Introduction: Navigating the Global Market for hunter irrigation valve solenoid

In the ever-evolving landscape of global irrigation solutions, sourcing reliable Hunter irrigation valve solenoids presents a significant challenge for B2B buyers. These essential components are pivotal for the efficient operation of irrigation systems, and understanding their specifications, compatibility, and applications is crucial for making informed purchasing decisions. This guide provides a comprehensive overview of Hunter irrigation valve solenoids, detailing the various types available—such as AC and DC-latching solenoids—and their specific applications across diverse agricultural and landscaping environments.

Navigating the complexities of supplier vetting, cost implications, and regional availability is no small feat, especially for international buyers in Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. This guide aims to empower these buyers by offering actionable insights into the performance features, installation requirements, and maintenance considerations of Hunter solenoids. By equipping businesses with the knowledge to evaluate suppliers and products effectively, we ensure that procurement teams can confidently select the best solutions to enhance their irrigation systems. Ultimately, this resource is designed to facilitate informed decisions that drive operational efficiency and sustainability in irrigation practices worldwide.

Understanding hunter irrigation valve solenoid Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Solenoid | Operates on 24 VAC; encapsulated design for protection against water intrusion | Commercial irrigation systems, large-scale agriculture | Pros: Reliable performance, easy installation. Cons: Higher energy consumption compared to DC options. |

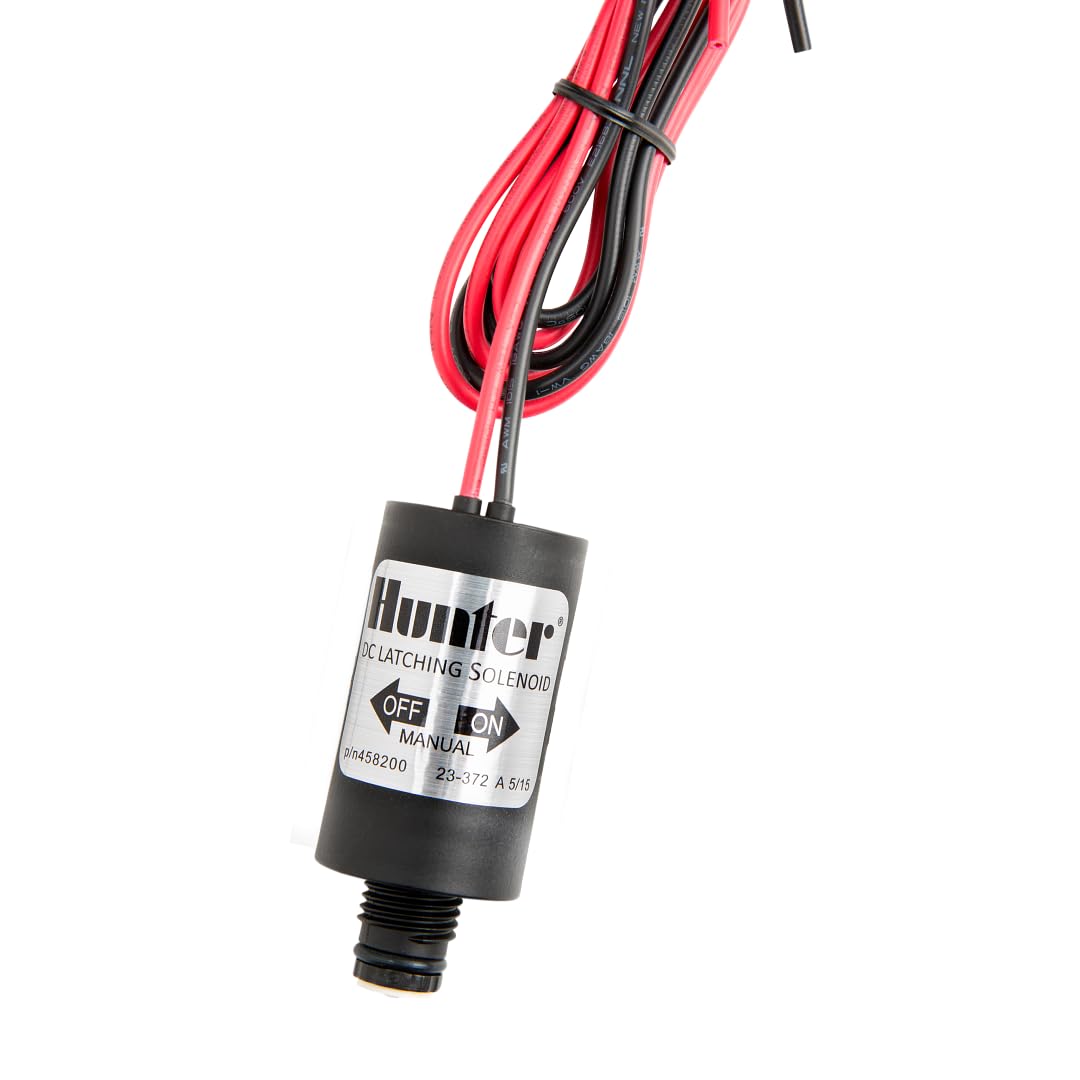

| DC-Latching Solenoid | Operates on 6-9 VDC; requires a pulse to latch/unlatch | Battery-operated systems, remote installations | Pros: Energy-efficient, ideal for battery-operated controllers. Cons: Requires careful wiring for reliable operation. |

| Hybrid Solenoid | Compatible with both AC and DC; versatile for various applications | Mixed-use environments, diverse irrigation setups | Pros: Flexibility in usage, fewer inventory requirements. Cons: Potentially higher initial cost. |

| High-Pressure Solenoid | Designed for maximum operating pressure of 220 PSI | Commercial landscapes, sports fields | Pros: Robust performance under pressure, suitable for challenging environments. Cons: May require specialized installation. |

| Quick-Connect Solenoid | Features a manual quarter-turn on/off control; easy servicing | Residential and commercial irrigation systems | Pros: Simplified maintenance, user-friendly design. Cons: May not be suitable for high-flow applications. |

What Are the Key Characteristics of AC Solenoids?

AC solenoids operate on 24 VAC and are known for their robust encapsulated design, which protects critical components from water intrusion. They are ideal for commercial irrigation systems and large-scale agricultural applications where reliable performance is essential. Buyers should consider installation ease and the potential for higher energy consumption compared to DC options, which may impact long-term operational costs.

How Do DC-Latching Solenoids Enhance Energy Efficiency?

DC-latching solenoids function on 6-9 VDC and are designed for battery-operated systems. They receive a quick pulse from the controller to latch and unlatch, making them particularly suitable for remote installations where energy efficiency is crucial. B2B buyers must ensure proper wiring for reliable operation, as improper connections can lead to functionality issues.

What Advantages Do Hybrid Solenoids Offer?

Hybrid solenoids can operate on both AC and DC power sources, providing versatility for various applications. This adaptability makes them suitable for mixed-use environments, allowing businesses to streamline inventory management. While they offer flexibility, buyers should be aware of potentially higher initial costs compared to single-type solenoids.

Why Choose High-Pressure Solenoids for Commercial Use?

High-pressure solenoids are engineered to withstand maximum operating pressures of up to 220 PSI, making them ideal for demanding applications such as commercial landscapes and sports fields. Their robust design ensures reliable performance under challenging conditions. Buyers should consider the need for specialized installation, which may add to project costs.

How Do Quick-Connect Solenoids Simplify Maintenance?

Quick-connect solenoids incorporate a manual quarter-turn on/off control feature, facilitating easy servicing and maintenance. They are well-suited for both residential and commercial irrigation systems, where user-friendliness is a priority. However, they may not be the best choice for high-flow applications, so buyers should assess their specific irrigation needs.

Key Industrial Applications of hunter irrigation valve solenoid

| Industry/Sector | Specific Application of Hunter Irrigation Valve Solenoid | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems for crop management | Increases efficiency and water conservation in farming | Compatibility with existing systems, voltage specifications |

| Landscaping & Horticulture | Smart irrigation for public parks and gardens | Enhances aesthetic appeal and reduces labor costs | Durability against harsh weather, ease of installation |

| Golf Courses | Precision irrigation for fairways and greens | Promotes healthy turf while minimizing water waste | High-pressure tolerance, reliable performance under varying conditions |

| Sports Facilities | Automated watering systems for athletic fields | Ensures optimal playing conditions and player safety | Adaptability to different field sizes, maintenance requirements |

| Urban Development | Irrigation in residential and commercial complexes | Supports sustainable landscaping and increases property value | Energy efficiency, ease of integration with smart technology |

How is the Hunter Irrigation Valve Solenoid Used in Agriculture?

In the agriculture sector, Hunter irrigation valve solenoids are integral to automated irrigation systems that manage water distribution for crops. These solenoids ensure timely and efficient watering, reducing water waste and enhancing crop yield. International buyers, particularly from regions like Africa and South America, should consider the compatibility of these solenoids with existing irrigation infrastructure and their voltage specifications. This ensures seamless integration and operational reliability in diverse farming conditions.

What Role Do Hunter Solenoids Play in Landscaping and Horticulture?

In landscaping and horticulture, Hunter solenoids facilitate smart irrigation systems designed for public parks and gardens. By automating watering schedules, they not only reduce labor costs but also ensure that plants receive the optimal amount of water. Buyers in Europe, especially in countries with strict environmental regulations, must prioritize the durability of these solenoids against varying weather conditions to maintain aesthetic appeal while promoting sustainability.

How Do Golf Courses Benefit from Hunter Irrigation Solenoids?

Golf courses utilize Hunter irrigation valve solenoids for precision watering of fairways and greens, ensuring that turf remains healthy and vibrant. This technology allows for targeted irrigation, which minimizes water usage while maintaining optimal playing conditions. For buyers in the Middle East, where water scarcity is a concern, the high-pressure tolerance and reliable performance of these solenoids are crucial for adapting to local climate challenges.

What Are the Applications of Hunter Solenoids in Sports Facilities?

In sports facilities, automated watering systems powered by Hunter irrigation solenoids help maintain athletic fields. These systems ensure that grass remains healthy and safe for players, thus enhancing the overall experience for both athletes and spectators. Buyers from regions with varying field sizes must consider the adaptability of the solenoids and their maintenance requirements to ensure consistent performance across different sports environments.

How Do Urban Developers Use Hunter Irrigation Valve Solenoids?

Urban development projects incorporate Hunter irrigation valve solenoids to manage irrigation in residential and commercial complexes. These systems support sustainable landscaping practices, which can significantly increase property value. B2B buyers in Europe and the Middle East should focus on sourcing energy-efficient solutions that easily integrate with smart technology, ensuring that their developments are both modern and environmentally friendly.

3 Common User Pain Points for ‘hunter irrigation valve solenoid’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Solenoids for Diverse Irrigation Systems

The Problem: B2B buyers, especially those operating in regions like Africa and South America, often face challenges in sourcing solenoids that are compatible with various irrigation systems. The market is flooded with numerous brands and models, leading to confusion over compatibility and specifications. Buyers may find themselves purchasing solenoids that do not fit their existing valves, resulting in wasted time and financial resources. Furthermore, the lack of local distributors can complicate the procurement process, making it hard for buyers to get the right parts quickly.

The Solution: To navigate this issue, buyers should prioritize sourcing from well-established manufacturers like Hunter Industries, which provides a comprehensive range of solenoids designed for compatibility with their valves. When specifying solenoids, it is crucial to check the product specifications to ensure that the voltage and pressure ratings align with the existing irrigation systems. Buyers should consider using Hunter’s 24 VAC or DC-latching solenoids, as they are engineered for versatile use across different valve models. Establishing relationships with reliable local distributors or utilizing online platforms that offer detailed product descriptions and compatibility information can streamline the sourcing process and reduce the risk of purchasing the wrong parts.

Scenario 2: Challenges with Solenoid Durability in Harsh Environments

The Problem: In regions like the Middle East and parts of Europe, irrigation systems are often subjected to extreme weather conditions, including high temperatures and humidity. These environmental factors can lead to the premature failure of solenoids, which may not be built to withstand such harsh conditions. Buyers may encounter frequent replacements, resulting in increased operational costs and downtime in irrigation management, which is particularly detrimental for agricultural businesses reliant on efficient irrigation.

The Solution: To address durability concerns, buyers should invest in heavy-duty solenoids such as the Hunter encapsulated 24 VAC solenoid. This model is designed to prevent water intrusion and protect critical electronic components, thus ensuring longevity even in challenging conditions. Buyers should also consider implementing routine maintenance checks to inspect solenoid performance, particularly before and after extreme weather events. Additionally, opting for solenoids with robust materials and encapsulated designs can mitigate risks associated with environmental wear and tear. Investing in high-quality solenoids upfront can significantly reduce long-term costs and improve the reliability of irrigation systems.

Scenario 3: Inefficiencies in Solenoid Installation and Operation

The Problem: Many B2B buyers encounter difficulties with the installation and operation of solenoids, particularly when integrating them into existing irrigation setups. This can lead to inefficiencies such as improper valve operation, which may cause under- or over-watering of crops. In addition, the need for specialized tools or technical expertise for installation can further complicate the process, especially for buyers in remote areas where skilled labor may not be readily available.

The Solution: To streamline installation and ensure proper operation, buyers should choose solenoids that are designed for easy installation, such as the Hunter models that feature pre-wired leads and manual quarter-turn on/off controls. Providing training sessions or instructional materials on how to install and troubleshoot solenoids can empower staff and improve operational efficiency. For buyers facing geographical constraints, leveraging video tutorials and online resources from manufacturers can be beneficial. Additionally, investing in battery-operated controllers compatible with Hunter solenoids can enhance flexibility and reduce dependency on electrical infrastructure, making irrigation management more efficient and less labor-intensive.

Strategic Material Selection Guide for hunter irrigation valve solenoid

What Materials Are Commonly Used in Hunter Irrigation Valve Solenoids?

When selecting materials for Hunter irrigation valve solenoids, several factors influence the decision-making process, particularly for international B2B buyers. Understanding the key properties, advantages, disadvantages, and specific considerations for different materials is crucial for ensuring optimal performance and compliance with regional standards.

How Does Plastic Perform in Hunter Irrigation Valve Solenoids?

Plastic is a prevalent material choice for solenoids due to its lightweight nature and excellent corrosion resistance. Commonly used plastics, such as polycarbonate and polypropylene, can withstand temperatures up to 70°C and pressures of around 200 PSI.

Pros: The primary advantages of plastic include its low cost and ease of manufacturing, making it suitable for mass production. Additionally, plastic solenoids are resistant to various chemicals, which enhances their longevity in diverse environments.

Cons: However, plastic may not be as durable as metal options, particularly under extreme temperature variations or high-stress conditions. It can also be less effective in applications requiring high-pressure ratings.

Impact on Application: Plastic solenoids are ideal for irrigation systems where chemical exposure is a concern, such as in agricultural applications with fertilizers.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards for plastics, such as ASTM or ISO certifications, to guarantee product safety and performance.

What Role Does Metal Play in Hunter Irrigation Valve Solenoids?

Metals, particularly brass and stainless steel, are often used in solenoid construction due to their superior strength and durability. Brass solenoids can handle higher temperatures (up to 120°C) and pressures (up to 220 PSI), making them suitable for more demanding applications.

Pros: The primary advantage of metal solenoids is their robustness, which ensures a longer lifespan even in harsh environments. They also provide excellent electrical conductivity, which is crucial for efficient operation.

Cons: The downside includes higher manufacturing costs and potential susceptibility to corrosion, particularly in saline or acidic environments.

Impact on Application: Metal solenoids are particularly effective in high-pressure irrigation systems and areas with extreme weather conditions.

Considerations for International Buyers: Buyers from Europe, particularly Germany, should be aware of compliance with DIN standards for metal components, ensuring they meet the necessary quality and safety benchmarks.

How Do Composite Materials Enhance Hunter Irrigation Valve Solenoids?

Composite materials, which combine plastic and metal, offer a unique blend of properties. These materials can withstand temperatures up to 90°C and pressures of 200 PSI, making them versatile for various applications.

Pros: The key advantage of composites is their enhanced durability and resistance to corrosion while remaining lightweight. This makes them suitable for applications where both strength and weight are critical.

Cons: However, composites can be more complex to manufacture, leading to higher costs. Additionally, they may not perform as well in extreme thermal conditions compared to pure metals.

Impact on Application: Composite solenoids are well-suited for environments where weight reduction is essential, such as in portable irrigation systems.

Considerations for International Buyers: Buyers should check for compliance with international standards like JIS in Japan or ISO, especially when dealing with composite materials that may have specific requirements.

Summary Table of Material Selection for Hunter Irrigation Valve Solenoids

| Material | Typical Use Case for hunter irrigation valve solenoid | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Agricultural irrigation systems with chemical exposure | Low cost and excellent corrosion resistance | Less durable under extreme conditions | Low |

| Metal (Brass) | High-pressure irrigation systems | Superior strength and durability | Higher cost and potential corrosion | High |

| Composite | Portable irrigation systems | Lightweight with enhanced durability | More complex to manufacture | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions that align with both performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hunter irrigation valve solenoid

What Are the Main Stages of Manufacturing Hunter Irrigation Valve Solenoids?

The manufacturing process for Hunter irrigation valve solenoids is a complex series of stages designed to ensure durability, reliability, and efficiency. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing and Quality Control

The first step in the manufacturing process is sourcing high-quality materials. Hunter Industries uses heavy-duty plastics and metals that are resistant to corrosion and wear. Raw materials undergo rigorous inspection and testing to meet specifications, ensuring they can withstand the demands of irrigation systems. This stage is crucial, as the quality of materials directly affects the performance and longevity of the solenoids.

Forming: Precision Engineering Techniques

Once materials are prepared, they are subjected to precision engineering techniques. This includes molding and machining processes that shape the components of the solenoids. For example, the encapsulated design of the 24 VAC solenoid is created through injection molding, which ensures a tight seal against water intrusion. Advanced CNC (Computer Numerical Control) machines are often used to achieve high precision in the components, which is vital for the solenoid’s functionality.

Assembly: Integrating Components for Functionality

The assembly stage involves integrating various components, such as coils, plunger assemblies, and wire leads. Skilled technicians follow strict assembly guidelines to ensure that each solenoid is assembled correctly. This includes pre-wiring the solenoids with UL-approved wire, which is essential for safety and compliance. The captive plunger design simplifies servicing and minimizes the risk of losing internal parts during maintenance.

Finishing: Quality Assurance and Testing

The final stage involves finishing processes that may include cleaning, coating, and additional inspections. Each solenoid undergoes a series of tests to verify its performance under specified conditions. This is where quality assurance becomes critical, as it ensures that every product meets Hunter’s high standards before it reaches the market.

How Is Quality Assurance Implemented in the Manufacturing of Solenoids?

Quality assurance (QA) is an integral part of the manufacturing process for Hunter irrigation valve solenoids. Hunter Industries adheres to several international and industry-specific standards to ensure product quality and safety.

Which International Standards Are Relevant to Quality Assurance?

Hunter Industries complies with ISO 9001, a widely recognized quality management standard. This certification demonstrates a commitment to quality and continuous improvement in manufacturing processes. Additionally, products may carry CE marking, indicating compliance with European safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process ensure that each component meets design specifications.

- Final Quality Control (FQC): At this stage, the finished solenoids undergo rigorous testing to ensure they perform as intended under various conditions.

What Common Testing Methods Are Used for Solenoids?

Testing methods for Hunter irrigation valve solenoids include:

- Electrical Testing: Ensuring that solenoids operate effectively at specified voltages and currents.

- Pressure Testing: Verifying that solenoids can withstand maximum operating pressure without leakage.

- Durability Testing: Simulating long-term use to assess wear and tear on the solenoids.

These tests are crucial for identifying any potential defects before the products are shipped to customers.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source Hunter irrigation valve solenoids should consider several strategies to verify supplier quality control:

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is an effective way to assess the quality control measures in place. Buyers can request access to audit reports that detail the supplier’s adherence to quality standards and certifications. Regular audits can help build trust and ensure that suppliers maintain their quality commitments over time.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These inspections can occur at various stages of production, offering buyers peace of mind that the products they receive will meet their expectations.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying standards and regulations governing product quality. For instance, European buyers may place a higher emphasis on CE compliance, while Middle Eastern markets may prioritize specific local certifications. Buyers should familiarize themselves with these regional requirements to ensure compliance and avoid potential import issues.

What Role Do Cultural and Economic Factors Play in Quality Perception?

Cultural and economic factors can also influence perceptions of quality. Buyers from emerging markets may prioritize cost-effectiveness, while buyers from developed regions may emphasize high-quality standards. Understanding these differences can help suppliers tailor their offerings to meet the diverse needs of their international clientele.

Conclusion: Ensuring Quality in Hunter Irrigation Valve Solenoids

In summary, the manufacturing and quality assurance processes for Hunter irrigation valve solenoids are designed to ensure that products meet high standards of reliability and performance. By understanding these processes and implementing best practices for supplier evaluation, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hunter irrigation valve solenoid’

The following practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for Hunter irrigation valve solenoids. This checklist will ensure that you make informed purchasing decisions, optimizing both functionality and cost-effectiveness.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider the type of solenoid you need—either AC or DC-latching—and ensure compatibility with your existing Hunter irrigation valves. This step is crucial as it establishes the foundation for your procurement strategy and ensures that the components will work seamlessly within your irrigation system.

Step 2: Research Supplier Options

Conduct thorough research on potential suppliers specializing in irrigation components. Look for suppliers with a strong reputation in your region, such as those with experience in Africa, South America, the Middle East, and Europe. Focus on those who offer a comprehensive range of Hunter products, as this indicates reliability and expertise in the field.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record of delivering quality products on time, as this will help mitigate risks associated with procurement.

- Consider Reviews and Testimonials: Seek feedback from previous customers to gauge the supplier’s reliability and service quality.

- Assess After-Sales Support: Evaluate the level of technical support and warranty offered for the solenoids.

Step 4: Verify Product Certifications and Standards

Ensure that the solenoids you plan to procure meet international quality and safety standards. This verification is essential to ensure compliance with local regulations and to guarantee the longevity and performance of the product.

- Check for UL and CE certifications: These certifications signify adherence to rigorous safety and performance standards.

- Inquire About Material Quality: Confirm that the solenoids are constructed from durable, weather-resistant materials.

Step 5: Request Detailed Product Specifications

Obtain detailed specifications for the Hunter irrigation valve solenoids you are considering. This includes electrical ratings, operating pressure limits, and installation requirements. Understanding these details will help ensure compatibility with your irrigation system and aid in future maintenance.

- Review the Manufacturer’s Data Sheets: These documents provide critical information about performance metrics and installation guidelines.

- Consider Energy Efficiency: Evaluate the power requirements and energy consumption of the solenoids to optimize operational costs.

Step 6: Negotiate Pricing and Terms

Once you have identified suitable suppliers and products, initiate negotiations regarding pricing and terms of sale. Be prepared to discuss bulk purchase discounts, payment terms, and delivery schedules to ensure favorable conditions for your procurement.

- Explore Payment Options: Consider various payment methods and their implications for your cash flow.

- Discuss Shipping and Handling Costs: Clarify the logistics involved, especially if sourcing from international suppliers.

Step 7: Finalize Your Purchase and Confirm Delivery Details

After reaching an agreement, finalize your order and confirm delivery timelines. Ensure you receive a purchase order and any necessary documentation to facilitate smooth transactions.

- Establish Communication Channels: Maintain open lines of communication with your supplier to address any issues that may arise during the shipping process.

- Plan for Installation and Maintenance: Consider scheduling installation support or training if necessary, to ensure optimal use of the solenoids.

By following this checklist, B2B buyers can enhance their sourcing process for Hunter irrigation valve solenoids, ensuring they select the right products from reputable suppliers while optimizing their investment.

Comprehensive Cost and Pricing Analysis for hunter irrigation valve solenoid Sourcing

What Are the Key Cost Components for Sourcing Hunter Irrigation Valve Solenoids?

When sourcing Hunter irrigation valve solenoids, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The choice of materials used in solenoid construction significantly affects pricing. Heavy-duty plastics and metals, which enhance durability and performance, typically incur higher costs.

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this can impact quality and consistency.

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient production processes can help minimize these overheads, translating into better pricing for buyers.

Tooling: Initial tooling costs for custom solenoids or specialized production runs can be substantial. Buyers should consider these costs when evaluating pricing, especially for low-volume orders.

Quality Control (QC): Investing in robust QC processes ensures reliability and performance, but this can also increase the overall cost. Buyers may wish to evaluate suppliers based on their QC standards to balance cost and quality.

Logistics: Shipping costs can vary widely based on the origin and destination of the products. International buyers must account for tariffs, taxes, and transportation fees, which can significantly affect total costs.

Margin: Suppliers typically build a margin into their pricing, which can vary based on market demand, competition, and brand reputation. Understanding the market dynamics can help buyers negotiate better terms.

How Do Price Influencers Impact the Sourcing of Hunter Irrigation Valve Solenoids?

Several factors influence the pricing of Hunter irrigation valve solenoids, particularly for international buyers:

Volume/MOQ: Larger order quantities often lead to lower per-unit costs. Buyers should assess their needs and negotiate minimum order quantities (MOQ) to benefit from economies of scale.

Specifications and Customization: Custom features or specifications can raise costs. Buyers should clearly define their requirements to avoid unexpected expenses.

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO standards) can justify premium pricing. Buyers should weigh the benefits of investing in certified products against their budget constraints.

Supplier Factors: The reputation, reliability, and financial stability of suppliers can impact pricing. A trusted supplier may command higher prices but offer better service and warranty support.

Incoterms: The choice of Incoterms (International Commercial Terms) affects who is responsible for shipping, insurance, and tariffs. Buyers should carefully select Incoterms that align with their logistical capabilities and budget.

What Tips Can Help Buyers Optimize Costs When Sourcing Hunter Irrigation Valve Solenoids?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing costs involves strategic planning and negotiation:

Negotiate Effectively: Building a good relationship with suppliers can facilitate better pricing. Open discussions about long-term partnerships can lead to discounts or favorable payment terms.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and operational costs. Opting for higher-quality solenoids may reduce long-term expenses, improving overall value.

Understand Pricing Nuances: Be aware of regional pricing trends and currency fluctuations. This knowledge can aid in negotiating better deals and avoiding overpayment.

Leverage Local Distributors: Local distributors often have a better understanding of market dynamics and can offer competitive pricing. They can also assist with logistics and reduce lead times.

Stay Informed on Market Trends: Keeping abreast of industry trends and technological advancements can provide insights into potential cost-saving opportunities, such as new materials or manufacturing techniques.

Disclaimer on Indicative Prices

Prices for Hunter irrigation valve solenoids can vary widely based on factors such as supplier location, order quantity, and customization options. The prices mentioned in supplier catalogs should be viewed as indicative and may change based on market conditions and individual negotiations. Always confirm final pricing with the supplier prior to placing orders.

Alternatives Analysis: Comparing hunter irrigation valve solenoid With Other Solutions

Understanding Alternatives to Hunter Irrigation Valve Solenoids

In the landscape of irrigation systems, the choice of solenoids can significantly impact performance, efficiency, and overall operational costs. While the Hunter irrigation valve solenoid is a well-regarded option, it’s essential for international B2B buyers to consider alternative solutions that may better suit their specific needs, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. This section examines two viable alternatives to the Hunter irrigation valve solenoid: the Rain Bird Solenoid and the Toro Solenoid.

Comparison Table

| Comparison Aspect | Hunter Irrigation Valve Solenoid | Rain Bird Solenoid | Toro Solenoid |

|---|---|---|---|

| Performance | Reliable operation with high durability; encapsulated design prevents water intrusion | Offers good performance; compatible with a variety of Rain Bird valves | Solid performance; various models for different applications |

| Cost | Moderate cost, typically around $34.32 for the DC-latching model | Slightly lower cost, usually priced around $30 | Generally competitive, with prices ranging from $25 to $35 |

| Ease of Implementation | User-friendly installation; no tools required | Easy installation; also tool-free, but slightly more complex wiring | Simple installation, but some models require additional setup |

| Maintenance | Minimal maintenance required; captive plunger simplifies servicing | Requires occasional checks; reliable but less user-friendly than Hunter | Regular maintenance may be needed; some parts can be harder to access |

| Best Use Case | Ideal for battery-operated systems and regions with varying voltage | Best for standard irrigation systems with Rain Bird products | Suitable for both residential and commercial applications, particularly where a range of valve types is needed |

Detailed Breakdown of Alternatives

Rain Bird Solenoid

Rain Bird solenoids are a popular choice among irrigation professionals due to their compatibility with a wide range of Rain Bird valves. They typically offer solid performance and ease of installation, making them a suitable option for those already invested in the Rain Bird ecosystem. The main advantage lies in their lower cost compared to Hunter solenoids, which can be appealing for budget-conscious buyers. However, while installation is straightforward, the wiring can be slightly more complex, which may require additional attention during setup.

Toro Solenoid

Toro solenoids provide reliable performance and are designed to work with various Toro valve models. They are generally priced competitively, making them an attractive option for buyers looking for value. Toro solenoids can be easy to install; however, some models may necessitate additional setup steps, which could complicate the installation process for less experienced users. Maintenance can be more demanding than with Hunter solenoids, as certain components may be less accessible for servicing. Nevertheless, Toro solenoids can serve well in both residential and commercial irrigation setups, offering versatility across different applications.

Conclusion: How to Choose the Right Solenoid for Your Needs

When deciding on an irrigation solenoid, B2B buyers must assess their specific operational requirements, budget constraints, and existing system compatibility. The Hunter irrigation valve solenoid stands out for its durability and ease of use, particularly in battery-operated systems. However, alternatives like Rain Bird and Toro solenoids offer valuable options that may align better with specific operational contexts or budgetary needs. By carefully weighing the performance, cost, maintenance demands, and best use cases of each option, buyers can make informed decisions that optimize their irrigation systems for efficiency and effectiveness.

Essential Technical Properties and Trade Terminology for hunter irrigation valve solenoid

What Are the Essential Technical Properties of Hunter Irrigation Valve Solenoids?

Understanding the technical properties of Hunter irrigation valve solenoids is crucial for B2B buyers to ensure they select the right components for their irrigation systems. Here are some key specifications that define the performance and compatibility of these solenoids:

Voltage Specifications

– Definition: The operational voltage range for solenoids, such as 24 VAC for AC solenoids and 6-9 VDC for DC-latching solenoids.

– Importance: Knowing the voltage requirements helps buyers select compatible controllers and prevents electrical failures, ensuring efficient operation across various irrigation setups.Current Ratings

– Definition: The current draw of the solenoid, for example, 350 mA inrush and 190 mA holding for the 24 VAC solenoid.

– Importance: Understanding current ratings is essential for assessing energy consumption and ensuring that electrical circuits can handle the load without tripping breakers or causing damage.Coil Resistance

– Definition: The resistance of the solenoid coil, with a nominal value of 4.8 ohms for the DC-latching solenoid.

– Importance: This specification is critical for calculating the power consumption and ensuring compatibility with battery-operated systems. It also affects the solenoid’s responsiveness and efficiency.Maximum Operating Pressure

– Definition: The highest pressure at which the solenoid can operate safely, such as 220 PSI for AC solenoids.

– Importance: Buyers need to match the solenoid’s pressure rating with their irrigation system’s requirements to prevent malfunctions and leaks, which could lead to costly repairs and water wastage.Material Grade

– Definition: The quality and durability of materials used in the solenoid’s construction, typically heavy-duty plastic for encapsulated designs.

– Importance: High-grade materials ensure longevity and resistance to environmental factors, such as moisture and UV exposure, which is particularly important in diverse climates found in Africa, South America, and the Middle East.Wire Leads

– Definition: The specifications of the wire leads, often 18′ of 18 AWG UL-approved wire.

– Importance: Adequate wire length and gauge ensure easy installation and reliable electrical connections, which are vital for maintaining system integrity.

What Are the Common Trade Terms Related to Hunter Irrigation Valve Solenoids?

Familiarity with industry terminology helps streamline communication and transactions between buyers and suppliers. Here are several essential trade terms:

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is vital for buyers looking for reliable components that meet specific quality standards and ensure compatibility with existing systems.MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budget planning and inventory management, especially for larger projects or businesses looking to stock components.RFQ (Request for Quotation)

– Definition: A document issued when an organization wants to buy a product or service and requests a quote from suppliers.

– Importance: Utilizing RFQs helps buyers obtain competitive pricing and terms, ensuring they make informed purchasing decisions.Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Importance: Understanding Incoterms aids in managing shipping costs, responsibilities, and risks associated with international transactions, which is particularly relevant for buyers in diverse global markets.Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Importance: Knowing lead times is essential for project planning and ensuring that irrigation systems can be installed or maintained without unnecessary delays.Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and the terms of repair or replacement.

– Importance: Familiarity with warranty terms helps buyers assess the reliability of the solenoids and understand their rights in case of defects, which is crucial for long-term investment decisions.

By understanding these technical properties and trade terms, B2B buyers can make informed choices when selecting Hunter irrigation valve solenoids, ensuring their systems operate efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the hunter irrigation valve solenoid Sector

Market Overview & Key Trends in the Hunter Irrigation Valve Solenoid Sector

The global irrigation market is witnessing a paradigm shift driven by the need for water conservation and efficient resource management. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where water scarcity poses a significant challenge to agricultural productivity. As a result, international B2B buyers are increasingly prioritizing advanced irrigation solutions, including Hunter irrigation valve solenoids, which offer reliable performance and energy efficiency.

Emerging technologies such as IoT-enabled controllers are reshaping how irrigation systems operate, enabling real-time monitoring and automated adjustments. This tech-savvy approach not only enhances system efficiency but also promotes sustainability by reducing water waste. Furthermore, the rise of smart agriculture is influencing sourcing trends, as buyers seek products that integrate seamlessly with existing smart systems.

Key market dynamics include a growing emphasis on durability and compatibility. Hunter’s solenoids, for instance, are designed to work with a wide range of valves, making them a versatile choice for buyers looking to streamline their procurement process. The focus on low-voltage and battery-operated options also aligns with the increasing demand for energy-efficient solutions that are both cost-effective and environmentally friendly.

International buyers must remain vigilant about sourcing from manufacturers that adhere to quality standards and provide comprehensive support. As the market evolves, understanding these trends will be crucial for making informed purchasing decisions.

How is Sustainability and Ethical Sourcing Impacting the Hunter Irrigation Valve Solenoid Market?

Sustainability is now a cornerstone of procurement strategies, especially in sectors like irrigation where environmental impact is significant. The Hunter irrigation valve solenoid sector is no exception; buyers are increasingly seeking products that not only perform efficiently but also contribute to sustainable practices.

The environmental implications of sourcing materials for solenoids are profound. Buyers should prioritize suppliers that utilize recycled materials and have transparent supply chains. Certifications such as ISO 14001 for environmental management systems can serve as indicators of a company’s commitment to sustainability.

Moreover, the trend towards ‘green’ products is gaining traction. Hunter’s solenoids, designed with energy efficiency in mind, align with this movement. The use of low-power designs not only reduces energy consumption but also lowers operational costs for end-users. By choosing ethically sourced and environmentally friendly products, businesses can enhance their reputation and meet the growing demand from consumers for sustainable practices.

As the global market continues to shift towards sustainable solutions, B2B buyers must incorporate these considerations into their sourcing strategies to remain competitive and responsible.

What is the Brief Evolution and History of Hunter Irrigation Valve Solenoids?

The history of Hunter irrigation valve solenoids is rooted in the broader evolution of irrigation technology, which has advanced significantly over the past few decades. Founded in the 1980s, Hunter Industries recognized the need for reliable and efficient irrigation solutions, leading to the development of solenoids that would serve as the backbone of electric valve systems.

Initially, solenoids were primarily mechanical devices, but advancements in electrical engineering have transformed them into sophisticated components capable of operating under a variety of conditions. Hunter’s focus on research and development has resulted in the introduction of energy-efficient options such as DC-latching solenoids, which cater to the growing demand for battery-operated irrigation systems.

Today, Hunter solenoids are synonymous with durability and reliability, making them a preferred choice for international B2B buyers looking for high-performance irrigation solutions. As the industry continues to innovate, the evolution of Hunter irrigation valve solenoids reflects broader trends towards automation, sustainability, and enhanced efficiency in agricultural practices.

Frequently Asked Questions (FAQs) for B2B Buyers of hunter irrigation valve solenoid

How do I solve compatibility issues with Hunter irrigation valve solenoids?

To resolve compatibility issues, ensure that the solenoid you are selecting matches the valve type you are using. Hunter solenoids are designed to be compatible with all Hunter irrigation valves. For battery-operated controllers, use the DC-latching solenoid, while for standard AC systems, opt for the 24V AC solenoid. Always check the specifications for voltage and current requirements to ensure proper operation. If you encounter any issues, consult the product manuals or reach out to your local distributor for assistance.What is the best solenoid for battery-operated irrigation systems?

The best option for battery-operated irrigation systems is the Hunter 9V DC-latching solenoid. This solenoid is engineered to work seamlessly with all plastic Hunter valves and operates efficiently with low power consumption. It uses a quick pulse from the controller to open and close the valve, which enhances battery life. Ensure that the wiring is correctly connected to maintain optimal performance and longevity.What are the minimum order quantities (MOQs) for Hunter irrigation valve solenoids?

Minimum order quantities (MOQs) can vary by supplier and region. Typically, distributors may have MOQs ranging from 10 to 50 units for Hunter irrigation valve solenoids. It is advisable to check with your selected distributor for specific MOQs, as some may offer flexibility for new customers or bulk orders. Always confirm terms before placing your order to avoid unexpected constraints.How can I vet suppliers for Hunter irrigation valve solenoids?

When vetting suppliers, consider factors such as their reputation, years in business, and customer reviews. Verify their certifications and whether they are authorized distributors of Hunter products. Request references from previous clients, and evaluate their responsiveness to inquiries. Additionally, assess their logistics capabilities to ensure timely delivery. A reliable supplier will provide transparency regarding product availability, pricing, and warranty terms.What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers. Common terms include 30% upfront and 70% before shipping, or payment upon delivery. Some suppliers may also accept letters of credit or escrow services for larger transactions. Always negotiate terms that provide you with sufficient security while ensuring the supplier’s confidence in the transaction. Understanding currency exchange rates and potential transaction fees is also crucial for budgeting.How do I ensure quality assurance for Hunter irrigation valve solenoids?

To ensure quality assurance, request product specifications, certifications, and test results from your supplier. It is advisable to establish a quality control process, which may include inspections upon receipt of goods and periodic audits of the supplier’s manufacturing processes. Consider sourcing samples before placing a large order to verify that the solenoids meet your standards. Establishing a clear return policy for defective items is also essential.What logistics considerations should I keep in mind when importing solenoids?

Logistics considerations include shipping methods, customs regulations, and import duties that may apply to your region. Choose a reliable freight forwarder experienced in handling irrigation products to navigate these complexities. Ensure that your supplier provides the necessary documentation, such as invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, factor in lead times for production and shipping to align with your project timelines.Can I customize Hunter irrigation valve solenoids for specific applications?

Customization options may be limited for Hunter irrigation valve solenoids, as they are typically standardized products. However, you can inquire with your supplier about specific requirements or modifications that may be possible, such as custom wiring lengths or specific packaging options. For larger projects, some manufacturers might accommodate unique specifications, so it’s worth discussing your needs upfront to explore available options.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Hunter Irrigation Valve Solenoid Manufacturers & Suppliers List

1. Hunter Industries – Solenoids

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: Solenoids from Hunter Industries are heavy-duty components designed for reliable operation and long life performance. They are available in two types: AC and DC-Latching solenoids. Key models include the 458200 DC-latching solenoid and the 606800 AC solenoid, both compatible with all Hunter irrigation valves. Specifications for the 606800 AC solenoid include a minimum opening/operating voltage of …

2. Hunter – Sprinkler Valves

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: Hunter Sprinkler Valves provide superior flow control and are essential for irrigation systems. They accommodate various conditions including low to high flow, clean to dirty water, and low to high pressure. Key products include: 1. Hunter SRV Valves 2. Hunter PGV Valves 3. Hunter PGV Jar Top Valves 4. Hunter PGV-ASV Valves 5. Hunter ICV Valves 6. Hunter IBV Valves 7. Hunter Accu-Sync 8. Hunter Qu…

3. Hunter – 60-6800 Replacement Solenoid

Domain: cheapsprinklers.com

Registered: 2014 (11 years)

Introduction: {“name”: “Hunter – 60-6800 Replacement Solenoid for Hunter Valves”, “sku”: “606800”, “price”: “$7.00”, “original_price”: “$19.15”, “availability”: “Backordered”, “features”: [“Compatible with all Hunter irrigation valves: ASV, PGV, SRV, ICV, HPV, and PGV Jar Top Valves”, “Replacement Solenoid”, “Energy-efficient, low-power design”, “Engineered with ultra-durable, heavy-duty materials for maximum l…

4. Hunter – Sprinkler Valve Maintenance Guide

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Hunter Sprinkler Valve; installed 18 years ago; solenoid replacement; bleeder valve adjustment; common maintenance tasks; operates on 24VAC; no polarity in wiring; potential issues include manual override, debris, electrical issues, pressure issues, and controller settings.

5. Facebook – Solenoid Replacement for Irrigation Systems

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: solenoid replacement for irrigation and sprinkler system

6. Hunter – Replacement Solenoid for Valves

Domain: irrigationdepot.ca

Registered: 2007 (18 years)

Introduction: {“Replacement Solenoid for Hunter Valves”:{“SKU”:”HV-SOLENOID”,”Description”:”Hunter Solenoid Assembly 24VAC – used to replace all solenoids on Hunter valves. Fits all Hunter valve models: ASV, ICV, HPV, PGV, SRV valves.”,”Price”:{“5+ units”:”21.55$ each”,”10+ units”:”19.16$ each”}},”Hunter PGV-100G Valves”:{“SKU”:”HV-PGV-100G”,”Description”:”1” Plastic globe valve (Female inlet/outlet)”,”Price”:{…

Strategic Sourcing Conclusion and Outlook for hunter irrigation valve solenoid

What are the Key Benefits of Strategic Sourcing for Hunter Irrigation Valve Solenoids?

In conclusion, strategic sourcing of Hunter irrigation valve solenoids is essential for international B2B buyers seeking reliability, efficiency, and long-term value. The heavy-duty construction of Hunter solenoids, designed for both AC and DC operations, ensures dependable performance across various irrigation systems. Their compatibility with all Hunter valves simplifies inventory management and reduces operational complexities, making them a preferred choice for diverse applications.

Investing in high-quality solenoids not only enhances system performance but also minimizes maintenance costs, a critical consideration for buyers in regions like Africa, South America, the Middle East, and Europe. As irrigation demands continue to evolve, securing a reliable supply of these solenoids will be paramount for sustaining agricultural productivity.

Looking ahead, international buyers are encouraged to establish robust partnerships with trusted distributors and manufacturers to streamline procurement processes. By prioritizing strategic sourcing, businesses can ensure they are equipped with the best products to meet the growing challenges of efficient irrigation. Embrace the future of irrigation solutions with Hunter’s innovative technology and strengthen your competitive edge in the market.