Introduction: Navigating the Global Market for how to wire irrigation valves

In the ever-evolving landscape of global agriculture, understanding how to wire irrigation valves effectively is a critical challenge for B2B buyers. As stakeholders navigate diverse environments—from the arid fields of Nigeria to the lush landscapes of Brazil—efficient irrigation systems become paramount for optimizing water usage and ensuring crop health. This guide serves as a comprehensive resource, detailing various types of irrigation valves, their applications in different agricultural settings, and best practices for wiring them to controllers.

Buyers will gain insights into essential components, such as solenoids, wire gauges, and connectors, while also addressing common pitfalls in wiring installations. We will explore supplier vetting processes to ensure quality and reliability, along with cost considerations that can impact budgeting and procurement strategies. By equipping B2B buyers with actionable knowledge, this guide empowers them to make informed purchasing decisions that enhance their irrigation systems’ performance and longevity.

Whether you’re operating in the Middle East’s challenging climates or Europe’s diverse agricultural landscape, understanding the intricacies of wiring irrigation valves will not only streamline operations but also contribute to sustainable farming practices. Dive into this guide to unlock the potential of your irrigation systems and elevate your agricultural business.

Understanding how to wire irrigation valves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Controller Wiring | Uses alternating current; typically for residential systems | Small to medium-sized agricultural setups | Pros: Widely available, cost-effective. Cons: Limited compatibility with DC valves. |

| DC Controller Wiring | Operates on direct current; energy-efficient | Large-scale farms, remote irrigation | Pros: Energy-efficient, ideal for remote areas. Cons: Higher initial cost, requires specific valves. |

| Multi-Conductor Wiring | Multiple wires in one cable; allows for easier expansion | Commercial landscaping and large estates | Pros: Simplifies installation, reduces connection points. Cons: May be more expensive and complex to install. |

| Home Run Wiring | Each valve wired directly to the controller | Residential and small commercial systems | Pros: Simplifies troubleshooting, reliable connections. Cons: Requires more wire, can be costly for large systems. |

| Waterproof Connectors | Specialized connectors to prevent moisture damage | All irrigation systems | Pros: Enhances durability, reduces maintenance. Cons: Higher upfront cost, requires careful installation. |

What are the Characteristics of AC Controller Wiring?

AC controller wiring is characterized by its use of alternating current, making it a common choice for small to medium-sized agricultural setups. This type of wiring is typically more affordable and readily available, making it appealing for budget-conscious buyers. However, it is essential to note that AC controllers are incompatible with DC valves, which limits flexibility in system design. Buyers should consider their long-term irrigation needs when opting for this wiring type.

How Does DC Controller Wiring Differ from Other Types?

DC controller wiring operates on direct current, offering energy efficiency and suitability for large-scale farms or remote irrigation systems. This type is particularly advantageous where power supply is inconsistent, as it can run on solar energy. While it has a higher initial investment due to the need for compatible DC valves, the long-term savings on energy and maintenance can be significant. Buyers should evaluate their specific irrigation requirements and energy sources before making a purchase.

What Advantages Does Multi-Conductor Wiring Provide?

Multi-conductor wiring features multiple wires bundled together, allowing for easier expansion of irrigation systems. This method is especially beneficial for commercial landscaping and large estates where multiple zones need to be managed efficiently. The primary advantage is the reduction of connection points, which simplifies installation and minimizes potential failure points. However, it can be more expensive and complex to install, so buyers should weigh the benefits against their budget and technical capabilities.

Why Choose Home Run Wiring?

Home run wiring involves running a separate wire from each valve directly to the controller, providing a straightforward and reliable connection. This wiring type is ideal for residential and small commercial systems, as it simplifies troubleshooting and ensures that each valve operates independently. While this method may require more wiring, which can increase costs, it enhances reliability and reduces the risk of failure. Buyers should consider their system size and potential future expansions when deciding on this wiring approach.

What Role Do Waterproof Connectors Play in Irrigation Systems?

Waterproof connectors are essential in irrigation systems as they protect electrical connections from moisture damage, which is a common cause of valve failures. These specialized connectors enhance the durability of the system and reduce maintenance needs. While they may increase the initial cost of installation, their long-term benefits in preventing electrical issues can lead to significant savings. Buyers should prioritize waterproof connectors, especially in regions prone to heavy rainfall or irrigation-related moisture.

Key Industrial Applications of how to wire irrigation valves

| Industry/Sector | Specific Application of how to wire irrigation valves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Wiring irrigation valves in large-scale farming systems | Enhanced water efficiency and crop yield | Availability of durable, weather-resistant components |

| Landscaping & Horticulture | Wiring valves for automated landscape irrigation systems | Reduced labor costs and improved landscape aesthetics | Compatibility with various controller types and systems |

| Commercial Real Estate | Wiring irrigation systems for commercial properties | Improved property value and tenant satisfaction | Compliance with local regulations and standards |

| Sports Facilities | Wiring irrigation for athletic fields and parks | Optimal turf health and reduced water usage | Need for reliable, high-performance components |

| Municipal Services | Wiring irrigation systems for public parks and gardens | Sustainable water management and community appeal | Sourcing from local suppliers for ease of maintenance |

How is Wiring Irrigation Valves Essential in Agriculture?

In the agriculture sector, wiring irrigation valves is critical for effective water management in large-scale farming operations. By automating irrigation systems, farmers can enhance water efficiency and optimize crop yields, which is vital in regions facing water scarcity. Buyers need to ensure that the wiring components are durable and weather-resistant, as conditions can vary significantly in places like Brazil and Nigeria. Additionally, having access to local suppliers for timely maintenance can mitigate operational downtimes.

What Role Does Wiring Play in Landscaping and Horticulture?

In landscaping and horticulture, the ability to wire irrigation valves effectively allows for the automation of watering systems, leading to reduced labor costs and improved aesthetics. This is particularly beneficial in urban areas where maintaining green spaces is essential for environmental sustainability. Buyers should prioritize compatibility with various irrigation controllers and systems to ensure seamless integration. Moreover, sourcing high-quality, multi-stranded wires can enhance the longevity and reliability of these systems.

How is Wiring Irrigation Valves Beneficial for Commercial Real Estate?

For commercial real estate, effective wiring of irrigation systems is essential for maintaining lush landscapes, which can significantly enhance property value and tenant satisfaction. Automated systems reduce the need for manual watering, thereby cutting labor costs. Buyers in this sector must consider compliance with local regulations regarding water usage and irrigation systems. Additionally, they should focus on sourcing components that can withstand varying climatic conditions to ensure long-term functionality.

Why is Proper Wiring Crucial for Sports Facilities?

Wiring irrigation systems in sports facilities ensures optimal turf health while minimizing water usage, which is crucial for maintaining playable fields. Automated irrigation allows for precise watering schedules, promoting healthy grass growth and reducing the likelihood of overwatering. Buyers need to source high-performance components to withstand heavy use and environmental stressors. Ensuring that these systems are easy to maintain can also contribute to long-term cost savings.

How Does Wiring Affect Municipal Services?

In municipal services, effective wiring of irrigation systems for public parks and gardens plays a vital role in sustainable water management and enhancing community appeal. Automated systems help municipalities conserve water while maintaining attractive green spaces for residents and visitors. Buyers should consider sourcing from local suppliers to facilitate easier maintenance and repairs. Additionally, adherence to local environmental regulations is paramount to ensure compliance and promote sustainability initiatives.

3 Common User Pain Points for ‘how to wire irrigation valves’ & Their Solutions

Scenario 1: Ensuring Reliable Connections for Long-Term Use

The Problem:

B2B buyers often face challenges with unreliable connections when wiring irrigation valves, especially in regions with varying weather conditions. Inconsistent electrical connections can lead to valve malfunctions, resulting in inefficient irrigation systems that waste water or fail to deliver adequate moisture to crops. This issue is particularly pressing for agricultural businesses in areas like Brazil or Nigeria, where irrigation is critical for crop yields. Buyers may find themselves frequently troubleshooting these systems, leading to increased maintenance costs and operational downtime.

The Solution:

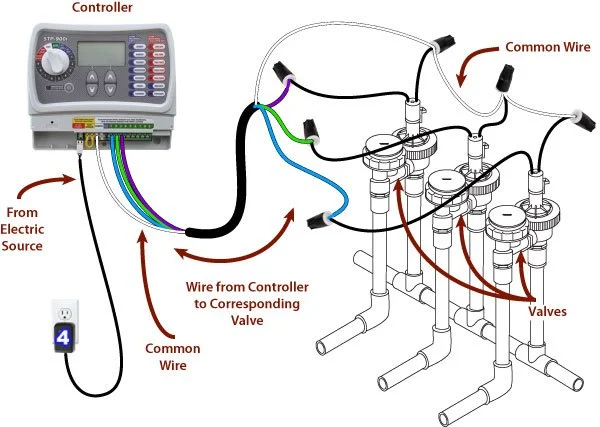

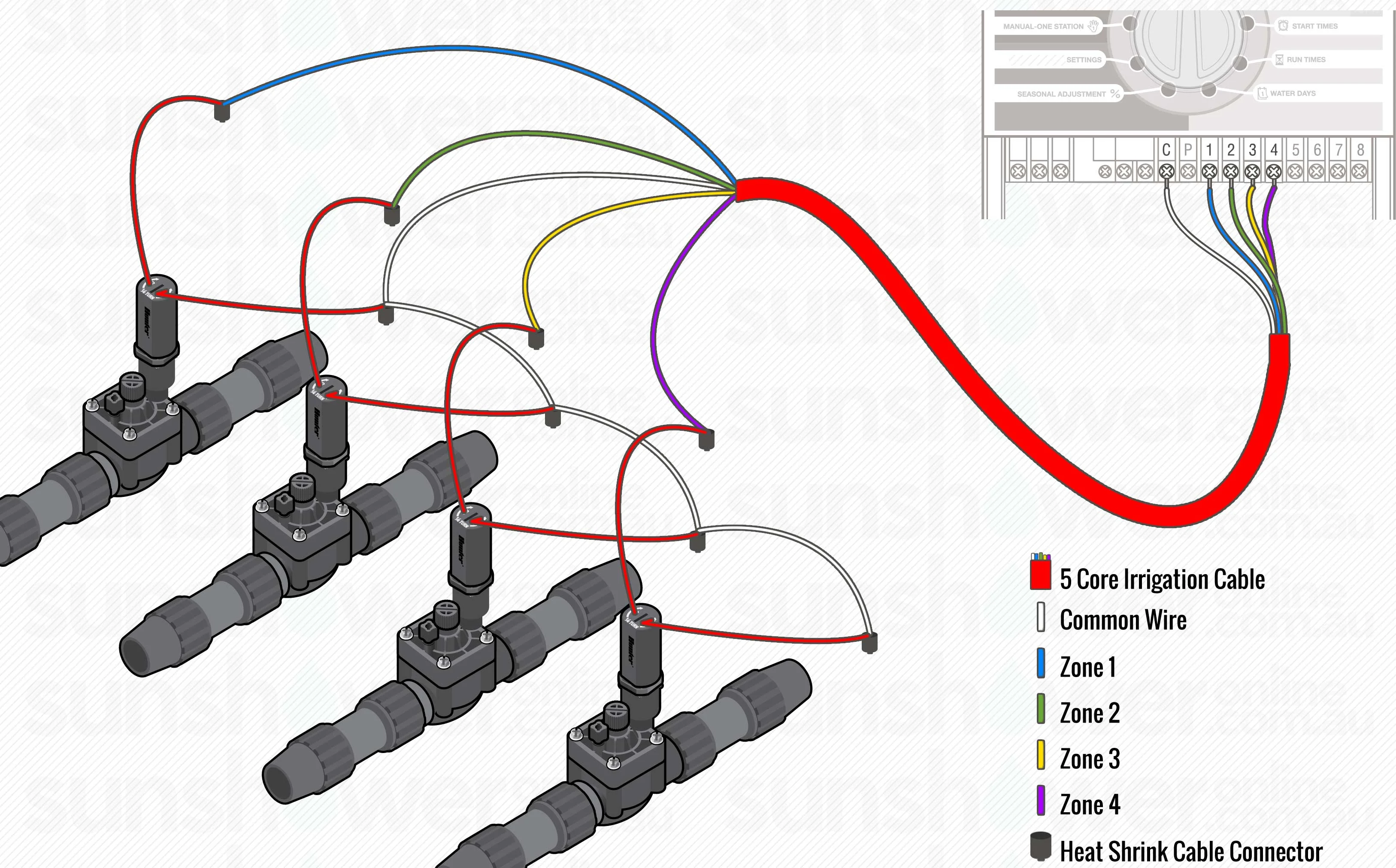

To ensure reliable connections, it is essential to use high-quality, waterproof connectors that can withstand moisture and corrosion. Buyers should consider sourcing connectors specifically designed for irrigation applications. Additionally, using multi-strand wires, such as 18-gauge, can enhance flexibility and reduce the chances of breakage. It is also advisable to implement a “homerun” wiring method, where each valve is connected directly to the controller with its own dedicated wire. This not only minimizes potential points of failure but also simplifies troubleshooting. Lastly, ensure that all connections are tightly secured with waterproof caps, as loose connections are a common source of issues. Regular inspections can also help identify wear and tear before they escalate into significant problems.

Scenario 2: Navigating Different Types of Controllers and Valves

The Problem:

Another common pain point arises from the complexity of matching different types of irrigation controllers with the appropriate valves. Many businesses, particularly those expanding their irrigation systems, may mistakenly purchase AC valves when their controllers are DC-based (or vice versa), leading to compatibility issues. This problem is exacerbated in diverse markets, where a lack of standardized products can confuse buyers, resulting in wasted time and resources.

The Solution:

To avoid compatibility issues, it is crucial for buyers to clearly identify the type of controller they are using before sourcing valves. When purchasing, they should verify the specifications of both the controller and the valves. A simple checklist can be created to ensure that the voltage and type (AC or DC) match. Additionally, buyers should consider investing in a universal controller that can accommodate various types of valves, providing greater flexibility for future expansions. Furthermore, maintaining a catalog of all components used in the irrigation system can help streamline future purchases and upgrades. Training staff to understand the importance of compatibility in irrigation systems will also mitigate this issue.

Scenario 3: Planning for Future Expansion of Irrigation Systems

The Problem:

For many agricultural enterprises, especially in fast-developing regions like South America or Africa, the need to expand irrigation systems is a common scenario. However, many buyers overlook the importance of future-proofing their wiring setups. As they add more valves or zones, they may find themselves in a situation where their existing wiring cannot support the increased load or complexity, leading to costly retrofits or complete rewiring.

The Solution:

To plan effectively for future expansions, buyers should install a wiring system that accommodates potential growth. This can be achieved by using a larger gauge wire than initially needed, such as 14-gauge, which can handle higher loads and provide additional capacity for future valves. Furthermore, buyers should consider running an extra conductor or two to each valve location during the initial installation. This foresight allows for easier expansion without the need for extensive rewiring. It’s also beneficial to document the layout and components of the irrigation system, which can guide future enhancements and make the installation of new zones more straightforward. Investing in modular systems that are designed for scalability can also provide long-term benefits, ensuring that the irrigation infrastructure evolves alongside agricultural needs.

Strategic Material Selection Guide for how to wire irrigation valves

What Are the Key Materials for Wiring Irrigation Valves?

When selecting materials for wiring irrigation valves, several factors come into play, including performance properties, cost, and compatibility with various environmental conditions. Below, we analyze four common materials used in this application: copper, aluminum, PVC, and polyethylene.

How Does Copper Perform in Wiring Irrigation Valves?

Copper is a widely used material for electrical wiring due to its excellent conductivity and durability. It has a high-temperature rating, typically up to 200°C, and is resistant to corrosion, making it suitable for various environmental conditions.

Pros: Copper wires are highly conductive, ensuring efficient electrical flow, which is crucial for the operation of solenoids in irrigation valves. They also exhibit good mechanical strength and flexibility, allowing for easy installation.

Cons: However, copper is relatively expensive compared to other materials. Additionally, it is susceptible to corrosion in certain environments, particularly in acidic or saline conditions, which may limit its longevity.

Impact on Application: Copper’s compatibility with electrical systems makes it ideal for high-performance irrigation setups, but buyers must consider local soil and water conditions that could affect its lifespan.

What Are the Advantages of Aluminum Wiring?

Aluminum is another option for wiring irrigation valves, known for its lightweight and lower cost compared to copper. It typically has a temperature rating of around 90°C and offers decent corrosion resistance when properly coated.

Pros: The primary advantage of aluminum is its cost-effectiveness, making it a popular choice for large-scale irrigation projects. Its lightweight nature simplifies transportation and installation.

Cons: On the downside, aluminum has lower conductivity than copper, which can lead to energy losses. It is also more prone to oxidation, which can affect performance over time.

Impact on Application: While aluminum can be suitable for less demanding irrigation systems, international buyers should consider its limitations in high-temperature or high-humidity environments, which are common in regions like Africa and South America.

How Does PVC Contribute to Irrigation Valve Wiring?

Polyvinyl Chloride (PVC) is primarily used for insulation rather than the conductive wire itself. It is known for its excellent resistance to moisture and chemicals, making it a good choice for outdoor applications.

Pros: PVC is highly durable, resistant to corrosion, and can withstand various environmental stressors. It is also relatively inexpensive, making it an economical choice for insulation.

Cons: However, PVC has a lower temperature rating than metals, typically around 60°C. This limitation may affect its performance in high-temperature environments.

Impact on Application: In regions with high humidity or exposure to chemicals, PVC insulation can significantly enhance the longevity of wiring systems. Buyers should ensure compliance with local standards for electrical insulation.

What Role Does Polyethylene Play in Wiring Irrigation Valves?

Polyethylene (PE) is often used for both insulation and as a protective sheath for wiring. It offers excellent moisture resistance and is lightweight, making it easy to handle during installation.

Pros: PE is known for its flexibility and resistance to environmental stressors, including UV radiation. It is also cost-effective, which is beneficial for large irrigation projects.

Cons: The main limitation of polyethylene is its lower temperature tolerance, generally around 80°C, which can restrict its use in hotter climates.

Impact on Application: For regions with moderate temperatures, polyethylene is an excellent choice for wiring insulation. However, it is essential for international buyers to consider local climate conditions and potential regulatory requirements.

Summary Table of Material Selection for Wiring Irrigation Valves

| Material | Typical Use Case for how to wire irrigation valves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance irrigation systems | Excellent conductivity and durability | Higher cost and corrosion susceptibility | High |

| Aluminum | Cost-effective solutions for large-scale systems | Lightweight and economical | Lower conductivity and oxidation issues | Medium |

| PVC | Insulation for wiring in outdoor applications | Highly durable and moisture-resistant | Lower temperature rating than metals | Low |

| Polyethylene | Protective sheath for wiring | Flexible and UV resistant | Limited temperature tolerance | Low |

This strategic material selection guide provides a comprehensive overview of the various materials available for wiring irrigation valves, helping international B2B buyers make informed decisions based on their specific needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for how to wire irrigation valves

What Are the Key Stages in the Manufacturing Process of Irrigation Valve Wiring?

The manufacturing process for wiring irrigation valves involves several critical stages designed to ensure the final product is durable, reliable, and meets international standards. Each stage plays a vital role in the quality of the wiring systems, which are essential for efficient irrigation management.

Material Preparation: What Are the Initial Steps?

Material preparation is the first step in the manufacturing process. High-quality materials, including copper wire for conductivity and durable insulation materials, are selected based on the specific requirements of irrigation systems. Manufacturers often source materials that comply with international standards, such as ISO certifications, to ensure reliability and safety.

In this phase, raw materials are inspected for quality, with any subpar materials rejected. This initial quality control (IQC) helps prevent future failures in the wiring system, which could lead to costly repairs or replacements.

Forming: How Are Wires Processed?

Once materials are prepared, the forming stage begins. This involves cutting the copper wire to specific lengths and applying insulation. Techniques such as extrusion and molding are commonly used to create insulation that is both flexible and resistant to environmental factors such as moisture and UV exposure.

Manufacturers may also apply color-coding to wires during this stage, which aids in easy identification during installation. This attention to detail ensures that the wiring can be easily connected to irrigation controllers and solenoids, reducing the risk of installation errors.

Assembly: What Does the Wiring Assembly Process Entail?

The assembly stage is where the wiring components come together. Technicians will connect the wires to solenoids and waterproof connectors, ensuring that all connections are secure and compliant with safety standards. Techniques such as crimping and soldering are often employed to create strong, reliable connections.

During assembly, manufacturers may also implement in-process quality control (IPQC) checks to ensure each connection meets predefined specifications. This step is crucial for preventing future electrical failures, especially in regions with challenging environmental conditions.

Finishing: What Final Touches Are Applied to the Product?

In the finishing stage, assembled wiring systems undergo further quality checks and are prepared for packaging. This may involve applying protective coatings to prevent corrosion and damage from environmental factors. Additionally, final inspections are conducted to ensure compliance with international standards such as CE marking for products sold in Europe or API standards for specific industrial applications.

Quality assurance in this stage is critical, as it ensures that only products meeting high-performance criteria are shipped to customers. This includes verifying that wiring systems can withstand the pressures and conditions they will face in the field.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is an integral aspect of manufacturing irrigation valve wiring. It encompasses various international standards and industry-specific certifications to ensure the final product is safe, reliable, and efficient.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding international quality standards is essential. ISO 9001 is a widely recognized standard that outlines requirements for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate a commitment to quality, customer satisfaction, and continuous improvement.

In addition to ISO standards, products may also require compliance with industry-specific certifications such as CE marking for the European market, which ensures that products meet safety and health requirements. For buyers in the Middle East or Africa, ensuring compliance with regional standards can also be crucial for market entry.

What Are the Key Quality Control Checkpoints?

Throughout the manufacturing process, several quality control checkpoints are established to maintain high standards. These include:

Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet quality specifications.

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

Final Quality Control (FQC): A comprehensive inspection of the finished product to ensure it meets all specified requirements.

Common testing methods include electrical resistance tests, insulation resistance tests, and environmental testing to simulate real-world conditions. These tests help identify potential failures before products reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying the quality control processes of suppliers is crucial. Here are effective strategies to ensure suppliers meet high standards:

What Steps Can Buyers Take to Conduct Supplier Audits?

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and adherence to international standards. This hands-on approach provides insight into the supplier’s commitment to quality.

Requesting Quality Reports: Buyers should request documentation that outlines the supplier’s quality management practices, including any certifications (ISO, CE, etc.) and test results from previous batches.

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased review of the supplier’s operations. This is especially important for buyers in regions where direct access to suppliers may be limited.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances is particularly important for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. Buyers must consider:

Regional Compliance: Ensure that products meet local regulations and standards, which may differ from international ones.

Cultural Sensitivities: Understanding local business practices and expectations can facilitate better communication and partnership with suppliers.

Logistical Considerations: Factors such as shipping times, customs regulations, and potential delays can impact the supply chain and should be factored into quality assurance processes.

In conclusion, the manufacturing processes and quality assurance for wiring irrigation valves are complex but crucial for ensuring reliable irrigation solutions. By understanding these processes and actively engaging in supplier quality verification, B2B buyers can secure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to wire irrigation valves’

In the context of wiring irrigation valves, having a structured approach is essential for successful procurement and installation. This guide serves as a practical checklist to ensure that B2B buyers make informed decisions while sourcing components for their irrigation systems.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider the type of irrigation system you are installing, the number of zones, and the specific requirements of each valve. Make sure to include details such as wire gauge, solenoid voltage (AC or DC), and whether you need waterproof connectors.

Step 2: Research Reliable Suppliers

Identifying trustworthy suppliers is crucial for ensuring quality and reliability. Look for suppliers who specialize in irrigation components and have a proven track record in your target regions, such as Africa, South America, and Europe. Check for customer reviews, industry certifications, and their ability to provide local support.

Step 3: Evaluate Product Quality and Standards

Before making a purchase, evaluate the quality of the products offered by suppliers. Ensure that the valves and wiring meet international standards for durability and performance, particularly in varying climates. Look for products that are resistant to corrosion and UV damage, as these factors greatly affect longevity in outdoor settings.

Step 4: Request Technical Documentation

Obtain technical documentation for the irrigation valves and controllers you are considering. This includes wiring diagrams, installation guides, and compatibility information. Having access to detailed documentation will aid in proper installation and maintenance, minimizing the risk of operational issues later on.

Step 5: Verify Warranty and Support Services

Assess the warranty offered by suppliers on their products, as this can be a significant indicator of quality and reliability. A robust warranty demonstrates the supplier’s confidence in their product and provides peace of mind. Additionally, inquire about customer support services; efficient support can save you time and money during installation and troubleshooting.

Step 6: Consider Future Expansion Needs

When selecting wiring and valve options, think ahead to potential system expansions. Choose wiring solutions that can accommodate additional zones or valves in the future without requiring a complete overhaul of your system. This foresight can lead to cost savings and reduced operational disruptions down the line.

Step 7: Conduct a Cost-Benefit Analysis

Finally, perform a cost-benefit analysis to evaluate the financial implications of your choices. Consider not only the upfront costs but also the long-term savings associated with reliable products and potential maintenance expenses. A well-informed decision will ensure that your investment pays off in the long run.

By following this checklist, B2B buyers can navigate the complexities of sourcing irrigation valve wiring with confidence, ensuring that their systems are efficient, reliable, and future-proof.

Comprehensive Cost and Pricing Analysis for how to wire irrigation valves Sourcing

What Are the Key Cost Components in Wiring Irrigation Valves?

Wiring irrigation valves entails a multifaceted cost structure that includes several key components. The primary cost elements are materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Materials: The costs of wire, connectors, and other components can vary significantly based on the gauge and type (e.g., multi-strand vs. solid). Standard wire gauges for irrigation systems typically range from 16 to 18 gauge, with waterproof connectors being essential for durability. For bulk purchases, negotiating prices with suppliers can yield significant savings.

Labor: Labor costs depend on local wage rates and the complexity of the installation. Skilled labor may command higher rates, but investing in experienced technicians can reduce long-term issues related to wiring errors.

Manufacturing Overhead: This includes costs associated with facilities, equipment maintenance, and administrative expenses. Understanding these overheads can help buyers assess the overall pricing structure of potential suppliers.

Tooling: The initial investment in tools for wiring and installation can be substantial. Buyers should consider whether the supplier provides these tools as part of the service or if they need to purchase them separately.

Quality Control: Rigorous QC processes can increase costs but are essential for ensuring reliability and reducing failures. Suppliers that prioritize QC may charge more, but they often provide better long-term value.

Logistics: Shipping costs can vary greatly depending on the origin of materials and destination. International buyers should be aware of potential tariffs, taxes, and shipping delays that can impact total expenses.

Margin: Suppliers typically add a margin to cover their costs and profit. Buyers should seek to understand the supplier’s margin structure to negotiate better deals.

How Do Price Influencers Affect Wiring Irrigation Valves Costs?

Several factors influence the pricing of wiring irrigation valves, particularly for international B2B buyers:

Volume and Minimum Order Quantity (MOQ): Larger orders can lead to lower per-unit costs. Buyers should assess their needs and negotiate bulk pricing where possible.

Specifications and Customization: Custom solutions may incur additional costs. Buyers should clarify their requirements early in the procurement process to avoid unexpected charges.

Materials: The choice of materials significantly impacts pricing. For instance, using high-quality, weather-resistant wires may lead to higher upfront costs but offer better durability and lower maintenance expenses.

Quality and Certifications: Products that meet international quality standards (e.g., ISO certifications) may be priced higher. However, these certifications can provide assurance of reliability, particularly in challenging climates.

Supplier Factors: The reputation, reliability, and service level of the supplier can influence pricing. Established suppliers may charge a premium, but they often provide better support and warranty services.

Incoterms: Understanding the International Commercial Terms (Incoterms) is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

What Buyer Tips Can Enhance Cost-Efficiency in Wiring Irrigation Valves?

To maximize cost-efficiency when sourcing wiring for irrigation valves, consider the following strategies:

Negotiate Wisely: Engage in open discussions with suppliers about pricing structures and potential discounts for bulk purchases. Building a strong relationship with suppliers can also lead to better terms.

Evaluate Total Cost of Ownership (TCO): Focus not only on initial costs but also on long-term expenses related to maintenance, durability, and replacement. Investing in higher-quality materials may result in lower TCO.

Be Aware of Pricing Nuances for International Buyers: Understand the economic conditions and currency fluctuations in your region. For instance, inflation rates in countries like Nigeria or Brazil can affect pricing stability and lead times.

Conduct Thorough Market Research: Compare prices and offerings from multiple suppliers. This can help identify the best value and ensure that you are not overpaying for certain components.

Consider Local Suppliers: Whenever feasible, sourcing from local suppliers can reduce logistics costs and lead times, ultimately enhancing your supply chain efficiency.

By strategically navigating these cost components and pricing influencers, B2B buyers can make informed decisions that drive value in their irrigation projects.

Alternatives Analysis: Comparing how to wire irrigation valves With Other Solutions

Exploring Alternatives to Wiring Irrigation Valves

In the realm of irrigation systems, wiring valves to controllers is a common method for managing water flow. However, several alternative solutions exist that can achieve similar objectives. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific needs and operational contexts.

| Comparison Aspect | How To Wire Irrigation Valves | Smart Irrigation Controllers | Wireless Irrigation Systems |

|---|---|---|---|

| Performance | Reliable for direct control; allows for zone management | High precision; can adjust based on weather data | Flexible; easy to expand or modify systems |

| Cost | Moderate initial investment for materials and labor | Higher upfront cost; often requires professional installation | Varies; may involve subscription services for monitoring |

| Ease of Implementation | Requires basic electrical skills; somewhat labor-intensive | Generally user-friendly but may require software setup | Easy to install; minimal wiring needed |

| Maintenance | Moderate; periodic checks needed for connections | Low; software updates may be required | Low; minimal physical maintenance, but battery replacement needed |

| Best Use Case | Traditional agricultural settings with established zones | Urban landscapes needing efficient water management | Remote areas or large properties where flexibility is key |

What Are the Pros and Cons of Smart Irrigation Controllers?

Smart irrigation controllers offer a technologically advanced alternative to traditional wiring methods. These devices utilize weather data and soil moisture levels to optimize watering schedules. The primary advantages include enhanced water efficiency and reduced operational costs over time. However, they typically come with a higher upfront cost and may necessitate professional installation, which can deter some users. Additionally, reliance on technology means that any software or connectivity issues could disrupt the irrigation process.

How Do Wireless Irrigation Systems Compare?

Wireless irrigation systems provide a flexible solution by eliminating the need for extensive wiring. These systems are particularly useful in remote or sprawling properties where traditional wiring may be impractical. They allow for easy expansion as new zones can be added without significant infrastructure changes. The major downsides include the potential for signal interference and the need for battery replacements, which could lead to maintenance challenges. Moreover, some wireless systems may involve subscription fees for advanced features like remote monitoring and control.

Conclusion: How Can B2B Buyers Choose the Right Irrigation Solution?

When selecting an irrigation solution, B2B buyers must assess their unique requirements, including the scale of their operation, budget constraints, and desired level of automation. For traditional settings with established zones, wiring valves to controllers may still be the most effective and economical choice. However, for those seeking advanced efficiency and ease of use, smart irrigation controllers or wireless systems may prove advantageous. Ultimately, understanding the strengths and weaknesses of each alternative will empower buyers to invest in a solution that aligns with their operational goals and enhances overall irrigation efficiency.

Essential Technical Properties and Trade Terminology for how to wire irrigation valves

What Are the Key Technical Properties for Wiring Irrigation Valves?

When wiring irrigation valves, several technical specifications are critical to ensure durability and functionality. Understanding these properties can significantly influence the performance of your irrigation system.

Wire Gauge: The gauge of the wire, typically ranging from 16 to 18 AWG (American Wire Gauge), determines the wire’s capacity to carry electrical current. A lower gauge indicates a thicker wire, which can handle more current without overheating. For B2B buyers, selecting the appropriate gauge is essential to prevent voltage drops and ensure reliable valve operation, especially in larger systems.

Material Composition: Most irrigation wiring is made from copper, known for its excellent conductivity. However, some systems may use aluminum, which is lighter and less expensive but not as efficient. The choice of material affects long-term reliability and maintenance costs, making it crucial for buyers to consider the environmental conditions (e.g., moisture, temperature) in their target markets.

Insulation Type: Insulation material, such as PVC or polyethylene, protects the wire from moisture and UV rays. The insulation’s thickness and quality directly impact the wire’s longevity and resistance to environmental stressors. Buyers must ensure the insulation meets local standards, especially in regions with extreme weather, to minimize failure rates.

Voltage Rating: Irrigation systems typically operate at low voltage (24V AC or DC). Understanding the voltage rating of both the wiring and the solenoids is essential for preventing electrical mishaps. Buyers should verify compatibility between the controller and the valves, as mismatched ratings can lead to system failures.

Temperature Tolerance: The ability of the wire and connectors to withstand temperature fluctuations is vital. Some regions may experience extreme heat or cold, which can degrade materials over time. Buyers should look for products rated for their local climate to ensure longevity and reliable performance.

Waterproof Connectors: Using waterproof connectors is critical for preventing corrosion and electrical failures due to moisture ingress. These connectors are designed to withstand exposure to water, ensuring the longevity of electrical connections. Buyers should prioritize waterproof options, especially in humid or rainy climates.

Which Trade Terminology Is Important for Wiring Irrigation Valves?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some commonly used terms relevant to wiring irrigation valves:

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers for high-quality components that ensure compatibility and performance in irrigation systems.

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management, particularly when sourcing components for large-scale irrigation projects.

RFQ (Request for Quotation): An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and terms of sale. For buyers, issuing RFQs can lead to competitive pricing and better terms, ensuring they get the best value for their investments.

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers navigate shipping, insurance, and liability, especially when sourcing products from different countries.

Lead Time: This refers to the amount of time between placing an order and receiving the goods. For irrigation projects, understanding lead times is essential for planning and ensuring timely implementation of systems.

Warranty Period: The warranty period is the duration during which a supplier guarantees the product against defects. Buyers should carefully review warranty terms to protect their investments, especially for components that will be exposed to harsh environmental conditions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when wiring irrigation valves, ensuring the efficiency and reliability of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the how to wire irrigation valves Sector

What Are the Current Market Dynamics and Key Trends in Wiring Irrigation Valves?

The global market for irrigation systems, particularly in the context of wiring irrigation valves, is witnessing significant growth driven by increasing agricultural demands, urbanization, and the need for efficient water management. Regions such as Africa, South America, the Middle East, and Europe are experiencing heightened interest in advanced irrigation technologies. Key trends include the adoption of smart irrigation systems equipped with IoT capabilities, which allow for remote monitoring and control of irrigation valves. This technology not only enhances efficiency but also reduces water wastage, a critical concern in water-scarce regions.

International B2B buyers are increasingly focused on sourcing high-quality wiring components that can withstand diverse environmental conditions. Factors such as climate resilience, durability, and ease of installation are becoming essential considerations. Additionally, the rise of e-commerce platforms is facilitating direct sourcing from manufacturers, enabling buyers to access a broader range of products while reducing costs. The trend towards modular systems is also notable, allowing for easy scalability as agricultural needs evolve.

Emerging markets, particularly in Africa and South America, are seeing a shift towards localized manufacturing to reduce lead times and improve supply chain resilience. This aligns with a growing preference for suppliers who can offer not just products but also comprehensive support services, including installation guidance and troubleshooting.

How Is Sustainability Influencing the Sourcing of Wiring Components for Irrigation Valves?

Sustainability has become a paramount concern in the irrigation sector, influencing the sourcing of materials and components used in wiring irrigation valves. The environmental impact of conventional materials, particularly in terms of energy consumption and waste generation, is prompting buyers to seek out alternatives that are more eco-friendly. This includes the use of recyclable materials and the integration of sustainable practices in the manufacturing process.

Ethical sourcing is also gaining traction as consumers and businesses alike demand transparency in supply chains. Companies that prioritize ethical practices, such as fair labor conditions and environmentally responsible sourcing, are often viewed more favorably by B2B buyers. Certifications for sustainable practices and materials, such as ISO 14001 for environmental management, are becoming increasingly important in the decision-making process.

Furthermore, the implementation of “green” technologies, such as solar-powered irrigation controllers and biodegradable wiring options, is reshaping the landscape. Buyers are encouraged to consider suppliers who not only offer compliant products but also demonstrate a commitment to sustainability through their operations and corporate social responsibility initiatives.

What Is the Evolution of Wiring Technology in Irrigation Systems?

The evolution of wiring technology in irrigation systems has been marked by significant advancements aimed at improving efficiency and reliability. Historically, irrigation systems relied heavily on basic electrical connections that were prone to failure due to environmental factors. However, with the advent of weather-resistant materials and improved insulation techniques, the durability of wiring components has significantly enhanced.

In recent years, the integration of smart technology has transformed traditional wiring approaches. The introduction of wireless communication and IoT-enabled devices allows for real-time monitoring and control of irrigation systems, reducing the need for complex wiring setups. This shift not only streamlines installation but also enhances the adaptability of irrigation systems to meet changing agricultural demands.

As the industry continues to innovate, the future of wiring technology in irrigation systems will likely focus on further enhancing connectivity, sustainability, and user-friendliness, ensuring that B2B buyers are equipped with the tools they need to optimize their irrigation practices.

Frequently Asked Questions (FAQs) for B2B Buyers of how to wire irrigation valves

How do I solve wiring issues with irrigation valves?

To troubleshoot wiring issues with irrigation valves, start by inspecting all connections for signs of corrosion or damage. Ensure that the wires are securely connected to both the solenoids and the controller, using waterproof connectors to prevent moisture damage. Test the continuity of each wire with a multimeter to identify any breaks or shorts. If problems persist, consider replacing faulty components, ensuring that you use appropriate wire gauge to support your system’s electrical demands.What is the best wire gauge for irrigation valves?

The best wire gauge for wiring irrigation valves typically ranges from 16 to 18 gauge. For most residential and small commercial systems, 18-gauge wire is adequate, while larger systems with longer distances may benefit from 16-gauge wire to reduce voltage drop. Always consider the specific requirements of your irrigation system and the length of the wire runs when selecting the appropriate gauge.How can I ensure the quality of irrigation valve components when sourcing internationally?

To ensure quality when sourcing irrigation valve components internationally, conduct thorough supplier vetting by reviewing certifications, customer testimonials, and past project examples. Request samples to evaluate material quality and performance before committing to bulk orders. Additionally, consider suppliers who comply with international quality standards, such as ISO 9001, to safeguard against subpar products.What are the typical minimum order quantities (MOQs) for irrigation valves?

Minimum order quantities (MOQs) for irrigation valves can vary widely among suppliers, typically ranging from 50 to 500 units. Factors influencing MOQs include the supplier’s production capabilities, the materials used, and the complexity of the product. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing a new product line or entering a new market.What payment terms should I expect when sourcing irrigation valves?

Payment terms when sourcing irrigation valves can differ significantly by supplier and region. Common terms include a 30% deposit upon order confirmation with the balance due before shipment. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established relationships. Always clarify payment terms upfront and consider using secure payment methods to protect your transaction.How do I customize irrigation valve specifications for my market?

Customizing irrigation valve specifications involves collaborating closely with your supplier to discuss your market’s unique needs. Provide detailed requirements regarding size, pressure ratings, and any specific features, such as solenoid type or materials that withstand local environmental conditions. Ensure that your supplier has the capability to produce customized solutions and ask for prototypes or drawings before finalizing designs.What logistics considerations should I keep in mind when importing irrigation valves?

When importing irrigation valves, consider logistics factors such as shipping costs, lead times, and customs regulations in your destination country. Work with a reliable freight forwarder who can navigate international shipping complexities and ensure compliance with local import laws. Additionally, factor in storage and distribution capabilities in your region to optimize supply chain efficiency.What quality assurance measures should I implement when sourcing irrigation valves?

Implement quality assurance measures such as regular inspections during production, third-party quality audits, and testing samples for durability and functionality. Establish clear quality standards and communicate them to your suppliers. Consider using performance metrics to evaluate the reliability of components and maintain a consistent feedback loop to address any issues promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 How To Wire Irrigation Valves Manufacturers & Suppliers List

1. Sprinkler Warehouse – Wiring Supplies

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Wiring supplies needed: 16-gauge or 18-gauge wire, waterproof connectors filled with silicone, color-coded wires, common white wire. Waterproof connectors protect against water damage and corrosion. Wires must be buried at least 6 inches deep and secured with plastic electrical staples when running up the side of a structure. Recommended products include LV 9000 wire connector, LV 9500 wire connec…

2. Rachio – 3 Wire Connectors & Toro Solenoids

Domain: community.rachio.com

Registered: 2013 (12 years)

Introduction: 3 Wire Connectors, ConnectOzo Electrical IDC 314-BOX; Toro Solenoids (Model: 89-0114); DryConn Small Waterproof Wire Connectors (Aqua, Orange, 20-Pack); Terminal blocks from Lowe’s; 18 gauge thermostat wire; Petroleum jelly or silicon grease for moisture protection.

3. The Lawn Forum – 18 Gauge Multi-Strand Wire

Domain: thelawnforum.com

Registered: 2017 (8 years)

Introduction: 18 gauge multi-strand wire is the industry standard for smaller residential lawns. Recommendations include running 2-pair wire to each valve from the controller, or using 5, 7, or 9 conductor wires depending on the configuration. Waterproof connectors are advised for durability. Overbuilding is suggested with options like 3x 18/10 wires or 18/2 wire for dedicated runs. It’s emphasized to use real …

4. Do It Yourself – Irrigation Valve Wire Connectors

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: Irrigation valve wire connectors are inexpensive components used in sprinkler systems. They may contain white dielectric paste for insulation. Users often discuss whether to reuse these connectors after exposure to open air, with recommendations leaning towards using new connectors for reliability. It’s also advised to clean the exposed ends of wires to ensure good conductivity.

5. Lawnsite – Marine Grade Crimp Connectors

Domain: lawnsite.com

Registered: 2000 (25 years)

Introduction: Marine grade crimp connectors with heat shrink, silicone grease for waterproofing, 10 copper wires inside a metal sheath wrapped in plastic.

6. Angi – Sprinkler System Installation Guide

Domain: angi.com

Registered: 1996 (29 years)

Introduction: Skill Level: Intermediate, Completion Time: 60 minutes, Cost: $50–$100, Tools Needed: Wire stripper, Screwdriver, Supplies Needed: Sprinkler valves, Sprinkler wires, Waterproof connectors.

7. Sprinkler Wire – UV Protection Essentials

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Ensure that the sprinkler wire selected is rated for UV exposure and suitable temperature range for your region. Consider placing a UV rated conduit to protect the wire above ground. Sprinkler system wiring is considered low voltage with few codes governing installation. The most important concern is to ensure the wire won’t get cut or damaged, making burying the wire recommended to protect it fro…

8. Simple Practical Beautiful – Water Supply Solutions

Domain: simplepracticalbeautiful.com

Registered: 2015 (10 years)

Introduction: 1. Water Supply Connection: Utilized a hose bib as the water supply, replaced an elbow joint with a T connection for water flow. 2. Shut-off Valve: Added a shut-off valve with a yellow handle for convenience, threaded on both ends with thread sealing tape. 3. Backflow Device: Required to prevent contamination, installed a separate backflow prevention device higher than the sprinkler valves, using …

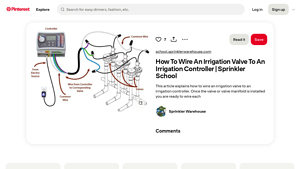

9. Pinterest – Irrigation Valve Wiring Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: How To Wire An Irrigation Valve To An Irrigation Controller | Sprinkler School

Strategic Sourcing Conclusion and Outlook for how to wire irrigation valves

What Are the Key Takeaways for Wiring Irrigation Valves?

In conclusion, the successful wiring of irrigation valves hinges on a few critical principles: selecting the right gauge wire, ensuring waterproof connections, and maintaining clear documentation of wire color coding. These practices mitigate the risk of future issues, enhancing system reliability and operational efficiency. Strategic sourcing of high-quality materials is paramount; investing in durable components today can lead to substantial cost savings and reduced maintenance needs in the long run.

How Can International Buyers Benefit from Strategic Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local environmental conditions and regulatory requirements is essential. Adopting a strategic sourcing approach allows companies to align their procurement strategies with their specific operational needs, ensuring compatibility and longevity of irrigation systems.

What’s Next for Your Irrigation Projects?

As you move forward, consider leveraging local suppliers who understand regional challenges and can offer customized solutions. Embrace innovation in irrigation technology to enhance water management efficiency. The future of irrigation is bright, and by taking proactive steps today, you can ensure your projects thrive in diverse climates and markets. Engage with trusted suppliers and experts to optimize your irrigation systems for lasting success.