Introduction: Navigating the Global Market for irrigation solenoid valve repair

The global market for irrigation solenoid valve repair presents a unique set of challenges for B2B buyers seeking reliable and efficient solutions. One of the most pressing issues is sourcing quality repair components that not only meet regional standards but also ensure longevity and performance under diverse environmental conditions. This guide offers a comprehensive overview of irrigation solenoid valve repair, detailing various types of valves, their applications, and the critical aspects of supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Brazil—will find valuable insights tailored to their specific needs. From understanding the intricacies of valve components to evaluating repair costs and potential suppliers, this guide empowers decision-makers to make informed choices that enhance operational efficiency and reduce downtime.

By addressing key considerations such as material quality, compatibility with existing systems, and maintenance practices, this resource aims to streamline the procurement process. Armed with this knowledge, businesses can confidently navigate the complexities of the irrigation solenoid valve repair market, ensuring they select the best solutions that align with their operational goals and regional requirements.

Understanding irrigation solenoid valve repair Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Solenoid Repair | Disassembly, cleaning, and replacing damaged parts | Agriculture, landscaping, irrigation | Pros: Cost-effective; Cons: Time-consuming, requires skilled labor. |

| Electrical Wire Repair | Soldering or splicing severed wires | Large-scale irrigation systems | Pros: Quick fix; Cons: Risk of future failure if not done correctly. |

| Diaphragm Replacement | Focus on replacing worn or damaged diaphragms | Commercial irrigation setups | Pros: Improved efficiency; Cons: Requires specific parts, may involve downtime. |

| Solenoid Coil Replacement | Replacement of the entire solenoid coil assembly | Industrial irrigation applications | Pros: Simple and effective; Cons: Higher upfront costs compared to repairs. |

| Custom Valve Solutions | Tailored repairs or modifications for specific needs | Specialized agricultural operations | Pros: Optimized performance; Cons: Potentially higher costs and longer lead times. |

What Are the Key Characteristics of Standard Solenoid Repair?

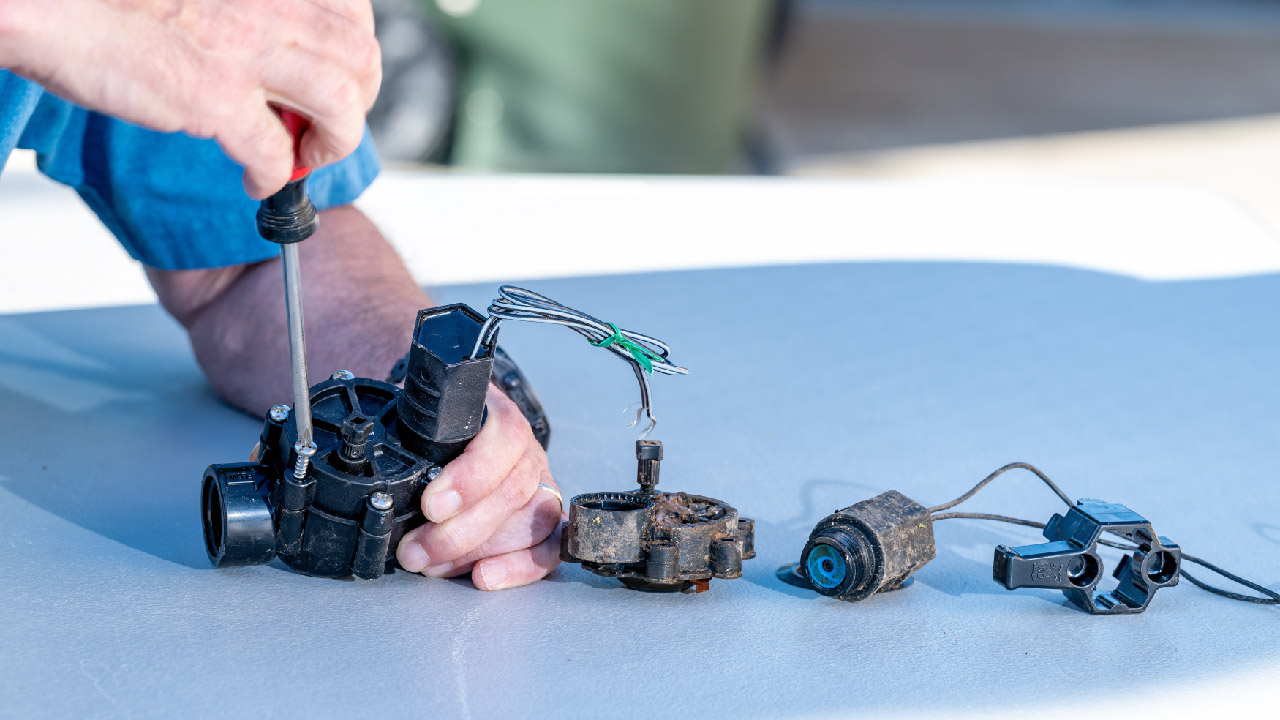

Standard solenoid repair involves disassembling the valve, cleaning internal components, and replacing any damaged parts such as diaphragms or gaskets. This method is particularly suitable for routine maintenance and can be performed on various valve models. B2B buyers should consider the labor skill required and the time investment, as these repairs can be intricate. While this approach is cost-effective, it may not be ideal for high-volume operations where speed is critical.

Why Is Electrical Wire Repair Important for Solenoid Valves?

Electrical wire repair addresses issues with severed or damaged wiring that can prevent solenoid valves from functioning correctly. This type of repair is essential for large-scale irrigation systems where downtime can lead to significant losses. B2B buyers should weigh the benefits of a quick fix against the potential for future issues if the repair is not done properly. Proper sealing and anchoring of the wire are crucial to ensure longevity and reliability.

When Should You Consider Diaphragm Replacement?

Diaphragm replacement is necessary when the rubber component becomes worn or damaged, affecting the valve’s ability to open and close effectively. This type of repair is common in commercial irrigation setups where efficiency is paramount. B2B buyers should assess the availability of specific diaphragm parts and consider the downtime associated with this repair. While it can lead to improved valve performance, it also requires careful handling to avoid further damage during replacement.

What Are the Benefits of Solenoid Coil Replacement?

Solenoid coil replacement involves swapping out the entire solenoid assembly when repairs are no longer viable. This method is straightforward and particularly beneficial for industrial irrigation applications where reliability is critical. B2B buyers should consider the higher upfront costs associated with coil replacement but recognize that it can lead to longer-lasting solutions. Ensuring compatibility with existing systems is essential for a seamless transition.

How Can Custom Valve Solutions Enhance Performance?

Custom valve solutions provide tailored repairs or modifications to meet specific operational needs. This approach is ideal for specialized agricultural operations where standard repairs may not suffice. B2B buyers should evaluate the potential for optimized performance against the higher costs and longer lead times associated with custom solutions. Collaborating with experienced suppliers can ensure that the customizations effectively address unique challenges in irrigation systems.

Key Industrial Applications of irrigation solenoid valve repair

| Industry/Sector | Specific Application of irrigation solenoid valve repair | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Repairing solenoid valves in large-scale irrigation systems | Enhances water efficiency and crop yield, reducing operational costs | Availability of replacement parts and skilled technicians |

| Landscaping | Maintenance of solenoid valves in commercial landscaping projects | Ensures consistent water supply, improving plant health and aesthetics | Local service providers with expertise in valve types |

| Municipal Water Supply | Repairing valves in public irrigation systems for parks and gardens | Maintains public spaces and reduces water wastage | Compliance with local regulations and standards |

| Golf Courses | Servicing solenoid valves in irrigation systems for golf course upkeep | Ensures optimal turf conditions, enhancing playability and aesthetics | Access to specialized components and timely service |

| Industrial Facilities | Repairing solenoid valves in cooling water systems for industrial plants | Prevents downtime and maintains operational efficiency | Compatibility with existing systems and reliability of repairs |

How Does Irrigation Solenoid Valve Repair Benefit the Agriculture Sector?

In agriculture, irrigation solenoid valve repair is crucial for maintaining efficient water distribution systems across vast fields. When valves malfunction, it can lead to overwatering or underwatering, adversely affecting crop yields. By ensuring that solenoid valves are operational, farmers can optimize water usage, which is especially vital in regions prone to drought, such as parts of Africa and the Middle East. Buyers in this sector should prioritize sourcing durable components and skilled technicians familiar with local agricultural practices and conditions.

What Role Does Solenoid Valve Repair Play in Landscaping Projects?

In commercial landscaping, the reliability of irrigation systems is paramount for maintaining the health of plants and aesthetic appeal of outdoor spaces. Regular repair and maintenance of solenoid valves can prevent leaks and ensure a consistent water supply. This is particularly relevant in regions like South America, where landscaping is often exposed to harsh weather conditions. Buyers should seek local service providers who understand the specific valve requirements for different landscaping projects to ensure effective and timely repairs.

How Can Municipal Water Supply Systems Benefit from Solenoid Valve Repair?

Municipal water supply systems rely on well-functioning irrigation solenoid valves to maintain public parks and gardens. Repairing these valves ensures that public spaces remain vibrant and well-watered, while also minimizing water wastage. In Europe, where sustainability is a growing concern, municipalities must prioritize sourcing parts that comply with local regulations. Additionally, having access to reliable repair services can significantly enhance the efficiency of public irrigation systems.

Why is Solenoid Valve Maintenance Important for Golf Courses?

Golf courses depend on meticulously maintained irrigation systems to keep their greens in optimal condition. Regular repair of solenoid valves is essential to prevent issues like uneven watering, which can lead to poor playing conditions. Golf course managers, especially in regions like Brazil where high humidity can affect equipment, should focus on sourcing specialized components and ensuring quick access to repair services to minimize downtime and maintain course quality.

How Do Industrial Facilities Utilize Solenoid Valve Repair?

In industrial settings, solenoid valves often play a critical role in managing cooling water systems. Repairing these valves prevents operational disruptions that can lead to costly downtime. Industries in the Middle East and Africa, where water management is crucial for cooling processes, should prioritize sourcing compatible repair parts and reliable technicians. Ensuring that these systems are maintained not only supports operational efficiency but also contributes to overall sustainability efforts in resource management.

3 Common User Pain Points for ‘irrigation solenoid valve repair’ & Their Solutions

Scenario 1: Inconsistent Water Flow Due to Clogged Valves

The Problem:

B2B buyers, particularly those managing large agricultural operations or municipal irrigation systems, often encounter the issue of inconsistent water flow caused by clogged irrigation solenoid valves. These clogs can be due to debris, sediment, or organic matter that accumulates over time. This situation not only disrupts the irrigation schedule but also leads to uneven crop watering, which can ultimately affect yield and quality. Buyers may feel frustrated as they struggle to maintain optimal irrigation efficiency while dealing with these unexpected interruptions.

The Solution:

To effectively address this issue, buyers should implement a routine maintenance schedule that includes regular inspections and cleaning of solenoid valves. When clogs are detected, disassemble the valve carefully, noting the arrangement of parts for reassembly. Clean all components, especially the ports and diaphragm, ensuring they are free from debris. After cleaning, it is advisable to flush the system with water to remove any residual sediment. Additionally, investing in quality filtration systems upstream can significantly reduce the amount of debris entering the valves, prolonging their lifespan and maintaining consistent water flow. By proactively managing maintenance, buyers can minimize operational disruptions and enhance overall irrigation efficiency.

Scenario 2: Electrical Failures Caused by Severed Wires

The Problem:

Another common challenge faced by B2B buyers is the failure of irrigation solenoid valves due to severed electrical wires, often caused by environmental factors or pests. For instance, in regions where animals are prevalent, chew-through wires can lead to solenoid malfunction, preventing the irrigation system from opening or closing as needed. This not only halts the irrigation process but can also lead to significant water waste or crop stress due to lack of timely watering, creating a ripple effect on agricultural productivity.

The Solution:

To mitigate this risk, buyers should ensure proper installation of solenoid wires, elevating them above ground level to reduce exposure to potential damage. If wires are severed, a careful inspection is necessary to determine if soldering or replacing the solenoid coil is the best option. For soldering, clean the wire ends and use a high-quality electrical soldering flux to ensure a secure connection. After completing the repair, protect the joint with a non-conductive epoxy to guard against moisture and corrosion. Furthermore, sourcing weather-resistant wire materials can greatly reduce the likelihood of future issues. By adopting these practices, buyers can enhance the durability of their systems and ensure reliable operation.

Scenario 3: Difficulty Sourcing Compatible Replacement Parts

The Problem:

B2B buyers, especially those operating in regions with limited access to irrigation supply chains, often face challenges in sourcing compatible replacement parts for solenoid valves. This can lead to extended downtime for irrigation systems, impacting agricultural operations and potentially resulting in financial losses. The frustration stems not only from the delay in repairs but also from the difficulty in identifying the right parts that are compatible with existing systems, especially for older or less common valve models.

The Solution:

To overcome this challenge, buyers should establish relationships with multiple suppliers, including local distributors and international manufacturers, to ensure a steady supply of compatible parts. Keeping a detailed inventory of existing valve models and their specifications will facilitate quicker identification of necessary replacement components. Additionally, leveraging online platforms and marketplaces that specialize in irrigation supplies can help buyers locate hard-to-find parts. It may also be beneficial to invest in universal solenoid valves that are compatible with various systems, reducing dependency on specific brands. By diversifying sourcing strategies and maintaining thorough documentation, buyers can enhance their operational resilience and minimize downtime.

Strategic Material Selection Guide for irrigation solenoid valve repair

When selecting materials for irrigation solenoid valve repair, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials used in the repair of solenoid valves: brass, PVC, stainless steel, and rubber. Each material presents unique characteristics that can significantly impact the performance and longevity of the valves.

What Are the Key Properties of Brass for Solenoid Valve Repair?

Brass is a popular choice for solenoid valve components due to its excellent corrosion resistance and mechanical strength. It typically has a temperature rating of up to 180°C (356°F) and can withstand moderate pressure levels. Brass components are often used in the valve body and fittings, where durability is critical.

Pros: Brass is highly durable, resistant to rust, and has good machinability, making it suitable for complex designs. It also provides a reliable seal, which is essential for preventing leaks.

Cons: However, brass can be more expensive than other materials, and its performance can degrade in highly acidic or alkaline environments. Additionally, brass components may require more complex manufacturing processes, which can increase lead times.

How Does PVC Compare for Solenoid Valve Repair?

PVC (polyvinyl chloride) is widely used in irrigation systems due to its lightweight nature and resistance to corrosion. PVC fittings and valves can typically handle temperatures up to 60°C (140°F) and pressures around 10 bar (145 psi).

Pros: The primary advantage of PVC is its low cost and ease of installation. It is also resistant to many chemicals, making it suitable for various media in irrigation systems.

Cons: The main limitation of PVC is its lower temperature and pressure ratings compared to metals. It can become brittle over time, especially when exposed to UV light, which may lead to failures in outdoor applications.

What Advantages Does Stainless Steel Offer for Solenoid Valve Repair?

Stainless steel is renowned for its strength and corrosion resistance, making it an excellent choice for harsh environments. It can withstand high temperatures (up to 300°C or 572°F) and pressures, making it suitable for demanding applications.

Pros: The key advantage of stainless steel is its longevity and ability to resist corrosion from various chemicals and environmental conditions. It is also highly durable and can handle mechanical stress without deforming.

Cons: On the downside, stainless steel is generally more expensive than brass or PVC. Its manufacturing processes can also be complex, leading to higher costs and longer lead times.

What Role Does Rubber Play in Solenoid Valve Repair?

Rubber is primarily used for seals and diaphragms within solenoid valves. It provides flexibility and a tight seal, essential for preventing leaks. Depending on the type, rubber can withstand temperatures ranging from -40°C to 100°C (-40°F to 212°F).

Pros: The primary benefit of rubber is its excellent sealing capabilities and resistance to wear and tear. It is also relatively inexpensive and easy to source.

Cons: However, rubber may degrade over time due to exposure to UV light and harsh chemicals. It also has limited temperature and pressure ratings compared to metals, which can affect its suitability in high-demand applications.

Summary Table of Material Selection for Solenoid Valve Repair

| Material | Typical Use Case for irrigation solenoid valve repair | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Valve bodies and fittings | Excellent corrosion resistance and durability | Higher cost and complex manufacturing | Medium |

| PVC | Low-pressure irrigation systems | Low cost and easy installation | Lower temperature/pressure ratings | Low |

| Stainless Steel | High-pressure and harsh environment applications | Long-lasting and highly corrosion-resistant | Higher cost and complex manufacturing | High |

| Rubber | Seals and diaphragms | Great sealing capabilities | Degrades under UV exposure and limited ratings | Low |

In conclusion, selecting the right material for irrigation solenoid valve repair is crucial for ensuring optimal performance and longevity. Each material offers distinct advantages and disadvantages that should be carefully weighed against the specific requirements of the application, particularly in diverse international markets. Understanding these factors will enable B2B buyers to make informed decisions that align with their operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation solenoid valve repair

What Are the Main Stages of Manufacturing for Irrigation Solenoid Valve Repair?

The manufacturing process for irrigation solenoid valve repair is critical in ensuring that the components function effectively and meet the operational demands of irrigation systems. This process typically includes several key stages: material preparation, forming, assembly, and finishing.

Material Preparation: The first stage involves selecting high-quality materials that can withstand the pressures and corrosive environments typical in irrigation applications. Common materials include brass, stainless steel, and durable plastics. Suppliers should ensure that all materials comply with relevant international standards, which can affect performance and longevity.

Forming: In this stage, components such as valve bodies, diaphragms, and solenoids are manufactured through processes like casting, machining, or injection molding. Precision is crucial here, as even minor deviations can lead to leaks or operational failures. Techniques such as CNC machining are often employed to ensure that components meet exact specifications.

Assembly: Once the individual parts are manufactured, they are assembled into complete solenoid valves. This process may involve manual assembly or automated systems, depending on the scale of production. Key considerations during assembly include the alignment of components, the application of gaskets or seals, and ensuring that the electrical connections are secure.

Finishing: The final stage includes surface treatments such as plating, painting, or coating to enhance corrosion resistance and aesthetics. This step is vital for ensuring the longevity of the valves, especially in harsh outdoor environments. Quality checks during this phase ensure that all parts are free from defects and that protective coatings meet industry standards.

How Do Quality Control Measures Ensure Reliability in Irrigation Solenoid Valve Repair?

Quality control (QC) is an essential aspect of the manufacturing process, particularly in industries where reliability is paramount. For irrigation solenoid valve repair, adherence to international and industry-specific standards is critical.

Relevant International Standards: Many manufacturers adhere to ISO 9001 standards, which focus on quality management systems. This certification indicates that the manufacturer has established a robust framework for quality assurance. Additionally, compliance with CE marking or API standards may be necessary depending on the market and application.

QC Checkpoints: Quality control involves several checkpoints throughout the manufacturing process, including:

– Incoming Quality Control (IQC): This step verifies that raw materials meet specified standards before they enter the production line.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations are identified and rectified in real time.

– Final Quality Control (FQC): After assembly, the finished products undergo rigorous testing to ensure they meet performance criteria.Common Testing Methods: Various testing methods are employed to ensure the functionality and reliability of irrigation solenoid valves. These may include:

– Leak Testing: Valves are pressurized to check for leaks, ensuring that they will perform correctly in the field.

– Electrical Testing: For solenoid components, electrical continuity tests confirm that wiring and solenoid function as intended.

– Durability Testing: Valves are subjected to simulated field conditions to assess their performance over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability and compliance with local standards.

Supplier Audits: Conducting regular audits of potential suppliers is one of the most effective ways to assess their quality control processes. During an audit, buyers can review documentation related to quality management systems, inspect manufacturing facilities, and observe QC practices in action.

Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, results from testing, and compliance with relevant standards. These documents serve as evidence of the supplier’s commitment to quality and can help buyers make informed decisions.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can focus on specific aspects of the manufacturing process and provide reports that highlight any areas of concern.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing irrigation solenoid valves from global suppliers. Understanding these nuances can help mitigate risks and ensure compliance with local regulations.

Regulatory Compliance: Different regions may have specific regulations governing irrigation equipment. Buyers should ensure that suppliers comply with local standards, such as CE marking in Europe or NSF certification for products used in potable water systems.

Cultural Considerations: Quality expectations and manufacturing practices can vary significantly across cultures. It is essential for buyers to communicate their quality expectations clearly and to understand the local manufacturing environment.

Language Barriers: Miscommunication can lead to misunderstandings regarding quality expectations. Buyers should ensure that all quality documentation is available in a language they understand or consider engaging translators or local representatives.

Logistics and Supply Chain Integrity: The integrity of the supply chain can impact quality. Buyers should assess suppliers’ logistics capabilities and their ability to maintain consistent quality throughout the transportation and storage processes.

By understanding the manufacturing processes and quality assurance measures associated with irrigation solenoid valve repair, B2B buyers can make informed decisions that enhance their supply chain reliability and operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation solenoid valve repair’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure services or components for irrigation solenoid valve repair. Proper sourcing is crucial for ensuring efficient repairs, minimizing downtime, and maintaining the integrity of irrigation systems. By following this checklist, businesses can streamline their procurement process and enhance their operational efficiency.

Step 1: Define Your Technical Specifications

Clearly outline the requirements for the solenoid valve repair.

Understanding the specific needs of your irrigation system is essential. Consider factors such as the valve type, size, and any unique features that may affect repair processes. This clarity will help you communicate effectively with suppliers and ensure compatibility with existing infrastructure.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers.

Look for companies that specialize in irrigation equipment and repairs, focusing on their experience and customer reviews. Utilize online resources, industry forums, and trade shows to gather information. This research will help you compile a shortlist of potential suppliers who can meet your needs.

Step 3: Verify Supplier Certifications

Ensure suppliers have the necessary certifications and qualifications.

Certifications can indicate a supplier’s adherence to industry standards and regulations, which is crucial for maintaining quality and safety. Request documentation for certifications such as ISO or relevant local certifications that are recognized in your region, ensuring that the supplier meets the necessary compliance requirements.

Step 4: Evaluate Repair Capabilities

Assess the supplier’s ability to handle specific repair needs.

Inquire about the types of repairs they specialize in, including solenoid replacements, wiring fixes, and diaphragm replacements. Understanding their capabilities will help you determine if they can address your unique challenges effectively, ensuring a swift and reliable repair process.

Step 5: Request Detailed Quotes

Obtain comprehensive quotes from shortlisted suppliers.

Ensure the quotes include itemized costs for labor, parts, and any additional fees. This transparency will allow you to compare different suppliers effectively and avoid unexpected expenses. Consider requesting multiple quotes to gauge the market rate and ensure competitive pricing.

Step 6: Check References and Case Studies

Request references and case studies from previous clients.

Engaging with past customers can provide insights into the supplier’s reliability and quality of work. Pay attention to their experiences regarding timeliness, customer service, and the effectiveness of repairs. This step will help you make an informed decision based on real-world feedback.

Step 7: Confirm After-Sales Support

Ensure the supplier offers adequate after-sales support.

Reliable after-sales support is essential for addressing any issues that may arise post-repair. Inquire about warranties, service agreements, and the availability of technical support. A supplier that stands by their work can significantly enhance your operational continuity and peace of mind.

By following this checklist, B2B buyers can efficiently navigate the procurement process for irrigation solenoid valve repair, ensuring they partner with qualified suppliers who can meet their specific needs.

Comprehensive Cost and Pricing Analysis for irrigation solenoid valve repair Sourcing

What Are the Key Cost Components in Irrigation Solenoid Valve Repair?

Understanding the cost structure for irrigation solenoid valve repair is crucial for B2B buyers seeking to manage expenses effectively. The primary cost components include:

Materials: The cost of replacement parts such as solenoids, diaphragms, gaskets, and any other necessary components. Quality and material specifications can greatly affect prices, with rubber and metal parts being more expensive than plastic counterparts.

Labor: Labor costs can vary significantly based on the complexity of the repair and the region. Skilled technicians may command higher wages, but their expertise can lead to more efficient repairs, ultimately reducing downtime.

Manufacturing Overhead: This encompasses the indirect costs associated with production, including facility maintenance, utilities, and administrative expenses. These costs are typically spread across all products and repairs, influencing overall pricing.

Tooling: Specialized tools for valve disassembly and assembly can incur costs. If a repair facility needs to invest in new tooling for unique valve types, these expenses will reflect in the service pricing.

Quality Control (QC): Ensuring that repairs meet industry standards requires a robust QC process. Costs associated with testing and certification can be substantial, especially for valves used in high-stakes agricultural applications.

Logistics: Transportation costs for parts and the repaired valves can add to the overall expense. This is particularly significant for international buyers who must consider import tariffs, shipping fees, and potential delays.

Margin: Suppliers often include a margin to cover their risks and ensure profitability. This can vary by supplier and region, influenced by competition and market demand.

How Do Price Influencers Affect the Cost of Valve Repairs?

Several factors can influence the pricing of irrigation solenoid valve repair services:

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced costs per unit due to economies of scale. Buyers should negotiate for volume discounts, especially if they require ongoing maintenance for multiple systems.

Specifications and Customization: Custom-designed valves or those with specific features may incur higher repair costs. Buyers should weigh the benefits of custom solutions against the potential for increased expenses.

Materials and Quality Certifications: The choice of materials directly impacts costs. Higher-quality components may have a higher upfront price but could lead to lower maintenance costs over time. Certifications ensuring compliance with international standards can also add to the price.

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their expertise and service quality, while newer entrants may offer lower prices to gain market share.

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. They dictate responsibilities for shipping, insurance, and tariffs, which can significantly affect the total cost.

What Tips Can Buyers Use to Optimize Their Costs?

B2B buyers can adopt several strategies to enhance cost-efficiency in sourcing irrigation solenoid valve repair services:

Negotiate Terms: Engage in discussions with suppliers about pricing structures, especially for bulk orders. Establishing long-term relationships can lead to better terms and discounts.

Evaluate Total Cost of Ownership (TCO): Consider not just the initial repair costs but also the long-term implications, such as reliability and maintenance frequency. Investing in higher-quality repairs may save money in the long run.

Understand Pricing Nuances for International Buyers: Be aware of regional pricing differences, currency fluctuations, and import duties when sourcing from different countries. This knowledge is particularly important for buyers in Africa, South America, the Middle East, and Europe.

Request Detailed Quotes: Ensure that quotes include a breakdown of all costs. This transparency allows for better comparison between suppliers and helps identify areas for potential savings.

Disclaimer on Indicative Prices

Prices in the irrigation solenoid valve repair market can vary widely based on the factors outlined above. It is advisable for buyers to conduct thorough market research and consult multiple suppliers to obtain the most accurate and competitive pricing for their specific needs.

Alternatives Analysis: Comparing irrigation solenoid valve repair With Other Solutions

In the realm of irrigation management, solenoid valve repair is a critical process for maintaining effective water distribution systems. However, businesses may explore alternative methods to address valve issues, each with its own set of advantages and disadvantages. This analysis will compare irrigation solenoid valve repair with two viable alternatives: complete valve replacement and the use of smart irrigation systems.

Comparison Table

| Comparison Aspect | Irrigation Solenoid Valve Repair | Complete Valve Replacement | Smart Irrigation Systems |

|---|---|---|---|

| Performance | Restores functionality if components are intact | New valves provide optimal performance | Adaptive watering based on real-time data |

| Cost | Low to moderate, depending on parts needed | Higher upfront cost for new valves | Varies widely; initial investment can be significant |

| Ease of Implementation | Requires technical skill and time | Straightforward installation | Requires setup and calibration; may need training |

| Maintenance | Moderate; regular inspections needed | Low, once installed | High; software updates and maintenance required |

| Best Use Case | Cost-effective for minor issues | Ideal for extensive damage or outdated systems | Best for optimizing water use and reducing waste |

What Are the Pros and Cons of Each Alternative?

Complete Valve Replacement

Replacing the entire solenoid valve is often the most effective solution for severe malfunctions. New valves eliminate the risk of recurring issues associated with older models, ensuring reliable operation. However, this option can be significantly more expensive than repair, particularly for businesses managing multiple irrigation systems. Additionally, installation may require skilled labor, leading to downtime while new parts are sourced and fitted. This method is best suited for situations where the existing valves are outdated or have sustained extensive damage.

Smart Irrigation Systems

Smart irrigation systems leverage technology to optimize water usage, often incorporating sensors, timers, and weather data. This solution can lead to substantial water savings and improved efficiency. However, the initial investment can be steep, especially for large-scale operations. Implementation can also be complex, requiring technical expertise for setup and ongoing maintenance. While these systems do not directly repair solenoid valves, they can reduce wear and tear on the irrigation infrastructure by ensuring that water is applied only when needed. This method is particularly beneficial for organizations looking to enhance sustainability and efficiency in their irrigation practices.

Conclusion: How Should a B2B Buyer Choose the Right Solution?

When selecting an irrigation solution, B2B buyers should evaluate their specific needs, budget constraints, and long-term operational goals. If the issue with a solenoid valve is minor and the infrastructure is otherwise sound, repair can be a cost-effective choice. For companies facing frequent failures or managing older systems, a complete valve replacement may be warranted. Conversely, businesses aiming for sustainability and efficiency may find that investing in smart irrigation systems aligns best with their objectives. Ultimately, the decision should consider both immediate needs and long-term benefits to ensure effective irrigation management.

Essential Technical Properties and Trade Terminology for irrigation solenoid valve repair

What Are the Key Technical Properties of Irrigation Solenoid Valves?

When considering irrigation solenoid valve repair, understanding the essential technical properties is crucial for ensuring efficient operation and longevity of the system. Here are several critical specifications to be aware of:

Material Grade:

– Most solenoid valves are constructed from materials such as PVC, brass, or stainless steel. The choice of material affects durability, resistance to corrosion, and overall performance in various environmental conditions. For instance, stainless steel is preferred in saline or acidic environments due to its corrosion resistance, while PVC is often used in less demanding applications. B2B buyers must consider material grade to ensure compatibility with their specific irrigation needs.Operating Pressure:

– This specification indicates the maximum pressure the valve can withstand during operation, typically measured in pounds per square inch (PSI). Different systems require valves designed for specific pressure ranges. Understanding the operating pressure is vital for preventing valve failure, which can lead to costly downtime and repairs.Flow Rate:

– Measured in gallons per minute (GPM) or liters per minute (LPM), the flow rate defines how much water can pass through the valve in a given time. Selecting a valve with the appropriate flow rate is essential to meet the irrigation requirements of various crops or landscapes. An incorrect flow rate can result in under-irrigation or over-irrigation, affecting crop yield and water usage efficiency.Voltage Rating:

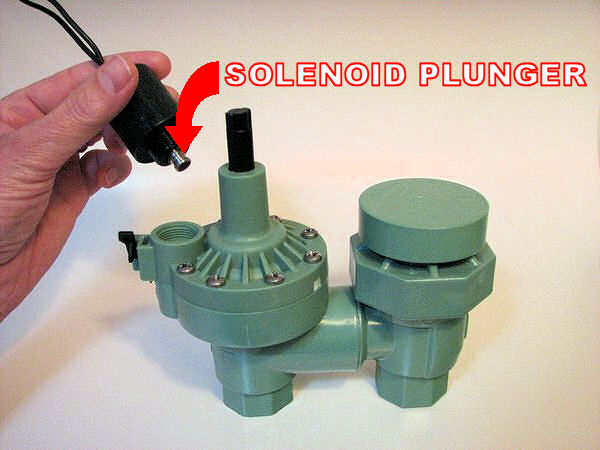

– Solenoid valves typically operate on specific voltage ratings, such as 24V AC or 12V DC. Ensuring the correct voltage rating is critical for the solenoid to function properly. Mismatched voltage can lead to solenoid failure or erratic operation, impacting the entire irrigation system’s reliability.Diaphragm Type:

– The diaphragm is a critical component that controls the flow of water through the valve. Different types of diaphragms (e.g., rubber, silicone) can affect the valve’s responsiveness and durability. Understanding the diaphragm type helps in selecting the right replacement parts and ensuring the valve can handle the specific chemicals or fertilizers in the irrigation system.Temperature Range:

– This property defines the maximum and minimum temperatures the valve can endure without failure. This specification is particularly important in regions with extreme temperatures, as valves that cannot withstand local conditions may degrade or fail prematurely.

What Are Common Trade Terms in Irrigation Solenoid Valve Repair?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some key terms relevant to irrigation solenoid valve repair:

OEM (Original Equipment Manufacturer):

– OEM refers to companies that produce parts or equipment that are sold under another brand name. In the context of irrigation solenoid valves, understanding OEM components is vital for ensuring compatibility and quality in repairs.MOQ (Minimum Order Quantity):

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps B2B buyers plan their purchases effectively, particularly for components like solenoid valves that may require bulk ordering for cost efficiency.RFQ (Request for Quotation):

– An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. In the context of solenoid valve repair, submitting an RFQ can help buyers obtain competitive pricing and understand delivery timelines.Incoterms:

– These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to navigate shipping, insurance, and delivery logistics effectively when sourcing solenoid valves from global suppliers.Lead Time:

– Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time is important for planning repairs and maintenance schedules, especially in agriculture where timing can significantly impact crop health.Warranty Period:

– This term defines the duration during which a product is guaranteed against defects or failures. Understanding the warranty period for solenoid valves can provide buyers with confidence in their purchase and insights into potential long-term costs associated with repairs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding irrigation solenoid valve repairs, ensuring the efficiency and reliability of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation solenoid valve repair Sector

What Are the Key Market Dynamics and Trends Impacting the Irrigation Solenoid Valve Repair Sector?

The global irrigation solenoid valve repair market is shaped by several interlinked dynamics, particularly relevant for B2B buyers in Africa, South America, the Middle East, and Europe. A primary driver is the increasing demand for efficient agricultural practices, where reliable irrigation systems are crucial for maximizing crop yields. As agriculture becomes more technology-driven, there is a growing reliance on automated systems, including solenoid valves. This shift is pushing businesses to seek out reliable repair services to ensure minimal downtime and optimal operation of their irrigation systems.

Emerging technologies such as IoT (Internet of Things) are also influencing the market. Smart irrigation systems equipped with sensors and automated valves allow for real-time monitoring and management, leading to a surge in demand for compatible repair services. B2B buyers should prioritize suppliers who offer advanced technical support and can integrate new technologies into existing systems. Moreover, the rise of e-commerce platforms is simplifying the sourcing process, allowing international buyers to access a broader range of products and services.

Another critical trend is the growing emphasis on localized sourcing. With supply chain disruptions becoming more common, businesses are increasingly favoring local service providers who can offer timely repairs and maintenance. This approach not only reduces lead times but also helps mitigate risks associated with international shipping. Buyers are encouraged to assess the regional capabilities of their suppliers to ensure responsive service and support.

How Is Sustainability Shaping Ethical Sourcing in Irrigation Solenoid Valve Repair?

Sustainability has become a pivotal consideration in the irrigation solenoid valve repair sector, influencing both sourcing practices and product offerings. The environmental impact of irrigation systems, particularly in water-scarce regions, has led to a heightened focus on sustainable practices. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to environmentally friendly operations, including responsible waste management and energy-efficient repairs.

Ethical supply chains are vital for fostering trust and transparency in business relationships. Buyers should prioritize suppliers who adhere to ethical sourcing guidelines, ensuring that materials used in repairs and replacements are sourced responsibly. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as benchmarks for evaluating supplier commitment to sustainability.

Furthermore, the use of “green” materials in repairs, such as biodegradable lubricants or recyclable components, is gaining traction. Buyers looking to enhance their sustainability credentials should inquire about suppliers’ practices in using eco-friendly materials and methods. This alignment not only aids in compliance with local regulations but also enhances brand reputation among environmentally conscious consumers.

How Has the Irrigation Solenoid Valve Repair Sector Evolved Over Time?

The irrigation solenoid valve repair sector has undergone significant evolution, shaped by advancements in technology and changing agricultural practices. Initially, repairs were largely manual, relying on basic tools and techniques. However, as irrigation technology has advanced, the complexity of solenoid valves has increased, necessitating more sophisticated repair methods.

With the introduction of automated and smart irrigation systems, the focus has shifted to integrating repairs with modern technologies. This transition has led to the development of specialized training programs and certifications for technicians, ensuring they possess the necessary skills to handle advanced systems. Additionally, the rise of digital platforms for sourcing repair services has streamlined access for B2B buyers, allowing for more efficient procurement processes.

Overall, the sector’s evolution reflects a broader trend towards modernization in agriculture, emphasizing the need for reliable, efficient, and sustainable irrigation solutions. B2B buyers should stay informed about these developments to make strategic decisions that enhance their operational efficiency and sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation solenoid valve repair

How do I solve a solenoid valve that won’t open?

If your solenoid valve fails to open, the issue often lies with the solenoid coil or wiring. Start by inspecting the wiring for any signs of damage or disconnection. If the wiring appears intact, test the solenoid coil for continuity using a multimeter. If it shows no continuity, the coil is likely defective and should be replaced. Additionally, check for debris inside the valve that might obstruct movement. Cleaning the valve and ensuring all components are functioning can also resolve the issue.What is the best way to clean an irrigation solenoid valve?

To effectively clean an irrigation solenoid valve, begin by disassembling the valve, noting the arrangement of parts. Remove the solenoid and inspect the plunger for smooth movement. Clean the valve body and lid, paying special attention to ports and the diaphragm. Ensure no debris is present that could block water flow. After cleaning, reassemble the valve, replacing any worn components. Flushing the valve with water after disassembly helps clear any residual dirt before reassembly.How do I choose a reliable supplier for irrigation solenoid valve repair parts?

Selecting a reliable supplier involves researching their reputation and customer reviews. Look for suppliers with extensive experience in irrigation systems and a solid history of customer service. Verify their certifications and quality assurance processes to ensure the parts meet international standards. Additionally, consider suppliers who offer customization options to meet specific needs. Establish clear communication to assess their responsiveness and willingness to support your requirements.What are the typical minimum order quantities (MOQ) for irrigation solenoid valve repair parts?

MOQs for irrigation solenoid valve repair parts can vary significantly among suppliers. Generally, local suppliers may have lower MOQs, while international suppliers might require larger quantities due to shipping costs and production efficiencies. When negotiating, inquire about flexibility in MOQs, especially if you are testing a new supplier or are a smaller business. Some suppliers may offer sample orders or tiered pricing based on order size.What payment terms should I expect when sourcing irrigation solenoid valve repairs internationally?

Payment terms for international sourcing can vary, but common practices include upfront payments, letters of credit, or payment upon delivery. Negotiate terms that align with your cash flow and risk management strategies. Consider using escrow services for larger transactions to ensure both parties fulfill their obligations. Always confirm the currency used and any additional fees that may apply, such as transaction fees or international transfer charges.How can I ensure quality assurance (QA) for irrigation solenoid valve repair parts?

To ensure quality assurance, request detailed specifications and certifications from your supplier. Implement a robust inspection process upon receiving parts, including visual inspections and functional tests. Collaborate with suppliers who offer warranties or guarantees on their products, as this reflects their confidence in quality. Establish a clear communication channel for addressing any quality concerns and consider conducting periodic audits of your supplier’s manufacturing processes.What logistics considerations should I keep in mind when sourcing internationally?

Logistics are critical when sourcing internationally, particularly in terms of shipping times, customs regulations, and potential tariffs. Choose suppliers who have experience with international shipping and can provide reliable shipping options. Understand the customs requirements for your region and ensure all documentation is in order to avoid delays. It’s also wise to account for potential shipping disruptions and have contingency plans in place to minimize impact on your operations.What should I do if I encounter issues after purchasing solenoid valve repair parts?

If you experience issues after purchasing, first consult the supplier’s warranty or return policy. Document the problems with photos and detailed descriptions, and communicate promptly with the supplier. Most reputable suppliers will assist with troubleshooting or offer replacements if the products are faulty. Establishing a good relationship with your supplier can facilitate smoother resolutions in case of future issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Irrigation Solenoid Valve Repair Manufacturers & Suppliers List

1. Irrigation Tutorials – Solenoid Valve

Domain: irrigationtutorials.com

Registered: 2001 (24 years)

Introduction: Product: Irrigation Solenoid Valve (also known as electric valve or automatic sprinkler valve). Key Features: 1. Common failure reasons: stuck debris (sand, twigs, insects, snails) preventing closure; bad solenoid or wiring preventing opening. 2. Maintenance involves disassembly, cleaning, and inspection. 3. Anti-siphon type valve commonly used in home sprinkler systems. 4. Solenoid removal: unscr…

2. Irritrol – 2400 Solenoid Replacement

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Irritrol 2400 solenoid; replacement solenoid available for less than $15; installation requires no special tools; solenoid twists off for easy replacement; available at local sprinkler supply stores or Home Depot.

3. JustAnswer – Irrigation System Solenoid Solutions

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Irrigation system valve issues related to solenoid problems. A broken or corroded solenoid wire can cause the valve to remain open continuously by preventing the solenoid from receiving the off signal. The solenoid is an electromechanical component that regulates water flow through the valve. Regular inspection of wiring for breaks, corrosion, or loose connections is recommended. Use a multimeter …

4. Irrigation Valve Replacement – Key Strategies

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: This article covers the strategies and pitfalls of how to replace an irrigation valve solenoid. It discusses two methods for replacing a valve: replacing just the top (guts) or the entire valve unit. Key components that may need replacement include the diaphragm, solenoid, and ports. It is recommended to use the same brand and model for replacement parts. The article also explains the difference b…

5. Horizon – Irrigation Valve Troubleshooting

Domain: horizononline.com

Registered: 1997 (28 years)

Introduction: Horizon offers troubleshooting guidance for irrigation valves, including steps for electrical and mechanical checks. Key products mentioned include the Checkmate 3, Checker Plus, and Checker Jr. for solenoid operation verification. Replacement parts and valve repair kits are available at Horizon stores.

Strategic Sourcing Conclusion and Outlook for irrigation solenoid valve repair

How Can Strategic Sourcing Enhance Your Irrigation Solenoid Valve Repair Operations?

In conclusion, strategic sourcing plays a pivotal role in optimizing irrigation solenoid valve repair processes. By prioritizing high-quality components and reliable suppliers, businesses can minimize downtime and enhance operational efficiency. Key takeaways include the importance of understanding the specific needs of your irrigation systems, investing in quality repairs over quick fixes, and fostering strong relationships with suppliers who understand the unique challenges faced in diverse markets.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of the irrigation sector, embracing a strategic sourcing mindset will empower them to make informed decisions. This approach not only ensures the longevity and reliability of solenoid valves but also contributes to sustainable agricultural practices.

Looking ahead, we encourage you to evaluate your sourcing strategies critically. Invest in partnerships that align with your operational goals and market demands. By doing so, you can enhance the resilience of your irrigation systems and drive growth in your business. Take the next step—reach out to potential suppliers today and explore how they can support your irrigation solenoid valve repair needs effectively.