Introduction: Navigating the Global Market for irrigation valve locator

In the ever-evolving landscape of agricultural technology, sourcing an effective irrigation valve locator can present significant challenges for B2B buyers across diverse international markets. A malfunctioning irrigation system can lead to substantial water waste and increased operational costs, underscoring the importance of accurate valve location for maintenance and troubleshooting. This guide provides a comprehensive exploration of irrigation valve locators, detailing various types, applications, and the critical factors to consider when sourcing these essential tools.

From understanding the different technologies available—such as wire and valve locators—to identifying key suppliers and evaluating costs, this resource is designed to empower international buyers from regions including Africa, South America, the Middle East, and Europe, particularly Germany and Saudi Arabia. By leveraging this guide, businesses can streamline their purchasing processes, ensuring they invest in the most suitable and cost-effective solutions for their irrigation systems.

Moreover, we emphasize the importance of supplier vetting, helping you navigate potential partnerships with confidence. With actionable insights and expert recommendations, you will be equipped to make informed decisions that enhance operational efficiency and sustainability in your agricultural practices.

Understanding irrigation valve locator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wire and Valve Locator | Utilizes a transmitter and receiver to trace wires; detects valve solenoids and breaks. | Landscape maintenance, irrigation system installation, troubleshooting. | Pros: Accurate, efficient, reduces damage risk. Cons: Requires training for effective use. |

| Ground Fault Locator | Identifies electrical faults in irrigation systems; useful for diagnosing issues with wiring. | Electrical maintenance, troubleshooting for commercial irrigation systems. | Pros: Prevents costly repairs, enhances safety. Cons: Limited to electrical issues only. |

| Solenoid Activator and Locator | Combines solenoid activation with valve location capabilities; ideal for immediate repairs. | Emergency repairs, quick diagnostics in large irrigation systems. | Pros: Quick response time, dual functionality. Cons: Higher cost, may not be necessary for all businesses. |

| Passive Wire Tracer | Operates without a power source; ideal for locating buried wires and valves. | Residential and small commercial irrigation systems. | Pros: Cost-effective, easy to use. Cons: Less precise than active locators, may require manual effort. |

| Rental Valve Locator | Available as a rental option; typically includes various locator tools for short-term use. | Contractors, maintenance companies needing temporary solutions. | Pros: Cost-effective for short-term needs, access to advanced tools. Cons: Limited availability, potential for damage fees. |

What Are the Key Characteristics of Wire and Valve Locators?

Wire and valve locators are essential tools for professionals in irrigation systems, providing accurate tracing of wires and detecting solenoids. They are widely used in landscape maintenance and installation, enabling technicians to troubleshoot issues efficiently. When purchasing, businesses should consider the accuracy of the device, ease of use, and the training required to operate it effectively. A well-trained team can significantly reduce the time spent on repairs and maintenance.

How Do Ground Fault Locators Enhance Safety in Irrigation Systems?

Ground fault locators are specialized tools designed to identify electrical faults, making them crucial for diagnosing wiring issues in irrigation systems. These locators are particularly beneficial in commercial applications where safety and reliability are paramount. When evaluating a ground fault locator, businesses should focus on its sensitivity, ease of use, and the ability to prevent costly repairs. Investing in this technology not only enhances safety but also prolongs the lifespan of electrical components.

Why Choose a Solenoid Activator and Locator for Immediate Repairs?

A solenoid activator and locator is a versatile tool that allows for the quick activation of solenoids while simultaneously locating valves. This dual functionality is invaluable in emergency situations where rapid diagnosis and repair are required. Companies should consider the cost versus the potential downtime when deciding on this tool. While it may come at a higher price point, the ability to resolve issues swiftly can lead to significant savings in labor costs and system efficiency.

What Advantages Do Passive Wire Tracers Offer for Small Systems?

Passive wire tracers are ideal for smaller irrigation systems, allowing users to locate buried wires and valves without the need for a power source. They are particularly cost-effective and straightforward, making them accessible for residential and small commercial applications. However, businesses should be aware that while they are easy to use, they may not provide the precision of more advanced tools. For companies with limited budgets, passive wire tracers can be an excellent first step into the world of irrigation diagnostics.

How Can Renting Valve Locators Benefit Contractors?

Renting valve locators offers contractors flexibility and cost savings, particularly for short-term projects or specialized tasks. This option allows access to advanced tools without the long-term investment, making it ideal for maintenance companies that need specific locators occasionally. When considering rentals, businesses should evaluate the terms, availability, and potential additional fees for damages. Renting can be a strategic choice for companies looking to manage costs while still providing high-quality service.

Key Industrial Applications of irrigation valve locator

| Industry/Sector | Specific Application of irrigation valve locator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Locating valves in extensive irrigation systems | Minimizes downtime and repair costs by quickly identifying issues | Ensure compatibility with existing systems and local support |

| Landscaping and Golf Courses | Maintenance of irrigation systems for turf and ornamental plants | Enhances the health and aesthetics of landscapes and golf courses | Look for durable, weather-resistant equipment |

| Municipal Water Management | Identifying and repairing valves in urban irrigation networks | Reduces water wastage and improves system efficiency | Consider tools that comply with local regulations |

| Construction and Development | Ensuring proper installation of irrigation systems in new projects | Prevents future complications and costly repairs | Assess rental options for short-term projects |

| Environmental Management | Monitoring and maintaining irrigation in conservation areas | Supports sustainable practices and resource management | Evaluate tools for precision and depth capabilities |

How is an irrigation valve locator used in agriculture, and what problems does it solve?

In agriculture, irrigation valve locators are crucial for managing extensive irrigation systems. Farmers often face challenges in locating buried valves, especially in large fields where visibility is limited. By using a valve locator, agricultural businesses can quickly identify malfunctioning valves, reducing downtime and repair costs. For international buyers in regions like Africa and South America, sourcing locators that are compatible with local irrigation systems and have robust support services is essential to ensure effective use.

Why are irrigation valve locators important for landscaping and golf courses?

In landscaping and golf course management, maintaining healthy turf and ornamental plants is vital. Irrigation valve locators help identify hidden valves that may be obstructed by soil or vegetation, facilitating timely repairs and maintenance. This capability enhances the health and aesthetics of the landscape, ultimately leading to higher customer satisfaction. Buyers from Europe and the Middle East should consider durable, weather-resistant equipment that can withstand various environmental conditions while ensuring ease of use.

How do municipal water management systems benefit from using irrigation valve locators?

Municipal water management systems utilize irrigation valve locators to identify and repair valves in urban irrigation networks. This technology reduces water wastage and enhances the efficiency of water distribution, which is increasingly important in regions facing water scarcity. For municipalities in regions like Saudi Arabia and Germany, it’s crucial to source tools that comply with local regulations and standards to ensure effective integration into existing systems.

What role do irrigation valve locators play in construction and development projects?

In construction and development, irrigation valve locators are essential for ensuring proper installation of irrigation systems in new projects. By accurately locating existing valves, construction teams can avoid damaging these components during excavation or landscaping. This proactive approach prevents future complications and costly repairs, making it an invaluable tool for contractors. Buyers should assess rental options for short-term projects, especially in regions with fluctuating project timelines.

How do irrigation valve locators support environmental management efforts?

Irrigation valve locators are vital in environmental management, particularly for monitoring and maintaining irrigation in conservation areas. These tools enable organizations to quickly address issues with irrigation systems, supporting sustainable practices and effective resource management. For international buyers focused on environmental sustainability, evaluating tools for precision and depth capabilities is critical to ensure they meet the specific demands of conservation efforts.

3 Common User Pain Points for ‘irrigation valve locator’ & Their Solutions

Scenario 1: Difficulty Locating Hidden Irrigation Valves

The Problem: B2B buyers often encounter significant challenges when trying to locate hidden irrigation valves within their landscape. These valves, essential for the operation of irrigation systems, are frequently obscured by overgrown grass, mulch, or even buried directly in the soil. This can lead to costly downtime during irrigation maintenance, as teams may spend hours or even days searching for malfunctioning valves, especially in extensive agricultural or commercial properties. Such inefficiencies not only increase labor costs but can also disrupt irrigation schedules, affecting crop health or landscape aesthetics.

The Solution: To effectively address this pain point, investing in a high-quality irrigation valve locator is crucial. These devices, like the Tempo Wire and Valve Locator, are designed specifically for tracing the wire paths that connect to the valves. When using a valve locator, start by marking the area where you suspect the valves are located based on previous installations or blueprints. Use the locator’s transmitter to send a signal along the wire, and follow the audible or visual indicators to trace the path. This method minimizes soil disruption and allows for a precise pinpointing of the valve locations. Additionally, training maintenance staff in the proper use of these devices can significantly reduce the time spent locating valves, ultimately leading to more efficient system upkeep and lower operational costs.

Scenario 2: Inconsistent Valve Performance Due to Electrical Issues

The Problem: Another common issue faced by B2B buyers is inconsistent valve performance, often caused by electrical problems such as broken wires or faulty solenoids. This inconsistency can lead to uneven watering, affecting crop yields and increasing water waste. In regions where water resources are scarce, like parts of Africa and the Middle East, such inefficiencies can have dire economic and environmental consequences.

The Solution: A proactive approach involves using a wire locator in conjunction with routine maintenance checks. When you suspect electrical issues, first inspect the irrigation system for visible signs of damage. Then, utilize the wire locator to identify breaks or nicks in the wiring that could be causing the problem. This tool can help trace the entire wiring path, allowing maintenance teams to quickly identify and address issues without extensive digging or disruption. Furthermore, sourcing high-quality replacement parts and establishing a regular maintenance schedule will ensure that the irrigation system operates efficiently. By addressing electrical problems promptly and systematically, businesses can maintain optimal irrigation performance and conserve valuable water resources.

Scenario 3: High Rental Costs for Valve Locating Equipment

The Problem: For many B2B buyers, particularly small to mid-sized enterprises in developing markets, the high cost of purchasing irrigation valve locators can be prohibitive. This financial barrier often forces companies to either forgo acquiring the necessary tools or rely on expensive third-party services for maintenance, which can diminish their profit margins. Consequently, businesses may struggle to maintain their irrigation systems effectively, resulting in reduced productivity.

The Solution: To mitigate these costs, consider renting valve locating equipment instead of purchasing it outright. Many suppliers offer rental programs that allow businesses to access high-quality tools like the Tempo Wire and Valve Locator at a fraction of the purchase price. For instance, a two-day rental can cost as little as $55, making it a cost-effective solution for companies needing the equipment only occasionally. When planning maintenance work, schedule the rental in advance to ensure availability. Additionally, establish relationships with local suppliers or tool rental companies to negotiate better rates or bundled services. By leveraging rental options, businesses can maintain their irrigation systems without incurring significant capital expenditures, ultimately enhancing their operational efficiency and bottom line.

Strategic Material Selection Guide for irrigation valve locator

What Are the Key Materials Used in Irrigation Valve Locators?

When selecting materials for irrigation valve locators, it is essential to consider their properties, advantages, disadvantages, and the specific needs of international markets. The most commonly used materials include plastic, metal, rubber, and composite materials. Each material offers unique characteristics that can impact performance and suitability for various applications.

How Does Plastic Compare for Use in Irrigation Valve Locators?

Plastic is a prevalent choice for irrigation valve locators due to its lightweight nature and corrosion resistance. Common types include PVC and polyethylene, which can withstand moderate temperature and pressure conditions.

Pros: Plastic is generally cost-effective and easy to manufacture, making it suitable for mass production. Its resistance to corrosion ensures longevity, particularly in environments with high humidity or exposure to chemicals.

Cons: While plastic is durable, it may not perform well under extreme temperatures or high-pressure conditions. Additionally, its structural integrity can be compromised over time due to UV exposure, making it less ideal for long-term outdoor applications.

Impact on Application: Plastic locators are compatible with most irrigation systems but may not be suitable for areas with extreme weather conditions.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, particularly regarding UV resistance and temperature ratings.

What Role Does Metal Play in Irrigation Valve Locators?

Metal materials, such as stainless steel and aluminum, are often used for their strength and durability. They can withstand higher pressures and temperatures compared to plastic.

Pros: Metals provide excellent longevity and can resist mechanical wear and tear. Stainless steel, in particular, offers superior corrosion resistance, making it suitable for harsh environments.

Cons: The primary drawback is the higher cost associated with metal components, along with increased manufacturing complexity. Metal locators can also be heavier, which may affect portability.

Impact on Application: Metal locators are ideal for heavy-duty applications, such as municipal irrigation systems or golf courses, where durability is crucial.

Considerations for International Buyers: Compliance with local standards for metal components is vital. Buyers in Europe, for instance, may prefer products meeting EU regulations for materials used in irrigation systems.

How Important Are Rubber Components in Irrigation Valve Locators?

Rubber is often used in seals and gaskets within irrigation valve locators to prevent leaks and ensure proper functioning.

Pros: Rubber is highly flexible and provides excellent sealing capabilities, which is crucial for maintaining system integrity. It also offers good resistance to temperature fluctuations.

Cons: Over time, rubber can degrade due to exposure to UV light and ozone, leading to potential failures in sealing. It may also require more frequent replacement compared to other materials.

Impact on Application: Rubber components are essential for ensuring that locators function correctly, particularly in systems where water pressure is variable.

Considerations for International Buyers: Buyers should look for rubber materials that comply with international standards for durability, especially in regions with intense sunlight, such as Africa and the Middle East.

What Are the Advantages of Composite Materials in Irrigation Valve Locators?

Composite materials combine various elements, such as plastics reinforced with fiberglass, to enhance performance characteristics.

Pros: Composites can offer superior strength-to-weight ratios and excellent resistance to environmental factors. They can be tailored for specific applications, making them versatile.

Cons: The manufacturing process for composites can be more complex and costly, which may lead to higher prices for end products. Additionally, not all composites are recyclable, raising sustainability concerns.

Impact on Application: Composites are suitable for high-performance applications where weight and strength are critical, such as in portable valve locators.

Considerations for International Buyers: Buyers should ensure that composite materials meet local environmental regulations and standards for performance.

Summary Table of Material Selection for Irrigation Valve Locators

| Material | Typical Use Case for irrigation valve locator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | General irrigation systems | Lightweight and corrosion-resistant | Vulnerable to UV degradation | Low |

| Metal | Heavy-duty applications | High strength and durability | Higher cost and weight | High |

| Rubber | Seals and gaskets in locators | Excellent sealing capabilities | Degrades over time due to UV exposure | Medium |

| Composite | High-performance portable locators | Superior strength-to-weight ratio | Complex manufacturing and higher cost | Medium to High |

This comprehensive analysis of materials provides valuable insights for B2B buyers looking to make informed decisions regarding irrigation valve locators, ensuring that they select the most suitable options for their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve locator

What Are the Key Stages in the Manufacturing Process of Irrigation Valve Locators?

The manufacturing process for irrigation valve locators involves several critical stages, ensuring the final product meets operational demands and quality standards.

1. Material Preparation

The first step in manufacturing irrigation valve locators is material preparation. Manufacturers typically use high-quality materials such as durable plastics and metals that withstand environmental stressors. Plastics are often used for housing components, while metals like brass or stainless steel are common for internal mechanisms to enhance durability and functionality. Suppliers must conduct a thorough assessment of raw materials to ensure they meet specifications and performance criteria.

2. Forming Techniques

Once materials are prepared, the next stage involves forming techniques. Common methods include injection molding for plastic parts and machining for metal components. Injection molding allows for precise shapes and intricate designs, which are essential for the ergonomic and functional aspects of valve locators. Metal components may undergo processes such as CNC machining or stamping to achieve the required dimensions and tolerances.

3. Assembly Process

After individual components are formed, they move to the assembly stage. This process often employs both automated and manual techniques. Automated assembly lines can increase efficiency, particularly for repetitive tasks, while skilled technicians may handle complex assemblies that require precision. It’s crucial that every assembly step is documented, as this traceability can be vital for quality assurance and customer accountability.

4. Finishing Touches

The final manufacturing stage is finishing, which includes processes such as coating, painting, and surface treatment. These treatments not only enhance the aesthetic appeal of the valve locators but also provide protection against corrosion and wear. For instance, anodizing aluminum parts can increase their resistance to environmental damage. Quality inspections are integrated into this stage to ensure that the finished products meet both aesthetic and functional standards.

How Is Quality Assurance Implemented in Manufacturing Irrigation Valve Locators?

Quality assurance is paramount in the manufacturing of irrigation valve locators to ensure reliability and performance. Various international and industry-specific standards guide these processes.

Relevant International Standards

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on establishing and maintaining an effective quality management system. This standard emphasizes continuous improvement, customer satisfaction, and regulatory compliance, making it highly relevant for B2B buyers seeking reliable suppliers.

In addition to ISO certifications, products intended for the European market may require compliance with CE marking, indicating they meet health, safety, and environmental protection standards. For more specialized applications, industry standards such as those from the American Petroleum Institute (API) may apply, especially for products intended for use in conjunction with oil and gas systems.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to maintain high standards. Common checkpoints include:

Incoming Quality Control (IQC): This initial checkpoint involves assessing raw materials and components as they arrive at the facility. Quality inspectors verify that materials meet specified standards before they enter the production line.

In-Process Quality Control (IPQC): During production, various inspections occur to monitor the manufacturing process. This could include measurements of critical dimensions and checks for defects. Statistical Process Control (SPC) techniques may be used to analyze process data and ensure consistent quality.

Final Quality Control (FQC): After assembly, a comprehensive final inspection is conducted. This includes functional testing of the valve locators to ensure they operate correctly under simulated conditions. Any product failing to meet quality standards is either reworked or discarded.

What Testing Methods Are Commonly Used to Ensure Quality in Irrigation Valve Locators?

Testing methods play a vital role in ensuring that irrigation valve locators are reliable and perform as expected. Common testing techniques include:

Functional Testing: This involves operating the valve locator under various conditions to verify its functionality. This could include checking the response time of the solenoid and the accuracy of the locator signals.

Environmental Testing: Products may undergo tests to simulate extreme environmental conditions, such as temperature fluctuations, humidity, and exposure to UV light. This helps ensure that the locators will perform reliably in diverse climates, particularly in regions like Africa and the Middle East, where conditions can be harsh.

Electrical Testing: For electronic components, manufacturers conduct tests to measure electrical performance, including resistance, voltage, and current flow. This is crucial for ensuring that the locators operate efficiently and safely.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those in international markets, should take proactive steps to verify the quality control practices of potential suppliers.

Conducting Supplier Audits

One effective method is to conduct supplier audits. This involves visiting the manufacturing facility to assess quality control processes firsthand. During the audit, buyers should evaluate the supplier’s adherence to international standards, their quality management system, and how they handle non-conformance issues.

Reviewing Quality Control Reports

Buyers should request and review quality control reports that detail testing results, inspection records, and compliance with standards. These documents provide insight into the supplier’s commitment to quality and their ability to deliver reliable products consistently.

Engaging Third-Party Inspection Services

Employing third-party inspection services can further enhance confidence in supplier quality. These independent firms can conduct thorough inspections and testing on behalf of buyers, providing an unbiased assessment of the products before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential.

Regulatory Compliance

Different regions may have varying regulations and standards that must be met. Buyers should ensure that suppliers are compliant with local regulations and international standards pertinent to their market. This may involve additional certifications or testing requirements specific to the region.

Cultural Considerations

Cultural factors can also influence quality control practices. Buyers should be aware of regional manufacturing practices and how they may affect product quality. Building strong relationships with suppliers and engaging in transparent communication can help bridge these gaps and ensure that quality expectations are met.

By understanding the manufacturing processes and quality assurance practices associated with irrigation valve locators, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve locator’

This guide serves as a practical checklist for B2B buyers seeking to procure an irrigation valve locator. Understanding the technical requirements, supplier capabilities, and the specific needs of your irrigation system will ensure you make an informed decision.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline the technical requirements of the irrigation valve locator you need. Consider factors like the type of valves in your system, the depth at which they are buried, and the specific functionalities you require, such as wire tracing or solenoid activation. This step is crucial as it helps narrow down the options that meet your operational needs.

Step 2: Research Available Technologies

Different models of irrigation valve locators utilize various technologies, such as passive or active locating methods. Evaluate the pros and cons of each technology:

– Passive Locators: These detect existing signals and are often simpler and more cost-effective.

– Active Locators: These send out signals to trace wires and can pinpoint locations more accurately, albeit at a higher cost. Understanding these technologies will allow you to select a locator that best fits your operational requirements.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers before making a commitment. Look for established companies with a strong reputation in the irrigation industry. Request documentation such as:

– Company profiles and certifications.

– Case studies or testimonials from other clients, especially those in your region.

– Details about their customer service and support post-purchase. This due diligence can help mitigate risks associated with your investment.

Step 4: Request Product Demonstrations or Trials

Whenever possible, ask suppliers for a demonstration of the irrigation valve locator you’re considering. This could be in the form of:

– On-site trials to see the equipment in action.

– Video demonstrations showcasing the product’s capabilities. Observing the product’s performance firsthand can provide valuable insights into its ease of use and efficiency.

Step 5: Compare Pricing Structures and Warranty Options

Pricing can vary significantly among suppliers, so it’s important to compare quotes carefully. Look beyond just the upfront costs; consider:

– Total Cost of Ownership (TCO): This includes maintenance, training, and potential repairs.

– Warranty terms: Ensure that the warranty covers defects and offers adequate support for repairs or replacements. A solid warranty can safeguard your investment against unforeseen issues.

Step 6: Check for After-Sales Support and Training

Effective after-sales support is vital for the successful implementation of any new technology. Inquire about:

– Training sessions for your team on how to use the locator effectively.

– Availability of technical support in case of operational issues or questions. Strong support can significantly reduce downtime and enhance the efficiency of your irrigation management.

Step 7: Finalize Your Procurement Plan

Once you’ve gathered all necessary information, finalize your procurement strategy. Ensure that all stakeholders are aligned on the selected product and supplier. Prepare a purchase order that outlines the terms of sale, delivery timelines, and payment terms. A well-structured plan will facilitate a smooth procurement process and ensure your investment aligns with your operational goals.

By following this checklist, B2B buyers can make informed decisions when sourcing irrigation valve locators, ensuring they meet their specific needs while also optimizing their irrigation management strategies.

Comprehensive Cost and Pricing Analysis for irrigation valve locator Sourcing

What Are the Key Cost Components in Sourcing Irrigation Valve Locators?

Understanding the cost structure of irrigation valve locators is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

Materials: The choice of materials directly impacts the cost. Plastic valves are typically less expensive and suitable for residential applications, while metal valves, necessary for heavy-duty environments like golf courses, can significantly increase costs. Buyers should consider the specific application when assessing material needs.

Labor: Labor costs vary significantly depending on the region of production. Countries with lower labor costs may offer more competitive pricing but could compromise quality. Ensure that the supplier adheres to fair labor practices to avoid ethical concerns.

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Suppliers with efficient operations may pass on savings, while those with higher overheads will reflect these costs in their pricing.

Tooling and Quality Control: Initial tooling costs can be substantial, especially for custom designs. Quality control processes are also essential, particularly for products that will face rigorous use. Ensure that QC practices are in place to minimize defects and returns.

Logistics: Transportation costs can fluctuate based on distance, shipping methods, and regional tariffs. For international buyers, understanding logistics costs, including import duties and taxes, is crucial for accurate budgeting.

Margin: Suppliers typically add a margin to their costs to ensure profitability. Margins can vary based on market competition, demand, and supplier reputation.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence pricing for irrigation valve locators, impacting overall procurement strategies for buyers.

Volume/MOQ: Purchasing in bulk often leads to significant discounts. Understanding the minimum order quantities (MOQs) is essential for negotiating favorable terms.

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether the additional expense aligns with their operational needs.

Material Quality and Certifications: Higher quality materials often come with certifications that may be required for specific applications. While these can raise initial costs, they may reduce long-term maintenance expenses.

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers with a track record of quality may charge more but can offer assurance regarding product performance.

Incoterms: Understanding the terms of sale is vital for managing costs effectively. Incoterms determine who is responsible for shipping, insurance, and tariffs, influencing the final price paid by the buyer.

What Buyer Tips Should International B2B Buyers Consider?

When sourcing irrigation valve locators, buyers should keep the following tips in mind to maximize cost-efficiency:

Negotiation: Always negotiate terms, especially for larger orders. Suppliers may be willing to offer discounts or improved payment terms, particularly for repeat business.

Total Cost of Ownership (TCO): Consider not only the purchase price but also the TCO, which includes installation, maintenance, and potential downtime costs. A cheaper initial purchase may lead to higher long-term costs if the product requires frequent repairs or replacements.

Pricing Nuances for International Buyers: Different regions may experience varying pricing structures due to local demand, currency fluctuations, and import duties. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these dynamics.

Disclaimer on Indicative Prices: Always remember that prices are subject to change based on market conditions and supplier pricing strategies. It’s crucial to obtain updated quotes and understand the basis for pricing changes.

By considering these factors, international B2B buyers can navigate the complexities of sourcing irrigation valve locators more effectively, ensuring they make informed and strategic purchasing decisions.

Alternatives Analysis: Comparing irrigation valve locator With Other Solutions

Understanding Alternatives to Irrigation Valve Locators

When it comes to efficiently managing irrigation systems, having the right tools for locating valves is crucial. While irrigation valve locators are specifically designed for this purpose, there are alternative methods and technologies that can also achieve similar outcomes. Understanding these alternatives can help B2B buyers make informed decisions based on performance, cost, and ease of use.

Comparison Table of Irrigation Valve Locators and Alternatives

| Comparison Aspect | Irrigation Valve Locator | Wire Tracing Device | Professional Service |

|---|---|---|---|

| Performance | High accuracy in valve location | Moderate accuracy; dependent on operator skill | High accuracy; expert knowledge |

| Cost | Medium to high initial investment | Low to medium rental cost | High; ongoing service fees |

| Ease of Implementation | User-friendly; minimal training needed | Requires some technical knowledge | No implementation needed; just hire professionals |

| Maintenance | Minimal; occasional battery replacement | Low; depends on usage frequency | None; service provider handles it |

| Best Use Case | Ideal for regular maintenance and DIY projects | Suitable for occasional use or troubleshooting | Best for large-scale or complex systems |

What Are the Benefits and Drawbacks of Wire Tracing Devices?

Wire tracing devices, while not specifically designed for irrigation, can serve as an alternative to locate buried valves. These devices work by following the electrical path from the controller to the valve. They are generally more affordable to rent than purchasing a dedicated valve locator. However, they require some technical knowledge to operate effectively and might not provide the same level of accuracy as specialized locators. Their best use case is for occasional troubleshooting, making them ideal for smaller operations or DIY maintenance.

How Do Professional Services Compare to Using an Irrigation Valve Locator?

Hiring professional services for valve locating can yield high accuracy due to the expertise of trained technicians. This option eliminates the need for equipment purchase or rental and is especially beneficial for complex or large-scale irrigation systems where locating valves can be particularly challenging. However, this method comes with higher ongoing costs and may not be feasible for smaller operations or budget-conscious businesses. It is best suited for companies that require regular maintenance but lack the in-house expertise or resources to perform the work themselves.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right valve locating solution, B2B buyers must consider their specific operational needs and budget constraints. For companies with regular maintenance requirements, investing in an irrigation valve locator may be the most effective choice due to its accuracy and ease of use. Conversely, for those who only need to locate valves sporadically, a wire tracing device or professional service may offer a more cost-effective solution. Ultimately, understanding the unique circumstances of the irrigation system and the resources available will guide buyers to the most suitable option.

Essential Technical Properties and Trade Terminology for irrigation valve locator

What Are the Key Technical Properties of an Irrigation Valve Locator?

When evaluating an irrigation valve locator, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some essential properties that B2B buyers should consider:

Material Composition

– Definition: The materials used in the construction of the valve locator, typically high-grade plastics or metals.

– Importance: Durable materials ensure longevity and reliability, especially in harsh outdoor conditions. For instance, corrosion-resistant materials are vital for longevity in humid or saline environments.Operating Voltage

– Definition: The voltage required to operate the locator, commonly found in low-voltage models ranging from 12V to 24V.

– Importance: Ensuring compatibility with existing systems is essential. Incorrect voltage can lead to equipment failure or safety hazards. Buyers should also consider energy efficiency to reduce operational costs.Detection Range

– Definition: The maximum distance over which the locator can effectively identify valve locations, often measured in feet or meters.

– Importance: A greater detection range allows for more efficient operation, particularly in large agricultural fields or extensive landscaping projects. This reduces labor time and increases productivity.Battery Life

– Definition: The duration the device can operate on a single charge or set of batteries, typically expressed in hours.

– Importance: Long battery life is crucial for minimizing downtime during field operations. B2B buyers should assess battery options and availability for replacements to ensure consistent usage.Signal Frequency

– Definition: The frequency at which the locator operates, affecting its ability to distinguish between different wire paths and detect faults.

– Importance: Higher frequencies can improve accuracy and reduce interference from other signals, which is essential in complex irrigation systems. This precision is particularly beneficial when locating buried valves in densely landscaped areas.

What Are the Common Trade Terms Used in the Irrigation Valve Locator Industry?

Understanding industry jargon can help B2B buyers navigate negotiations and procurement processes more effectively. Here are some common terms:

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Identifying OEMs can be essential for ensuring quality and compatibility when sourcing irrigation valve locators and their components.MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Understanding MOQ is vital for budgeting and inventory management. Buyers should negotiate MOQs that align with their project needs to avoid excess inventory costs.RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and availability for specific products.

– Significance: Utilizing RFQs can streamline the purchasing process by ensuring that multiple suppliers provide competitive pricing and terms, allowing buyers to make informed decisions.Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers.

– Significance: Familiarity with Incoterms is essential for international transactions, as they clarify shipping responsibilities, risk management, and cost allocation.Lead Time

– Definition: The time taken from placing an order to its delivery.

– Significance: Understanding lead times is crucial for project planning and ensuring timely completion of irrigation installations. Longer lead times may necessitate adjustments to project timelines or strategies.Warranty Terms

– Definition: The conditions under which a product can be repaired or replaced by the manufacturer.

– Significance: Clear warranty terms provide peace of mind for buyers, ensuring that they are protected against defects and can maintain operational efficiency without incurring additional costs.

By grasping these technical properties and trade terminologies, B2B buyers in the irrigation sector can enhance their purchasing strategies, ensuring that they select the most suitable valve locators for their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve locator Sector

What Are the Current Market Dynamics and Key Trends in the Irrigation Valve Locator Sector?

The irrigation valve locator market is witnessing a transformation driven by technological advancements and increasing demand for efficient irrigation management. Key global drivers include the growing need for sustainable agricultural practices and the optimization of water resources, especially in arid regions across Africa and the Middle East. International B2B buyers are increasingly seeking innovative solutions that enhance the efficiency of irrigation systems, minimize water wastage, and reduce operational costs. Emerging technologies such as smart irrigation systems and automated valve locators are gaining traction, enabling precise control and monitoring of irrigation processes.

In terms of sourcing trends, there is a noticeable shift towards digital procurement platforms that streamline the purchasing process. Buyers are leveraging e-commerce solutions to access a broader range of irrigation valve locators, with options for rental services becoming more prevalent. This trend is particularly relevant for markets in South America and Europe, where businesses are looking for cost-effective solutions without compromising on quality. Additionally, the incorporation of IoT (Internet of Things) technologies in irrigation systems is reshaping how valve locators are designed, offering enhanced connectivity and data analytics capabilities.

As the market evolves, buyers must remain vigilant to shifts in regulatory standards and environmental considerations, which can significantly impact sourcing decisions. Understanding these dynamics is crucial for international buyers looking to establish a competitive edge in the irrigation sector.

How Does Sustainability Influence Sourcing in the Irrigation Valve Locator Sector?

Sustainability is becoming an integral factor in the sourcing strategies of B2B buyers in the irrigation valve locator market. The environmental impact of irrigation practices is under scrutiny, prompting businesses to prioritize eco-friendly products. This includes sourcing from suppliers that adhere to sustainable manufacturing processes and utilizing materials that are recyclable or biodegradable.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly interested in understanding the sourcing origins of their products, ensuring that suppliers uphold labor rights and environmental standards. This trend is particularly relevant in regions like Africa and South America, where ethical sourcing can significantly influence brand reputation and consumer trust.

The demand for “green” certifications is on the rise, with buyers actively seeking out products that meet recognized environmental standards. These certifications not only validate the sustainability claims of suppliers but also provide buyers with assurance regarding the ecological impact of their purchases. As the irrigation industry faces increasing pressure to minimize its carbon footprint, embracing sustainable practices will be essential for companies aiming to thrive in a competitive market.

What Is the Brief Evolution and History of Irrigation Valve Locators?

The evolution of irrigation valve locators can be traced back to the early 20th century when manual methods were predominantly used to find and manage irrigation systems. Initial designs focused on simple mechanical devices that relied on physical inspection and probing. Over the decades, advancements in technology led to the introduction of electronic valve locators, which significantly improved the efficiency and accuracy of locating hidden valves in complex irrigation setups.

In recent years, the integration of digital technologies, such as GPS and IoT, has further transformed the landscape. These innovations allow for real-time monitoring and precise control of irrigation systems, catering to the growing demand for smart agricultural solutions. As the industry continues to evolve, the focus on sustainability and efficiency remains a driving force behind the development of new irrigation valve locator technologies, providing B2B buyers with innovative tools to enhance their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve locator

How do I solve the problem of locating hidden irrigation valves?

To effectively locate hidden irrigation valves, start by identifying likely areas such as near sprinkler heads or existing valve boxes. If the valves are buried, gently probe the soil and look for valve box covers. Utilizing a wire locator can significantly ease the process by tracing the wires from the controller to the valves. If these methods fail, consulting the original installation blueprints or hiring a professional service may be necessary to avoid damaging the irrigation system.What is the best irrigation valve locator for commercial applications?

For commercial applications, the Tempo Wire and Valve Locator is highly recommended due to its robust features. It can effectively locate wire paths, detect breaks, and identify solenoid valves. This locator offers adjustable transmit power for maximum performance over longer distances, making it suitable for extensive irrigation systems typical in commercial settings. Additionally, it includes rugged headphones and a long-nose receiver wand for ease of use in challenging environments.What are the key considerations when sourcing irrigation valve locators internationally?

When sourcing irrigation valve locators internationally, consider factors such as product quality, supplier reliability, and compliance with local regulations. It’s essential to vet suppliers through references, reviews, and their production capabilities. Assess their ability to provide after-sales support and warranty terms. Additionally, ensure that they can meet your specific needs regarding customization options and minimum order quantities (MOQ) to suit your business requirements.What is the typical minimum order quantity (MOQ) for irrigation valve locators?

The minimum order quantity (MOQ) for irrigation valve locators can vary significantly by supplier, ranging from a few units to several hundred. It’s advisable to inquire directly with potential suppliers to understand their MOQ policies. Some manufacturers may offer flexibility for first-time buyers or smaller businesses. Negotiating terms can also lead to favorable arrangements, especially if you plan to establish a long-term partnership.What payment terms should I expect when purchasing irrigation valve locators?

Payment terms for purchasing irrigation valve locators can vary widely among suppliers. Common options include upfront payment, partial payment upon order confirmation, and balance before shipment. Some suppliers may offer credit terms, especially for established businesses. It’s crucial to discuss and agree upon payment terms in writing to avoid misunderstandings. Additionally, consider using secure payment methods and platforms that provide buyer protection.How can I ensure quality assurance (QA) for irrigation valve locators?

To ensure quality assurance (QA) for irrigation valve locators, request samples before placing large orders. Evaluate the product’s performance and durability under real-world conditions. It’s also advisable to inquire about the supplier’s QA processes, including testing protocols and certifications. Regular communication and feedback loops with the supplier can help maintain quality standards throughout the production and delivery processes.What logistics considerations should I be aware of when importing irrigation valve locators?

When importing irrigation valve locators, consider logistics factors such as shipping methods, customs regulations, and delivery times. Choose reliable freight forwarders with experience in handling similar products to minimize delays. Be aware of any import duties or taxes that may apply, and ensure that all documentation is accurate and complete to facilitate smooth customs clearance. Establishing clear timelines and communication with your supplier can also help manage logistics effectively.How can I customize irrigation valve locators to meet specific needs?

Customization options for irrigation valve locators often depend on the supplier’s capabilities. Discuss your specific requirements, such as modifications in design, functionality, or branding. Many suppliers are willing to accommodate requests for tailored features, especially for bulk orders. Ensure that all customization details are documented in the contract to avoid misunderstandings during production. Engaging in a collaborative approach can lead to innovative solutions that enhance the utility of the locators for your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Irrigation Valve Locator Manufacturers & Suppliers List

1. Hunter – Wire/Valve Locator

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: Locating Irrigation Wires and Valves with a Wire/Valve Locator. Products Used: X2™ with WAND, X-Core™, Pro-C®, HPC, Pro-HC, ICC2, HCC. The video demonstrates how to set up a wire and valve locator, locate a valve, track and mark wire locations for troubleshooting, and determine wire depth. Wire tracing is suggested for locating mainlines buried in the same trench as wires. A Ground Fault Locator i…

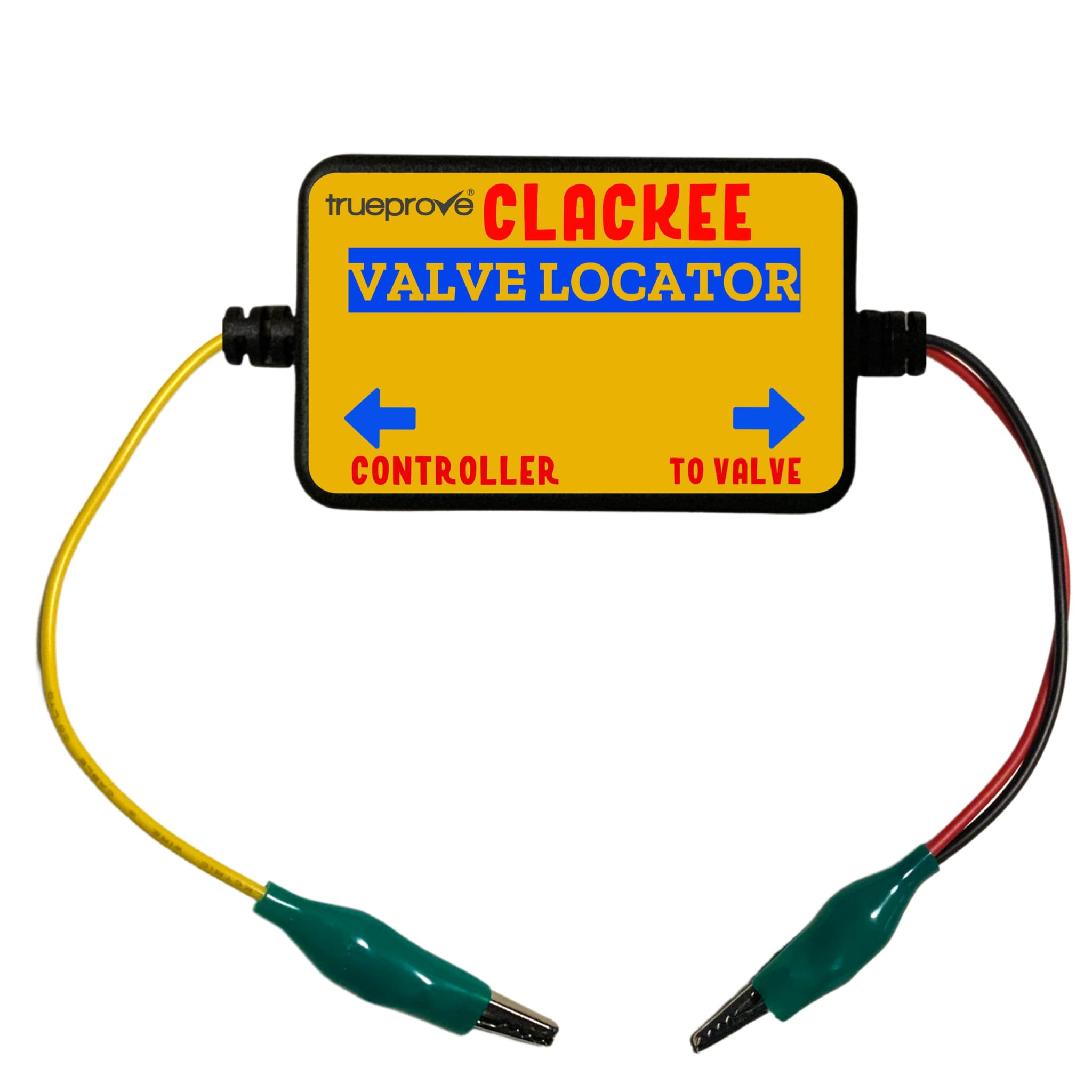

2. NOYAFA – NF-826 Underground Valve Locator

Domain: noyafa.com

Registered: 2006 (19 years)

Introduction: NOYAFA NF-826 Underground Valve Locator: A handy device designed to locate buried sprinkler valves and boxes without digging. It includes a receiver device with a probe and a transmitter device with 2 crocodile clamps. The device operates by attaching electric wires to the clamps and switching to the SCAN function to trace underground facilities.

Strategic Sourcing Conclusion and Outlook for irrigation valve locator

In conclusion, the strategic sourcing of irrigation valve locators is crucial for ensuring efficient and effective irrigation system management. As highlighted throughout this guide, investing in high-quality tools and technologies enhances operational efficiency and reduces downtime, which is particularly vital in regions with varying climatic conditions such as Africa, South America, the Middle East, and Europe. By prioritizing reliable valve locators, businesses can minimize costly disruptions caused by undetected valve issues, ultimately leading to more sustainable water usage and improved agricultural yields.

Moreover, leveraging rental options for specialized tools can provide flexibility and cost savings, allowing businesses to access advanced technology without the burden of ownership. This approach is especially beneficial for companies operating in diverse markets where adaptability is key.

Looking ahead, international B2B buyers should actively seek partnerships with reputable suppliers that offer comprehensive support and training in the use of these tools. By doing so, they can ensure the longevity of their irrigation systems and contribute to the overall enhancement of agricultural practices. Embrace the future of irrigation management—invest in strategic sourcing today to unlock greater efficiency and sustainability in your operations.