Introduction: Navigating the Global Market for how to change irrigation valve

In the rapidly evolving landscape of global agriculture, the ability to efficiently change irrigation valves is crucial for businesses aiming to enhance productivity and sustainability. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe grapple with water scarcity and management challenges, understanding how to replace these essential components becomes increasingly vital. This guide provides a comprehensive overview of the irrigation valve replacement process, covering various types of valves, their applications, and the specific tools required for effective maintenance.

Throughout this guide, we delve into the critical aspects of sourcing high-quality valves, evaluating suppliers, and navigating the complexities of cost considerations. By providing actionable insights and best practices, this resource empowers businesses to make informed purchasing decisions that align with their operational needs. Whether you’re a contractor managing multiple projects or a facility manager overseeing agricultural operations, understanding the intricacies of irrigation valve replacement can lead to significant cost savings and improved system reliability.

Moreover, we address common challenges faced by B2B buyers, such as compatibility issues, regulatory compliance, and the importance of selecting the right materials for different climates. With this knowledge, businesses can optimize their irrigation systems, ensuring that they remain competitive in a global market that increasingly prioritizes sustainability and resource efficiency.

Understanding how to change irrigation valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Control Valves | Operated manually; typically less expensive. | Small-scale agricultural operations. | Pros: Low cost, easy to install. Cons: Labor-intensive, not suitable for large areas. |

| Electric Solenoid Valves | Automated operation via electrical signals. | Commercial landscaping and large farms. | Pros: Efficient, reduces labor costs. Cons: Higher initial investment, requires electrical setup. |

| Anti-Siphon Valves | Prevents backflow; typically positioned above the highest sprinkler head. | Residential and commercial irrigation. | Pros: Protects water supply, complies with regulations. Cons: Installation can be complex, requires space. |

| PVC Ball Valves | Durable, offers a full flow with minimal resistance. | Industrial irrigation systems. | Pros: Long-lasting, low maintenance. Cons: Requires specific fittings, may be more expensive. |

| Zone Control Valves | Manages multiple zones within an irrigation system. | Large agricultural fields and parks. | Pros: Efficient water usage, customizable zones. Cons: More complex installation, higher cost. |

What Are Manual Control Valves and Their B2B Suitability?

Manual control valves are operated by hand, making them straightforward and cost-effective for small-scale agricultural operations. These valves are typically used in environments where automated systems are not feasible due to budget constraints or the scale of irrigation required. Buyers should consider the labor implications, as these valves necessitate manual intervention, which may not be efficient for larger operations.

How Do Electric Solenoid Valves Enhance Efficiency?

Electric solenoid valves automate the irrigation process through electrical signals, making them ideal for commercial landscaping and large farms. This type of valve significantly reduces labor costs and improves efficiency, as they can be programmed to operate at specific times. However, they require an initial investment in electrical infrastructure, which can be a barrier for some buyers.

Why Choose Anti-Siphon Valves for Compliance?

Anti-siphon valves are designed to prevent backflow, ensuring that the irrigation system does not contaminate the water supply. They are essential for both residential and commercial irrigation systems, particularly in areas where local regulations mandate their use. While they protect water quality, the installation can be complex and may require additional space above the highest sprinkler head.

What Advantages Do PVC Ball Valves Offer?

PVC ball valves are known for their durability and ability to provide full flow with minimal resistance, making them suitable for industrial irrigation systems. They are long-lasting and require low maintenance, presenting a strong value proposition for B2B buyers in sectors that demand reliability. However, they necessitate specific fittings, which can increase costs and complicate procurement.

How Do Zone Control Valves Optimize Water Usage?

Zone control valves allow for the management of multiple zones within an irrigation system, making them particularly beneficial for large agricultural fields and parks. This capability optimizes water usage by enabling targeted irrigation based on specific zone requirements. While they offer customization and efficiency, the complexity of installation and higher costs can deter some buyers, making it essential to assess overall system needs before purchasing.

Key Industrial Applications of how to change irrigation valve

| Industry/Sector | Specific Application of how to change irrigation valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Replacing valves in large-scale irrigation systems | Ensures optimal water distribution, enhancing crop yield and reducing water waste. | Sourcing durable, weather-resistant valves suitable for local climates. |

| Landscaping & Turf Management | Maintenance of irrigation systems in parks and golf courses | Improves aesthetic quality and health of green spaces, attracting more visitors and customers. | Valves must be compatible with existing systems and adhere to local regulations. |

| Horticulture & Nurseries | Upgrading valves for efficient watering of plants | Enhances plant growth through better water management, leading to higher sales. | Need for specialized valves that can handle specific plant watering requirements. |

| Municipal Water Management | Replacing valves in urban irrigation systems | Supports sustainable urban development by optimizing water usage in public spaces. | Compliance with municipal standards and availability of local suppliers is critical. |

| Construction & Development | Installing valves in new residential or commercial projects | Facilitates effective landscape management, increasing property value and appeal. | Consideration of valve types that meet building codes and environmental regulations. |

How is ‘how to change irrigation valve’ Applied in Agriculture?

In the agriculture sector, changing irrigation valves is crucial for maintaining effective water distribution across large fields. These valves control the flow of water to crops, ensuring that they receive adequate hydration without wastage. The replacement of old or malfunctioning valves not only prevents water loss but also enhances crop yield, which is vital for farmers operating in regions facing water scarcity. Buyers in this sector should focus on sourcing durable valves that can withstand harsh weather conditions typical of Africa and South America.

What Role Does Valve Replacement Play in Landscaping & Turf Management?

In landscaping and turf management, regularly changing irrigation valves is essential for maintaining the health of parks, gardens, and golf courses. Efficient irrigation systems ensure that green spaces remain lush and visually appealing, which is important for attracting visitors and maintaining property values. Buyers must ensure that the valves they procure are compatible with existing irrigation systems and meet local regulations to avoid costly adjustments during installation.

How Does Valve Maintenance Impact Horticulture & Nurseries?

For horticulture and nurseries, the ability to efficiently water plants is critical to growth and sales. Replacing old valves allows for precise control over water delivery, which is essential for different plant types that may have varying hydration needs. This not only supports healthier plants but also increases production efficiency. Buyers in this sector should consider specialized valves that cater to specific watering requirements, ensuring optimal growth conditions for their products.

Why is Valve Replacement Important for Municipal Water Management?

Municipal water management relies on effective irrigation systems to maintain public parks and green spaces. Changing irrigation valves helps to optimize water usage, contributing to sustainable urban development. This is particularly important in regions where water conservation is a priority. Buyers need to ensure that the valves comply with municipal standards and are sourced from local suppliers to facilitate timely maintenance and repairs.

How Do Construction & Development Projects Benefit from Proper Valve Installation?

In construction and development, the installation of irrigation valves is a key component of landscape management in new residential or commercial projects. Properly functioning valves ensure that landscapes remain healthy, enhancing property value and appeal to potential buyers. It is essential for developers to consider valve types that not only meet building codes but also align with environmental regulations, ensuring sustainable development practices.

3 Common User Pain Points for ‘how to change irrigation valve’ & Their Solutions

Scenario 1: Difficulty Identifying the Correct Valve Type

The Problem: One of the most common challenges faced by B2B buyers when changing an irrigation valve is the identification of the correct valve type. With various types of valves available—such as manual, automatic, anti-siphon, and pressure-regulating—choosing the wrong valve can lead to system inefficiencies or even damage. This problem is particularly acute in regions with varying irrigation regulations and standards, where compatibility with existing systems is crucial. The confusion can result in wasted time and financial resources, as well as potential disruptions to irrigation schedules.

The Solution: To effectively identify the correct valve type, it is essential to conduct a thorough assessment of the existing irrigation system. Start by documenting the specifications of the current valve, including its size, type, and functionality. Utilize a checklist that includes valve pressure ratings, flow rates, and compatibility with existing piping materials. For international buyers, consider leveraging local suppliers or consulting with regional irrigation experts who understand local regulations and product standards. Additionally, investing in a comprehensive catalog or digital tool that outlines various valve types and their applications can streamline the selection process. By ensuring that the correct valve is sourced, businesses can prevent costly mistakes and maintain efficient irrigation operations.

Scenario 2: Problems with Water Shut-Off

The Problem: Another significant pain point for B2B buyers is the challenge of shutting off the water supply effectively before replacing the irrigation valve. In many cases, the main shut-off valve may be difficult to locate, or it may be corroded and hard to operate. This can lead to water gushing out during the valve replacement process, creating a mess and increasing the risk of property damage. In regions with inconsistent plumbing infrastructure, this issue is particularly pronounced, complicating the replacement process further.

The Solution: To mitigate this problem, it is advisable to conduct a pre-inspection of the irrigation system and its shut-off mechanisms. Create a map of the irrigation system that highlights the location of the main shut-off valve and any auxiliary valves. Regular maintenance should include testing the functionality of these valves to ensure they can be easily operated when needed. Additionally, consider installing an accessible shut-off valve closer to the irrigation system for easier access during emergencies. When preparing for a valve replacement, have a contingency plan, such as using temporary plugs or caps to minimize water flow while the old valve is being removed. This proactive approach not only saves time but also helps maintain a clean working environment.

Scenario 3: Leakage from Improper Sealing

The Problem: After changing an irrigation valve, leakage is a frequent issue that B2B buyers encounter. This can arise from improper sealing of the connections, particularly with threaded or PVC joints. When water leaks occur, it can lead to wasted resources, increased water bills, and potential damage to surrounding areas, especially in regions prone to flooding or water accumulation. The issue is compounded when teams lack the necessary training or experience to properly seal connections.

The Solution: To ensure watertight seals, it is crucial to follow best practices during installation. Start by carefully cleaning the ends of the pipes and the valve to remove any debris or old sealant. When using threaded connections, apply Teflon tape generously but not excessively, wrapping it in the direction of the thread to ensure a snug fit. For PVC connections, use high-quality primer and solvent cement, ensuring that both surfaces are adequately coated before joining them. To further safeguard against leaks, conduct a pressure test on the system after installation. This involves temporarily pressurizing the system and observing for any signs of leakage before backfilling the valve box. For teams lacking experience, consider organizing training sessions or workshops focused on proper sealing techniques, which can significantly enhance the reliability of irrigation systems.

Strategic Material Selection Guide for how to change irrigation valve

When selecting materials for irrigation valves, it’s crucial for B2B buyers to consider the properties, advantages, and limitations of each material type. This ensures that the chosen valve will perform effectively in the specific environmental conditions and media it will encounter. Below is an analysis of common materials used in irrigation valve manufacturing.

What Are the Key Properties of PVC for Irrigation Valves?

Polyvinyl Chloride (PVC) is widely used in irrigation systems due to its excellent chemical resistance and lightweight nature. PVC valves typically have a temperature rating of up to 140°F (60°C) and can handle moderate pressure, making them suitable for many irrigation applications. They are resistant to corrosion, which is particularly beneficial in areas with high salinity or chemical exposure.

Pros: PVC is cost-effective, easy to install, and requires minimal maintenance. Its lightweight nature allows for simpler handling and installation, reducing labor costs.

Cons: However, PVC can become brittle over time, especially when exposed to UV light or extreme temperatures. It also has limited flexibility, which may lead to cracking under stress.

Impact on Application: PVC is compatible with a wide range of irrigation media, including water with low concentrations of chemicals. However, it may not be suitable for high-temperature applications or where high pressures are expected.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, especially in areas where UV exposure is high.

How Does Brass Compare as a Material for Irrigation Valves?

Brass is another popular choice for irrigation valves due to its durability and strength. It can withstand higher temperatures (up to 200°F or 93°C) and pressures, making it ideal for more demanding applications. Brass also offers excellent corrosion resistance, particularly in freshwater environments.

Pros: The durability of brass results in a longer lifespan for valves, reducing replacement frequency. Its robust nature also allows for a tighter seal, minimizing leaks.

Cons: On the downside, brass is generally more expensive than PVC and may require more complex manufacturing processes. Additionally, it can be susceptible to dezincification in certain water conditions, leading to material degradation.

Impact on Application: Brass valves are suitable for high-pressure systems and can handle a variety of media, including those with higher temperatures. However, they may not be ideal for saline environments without protective coatings.

Considerations for International Buyers: Compliance with local standards and awareness of the specific water quality in regions like South America and Europe is essential, as varying mineral contents can affect brass performance.

What Role Does Stainless Steel Play in Irrigation Valve Applications?

Stainless steel is known for its exceptional corrosion resistance and strength, making it a premium choice for irrigation valves. It can handle high temperatures (up to 300°F or 149°C) and pressures, making it suitable for industrial applications.

Pros: The longevity and durability of stainless steel valves often justify the higher initial cost. They are resistant to rust and corrosion, ensuring reliable performance over time.

Cons: The main drawback is the cost, as stainless steel is significantly more expensive than both PVC and brass. Additionally, it can be heavier, which may complicate installation.

Impact on Application: Stainless steel is ideal for applications involving aggressive media, including saline or chemically treated water. Its robustness makes it suitable for high-stress environments.

Considerations for International Buyers: Buyers in Europe and the Middle East should consider the specific grades of stainless steel (e.g., 304 vs. 316) based on the environmental conditions and regulatory standards in their region.

How Does Polypropylene Fit into the Irrigation Valve Material Landscape?

Polypropylene is increasingly being used in irrigation systems due to its excellent chemical resistance and lightweight properties. It typically operates effectively at temperatures up to 180°F (82°C) and is resistant to a variety of chemicals.

Pros: Polypropylene is cost-effective and offers good flexibility, making it less prone to cracking under stress. It is also lightweight, facilitating easier installation.

Cons: However, it has lower mechanical strength compared to brass and stainless steel, which may limit its use in high-pressure applications.

Impact on Application: Polypropylene valves are suitable for non-potable water applications and are often used in agricultural settings where chemical exposure is a concern.

Considerations for International Buyers: Buyers should ensure that polypropylene valves meet local regulations and standards, particularly in regions like Africa where agricultural chemicals may be prevalent.

Summary Table

| Material | Typical Use Case for how to change irrigation valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Residential irrigation systems | Cost-effective and lightweight | Brittle over time, limited temperature range | Low |

| Brass | High-pressure irrigation systems | Durable and long-lasting | More expensive, susceptible to dezincification | Med |

| Stainless Steel | Industrial and high-stress applications | Exceptional corrosion resistance | High cost and heavier weight | High |

| Polypropylene | Non-potable water applications in agriculture | Good chemical resistance and flexibility | Lower mechanical strength, limited pressure use | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for how to change irrigation valve

What Are the Main Stages of Manufacturing for Irrigation Valves?

The manufacturing process for irrigation valves involves several critical stages that ensure the final product meets quality and performance standards. Each stage plays a vital role in producing a reliable and efficient valve.

Material Preparation: The first step involves selecting high-quality raw materials, typically brass, PVC, or other durable plastics. These materials are assessed for their corrosion resistance and mechanical properties. Advanced techniques such as computer-aided design (CAD) are often used to optimize the design for manufacturing efficiency and product durability.

Forming: During this stage, the raw materials undergo processes such as casting, molding, or machining. For brass valves, casting is a common method, while PVC valves are usually produced through injection molding. Precision machining ensures that all components are manufactured to exact specifications, which is crucial for achieving proper fit and functionality.

Assembly: After individual components are formed, they are assembled into the final product. This process may involve manual labor or automated systems, depending on the manufacturer’s capabilities. Quality checks are often integrated into this stage to ensure that all components fit together correctly and function as intended.

Finishing: The final stage includes surface treatments, such as plating or coating, which enhance the valve’s resistance to environmental factors. This stage also involves the application of seals and gaskets, crucial for preventing leaks. Quality assurance measures are critical here to confirm that the finishing processes do not compromise the valve’s integrity.

How Is Quality Assurance Implemented in the Manufacturing Process?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for irrigation valves, aimed at ensuring that products meet specified requirements and standards.

International Standards Compliance: Many manufacturers adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with these standards is critical for ensuring consistent quality across production batches. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the valve’s intended use.

Quality Control Checkpoints: Quality control (QC) is typically divided into several checkpoints during the manufacturing process:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet the required specifications.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections and testing are conducted to monitor quality and identify any deviations early.

– Final Quality Control (FQC): Before products are shipped, they undergo rigorous testing to confirm they meet design specifications and performance criteria.Common Testing Methods: Various testing methods are employed to ensure product reliability, including:

– Pressure Testing: Valves are subjected to high-pressure conditions to evaluate their performance under stress.

– Leak Testing: This involves submerging valves in water to check for any leaks.

– Functional Testing: Ensuring that the valve operates correctly under simulated working conditions is crucial for confirming its performance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those operating in international markets such as Africa, South America, the Middle East, and Europe, must ensure that their suppliers adhere to stringent quality control processes. Here are some strategies to verify supplier QC:

Supplier Audits: Conducting regular audits of suppliers’ manufacturing facilities is an effective way to assess their adherence to quality standards. Audits can be performed by the buyer or outsourced to third-party organizations specializing in quality assessments.

Quality Assurance Reports: Requesting detailed QA reports from suppliers can provide insights into their manufacturing processes and quality control measures. These reports should outline the testing methods used, compliance with international standards, and any certifications obtained.

Third-Party Inspections: Engaging third-party inspection services can help verify that the products meet required specifications before they are shipped. This is particularly important for B2B buyers dealing with large orders or high-value components.

Certifications and Documentation: Buyers should request copies of relevant certifications and documentation that demonstrate compliance with international and industry-specific standards. This includes ISO certifications, CE marks, and any other applicable quality assurance credentials.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers need to navigate specific challenges related to quality control that may differ based on regional practices and regulations. Here are key considerations:

Regional Compliance Standards: Different regions may have varying compliance requirements for irrigation valves. Understanding local regulations in markets such as Saudi Arabia, Nigeria, or other countries in Africa and South America is essential for ensuring that products meet local safety and performance standards.

Cultural and Communication Barriers: Effective communication with suppliers across different cultures can pose challenges. Buyers should establish clear quality expectations and maintain open lines of communication to minimize misunderstandings regarding product specifications.

Logistical Challenges: The logistics of transporting goods across borders can impact product quality. Ensuring that suppliers have robust logistics management systems in place is crucial to avoid damage during transit and to ensure timely delivery of quality products.

Building Long-term Relationships: Establishing long-term partnerships with reliable suppliers can enhance quality assurance. Buyers should invest time in nurturing these relationships, as trust and collaboration often lead to improved product quality and responsiveness to quality concerns.

By understanding the manufacturing processes and quality assurance measures associated with irrigation valves, B2B buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to change irrigation valve’

Introduction

This practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure the necessary components and expertise for changing irrigation valves. Understanding the process and ensuring you have the right materials and suppliers is crucial for effective irrigation management, particularly in regions where water conservation is paramount.

Step 1: Identify Your Specific Needs

Before initiating the procurement process, clearly define the specifications of the irrigation valve you need. Consider factors such as the type of irrigation system in use (e.g., drip, sprinkler), valve size, and compatibility with existing components.

- Sub-bullets:

- Evaluate the flow rate and pressure requirements.

- Determine if you need manual or automatic valves based on your irrigation strategy.

Step 2: Research and Select Quality Suppliers

Conduct thorough research to identify potential suppliers who specialize in irrigation valves. Look for companies with a strong reputation and positive reviews from other businesses in your region.

- Sub-bullets:

- Verify their experience and expertise in the irrigation sector.

- Check for certifications that ensure quality standards, such as ISO or local certifications relevant to your market.

Step 3: Request Detailed Product Specifications

When engaging with suppliers, request detailed product specifications for the valves they offer. This includes material composition, size options, and installation requirements.

- Sub-bullets:

- Ensure the valves are suitable for your environmental conditions, such as temperature and soil type.

- Ask for compatibility with existing irrigation systems to avoid future issues.

Step 4: Evaluate Supplier Support and Service

Assess the level of customer support and service provided by each supplier. This is critical, especially if you encounter issues during installation or operation.

- Sub-bullets:

- Inquire about warranty terms and after-sales support.

- Determine if they offer installation services or guidance, especially for complex systems.

Step 5: Compare Pricing and Payment Terms

Collect pricing information from multiple suppliers to compare costs effectively. Ensure you understand the payment terms, including any potential hidden fees related to shipping or installation.

- Sub-bullets:

- Look for bulk purchase discounts if you plan to order multiple valves.

- Assess the total cost of ownership, including maintenance and longevity of the valves.

Step 6: Check Delivery Times and Logistics

Confirm the delivery times and logistics options with your chosen suppliers. Timely delivery is crucial to avoid delays in your irrigation projects.

- Sub-bullets:

- Ask about shipping methods and costs.

- Ensure they can deliver to your location without additional complications.

Step 7: Finalize Your Order and Document Everything

Once you’ve selected a supplier and agreed on terms, finalize your order. Make sure to document all agreements, including delivery dates, payment terms, and warranty details.

- Sub-bullets:

- Keep copies of all correspondence for future reference.

- Ensure that there is a clear process for addressing any issues that may arise post-purchase.

By following this checklist, B2B buyers can effectively navigate the procurement process for irrigation valves, ensuring they select the right products and suppliers to meet their irrigation needs.

Comprehensive Cost and Pricing Analysis for how to change irrigation valve Sourcing

What Are the Key Cost Components in Changing an Irrigation Valve?

Changing an irrigation valve involves several cost components that B2B buyers should carefully consider. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The cost of the new sprinkler valve itself typically ranges from $20 to $40, depending on the specifications and quality. Additional materials such as PVC pipes, fittings, primer, and glue can add another $10 to $30. When sourcing these materials, buyers should consider the durability and compatibility with existing systems to avoid future costs.

Labor: Labor costs can vary significantly based on the complexity of the installation and local wage rates. For a straightforward valve replacement, labor may range from $50 to $150, depending on whether the work is done in-house or outsourced to a contractor. Buyers should assess their team’s skill level to determine if external help is necessary.

Manufacturing Overhead and Tooling: These costs are often embedded in the price of the materials. They cover expenses related to production facilities, machinery, and labor that are not directly tied to a specific product. Buyers should inquire about the overhead costs included in supplier pricing to ensure transparency.

Quality Control (QC): Effective QC processes ensure that the valves meet industry standards and specifications, which can influence pricing. Suppliers with rigorous QC measures may charge higher prices, but this can lead to long-term savings by reducing failure rates and maintenance needs.

Logistics: Shipping and handling costs are crucial, especially for international buyers. The cost of logistics can vary based on distance, mode of transport, and any customs duties or tariffs. Buyers should factor in these costs when evaluating total expenditures.

Margin: Suppliers typically add a profit margin to the total cost, which can range from 10% to 40%. Understanding the margin structure can help buyers negotiate better pricing.

How Do Price Influencers Affect Irrigation Valve Sourcing Decisions?

Several factors can influence the pricing of irrigation valves, making it essential for buyers to be aware of these elements.

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities can often lead to discounts. Buyers should negotiate MOQs to align with their needs while taking advantage of cost savings.

Specifications and Customization: Custom valves tailored to specific irrigation systems can lead to increased costs. Buyers should clearly define their requirements and explore off-the-shelf options to save money.

Materials and Quality Certifications: The choice of materials significantly impacts pricing. Higher-quality materials may come with a premium but can enhance system longevity. Additionally, certifications for quality and sustainability can affect costs and should be considered in sourcing decisions.

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers with a proven track record may charge more due to their reliability, while newer suppliers might offer lower prices to gain market share. Conducting thorough due diligence can help mitigate risks.

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon in contracts can affect overall costs. For instance, buyers opting for ‘Delivered Duty Paid’ (DDP) may incur higher upfront costs but benefit from reduced logistical burdens.

What Buyer Tips Can Help Optimize Costs in Irrigation Valve Sourcing?

B2B buyers can employ several strategies to optimize costs and enhance value when sourcing irrigation valves.

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders. Highlighting competitive quotes from other suppliers can strengthen your negotiating position.

Cost-Efficiency Analysis: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider maintenance costs, expected lifespan, and energy efficiency to make informed decisions.

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of regional pricing differences, currency fluctuations, and import duties that can affect overall costs. Establishing strong relationships with local suppliers can also facilitate better pricing and support.

Seek Long-term Partnerships: Building relationships with suppliers can lead to better pricing structures and priority service. Consider long-term contracts for consistent supply and potential discounts.

In conclusion, a comprehensive understanding of the cost structure and pricing influencers in irrigation valve sourcing can empower B2B buyers to make informed decisions that optimize their irrigation systems while managing budgets effectively.

Alternatives Analysis: Comparing how to change irrigation valve With Other Solutions

Introduction: Exploring Alternatives to Changing Irrigation Valves

When it comes to maintaining an effective irrigation system, changing the irrigation valve is a common solution to address issues like leaks or inadequate water flow. However, there are alternative methods and technologies that may provide similar benefits while addressing specific operational needs. This section will compare the traditional valve replacement process with two viable alternatives: automated irrigation systems and smart irrigation controllers.

Comparison Table

| Comparison Aspect | How To Change Irrigation Valve | Automated Irrigation Systems | Smart Irrigation Controllers |

|---|---|---|---|

| Performance | Restores flow and functionality | Highly efficient, tailored watering schedules | Optimizes water usage with real-time data |

| Cost | $20 – $40 per valve | $500 – $2,000 (initial investment) | $100 – $500 (varies by features) |

| Ease of Implementation | Moderate; requires manual labor and some technical skills | High; often requires professional installation | Moderate; can be self-installed but may require setup |

| Maintenance | Low; periodic checks for leaks | Moderate; needs regular checks for system integrity | Low; requires software updates and occasional sensor maintenance |

| Best Use Case | Small to medium-sized properties with traditional systems | Large agricultural operations or commercial landscapes | Residential or small commercial setups seeking efficiency |

Detailed Breakdown of Alternatives

Automated Irrigation Systems

Automated irrigation systems are advanced setups that utilize a network of pipes, valves, and sensors to deliver water based on pre-determined schedules. These systems are particularly beneficial for large agricultural operations or commercial landscapes where water efficiency is paramount.

Pros: They provide a high level of efficiency, ensuring that water is distributed according to the specific needs of various plant types and soil conditions. This can lead to significant water savings and reduced labor costs.

Cons: The initial investment can be substantial, ranging from $500 to $2,000, depending on the complexity of the system. Additionally, professional installation is often required, which can add to the overall cost and time before the system is operational.

Smart Irrigation Controllers

Smart irrigation controllers are devices that use weather data and soil moisture levels to optimize watering schedules. These controllers can be integrated with existing irrigation systems, making them a versatile option for enhancing water efficiency without a complete system overhaul.

Pros: They are relatively affordable, typically costing between $100 and $500, and can lead to significant water savings. Smart controllers are easy to install and can be set up by the end-user, making them accessible for residential and small commercial properties.

Cons: While they improve efficiency, they may require occasional maintenance and software updates. Additionally, their effectiveness is contingent on the accuracy of the sensors and data inputs, which may vary based on environmental conditions.

Conclusion: Choosing the Right Solution for Your Irrigation Needs

When selecting the right solution for irrigation management, B2B buyers must consider their specific operational requirements, budget constraints, and technical capabilities. For straightforward valve issues, replacing the irrigation valve may be the most cost-effective and immediate solution. However, for those managing larger properties or seeking long-term water conservation, investing in automated systems or smart controllers may offer greater efficiency and sustainability. Ultimately, understanding the unique needs of the irrigation system and the potential for future scalability will guide buyers in making the most informed decision.

Essential Technical Properties and Trade Terminology for how to change irrigation valve

What Key Technical Properties Should B2B Buyers Consider When Changing an Irrigation Valve?

When changing an irrigation valve, several technical properties are essential for ensuring compatibility, durability, and optimal performance. Understanding these specifications can help B2B buyers make informed decisions, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

1. Material Grade

The material grade of an irrigation valve significantly impacts its longevity and performance. Common materials include PVC, brass, and stainless steel. For example, PVC is lightweight and resistant to corrosion, making it suitable for various climates. In contrast, brass offers superior strength and durability, ideal for high-pressure applications. Selecting the appropriate material grade ensures that the valve can withstand environmental conditions and operational demands, reducing the need for frequent replacements.

2. Pressure Rating

Pressure rating indicates the maximum pressure the valve can handle without failure. This specification is critical for B2B buyers, especially in regions where water supply systems may experience fluctuations. Valves typically come with pressure ratings ranging from 10 to 150 psi. Ensuring that the selected valve matches the system’s pressure requirements helps prevent leaks and operational failures, ensuring efficient irrigation.

3. Flow Rate

The flow rate, measured in gallons per minute (GPM), determines how much water can pass through the valve in a given time. For irrigation systems, matching the flow rate of the valve with the system’s requirements is crucial for optimal performance. An inadequate flow rate can lead to insufficient irrigation coverage, while an excessively high flow rate may cause system damage. B2B buyers should consult flow rate charts to identify valves that align with their specific irrigation needs.

4. Size and Compatibility

Irrigation valves come in various sizes, typically measured in inches. Ensuring compatibility between the valve and existing piping is essential for a successful installation. B2B buyers should pay attention to both the valve’s size and the type of connections (e.g., threaded or slip-fit) to avoid installation challenges. Incompatible sizes can lead to leaks and inefficiencies, impacting the overall effectiveness of the irrigation system.

5. Electrical Specifications

For automated irrigation systems, understanding the electrical specifications, such as voltage and current ratings, is vital. Valves often require specific electrical inputs to operate solenoids effectively. B2B buyers should verify that the new valve’s electrical requirements match those of the existing system to ensure seamless integration and functionality.

What Are Common Trade Terminology and Jargon Related to Irrigation Valves?

Familiarity with industry terminology is essential for B2B buyers when navigating the procurement process for irrigation valves. Understanding these terms can facilitate smoother transactions and improve communication with suppliers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of irrigation valves, OEM parts ensure compatibility and quality, as they are designed to meet specific system requirements. B2B buyers should consider sourcing OEM valves to maintain system integrity.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest order size a supplier is willing to process. Understanding MOQ is crucial for B2B buyers, especially when managing inventory. Suppliers may have different MOQs based on valve type and material, impacting purchasing decisions and overall cost management.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. B2B buyers should utilize RFQs when seeking irrigation valves, as this helps ensure competitive pricing and clear terms of service. A well-structured RFQ can streamline the procurement process and enhance supplier relationships.

4. Incoterms

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight) is essential for B2B buyers involved in importing irrigation valves. Clear knowledge of these terms can mitigate risks associated with shipping and delivery.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is critical for effective project planning and inventory management. Buyers should communicate with suppliers to ascertain lead times for irrigation valves, especially in regions with varying logistical challenges.

By grasping these technical properties and industry terms, B2B buyers can enhance their decision-making processes when changing irrigation valves, ultimately leading to more efficient and effective irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the how to change irrigation valve Sector

What Are the Key Market Dynamics Impacting the Irrigation Valve Sector?

The irrigation valve sector is experiencing significant growth driven by the increasing demand for efficient water management solutions across agricultural and landscaping sectors globally. Key drivers include rising water scarcity issues, particularly in regions like Africa and the Middle East, prompting a shift towards more sustainable irrigation practices. Moreover, the global push for smart agriculture is leading to the integration of advanced technologies, such as IoT-enabled irrigation systems. These innovations enhance efficiency and reduce water wastage, making them attractive to B2B buyers.

Emerging trends in sourcing highlight a growing preference for suppliers that offer customizable solutions. Buyers are increasingly looking for valves that can be tailored to specific irrigation needs, ensuring compatibility with existing systems. Additionally, there is a noticeable shift towards online procurement platforms that facilitate easy comparison of products and suppliers, thereby streamlining the purchasing process. For international buyers, especially in developing regions, this digital transformation is vital for accessing a broader range of products and competitive pricing.

Market dynamics are also influenced by regulatory changes aimed at improving water use efficiency. Many countries are implementing stricter regulations around water usage in agriculture, compelling businesses to invest in modern irrigation systems. This regulatory environment creates opportunities for suppliers who can provide compliant, innovative solutions.

How Important Is Sustainability and Ethical Sourcing in the Irrigation Valve Market?

Sustainability is becoming a cornerstone of business strategies in the irrigation valve sector. The environmental impact of irrigation practices is under scrutiny, with significant attention on reducing water wastage and minimizing chemical runoff. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or eco-friendly manufacturing processes.

Ethical sourcing is another critical factor influencing purchasing decisions. Buyers are more aware of the supply chain’s impact on local communities and the environment. As such, there is a growing demand for suppliers who can provide transparency in their sourcing practices, ensuring that materials are obtained responsibly and ethically. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance a supplier’s appeal, offering reassurances to buyers regarding their commitment to sustainability.

The adoption of green materials, such as biodegradable plastics or sustainably sourced metals, is becoming more prevalent. By aligning with suppliers that prioritize eco-friendly materials, businesses can reduce their carbon footprint while meeting regulatory requirements and consumer expectations.

What Is the Historical Context of the Irrigation Valve Market?

The irrigation valve market has evolved significantly over the past few decades, transitioning from traditional manual systems to sophisticated automated solutions. Early irrigation systems primarily relied on mechanical valves that required manual operation, which was labor-intensive and prone to inefficiencies.

The introduction of electric and solenoid valves in the late 20th century marked a pivotal shift, allowing for automated control of irrigation systems. This innovation not only improved efficiency but also paved the way for advancements such as smart controllers and IoT integration. Today, the market is characterized by a blend of traditional craftsmanship and cutting-edge technology, providing B2B buyers with a wide array of options tailored to their specific irrigation needs.

As global awareness of water conservation increases, the evolution of irrigation valves continues to be driven by technological advancements and a heightened focus on sustainability, positioning the sector for further growth and innovation in the coming years.

Frequently Asked Questions (FAQs) for B2B Buyers of how to change irrigation valve

How do I solve a leaking irrigation valve issue?

To resolve a leaking irrigation valve, first, turn off the water supply to prevent further water loss. Then, excavate around the valve to access it. Inspect for visible cracks or damage, and if necessary, remove the valve by cutting the PVC pipe on either side. Replace it with a new valve, ensuring proper sealing with Teflon tape or PVC glue to prevent future leaks. After installation, turn the water back on and monitor for any leaks before backfilling the valve box.What is the best irrigation valve for a commercial setup?

For commercial irrigation systems, consider using anti-siphon valves, which prevent backflow and contamination of the water supply. Look for durable materials, such as brass or high-quality PVC, that can withstand varying pressures and environmental conditions. Ensure the valve is compatible with your existing system’s specifications, including flow rate and pressure requirements, to maintain efficiency and reliability in your irrigation operations.What factors should I consider when sourcing irrigation valves internationally?

When sourcing irrigation valves internationally, consider factors such as supplier reliability, compliance with local regulations, and the quality of materials used. Assess the supplier’s experience in the industry and their ability to provide technical support. Additionally, examine their production capacity, lead times, and logistics capabilities to ensure timely delivery. Check for certifications or quality assurance standards that align with your operational needs.How can I verify the quality of irrigation valves before purchasing?

To verify the quality of irrigation valves, request product samples or specifications from suppliers. Check for certifications like ISO or local compliance standards. Conduct a quality assurance audit if possible, focusing on material durability, performance under pressure, and resistance to environmental factors. Reading reviews or testimonials from other B2B customers can provide insights into the supplier’s reliability and product quality.What are the typical minimum order quantities (MOQ) for irrigation valves?

Minimum order quantities (MOQ) for irrigation valves can vary widely based on the supplier and the type of valve. Generally, MOQs may range from 50 to 500 units. It’s essential to discuss with your supplier to understand their specific MOQ and negotiate if necessary. Consider the implications of MOQ on your inventory management and cash flow, especially if you’re testing a new product line.What payment terms are commonly used for international purchases of irrigation equipment?

Common payment terms for international purchases include letters of credit, advance payments, and open account terms. Letters of credit provide security for both buyers and suppliers, while advance payments may be required for larger orders. Open account terms allow for payment after delivery but may be riskier. Always ensure clarity on payment terms and conditions before finalizing any agreements to avoid disputes.How do I handle logistics for importing irrigation valves?

Handling logistics for importing irrigation valves involves selecting a reliable freight forwarder who can manage shipping, customs clearance, and delivery. Assess shipping options based on cost, transit time, and reliability. Ensure all documentation, such as invoices and packing lists, is accurate to avoid delays at customs. Be aware of local import regulations and tariffs that may affect your overall costs.What should I do if I need a customized irrigation valve?

If you require a customized irrigation valve, communicate your specifications clearly to potential suppliers, including dimensions, materials, and performance requirements. Request prototypes or samples to ensure the design meets your needs. Discuss lead times and any additional costs associated with customization. Establish a strong relationship with your supplier to facilitate effective collaboration throughout the design and manufacturing process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 How To Change Irrigation Valve Manufacturers & Suppliers List

1. Apollo – Slide Repair Coupler

2. The Spruce – Sprinkler Valve Replacement Guide

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Working Time: 1 hr, 30 mins; Total Time: 1 – 2 hrs; Skill Level: Intermediate; Estimated Cost: $20 to $40; Yield: Replace one sprinkler valve; Symptoms of faulty valve: leaks, poor water flow, heads that don’t work; Tools needed: reciprocating saw, PVC pipe cutter, or hacksaw, utility knife or sandpaper, tongue-and-groove pliers; Materials needed: new sprinkler valve, PVC MIP adapters (2 or more),…

3. JustAnswer – Sprinkler Valve System

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Four sprinkler valves for a lawn and garden watering system, labeled as 3/4″ fairway, with a maximum pressure of 160 psi and a maximum temperature of 10 degrees Fahrenheit. The valves are connected to a timer system. Issues include faulty solenoids and a stripped shut-off cross on one valve.

4. Rainbird – DVF Valves & Alternatives

Domain: thelawnforum.com

Registered: 2017 (8 years)

Introduction: Valves: Rainbird DVF; Alternative Valves: Orbit valves with unions; Union adapters: Inquiry about availability; Installation method: Suggestion to use unions for easy removal; Alternative method: Using 1″ slip-thread fittings for cost-saving; Additional components: 100-mesh screen for MP Rotators, male slip-thread with brass ball valve hose-bib for blow-out and curb-pressure water supply.

5. DIY – PVC Rainbird Valve and Accessories

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: PVC Rainbird valve, anti-syphon valve, PVC saw (wire-saw or click-on saw), PVC cement, purple primer, threaded adaptor fittings (x2), Teflon tape, crescent wrench.

6. Arrowhead-Champion – Vacuum Breaker

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Champion Classic 3/4″ As Max PSI 150 466 Max Temp 110o, Manufacturer: Arrowhead-Champion, Vacuum Breaker, Automatic Actuator, Anti-Siphon with Union, Made in the USA.

7. Irritrol – 5 in. Rotor | Hydro-Rain – 4 in. Pop-Up Rotor

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Irritrol Rotor 5 in. | 550R, Hydro-Rain Pop-Up Rotor 4 in. | HRX-075

8. HWD – Irrigation Valve

Domain: hwd.com

Registered: 1995 (30 years)

Introduction: Irrigation valve: controls irrigation zones and manages water flow in gardens. Commonly causes outdoor leaks. Tools needed for replacement: new valve, adjustable pliers, plumber’s tape. Replacement steps include turning off water, relieving pressure, disconnecting wires, cleaning pipe threads, applying plumber’s tape, and reconnecting everything. Ensure correct water flow direction and test the ir…

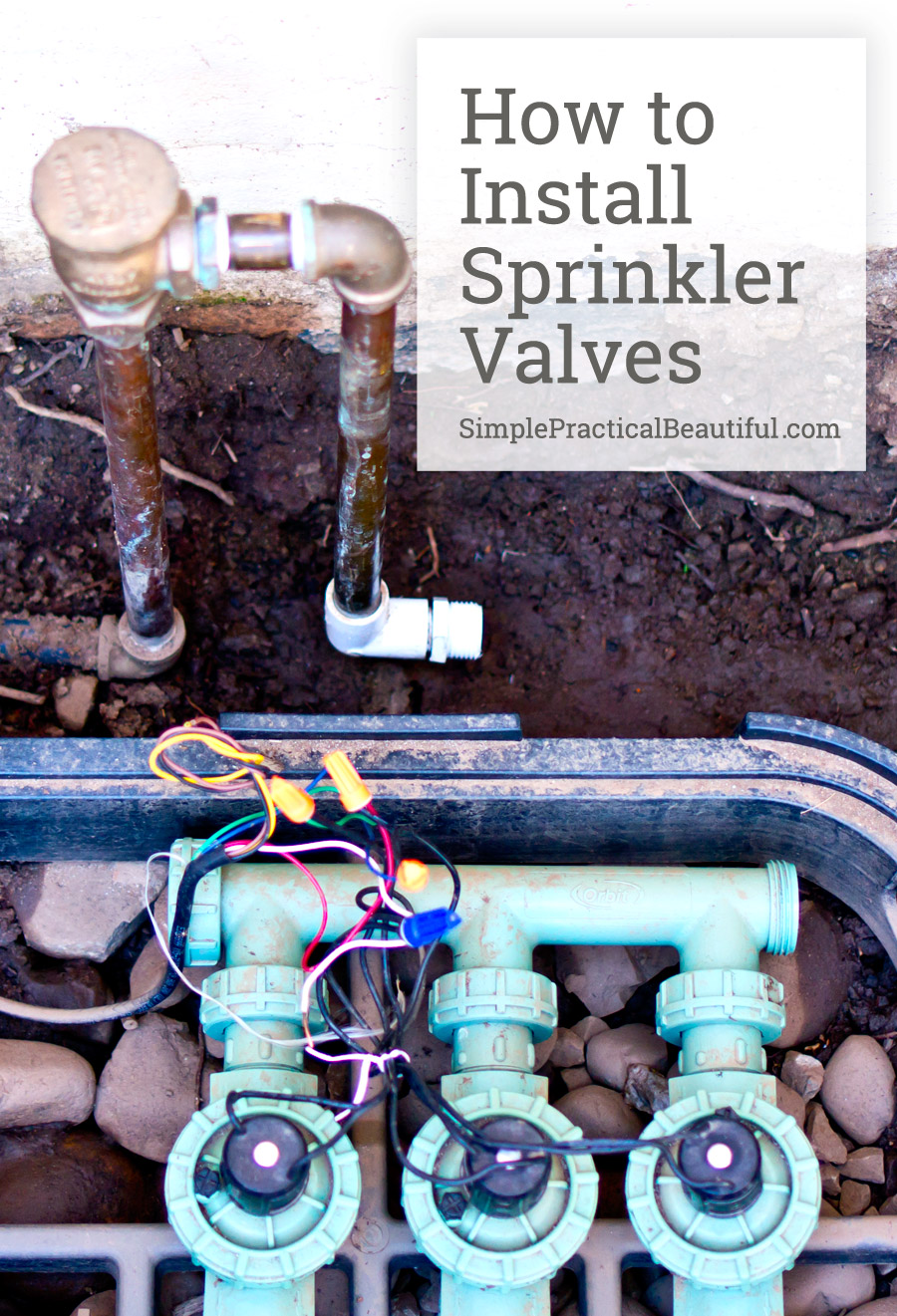

9. Simple Practical Beautiful – Water Supply Connection System

Domain: simplepracticalbeautiful.com

Registered: 2015 (10 years)

Introduction: 1. **Water Supply Connection**: The backyard had a hose bib as the water supply. A T connection was used to allow water to flow to the irrigation valves. 2. **Shut-off Valve**: Added to allow work on the irrigation system without turning off the water to the whole house. Features a small yellow handle that turns vertical to let water through or horizontal to stop it. 3. **Backflow Prevention Devic…

10. Rain Bird – 100DVFSS Valve

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Valves: Rain Bird 100DVFSS – 1 in. Slip x Slip ‘Street’ elbows (one end is male, other end is female); Supplies: Solvent glue, Hacksaw (preferably one with an extending blade), Irrigation wire nuts (or house wiring nuts with hot melt glue), Optional: 1in to 3/4in reducing bushings if you have 1in supply and 3/4 sprinkler lines.

Strategic Sourcing Conclusion and Outlook for how to change irrigation valve

In conclusion, effectively changing an irrigation valve is critical for maintaining a well-functioning irrigation system, which directly impacts agricultural productivity and water management in regions such as Africa, South America, the Middle East, and Europe. The process involves careful planning, precise execution, and the right tools, emphasizing the importance of selecting high-quality materials and components. B2B buyers should prioritize sourcing valves that meet specific regional requirements and standards, considering factors such as durability, compatibility, and cost-effectiveness.

Strategic sourcing not only enhances operational efficiency but also ensures long-term sustainability in irrigation practices. By establishing reliable supplier relationships and investing in quality parts, businesses can mitigate risks associated with valve failures, such as water loss and system inefficiencies.

As global agricultural demands continue to rise, now is the time for international B2B buyers to proactively address their irrigation needs. By adopting best practices in valve replacement and sourcing, companies can position themselves for success in an increasingly competitive market. Take the next step in optimizing your irrigation systems and explore strategic partnerships that align with your business goals.