Introduction: Navigating the Global Market for irrigation valve diagram

In the dynamic landscape of global agriculture, sourcing the right irrigation valve diagram is crucial for optimizing irrigation systems across diverse environments. International B2B buyers face the pressing challenge of identifying the most effective solutions that cater to their specific regional needs, whether in the arid expanses of Saudi Arabia or the lush fields of Nigeria. This comprehensive guide offers an in-depth exploration of various irrigation valve types, their applications, and the intricacies of valve anatomy, empowering buyers to make informed decisions that align with their operational goals.

Understanding the components and functionality of irrigation valves is essential for ensuring the longevity and efficiency of irrigation systems. This guide delves into essential topics, including valve body types, maintenance strategies, and troubleshooting tips, all designed to equip buyers with the knowledge necessary to navigate supplier options effectively. Additionally, we provide insights on cost considerations, supplier vetting processes, and best practices for procurement, tailored specifically for buyers from Africa, South America, the Middle East, and Europe.

By leveraging the information presented in this guide, B2B buyers can enhance their purchasing strategies, ensuring they invest in high-quality irrigation solutions that support sustainable agricultural practices and meet the demands of their unique markets.

Understanding irrigation valve diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Screw Top Valve | Disassembled via screws; robust construction | Agricultural irrigation systems | Pros: Easy maintenance; durable. Cons: Can be cumbersome to open. |

| Jar Top Valve | Unscrews like a jar; simpler access to internal parts | Residential and commercial gardens | Pros: Quick access for repairs; less chance of losing parts. Cons: Potentially less durable. |

| Electric Solenoid Valve | Automated operation via electrical signals | Large-scale irrigation systems | Pros: Efficient and precise control; ideal for automation. Cons: Requires electrical infrastructure; potential for electrical failures. |

| Manual Control Valve | Operated manually; simple design | Small gardens, DIY projects | Pros: Low cost; easy to operate. Cons: Labor-intensive; less efficient for large systems. |

| Flow Control Valve | Adjustable flow settings; enhances system flexibility | Golf courses, parks, and farms | Pros: Customizable water delivery; reduces water waste. Cons: More complex installation; higher initial cost. |

What Are the Characteristics of Screw Top Valves?

Screw top valves are characterized by their robust construction and the need for screws to access internal components. This type is particularly suitable for agricultural irrigation systems where durability is essential. When purchasing, B2B buyers should consider the ease of maintenance, as the screws can be cumbersome to manage, especially in large installations. However, their longevity and reliability make them a favored choice in demanding environments.

How Do Jar Top Valves Differ From Other Types?

Jar top valves are designed for quick disassembly, resembling the action of unscrewing a jar lid. This feature makes them advantageous for residential and commercial gardens where frequent access may be necessary for repairs or adjustments. B2B buyers should appreciate the ease of access provided by this design, although they may be less durable than screw top options. The ability to quickly service these valves can significantly reduce downtime in irrigation operations.

What Are the Benefits of Electric Solenoid Valves?

Electric solenoid valves are automated systems that respond to electrical signals from irrigation controllers. They are widely used in large-scale irrigation systems, allowing for efficient and precise control over water delivery. B2B buyers must consider the necessity of an established electrical infrastructure, as these valves require electricity to function. While they offer significant operational efficiency, potential electrical failures can pose challenges, requiring buyers to weigh the benefits against their operational capabilities.

Why Choose Manual Control Valves for Small Projects?

Manual control valves are straightforward and cost-effective, making them suitable for small gardens and DIY irrigation projects. Their simple design allows for easy operation without the need for complex systems. However, B2B buyers should be aware that while they are low-cost, they can be labor-intensive, especially in larger installations where frequent adjustments are needed. The simplicity of these valves makes them appealing for buyers looking for straightforward solutions.

How Do Flow Control Valves Enhance Irrigation Systems?

Flow control valves allow users to adjust water flow settings, providing enhanced flexibility in irrigation management. These valves are particularly beneficial for applications in golf courses, parks, and farms where water conservation is critical. B2B buyers should consider the initial installation complexity and cost, as these valves can be more intricate than standard options. However, the ability to customize water delivery can lead to significant long-term savings and resource efficiency, making them a worthwhile investment.

Key Industrial Applications of irrigation valve diagram

| Industry/Sector | Specific Application of irrigation valve diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems for crop management | Ensures efficient water usage, improving crop yield | Durability, compatibility with local water sources, and ease of maintenance. |

| Landscaping | Residential and commercial landscape irrigation | Enhances aesthetic appeal while conserving water | Availability of various valve types and sizes, local regulations on irrigation. |

| Greenhouse Operations | Controlled environment irrigation systems | Optimizes water delivery for sensitive plants | Precision in flow control, adaptability to varying greenhouse conditions. |

| Sports Turf Management | Irrigation systems for sports fields | Maintains healthy turf, ensuring optimal playing conditions | Robust design for high usage, resistance to wear and tear. |

| Municipal Water Supply | Public park and garden irrigation systems | Supports community beautification and environmental health | Compliance with local regulations, cost-effectiveness, and reliability. |

How is the ‘Irrigation Valve Diagram’ Utilized in Agriculture?

In agriculture, the irrigation valve diagram serves as a critical blueprint for designing automated irrigation systems that manage water distribution efficiently across vast crop fields. These systems help farmers optimize water usage, significantly enhancing crop yields while reducing waste. International buyers, particularly in regions like Africa and South America, must consider local water availability and quality when sourcing these valves, ensuring compatibility with their irrigation practices and climate conditions.

What Role Does the ‘Irrigation Valve Diagram’ Play in Landscaping?

For landscaping businesses, the irrigation valve diagram is essential for developing both residential and commercial irrigation systems. These diagrams assist in planning installations that enhance the aesthetic appeal of gardens and lawns while promoting water conservation. Buyers from the Middle East and Europe should prioritize sourcing valves that meet local regulations and are designed for ease of maintenance, as this can significantly reduce long-term operational costs.

Why is the ‘Irrigation Valve Diagram’ Important for Greenhouse Operations?

In greenhouse operations, the irrigation valve diagram is crucial for establishing controlled environment irrigation systems that cater to the specific needs of various plants. It allows for precise water delivery, crucial for maintaining optimal growing conditions. Buyers in Europe and the Middle East should focus on valves that offer adjustable flow controls to adapt to the diverse humidity and temperature conditions found in greenhouses.

How is the ‘Irrigation Valve Diagram’ Used in Sports Turf Management?

Sports turf management relies heavily on the irrigation valve diagram to create effective irrigation systems for fields. These systems ensure that turf remains healthy and playable, especially in regions with variable climates. Buyers, particularly from regions with high sports activity like Saudi Arabia, should consider valves that are durable and resistant to wear, as these systems are often subject to heavy usage.

What is the Significance of the ‘Irrigation Valve Diagram’ in Municipal Water Supply?

Municipalities utilize the irrigation valve diagram for managing public park and garden irrigation systems. These diagrams facilitate the design of systems that support community beautification and environmental health. Buyers from various regions must ensure that sourced valves comply with local regulations regarding public water use, emphasizing reliability and cost-effectiveness to maximize community benefits.

3 Common User Pain Points for ‘irrigation valve diagram’ & Their Solutions

Scenario 1: Understanding Valve Types for Optimal Performance

The Problem: B2B buyers often struggle with the variety of irrigation valve types, such as screw-top and jar-top valves, which can lead to confusion during installation or maintenance. Misidentifying valve types can result in improper handling, leading to system inefficiencies and increased costs. For instance, a contractor in Saudi Arabia might purchase the wrong valve type for a specific project, wasting both time and resources.

The Solution: To avoid confusion, it is essential to familiarize yourself with the different types of irrigation valves. Utilize detailed irrigation valve diagrams that clearly illustrate each valve type and its components. When sourcing valves, ensure that the supplier provides comprehensive diagrams, including installation instructions. Create a standardized checklist that includes valve type identification, operational features, and potential maintenance issues. This proactive approach will enable your team to select the right valve type for each project, enhancing operational efficiency and reducing costs.

Scenario 2: Troubleshooting Common Valve Issues

The Problem: Frequent issues with irrigation valves, such as failure to open or close, can lead to significant operational disruptions. For instance, a farmer in Nigeria may find that a valve controlling a vital irrigation zone is malfunctioning, jeopardizing crop health. This scenario can create stress for businesses that rely on timely irrigation to maintain production levels.

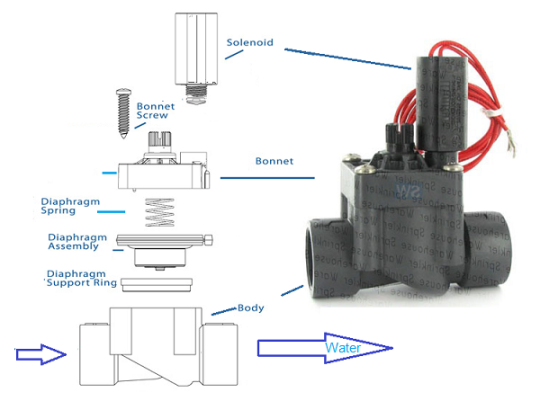

The Solution: Implement a systematic troubleshooting guide based on the valve diagrams. Start by educating your team on the internal components of the valve, such as the diaphragm and solenoid, as shown in the diagrams. Encourage regular maintenance checks to identify issues before they escalate. For example, if a valve is not closing, inspect the diaphragm for debris that may prevent a proper seal. Providing training sessions on using these diagrams for troubleshooting will empower your team to swiftly address issues, thereby minimizing downtime and protecting crop yields.

Scenario 3: Locating and Accessing Buried Valves Efficiently

The Problem: Locating buried irrigation valves can be a daunting task for B2B buyers, particularly in large agricultural projects where multiple zones are in play. For example, a landscaping company in South America may face delays in locating valves, leading to increased labor costs and project timelines. This inefficiency can impact customer satisfaction and profitability.

The Solution: To streamline the process of locating buried valves, incorporate detailed diagrams that mark the locations of all valves within the irrigation system. When designing the system, include features such as above-ground markers or accessible valve boxes, as indicated in the diagrams. Train your team to use ground-penetrating radar (GPR) technology for precise detection of underground components. Regularly updating the valve diagrams to reflect any changes made during maintenance will create a reliable reference tool. This approach not only saves time but also enhances the overall efficiency of your irrigation operations, ultimately leading to better service delivery and customer satisfaction.

Strategic Material Selection Guide for irrigation valve diagram

What Are the Common Materials Used in Irrigation Valves?

When selecting materials for irrigation valves, several factors must be considered, including performance properties, durability, cost, and suitability for specific applications. Below is an analysis of four common materials used in irrigation valve manufacturing: PVC, brass, stainless steel, and polyethylene.

How Does PVC Perform in Irrigation Valve Applications?

Key Properties: PVC (Polyvinyl Chloride) is a lightweight, corrosion-resistant plastic that can withstand temperatures up to 60°C (140°F) and pressures up to 10 bar (145 psi). Its chemical resistance makes it suitable for various irrigation applications.

Pros & Cons: PVC is relatively inexpensive and easy to manufacture, making it a popular choice for budget-conscious projects. However, its lower temperature and pressure ratings compared to metals can limit its use in high-stress environments. Additionally, PVC can become brittle over time when exposed to UV light, necessitating protective measures.

Impact on Application: PVC is compatible with water and many fertilizers, making it suitable for agricultural irrigation systems. However, it may not be ideal for applications involving high temperatures or aggressive chemicals.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards (e.g., ASTM D1784) and consider the impact of UV exposure in sunny climates.

What Advantages Does Brass Offer for Irrigation Valves?

Key Properties: Brass is a durable alloy primarily composed of copper and zinc. It has excellent corrosion resistance, can withstand high temperatures (up to 200°C or 392°F), and operates effectively under high pressures.

Pros & Cons: Brass valves are known for their longevity and reliability, making them suitable for demanding applications. However, they are more expensive than PVC and can be prone to dezincification in certain water conditions, which may lead to failure.

Impact on Application: Brass is particularly effective in potable water applications and is often used in commercial irrigation systems where durability is paramount.

Considerations for International Buyers: Buyers should check for compliance with drinking water standards (e.g., NSF/ANSI 61) and be aware of the potential for dezincification in specific water conditions, particularly in tropical climates.

How Does Stainless Steel Compare in Terms of Performance?

Key Properties: Stainless steel is highly resistant to corrosion and can endure extreme temperatures and pressures. It is often rated for temperatures exceeding 200°C (392°F) and pressures up to 20 bar (290 psi).

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for harsh environments. However, it is one of the most expensive materials and can be challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel valves are suitable for applications involving aggressive chemicals or high-pressure systems, making them ideal for industrial irrigation setups.

Considerations for International Buyers: Buyers should ensure compliance with international standards (e.g., ASTM A312) and consider the cost implications, especially in regions with budget constraints.

What Role Does Polyethylene Play in Irrigation Valve Design?

Key Properties: Polyethylene is a flexible plastic that can withstand temperatures up to 80°C (176°F) and is resistant to various chemicals. It is lightweight and easy to install.

Pros & Cons: The flexibility of polyethylene makes it suitable for various installations, especially in uneven terrain. However, it has lower pressure ratings compared to metals and may not be suitable for high-stress applications.

Impact on Application: Polyethylene is commonly used in drip irrigation systems and for low-pressure applications, making it ideal for agricultural settings.

Considerations for International Buyers: Buyers should ensure that the polyethylene used complies with relevant standards (e.g., ASTM D1248) and consider local environmental conditions that may affect the material’s longevity.

Summary of Material Selection for Irrigation Valves

| Material | Typical Use Case for irrigation valve diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Budget-friendly irrigation systems | Inexpensive and easy to manufacture | Limited temperature and pressure ratings | Low |

| Brass | Potable water and commercial systems | Durable and reliable | Expensive and prone to dezincification | Med |

| Stainless Steel | Industrial and high-pressure applications | Excellent corrosion resistance | High cost and manufacturing complexity | High |

| Polyethylene | Drip irrigation and low-pressure systems | Flexible and easy to install | Lower pressure ratings | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on their specific irrigation needs and local conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve diagram

What Are the Main Stages of Manufacturing Irrigation Valves?

The manufacturing process for irrigation valves is a multi-step procedure that requires precision and adherence to quality standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Irrigation Valve Production?

Material preparation is crucial as it ensures that the components of the irrigation valve meet specific performance criteria. Manufacturers typically use materials such as PVC, brass, and stainless steel, selected for their durability and resistance to corrosion.

Before production, raw materials undergo rigorous inspections to verify their quality. This might include checking for impurities and ensuring that the materials meet the specified chemical composition. Suppliers often provide certificates of compliance, which can be vital for B2B buyers looking to ensure the integrity of the materials used.

What Forming Techniques Are Used in Irrigation Valve Manufacturing?

Once the materials are prepared, forming techniques are employed to create the various components of the irrigation valve. Common techniques include:

- Injection Molding: This is particularly prevalent for PVC components, where molten plastic is injected into molds to form valve bodies and other parts.

- Machining: For metal components, machining techniques such as turning and milling are utilized to achieve precise dimensions and tolerances.

- Die Casting: This method is often used for creating intricate metal parts, ensuring strength and durability.

Each of these techniques requires specialized equipment and skilled operators to maintain quality and efficiency.

How Are Irrigation Valves Assembled?

The assembly stage involves bringing together all the individual components—such as the valve body, diaphragm, solenoid, and other internal mechanisms. This process is typically done in a clean and controlled environment to avoid contamination.

Assembly Techniques:

– Automated Assembly: Many manufacturers employ automated systems for tasks like inserting solenoids and sealing components. This enhances consistency and reduces labor costs.

– Manual Assembly: Critical components may still require manual assembly by skilled technicians to ensure proper fit and function.

Quality checks are integrated throughout the assembly process. For instance, each valve may undergo a functional test to verify that it operates correctly under pressure.

What Finishing Processes Are Used for Irrigation Valves?

Finishing processes enhance the durability and aesthetic appeal of irrigation valves. Common finishing techniques include:

- Coating: Protective coatings, such as epoxy or powder coating, may be applied to metal parts to prevent corrosion and improve appearance.

- Polishing: This is often performed on brass components to enhance visual appeal and reduce friction in mechanical parts.

Final inspections during the finishing stage ensure that the valves meet the necessary aesthetic and functional standards.

What Quality Control Standards Are Relevant for Irrigation Valves?

Quality assurance is a critical aspect of the manufacturing process for irrigation valves. International standards such as ISO 9001 provide a framework for establishing quality management systems, which is essential for maintaining product quality consistently.

How Do Industry-Specific Standards Impact Quality Control?

In addition to general quality standards, there are industry-specific certifications that can be crucial for irrigation valve manufacturers. For instance:

- CE Marking: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: The American Petroleum Institute standards may apply to valves used in specific applications, ensuring they meet industry-specific performance criteria.

B2B buyers should verify that suppliers have the necessary certifications, as this reflects a commitment to quality.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that each valve meets the required standards. Common checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): This includes monitoring and inspecting products at various stages of manufacturing to identify any deviations from quality standards.

- Final Quality Control (FQC): Before products are shipped, final inspections and testing are conducted to ensure that each valve functions correctly and meets all specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are effective strategies:

- Audits: Conducting supplier audits can provide insights into their manufacturing practices and quality control measures. This includes reviewing their quality management system and observing the production process firsthand.

- Quality Reports: Requesting detailed quality assurance reports can help buyers understand the frequency of inspections and the results of any testing performed.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s adherence to quality standards.

What Quality Control Nuances Should International Buyers Be Aware Of?

When sourcing irrigation valves internationally, buyers from regions such as Africa, South America, the Middle East, and Europe must consider various nuances:

- Regulatory Compliance: Different countries may have specific regulations regarding irrigation products. Familiarizing oneself with these can prevent compliance issues.

- Cultural Differences: Understanding cultural attitudes towards quality assurance and manufacturing can help establish better relationships with suppliers.

- Logistical Challenges: Ensure that suppliers can meet quality standards despite potential logistical challenges that may arise during international shipping.

Conclusion

In-depth knowledge of the manufacturing processes and quality assurance practices for irrigation valves is crucial for B2B buyers. By understanding the stages of production, relevant standards, and quality control measures, buyers can make informed decisions that lead to successful procurement outcomes. This diligence not only ensures the reliability of irrigation systems but also enhances long-term partnerships with suppliers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve diagram’

In the competitive landscape of irrigation systems, understanding the intricacies of irrigation valve diagrams is essential for effective procurement and system management. This guide will help B2B buyers navigate the sourcing process for irrigation valve diagrams, ensuring they make informed decisions that meet their operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider the type of irrigation system you have and the specific functionalities you require from the valves. This may include parameters such as valve size, flow rate, and compatibility with existing systems.

- Assess System Requirements: Identify the zones in your irrigation setup and the corresponding valve requirements for each zone.

- Document Standards: Ensure your specifications align with industry standards for quality and performance.

Step 2: Research and Identify Reputable Suppliers

Researching potential suppliers is critical to ensure you partner with trustworthy manufacturers. Look for companies that specialize in irrigation technology and have a proven track record in your target markets.

- Utilize Industry Networks: Leverage industry associations and trade shows to gather recommendations and insights on reliable suppliers.

- Check Online Reviews: Assess suppliers based on customer feedback and case studies to gauge their reliability and service quality.

Step 3: Request Detailed Product Information

Once you’ve shortlisted potential suppliers, request comprehensive product information, including detailed diagrams of the irrigation valves. This helps you understand the product better and evaluate its suitability.

- Ask for Technical Data Sheets: These should include specifications, installation instructions, and maintenance guidelines.

- Evaluate Compatibility: Ensure the diagrams provide information on how these valves integrate with your existing systems.

Step 4: Verify Supplier Certifications and Compliance

Confirm that your selected suppliers comply with relevant industry standards and certifications. This step is crucial to ensure product quality and regulatory compliance, especially in international markets.

- Look for ISO Certifications: Suppliers with ISO certifications demonstrate a commitment to quality management.

- Check for Local Compliance: Make sure the products meet local regulations applicable in your region, such as those in Africa, South America, the Middle East, and Europe.

Step 5: Assess Pricing and Payment Terms

Understanding the pricing structure and payment terms is vital for budget planning. Compare costs among different suppliers while considering the total cost of ownership, including shipping, installation, and maintenance.

- Request Quotes: Obtain detailed quotes that break down costs to identify any hidden fees.

- Negotiate Payment Terms: Discuss flexible payment options that may suit your cash flow needs, especially for large orders.

Step 6: Evaluate After-Sales Support and Warranty

After-sales support can significantly impact the longevity of your irrigation system. Ensure that suppliers offer robust support and warranty options to address any issues that arise post-purchase.

- Inquire About Training: Suppliers should provide training resources or support for installation and maintenance.

- Understand Warranty Terms: A comprehensive warranty can protect your investment and reduce future repair costs.

Step 7: Finalize Your Order and Monitor Delivery

Once you are satisfied with your supplier choice and terms, proceed to finalize your order. Maintain clear communication with the supplier regarding delivery timelines and any logistical considerations.

- Confirm Order Details: Double-check specifications, quantities, and delivery dates before placing the order.

- Track Delivery: Monitor the shipment to ensure timely arrival and address any discrepancies promptly.

By following this step-by-step checklist, B2B buyers can effectively source irrigation valve diagrams that meet their operational requirements while ensuring quality and reliability in their irrigation systems.

Comprehensive Cost and Pricing Analysis for irrigation valve diagram Sourcing

What Are the Key Cost Components in Sourcing Irrigation Valve Diagrams?

When sourcing irrigation valve diagrams, understanding the cost structure is crucial for effective budgeting and financial planning. The primary components include:

Materials: The choice of materials directly impacts costs. High-quality plastics, metals, and rubber components used in valves can vary significantly in price. For example, valves constructed from corrosion-resistant materials may have a higher initial cost but offer longer service life, thus reducing long-term expenses.

Labor: Labor costs encompass the wages of skilled workers involved in design, manufacturing, and assembly. In regions with higher labor costs, such as parts of Europe, this can significantly influence overall pricing.

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

Tooling: The initial investment in tools and molds for manufacturing irrigation valve diagrams can be substantial. However, amortizing these costs over large production runs can lead to lower per-unit costs.

Quality Control (QC): Implementing rigorous QC measures ensures that products meet specified standards, which can raise costs initially but is crucial for minimizing returns and defects.

Logistics: Transportation and handling costs play a significant role, especially for international shipments. Factors such as distance, shipping method, and local customs regulations can affect logistics costs.

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding market rates can help buyers negotiate better deals.

How Do Price Influencers Impact the Cost of Irrigation Valve Diagrams?

Several factors influence the pricing of irrigation valve diagrams, including:

Volume/MOQ: Larger orders often qualify for discounts, making it essential for buyers to assess their needs accurately. Minimum Order Quantities (MOQs) can also dictate pricing structures.

Specifications and Customization: Tailored designs or specific features can increase costs. Buyers should weigh the necessity of custom features against potential price increases.

Materials and Quality Certifications: Higher-grade materials and certifications (like ISO or CE) can elevate costs but may be essential for compliance and performance, especially in regulated markets.

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their perceived quality and service.

Incoterms: Understanding Incoterms is vital for assessing total costs. Different terms can shift responsibilities for shipping and insurance, impacting overall pricing.

What Are Effective Buyer Tips for Negotiating Irrigation Valve Diagram Prices?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

Negotiation: Leverage volume and commitment to negotiate better terms. Building long-term relationships with suppliers can lead to favorable pricing structures over time.

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes purchase price, operational costs, maintenance, and disposal. This holistic approach can uncover hidden costs and guide purchasing decisions.

Pricing Nuances: Be aware of regional pricing trends and currency fluctuations, which can affect costs significantly. Understanding local market conditions is essential for making informed decisions.

Documentation and Communication: Ensure all specifications, terms, and conditions are clearly documented. Effective communication with suppliers can help prevent misunderstandings that may lead to unexpected costs.

Disclaimer on Indicative Prices

Prices for irrigation valve diagrams can vary widely based on the aforementioned factors. Therefore, it is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always consider the context of your specific needs and local market conditions when evaluating costs.

Alternatives Analysis: Comparing irrigation valve diagram With Other Solutions

Understanding Alternative Solutions to Irrigation Valve Diagrams

In the realm of agricultural and landscape irrigation, various solutions are available to manage water distribution efficiently. While the irrigation valve diagram serves as a critical tool for understanding the functionality and components of irrigation systems, it is essential to evaluate other viable alternatives. This comparison will help B2B buyers make informed decisions based on their specific needs, budget, and operational contexts.

Comparison of Irrigation Valve Diagram with Alternative Solutions

| Comparison Aspect | Irrigation Valve Diagram | Smart Irrigation Controllers | Drip Irrigation Systems |

|---|---|---|---|

| Performance | High, precise control of water flow | Excellent, optimizes water usage based on weather and soil data | Efficient, minimizes water waste by delivering water directly to plant roots |

| Cost | Moderate (initial design and installation) | High (technology and setup costs) | Variable (low initial but may require ongoing maintenance) |

| Ease of Implementation | Moderate (requires technical knowledge) | Complex (requires installation and setup of sensors) | Easy (can be installed with minimal training) |

| Maintenance | Moderate (occasional repairs needed) | High (requires software updates and sensor maintenance) | Low (less frequent maintenance, mainly checking emitters) |

| Best Use Case | Suitable for large agricultural fields needing detailed control | Ideal for smart farms and regions with variable climates | Best for gardens and landscapes with specific plant needs |

In-Depth Analysis of Alternatives

Smart Irrigation Controllers

Smart irrigation controllers utilize advanced technology to automate the irrigation process. They adjust watering schedules based on real-time weather data, soil moisture levels, and plant needs. The primary advantage of this solution is its ability to optimize water usage, leading to significant savings on water costs. However, the initial investment can be substantial, and ongoing maintenance, including software updates and sensor checks, can be complex. This solution is best suited for large-scale agricultural operations or urban landscaping where water conservation is a priority.

Drip Irrigation Systems

Drip irrigation systems are designed to deliver water directly to the roots of plants, minimizing evaporation and runoff. This method is particularly effective for gardens and landscapes that require consistent moisture without overwatering. The ease of installation makes it accessible for many users, and the low maintenance requirements are appealing. However, the initial costs can vary based on the scale of the installation, and users may face challenges with emitter clogging if not properly maintained. Drip irrigation is an excellent choice for regions with limited water resources, ensuring efficient water delivery.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between an irrigation valve diagram and alternative solutions, B2B buyers should consider their specific operational context, budget, and performance needs. The irrigation valve diagram is particularly beneficial for those requiring detailed control over water flow, while smart irrigation controllers and drip systems offer innovative solutions for optimizing water use and reducing waste. By assessing the unique characteristics and benefits of each option, businesses can make informed decisions that align with their irrigation goals and sustainability objectives.

Essential Technical Properties and Trade Terminology for irrigation valve diagram

What Are the Essential Technical Properties of an Irrigation Valve?

Understanding the technical specifications of irrigation valves is crucial for B2B buyers involved in agricultural and landscaping projects. Here are some critical specifications to consider:

Material Grade:

Irrigation valves are typically constructed from materials like PVC, brass, or stainless steel. The material grade affects durability, resistance to corrosion, and suitability for various water qualities. For instance, brass valves are ideal for high-pressure systems, while PVC valves are lighter and more cost-effective for low-pressure applications. Selecting the right material can enhance the longevity of the irrigation system, reducing long-term maintenance costs.Pressure Rating:

This specification indicates the maximum pressure the valve can withstand, usually measured in PSI (pounds per square inch). For regions with high water pressure, like some areas in Europe or the Middle East, choosing a valve with an appropriate pressure rating is essential to prevent leaks or failures that could lead to costly repairs and water waste.Flow Rate:

The flow rate, measured in gallons per minute (GPM), determines how much water can pass through the valve. This specification is vital for ensuring that the irrigation system can deliver sufficient water to crops or landscapes without overloading the system. Buyers should consider the specific requirements of their irrigation zones to select valves that meet their flow needs.Diaphragm Type:

The diaphragm is a key component in controlling water flow. Options may include rubber, silicone, or thermoplastic diaphragms, each offering different levels of durability and resistance to various water conditions. Understanding diaphragm types helps buyers choose valves that will perform reliably under specific environmental conditions, such as high salinity or varying pH levels.Operating Voltage:

Many irrigation valves operate using solenoids that require specific voltages, typically 24V AC or 12V DC. Knowing the operating voltage is crucial for compatibility with existing systems and for ensuring efficient operation. Mismatched voltage can lead to system failures or damage to electronic components.Tolerance Levels:

Tolerance levels refer to the acceptable variations in dimensions for valve components. Proper tolerances ensure that parts fit together correctly, which is critical for preventing leaks and ensuring reliable operation. Understanding these specifications helps B2B buyers ensure quality and compatibility with other system components.

What Trade Terminology Should B2B Buyers Know for Irrigation Valves?

Familiarity with industry terminology is vital for effective communication and procurement in the irrigation sector. Here are essential terms to understand:

OEM (Original Equipment Manufacturer):

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing valves, knowing whether a supplier is an OEM can help buyers ensure they are getting high-quality, reliable components.MOQ (Minimum Order Quantity):

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for large projects that may require significant quantities of valves.RFQ (Request for Quotation):

An RFQ is a formal document issued by buyers to solicit price quotes from suppliers. Crafting a clear RFQ can lead to better pricing and terms, allowing buyers to compare offers effectively.Incoterms (International Commercial Terms):

These are standardized terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps buyers understand shipping costs, risk responsibilities, and delivery timelines, which is particularly important when sourcing from international suppliers.Lead Time:

This term refers to the time it takes from placing an order to receiving it. Understanding lead times is essential for project planning and ensuring that irrigation systems are installed promptly to meet agricultural cycles or landscaping needs.Valve Actuation:

This refers to the method used to operate the valve, which can be manual or automatic (electric, hydraulic, etc.). Knowing the actuation type helps buyers choose valves compatible with their irrigation systems, ensuring efficient operation and control.

Understanding these technical properties and trade terminologies will empower B2B buyers to make informed decisions when sourcing irrigation valves, ultimately enhancing the efficiency and effectiveness of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve diagram Sector

What Are the Key Market Dynamics and Trends in the Irrigation Valve Diagram Sector?

The global irrigation valve market is witnessing significant transformation driven by technological advancements and the urgent need for sustainable agricultural practices. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly focused on optimizing water usage due to growing concerns about water scarcity and climate change. This is leading to a surge in demand for efficient irrigation systems, which prominently feature advanced valve diagrams. Key trends include the integration of IoT technology for remote monitoring and control, enabling real-time adjustments to irrigation systems based on environmental conditions. Furthermore, automation in irrigation management is gaining traction, with smart controllers that can adjust valve operations based on data analytics, enhancing system efficiency.

In addition to technology, buyers are prioritizing products that offer durability and reliability, given the harsh conditions often found in agricultural settings. The rising importance of precision agriculture is also influencing the market, as it necessitates the use of sophisticated irrigation systems that can deliver water accurately to crops. Consequently, suppliers must be agile in adapting to these trends, ensuring that their products not only meet current demands but also anticipate future needs. This dynamic landscape presents opportunities for B2B buyers to leverage innovations in irrigation valves to enhance productivity and sustainability in their operations.

How Is Sustainability Shaping the Sourcing of Irrigation Valve Diagrams?

Sustainability has become a crucial factor in the sourcing of irrigation valve systems. International B2B buyers are increasingly aware of the environmental impacts of their purchasing decisions. The irrigation sector is under pressure to reduce its carbon footprint and promote water conservation. As a result, ethical sourcing has gained prominence, with businesses seeking suppliers who adhere to sustainable practices. This includes the use of eco-friendly materials and production processes that minimize waste and energy consumption.

Certifications such as ISO 14001 for environmental management and compliance with REACH regulations are becoming essential for suppliers looking to attract international buyers. Furthermore, the trend towards using recyclable and biodegradable materials in the manufacturing of irrigation valves aligns with the growing consumer demand for sustainable products. By prioritizing ethical supply chains, businesses not only improve their marketability but also contribute positively to their communities and ecosystems, fostering long-term relationships with environmentally-conscious partners.

How Has the Irrigation Valve Market Evolved Over Time?

The evolution of the irrigation valve market reflects broader trends in agricultural technology and water management. Historically, irrigation systems relied heavily on manual controls and basic mechanical valves, which were often inefficient and prone to failure. As agriculture expanded and water scarcity became more pronounced, the need for more sophisticated solutions emerged.

In the late 20th century, the introduction of electric solenoid valves revolutionized the sector, allowing for automated control that improved efficiency and reduced labor costs. The advent of digital technology in the 21st century has further transformed irrigation systems, with smart technology enabling precise control and real-time monitoring. Today, the integration of IoT and data analytics into irrigation valve systems represents the latest evolution, offering unprecedented control over water usage and resource management. This historical trajectory highlights the importance of innovation in meeting the challenges posed by climate change and water scarcity, making it essential for B2B buyers to stay informed about emerging technologies and practices in the irrigation sector.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve diagram

How do I solve common issues with irrigation valves?

To resolve common irrigation valve issues, first identify the problem—common problems include leaks, failure to open or close, and debris blockage. For leaks, inspect seals and gaskets for wear and replace them if necessary. If the valve fails to open or close, check the solenoid and electrical connections for damage. Regular maintenance, such as cleaning debris from inside the valve, is crucial to prevent these issues. Always refer to the specific irrigation valve diagram for guidance on disassembly and part identification to ensure accurate repairs.What is the best type of irrigation valve for my agricultural needs?

The best type of irrigation valve depends on your specific agricultural requirements, including the scale of your operation, water source, and desired control level. For large-scale applications, automatic solenoid valves are ideal due to their efficiency and ease of use. In contrast, manual valves may suffice for smaller operations. Additionally, consider valve types such as jar-top or screw-top based on accessibility and maintenance needs. Consulting with irrigation experts or suppliers can provide tailored recommendations based on your unique circumstances.How can I verify the reliability of a supplier for irrigation valves?

To verify the reliability of a supplier, research their history, customer reviews, and industry reputation. Request references from previous clients and inquire about their experience with product quality and service. Additionally, check if the supplier complies with international standards and certifications relevant to irrigation systems. Engaging in a trial order can also help assess the supplier’s responsiveness and product performance before committing to larger orders.What are the typical minimum order quantities (MOQ) for irrigation valves?

Minimum order quantities (MOQ) for irrigation valves can vary significantly depending on the supplier and the valve type. Generally, MOQs can range from 50 to 200 units. However, some suppliers may offer flexibility for new clients or bulk purchasing agreements. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that suit your purchasing strategy while ensuring you meet their MOQ requirements.What payment terms should I expect when sourcing irrigation valves internationally?

Payment terms for international purchases of irrigation valves can vary widely. Common arrangements include advance payments, letters of credit, or payment upon delivery. Ensure to clarify the terms before finalizing your order, including any penalties for late payment and currency exchange considerations. It’s essential to establish secure and transparent payment methods to protect your investment and maintain good supplier relationships.How do I ensure quality assurance (QA) for irrigation valves?

To ensure quality assurance for irrigation valves, request detailed product specifications and certifications from your supplier. Conduct regular quality checks upon receiving shipments, focusing on dimensions, material integrity, and functionality. Establish a quality control process that includes testing valves under operational conditions to confirm performance. Collaborating with suppliers that have robust QA processes and industry certifications can further ensure you receive high-quality products.What logistics considerations should I keep in mind when importing irrigation valves?

When importing irrigation valves, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Choose reliable freight forwarders familiar with agricultural equipment imports to navigate international shipping complexities. Understand the tariff classifications and duties applicable to your products to avoid unexpected costs. Additionally, confirm that the supplier can accommodate your preferred shipping schedule to ensure timely delivery.How can I customize irrigation valves for specific applications?

Customization of irrigation valves can be achieved by collaborating closely with your supplier. Discuss your specific application needs, such as flow rates, pressure requirements, and control mechanisms. Many manufacturers offer options for different materials, sizes, and features, allowing you to tailor products to your irrigation system. Providing detailed specifications and working with suppliers who have engineering capabilities can facilitate the development of customized solutions that meet your operational demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Irrigation Valve Diagram Manufacturers & Suppliers List

1. Sprinkler Warehouse – Irrigation Valve Components

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Parts of an irrigation valve include:

1. Solenoid: An electric cylinder that receives messages from the sprinkler system controller to control the diaphragm’s movement.

2. Diaphragm: A rubber plug that opens or shuts off the flow of water.

3. Wire Spring: Located behind the diaphragm.

4. Lid: Can be a jar-top lid or secured with screws.

5. Bleed Screw: Used to manually control the flow of wat…

2. Pinterest – Irrigation System Solutions

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Sprinkler valve diagram, different types of irrigation systems, how to replace an irrigation valve solenoid, wiring an irrigation valve to an irrigation controller, step-by-step guide for sprinkler valve repair, DIY sprinkler valve installation, designing a sprinkler system, winterizing irrigation systems with Febco 765-1 backflow preventer, troubleshooting and repairing irrigation systems, plumbi…

3. Superior – Master Valve 3300 Series

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Master valve (normally open, Superior 3300 series)

4. Sunshower – Irrigation Valves

Domain: sunshoweronline.com.au

Introduction: Irrigation valves are operated by an irrigation controller and are essential for the effective functioning of an automatic irrigation system. There are two main types of irrigation valve bodies: Screw Top and Jar Top. The Screw Top Valve is disassembled by removing screws, while the Jar Top Valve is opened by unscrewing a collar. Inside the valve, there are three main parts: the base, the inside (…

5. Hunter – Irrigation Valves

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: Valves operate by allowing water to enter from the system main line, exerting force against the diaphragm. A small orifice in the diaphragm permits water flow to the upper chamber, which then travels to the solenoid area. The solenoid features a spring-loaded piston that covers the inlet port when the valve is closed. The design ensures that the valve remains closed until the water in the upper ch…

6. The Spruce – Lawn Sprinkler Irrigation Valves

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Lawn sprinkler irrigation valves are essential components in an irrigation system, controlling the flow of water to different zones in a yard or garden. They can be located above ground, typically near the water source, or buried in the ground within valve boxes. Above-ground valves are often found around the perimeter of the house or garage, while buried valves are usually housed in green or blac…

7. The Lawn Forum – Irrigation System Overview

Domain: thelawnforum.com

Registered: 2017 (8 years)

Introduction: This company, The Lawn Forum – Irrigation System Overview, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. GP Steel – Cast Iron Sprinkler Valve Parts

Domain: gpsteel.com

Registered: 2000 (25 years)

Introduction: This company, GP Steel – Cast Iron Sprinkler Valve Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for irrigation valve diagram

In conclusion, understanding the intricacies of irrigation valve diagrams is crucial for optimizing irrigation systems, especially in diverse agricultural landscapes across Africa, South America, the Middle East, and Europe. Strategic sourcing of high-quality irrigation valves can significantly enhance operational efficiency, reduce maintenance costs, and ensure sustainable water usage. Buyers should prioritize suppliers who offer comprehensive product insights, robust technical support, and innovative solutions tailored to regional needs.

As the global demand for efficient irrigation systems rises, investing in advanced irrigation technologies becomes imperative. International buyers are encouraged to leverage partnerships with reputable manufacturers and distributors who understand local market dynamics and provide reliable products.

Looking ahead, embracing the latest innovations in irrigation valve technology will not only improve agricultural productivity but also contribute to water conservation efforts. Now is the time to act—explore your options, engage with industry experts, and position your business at the forefront of sustainable irrigation solutions. Together, we can cultivate a greener future.