Introduction: Navigating the Global Market for 30 inch irrigation valve box

In the ever-evolving landscape of global agriculture, sourcing a reliable 30-inch irrigation valve box is crucial for ensuring efficient water management. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, face the challenge of navigating diverse supplier offerings while ensuring product quality and compliance with local regulations. This guide serves as a comprehensive resource, addressing key aspects such as the various types of irrigation valve boxes, their applications, supplier vetting processes, and cost considerations.

Within these pages, we will delve into the essential features of 30-inch irrigation valve boxes, from material durability to design specifications that cater to different irrigation systems. We will also explore the significance of UV-resistant materials and corrosion-proof designs, which are critical for long-term performance in challenging environments. By equipping buyers with actionable insights and best practices, this guide empowers informed purchasing decisions, enabling companies to enhance their agricultural efficiency and sustainability.

Furthermore, we will provide strategies for evaluating potential suppliers, ensuring that you select partners who not only meet your technical specifications but also align with your operational goals. With this knowledge, B2B buyers can confidently navigate the complexities of the global market, securing the right irrigation solutions to meet their unique needs.

Understanding 30 inch irrigation valve box Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rectangular Valve Box | 30″ x 17″ dimensions, UV-resistant materials | Large-scale irrigation systems, municipal use | Pros: Durable, versatile; Cons: May require more space than smaller options. |

| Bolt-Down Cover Valve Box | Enhanced security with bolt-down lid, robust construction | Commercial properties, high-traffic areas | Pros: Increased protection, stability; Cons: Higher initial cost. |

| Tapered Design Valve Box | Tapered walls for easier installation, reduced soil pressure | Agricultural fields, landscaping projects | Pros: Easier to install, less prone to collapsing; Cons: Limited space inside. |

| Meter and Access Combination Box | Integrated access for meters and valves, multi-use functionality | Utility management, water resource facilities | Pros: Multi-functional, space-saving; Cons: More complex design may require specialized knowledge. |

| Color-Coded Valve Box | Available in various colors for easy identification | Residential and commercial irrigation systems | Pros: Quick identification, compliance with local regulations; Cons: Color options may be limited. |

What are the characteristics of Standard Rectangular Valve Boxes?

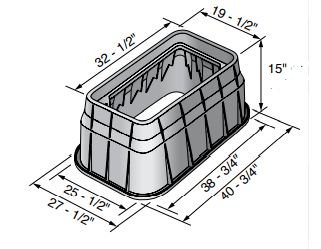

Standard rectangular valve boxes measuring 30 inches by 17 inches are often constructed from durable, UV-resistant materials, making them suitable for various environmental conditions. These boxes are widely used in large-scale irrigation systems and municipal applications due to their robust design and capacity to house multiple valves. Buyers should consider the installation space and potential accessibility issues, as these boxes can require more area compared to smaller models.

Why choose a Bolt-Down Cover Valve Box for commercial applications?

Bolt-down cover valve boxes provide enhanced security and stability, making them ideal for commercial properties and high-traffic areas. The robust construction ensures that the box withstands heavy loads and environmental stressors. While the initial investment may be higher, the long-term durability and reduced maintenance costs make this option appealing for businesses looking to safeguard their irrigation systems.

How does a Tapered Design Valve Box improve installation?

Tapered design valve boxes feature sloped walls that facilitate easier installation and reduce soil pressure, making them particularly advantageous for agricultural fields and landscaping projects. This design minimizes the risk of collapsing under soil weight, ensuring a secure housing for irrigation components. Buyers should weigh the benefits of ease of installation against the limited internal space, which may affect the number of valves accommodated.

What are the advantages of Meter and Access Combination Boxes?

Meter and access combination boxes offer integrated access for both meters and valves, providing multi-use functionality that is particularly beneficial for utility management and water resource facilities. These boxes can save space and streamline operations by consolidating multiple functions into one unit. However, the more complex design may necessitate specialized knowledge for installation and maintenance, which buyers should factor into their purchasing decisions.

How do Color-Coded Valve Boxes enhance operational efficiency?

Color-coded valve boxes are available in various hues to facilitate quick identification, which is essential for efficient irrigation management in both residential and commercial systems. This feature not only aids in compliance with local regulations but also enhances operational efficiency by reducing the time needed to locate specific valves. Buyers should consider the availability of color options and whether they align with their operational needs.

Key Industrial Applications of 30 inch irrigation valve box

| Industry/Sector | Specific Application of 30 inch irrigation valve box | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Water management for large-scale irrigation systems | Enhances water distribution efficiency, reducing costs | Durability against UV and weather, compatibility with existing systems |

| Landscaping & Horticulture | Control of irrigation systems in parks and gardens | Ensures optimal water delivery, supporting plant health | Size and access features, ease of installation and maintenance |

| Municipal Water Supply | Infrastructure for urban irrigation networks | Supports sustainable water management practices | Compliance with local regulations, material quality, and resilience |

| Oil & Gas | Valve access for water injection in drilling operations | Facilitates timely maintenance, reducing downtime | Material resistance to corrosive environments, security features |

| Sports Facilities | Management of irrigation for large sports fields | Maintains field quality and reduces water waste | Size specifications, ease of access for maintenance, and durability |

How is the 30 Inch Irrigation Valve Box Used in Agriculture?

In the agriculture sector, a 30-inch irrigation valve box is essential for managing water distribution in large-scale irrigation systems. These valve boxes house control valves that regulate water flow to different sections of farmland, ensuring that crops receive adequate hydration. By optimizing water usage, businesses can significantly reduce operational costs and improve crop yields. Buyers in this sector should consider the box’s durability against UV rays and extreme weather conditions, as well as its compatibility with existing irrigation infrastructure to ensure seamless integration.

What are the Applications in Landscaping and Horticulture?

In landscaping and horticulture, the 30-inch irrigation valve box is utilized to control irrigation systems in parks, gardens, and residential landscapes. It allows for precise water delivery, which is crucial for maintaining the health of various plant species. This application helps landscape architects and horticulturists ensure that their designs thrive while minimizing water waste. Sourcing considerations for these buyers include the size and access features of the valve box, as well as its ease of installation and maintenance to keep landscapes in optimal condition.

How Does it Benefit Municipal Water Supply Systems?

Municipal water supply systems employ 30-inch irrigation valve boxes as part of their infrastructure to manage urban irrigation networks. These boxes facilitate the controlled distribution of water for public parks, sports fields, and other green spaces, supporting sustainable water management practices. By integrating these valve boxes, municipalities can ensure efficient water use and reduce operational costs. Buyers should focus on compliance with local regulations, the quality of materials used, and the overall resilience of the valve boxes to withstand urban environmental challenges.

What Role Does it Play in the Oil & Gas Industry?

In the oil and gas industry, a 30-inch irrigation valve box is crucial for managing water injection systems used during drilling operations. These valve boxes provide access to control valves that regulate water flow, enabling timely maintenance and minimizing downtime. The efficient management of water resources is vital for operational success in this sector. Buyers should prioritize material resistance to corrosive environments and security features to protect these critical components from unauthorized access.

How is it Used in Sports Facilities?

Sports facilities utilize 30-inch irrigation valve boxes for the efficient management of irrigation systems that maintain the quality of large sports fields. These boxes allow for precise control over water distribution, ensuring fields remain healthy and playable while minimizing water waste. By investing in reliable valve boxes, facility managers can enhance the longevity of their turf and improve overall player experience. Key sourcing considerations include size specifications, ease of access for maintenance, and the durability of materials to withstand heavy usage.

3 Common User Pain Points for ’30 inch irrigation valve box’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right Valve Box for Specific Applications

The Problem: B2B buyers often encounter challenges when selecting the appropriate 30-inch irrigation valve box for their specific applications. With various valve boxes available, differentiating between those designed for irrigation control versus those intended for drainage can be overwhelming. This confusion can lead to purchasing the wrong product, resulting in costly delays, project setbacks, and potential damage to the irrigation system.

The Solution: To mitigate this issue, buyers should start by clearly defining their project requirements. This includes understanding the specific applications for which the valve box will be used, such as whether it will house irrigation control valves, water meters, or other utilities. Once requirements are established, buyers should consult with manufacturers or suppliers who offer detailed product catalogs, including specifications and intended uses. Engaging in discussions with sales representatives can also provide valuable insights into the best options available. Additionally, consider utilizing digital tools or software that help visualize the installation and compatibility of the valve box with existing systems. This proactive approach will ensure the right selection, saving time and resources in the long run.

Scenario 2: Concerns Over Durability and Weather Resistance

The Problem: Many international buyers, especially in regions with extreme weather conditions like the Middle East and parts of Africa, are concerned about the durability of the 30-inch irrigation valve box. Factors such as high temperatures, UV exposure, and heavy rainfall can lead to premature wear and tear, affecting the overall functionality of the irrigation system. Buyers may worry that a lack of durability could mean frequent replacements, which not only increases costs but also disrupts agricultural or landscaping operations.

The Solution: To address these concerns, it is crucial to choose a valve box made from high-quality materials that offer UV resistance and structural integrity. Buyers should look for products that specify the use of materials like high-density polyethylene (HDPE) or structural foam, which are known for their durability and weather resistance. When sourcing these boxes, verify that they come with industry certifications or warranties that guarantee performance under harsh conditions. It is also beneficial to inquire about maintenance recommendations from manufacturers, as proper care can extend the lifespan of the valve box. Educating the procurement team on the importance of selecting high-performance materials will ensure that the irrigation system remains operational and efficient throughout its intended lifespan.

Scenario 3: Challenges with Installation and Maintenance

The Problem: Installation and maintenance of the 30-inch irrigation valve box can present significant challenges for B2B buyers, particularly if their teams lack the necessary expertise or resources. Improper installation can lead to misalignment, inadequate sealing, and ultimately system failures, while maintenance issues can arise if the box is not easily accessible or designed for efficient servicing.

The Solution: To overcome installation and maintenance challenges, buyers should prioritize selecting valve boxes designed with user-friendly features that simplify both processes. This includes boxes with overlapping lids that provide secure closures, minimizing the risk of water ingress. Additionally, buyers should invest in training their installation teams on best practices for setting up and maintaining the valve boxes. This could involve workshops or instructional materials from manufacturers that outline step-by-step installation procedures and maintenance schedules. Furthermore, opting for valve boxes with integrated access points can facilitate easier inspections and repairs. By emphasizing training and selecting products that support ease of use, buyers can significantly reduce the likelihood of installation errors and maintenance headaches.

Strategic Material Selection Guide for 30 inch irrigation valve box

When selecting materials for a 30-inch irrigation valve box, it is essential to consider the properties, advantages, and limitations of various materials. Here, we analyze four common materials used in the manufacturing of irrigation valve boxes: High-Density Polyethylene (HDPE), Polypropylene (PP), Reinforced Concrete, and Fiberglass Reinforced Plastic (FRP). Each material has unique characteristics that impact performance, durability, and suitability for specific applications.

What are the Key Properties of High-Density Polyethylene (HDPE) for Irrigation Valve Boxes?

HDPE is a widely used material known for its excellent chemical resistance and durability. It typically withstands temperatures ranging from -40°F to 120°F (-40°C to 49°C) and can handle moderate pressure levels without deforming. Its UV resistance ensures longevity when exposed to sunlight, making it suitable for outdoor applications.

Pros: HDPE is lightweight, cost-effective, and easy to manufacture. It is resistant to corrosion, making it ideal for environments with high moisture or chemical exposure.

Cons: While HDPE is durable, it may not withstand extreme temperatures or heavy loads as effectively as other materials. Its lower rigidity can also lead to deformation under excessive pressure.

Impact on Application: HDPE is compatible with various media, including water and irrigation chemicals, making it a versatile choice for irrigation systems.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or ISO certifications. HDPE is commonly accepted in many regions, including Africa and South America, but specific regulations may vary.

How Does Polypropylene (PP) Compare as a Material for Valve Boxes?

Polypropylene is another thermoplastic material known for its excellent chemical resistance and low moisture absorption. It can handle temperatures up to 200°F (93°C) and offers good impact resistance.

Pros: PP is lightweight and has a high tensile strength, making it durable in various environmental conditions. Its resistance to acids and bases makes it suitable for agricultural applications.

Cons: Polypropylene can become brittle in low temperatures, limiting its use in colder climates. Additionally, it may not have the same UV resistance as HDPE, which could lead to degradation over time.

Impact on Application: PP is suitable for irrigation systems that utilize fertilizers or other chemicals due to its chemical compatibility.

Considerations for International Buyers: Buyers in regions like the Middle East should verify that the PP products meet local standards and regulations, especially in terms of chemical safety.

What are the Advantages of Using Reinforced Concrete for Irrigation Valve Boxes?

Reinforced concrete is a robust material known for its strength and durability. It can withstand high pressure and is resistant to environmental stresses, making it suitable for heavy-duty applications.

Pros: The primary advantage of reinforced concrete is its structural integrity and longevity. It is highly resistant to impact and can endure harsh weather conditions.

Cons: The weight of reinforced concrete makes it challenging to transport and install. Additionally, it is more expensive than plastic alternatives and requires more complex manufacturing processes.

Impact on Application: Reinforced concrete is ideal for applications requiring significant load-bearing capacity, such as in agricultural settings with heavy machinery.

Considerations for International Buyers: Compliance with local construction standards and regulations is crucial. Buyers should also consider the logistics of transporting heavy materials, especially in regions with underdeveloped infrastructure.

How Does Fiberglass Reinforced Plastic (FRP) Perform for Valve Boxes?

FRP combines the lightweight properties of plastic with the strength of fiberglass, providing excellent durability and corrosion resistance. It can handle a wide temperature range and is resistant to various chemicals.

Pros: FRP is lightweight, making it easy to handle and install. Its resistance to corrosion ensures a long lifespan, even in harsh environments.

Cons: The initial cost of FRP can be higher than plastic alternatives, and it may require specialized manufacturing techniques. Additionally, its performance can be affected by UV exposure unless properly treated.

Impact on Application: FRP is well-suited for applications involving aggressive chemicals, making it a good choice for irrigation systems that use various fertilizers.

Considerations for International Buyers: Buyers should ensure that FRP products meet international standards for quality and safety. Understanding local market preferences is also essential, as some regions may favor traditional materials over composites.

Summary Table of Material Selection for 30-Inch Irrigation Valve Boxes

| Material | Typical Use Case for 30 inch irrigation valve box | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene | General irrigation applications | Excellent chemical resistance | Limited load-bearing capacity | Low |

| Polypropylene | Agricultural irrigation systems | High tensile strength | Brittle in low temperatures | Low |

| Reinforced Concrete | Heavy-duty agricultural applications | Superior strength and durability | Heavy and costly to transport | High |

| Fiberglass Reinforced Plastic | Chemical-intensive irrigation systems | Lightweight and corrosion-resistant | Higher initial cost | Medium |

This analysis provides a comprehensive overview of the materials suitable for 30-inch irrigation valve boxes, offering valuable insights for international B2B buyers in their decision-making process.

In-depth Look: Manufacturing Processes and Quality Assurance for 30 inch irrigation valve box

What Are the Key Stages in the Manufacturing Process of a 30 Inch Irrigation Valve Box?

The manufacturing of a 30-inch irrigation valve box involves several critical stages, each designed to ensure durability, functionality, and compliance with international standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for the Manufacturing Process?

The process begins with the selection of high-density polyethylene (HDPE) or other durable materials that can withstand environmental stressors such as UV exposure and temperature variations. These materials are sourced from reputable suppliers who provide certification of their properties. Once the materials are received, they undergo an Incoming Quality Control (IQC) inspection to verify compliance with specifications. This step is crucial for ensuring that only the best quality materials are used in production.

What Techniques Are Used in the Forming Stage?

After material preparation, the next stage is forming. This often involves injection molding, a technique that allows for precise shaping of the valve box components. For larger boxes like the 30-inch variant, manufacturers may utilize advanced molds that ensure uniform thickness and structural integrity. This process is critical in maintaining the box’s strength and durability, particularly against soil pressure and water exposure.

How Does Assembly Work in the Manufacturing Process?

Once the individual components are formed, they move to the assembly stage. This step includes integrating the box with its lid, ensuring that all seals and joints are securely fitted to prevent leaks. Quality checks are performed during assembly to ensure that components fit correctly and that there are no defects. This may involve visual inspections and measurements to verify dimensions against specifications.

What Finishing Processes Are Involved?

The finishing stage includes applying UV inhibitors to protect against degradation from sunlight exposure, which is particularly important for outdoor applications. Additionally, any necessary markings or labels, such as those indicating the box’s purpose (irrigation control valve, reclaimed water, etc.), are applied. The final product undergoes a Full Quality Control (FQC) inspection before packaging to ensure that it meets all design and performance specifications.

What International Standards and Quality Assurance Practices Are Relevant?

For B2B buyers, understanding the quality assurance processes is essential. Manufacturers of irrigation valve boxes often adhere to international standards such as ISO 9001, which ensures consistent quality management systems. In addition to ISO certifications, compliance with industry-specific standards like CE marking for products sold within the European Union or API standards for performance can be critical.

How Are Quality Control Checkpoints Implemented?

Quality control checkpoints are integrated at various stages of the manufacturing process. These include:

- Incoming Quality Control (IQC): Checks the quality of raw materials upon arrival.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects early.

- Final Quality Control (FQC): Ensures that the finished product meets all specifications before it is shipped.

These checkpoints help to minimize defects and ensure that the final product is reliable and meets the rigorous demands of end-users.

What Common Testing Methods Are Used for Quality Assurance?

Common testing methods for irrigation valve boxes include:

- Dimensional Testing: To ensure that the product meets specified dimensions.

- Pressure Testing: To evaluate the box’s ability to withstand pressure without leaking.

- UV Resistance Testing: To assess the durability of materials under prolonged UV exposure.

- Impact Testing: To determine how well the box can withstand external forces.

These tests help verify that the boxes will perform well in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some actionable steps:

- Supplier Audits: Conduct on-site audits to assess manufacturing practices, quality control measures, and overall compliance with standards.

- Request Quality Reports: Ask suppliers for documentation of their quality control processes, including testing results and certifications.

- Third-party Inspections: Engage third-party inspection services to conduct independent assessments of the manufacturing process and final products.

These measures can help mitigate risks associated with product quality and ensure that suppliers meet the buyer’s specifications.

What Are the Specific Quality Control and Certification Nuances for International Buyers?

International buyers should be aware of the nuances related to quality control and certification that may vary by region. For instance, while ISO certifications are widely recognized, certain markets may have additional local certifications that are required for product acceptance. Understanding these regional requirements is essential for compliance and market entry.

Moreover, buyers should consider the logistical aspects of quality assurance, such as shipping and handling practices that could affect product integrity. Ensuring that suppliers have robust handling procedures will further enhance the reliability of the products received.

Conclusion

The manufacturing processes and quality assurance practices for a 30-inch irrigation valve box are multifaceted and critical for ensuring a reliable product. By understanding these processes, B2B buyers can make informed decisions and select suppliers that meet their quality standards, ultimately leading to successful project outcomes. As the demand for irrigation solutions grows globally, particularly in regions like Africa, South America, the Middle East, and Europe, a focus on quality and compliance will be paramount in maintaining competitive advantage.

Practical Sourcing Guide: A Step-by-Step Checklist for ’30 inch irrigation valve box’

Introduction

Sourcing a 30-inch irrigation valve box requires careful consideration of various factors to ensure you select the right product and supplier for your needs. This guide provides a practical checklist for B2B buyers, focusing on essential steps that facilitate informed purchasing decisions while maximizing value and minimizing risks.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, outline the specific technical requirements for your 30-inch irrigation valve box. Consider the intended application, environmental conditions, and any relevant industry standards.

– Material: Ensure the box is made from durable materials, such as HDPE or structural foam, which can withstand harsh weather.

– Design Features: Look for UV inhibitors for longevity and options like overlapping lids for enhanced protection.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in irrigation valve boxes. Utilize online directories, trade shows, and industry publications to compile a list of potential vendors.

– Supplier Location: Consider suppliers in regions with established irrigation practices, as they may offer better insights and products tailored to specific climates.

– Market Presence: Evaluate the supplier’s experience in the industry and their ability to meet large orders.

Step 3: Evaluate Product Quality and Compliance

Assess the quality of the valve boxes offered by potential suppliers. Request samples or product specifications to verify that they meet your technical requirements.

– Certifications: Check for compliance with relevant international standards or certifications that ensure product reliability and safety.

– Durability Testing: Inquire about testing protocols that demonstrate the box’s resistance to corrosion, abrasion, and environmental stressors.

Step 4: Verify Supplier Certifications

Confirm that the suppliers possess necessary certifications and licenses that validate their operations. This is crucial for ensuring product quality and legal compliance.

– ISO Certifications: Look for ISO 9001 or similar certifications that indicate quality management systems are in place.

– Local Regulations: Ensure that the supplier adheres to regional regulations, especially if you are sourcing from different countries.

Step 5: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes that break down the costs associated with the 30-inch irrigation valve boxes.

– Cost Analysis: Analyze not only the base price but also shipping, customs, and potential bulk discounts for larger orders.

– Value Over Price: Consider the overall value, including product quality, warranty, and after-sales support, rather than making decisions solely based on price.

Step 6: Assess Delivery and Lead Times

Understanding delivery schedules and lead times is critical for maintaining your project timelines. Discuss these aspects with your shortlisted suppliers.

– Production Capacity: Ensure the supplier has the capacity to meet your delivery requirements without compromising quality.

– Logistics: Inquire about their shipping methods and any potential delays based on geographic factors, especially for international orders.

Step 7: Establish Communication and Support Channels

Once you select a supplier, establish clear lines of communication for ongoing support and inquiries.

– Dedicated Contacts: Ensure you have a designated point of contact for addressing any concerns or questions during the sourcing process.

– Post-Sale Support: Discuss the availability of technical support or assistance with installation, which can be crucial for successful implementation.

By following this checklist, B2B buyers can systematically approach the sourcing of a 30-inch irrigation valve box, ensuring that they make informed decisions that align with their operational needs and strategic objectives.

Comprehensive Cost and Pricing Analysis for 30 inch irrigation valve box Sourcing

What Are the Key Cost Components for Sourcing a 30-Inch Irrigation Valve Box?

When analyzing the cost structure for a 30-inch irrigation valve box, several key components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The primary materials used in valve boxes often include high-density polyethylene (HDPE) or structural foam, which offer durability and UV resistance. The cost of raw materials can fluctuate based on global market trends, impacting overall pricing.

Labor: Labor costs vary significantly depending on the region of production. Countries with lower labor costs may offer more competitive pricing but could compromise on quality if not monitored closely.

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs.

Tooling: Initial tooling costs can be significant, especially for custom designs. However, once established, these costs are amortized over larger production runs, making larger orders more cost-effective.

Quality Control: Ensuring that products meet quality standards incurs additional costs but is essential for maintaining brand reputation and compliance with international standards.

Logistics: Transportation and shipping costs can vary widely based on the destination. Factors such as distance, shipping method, and fuel prices will influence logistics costs.

Margin: Suppliers will typically include a profit margin, which can vary based on market competition and perceived value. Understanding the typical margins in your target market can help in negotiations.

How Do Price Influencers Affect the Cost of a 30-Inch Irrigation Valve Box?

Several factors influence the final pricing of a 30-inch irrigation valve box beyond the basic cost components.

Volume/MOQ: Larger orders often qualify for volume discounts, reducing the per-unit cost significantly. Buyers should consider their long-term needs to maximize cost-efficiency.

Specifications and Customization: Custom designs or specific material requirements can increase costs. Be clear about your specifications to avoid unexpected charges.

Material Quality and Certifications: High-quality materials or those with specific certifications (like ISO or NSF) may come at a premium. However, investing in quality can reduce maintenance and replacement costs over time.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better assurance of quality and service.

Incoterms: The chosen Incoterms can impact overall costs, especially in international trade. Understanding who is responsible for shipping, insurance, and tariffs is crucial for accurate cost assessment.

What Tips Can Help Buyers Negotiate Better Prices for 30-Inch Irrigation Valve Boxes?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance their purchasing outcomes:

Negotiate Terms: Always negotiate terms of sale, including payment terms, delivery schedules, and warranties. Clear communication can lead to better pricing and service.

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like shipping, installation, and long-term maintenance. A lower upfront cost might lead to higher TCO if quality is compromised.

Understand Pricing Nuances: Familiarize yourself with local market conditions and pricing norms. This knowledge can empower you during negotiations and help identify fair pricing.

Research Multiple Suppliers: Diversifying your supplier base can lead to competitive pricing. Compare offerings from various manufacturers to find the best balance of cost and quality.

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming deals or new products.

Disclaimer on Indicative Prices

Please note that the prices referenced in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Always request updated quotes and conduct thorough due diligence when sourcing products.

Alternatives Analysis: Comparing 30 inch irrigation valve box With Other Solutions

When considering irrigation solutions, it’s essential for B2B buyers to explore various options that can effectively manage water flow in agricultural and landscaping applications. The 30-inch irrigation valve box is a popular choice, but several alternative solutions offer unique advantages depending on specific requirements. Below, we will compare the 30-inch irrigation valve box against two viable alternatives: automated irrigation controllers and underground irrigation systems.

| Comparison Aspect | 30 Inch Irrigation Valve Box | Automated Irrigation Controller | Underground Irrigation System |

|---|---|---|---|

| Performance | High durability and protection against environmental factors | Offers precise water management and scheduling | Efficient water distribution directly to plant roots |

| Cost | Moderate initial investment; long-term cost savings | Higher initial cost due to technology | Varies widely based on installation complexity |

| Ease of Implementation | Simple installation; requires minimal tools | Requires programming and setup, may need expert help | Complex installation; may require professional assistance |

| Maintenance | Low maintenance; periodic checks recommended | Requires software updates and occasional troubleshooting | Moderate maintenance; regular checks needed to prevent clogs |

| Best Use Case | Ideal for controlling multiple irrigation lines in large areas | Best for precision agriculture and automated systems | Suited for extensive landscape areas where surface irrigation is impractical |

What Are the Advantages and Disadvantages of Automated Irrigation Controllers?

Automated irrigation controllers are designed to optimize water usage through programmable schedules and sensor integration. The primary advantage of these systems is their ability to provide precise water management based on environmental conditions, which can lead to significant water savings and healthier plants. However, the higher initial investment and the need for technical expertise for setup may deter some buyers. Additionally, ongoing maintenance and software updates can add to the overall cost.

How Do Underground Irrigation Systems Compare?

Underground irrigation systems involve the installation of pipes and emitters beneath the soil surface, delivering water directly to plant roots. This method is highly efficient, reducing evaporation and runoff. Its best use case is in larger landscapes or agricultural fields where traditional surface irrigation methods may not be feasible. However, the installation process can be complex and costly, requiring professional assistance. Maintenance is necessary to ensure the system remains unclogged and operates effectively.

How to Choose the Right Irrigation Solution for Your Needs?

When selecting the right irrigation solution, B2B buyers should assess their specific needs, including the scale of their operation, budget constraints, and desired level of automation. The 30-inch irrigation valve box is an excellent choice for those looking for a durable and straightforward solution. In contrast, automated controllers may be ideal for precision-focused applications, while underground systems are suitable for extensive areas where surface irrigation is impractical. By weighing the pros and cons of each option, buyers can make informed decisions that align with their operational goals and environmental considerations.

Essential Technical Properties and Trade Terminology for 30 inch irrigation valve box

What Are the Key Technical Properties of a 30 Inch Irrigation Valve Box?

When considering a 30 inch irrigation valve box, several technical specifications are critical to ensure optimal performance and longevity. Understanding these properties can significantly impact purchasing decisions for B2B buyers across various regions.

1. Material Grade and Composition

The most common materials used for valve boxes include high-density polyethylene (HDPE) and polypropylene. These materials are favored for their durability, resistance to UV radiation, and ability to withstand harsh environmental conditions. For B2B buyers, selecting the right material ensures that the valve box will not degrade under exposure to sunlight or extreme temperatures, thus minimizing maintenance costs and extending service life.

2. Wall Thickness

The wall thickness of a valve box typically ranges from 0.2 to 0.32 inches. A thicker wall enhances structural integrity, making the box more resistant to impacts and external pressures. For B2B operations, this specification is crucial as it can prevent damage during installation and operation, thereby reducing the risk of costly repairs or replacements.

3. Load Rating

Load ratings are essential for determining the maximum weight the valve box can support without compromising its structural integrity. A 30 inch irrigation valve box should ideally have a load rating that accommodates the specific environmental conditions it will face, such as vehicular traffic in urban settings. B2B buyers must ensure that the selected valve box meets these load requirements to avoid failure under operational stresses.

4. UV Resistance

UV resistance is a critical property, especially in regions with intense sunlight. Many valve boxes incorporate UV inhibitors in their materials to prevent degradation over time. For B2B buyers, ensuring that the valve box has adequate UV resistance can lead to lower replacement frequency and reduced lifecycle costs.

5. Color and Identification

Valve boxes are available in various colors such as green, black, and purple, often indicating their specific use (e.g., irrigation, sewer, reclaimed water). This color-coding can facilitate easier identification and compliance with local regulations. B2B purchasers should consider local standards and operational needs when selecting the color of the valve box.

What Are the Common Trade Terms Associated with 30 Inch Irrigation Valve Boxes?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms relevant to the procurement of 30 inch irrigation valve boxes.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of valve boxes, knowing if a product is OEM can assure buyers of quality and compatibility with existing systems, which is vital for ensuring seamless integration into irrigation networks.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For B2B buyers, understanding the MOQ is crucial for budgeting and inventory management. Purchasing below this quantity may result in higher costs or unavailability of the product.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific goods or services. B2B buyers should use RFQs to compare prices, terms, and conditions from different suppliers, enabling informed purchasing decisions and potentially better negotiation outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help B2B buyers understand shipping costs, risks, and liability, ensuring smoother logistics operations.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. Knowing the lead time for valve boxes is essential for project planning and ensuring that irrigation systems can be installed on schedule. B2B buyers should consider this factor when selecting suppliers to avoid delays.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when procuring 30 inch irrigation valve boxes, ensuring they meet their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the 30 inch irrigation valve box Sector

What Are the Current Market Dynamics for the 30 Inch Irrigation Valve Box Sector?

The global market for irrigation systems is witnessing robust growth, driven by increasing agricultural demands and the need for efficient water management solutions. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek to optimize irrigation practices, the demand for 30 inch irrigation valve boxes is on the rise. These products are essential for controlling water flow in large-scale irrigation systems, which are increasingly vital for food production and sustainable agriculture.

Emerging trends in technology, such as the integration of smart irrigation systems, are influencing sourcing decisions. Advanced valve boxes equipped with IoT capabilities allow for remote monitoring and management, enhancing efficiency and reducing water waste. Additionally, the increasing adoption of precision agriculture techniques is driving the demand for customizable and adaptable valve solutions. Buyers should consider suppliers that offer a diverse range of products, including those with varying materials and designs to meet specific agricultural needs.

Furthermore, geopolitical factors and climate change are reshaping sourcing strategies. International buyers must stay informed about local regulations and import tariffs that could affect procurement costs. In regions such as Saudi Arabia and Brazil, where water scarcity is a pressing issue, sourcing durable and reliable irrigation valve boxes becomes paramount to ensure long-term operational efficiency.

How Important Are Sustainability and Ethical Sourcing in the Procurement of 30 Inch Irrigation Valve Boxes?

Sustainability is becoming a critical focus in the procurement of irrigation systems, including 30 inch valve boxes. Buyers are increasingly aware of the environmental impact of their sourcing decisions. Valve boxes made from recycled or eco-friendly materials not only minimize the carbon footprint but also align with global initiatives aimed at promoting sustainable agriculture.

The importance of ethical supply chains cannot be overstated. Buyers should prioritize suppliers who adhere to fair labor practices and responsible sourcing. Certifications such as ISO 14001 for environmental management and LEED for sustainable products can provide assurance that the materials used in valve boxes meet stringent environmental standards. By choosing products that are certified green, businesses can enhance their brand reputation and appeal to environmentally conscious customers.

Moreover, the adoption of sustainable practices can lead to cost savings in the long run. Durable valve boxes that withstand harsh environmental conditions reduce the frequency of replacements, leading to lower operational costs. International buyers should engage with suppliers that are committed to sustainability and can provide transparency regarding their sourcing practices.

How Has the 30 Inch Irrigation Valve Box Sector Evolved Over Time?

The evolution of the 30 inch irrigation valve box sector can be traced back to the increasing need for efficient water management in agriculture. Initially, valve boxes were simple structures made from metal or concrete. However, advancements in materials science have led to the development of high-density polyethylene (HDPE) and other composite materials that are lighter, more durable, and resistant to corrosion.

As agriculture has modernized, so too has the functionality of valve boxes. The introduction of modular designs allows for easier installation and maintenance, catering to the needs of diverse agricultural practices across different regions. Today, the market is characterized by a variety of sizes, colors, and functionalities, enabling buyers to select products that best fit their specific irrigation systems.

In conclusion, understanding the current market dynamics, prioritizing sustainability, and recognizing the historical context of the 30 inch irrigation valve box sector will empower international B2B buyers to make informed sourcing decisions that meet the challenges of modern agriculture.

Frequently Asked Questions (FAQs) for B2B Buyers of 30 inch irrigation valve box

How do I choose the right supplier for a 30 inch irrigation valve box?

Selecting the right supplier is crucial for ensuring quality and reliability. Start by researching potential suppliers’ reputations through customer reviews and industry recommendations. Look for suppliers who have a track record in manufacturing irrigation products and offer certifications for quality assurance. It’s also beneficial to request samples to evaluate product quality firsthand. Consider suppliers that provide clear communication and support throughout the purchasing process, as this can be indicative of their customer service standards.What are the common materials used in 30 inch irrigation valve boxes?

Most 30 inch irrigation valve boxes are constructed from durable materials such as high-density polyethylene (HDPE) or polypropylene. These materials are resistant to UV rays, chemicals, and extreme weather conditions, making them suitable for outdoor use. Additionally, some boxes may feature reinforced structures for added strength and durability. When selecting a valve box, ensure it meets the specific environmental conditions of your installation site, especially in regions with extreme temperatures or heavy rainfall.What customization options are available for 30 inch irrigation valve boxes?

Customization options for 30 inch irrigation valve boxes can include color choices, lid designs, and specific measurements to fit unique installation requirements. Some suppliers may also offer branding options, allowing you to incorporate your company logo on the box. It’s essential to communicate your specific needs to the supplier and confirm whether they can accommodate these customizations within your required lead time.What is the minimum order quantity (MOQ) for 30 inch irrigation valve boxes?

Minimum order quantities for 30 inch irrigation valve boxes can vary significantly between suppliers. Typically, MOQs range from 10 to 100 units, depending on the manufacturer and the customization options selected. Be sure to inquire about the MOQ when contacting potential suppliers, as this can impact your purchasing strategy. Some suppliers may offer flexibility on MOQs for first-time buyers or larger orders, so it’s worth discussing your needs with them.What payment terms should I expect when ordering from international suppliers?

Payment terms can vary widely depending on the supplier and the region. Common practices include upfront payment, partial payment upon order confirmation, and the remaining balance before shipment. It’s advisable to negotiate terms that provide you with adequate security while ensuring the supplier is protected. Additionally, consider using secure payment methods such as letters of credit or escrow services, especially for larger orders, to mitigate risks associated with international transactions.How can I ensure the quality of the irrigation valve boxes I purchase?

To ensure product quality, request detailed specifications and certifications from suppliers. Look for third-party testing reports that confirm compliance with international quality standards. It’s also beneficial to establish a quality assurance process, including on-site inspections or third-party audits of the manufacturing facilities. Discuss warranty terms with the supplier to protect your investment and ensure you have recourse in case of defects.What logistics considerations should I keep in mind for shipping 30 inch irrigation valve boxes?

When planning logistics, consider factors such as shipping method, costs, and delivery times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Additionally, ensure you understand the import regulations and duties for your country, which can affect your overall costs. Collaborating with a freight forwarder experienced in international shipping can help streamline the process and mitigate potential issues.What are the best practices for maintaining irrigation valve boxes?

Regular maintenance of irrigation valve boxes is essential for ensuring longevity and functionality. Inspect boxes periodically for signs of wear, damage, or obstructions. Clean the interiors and ensure that any drainage mechanisms are functioning properly to prevent water accumulation. Additionally, check for any visible cracks or discoloration, which may indicate UV damage or material fatigue, and replace the boxes as needed to maintain effective irrigation operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 30 Inch Irrigation Valve Box Manufacturers & Suppliers List

1. NDS – Valve Boxes

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: NDS Valve Boxes are manufactured in Lindsay, CA, and come in various sizes from 6″ round to 17″ x 30″ rectangular. Available colors for covers include black, green, purple, gray, and sand, with designations for irrigation control valve, water, sewer, electric, reclaimed water, cable TV, and telephone. All boxes and lids contain UV inhibitors for durability in sunlight. Examples of products include…

2. Drainage Connect – Valve Boxes

Domain: drainageconnect.com

Registered: 2016 (9 years)

Introduction: Valve boxes are available in a variety of sizes ranging from a 6-inch round valve box to a 17″ x 30″ rectangular box. They come with covers in colors such as black, green, purple, gray, and sand, and are designated for uses including irrigation control valve, water, sewer, electric, reclaimed water, cable TV, and telephone. Specific products include: NDS Jumbo Valve Box and Cover ($99.26), NDS 6″ …

3. Ferguson – NDS 30 in. Irrigation Valve Box

Domain: ferguson.com

Registered: 1999 (26 years)

Introduction: NDS 30 in. Irrigation Valve Box with Cover in Green

4. NDS – Pro-Spec® Series Valve Boxes & Covers

Domain: ndspro.com

Registered: 1996 (29 years)

Introduction: Pro-Spec® Series Valve Boxes & Covers are engineered for heavy-duty use with the following key features: thick, corrugated sidewalls for added strength while reducing weight; structural reinforcing ribs for support; reinforced covers that handle heavier loads than Standard Series; overlapping cover to prevent dirt and debris from entering; built-in pipe holes for irrigation piping; select models f…

5. Rainbird – Jumbo Valve Box – Body Only

Domain: store.rainbird.com

Registered: 1995 (30 years)

Introduction: {“model”:”VBJMBB”,”name”:”Jumbo Valve Box – Body Only”,”special_price”:”$63.60″,”list_price”:”$84.80″,”in_stock”:”true”,”sku”:”A11433MX”,”dimensions”:{“length”:”26.3 inches (66.8 cm)”,”width”:”19.8 inches (50.3 cm)”,”height”:”12.1 inches (30.7 cm)”},”material”:”Plastic”,”features”:[“100 percent recycled materials”,”LEED compliant”,”Pipe-hole knockouts for easy pipe placement”,”Stacking and interlo…

6. Facebook – Custom Valve Box

7. NDS – Pro-Spec™ Valve Box

Domain: cheapsprinklers.com

Registered: 2014 (11 years)

Introduction: NDS Pro-Spec™ 17″ x 30″ x 15″ Valve Box, Overlapping Bolt-Down Cover, ICV Colors: Black Box/Green Lid, Includes: 2 x 1/2” x 3/8” stainless steel bolts and zinc washers, Box includes 3/8-16 brass nuts, Made in USA, Designed for professional contractor and heavy-duty use, Load rating: Pedestrian & lawn care equipment, Weight: 41.2 lbs, Product Class: 20ND, Tapered body with minimum wall thickness of…

8. VBSPRH – Super Jumbo Valve Box

Domain: plumbingforums.com

Registered: 2009 (16 years)

Introduction: VBSPRH – Super Jumbo Valve Box – Black Body With Green Lid + 2 Locks; Size: 40 inches by 36 inches; Material: Composite or PVC deck boards; Price for PVC deck board: $120.00 for 16 feet; UV resistant; Suitable for coastal areas.

Strategic Sourcing Conclusion and Outlook for 30 inch irrigation valve box

In navigating the complexities of sourcing a 30-inch irrigation valve box, international buyers must recognize the critical importance of strategic sourcing practices. By leveraging a well-researched approach, businesses can identify reliable suppliers that provide high-quality products tailored to their specific regional needs. Key considerations include evaluating the durability and UV resistance of materials, ensuring compliance with local regulations, and understanding pricing dynamics across different markets.

Moreover, the variety of available designs—ranging from color-coded covers for easy identification to robust construction for longevity—offers buyers flexibility and adaptability in their operations. This strategic sourcing not only enhances operational efficiency but also contributes to sustainable practices by minimizing replacement costs and maximizing resource utilization.

Looking ahead, as global demand for efficient irrigation solutions continues to grow, particularly in regions such as Africa, South America, the Middle East, and Europe, B2B buyers are encouraged to prioritize long-term partnerships with reputable manufacturers. Engaging in proactive discussions and seeking tailored solutions will not only secure competitive pricing but also foster innovation in irrigation technology. Embrace the opportunity to elevate your sourcing strategy today, and ensure your projects are equipped with the best solutions for tomorrow’s challenges.