conditions. International buyers, particularly from regions like Africa and South America, should prioritize sourcing valves that offer durability and ease of maintenance to ensure long-term performance in challenging environments.

What Role Do Slurry Knife Gate Valves Play in Wastewater Treatment?

In wastewater treatment facilities, slurry knife gate valves facilitate the handling of thick sludge, which can pose significant challenges during treatment processes. These valves ensure a consistent flow, which is vital for the efficiency of treatment systems. Their ability to provide tight shut-off prevents leaks, contributing to environmental compliance and reducing operational risks. Buyers in Europe and the Middle East should consider valves that can handle varying sludge compositions and temperatures to optimize treatment outcomes.

How Do Slurry Knife Gate Valves Improve Pulp and Paper Production?

In the pulp and paper industry, slurry knife gate valves are employed to control the flow of pulp stock during processing. Their precision in managing flow rates helps minimize waste and enhance production efficiency. These valves must be resistant to corrosive chemicals and capable of handling solid content effectively. B2B buyers in this sector, especially in Germany, should focus on sourcing valves that meet specific industry standards for reliability and performance to ensure seamless integration into their production lines.

Why Are Slurry Knife Gate Valves Essential in Oil and Gas Operations?

In the oil and gas industry, slurry knife gate valves are critical for isolating hydrocarbon slurries in high-pressure environments. They prevent leaks and ensure safe operations, making them indispensable in processing and transportation systems. Buyers should look for valves with high-pressure ratings and bi-directional flow capabilities to meet the stringent safety and operational requirements of the sector. Sourcing from reputable manufacturers who guarantee zero leakage features is essential for compliance and safety.

How Are Slurry Knife Gate Valves Utilized in Chemical Processing?

Chemical processing often involves the transfer of aggressive slurries, and slurry knife gate valves provide a safe and efficient solution for this task. They are designed to handle a variety of chemical compositions while ensuring tight sealing to prevent leaks and contamination. International buyers should prioritize sourcing valves that offer chemical compatibility and robust sealing mechanisms. Additionally, ease of maintenance is a key consideration, as it can significantly reduce downtime and operational costs in chemical processing facilities.

3 Common User Pain Points for ‘slurry knife gate valve’ & Their Solutions

Scenario 1: Inefficient Slurry Flow Management in Heavy-Duty Applications

The Problem: B2B buyers in industries like mining or wastewater management often face the challenge of managing slurry flow in heavy-duty applications. Traditional valves can lead to turbulence, pressure drops, and solid accumulation, resulting in inefficiencies and increased maintenance costs. Buyers may find that their current isolation valves do not provide adequate sealing, leading to leaks that can disrupt operations and cause costly downtime.

The Solution: To overcome these challenges, sourcing high-quality slurry knife gate valves specifically designed for heavy-duty applications is critical. Look for valves with a bi-directional flow feature and a double-seated design, which ensures effective isolation while minimizing turbulence and preventing solid buildup. Brands like Bray or Clarkson offer valves with advanced elastomer technology and dynamic self-adjusting seals that provide bubble-tight shut-off. When specifying these valves, ensure they meet industry standards for pressure and temperature ratings that align with your operational needs. Regular maintenance checks should also be scheduled to ensure the valve performance is optimized, as proactive care can significantly extend the lifespan of your equipment.

Scenario 2: High Maintenance and Frequent Downtime

The Problem: Many businesses experience high maintenance costs and frequent downtime due to the wear and tear on their valve systems. This issue is exacerbated in industries that handle abrasive slurries, where standard valves may require regular replacement of packing and seals, leading to labor-intensive maintenance and operational delays.

The Solution: Investing in slurry knife gate valves with features designed for durability and ease of maintenance can significantly reduce downtime and maintenance costs. Opt for valves that have minimal contact with the flowing slurry, such as those with wear-resistant sleeves, which can drastically reduce wear and extend service life. For instance, valves with a one-piece body design eliminate the need for multiple seals and reduce leakage points. Furthermore, look for valves that allow for easy access to service parts, like ring sleeves, which can be replaced quickly without dismantling the entire valve assembly. Training your maintenance team on these new systems will also empower them to perform routine checks and replacements efficiently, ensuring minimal disruption to operations.

Scenario 3: Compatibility Issues with Existing Systems

The Problem: As industries evolve, B2B buyers often find that their current slurry valve systems are incompatible with new processes or equipment, leading to inefficiencies and the need for costly retrofitting. This scenario is particularly common in expanding operations where new machinery must integrate seamlessly with existing infrastructure.

The Solution: To mitigate compatibility issues, conduct a thorough assessment of your current system before purchasing new slurry knife gate valves. Engage with suppliers who offer customizable solutions that can be tailored to fit your existing infrastructure. Select valves with adaptable frame designs that can be easily modified for different actuators or configurations without the need for welding or extensive modifications. Ensure that the valves you choose are compatible with the specific slurry types and flow rates your operation requires. Additionally, collaborating with valve manufacturers for a detailed consultation can provide insights into the best practices for integration and help you avoid potential pitfalls in compatibility, thus ensuring a smoother transition and enhanced operational efficiency.

Strategic Material Selection Guide for slurry knife gate valve

What Are the Key Materials Used in Slurry Knife Gate Valves?

When selecting a slurry knife gate valve, the choice of material is crucial for ensuring optimal performance and longevity. Different materials offer distinct properties that can significantly affect the valve’s effectiveness in various applications. Below is an analysis of four common materials used in slurry knife gate valves: stainless steel, cast iron, carbon steel, and elastomers.

How Does Stainless Steel Perform in Slurry Knife Gate Valves?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures (up to 1,200°F or 650°C). It also offers good pressure ratings, making it suitable for high-pressure applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to corrosive media, which is essential in industries like mining and wastewater treatment. However, it tends to be more expensive than other materials, and manufacturing can be complex due to its hardness.

Impact on Application: Stainless steel is particularly effective in applications involving aggressive slurries, such as those found in chemical processing and oil and gas. Its compatibility with a wide range of media makes it a versatile choice.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A351 or DIN 1.4401 for stainless steel. In regions like Europe and South America, certification of materials to meet local regulations is critical.

What Role Does Cast Iron Play in Slurry Knife Gate Valves?

Key Properties: Cast iron is known for its excellent wear resistance and ability to handle moderate temperatures (up to 500°F or 260°C). It is also relatively inexpensive compared to other materials.

Pros & Cons: The advantages of cast iron include its robustness and cost-effectiveness, making it a popular choice for less demanding applications. However, it is prone to corrosion, especially in acidic or alkaline environments, which can limit its lifespan.

Impact on Application: Cast iron is suitable for applications involving less aggressive slurries, such as municipal wastewater treatment. Its weight and brittleness can be a disadvantage in dynamic environments.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM A126 or JIS G5502. In regions like Africa and the Middle East, the availability of cast iron can be a significant factor in procurement.

How Does Carbon Steel Compare for Slurry Knife Gate Valves?

Key Properties: Carbon steel offers good strength and ductility, with temperature ratings up to 800°F (427°C). It is also relatively easy to machine, making it a popular choice for custom applications.

Pros & Cons: The main advantage of carbon steel is its balance between cost and performance. However, it has lower corrosion resistance compared to stainless steel and may require protective coatings for certain applications.

Impact on Application: Carbon steel is often used in applications where the slurry is less corrosive, such as in mining and mineral processing. Its adaptability makes it suitable for various media.

Considerations for International Buyers: Compliance with standards like ASTM A106 or DIN 17100 is essential. Buyers in South America and Europe should also consider the availability of certified carbon steel products.

What Advantages Do Elastomers Offer in Slurry Knife Gate Valves?

Key Properties: Elastomers, often used for seals and sleeves, provide excellent flexibility and resistance to wear and tear. They can handle temperatures typically up to 300°F (150°C) and are effective in preventing leakage.

Pros & Cons: The key advantage of elastomers is their ability to create a tight seal, which is crucial in preventing slurry leakage. However, they may degrade over time, especially in extreme temperatures or chemical environments.

Impact on Application: Elastomers are particularly useful in applications where solid particles are present, as they can accommodate movement and prevent wear on the valve body.

Considerations for International Buyers: Buyers should ensure that elastomers meet industry standards such as ASTM D2000 or ISO 1629. In regions like Europe, specific certifications may be required for food-grade applications.

Summary Table of Material Selection for Slurry Knife Gate Valves

| Material | Typical Use Case for Slurry Knife Gate Valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Aggressive chemical processing | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Cast Iron | Municipal wastewater treatment | Cost-effective and robust | Prone to corrosion | Low |

| Carbon Steel | Mining and mineral processing | Good strength and ductility | Lower corrosion resistance | Medium |

| Elastomers | Sealing applications in various slurries | Creates tight seals | Degrades under extreme conditions | Medium |

This comprehensive analysis provides international B2B buyers with actionable insights into the material selection for slurry knife gate valves, ensuring informed decision-making tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for slurry knife gate valve

What Are the Key Manufacturing Processes for Slurry Knife Gate Valves?

The manufacturing of slurry knife gate valves involves several critical stages, each designed to ensure the final product meets the rigorous demands of industrial applications. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

How Is Material Prepared for Slurry Knife Gate Valves?

The manufacturing process begins with material selection, which is crucial for ensuring durability and resistance to wear and corrosion. Common materials include stainless steel, carbon steel, and various elastomers, chosen based on the specific application requirements.

Once the materials are selected, they undergo preparation, which typically involves cutting, machining, and treating the raw materials to achieve the desired specifications. This stage often includes processes such as heat treatment to enhance material strength and hardness, ensuring that the valves can withstand high pressures and abrasive slurries.

What Techniques Are Used in Forming Slurry Knife Gate Valves?

The forming stage is where the prepared materials are shaped into the components of the valve. This can involve several techniques:

Casting: Many slurry knife gate valves are produced through casting processes, which allow for complex shapes and high durability. The molten metal is poured into molds to create the body and other components.

Machining: Precision machining is employed to achieve tight tolerances. Techniques such as CNC milling and turning are used to create the valve seats and gates, ensuring smooth operation and effective sealing.

Welding and Assembly: After forming, the components are assembled. This may involve welding or bolting parts together, depending on the design. Advanced techniques such as robotic welding can improve consistency and reduce the risk of defects.

How Is the Finishing Process Completed for Slurry Knife Gate Valves?

The finishing stage involves surface treatments that enhance the valve’s performance and longevity. Common practices include:

Coating: Protective coatings are applied to prevent corrosion and wear. Options may include epoxy, polyurethane, or other specialized coatings designed for harsh environments.

Polishing: For certain applications, polishing the internal surfaces can reduce friction and facilitate better flow characteristics, minimizing pressure loss.

Quality Control Inspections: Throughout the finishing process, various inspections are conducted to ensure that each valve meets the specified tolerances and surface finish requirements.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is paramount in the manufacturing of slurry knife gate valves, as these products are often used in critical applications. Buyers should be familiar with both international and industry-specific standards to assess potential suppliers.

Which International Standards Apply to Slurry Knife Gate Valve Manufacturing?

ISO 9001 is the most widely recognized international standard for quality management systems. Manufacturers that adhere to this standard demonstrate their commitment to consistent quality and continuous improvement. Additionally, industry-specific certifications may include:

CE Marking: Indicates compliance with European safety and environmental requirements.

API (American Petroleum Institute): Relevant for valves used in the oil and gas industry, ensuring they meet specific performance and safety criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated throughout the manufacturing process with several key checkpoints:

Incoming Quality Control (IQC): Materials and components are inspected upon arrival to verify they meet required specifications. This prevents defects from entering the production line.

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process. This includes measuring dimensions, checking weld quality, and ensuring adherence to design specifications.

Final Quality Control (FQC): Once the valve is assembled, a final inspection is performed. This may involve pressure testing, leak testing, and functional testing to ensure the valve operates correctly under specified conditions.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should employ several verification methods:

What Steps Can Buyers Take to Audit Suppliers?

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational capabilities of potential suppliers. This firsthand observation can provide valuable insights into the supplier’s commitment to quality.

Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality control processes, including inspection reports, test results, and certifications. Buyers should review these documents to ensure compliance with relevant standards.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can be particularly valuable for buyers operating in regions with diverse regulatory environments.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, must consider various nuances when assessing quality control:

Regulatory Compliance: Different countries have varying regulations concerning manufacturing standards. Buyers should ensure that suppliers comply with the regulations applicable in their region.

Cultural Differences: Understanding cultural attitudes towards quality and customer service can help buyers establish more effective communication and expectations with suppliers.

Logistics and Supply Chain: The complexity of international shipping can affect the delivery and integrity of products. Buyers should inquire about how suppliers manage logistics and ensure product quality during transit.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for slurry knife gate valves equips B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on material preparation, forming techniques, finishing processes, and stringent quality control measures, buyers can select suppliers that meet their operational needs and ensure reliable performance in demanding applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘slurry knife gate valve’

In the competitive landscape of industrial procurement, sourcing a slurry knife gate valve requires a systematic approach to ensure reliability and efficiency. This guide provides a step-by-step checklist to assist B2B buyers in making informed decisions.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for the slurry knife gate valve. Consider factors such as size, pressure rating, and temperature tolerance, which are crucial for operational compatibility.

– Key Considerations:

– Determine the valve size based on your piping system.

– Ensure the pressure and temperature ratings align with your operational conditions to avoid failures.

Step 2: Assess the Application Needs

Understanding the specific application is vital for selecting the right valve. Slurry knife gate valves are often used in industries such as mining, wastewater management, and chemical processing, where they handle abrasive and viscous materials.

– Application Focus:

– Identify the type of slurry (e.g., tailings, coal) and its properties (e.g., viscosity, particle size).

– Evaluate the need for features such as bi-directional flow or zero leakage capabilities to enhance performance in your specific application.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your technical and operational needs. Request detailed company profiles, product catalogs, and references from clients in similar industries.

– Supplier Assessment:

– Look for suppliers with a proven track record in manufacturing slurry knife gate valves.

– Consider suppliers that offer customization options to tailor the valve design to your unique requirements.

Step 4: Verify Certifications and Standards Compliance

Ensure that the valves comply with relevant international and local standards, which can vary by region. Certifications can provide assurance regarding quality and safety.

– Compliance Check:

– Look for certifications such as ISO 9001 or industry-specific standards (e.g., API, ANSI).

– Confirm that the valves have undergone rigorous testing for durability and performance.

Step 5: Request Samples and Conduct Testing

Before finalizing your order, request samples to evaluate the quality and performance of the valves. Conduct thorough testing under conditions that simulate actual operational environments.

– Testing Importance:

– Assess the valve’s sealing capabilities and resistance to wear and tear.

– Ensure the valve operates smoothly without leaks or operational failures.

Step 6: Understand Warranty and After-Sales Support

A robust warranty and reliable after-sales support are critical for minimizing downtime and maintenance costs. Clarify the terms of the warranty and the support services offered by the supplier.

– Warranty Insights:

– Check the warranty duration and coverage details.

– Inquire about the availability of replacement parts and maintenance services.

Step 7: Negotiate Terms and Finalize Purchase

Once you’ve selected a supplier, negotiate the purchase terms, including pricing, delivery schedules, and payment options. Clear communication can lead to better deals and long-term partnerships.

– Negotiation Tips:

– Be transparent about your budget and expectations to facilitate a win-win agreement.

– Consider long-term contracts for better pricing and reliability in supply.

Following this comprehensive checklist will streamline your sourcing process and help you secure high-quality slurry knife gate valves that meet your operational needs.

Comprehensive Cost and Pricing Analysis for slurry knife gate valve Sourcing

What are the Key Cost Components for Sourcing Slurry Knife Gate Valves?

When sourcing slurry knife gate valves, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

Materials: The choice of materials directly impacts cost. Common materials like cast iron, stainless steel, and specialized alloys offer different price points and performance characteristics. High-quality elastomers for seals are also critical and can significantly affect pricing.

Labor: Manufacturing labor costs vary by region. In countries with higher labor costs, such as Germany, the final price may reflect this. Conversely, sourcing from regions with lower labor costs, like parts of South America, may yield savings.

Manufacturing Overhead: This includes costs related to utilities, maintenance, and operational expenses. Factories with advanced technology may have higher overhead but can produce valves with tighter tolerances and better quality.

Tooling: Initial tooling costs can be substantial, especially for custom valves. These costs are often amortized over larger production runs, so understanding the minimum order quantity (MOQ) is crucial for cost-efficient sourcing.

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards, such as ISO certifications. Investing in quality control can increase upfront costs but reduce long-term expenses associated with failures and replacements.

Logistics: Shipping costs can vary significantly based on the supplier’s location, chosen Incoterms, and the destination. International shipping may incur additional tariffs and fees, which should be factored into the total cost.

Margin: Suppliers will include their profit margin in the final price. This can vary based on market demand, competition, and supplier reputation.

How Do Price Influencers Affect the Cost of Slurry Knife Gate Valves?

Several factors influence the pricing of slurry knife gate valves:

Volume/MOQ: Suppliers typically offer better pricing for bulk orders. Understanding your consumption needs can help negotiate favorable terms.

Specifications and Customization: Custom features or specific certifications can lead to higher costs. Clearly defining your specifications upfront can help streamline the quoting process and avoid unexpected charges.

Materials: As noted earlier, material choices play a significant role in pricing. Opting for more durable materials can reduce long-term operational costs, justifying a higher initial investment.

Quality and Certifications: Valves that meet stringent quality and safety standards may command higher prices. However, these investments can lead to fewer maintenance issues and improved operational efficiency.

Supplier Factors: Established suppliers may offer higher prices due to their reputation and proven reliability. Newer suppliers might provide lower prices to build their market presence but may lack the same level of quality assurance.

Incoterms: The chosen Incoterms can significantly influence the overall cost. Terms like CIF (Cost, Insurance, and Freight) include shipping and insurance, while EXW (Ex Works) places the responsibility on the buyer, potentially increasing logistics costs.

What Buyer Tips Can Help Optimize Costs When Sourcing Slurry Knife Gate Valves?

Negotiate Effectively: Engage with multiple suppliers to compare quotes and negotiate terms. Highlighting potential for bulk orders or long-term contracts can encourage suppliers to offer better pricing.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and expected lifespan. A valve with a higher initial cost may offer lower total costs over its lifespan due to reduced failures and maintenance.

Understand Pricing Nuances for International Buyers: When purchasing from regions like Africa, South America, or the Middle East, be aware of currency fluctuations, import duties, and local regulations that may affect pricing.

Request Detailed Quotes: Ensure quotes include a breakdown of all costs, including materials, labor, shipping, and any additional fees. This transparency allows for better comparisons and informed decision-making.

Stay Informed on Market Trends: Keeping abreast of material costs and industry trends can help buyers anticipate price changes and adjust sourcing strategies accordingly.

Disclaimer

The prices and cost structures mentioned are indicative and subject to change based on market conditions, supplier negotiations, and specific project requirements. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing slurry knife gate valve With Other Solutions

Introduction to Alternative Solutions for Slurry Management

In industries dealing with challenging materials, selecting the right valve solution is crucial for operational efficiency and system integrity. While slurry knife gate valves are popular for their reliability in isolating and controlling slurry flow, it is important to consider other technologies that may provide similar or enhanced functionalities. This analysis compares slurry knife gate valves with two viable alternatives: pinch valves and ball valves, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Slurry Knife Gate Valve | Pinch Valve | Ball Valve |

|---|---|---|---|

| Performance | Excellent for heavy-duty applications with minimal leakage. | Suitable for slurries; can handle high solids content. | Good for clean fluids; less effective with high solid content. |

| Cost | Moderate initial investment; long-term savings due to low maintenance. | Generally lower upfront cost; may incur higher maintenance costs. | Higher initial cost; generally lower maintenance needs. |

| Ease of Implementation | Requires specific installation techniques; moderate complexity. | Simple installation; flexible in piping configurations. | Straightforward installation; standard fittings available. |

| Maintenance | Low maintenance due to fewer moving parts; requires periodic inspection. | Moderate maintenance; rubber sleeves need replacement over time. | Low maintenance; reliable operation with minimal wear. |

| Best Use Case | Ideal for mining, wastewater management, and pulp and paper industries. | Suitable for applications with high solids and corrosive materials. | Best for clean water, gas, and other low-viscosity fluids. |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of Pinch Valves?

Pinch valves operate by compressing a flexible sleeve to control flow, making them effective for slurries with high solid content. Their design allows for a full bore that minimizes pressure drops and turbulence, ensuring efficient flow. While pinch valves typically have a lower upfront cost compared to slurry knife gate valves, they may require more frequent maintenance due to wear on the rubber sleeves. This can lead to increased operational downtime, especially in demanding environments where the cost of valve failure can be significant.

How Do Ball Valves Compare in Slurry Applications?

Ball valves are known for their reliability and ease of use, primarily in clean fluid applications. They provide a tight seal and are generally low maintenance, which makes them attractive for many industries. However, ball valves struggle with slurries that contain high solids due to the risk of clogging and wear. Their higher initial cost and less effective performance in challenging environments limit their applicability in sectors like mining or wastewater treatment, where slurry knife gate valves would excel.

Conclusion: How to Choose the Right Valve Solution

When selecting a valve solution for slurry management, B2B buyers should consider the specific requirements of their applications, including the nature of the materials being handled, budget constraints, and maintenance capabilities. Slurry knife gate valves stand out in heavy-duty applications due to their reliability and low maintenance needs, making them suitable for industries like mining and wastewater management. In contrast, pinch valves may offer a cost-effective alternative for less demanding applications, while ball valves are best reserved for clean fluids. By carefully evaluating these options, buyers can ensure they choose the most effective solution tailored to their operational needs.

Essential Technical Properties and Trade Terminology for slurry knife gate valve

What Are the Essential Technical Properties of Slurry Knife Gate Valves?

Understanding the technical properties of slurry knife gate valves is critical for B2B buyers, especially in industries such as mining, wastewater treatment, and chemical processing. Here are some key specifications to consider:

1. Material Grade

The material used in the construction of slurry knife gate valves typically includes stainless steel, carbon steel, and various alloys. The choice of material affects the valve’s resistance to corrosion, wear, and overall durability. For example, stainless steel is often preferred in applications involving abrasive slurries due to its superior resistance to corrosion and wear. Selecting the right material is crucial for ensuring longevity and reducing maintenance costs.

2. Pressure and Temperature Ratings

Pressure rating indicates the maximum pressure the valve can withstand, while temperature rating specifies the operational temperature limits. Most slurry knife gate valves are designed to handle pressures ranging from 10 to 200 psi and temperatures up to 300°F (150°C). Understanding these ratings helps buyers select valves suitable for their specific operational conditions, preventing premature failure and ensuring safety.

3. End Connection Type

Common end connection types for slurry knife gate valves include wafer, flanged, and butt-weld connections. The choice of connection impacts installation and compatibility with existing piping systems. Wafer-style valves, for instance, are often used in tight spaces and offer a compact design, while flanged connections provide greater stability and ease of maintenance. This selection is vital for ensuring seamless integration into a process system.

4. Shutoff Class

The shutoff class defines the valve’s ability to prevent leakage when closed. A zero leakage rating is ideal for applications where even minimal leakage can lead to significant operational issues. This property is particularly important in industries dealing with hazardous materials, as it contributes to safety and environmental compliance.

5. Size Range

Slurry knife gate valves come in various sizes, typically ranging from NPS 2 to 24 (DN 50 to 600). The size affects the flow capacity and the specific application suitability. Choosing the correct valve size ensures optimal flow management and operational efficiency in processes involving slurries.

6. Design Features

Advanced design features such as dynamic self-adjusting seals and unobstructed flow paths enhance the valve’s performance. These features minimize maintenance needs and ensure smooth operation, reducing downtime in critical applications. Understanding these design elements can significantly influence the decision-making process for B2B buyers.

What Common Trade Terms Should B2B Buyers Know About Slurry Knife Gate Valves?

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are some important trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can clarify product sourcing and quality assurance, as OEM products often come with guarantees of performance and reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This term is crucial for buyers to understand, as it affects budgeting and inventory management. Knowing the MOQ helps in planning purchases and ensuring that suppliers meet operational needs without excessive surplus.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. For B2B buyers, issuing RFQs is a key step in the procurement process, allowing them to compare offers and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for buyers involved in cross-border procurement, as they clarify shipping responsibilities, risks, and costs.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. For buyers, understanding lead times is essential for planning and inventory management, especially in industries where downtime can lead to significant losses.

6. Warranty

A warranty is a promise from the manufacturer regarding the quality and longevity of the product. For B2B buyers, understanding warranty terms can provide peace of mind and protect against unexpected failures or defects, ensuring a good return on investment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product reliability in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the slurry knife gate valve Sector

What Are the Current Market Dynamics and Trends in the Slurry Knife Gate Valve Sector?

The slurry knife gate valve market is witnessing significant growth, driven by increasing demand from various industries, including mining, wastewater treatment, and oil and gas. Factors such as the need for efficient flow control in abrasive and viscous materials are propelling the adoption of these valves. In regions like Africa and South America, mining activities are on the rise, leading to heightened demand for robust valve solutions capable of handling challenging slurries. Similarly, the Middle East and Europe are focusing on upgrading infrastructure and improving waste management systems, further boosting the market.

Emerging technologies are reshaping the sourcing landscape, with innovations in valve design, materials, and automation. For instance, the integration of elastomer technology and bi-directional flow designs enhances valve reliability and performance, allowing for smoother operations and reduced maintenance. International B2B buyers are increasingly seeking suppliers that offer smart solutions, such as predictive maintenance capabilities and digital monitoring systems, which can optimize operational efficiency and minimize downtime.

Moreover, the trend toward consolidation among valve manufacturers is reshaping the competitive landscape. Buyers now have access to a more comprehensive range of products from fewer suppliers, which can simplify procurement processes. However, this concentration also means that buyers must carefully evaluate supplier reliability and product quality to ensure they meet specific application requirements.

How Is Sustainability Influencing B2B Sourcing in the Slurry Knife Gate Valve Sector?

The emphasis on sustainability and ethical sourcing is becoming paramount in the slurry knife gate valve sector. Environmental impacts associated with manufacturing processes and product lifecycle are under scrutiny, prompting businesses to seek out valves that are not only efficient but also environmentally friendly. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as reducing waste and utilizing recyclable materials in their products.

Certifications such as ISO 14001 (Environmental Management) and products made from ‘green’ materials are becoming essential criteria for procurement decisions. Manufacturers that adopt eco-friendly production methods and materials will likely see increased interest from international buyers. Furthermore, companies are focusing on lifecycle assessments (LCA) to evaluate the overall environmental impact of their products, which can enhance their market positioning.

In addition to environmental concerns, ethical supply chains are gaining traction. Buyers are demanding transparency regarding sourcing practices, labor conditions, and the overall integrity of the supply chain. Suppliers that can provide evidence of ethical sourcing and sustainable practices are likely to gain a competitive edge in the global market.

What Is the Historical Context of Slurry Knife Gate Valves in B2B Applications?

The slurry knife gate valve has evolved significantly since its inception, initially designed for simple on-off applications. Over the decades, advancements in materials and engineering have transformed these valves into robust solutions capable of withstanding the rigors of handling slurries in various industries. The introduction of features such as self-adjusting seals and bi-directional flow capabilities has enhanced their functionality, making them indispensable in sectors like mining, wastewater treatment, and chemical processing.

As industries continue to innovate, the slurry knife gate valve is expected to further evolve, integrating smart technologies and sustainable practices to meet the demands of modern applications. This historical context is crucial for B2B buyers to understand the progression of these valves and their suitability for current and future applications.

Frequently Asked Questions (FAQs) for B2B Buyers of slurry knife gate valve

How do I solve issues with leakage in slurry knife gate valves?

To address leakage in slurry knife gate valves, ensure that you select valves designed for zero leakage, such as those with double-seated designs and elastomer sleeves that provide tight shut-off. Regular maintenance is crucial; inspect and replace worn components like seals and sleeves as needed. Additionally, consider implementing a monitoring system for early detection of leaks, which can minimize downtime and prevent costly repairs.What is the best slurry knife gate valve for harsh environments?

For harsh environments, look for slurry knife gate valves that feature robust construction materials, such as stainless steel or cast iron, and advanced sealing technologies. Valves with bi-directional flow capabilities and no seat cavities to collect solids are ideal. Brands like Flowrox and Clarkson offer high-performance options that can withstand extreme conditions, ensuring reliability and durability in applications like mining and wastewater management.What factors should I consider when sourcing slurry knife gate valves internationally?

When sourcing slurry knife gate valves internationally, consider factors such as the supplier’s reputation, product certifications, and compliance with international standards. Evaluate the quality of materials and construction, as well as the availability of after-sales support and spare parts. Additionally, assess the supplier’s experience in your specific industry, as this can impact the suitability of the valve for your application.What is the typical minimum order quantity (MOQ) for slurry knife gate valves?

Minimum order quantities for slurry knife gate valves vary by manufacturer and supplier. Typically, MOQs can range from 10 to 50 units. It’s advisable to discuss your specific needs with the supplier, as many are willing to accommodate lower quantities for first-time buyers or pilot projects. Establishing a good relationship with the supplier may also lead to more favorable terms in future orders.How can I ensure quality assurance when purchasing slurry knife gate valves?

To ensure quality assurance when purchasing slurry knife gate valves, request documentation of compliance with industry standards, such as ISO certifications. Ask for detailed product specifications, including testing results for pressure and leakage. Conducting a factory audit can also provide insights into the manufacturing processes. Additionally, consider suppliers that offer warranties or guarantees on their products to further protect your investment.What payment terms are commonly offered by suppliers of slurry knife gate valves?

Payment terms for slurry knife gate valves vary by supplier and can range from advance payments to net 30 or net 60 days after delivery. Some suppliers may also offer financing options or payment via letters of credit, especially for larger orders. It’s important to negotiate payment terms that suit your cash flow while ensuring the supplier’s confidence in fulfilling the order.What logistics considerations should I keep in mind when importing slurry knife gate valves?

When importing slurry knife gate valves, consider logistics aspects such as shipping costs, lead times, and customs regulations in your country. Ensure you have a reliable freight forwarder who can navigate international shipping complexities. Additionally, assess the packing and handling requirements to prevent damage during transit. It’s also wise to account for potential delays in customs clearance that may affect your project timelines.Can slurry knife gate valves be customized for specific applications?

Yes, many manufacturers offer customization options for slurry knife gate valves to meet specific application requirements. Customizations may include size, material, end connections, and special sealing technologies. When discussing your needs with suppliers, provide detailed information about the application environment, including temperature, pressure, and the type of slurry being handled. This will help ensure that the customized valve meets your operational demands effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Slurry Knife Gate Valve Manufacturers & Suppliers List

1. Emerson – Clarkson KGD Wafer Style Slurry Knife Gate Valve

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Clarkson KGD Wafer Style Slurry Knife Gate Valve, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Orbinox – Slurry Knife Gate Valve

Domain: orbinox.com

Registered: 1997 (28 years)

Introduction: Slurry Knife Gate Valve, designed for handling slurries and viscous fluids, features a robust construction for durability, offers tight shut-off capabilities, suitable for various industrial applications, available in different sizes and materials, includes options for manual or automated operation, and is ideal for use in mining, pulp and paper, and wastewater treatment industries.

3. Vinson Process – Clarkson & Emerson Knife Gate Valves

Domain: vinsonprocess.com

Registered: 2005 (20 years)

Introduction: This company, Vinson Process – Clarkson & Emerson Knife Gate Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Red Valve – Knife Gate Valves

Domain: redvalve.com

Registered: 1995 (30 years)

Introduction: Knife Gate Valves from Red Valve are designed for handling tough slurries and are suitable for a variety of industries and applications. Key features include precision-machined gates, heavy-duty top works, and cast-iron bodies available up to 24 inches, ensuring ruggedness and dependability. Additional features include replaceable wear seats, simplified packing replacement, and solid stainless ste…

5. Stafsjo – SLV Knife Gate Valve

Domain: stafsjo.com

Registered: 1996 (29 years)

Introduction: Knife gate valve SLV: Compact push through slurry knife gate valve. Available size range: DN 50 – DN 900 (2” – 36”). Features superior flow characteristics, reliable bi-directional shut-off performance in abrasive and demanding mineral processing applications. Modular design allows customization with actuators and automation accessories. Standard materials include a nodular iron valve body and dup…

6. Valmet – Flowrox™ Slurry Knife Gate Valves

Domain: valmet.com

Registered: 1991 (34 years)

Introduction: Flowrox™ slurry knife gate valves are designed for handling abrasive and corrosive slurries in various industries. They feature a robust construction for durability and reliability, ensuring minimal leakage and maintenance. The valves are available in different sizes and materials to suit specific application requirements. Key benefits include easy installation, low operational costs, and the abil…

7. Cornerstone Controls – Clarkson Model KGF Knife Gate Valve

Domain: cornerstonecontrols.com

Registered: 1998 (27 years)

Introduction: Clarkson Model KGF/KGF-HP Knife Gate Valve

Strategic Sourcing Conclusion and Outlook for slurry knife gate valve

What Are the Key Takeaways for Strategic Sourcing of Slurry Knife Gate Valves?

In the competitive landscape of slurry knife gate valves, strategic sourcing emerges as a critical driver of operational efficiency and cost-effectiveness. Buyers must prioritize valves that offer robust performance in challenging environments, ensuring zero leakage and minimal maintenance. Key features such as bi-directional flow, wear-resistant materials, and simplified servicing are essential considerations that enhance reliability and reduce downtime.

How Can International Buyers Benefit from Strategic Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to significant competitive advantages. By partnering with reputable manufacturers who adhere to high-quality standards, buyers can ensure the longevity and effectiveness of their valve systems. Moreover, understanding local supply chain dynamics can help in negotiating favorable terms and improving delivery timelines.

What’s Next for Your Sourcing Strategy?

As industries continue to evolve, the demand for advanced slurry knife gate valves is set to rise. Now is the time to reassess your sourcing strategy and seek innovative solutions that can meet future challenges. Explore partnerships with established valve manufacturers and invest in technologies that promise enhanced performance and sustainability. By doing so, you position your business for success in a rapidly changing market landscape.