Introduction: Navigating the Global Market for anti syphon valve irrigation

In an increasingly interconnected world, international B2B buyers face the challenge of sourcing reliable anti-siphon valve irrigation systems that not only meet regulatory standards but also ensure the safety of potable water supplies. These critical components protect against contamination, making them essential in various agricultural and landscaping applications across diverse climates and terrains. This guide serves as a comprehensive resource, exploring the different types of anti-siphon valves, their applications, and the importance of proper installation and maintenance.

We delve into the intricacies of supplier vetting, offering insights into how to evaluate potential partners based on quality, reliability, and compliance with local regulations. Additionally, we provide an overview of cost considerations, ensuring that buyers can make informed financial decisions while maximizing value. By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—specifically in markets like Nigeria and Saudi Arabia—with the knowledge needed to navigate this complex landscape, this guide empowers them to secure the best anti-siphon valve solutions for their irrigation needs.

Investing in the right anti-siphon valve not only safeguards water quality but also enhances the efficiency of irrigation systems, ultimately supporting sustainable agricultural practices and responsible resource management.

Understanding anti syphon valve irrigation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Anti-Siphon Valves | Automated operation with solenoid, flow control options | Commercial landscaping, large gardens | Pros: Efficient, precise control. Cons: Higher initial cost. |

| Manual Anti-Siphon Valves | Requires manual operation, typically more straightforward | Residential gardens, small-scale applications | Pros: Lower cost, easy to install. Cons: Labor-intensive. |

| Pressure Regulating Anti-Siphon Valves | Integrated pressure regulation for optimal performance | Agricultural irrigation, golf courses | Pros: Protects against pressure fluctuations. Cons: More complex installation. |

| Heavy-Duty Anti-Siphon Valves | Durable construction, suitable for harsh conditions | Industrial applications, commercial farms | Pros: Long-lasting, reliable under stress. Cons: Heavier and more expensive. |

| Low-Flow Anti-Siphon Valves | Designed for low water flow applications | Drip irrigation, small-scale agriculture | Pros: Ideal for water conservation. Cons: Limited flow capacity. |

What Are Electric Anti-Siphon Valves and Their Applications?

Electric anti-siphon valves operate automatically through a solenoid, allowing for efficient management of irrigation systems. Their ability to integrate flow control options makes them highly suitable for commercial landscaping and large gardens where precise water application is crucial. Buyers should consider their initial investment against long-term efficiency gains, as these valves often lead to reduced water waste and lower operational costs.

How Do Manual Anti-Siphon Valves Work in Smaller Applications?

Manual anti-siphon valves are simpler devices that require human intervention to operate. They are typically less expensive and easier to install, making them a popular choice for residential gardens and small-scale applications. While they offer cost savings, buyers must weigh these benefits against the labor required for manual operation, which can be a drawback in larger setups.

What Are the Benefits of Pressure Regulating Anti-Siphon Valves?

Pressure regulating anti-siphon valves are designed to maintain optimal pressure levels within irrigation systems, which is essential for agricultural irrigation and golf courses. These valves prevent pressure fluctuations that can damage irrigation components and ensure efficient water distribution. Buyers should note that while they provide significant operational advantages, their installation can be more complex and may require specialized knowledge.

Why Choose Heavy-Duty Anti-Siphon Valves for Industrial Use?

Heavy-duty anti-siphon valves are built to withstand harsh environmental conditions, making them ideal for industrial applications and commercial farms. Their robust construction ensures reliability and longevity, even under significant stress. While these valves are typically heavier and more expensive, their durability can lead to lower maintenance costs over time, making them a wise investment for B2B buyers focused on long-term performance.

What Are the Considerations for Low-Flow Anti-Siphon Valves?

Low-flow anti-siphon valves cater specifically to applications with minimal water flow requirements, such as drip irrigation systems used in small-scale agriculture. These valves are essential for water conservation efforts and can enhance sustainability practices. However, potential buyers should be aware of their limited flow capacity, which may not be suitable for larger irrigation needs.

Key Industrial Applications of anti syphon valve irrigation

| Industry/Sector | Specific Application of Anti-Siphon Valve Irrigation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation systems for crop production | Ensures safe water supply, preventing contamination and supporting healthy crop growth | Compliance with local regulations on water safety, durability in harsh climates |

| Horticulture | Greenhouse irrigation systems | Protects potable water sources while optimizing water use for plant health | Compatibility with existing systems, ease of installation and maintenance |

| Landscaping | Residential and commercial landscape irrigation | Enhances aesthetics and sustainability while safeguarding against waterborne pollutants | Flow control features, size and pressure compatibility, warranty and support |

| Golf Courses | Irrigation for fairways and greens | Maintains high-quality turf while preventing backflow of contaminants | High-pressure tolerance, reliability, and ease of operation in varying conditions |

| Sports Facilities | Irrigation systems for stadiums and athletic fields | Ensures optimal playing conditions and protects water sources from contamination | Robust construction for outdoor use, energy efficiency, and maintenance requirements |

How Are Anti-Siphon Valves Used in Agriculture?

In agriculture, anti-siphon valves are critical for irrigation systems that supply water to crops. These valves prevent contaminated water from flowing back into the main water supply, ensuring that the irrigation process does not compromise water quality. For international B2B buyers, especially in regions like Africa and South America, selecting valves that comply with local agricultural regulations is essential. Additionally, durability in harsh climates and the ability to withstand high flow rates are key considerations.

What Role Do Anti-Siphon Valves Play in Horticulture?

In horticulture, anti-siphon valves are used in greenhouse irrigation systems to maintain a clean water supply while optimizing water usage for plant health. The valves allow for precise control of water flow, which is vital in settings where water quality can significantly impact plant growth. Buyers in the Middle East and Europe should look for valves that are easy to install and maintain, ensuring seamless integration with existing irrigation systems.

How Do Anti-Siphon Valves Benefit Landscaping Projects?

For landscaping applications, both residential and commercial, anti-siphon valves enhance the aesthetic appeal and sustainability of the environment. By preventing backflow contamination, these valves ensure that the water used for irrigation remains free of pollutants. Businesses should consider the flow control features of the valves, ensuring they can handle the specific water requirements of different landscapes, while also factoring in the ease of maintenance and warranty support.

Why Are Anti-Siphon Valves Important for Golf Courses?

Golf courses utilize anti-siphon valves in their irrigation systems to maintain lush fairways and greens. These valves help prevent the backflow of potentially harmful contaminants into the irrigation water, which is crucial for maintaining high-quality turf. When sourcing valves, golf course managers should prioritize those with high-pressure tolerance and reliability, as well as energy efficiency to reduce operational costs, especially in regions with variable weather conditions.

How Do Anti-Siphon Valves Support Sports Facilities?

Sports facilities rely on anti-siphon valves for their irrigation systems to ensure optimal playing conditions. These valves protect the water supply from contamination while maintaining the health of the grass fields. For B2B buyers in this sector, sourcing robust and energy-efficient valves that can withstand outdoor conditions is essential. Furthermore, understanding maintenance requirements and ease of operation will contribute to the long-term functionality of the irrigation system.

3 Common User Pain Points for ‘anti syphon valve irrigation’ & Their Solutions

Scenario 1: Ensuring Compliance with Local Regulations for Anti-Siphon Valves

The Problem: Many B2B buyers, particularly in regions like Africa and the Middle East, face the challenge of navigating complex local regulations regarding water safety and irrigation systems. These regulations often mandate the installation of backflow prevention devices, such as anti-siphon valves, to protect potable water sources from contamination. Failure to comply can lead to legal repercussions, fines, and significant project delays, which can impact operational timelines and costs.

The Solution: To ensure compliance, buyers should first consult with local plumbing codes and regulatory bodies to understand specific requirements related to anti-siphon valves. Partnering with suppliers who provide comprehensive product documentation can also facilitate compliance. When sourcing anti-siphon valves, ensure they meet local standards and are certified by relevant authorities. Additionally, consider investing in training for installation teams on proper compliance practices and the importance of maintaining proper valve operation. This proactive approach not only safeguards against legal issues but also enhances the overall reliability of the irrigation system.

Scenario 2: Dealing with High Maintenance Costs and Downtime

The Problem: In commercial irrigation systems, especially in arid regions like parts of Africa and South America, high maintenance costs and equipment downtime can be significant pain points. Anti-siphon valves may require frequent repairs or replacements due to harsh environmental conditions, leading to unplanned expenses and interruptions in irrigation schedules. This can affect crop yields and overall operational efficiency, making it critical for businesses to find a reliable solution.

The Solution: Selecting high-quality, durable anti-siphon valves designed for harsh conditions can significantly reduce maintenance costs. Buyers should look for valves made from materials such as stainless steel or high-grade plastics that can withstand extreme temperatures and corrosive environments. Additionally, implementing a preventive maintenance program that includes regular inspections and cleaning can help identify issues before they escalate. Suppliers that offer warranties and robust customer support can also provide peace of mind and assist in minimizing downtime due to valve failure.

Scenario 3: Optimizing Irrigation Efficiency for Varied Crop Types

The Problem: Many agricultural businesses struggle with optimizing their irrigation systems to cater to different crop types with varying water needs. An inefficient system can lead to overwatering or underwatering, affecting crop health and yield. Anti-siphon valves play a crucial role in managing water flow, yet improper installation or selection can hinder their performance.

The Solution: To enhance irrigation efficiency, buyers should conduct a thorough assessment of their irrigation needs, considering factors such as soil type, crop requirements, and climate conditions. When specifying anti-siphon valves, opt for models with adjustable flow control features, which allow for precise water management tailored to specific crops. Additionally, integrating smart irrigation technology, such as moisture sensors and automated timers, can further optimize water usage. Collaborating with irrigation specialists can provide valuable insights into the best practices for installing and using anti-siphon valves, ensuring that the system operates at peak efficiency while meeting the diverse needs of different crops.

Strategic Material Selection Guide for anti syphon valve irrigation

What Are the Common Materials Used in Anti-Siphon Valves for Irrigation?

When selecting materials for anti-siphon valves in irrigation systems, it is crucial to consider properties such as corrosion resistance, temperature and pressure ratings, and overall durability. Below, we analyze four common materials used in the construction of these valves, focusing on their performance, advantages, and limitations from a B2B perspective.

How Do Brass Anti-Siphon Valves Perform?

Brass is a popular choice for anti-siphon valves due to its excellent corrosion resistance and durability. It can withstand high pressures and temperatures, making it suitable for various irrigation applications. Brass valves typically have a pressure rating of up to 150 PSI and can operate effectively in temperatures ranging from -20°F to 180°F.

Pros: Brass is highly durable and resistant to corrosion, which is vital for irrigation systems exposed to moisture and various chemicals. It also has good machinability, allowing for complex designs.

Cons: The primary drawback of brass is its cost, which is generally higher than plastic alternatives. Additionally, brass can be susceptible to dezincification if exposed to aggressive water conditions.

Impact on Application: Brass valves are compatible with potable water systems, making them ideal for applications where water quality is a concern.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and the Middle East should ensure that brass valves meet local water quality regulations.

What Are the Advantages of Plastic Anti-Siphon Valves?

Plastic materials, particularly PVC and ABS, are widely used in anti-siphon valves due to their lightweight nature and resistance to corrosion. These materials are typically rated for pressures up to 150 PSI and can handle temperatures from 32°F to 140°F.

Pros: Plastic valves are cost-effective and lightweight, making installation easier. They are also resistant to a wide range of chemicals, which is beneficial in agricultural settings.

Cons: Plastic materials may not be as durable as brass, especially in high-temperature applications. They can also be prone to UV degradation if not properly protected.

Impact on Application: Plastic valves are suitable for non-potable water applications and are often used in agricultural irrigation systems.

Considerations for International Buyers: Buyers should verify that the plastic materials comply with local standards, particularly in regions with stringent regulations regarding water quality.

How Do Stainless Steel Anti-Siphon Valves Compare?

Stainless steel is another robust option for anti-siphon valves, known for its exceptional strength and corrosion resistance. Stainless steel valves can typically handle pressures up to 250 PSI and operate effectively in temperatures ranging from -40°F to 300°F.

Pros: The durability and longevity of stainless steel make it an excellent choice for harsh environments. It is also resistant to rust and pitting, ensuring reliable performance over time.

Cons: The primary disadvantage is the higher cost compared to brass and plastic options. Additionally, stainless steel can be heavier, which may complicate installation.

Impact on Application: Stainless steel valves are suitable for both potable and non-potable water applications, making them versatile for various irrigation needs.

Considerations for International Buyers: Buyers in regions like Europe should ensure compliance with EU standards for materials used in potable water systems.

What Role Does Aluminum Play in Anti-Siphon Valves?

Aluminum is a lightweight and corrosion-resistant material that is increasingly used in anti-siphon valves. It typically has a pressure rating of up to 150 PSI and can handle temperatures from -20°F to 180°F.

Pros: Aluminum is lightweight and offers good resistance to corrosion, making it suitable for many irrigation applications. Its lower cost compared to stainless steel is also an advantage.

Cons: Aluminum may not be as durable as brass or stainless steel and can be susceptible to corrosion in highly acidic or alkaline environments.

Impact on Application: Aluminum valves are often used in agricultural irrigation systems where weight savings are essential.

Considerations for International Buyers: Buyers should check for compliance with local standards, particularly in regions with specific regulations regarding materials in contact with water.

Summary Table of Material Selection for Anti-Siphon Valves

| Material | Typical Use Case for anti siphon valve irrigation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Potable water systems | Excellent corrosion resistance | Higher cost, susceptible to dezincification | High |

| Plastic | Non-potable agricultural irrigation | Cost-effective, lightweight | Less durable, UV degradation risk | Low |

| Stainless Steel | Harsh environments, both potable and non-potable | Exceptional strength and longevity | Higher cost, heavier | High |

| Aluminum | Agricultural irrigation | Lightweight, good corrosion resistance | Less durable in extreme conditions | Medium |

This guide aims to provide B2B buyers with actionable insights into material selection for anti-siphon valves in irrigation systems, ensuring they make informed decisions that align with their operational needs and local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for anti syphon valve irrigation

What Are the Main Stages of Manufacturing Anti-Siphon Valves for Irrigation?

The manufacturing of anti-siphon valves involves several critical stages that ensure both quality and functionality. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with the selection of high-quality materials, typically brass, stainless steel, or durable plastics that can withstand harsh environmental conditions. Suppliers must ensure that raw materials meet specific mechanical and chemical properties. This often involves material testing to verify compliance with international standards.

Forming: In this stage, the raw materials are shaped into the desired components using techniques such as casting, machining, or injection molding. For instance, brass valves may be machined to achieve precise dimensions, while plastic components are often produced through injection molding to ensure consistency and scalability. Advanced technologies like CNC machining may also be employed for enhanced accuracy.

Assembly: After forming, components are assembled using automated or manual processes. This stage includes the installation of essential parts such as diaphragms, springs, and seals. Quality checks during assembly are crucial to ensure that all parts fit correctly and function as intended. Automated assembly lines may include robotic systems that enhance precision and efficiency.

Finishing: The final stage involves surface treatments such as plating, painting, or sealing to enhance durability and corrosion resistance. This stage also includes rigorous cleaning processes to eliminate any contaminants. Proper finishing not only improves the aesthetic appeal but also extends the lifespan of the valves.

Which Key Techniques Are Utilized in Manufacturing Anti-Siphon Valves?

Several techniques are pivotal in the manufacturing of anti-siphon valves, each contributing to the overall quality and efficiency of the production process.

CNC Machining: This technique is vital for achieving high precision in valve components, allowing manufacturers to create intricate designs that meet strict specifications.

Injection Molding: Commonly used for plastic components, injection molding offers scalability and consistency, making it easier to produce large quantities with minimal defects.

Hydrostatic Testing: This method checks for leaks and ensures the integrity of the valves under pressure. It is an essential step to confirm that the valves can withstand the operational pressures they will encounter in the field.

Surface Treatments: Techniques such as anodizing or plating improve corrosion resistance and longevity, crucial for valves exposed to various environmental conditions.

How Is Quality Assurance Implemented in Anti-Siphon Valve Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of anti-siphon valves, ensuring that each product meets required standards and functions effectively.

International Standards Compliance: Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards signifies a commitment to quality and continuous improvement.

Industry-Specific Certifications: In addition to general standards, anti-siphon valves may require certifications such as CE marking (European Conformity) or API (American Petroleum Institute) standards, particularly for valves intended for use in specific industries or regions.

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This stage involves testing raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, random samples are tested to identify any deviations from quality standards.

– Final Quality Control (FQC): Once production is complete, finished valves undergo rigorous testing, including hydrostatic and functional tests, to verify performance.

What Testing Methods Are Commonly Used for Anti-Siphon Valves?

Various testing methods are employed to ensure the reliability and performance of anti-siphon valves. These include:

Pressure Testing: Valves are subjected to pressure tests to ensure they can handle the specified operational pressures without leaking.

Flow Testing: This method evaluates the valve’s flow characteristics, ensuring that it operates efficiently within the expected flow rates.

Durability Testing: Valves may undergo cycling tests to simulate long-term use, helping to identify potential failures over time.

Environmental Testing: For valves intended for harsh conditions, environmental testing simulates exposure to extreme temperatures, humidity, and corrosive elements to ensure durability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure the reliability of anti-siphon valves.

Supplier Audits: Conducting audits of potential suppliers provides insight into their manufacturing processes, quality control measures, and overall compliance with international standards.

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the testing methods and results associated with the valves.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and the integrity of the products.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers must navigate various quality control and certification nuances when sourcing anti-siphon valves.

Understanding Local Regulations: Different regions may have specific regulations regarding valve performance and safety. Buyers should familiarize themselves with these requirements to ensure compliance.

Documentation Requirements: Importing anti-siphon valves often requires extensive documentation, including quality certifications, safety data sheets, and compliance certificates. Ensuring these documents are in order can facilitate smoother customs processes.

Cultural Considerations: Engaging with suppliers from different cultures may require an understanding of their business practices, communication styles, and negotiation tactics, which can affect quality assurance efforts.

By understanding the manufacturing processes and quality assurance measures associated with anti-siphon valves, B2B buyers can make informed decisions, ensuring they procure reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘anti syphon valve irrigation’

Introduction

This practical sourcing guide serves as a step-by-step checklist for B2B buyers seeking to procure anti-siphon valve irrigation systems. These valves are essential for preventing contaminated water from re-entering the clean water supply, making them crucial for any irrigation system connected to potable water. By following this checklist, you can ensure that you make informed decisions while sourcing high-quality anti-siphon valves that meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. Consider factors such as valve size, flow rate, pressure ratings, and material specifications.

– Key Considerations: Identify the specific needs of your irrigation system, including the types of crops or plants being watered, which can influence the choice of valve.

Step 2: Research Compliance Standards

Understanding local regulations and compliance standards is vital for sourcing anti-siphon valves. Many regions require specific certifications to ensure safety and functionality.

– What to Look For: Verify that the valves meet local plumbing codes and are certified for use in your intended application, particularly if you are sourcing internationally.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, case studies, and references from businesses in your industry or region.

– Supplier Assessment: Look for suppliers with a proven track record in the irrigation sector, especially those who have successfully served clients in similar geographic areas.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the anti-siphon valves to evaluate their performance. Testing samples can help you assess the quality and functionality of the products.

– Testing Criteria: Check for ease of installation, durability in harsh environments, and the effectiveness of the backflow prevention mechanism.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers and tested their products, engage in negotiations. Discuss pricing, payment terms, and shipping options to find a mutually beneficial arrangement.

– Cost Considerations: Be aware of total costs, including shipping and any potential import duties, especially when sourcing from international suppliers.

Step 6: Confirm Warranty and Support

Before finalizing your order, ensure that the supplier offers a solid warranty and post-purchase support. This step is crucial for addressing any issues that may arise after installation.

– Support Evaluation: Confirm the availability of technical support and repair services, which can be vital for maintaining system performance over time.

Step 7: Plan for Installation and Maintenance

Once your anti-siphon valves are procured, develop a clear installation and maintenance plan. Proper installation is key to ensuring the effectiveness of the valves.

– Installation Guidelines: Consider hiring experienced professionals for installation and establish a routine maintenance schedule to check for wear and functionality, helping prolong the lifespan of your irrigation system.

By following this checklist, B2B buyers can confidently navigate the procurement process for anti-siphon valve irrigation systems, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for anti syphon valve irrigation Sourcing

What Are the Key Cost Components in Anti-Siphon Valve Irrigation Sourcing?

When sourcing anti-siphon valves for irrigation systems, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The type of materials used significantly impacts the cost. High-quality materials like stainless steel and durable plastics may raise costs but ensure longevity and reliability.

Labor: Labor costs vary by region and can affect the overall price. Skilled labor for manufacturing and assembly may be more expensive but can improve product quality.

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can help reduce these costs.

Tooling: Initial tooling costs for custom designs can be substantial, especially for specialized valves. However, investing in quality tooling can yield better precision and efficiency in production.

Quality Control (QC): Rigorous QC processes ensure that the valves meet industry standards and customer specifications, which can add to the overall cost but is essential for avoiding future liabilities.

Logistics: Shipping and handling costs are significant, especially for international buyers. Factors such as distance, mode of transport, and local import duties can greatly affect the final price.

Margin: Suppliers will add a markup to cover their costs and profit margin. Understanding the typical margins in the industry can assist buyers in negotiating better deals.

How Do Price Influencers Affect Anti-Siphon Valve Costs?

Several factors influence the pricing of anti-siphon valves, particularly for international buyers:

Volume/MOQ: Minimum order quantities (MOQ) can dictate pricing. Larger orders typically reduce the per-unit cost due to economies of scale. Buyers should evaluate their needs to optimize order sizes.

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether they need these customizations or if standard products suffice for their applications.

Materials: The choice of materials not only affects durability but also pricing. Buyers should balance cost with the need for high-quality, long-lasting components.

Quality and Certifications: Products that meet international quality standards or certifications may have higher price tags. However, these certifications can be crucial for compliance and performance in various markets.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more but can offer better service and product assurance.

Incoterms: Understanding the Incoterms (International Commercial Terms) relevant to shipping can significantly affect total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks.

What Are the Best Practices for Negotiating Anti-Siphon Valve Prices?

For international B2B buyers, effective negotiation can lead to significant savings:

Research and Prepare: Understanding market prices and supplier capabilities allows buyers to negotiate from an informed position. Comparative analysis can reveal where suppliers may have flexibility.

Discuss Total Cost of Ownership (TCO): Emphasizing the long-term benefits of quality products can justify higher upfront costs. Buyers should consider maintenance, durability, and performance over time when evaluating proposals.

Leverage Volume Discounts: If possible, consolidate orders across multiple projects to negotiate better pricing based on higher volume commitments.

Be Aware of Pricing Nuances in Different Regions: Factors such as local labor costs, tariffs, and currency fluctuations can affect pricing. Buyers should factor these elements into their negotiations to avoid surprises.

Conclusion

Navigating the complexities of sourcing anti-siphon valves requires a keen understanding of cost structures and pricing influences. By considering the key cost components, price influencers, and negotiation tactics, international buyers can make informed decisions that optimize their investments in irrigation solutions. Keep in mind that prices can fluctuate based on market conditions, so it’s advisable to seek multiple quotes and assess all factors before finalizing any agreements.

Alternatives Analysis: Comparing anti syphon valve irrigation With Other Solutions

Exploring Alternatives to Anti-Siphon Valve Irrigation

When evaluating irrigation solutions, understanding the alternatives to anti-siphon valve irrigation is crucial for B2B buyers. Each method has its unique advantages and drawbacks, impacting performance, cost, and ease of implementation. This analysis will delve into how anti-siphon valve irrigation compares with other viable irrigation methods, allowing buyers to make informed decisions tailored to their specific needs.

| Comparison Aspect | Anti Syphon Valve Irrigation | Drip Irrigation | Surface Irrigation |

|---|---|---|---|

| Performance | Effective in preventing backflow and contamination; ideal for small to medium areas. | Highly efficient water use; minimizes evaporation and runoff; suitable for various crops. | Simple and low-cost; effective for large areas with adequate water supply. |

| Cost | Moderate initial investment; ongoing maintenance costs. | Higher initial setup cost; long-term savings on water. | Low initial cost; potential for high labor costs. |

| Ease of Implementation | Requires above-ground installation; relatively simple to set up. | Complex installation; requires careful planning and layout. | Easy to implement on flat terrains; less technical expertise needed. |

| Maintenance | Regular checks necessary to ensure functionality; low maintenance. | Requires regular maintenance to prevent clogging; can be labor-intensive. | Minimal maintenance; dependent on water supply management. |

| Best Use Case | Ideal for residential lawns and gardens; complies with potable water regulations. | Best for high-value crops; efficient in water-scarce regions. | Suitable for large agricultural fields; effective in areas with abundant water supply. |

In-Depth Analysis of Alternative Irrigation Methods

Drip Irrigation

Drip irrigation involves a network of tubing and emitters that deliver water directly to the plant roots. This method is known for its efficiency, reducing water waste through evaporation and runoff. While the initial setup cost can be higher than anti-siphon valve irrigation, the long-term savings on water usage make it an attractive option, particularly in arid regions. However, the complexity of installation and maintenance can be a drawback, as systems may require regular checks to prevent clogging.

Surface Irrigation

Surface irrigation utilizes gravity to distribute water across fields, making it one of the oldest and simplest irrigation methods. It is particularly effective in large agricultural areas where water is plentiful. The low initial cost is appealing, but the method can lead to uneven water distribution and higher labor costs due to the need for manual management. Additionally, surface irrigation may not be suitable for all terrains, particularly those that are uneven or have drainage issues.

How to Choose the Right Irrigation Solution for Your Needs

Selecting the right irrigation method depends on various factors, including the specific agricultural context, budget constraints, and water availability. Anti-siphon valve irrigation is an excellent choice for buyers looking for a straightforward solution that complies with potable water regulations and minimizes contamination risks. In contrast, drip irrigation is preferable for high-value crops requiring precise water application, while surface irrigation can be suitable for larger agricultural operations with abundant water resources. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions that align with their operational goals and environmental conditions.

Essential Technical Properties and Trade Terminology for anti syphon valve irrigation

What Are the Key Technical Properties of Anti-Siphon Valves for Irrigation?

When selecting anti-siphon valves for irrigation systems, understanding their critical technical properties is essential for ensuring efficiency and compliance with safety standards. Here are some key specifications that B2B buyers should consider:

1. Material Grade

The material grade of an anti-siphon valve significantly influences its durability and performance. Common materials include PVC, brass, and stainless steel. PVC valves are lightweight and resistant to corrosion, making them ideal for low-pressure systems. Brass and stainless steel options provide higher strength and resistance to harsh environmental conditions, which is crucial for agricultural applications in regions like Africa and South America.

2. Pressure Rating

Pressure ratings indicate the maximum pressure the valve can withstand without failing. Most anti-siphon valves are rated between 15 to 150 PSI. Selecting a valve with an appropriate pressure rating is vital for avoiding leaks and ensuring the longevity of the irrigation system, particularly in high-pressure environments typical in arid regions.

3. Flow Rate

The flow rate, measured in gallons per minute (GPM), determines how much water can pass through the valve. It is essential to choose a valve that can accommodate the specific flow requirements of your irrigation system. A well-matched flow rate ensures optimal watering efficiency and prevents overwatering or under-watering of crops.

4. Installation Height

Anti-siphon valves must be installed above ground, typically at least 6 inches higher than the highest sprinkler head. This specification is crucial for effective backflow prevention. Understanding this requirement helps ensure compliance with local plumbing codes, which can vary by region, especially in the Middle East and Europe.

5. Internal Mechanism

The internal mechanism of the valve, such as a Buna-N diaphragm, plays a significant role in its performance. This material offers resilience in harsh water conditions, preventing leaks and ensuring reliable operation. A well-designed internal mechanism can enhance the valve’s lifespan and reduce maintenance costs.

6. Control Type

Anti-siphon valves can be either automatic or manual. Automatic valves allow for remote operation and can be integrated with irrigation controllers, enhancing convenience for large agricultural operations. Manual valves, while simpler, require physical intervention, which may not be feasible in extensive setups.

What Are Common Trade Terms in Anti-Siphon Valve Procurement?

Understanding industry terminology can enhance communication and negotiation in B2B transactions. Here are several common terms relevant to anti-siphon valve procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of anti-siphon valves, working with OEMs can ensure that the valves meet specific quality and performance standards, which is critical for maintaining system reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps B2B buyers plan their inventory and budget effectively, especially in regions where demand may fluctuate seasonally.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other relevant information for specific products. Issuing an RFQ can help buyers compare options and negotiate better terms, ensuring that they secure the best deal for anti-siphon valves.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping goods. Understanding Incoterms can help B2B buyers navigate shipping logistics and costs effectively, particularly when sourcing valves from international suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time is essential for planning irrigation projects, especially in agricultural settings where timing can impact crop yields.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and longevity of the product. Understanding warranty terms is vital for B2B buyers to ensure they are protected against defects and to assess the reliability of the supplier.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring anti-siphon valves, ensuring that they select the right products for their specific irrigation needs.

Navigating Market Dynamics and Sourcing Trends in the anti syphon valve irrigation Sector

What Are the Key Market Dynamics and Trends in the Anti-Siphon Valve Irrigation Sector?

The global anti-siphon valve irrigation market is witnessing significant growth, driven primarily by the increasing demand for efficient water management solutions amid rising water scarcity. Countries in Africa, South America, the Middle East, and Europe are prioritizing sustainable agricultural practices, which significantly influences their purchasing decisions. The adoption of advanced irrigation technologies, including smart valves that allow for remote monitoring and control, is becoming a notable trend. This trend aligns with the growing emphasis on precision agriculture, where data-driven insights optimize resource usage and enhance crop yields.

Moreover, regional regulations are evolving, with stricter guidelines on water quality and conservation prompting B2B buyers to seek products that not only comply with these standards but also offer enhanced reliability. In particular, regions like the Middle East and North Africa are experiencing a surge in demand for anti-siphon valves as part of broader initiatives to improve agricultural productivity and ensure safe drinking water supplies. The integration of IoT (Internet of Things) technology into irrigation systems is also gaining traction, allowing for real-time data collection and improved decision-making.

How Are Sustainability and Ethical Sourcing Impacting the Anti-Siphon Valve Market?

Sustainability has become a cornerstone of the anti-siphon valve irrigation sector, with buyers increasingly favoring products that minimize environmental impact. The production of anti-siphon valves using recycled materials or eco-friendly processes is gaining attention, as B2B buyers are more inclined to support suppliers who demonstrate a commitment to sustainable practices. Certifications such as ISO 14001 (Environmental Management) and other green labels can significantly influence purchasing decisions.

Additionally, ethical sourcing is crucial, particularly for international buyers concerned about the social and environmental implications of their supply chains. Ensuring that suppliers maintain fair labor practices and uphold environmental standards not only mitigates risk but also enhances brand reputation. As the market evolves, transparency in sourcing and the adoption of circular economy principles will likely become critical factors for businesses seeking to differentiate themselves in a competitive landscape.

What Is the Evolution of the Anti-Siphon Valve Technology?

The anti-siphon valve has evolved significantly from its early mechanical designs to today’s advanced automated systems. Initially developed to prevent backflow and protect potable water supplies, these valves have incorporated new technologies that enhance their functionality and efficiency. Modern anti-siphon valves feature improved materials, such as corrosion-resistant alloys and durable plastics, which extend their lifespan and reduce maintenance needs.

The integration of smart technology is a recent advancement, allowing for automated control and monitoring of irrigation systems. This evolution not only helps in maintaining optimal water usage but also aligns with the global shift towards smart farming solutions. As these technologies continue to develop, international B2B buyers must stay informed about innovations that can provide competitive advantages in their respective markets.

Frequently Asked Questions (FAQs) for B2B Buyers of anti syphon valve irrigation

How do I determine if my irrigation system needs an anti-siphon valve?

To ascertain whether your irrigation system requires an anti-siphon valve, check if it connects to a potable water supply without an existing backflow prevention device. Anti-siphon valves are essential for safeguarding your water supply from contamination and may also be mandated by local plumbing codes. If you’re operating in regions with stringent regulations, such as parts of Europe or the Middle East, it’s advisable to consult local codes or a plumbing professional to ensure compliance.What factors should I consider when choosing an anti-siphon valve for my irrigation system?

When selecting an anti-siphon valve, consider factors such as the valve’s size, pressure rating, and flow control features. It’s crucial to ensure that the valve is compatible with your irrigation system specifications and can handle the expected water pressure. Additionally, evaluate the valve’s construction material for durability in harsh environments, especially if you are sourcing products for regions in Africa or South America where conditions can be extreme.What are the minimum order quantities (MOQ) for anti-siphon valves from suppliers?

Minimum order quantities for anti-siphon valves can vary significantly based on the manufacturer and the region. Typically, MOQs range from a few dozen to several hundred units, especially for bulk orders. When negotiating with suppliers, inquire about their flexibility on MOQs, especially if you are a smaller business or testing a new market. Some suppliers may offer lower MOQs for specific product lines or during promotional periods.How can I vet suppliers of anti-siphon valves effectively?

Vetting suppliers requires thorough research. Start by checking their credentials, such as certifications and industry reputation. Request samples to evaluate product quality and performance. Additionally, read reviews from other B2B buyers and ask for references. If possible, visit their production facilities or attend trade shows to assess their operations. Engaging with suppliers that have experience in your target market, such as Africa or the Middle East, can also enhance reliability.What payment terms should I expect when sourcing anti-siphon valves internationally?

Payment terms can vary widely among suppliers and regions. Common practices include advance payments, letters of credit, or net payment terms (e.g., net 30 or net 60). It’s crucial to negotiate terms that provide security for both parties. For large orders, consider using escrow services to ensure that funds are released only upon satisfactory delivery. Always ensure that payment methods are secure and that you understand any associated fees or currency exchange implications.What quality assurance measures should I look for in anti-siphon valves?

When sourcing anti-siphon valves, ensure that suppliers adhere to strict quality assurance (QA) protocols. Look for certifications like ISO 9001, which indicate robust quality management systems. Request documentation on testing procedures, including pressure testing and material certifications. Additionally, inquire about warranty policies and return processes to safeguard your investment. This is particularly important in regions where product quality can significantly impact system performance.How can I ensure timely logistics for my anti-siphon valve orders?

To ensure timely logistics, collaborate closely with your supplier to establish clear shipping timelines and delivery expectations. Select suppliers with proven logistics capabilities and experience in international shipping. Discuss shipping methods, including air freight for urgent needs or sea freight for larger, cost-effective orders. Additionally, consider working with freight forwarders who can help navigate customs regulations and ensure that all necessary documentation is in order.What customization options are available for anti-siphon valves?

Many suppliers offer customization options for anti-siphon valves, including size, material, and additional features like flow control or specific pressure ratings. When discussing your needs, clearly outline the specifications required for your irrigation system. If you are targeting a specific market, such as agricultural projects in Africa or South America, inquire if the supplier can accommodate local standards or unique conditions, which can enhance the effectiveness of the valves in your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Anti Syphon Valve Irrigation Manufacturers & Suppliers List

1. Reddit – Anti-Siphon Valve

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Anti-siphon valve is designed to prevent the backflow of contaminated water into clean water lines. It is commonly used in irrigation systems and includes a water timer that shuts off and blocks water flow. Users have noted that these valves may cause a decrease in water pressure, typically losing 2-3 psi through a backflow preventer. The valve acts as a safety measure against potential backflow i…

2. Rainbird – DASASVF Anti-Siphon Valve

Domain: store.rainbird.com

Registered: 1995 (30 years)

Introduction: Product Name: DASASVF – Anti-Siphon Valves

Price: As low as $30.99 (List Price: $44.44)

SKU: DAS75100

Valve Type: Anti-Siphon

Material: Plastic

Valve Inlet/Outlet Configuration: NPT Female x NPT Female Threaded

Valve Options: Flow Control

Valve Series: ASVF

Operating Temperature: Up to 110° F (43° C)

Dimensions:

– Inlet and Outlet Center-to-Center Distance: 3 7/8″ (9.84 cm)

– Height: 6 1/4″ (…

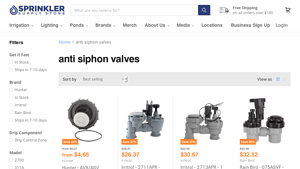

3. Hunter – AVB/ASV Repair Kit

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: {“products”:[{“name”:”Hunter AVB/ASV Repair Kit for Anti-Siphon Valve”,”sizes”:[“3/4 inch”,”1 inch”],”original_price”:”$8.27″,”current_price”:”$4.65″,”in_stock”:31},{“name”:”Irritrol 2711APR – 3/4” 2700 Series Anti-Siphon Valve”,”size”:”3/4 inch”,”features”:[“Electric Anti-Siphon Valve”,”Stainless Screw Bonnet”,”Flow Control”,”Solenoid: 24 VAC”],”dimensions”:”5 5/8 in. H x 3 in. W x 6 1/4 in. L”,”…

4. Orbit – FPT Manual Anti-Siphon Sprinkler Valves

Domain: orbitonline.com

Registered: 1999 (26 years)

Introduction: {“name”: “FPT Manual Anti-Siphon Sprinkler Valves”, “part_number”: “51016”, “sizes”: [{“size”: “3/4-in. FPT Brass Valve”, “price”: 39.99, “sku”: “51016”, “weight”: 885}, {“size”: “3/4-in. FPT Valve”, “price”: 14.99, “sku”: “51022P”, “weight”: 318}, {“size”: “1-in. FPT Valve”, “price”: 14.99, “sku”: “51023P”, “weight”: 340}], “description”: “The manual anti-siphon valve features a combination of an…

5. Sprinkler – Anti Siphon Valve Repair Solutions

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Sprinkler Anti Siphon Valve; common issue: leaking from cap; potential causes: dirt or blockage; repair options: clean or replace gasket; recommended gasket: A-139, 70A durometer, Buna-N O-ring; alternative gasket: A-329 O-ring; cost-effective solutions available from industrial supply companies.

6. Rainbird – AC Anti-Siphon Valve

Domain: dripworks.com

Registered: 1998 (27 years)

Introduction: Rainbird AC Anti-Siphon Valves

– Price: $24.95 (MSRP: You save)

– SKU: Q_VRBAS

– Available Diameters: 3/4″ and 1″

– Specifications:

– Female pipe thread (FPT) inlet and outlet

– Compatible with electric AC timers

– Pressure Range: 15 – 150 PSI

– Flow Range:

– 3/4″ valve: 0.2 – 22 GPM

– 1″ valve: 0.2 – 40 GPM

– Features:

– Automated or manual operation

– Complies with back-flow…

7. Rain Bird – 1 in. Plastic Anti-Siphon Irrigation Valve

Domain: cheapsprinklers.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Rain Bird 100ASVF 1 in. Plastic Residential Anti-Siphon Irrigation Valve with Flow Control”, “size”: “1 in.”, “material”: “Plastic”, “type”: “Anti-Siphon Irrigation Valve”, “features”: [“Flow Control”, “1 in. FPT Threads”], “application”: “Residential irrigation systems”}

8. HowStuffWorks – Anti-Siphon Valve

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: Anti-siphon valve; used in built-in lawn sprinkling systems; prevents backflow of water into the plumbing system; required by building codes in various locations including external hose connections and toilet fill valves; operates as a one-directional valve, often a spring-loaded flap; prevents contamination from sources like aquariums or pesticide tanks; important for health and safety.

Strategic Sourcing Conclusion and Outlook for anti syphon valve irrigation

In the rapidly evolving landscape of irrigation systems, anti-siphon valves play a critical role in ensuring the integrity of potable water supplies. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, sourcing high-quality anti-siphon valves is essential for compliance with local regulations and for protecting public health. These valves not only prevent backflow contamination but also enhance the efficiency of irrigation systems, making them a smart investment for any agricultural or landscaping project.

Strategic sourcing is vital in identifying reliable suppliers who can provide durable and efficient anti-siphon valves that meet the specific needs of diverse markets. Leveraging partnerships with reputable manufacturers can lead to cost savings, improved supply chain reliability, and access to innovative products that optimize irrigation performance.

As the demand for sustainable and efficient irrigation solutions continues to rise, now is the time for B2B buyers to evaluate their current supply chains and explore new opportunities. By prioritizing the procurement of advanced anti-siphon valves, businesses can not only safeguard their operations but also contribute to the broader goal of environmental sustainability. Invest in your irrigation future today—secure the right solutions for your projects and ensure a thriving, sustainable agricultural landscape.