Introduction: Navigating the Global Market for solar irrigation pump

In today’s rapidly evolving agricultural landscape, sourcing effective solar irrigation pumps is essential for enhancing productivity while minimizing costs. Many international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, face the challenge of ensuring reliable water supply systems that can operate efficiently in diverse environments. This guide offers a comprehensive examination of solar irrigation pumps, exploring various types, applications, and critical factors such as supplier vetting and cost analysis.

Navigating the global market for solar irrigation pumps requires an informed approach to selecting the right system that meets specific agricultural needs. From understanding the benefits of different pump technologies to evaluating the long-term savings associated with solar energy, this guide empowers businesses to make strategic purchasing decisions. We delve into the operational advantages of solar irrigation systems, including their adaptability for remote locations and reduced reliance on conventional energy sources.

By providing actionable insights and expert recommendations, this resource aims to equip B2B buyers with the knowledge necessary to invest in sustainable irrigation solutions. Whether you’re looking to improve crop yields in Brazil or enhance livestock watering systems in Saudi Arabia, this guide serves as your roadmap to successfully navigating the solar irrigation pump market.

Understanding solar irrigation pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Submersible Solar Pumps | Installed underwater; suitable for deep wells | Agriculture, livestock watering | Pros: Efficient for deep water; Cons: Installation can be complex. |

| Surface Solar Pumps | Positioned above ground; easy to install | Irrigation systems, ponds | Pros: Simple installation; Cons: Limited to shallow water sources. |

| Solar Well Pumps | Designed for extracting water from wells | Commercial farming, remote locations | Pros: Reliable in off-grid areas; Cons: Higher upfront costs. |

| Booster Pumps | Enhances pressure for existing irrigation systems | Large-scale agriculture | Pros: Increases efficiency; Cons: May require additional power sources. |

| Solar Pumping Systems | Integrated systems with panels, batteries, and pumps | Diverse agricultural applications | Pros: Complete solution; Cons: Maintenance can be intensive. |

What Are Submersible Solar Pumps and Their Applications?

Submersible solar pumps are designed to operate underwater, making them ideal for deep well applications. Their ability to pump water from significant depths makes them suitable for agricultural fields and livestock watering in regions where groundwater is the primary source. When considering a submersible pump, B2B buyers should evaluate the depth of their wells, the pump’s flow rate, and compatibility with solar panel systems to ensure optimal performance.

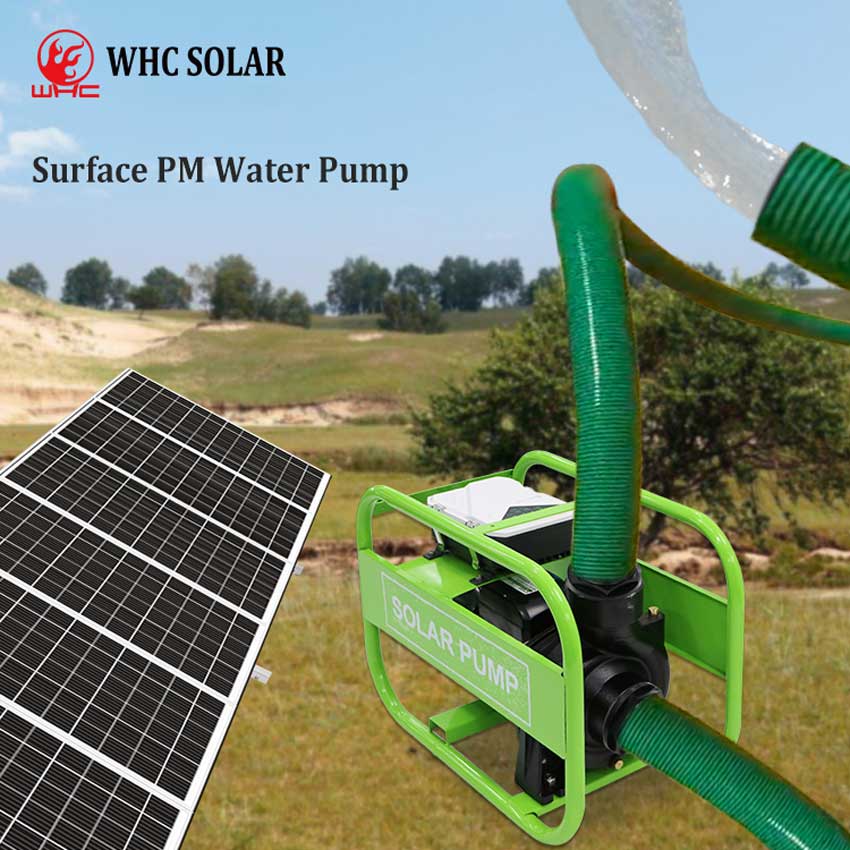

How Do Surface Solar Pumps Differ from Other Types?

Surface solar pumps are installed above ground and are typically easier to install compared to submersible options. They are best suited for shallow water sources, such as ponds or reservoirs, and are commonly used in irrigation systems. Buyers should consider the elevation difference between the water source and the irrigation site, as surface pumps may not be effective for higher elevations. Their straightforward installation process makes them an attractive option for businesses looking for quick deployment.

What Makes Solar Well Pumps a Reliable Choice for Businesses?

Solar well pumps are specifically designed for extracting water from wells, making them particularly useful in commercial farming and remote locations without access to the electrical grid. These pumps can provide a consistent water supply, which is crucial for agricultural productivity. B2B buyers should focus on the pump’s capacity, efficiency ratings, and warranty terms, as these factors will influence long-term operational costs and reliability.

In What Situations Are Booster Pumps Most Effective?

Booster pumps are used to enhance the pressure of existing irrigation systems, making them particularly effective in large-scale agricultural operations. These pumps can significantly increase water flow, ensuring that crops receive adequate hydration. When purchasing booster pumps, businesses should assess their current irrigation infrastructure and determine the required pressure levels to optimize performance. The integration of booster pumps can lead to improved efficiency but may necessitate additional power sources for optimal operation.

Why Consider Complete Solar Pumping Systems for Agricultural Needs?

Complete solar pumping systems integrate solar panels, batteries, and pumps into one cohesive unit, providing a versatile solution for diverse agricultural applications. These systems are particularly beneficial in off-grid areas where traditional power sources are unavailable. Buyers should evaluate the total capacity of the system, including the number of solar panels and battery life, to ensure it meets their water supply needs. While these systems offer a comprehensive solution, they may require more maintenance than simpler pump options, which is an important consideration for long-term planning.

Key Industrial Applications of solar irrigation pump

| Industry/Sector | Specific Application of Solar Irrigation Pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Drip Irrigation Systems for Crop Production | Reduces water costs, enhances crop yield, sustainable farming practices | Sizing based on crop type and land area, local solar insolation data |

| Livestock Farming | Water Supply for Livestock | Ensures consistent water supply, reduces operational costs, off-grid solution | Pump capacity based on herd size, durability in harsh climates |

| Horticulture | Automated Irrigation for Greenhouses | Optimizes water usage, increases plant health, energy savings | Compatibility with existing irrigation systems, scalability for future needs |

| Aquaculture | Pond Aeration and Water Circulation | Improves fish growth rates, maintains water quality, reduces energy costs | Pump efficiency, ability to operate in variable weather conditions |

| Off-Grid Communities | Water Supply for Remote Areas | Provides reliable water access, reduces dependence on grid electricity | Installation support, battery backup options, local maintenance services |

How Are Solar Irrigation Pumps Used in Agriculture?

In the agriculture sector, solar irrigation pumps are extensively used for drip irrigation systems, which enable precise water delivery directly to the plant roots. This method reduces water wastage and enhances crop yield by ensuring that crops receive the optimal amount of water. For international B2B buyers in regions like Africa and South America, understanding local solar insolation data is crucial for selecting the right pump size and system configuration to meet their specific crop needs.

What Role Do Solar Pumps Play in Livestock Farming?

Solar irrigation pumps provide a reliable water supply for livestock, particularly in remote areas where traditional power sources may be unavailable. These systems ensure that animals have access to clean water, which is vital for their health and productivity. Buyers should consider pump capacity based on herd size and the ability of the pump to withstand harsh environmental conditions, particularly in regions like Saudi Arabia and Brazil where temperatures can be extreme.

How Are Solar Irrigation Pumps Beneficial in Horticulture?

In horticulture, automated irrigation systems powered by solar pumps enhance water efficiency and promote healthier plant growth. By utilizing solar energy, these systems reduce operational costs and provide a sustainable solution for greenhouse management. For B2B buyers, compatibility with existing irrigation infrastructure and scalability for future expansion are key considerations when sourcing solar pumps for horticultural applications.

What Advantages Do Solar Pumps Offer in Aquaculture?

Aquaculture operations benefit from solar irrigation pumps through improved pond aeration and water circulation, which are essential for maintaining optimal fish growth conditions. These pumps help in regulating water quality and reducing energy costs associated with traditional pumping methods. Buyers should focus on pump efficiency and the ability to operate effectively under varying weather conditions to ensure reliable performance in aquaculture settings.

How Do Solar Pumps Serve Off-Grid Communities?

In off-grid communities, solar irrigation pumps are vital for providing consistent water access, reducing reliance on grid electricity. These systems are particularly beneficial in areas with limited infrastructure, as they can be tailored to meet local needs. When sourcing solar pumps, buyers should prioritize installation support, consider battery backup options for continuous operation, and evaluate the availability of local maintenance services to ensure long-term functionality.

3 Common User Pain Points for ‘solar irrigation pump’ & Their Solutions

Scenario 1: Inconsistent Water Supply for Irrigation Needs

The Problem: A common challenge faced by agricultural businesses using solar irrigation pumps is the inconsistency in water supply, particularly in regions with variable sunlight. For example, during the rainy season or cloudy weather, solar panels may not generate sufficient energy to power the pumps effectively. This inconsistency can lead to inadequate irrigation, negatively impacting crop yield and quality, and ultimately affecting profitability.

The Solution: To mitigate this issue, buyers should consider investing in solar irrigation pump systems that come with battery storage options. These systems can store excess energy generated during sunny periods, allowing pumps to operate even during low sunlight conditions. Additionally, it is advisable to conduct a thorough assessment of water requirements based on crop types and growth stages, and then size the solar pump accordingly. Engaging with a reputable supplier who can provide customized solutions and installation guidance will ensure that the system is optimized for specific agricultural needs, providing a more reliable water supply.

Scenario 2: High Initial Investment and ROI Concerns

The Problem: Many B2B buyers in the agricultural sector are deterred by the high initial costs associated with solar irrigation pump installations. The upfront investment can be significant, leading to concerns about the return on investment (ROI). Buyers often question whether the long-term savings on energy costs and operational efficiency will justify the initial expenditure, particularly in regions with fluctuating energy prices.

The Solution: A strategic approach for buyers is to perform a comprehensive cost-benefit analysis that includes potential energy savings, increased crop yields, and reduced water costs over time. Buyers should also explore financing options such as grants, subsidies, or loans specifically designed for renewable energy projects in agriculture. Working with an experienced solar solutions provider can help develop a financial model that outlines expected savings and payback periods. Moreover, buyers should prioritize suppliers that offer warranties and performance guarantees, ensuring that their investment is protected and that the solar system performs as expected.

Scenario 3: Installation and Maintenance Challenges

The Problem: After purchasing solar irrigation pumps, many B2B buyers face challenges related to installation and ongoing maintenance. Inadequate installation can lead to operational inefficiencies or equipment failures, while lack of proper maintenance can diminish the lifespan and performance of the solar pump system. This is particularly problematic in remote areas where skilled labor may be scarce.

The Solution: To overcome these challenges, buyers should seek out solar irrigation pump providers that offer comprehensive installation support and maintenance services. This could include training local staff on proper installation techniques and routine maintenance tasks to ensure the system operates optimally. Additionally, investing in systems that feature smart technology can help monitor pump performance and alert users to potential issues before they escalate. Establishing a regular maintenance schedule with clear guidelines from the manufacturer will also help in sustaining the pump’s efficiency, thus minimizing downtime and ensuring a steady water supply for irrigation.

By addressing these pain points with actionable solutions, B2B buyers can optimize their investment in solar irrigation pumps, enhancing their agricultural operations while reaping the benefits of sustainable energy solutions.

Strategic Material Selection Guide for solar irrigation pump

What Are the Key Materials Used in Solar Irrigation Pumps?

When selecting materials for solar irrigation pumps, it’s essential to consider their properties and performance characteristics. The right material can significantly impact the efficiency, durability, and overall effectiveness of the pump system. Below are analyses of four common materials used in the construction of solar irrigation pumps.

How Does Stainless Steel Perform in Solar Irrigation Pumps?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures exceeding 200 psi.

Pros & Cons: The durability of stainless steel makes it suitable for long-term applications, especially in harsh environments. However, it is relatively expensive compared to other materials, which can increase the overall cost of the pump. Manufacturing complexity is moderate, as stainless steel requires specialized welding techniques.

Impact on Application: Stainless steel is compatible with various media, including potable water and agricultural chemicals. Its corrosion resistance allows it to perform well in saline or acidic environments, which is particularly relevant for regions with challenging water conditions.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is crucial when sourcing stainless steel components. Buyers from regions like the Middle East and Africa should ensure that the material meets local regulations regarding corrosion resistance and safety.

What Role Does Polypropylene Play in Solar Irrigation Pumps?

Key Properties: Polypropylene is a lightweight thermoplastic with good chemical resistance and a temperature rating of around 180°F (82°C). It is less robust under pressure compared to metals, typically rated for applications below 100 psi.

Pros & Cons: The primary advantage of polypropylene is its cost-effectiveness and ease of manufacturing, making it suitable for low-budget projects. However, its lower durability and temperature resistance can limit its application in extreme environments.

Impact on Application: Polypropylene is compatible with various non-corrosive fluids, making it ideal for irrigation systems that do not involve harsh chemicals. However, its limitations in high-pressure applications may restrict its use in certain agricultural settings.

Considerations for International Buyers: Buyers should check for compliance with local standards and certifications, especially in regions like South America where agricultural regulations may vary. Understanding the specific chemical compatibility of polypropylene with local water sources is also essential.

How Does Aluminum Compare in Solar Irrigation Pumps?

Key Properties: Aluminum is lightweight, resistant to corrosion, and has a temperature rating of around 400°F (204°C). It can handle moderate pressures, usually up to 150 psi.

Pros & Cons: The lightweight nature of aluminum makes it easy to install and transport, which is beneficial for remote areas. However, it is less durable than stainless steel and may require protective coatings to enhance its corrosion resistance, adding to manufacturing complexity.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable irrigation systems. However, its susceptibility to corrosion in saline environments may limit its use in coastal regions.

Considerations for International Buyers: Compliance with international standards is critical, particularly in Europe where environmental regulations are stringent. Buyers should also consider the availability of aluminum in their local markets, as sourcing can vary by region.

Why Is PVC a Popular Choice for Solar Irrigation Pumps?

Key Properties: Polyvinyl chloride (PVC) is a plastic material known for its excellent chemical resistance and low cost. It has a temperature rating of about 140°F (60°C) and can handle low-pressure applications, typically below 80 psi.

Pros & Cons: PVC is highly cost-effective and easy to manufacture, making it a popular choice for budget-conscious projects. However, its lower temperature and pressure ratings limit its application in more demanding environments.

Impact on Application: PVC is suitable for transporting water and is often used in drip irrigation systems. Its compatibility with various agricultural chemicals makes it versatile, but it may not perform well in high-temperature applications.

Considerations for International Buyers: Buyers should ensure that PVC products meet local standards, particularly in regions with strict agricultural regulations. Understanding the specific environmental conditions in which PVC will be used is also important for ensuring long-term performance.

Summary Table of Material Selection for Solar Irrigation Pumps

| Material | Typical Use Case for solar irrigation pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure and corrosive environments | Excellent durability and corrosion resistance | High cost and manufacturing complexity | High |

| Polypropylene | Low-budget, non-corrosive applications | Cost-effective and easy to manufacture | Limited pressure and temperature resistance | Low |

| Aluminum | Lightweight, portable systems | Easy to install and transport | Less durable, requires coatings | Medium |

| PVC | Drip irrigation systems | Highly cost-effective | Low temperature and pressure ratings | Low |

This material selection guide provides valuable insights for B2B buyers looking to optimize their solar irrigation pump systems, ensuring they select the most appropriate materials based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for solar irrigation pump

What Are the Key Stages in the Manufacturing Process of Solar Irrigation Pumps?

The manufacturing process of solar irrigation pumps is multifaceted, involving several critical stages that ensure the final product is both efficient and durable. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Solar Irrigation Pumps?

Material preparation begins with sourcing high-quality components such as solar panels, pumps, controllers, and other electronic parts. Manufacturers often select corrosion-resistant materials like stainless steel or high-grade plastics to ensure longevity, especially in harsh environments common in agricultural settings.

Once the materials are sourced, they undergo rigorous quality checks to ensure they meet specific standards. This can include assessments for durability, conductivity, and efficiency. For instance, solar panels must meet performance metrics to guarantee effective energy conversion.

What Techniques Are Used in the Forming Stage?

During the forming stage, various techniques are employed to shape the components into their final forms. For solar panels, processes such as lamination and encapsulation are used to protect the photovoltaic cells from environmental damage. For the pumps, techniques like injection molding and machining are common, allowing for precision parts that fit together seamlessly.

In some cases, manufacturers utilize advanced techniques such as 3D printing for prototyping new designs or components. This not only speeds up the development process but also allows for customization based on specific customer requirements.

How Is the Assembly Process Conducted?

The assembly process involves bringing together all the prepared components into a cohesive unit. This stage often employs a combination of manual labor and automated systems to ensure precision and efficiency. Skilled technicians typically oversee the assembly of critical components, ensuring that electrical connections are secure and that all moving parts function smoothly.

Throughout the assembly process, manufacturers often implement real-time monitoring systems to identify any potential issues early on. This helps reduce waste and improve overall production efficiency.

What Finishing Techniques Are Applied to Solar Irrigation Pumps?

Finishing techniques are crucial for enhancing the durability and aesthetic appeal of solar irrigation pumps. This may include surface treatments such as powder coating or anodizing, which provide additional protection against corrosion and wear.

Finally, a thorough cleaning and inspection process is conducted to remove any contaminants that may have accumulated during manufacturing. This step is vital to ensure the pumps operate efficiently and have a long service life.

How Is Quality Assurance Implemented in Solar Irrigation Pump Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process, particularly for solar irrigation pumps that must perform reliably under varying conditions. Manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems, to ensure consistency and quality in production.

What International Standards Should B2B Buyers Look For?

International standards play a significant role in ensuring the reliability of solar irrigation pumps. ISO 9001 certification indicates that a manufacturer has implemented a quality management system that meets global standards. Additionally, industry-specific certifications such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) for components used in fluid systems are critical.

These certifications not only enhance product credibility but also ensure compliance with regulatory requirements in different regions. Buyers should prioritize suppliers with these certifications to mitigate risks associated with product quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically integrated into the manufacturing process to monitor quality at various stages. These include:

Incoming Quality Control (IQC): This initial checkpoint assesses the raw materials before production begins. Suppliers must provide documentation verifying that materials meet specified standards.

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to ensure that the assembly and forming processes adhere to quality standards.

Final Quality Control (FQC): Once the pumps are assembled, they undergo a final inspection, including functional testing to ensure they perform as expected under various conditions.

What Testing Methods Are Commonly Used?

Testing methods for solar irrigation pumps can vary, but common techniques include:

Performance Testing: Evaluating the pump’s efficiency and flow rate under simulated operational conditions.

Durability Testing: Subjecting the pump to extreme temperatures, humidity, and pressure to assess its resilience.

Electrical Testing: Ensuring that all electrical components meet safety standards and function correctly.

These tests help ensure that the final product not only meets customer expectations but also adheres to safety and environmental regulations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify a supplier’s quality control measures. This can include:

Conducting Audits: Regular audits of suppliers can help assess their compliance with quality standards. Buyers can request documentation of previous audits and corrective actions taken.

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports, including test results and compliance certifications.

Engaging Third-party Inspectors: For added assurance, buyers can hire third-party inspection services to evaluate the manufacturing process and product quality independently.

What Quality Control Nuances Should International Buyers Consider?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Different regions may have varying standards and regulations, which can impact product quality and compliance.

Buyers should familiarize themselves with local regulations and ensure that their suppliers are compliant. Additionally, language barriers and cultural differences may affect communication regarding quality standards, making it essential to establish clear expectations and maintain open lines of communication.

In summary, understanding the manufacturing processes and quality assurance measures for solar irrigation pumps is vital for B2B buyers. By prioritizing suppliers with robust QA systems and international certifications, businesses can ensure they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solar irrigation pump’

To assist B2B buyers in successfully procuring solar irrigation pumps, this guide provides a comprehensive checklist designed to streamline the sourcing process. By following these steps, you can ensure that you select a system that meets your specific agricultural needs and aligns with your operational goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for identifying the right solar irrigation pump. Consider factors such as flow rate, lift height, and the type of irrigation system you intend to use (drip, sprinkler, etc.). Additionally, evaluate the solar panel requirements necessary for optimal pump operation to ensure compatibility with your existing infrastructure.

Step 2: Assess Your Water Source and Requirements

Understanding your water source is vital for selecting an appropriate pump. Determine the depth of the water source, its quality, and the seasonal variability of water availability. This information will help you select a pump that can efficiently operate under your specific conditions and ensure a consistent water supply for irrigation.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, product catalogs, and case studies showcasing their experience in your region or industry. Look for customer testimonials and references to assess the performance of their products in similar agricultural environments.

Step 4: Verify Supplier Certifications and Standards

Confirm that your chosen suppliers adhere to international quality standards and certifications. Certifications such as ISO, CE, or local equivalents demonstrate a commitment to quality and safety. This step is crucial in ensuring that the equipment meets industry standards, reducing the risk of operational failures.

Step 5: Request Detailed Quotations

Once you’ve shortlisted potential suppliers, request detailed quotations. Ensure that the quotes include not only the price of the solar irrigation pumps but also installation costs, warranty terms, and after-sales support. Comparing these elements will provide a clearer picture of the total cost of ownership and help you make an informed decision.

Step 6: Consider After-Sales Support and Warranty

Evaluate the level of after-sales support offered by suppliers, including installation assistance and maintenance services. A solid warranty can protect your investment, so ensure that the terms are favorable and cover both parts and labor. This step is crucial for minimizing downtime and ensuring smooth operations post-purchase.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, finalize the purchase agreement. Ensure that all terms, including delivery timelines, payment schedules, and installation responsibilities, are clearly outlined. A well-defined agreement can prevent misunderstandings and ensure that both parties are aligned on expectations.

By following these steps, B2B buyers can effectively navigate the complexities of procuring solar irrigation pumps, ensuring a successful investment that enhances agricultural productivity.

Comprehensive Cost and Pricing Analysis for solar irrigation pump Sourcing

What Are the Key Cost Components of Solar Irrigation Pumps?

When sourcing solar irrigation pumps, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The raw materials, such as high-grade stainless steel for pump components, photovoltaic cells, and other electronic parts, significantly influence the overall price. Quality materials not only enhance durability but also improve efficiency, which can lead to long-term savings.

Labor: Skilled labor is essential for assembling solar irrigation pumps. Labor costs can vary significantly based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but it’s important to ensure that quality standards are maintained.

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead and reflect in the final pricing.

Tooling: Initial tooling costs can be substantial, particularly for custom or specialized pumps. Buyers should consider these costs when negotiating pricing, especially for bulk orders.

Quality Control (QC): Investing in rigorous quality control processes ensures that the pumps meet international standards, which is vital for buyers in different regions who may have varying certification requirements.

Logistics: Shipping costs can significantly impact the final price. Factors such as distance, mode of transportation, and customs duties should be factored into the logistics cost, especially for international buyers.

Margin: Suppliers typically build a margin into their pricing structure to cover operational costs and profit. Understanding the supplier’s margin can help in negotiating better prices.

How Do Price Influencers Impact Solar Irrigation Pump Costs?

Several factors can influence the pricing of solar irrigation pumps:

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Buyers should inquire about minimum order quantities (MOQ) and potential discounts for bulk orders.

Specifications/Customization: Customizing pumps to meet specific irrigation needs or site conditions can increase costs. However, tailored solutions may enhance efficiency and reliability, providing long-term value.

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) can elevate costs but ensure compliance with safety and performance standards, which is particularly crucial for international markets.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and customer support.

Incoterms: Understanding the terms of trade (Incoterms) is vital for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

What Are the Best Negotiation Tips for International B2B Buyers?

Effective negotiation is key to achieving cost-efficiency in sourcing solar irrigation pumps. Here are some actionable tips:

Research Market Prices: Before negotiations, conduct thorough market research to understand average prices and competitor offerings. This knowledge empowers buyers to negotiate from an informed position.

Emphasize Total Cost of Ownership (TCO): Consider the long-term savings that solar pumps offer. Highlighting the TCO, including maintenance and energy savings, can justify a higher upfront cost if the supplier is flexible on pricing.

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Suppliers are often more willing to negotiate with trusted partners.

Explore Alternative Suppliers: Don’t settle for the first quote. Exploring multiple suppliers can provide leverage in negotiations, allowing buyers to secure the best possible deal.

Be Aware of Regional Pricing Nuances: Different regions may have specific pricing structures influenced by local market conditions. Buyers from Africa, South America, the Middle East, and Europe should consider these nuances when negotiating.

Are There Any Disclaimers Regarding Indicative Prices?

While indicative prices for solar irrigation pumps can provide a general idea of the market, they can fluctuate based on the factors mentioned above. Buyers should always seek quotes from multiple suppliers and account for potential changes in material costs, labor rates, and logistics when planning their budgets.

Alternatives Analysis: Comparing solar irrigation pump With Other Solutions

When considering irrigation solutions, it is essential for B2B buyers to analyze various alternatives to solar irrigation pumps. Each option offers distinct benefits and drawbacks, impacting operational efficiency, cost, and sustainability. This section compares solar irrigation pumps with traditional diesel-powered pumps and electric pumps, providing insights to help buyers make informed decisions.

| Comparison Aspect | Solar Irrigation Pump | Diesel-Powered Pump | Electric Pump |

|---|---|---|---|

| Performance | High efficiency, works in remote areas; dependent on sunlight | High power output; suitable for large-scale operations | Reliable; consistent performance with grid access |

| Cost | Initial investment may be high, but low operational costs | High fuel and maintenance costs; lower initial investment | Moderate installation cost; higher electricity bills over time |

| Ease of Implementation | Requires solar panel installation; can be complex | Easy to install; minimal setup required | Requires electrical connections; installation may need expert help |

| Maintenance | Low maintenance; periodic checks needed for panels | High maintenance; engine servicing required | Moderate maintenance; electrical components need regular checks |

| Best Use Case | Ideal for off-grid farms and sustainable practices | Suitable for large agricultural operations with access to fuel | Effective in areas with reliable electricity supply |

What are the Pros and Cons of Diesel-Powered Pumps for Irrigation?

Diesel-powered pumps are a well-established alternative to solar irrigation pumps. They are known for their high power output, making them suitable for large-scale agricultural operations. Installation is relatively straightforward, and the initial costs are generally lower than those of solar systems. However, ongoing fuel costs can escalate, and maintenance is often cumbersome, as diesel engines require regular servicing and can be prone to breakdowns. Furthermore, reliance on fossil fuels raises sustainability concerns, especially in regions prioritizing eco-friendly practices.

How Do Electric Pumps Compare in Terms of Efficiency and Cost?

Electric pumps provide a consistent performance level, particularly in areas with stable electricity access. Their installation is generally less complex than solar systems, and they can be more cost-effective in regions where electricity is inexpensive. However, electric pumps incur higher operational costs due to electricity bills, and their dependence on the grid can be a significant drawback in remote areas. Maintenance needs are moderate, but the risk of power outages can disrupt irrigation schedules, making them less reliable in regions with unstable power supply.

How Should B2B Buyers Choose the Right Irrigation Solution?

When selecting the right irrigation solution, B2B buyers should carefully assess their specific needs, operational context, and long-term goals. Factors such as available resources, environmental considerations, and financial capacity will influence the decision. For buyers in remote areas with a focus on sustainability, solar irrigation pumps may offer the best long-term value despite higher initial costs. Conversely, those operating in well-connected regions may find electric pumps more practical, while diesel options could suit larger operations with immediate fuel access. Ultimately, understanding the unique advantages and limitations of each solution will empower buyers to make choices that align with their operational strategies.

Essential Technical Properties and Trade Terminology for solar irrigation pump

What Are the Key Technical Properties of Solar Irrigation Pumps?

Understanding the technical properties of solar irrigation pumps is essential for international B2B buyers, especially when evaluating products for agricultural needs in diverse markets like Africa, South America, the Middle East, and Europe. Here are some critical specifications to consider:

Flow Rate (GPM or L/min)

The flow rate indicates how much water the pump can deliver per minute, typically measured in gallons per minute (GPM) or liters per minute (L/min). This specification is vital for determining whether a pump can meet the irrigation needs of specific crops or livestock, ensuring adequate water supply in different growing conditions.Head Pressure (Feet or Meters)

Head pressure refers to the maximum height the pump can lift water, measured in feet or meters. This property is crucial for understanding the pump’s capability to transport water from deep wells or to elevated irrigation systems. Buyers must match the head pressure with their site conditions to ensure efficient operation.Solar Panel Compatibility

The compatibility of the pump with solar panel systems is essential, as it determines the energy source’s efficiency. Buyers should consider the voltage and wattage requirements of the pump, ensuring they can integrate it with the available solar infrastructure. This helps in optimizing energy use and reducing operational costs.Material Grade

The material used in the pump construction, such as stainless steel, plastic, or aluminum, affects durability and performance. Pumps made of high-grade materials are more resistant to corrosion and wear, particularly in harsh environmental conditions. This is particularly important for buyers in regions with extreme weather or saline water sources.Power Consumption (Watts)

Power consumption indicates the energy efficiency of the pump. Lower wattage pumps can help reduce energy costs, making them more sustainable and cost-effective in the long run. This specification is particularly relevant for buyers looking to minimize operational expenses in off-grid scenarios.Operating Temperature Range

This specification defines the temperature limits within which the pump can operate efficiently. Understanding the operating temperature range helps buyers ensure that the pump will function correctly in their local climate conditions, preventing potential failures during extreme weather events.

What Are Common Trade Terms Related to Solar Irrigation Pumps?

Familiarity with industry jargon is critical for effective communication and negotiation in the B2B sector. Here are some common terms related to solar irrigation pumps:

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. Understanding OEM relationships can help buyers identify quality assurance and warranty options, particularly when sourcing pumps from multiple suppliers.MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Buyers need to be aware of MOQ to plan their purchasing strategy effectively, especially when managing inventory or budgeting for large-scale agricultural projects.RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. Utilizing RFQs can streamline the procurement process, allowing buyers to compare offers from multiple suppliers and make informed purchasing decisions.Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for buyers to clarify shipping responsibilities, costs, and risks associated with the delivery of solar irrigation pumps.Warranty Period

This term refers to the duration during which a product is guaranteed against defects and failures. Knowing the warranty period is essential for assessing long-term reliability and support, particularly for critical equipment like irrigation pumps.Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. For agricultural operations that depend on timely irrigation, understanding lead time can help buyers plan their projects effectively and ensure that they have the necessary equipment when needed.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring they select the right solar irrigation pump solutions for their specific agricultural needs.

Navigating Market Dynamics and Sourcing Trends in the solar irrigation pump Sector

What Are the Key Market Trends Driving the Solar Irrigation Pump Sector?

The global market for solar irrigation pumps is experiencing significant growth, driven by an increasing demand for sustainable agricultural practices and water management solutions. Key drivers include the rising costs of electricity, the need for efficient water use in agriculture, and government incentives promoting renewable energy technologies. Regions such as Africa and South America are particularly ripe for this growth, as they face challenges like water scarcity and unreliable electricity supply. Solar irrigation pumps provide an effective solution, allowing farmers to access water without the heavy burden of electricity costs or extensive infrastructure investments.

Emerging technologies are also shaping the sourcing landscape. For instance, advancements in solar panel efficiency and battery storage systems are enhancing the performance and reliability of solar irrigation pumps. Additionally, digital platforms are facilitating easier access to information and procurement processes for international buyers, allowing them to compare products and suppliers more effectively. As the market matures, buyers are increasingly looking for integrated solutions that combine solar pumps with smart irrigation systems, enabling precise water management that can improve crop yields and reduce waste.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions?

Incorporating sustainability into sourcing decisions is becoming paramount for businesses in the solar irrigation pump sector. The environmental impact of traditional irrigation methods is significant, contributing to water depletion and energy consumption. By choosing solar-powered solutions, businesses can minimize their carbon footprint and support sustainable agriculture practices. Moreover, ethical sourcing is crucial; international buyers should prioritize suppliers that adhere to sustainable practices, such as responsible manufacturing processes and fair labor conditions.

Buyers should also consider certifications that indicate environmental responsibility. Certifications like ISO 14001 (Environmental Management) and Fair Trade can serve as benchmarks for suppliers. Utilizing materials that are recyclable or sourced from sustainable operations can further enhance a company’s commitment to ethical practices. In the long run, aligning with sustainable and ethical suppliers not only meets consumer demand for responsible products but can also enhance brand reputation and customer loyalty.

What Has Been the Evolution of the Solar Irrigation Pump Industry?

The solar irrigation pump sector has evolved significantly over the past few decades. Initially, solar pumps were primarily used in off-grid applications, primarily in remote areas lacking access to electricity. The technology has since advanced, with improved efficiency and affordability making solar pumps accessible to a wider audience, including commercial farms in developed regions.

As awareness of climate change and sustainable practices has grown, the adoption of solar irrigation pumps has surged. Today, these pumps are not only seen as a viable alternative to traditional pumps but are also integral to modern agricultural strategies aimed at maximizing water efficiency and sustainability. The future looks bright for solar irrigation, with continuous innovations expected to drive further adoption across diverse markets.

Frequently Asked Questions (FAQs) for B2B Buyers of solar irrigation pump

How do I choose the right solar irrigation pump for my agricultural needs?

Choosing the right solar irrigation pump involves assessing your specific water requirements, including flow rate, head height, and the type of irrigation system you plan to use (e.g., drip or sprinkler). Start by calculating the total volume of water needed for your crops and the distance the water needs to be pumped. Consult with suppliers who offer sizing tools or expert advice to ensure you select a pump that matches your agricultural setup while maximizing efficiency and sustainability.What is the best solar irrigation pump for regions with limited sunlight?

For areas with limited sunlight, consider solar irrigation pumps that come with hybrid systems or battery storage. These systems can store energy generated during sunny days to ensure consistent water supply even during cloudy weather. Look for pumps with high efficiency ratings and the ability to operate effectively with lower solar input. Additionally, some suppliers offer customizable solutions that can be tailored to specific environmental conditions in your region.What are the key factors to consider when vetting suppliers of solar irrigation pumps?

When vetting suppliers, consider their experience in the solar irrigation sector, customer reviews, and certifications related to quality and sustainability. Evaluate their product range to ensure they offer the specific types of pumps you need. Additionally, inquire about their after-sales support, warranty terms, and technical assistance. A reliable supplier should also provide transparent information regarding pricing, delivery timelines, and the ability to handle international shipping.What are the typical minimum order quantities (MOQs) for solar irrigation pumps?

MOQs for solar irrigation pumps can vary significantly between suppliers, ranging from a single unit to several dozen, depending on the manufacturer’s production capabilities and the product type. When sourcing, always clarify the MOQ with potential suppliers to ensure it aligns with your purchasing strategy. Some suppliers may offer flexibility for first-time buyers or smaller businesses, allowing you to place a trial order before committing to larger quantities.What payment terms should I expect when sourcing solar irrigation pumps internationally?

Payment terms can vary widely depending on the supplier and your negotiation. Common practices include upfront payment, partial payment upon order confirmation, and the balance upon delivery. Be sure to discuss and agree on payment methods such as wire transfers, letters of credit, or payment through escrow services to protect both parties. Understanding these terms upfront can help avoid delays in order processing and shipping.How can I ensure the quality of solar irrigation pumps from international suppliers?

To ensure quality, request product certifications and compliance with international standards, such as ISO or CE marking. Conducting factory audits or third-party inspections prior to shipment can also provide assurance of product quality. Additionally, consider suppliers that offer warranties and guarantees, which indicate confidence in their products. Engaging with other buyers or industry forums can provide insights into the supplier’s reputation and product reliability.What logistics considerations should I keep in mind when importing solar irrigation pumps?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Work with suppliers who have experience with international shipments to ensure compliance with local regulations. It’s vital to confirm shipping costs, insurance coverage, and estimated delivery times to avoid unexpected delays. Additionally, consider the availability of local support for installation and maintenance once the pumps arrive at your location.Can solar irrigation pumps be customized to fit specific agricultural needs?

Yes, many manufacturers offer customization options to meet specific agricultural needs. This can include modifications in pump size, flow rate, and integration with existing irrigation systems. When discussing customization, provide detailed information about your requirements and any environmental factors that may affect pump performance. Collaborating closely with suppliers during the design phase can lead to tailored solutions that enhance your irrigation efficiency and overall agricultural productivity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Solar Irrigation Pump Manufacturers & Suppliers List

1. RPS Solar Pumps – Solar Powered Well Pump Systems

Domain: rpssolarpumps.com

Registered: 2016 (9 years)

Introduction: RPS Solar Pumps offers solar powered well pump systems in various types and sizes, capable of pumping water up to 1000′ head. The pumps are suitable for livestock, irrigation, household backup, and off-grid living. They provide a 100% Water Assurance Guarantee, ensuring customers will have water after proper installation or their money back. The company has pumped over 12 billion gallons of water …

2. The Solar Store – Solar Water Pumps

Domain: thesolarstore.com

Registered: 2004 (21 years)

Introduction: Solar water pumps are a sustainable and cost-effective solution for well, irrigation, and livestock water needs. They come in various sizes and types, from small 12V pumps for low gallons per minute requirements to larger systems running off 6-panel solar arrays for commercial agriculture. Off-grid solar well pumps are useful in remote areas with limited access to electric power, pumping water fro…

3. Rock Solar – Solar Water Pumps

Domain: rocksolar.io

Registered: 2023 (2 years)

Introduction: Key Product Details:

– Collection: Solar Water Pumps

– Applications: Farming, Gardens, Remote Residences, Cottages

– Types: Brushless DC Pumps, Brush DC Pumps, Water Transfer Pumps

– Features: Reliable water supply, suitable for off-grid living

– Price Range: From $459.99 to $3,799.99

– Discounts: Up to 43% off on select products

– Available Sizes: 0.4HP to 4.0HP

– Voltage Options: 20-40V, 60-450V…

4. Black Forest Solar – Solar Irrigation Pump Kit 3000 GPH

Domain: firehosesupply.com

Registered: 2012 (13 years)

Introduction: Product Name: Solar Irrigation Pump Kit 3000 Gallons Per Hour (No Battery Needed)

Regular Price: $816,349.43

Availability: Factory Production Order, Ships In 1-2 Weeks

Shipping: Free Shipping

Product Type: Solar Pump Kit

Product Vendor: Black Forest Solar

Product SKU: 9MFS92K3OM-1

Minimum Order Quantity: 500 Units

Unit Cost for QTY 500: $1,047.30 Each (Factory EXW)

Unit Cost for QTY 1000: $990.42 …

5. Lorentz – Solar Pumping Systems

Domain: lorentz.de

Introduction: LORENTZ solar pumping systems are designed for irrigation in remote locations, transforming unused land into productive farms and improving crop yields. They can operate without grid power or diesel engines, making them suitable for areas with high sunlight and limited infrastructure. The systems support various irrigation methods including drip, sprinkler, pivot, and flood irrigation, and can pro…

6. Reddit – 2 HP Water Pump for Blueberry Irrigation

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 2 HP water pump, approximately 1500 watts, intended for irrigation of blueberries, requires operation for 1 hour on battery, consideration for 12V vs higher voltage system.

7. Solar Magazine – Solar Water Pumps

Domain: solarmagazine.com

Registered: 2004 (21 years)

Introduction: Solar water pumps are a clean, energy-efficient alternative to traditional electric and fuel-driven pumps, commonly used in residential, commercial, and agricultural irrigation. They consist of a photovoltaic (PV) array, an electric motor, and a pump. Solar pumps can be classified into direct current (DC) or alternating current (AC) systems, with brushless DC (BLDC) motors also available. The main…

8. Futurepump – Solar Pumps

Domain: shop.futurepump.com

Registered: 2013 (12 years)

Introduction: {“products”: [{“name”: “SE1 solar pump for one acre”, “reviews”: 12, “regular_price”: “$577.50”, “sale_price”: “$577.50”, “status”: “Sold out”}, {“name”: “SF2 solar pump for two acres”, “reviews”: 13, “regular_price”: “$723.33”, “sale_price”: “$723.33”, “status”: “Sold out”}, {“name”: “Float Switch”, “reviews”: 0, “regular_price”: “$70.00”, “sale_price”: “$70.00”, “status”: “Sold out”}, {“name”: “…

9. SunCulture – ClimateSmart Battery with RainMaker 2 System

Domain: sunculture.io

Registered: 2021 (4 years)

Introduction: SunCulture offers solar irrigation pumps designed for smallholder farmers, providing reliable access to water, irrigation, lighting, and mobile charging through off-grid solar technology. Key products include: 1. ClimateSmart Battery with RainMaker 2 System – Monthly Payment: Ksh.4,679, Deposit: Ksh. 6,499, Cash Price: Ksh. 94,999, Warranty: 30 months, Free Delivery and Installation. 2. ClimateSma…

Strategic Sourcing Conclusion and Outlook for solar irrigation pump

Why is Strategic Sourcing Essential for Solar Irrigation Pumps?

In today’s rapidly evolving agricultural landscape, the strategic sourcing of solar irrigation pumps has emerged as a critical component for businesses aiming to enhance operational efficiency and sustainability. By leveraging solar technology, buyers can not only reduce their reliance on traditional energy sources but also significantly lower operational costs. This is especially vital for international markets in Africa, South America, the Middle East, and Europe, where access to reliable energy can be a challenge.

What Should International Buyers Consider When Sourcing?

B2B buyers should prioritize suppliers that offer comprehensive support, including sizing assistance, installation guidance, and robust warranties, to ensure optimal performance of solar irrigation systems. The proven track record of suppliers in diverse agricultural settings can serve as a benchmark for quality and reliability. Additionally, understanding the local regulatory landscape and potential incentives for renewable energy can further enhance the value proposition of these systems.

How Can You Embrace the Future of Solar Irrigation?

Looking ahead, the integration of advanced technologies such as IoT and AI with solar irrigation systems promises to revolutionize water management in agriculture. Now is the time for international buyers to capitalize on these innovations. By forging strategic partnerships and investing in solar irrigation pumps, businesses can not only secure a sustainable water supply but also position themselves as leaders in the green revolution. Take the next step towards sustainable agriculture by exploring tailored solutions that meet your unique needs.