Introduction: Navigating the Global Market for cover for irrigation pump

In the ever-evolving landscape of agricultural technology, sourcing effective cover for irrigation pumps presents a critical challenge for B2B buyers aiming to protect their investments while ensuring operational efficiency. These covers not only safeguard pumps from environmental elements but also enhance the longevity of these essential components in diverse climates, from the arid regions of the Middle East to the tropical zones of South America. This comprehensive guide delves into various types of irrigation pump covers, their specific applications, and essential considerations for supplier vetting.

B2B buyers will find actionable insights on cost structures, material durability, and design innovations that cater to regional needs, enabling them to make informed purchasing decisions. By understanding the market dynamics and evaluating potential suppliers effectively, businesses can ensure they are investing in high-quality covers that meet their operational requirements. The guide is tailored specifically for international buyers, with a focus on regions like Africa, South America, the Middle East, and Europe—ensuring relevance for markets in Nigeria and Vietnam, among others.

Ultimately, this resource empowers businesses to navigate the complexities of the global market, equipping them with the knowledge to select the right irrigation pump covers that enhance performance and reliability while aligning with their strategic goals.

Understanding cover for irrigation pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mock Rock Covers | Natural stone appearance, durable materials | Landscaping, residential, commercial sites | Pros: Aesthetic appeal, UV resistant. Cons: Higher cost. |

| Plastic Enclosures | Lightweight, weather-resistant, customizable sizes | Agricultural, municipal irrigation systems | Pros: Cost-effective, easy to install. Cons: Less durable than metal. |

| Metal Covers | Heavy-duty, corrosion-resistant, secure locking mechanisms | Industrial applications, large-scale farms | Pros: Long lifespan, security. Cons: Heavier, may require professional installation. |

| Insulated Covers | Thermal insulation properties, designed for extreme climates | Cold weather regions, sensitive crops | Pros: Protects from freezing, energy-efficient. Cons: Higher upfront investment. |

| Valve Box Covers | Compact, designed specifically for valve protection | Irrigation systems, water management | Pros: Protects valves from debris and weather. Cons: Limited to valve applications. |

What Are the Characteristics of Mock Rock Covers?

Mock rock covers are designed to mimic the appearance of natural stone, providing an aesthetic enhancement to outdoor spaces. Made from durable materials, these covers are UV resistant and can withstand harsh weather conditions. They are particularly suitable for landscaping projects in residential and commercial settings, where visual appeal is crucial. B2B buyers should consider the initial investment, as these covers tend to be more expensive than standard options, but their longevity and appearance can justify the cost.

How Do Plastic Enclosures Benefit Agricultural Applications?

Plastic enclosures are lightweight and weather-resistant, making them an excellent choice for agricultural and municipal irrigation systems. They come in various customizable sizes, allowing buyers to select the perfect fit for their pumps. The cost-effectiveness of plastic makes it a popular choice among budget-conscious buyers. However, while they are easy to install, they may not offer the same level of durability as metal alternatives, which is a consideration for long-term use.

What Advantages Do Metal Covers Offer for Industrial Use?

Metal covers are heavy-duty solutions designed to protect irrigation pumps in industrial applications and large-scale farms. They feature corrosion-resistant materials and secure locking mechanisms, ensuring that pumps remain protected from theft and environmental damage. While these covers have a longer lifespan and provide excellent security, their weight can make installation more challenging. B2B buyers should weigh the benefits of durability and security against the potential need for professional installation.

Why Are Insulated Covers Essential in Cold Weather Regions?

Insulated covers are specifically designed to provide thermal protection, making them ideal for regions that experience extreme cold. These covers help prevent freezing, ensuring that irrigation systems remain functional year-round. B2B buyers in agricultural sectors with sensitive crops will find these covers particularly beneficial. While the upfront investment may be higher compared to standard options, the energy efficiency and protection they provide can lead to significant savings in the long run.

How Do Valve Box Covers Protect Irrigation Systems?

Valve box covers are compact solutions tailored for protecting valves within irrigation systems. Their design prevents debris and adverse weather conditions from damaging critical components. These covers are essential in water management applications where maintaining system integrity is crucial. However, their functionality is limited to valve protection, so buyers should ensure they meet specific needs before purchasing.

Key Industrial Applications of cover for irrigation pump

| Industry/Sector | Specific Application of cover for irrigation pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Protecting irrigation pumps in crop farming | Extends equipment lifespan and reduces maintenance costs | Material durability, UV resistance, and local climate adaptability |

| Landscaping & Horticulture | Concealing pumps in decorative landscapes | Enhances aesthetic appeal while ensuring pump functionality | Design options, size compatibility, and ease of installation |

| Municipal Water Management | Securing pumps in urban water supply systems | Ensures operational reliability and public safety | Compliance with local regulations and environmental standards |

| Construction | Covering pumps on construction sites | Protects pumps from damage during building operations | Portability and ease of removal for site changes |

| Oil & Gas | Shielding pumps in remote drilling locations | Minimizes equipment failure and operational downtime | Weather resistance and robustness against harsh environments |

How Is a Cover for Irrigation Pumps Used in Agriculture?

In the agriculture sector, covers for irrigation pumps are essential for protecting equipment from environmental factors such as rain, dust, and pests. By shielding pumps from these elements, businesses can significantly extend their lifespan and reduce maintenance costs. Buyers in this sector should consider materials that offer durability and UV resistance, particularly in regions with intense sunlight and varied weather conditions, such as parts of Africa and South America.

What Role Do Pump Covers Play in Landscaping and Horticulture?

In landscaping and horticulture, covers are used to conceal irrigation pumps within decorative environments. This not only maintains the aesthetic integrity of landscaped areas but also ensures the pumps remain functional and protected from potential vandalism or accidental damage. Buyers should focus on design options that blend seamlessly with the landscape while ensuring size compatibility with existing installations.

How Do Covers Benefit Municipal Water Management?

Municipal water management systems utilize covers to secure pumps in urban settings, ensuring that they operate reliably and safely. These covers protect against unauthorized access and environmental hazards, which is crucial for public health and safety. When sourcing, municipal buyers must ensure that products comply with local regulations and environmental standards, especially in densely populated regions.

Why Are Covers Important on Construction Sites?

On construction sites, irrigation pump covers are vital for protecting equipment from damage during building operations. They help maintain the functionality of pumps, ensuring that water supply systems remain operational throughout the construction phase. Buyers in this sector should look for portable options that can be easily removed or adjusted as the site layout changes, enhancing flexibility and efficiency.

How Do Pump Covers Enhance Oil and Gas Operations?

In the oil and gas industry, covers are used to shield pumps located in remote drilling locations from harsh environmental conditions. These covers minimize the risk of equipment failure and operational downtime, which can be costly. Buyers should prioritize weather-resistant materials that can withstand extreme conditions, ensuring that their investments are protected even in the most challenging environments.

3 Common User Pain Points for ‘cover for irrigation pump’ & Their Solutions

Scenario 1: Protecting Irrigation Pumps from Environmental Damage

The Problem: B2B buyers in regions with extreme weather conditions, such as high heat, heavy rainfall, or frost, often face significant challenges in protecting their irrigation pumps. These environmental factors can lead to costly damage, reducing pump efficiency and lifespan. For example, exposure to freezing temperatures can cause water in the pump to expand and crack the casing, while intense sun can degrade plastic components. This creates a pressing need for effective protective solutions that can withstand the rigors of local climates.

The Solution: To address these challenges, it’s crucial to select high-quality covers designed specifically for the environmental conditions of the region. B2B buyers should source covers made from UV-resistant materials that prevent sun damage and frost-resistant insulation to protect against freezing temperatures. When specifying a cover, consider options with reinforced seams and weatherproof features. Buyers can also enhance protection by regularly inspecting the covers for wear and tear and ensuring that they fit snugly over the pumps to prevent moisture accumulation. Partnering with reputable suppliers who understand local weather conditions can provide additional insights into the best products for specific environments.

Scenario 2: Ensuring Accessibility for Maintenance

The Problem: Many irrigation systems require regular maintenance to ensure optimal performance, yet covers can often hinder access to pumps, making maintenance cumbersome. This is particularly problematic for B2B buyers managing large agricultural operations or municipal systems where downtime can result in significant losses. A cover that is difficult to remove or does not provide adequate access can lead to delays in maintenance schedules and increased labor costs.

The Solution: To streamline maintenance processes, B2B buyers should look for covers that offer easy access features, such as hinged designs or removable panels. These designs allow quick access to the pump without the need for extensive disassembly, facilitating routine checks and repairs. Additionally, consider investing in covers with built-in access points for monitoring equipment, such as gauges or sensors, which can provide real-time data without removing the cover. Training staff on the proper methods for removing and replacing covers can also minimize downtime and improve efficiency during maintenance tasks.

Scenario 3: Managing Aesthetic and Compliance Requirements

The Problem: For many businesses, particularly those involved in landscaping or public works, aesthetic considerations and compliance with local regulations are critical. Unsightly pump installations can detract from the overall appearance of a property or project, leading to negative perceptions from clients or the community. Furthermore, certain regions may have regulations regarding the visibility of irrigation equipment, necessitating effective concealment solutions.

The Solution: B2B buyers should explore decorative covers that blend seamlessly with the surrounding environment, such as faux rock or natural-looking designs that enhance visual appeal. These options not only meet aesthetic requirements but also comply with local regulations regarding equipment visibility. When selecting covers, consider consulting with landscape architects or local authorities to ensure compliance with any specific guidelines. Furthermore, investing in customizable covers can provide branding opportunities, allowing companies to promote their identity while maintaining a professional appearance. Regularly reviewing local regulations can help ensure ongoing compliance and prevent potential fines or project delays.

Strategic Material Selection Guide for cover for irrigation pump

What Are the Key Materials for Covers for Irrigation Pumps?

When selecting materials for covers for irrigation pumps, several options are commonly considered, each with distinct properties and implications for performance, cost, and suitability in various environments. Below, we analyze four prevalent materials: Polyethylene, Fiberglass, Steel, and Concrete.

How Does Polyethylene Perform as a Cover Material?

Polyethylene (PE) is a widely used plastic known for its excellent chemical resistance and durability. It typically withstands temperatures ranging from -50°C to 80°C, making it suitable for various climates. The material is lightweight, which simplifies installation and reduces transportation costs.

Pros: Polyethylene is cost-effective, resistant to corrosion, and offers good UV stability, making it ideal for outdoor applications. Its flexibility allows it to absorb impacts without cracking.

Cons: While durable, PE can become brittle over time when exposed to extreme UV radiation, necessitating replacement sooner than other materials. It also has a lower temperature tolerance compared to some alternatives.

Impact on Application: Polyethylene is compatible with various media, including water and fertilizers, making it a versatile choice for irrigation systems.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations regarding plastic use and disposal. Understanding ASTM standards for plastics can guide purchasing decisions.

What Advantages Does Fiberglass Offer for Irrigation Pump Covers?

Fiberglass is another popular choice for irrigation pump covers, known for its strength and lightweight nature. It can handle temperatures up to 120°C and is resistant to corrosion, making it suitable for harsh environments.

Pros: Fiberglass is highly durable and can withstand extreme weather conditions. It is also non-corrosive and does not require extensive maintenance.

Cons: The manufacturing process for fiberglass can be complex and costly, leading to higher initial expenses. Additionally, it may not be as readily available in some regions compared to other materials.

Impact on Application: Fiberglass covers can be designed to accommodate specific shapes and sizes, providing tailored solutions for unique pump configurations.

Considerations for International Buyers: Compliance with local standards such as DIN or JIS is essential, especially in Europe and the Middle East, where regulations may dictate material specifications.

Why Choose Steel for Covers of Irrigation Pumps?

Steel, particularly galvanized steel, is favored for its strength and durability. It can withstand high pressures and temperatures, making it suitable for heavy-duty applications.

Pros: Steel offers exceptional strength and longevity, making it ideal for high-traffic areas. Its resistance to impact and mechanical stress is superior to many other materials.

Cons: Steel is prone to corrosion if not properly treated, which can lead to increased maintenance costs. It is also heavier, which can complicate installation and transportation.

Impact on Application: Steel covers are particularly effective in environments where mechanical protection is paramount, such as agricultural settings with heavy machinery.

Considerations for International Buyers: Buyers should check for compliance with corrosion resistance standards, particularly in humid or coastal regions. Understanding ASTM standards for steel can help ensure quality.

What Role Does Concrete Play in Pump Cover Applications?

Concrete is often used for covers in permanent installations due to its robustness and durability. It can withstand extreme weather conditions and heavy loads.

Pros: Concrete is highly durable and offers excellent protection against physical damage. It is also fire-resistant and can last for decades with minimal maintenance.

Cons: The weight of concrete makes it challenging to install and transport. Additionally, it is more expensive than other materials, which may not be feasible for all budgets.

Impact on Application: Concrete covers are ideal for permanent installations in high-traffic areas where durability is critical.

Considerations for International Buyers: Buyers should be aware of local regulations regarding concrete use and environmental impact, especially in regions prone to seismic activity.

Summary Table of Material Selection for Irrigation Pump Covers

| Material | Typical Use Case for cover for irrigation pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Lightweight, portable covers for small pumps | Cost-effective and flexible | UV degradation over time | Low |

| Fiberglass | Custom-shaped covers for harsh environments | High durability and low maintenance | Higher initial cost | Med |

| Steel | Heavy-duty applications in high-traffic areas | Exceptional strength | Corrosion risk if untreated | High |

| Concrete | Permanent installations requiring high durability | Long-lasting and fire-resistant | Heavy and expensive | High |

This strategic material selection guide provides a comprehensive overview of the key materials used for covers for irrigation pumps, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cover for irrigation pump

What Are the Main Manufacturing Processes for Covers for Irrigation Pumps?

The manufacturing of covers for irrigation pumps is a meticulous process that involves several key stages, each critical to ensuring the final product meets the necessary standards for durability, functionality, and aesthetic appeal.

Material Preparation: What Materials Are Commonly Used?

The first step in the manufacturing process is material selection and preparation. Common materials for irrigation pump covers include high-density polyethylene (HDPE), polypropylene, and sometimes metal alloys for added strength. These materials are chosen for their resistance to environmental factors such as UV radiation, moisture, and temperature fluctuations.

Once selected, materials undergo quality checks to ensure they meet specific criteria, such as thickness, flexibility, and weather resistance. This initial assessment is crucial, as the quality of raw materials directly influences the longevity and performance of the pump covers.

How Is the Forming Process Conducted?

The forming stage involves shaping the prepared materials into the desired cover forms. This can be achieved through several techniques, including:

Injection Molding: A common method for producing plastic covers, where melted plastic is injected into a mold. This method allows for high precision and the ability to create complex shapes.

Blow Molding: Often used for hollow covers, this technique involves inflating a heated plastic tube until it conforms to the mold’s shape.

Sheet Metal Forming: For metal covers, processes like stamping or bending are employed to achieve the desired shape.

Each method has its benefits and is selected based on the specific requirements of the irrigation pump cover, such as size, shape, and material properties.

What Assembly Techniques Are Used in Production?

Following the forming process, covers may require assembly, especially if they are designed with multiple components. This stage can include:

Welding or Bonding: For plastic covers, techniques like ultrasonic welding or adhesive bonding are common to ensure a strong seal between parts.

Mechanical Fastening: Metal covers often utilize screws, bolts, or rivets for assembly.

Quality control measures are also implemented during assembly to ensure that all components fit correctly and securely.

How Is the Finishing Process Completed?

The finishing stage is where the covers are treated to enhance their aesthetic and protective qualities. This may involve:

Surface Treatment: Processes such as painting, powder coating, or applying UV-resistant finishes are common to improve durability and aesthetics.

Quality Checks: Final inspections are conducted to ensure that the covers meet the specified dimensions, surface quality, and finish requirements.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical component of the manufacturing process for irrigation pump covers. International standards such as ISO 9001 are essential for ensuring consistent quality and continuous improvement in manufacturing processes.

Which International Standards Are Relevant?

In addition to ISO 9001, industry-specific standards may apply, such as:

CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

API Standards: The American Petroleum Institute provides guidelines that may be relevant for covers used in specific industrial applications.

Adherence to these standards can enhance product credibility and facilitate smoother international trade.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically structured around several checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This phase ensures that raw materials meet the required specifications before production begins.

In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help to identify and rectify issues in real-time, reducing waste and ensuring compliance with quality standards.

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing to verify that they meet all specifications and standards before being shipped to customers.

What Testing Methods Are Commonly Used for Irrigation Pump Covers?

Various testing methods are employed to validate the quality and performance of irrigation pump covers:

Mechanical Testing: This includes tensile strength tests, impact resistance tests, and fatigue tests to ensure the cover can withstand operational stresses.

Environmental Testing: Covers are often subjected to tests simulating extreme weather conditions to verify their durability and resistance to UV degradation, moisture, and temperature fluctuations.

Dimensional Testing: Ensures that the cover dimensions conform to specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are some actionable steps:

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing practices and adherence to quality standards.

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including IQC, IPQC, and FQC reports.

Third-Party Inspections: Engaging third-party inspection services can offer unbiased assessments of a supplier’s manufacturing capabilities and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances that may affect their purchasing decisions:

Regulatory Compliance: Different regions may have unique regulations regarding product safety and environmental impact. Understanding these can help avoid compliance issues.

Cultural Differences: Different regions may have varying expectations regarding quality, service, and communication. Establishing clear lines of communication and understanding cultural nuances can facilitate smoother transactions.

Logistical Considerations: Shipping and logistics can impact product quality. Ensure that suppliers have robust logistics strategies to protect products during transit.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance protocols for irrigation pump covers is essential for B2B buyers. By focusing on material selection, manufacturing techniques, and robust quality control measures, businesses can make informed decisions that enhance their operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cover for irrigation pump’

Introduction

In the global market for irrigation pump covers, selecting the right product is crucial for ensuring the longevity and efficiency of your irrigation systems. This guide provides a practical checklist to assist B2B buyers in making informed decisions when sourcing covers for irrigation pumps. By following these steps, you will be better equipped to choose the right supplier and product for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the sourcing process. Consider the size, material, and design requirements of the cover based on the specific pump models you are using. Ensure that your specifications account for environmental conditions, such as UV exposure, humidity, and temperature variations, which can affect the durability of the cover.

Step 2: Research Market Options

Conduct thorough market research to identify various types of irrigation pump covers available globally. Look for products that have proven durability and effectiveness in similar climates to your own. Pay attention to different materials such as plastic, fiberglass, or composite options, as these can significantly impact performance and cost.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s essential to conduct a comprehensive evaluation. Request detailed company profiles, including their history, product offerings, and customer reviews. Look for suppliers with experience in your region, as they may better understand local conditions and requirements.

- Check References: Ask for references from previous clients, especially those in similar industries, to gauge supplier reliability and product quality.

Step 4: Verify Compliance with Standards

Ensure that the products meet relevant industry standards and certifications. This is particularly important in regions with strict regulations regarding agricultural equipment. Compliance can affect not only product quality but also your business’s ability to operate legally and efficiently.

- Look for Certifications: Check for ISO certifications, environmental compliance, and any local standards applicable to irrigation systems in your region.

Step 5: Request Samples and Conduct Tests

Before finalizing your order, request samples of the pump covers you are considering. Conduct tests to assess their fit, durability, and resistance to environmental factors. This step is critical to confirm that the product meets your specifications and expectations.

- Evaluate Performance: Check for water resistance, UV stability, and ease of installation during your testing phase.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to finalize terms and conditions. Discuss pricing, payment terms, delivery schedules, and warranty options. Ensure that these terms align with your budget and operational timelines.

- Document Everything: Keep a written record of all agreements to avoid misunderstandings later on.

Step 7: Plan for After-Sales Support

Consider the after-sales support offered by the supplier. Reliable customer service can be invaluable, especially for ongoing maintenance and troubleshooting of your irrigation systems.

- Inquire About Support Services: Ask about warranty coverage, repair services, and availability of replacement parts to ensure long-term satisfaction with your purchase.

By adhering to this checklist, B2B buyers can make informed decisions when sourcing irrigation pump covers, ultimately leading to enhanced operational efficiency and reduced downtime.

Comprehensive Cost and Pricing Analysis for cover for irrigation pump Sourcing

What Are the Key Cost Components for Irrigation Pump Covers?

When sourcing covers for irrigation pumps, understanding the cost structure is crucial. The primary components that contribute to the overall cost include:

Materials: The choice of materials significantly impacts pricing. Common materials include high-density polyethylene (HDPE), fiberglass, and high-quality plastics designed for outdoor use. The more durable and weather-resistant the material, the higher the cost.

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. In countries with lower labor costs, such as Vietnam or some regions in Africa, the labor component may be less significant, allowing for competitive pricing.

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, equipment maintenance, and facility costs. A well-optimized production facility can reduce these overheads, positively influencing the final price.

Tooling: Initial costs for molds and tools can be substantial, especially for custom designs. However, these costs are amortized over larger production runs, making unit prices lower for bulk orders.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards, but it also adds to the cost. Certifications (e.g., ISO) can further impact pricing but are essential for buyers in regions with stringent quality requirements.

Logistics: Transportation costs can fluctuate based on location, shipping methods, and distance. Factors like Incoterms will determine who bears these costs, influencing the final price to the buyer.

Margin: Suppliers often include a profit margin that reflects their operational costs and market conditions. This margin can vary significantly depending on the supplier’s positioning and competition in the market.

How Do Price Influencers Impact the Cost of Irrigation Pump Covers?

Several factors can influence the pricing of irrigation pump covers:

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order volume. Larger orders can lead to significant discounts, making it essential for buyers to consider their purchasing strategy.

Specifications and Customization: Custom designs or specific features (like insulation or decorative finishes) typically increase costs. Buyers should weigh the benefits of customization against budget constraints.

Material Selection: Higher quality materials usually come at a premium. Buyers should assess the long-term benefits of investing in durable materials that may reduce replacement costs over time.

Quality Certifications: Products that meet international quality standards may have higher upfront costs but can result in savings through reduced failures and warranty claims.

Supplier Factors: The supplier’s reputation, reliability, and service level can affect pricing. Established suppliers may charge more but offer better support and quality assurance.

Incoterms: Understanding shipping terms can lead to cost savings. For instance, “Delivered Duty Paid” (DDP) means the supplier covers all costs until the product reaches the buyer, which can simplify budgeting.

What Tips Can Buyers Implement for Cost-Efficiency in Sourcing Irrigation Pump Covers?

Negotiate Pricing: Buyers should not hesitate to negotiate prices, especially for larger orders. Establishing a long-term relationship with suppliers can lead to better deals.

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, potential downtime, and replacement costs. Investing in higher quality covers may yield savings in the long run.

Understand Pricing Nuances for International Purchases: Buyers from Africa, South America, the Middle East, and Europe should be aware of fluctuations in currency, import duties, and local market conditions that could impact costs.

Leverage Local Suppliers When Possible: Sourcing from local manufacturers can reduce logistics costs and lead times, providing an edge in competitive markets.

Request Samples: Before committing to a large order, requesting samples can help assess quality and fit, ensuring that the final product meets expectations without costly surprises.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on multiple factors, including market conditions, supplier pricing strategies, and regional economic factors. Always conduct thorough market research and supplier evaluations to obtain the most accurate pricing information.

Alternatives Analysis: Comparing cover for irrigation pump With Other Solutions

Understanding Alternatives for Covering Irrigation Pumps

In the realm of irrigation, protecting pumps is crucial for ensuring longevity and efficiency. While a cover for irrigation pumps is a popular solution, various alternatives exist that may better suit specific needs and circumstances. This section explores the benefits and drawbacks of different solutions, enabling B2B buyers to make informed decisions.

Comparison of Irrigation Pump Covers and Alternative Solutions

| Comparison Aspect | Cover for Irrigation Pump | Insulated Housing | Protective Cage |

|---|---|---|---|

| Performance | Effective protection from weather and debris | Excellent thermal insulation; protects against extreme temperatures | Provides basic physical protection but limited against elements |

| Cost | Moderate ($50-$600) | Higher ($200-$800) | Lower ($30-$150) |

| Ease of Implementation | Generally easy to install; requires minimal tools | Requires professional installation for optimal effectiveness | Simple to install; user-friendly designs available |

| Maintenance | Low; occasional cleaning required | Moderate; insulation may require periodic checks | Low; simple to inspect and maintain |

| Best Use Case | Ideal for varied climates and long-term use | Best for extreme weather conditions | Suitable for basic protection in mild climates |

Detailed Breakdown of Alternatives

What are the Benefits and Drawbacks of Insulated Housing?

Insulated housing offers superior protection against extreme temperatures, making it an ideal choice in regions with harsh climates. The insulation maintains a stable temperature for the pump, enhancing its performance and lifespan. However, the higher cost and potential need for professional installation may deter some buyers. Additionally, while insulated housing provides excellent thermal protection, it may not be as effective against physical damage from debris compared to other solutions.

How Does a Protective Cage Compare?

A protective cage is a cost-effective alternative that provides basic physical protection for irrigation pumps. This solution is particularly beneficial in environments where debris and wildlife pose significant risks. The simplicity of installation makes it accessible for many users. However, protective cages lack insulation and may not offer adequate protection against harsh weather conditions. Therefore, they are best suited for mild climates where extreme temperatures and severe weather are not a concern.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating options for covering irrigation pumps, B2B buyers should carefully consider their specific requirements, including local climate conditions, budget constraints, and the level of protection needed. While covers for irrigation pumps provide a balanced solution, alternatives like insulated housing and protective cages each offer unique advantages and drawbacks. By understanding these differences, buyers can select the most appropriate solution that aligns with their operational needs and environmental challenges.

Essential Technical Properties and Trade Terminology for cover for irrigation pump

What Are the Key Technical Properties of Covers for Irrigation Pumps?

When selecting covers for irrigation pumps, understanding their technical properties is crucial for ensuring durability, functionality, and compliance with local standards. Here are some essential specifications:

Material Grade

Covers are typically made from materials such as high-density polyethylene (HDPE), fiberglass, or polycarbonate. The material grade impacts the cover’s strength, UV resistance, and ability to withstand temperature fluctuations. For example, HDPE is favored for its durability and resistance to chemicals, making it suitable for agricultural environments.Impact Resistance

This property measures how well the cover can withstand physical impacts without cracking or breaking. A higher impact resistance rating is essential in areas where debris or heavy machinery may pose a risk. This is particularly important in agricultural settings where covers may be exposed to harsh weather and operational hazards.Waterproof Rating

Covers must provide adequate protection against water ingress, especially in regions with heavy rainfall. This is quantified through ingress protection (IP) ratings, with IP68 being the highest standard, indicating complete protection against dust and immersion in water. A waterproof cover ensures the longevity of the pump by preventing rust and electrical failures.Temperature Tolerance

The ability of a cover to withstand extreme temperatures is vital, especially in regions that experience significant thermal variations. Covers should have specified temperature ranges, indicating their suitability for hot climates in Africa or colder regions in Europe. This property helps prevent warping or degradation over time.Ventilation Features

Adequate ventilation is essential to prevent overheating and condensation within the cover. Many designs include vents or perforations that allow airflow while keeping contaminants out. This is particularly important for maintaining the operational efficiency of pumps.Dimensions and Fit

Covers come in various sizes and shapes, tailored to specific pump models. Accurate dimensions ensure a snug fit, protecting the pump effectively from environmental factors. When sourcing covers, buyers should provide precise specifications to avoid compatibility issues.

What Common Trade Terminology Should B2B Buyers Know?

Understanding trade terminology can streamline the purchasing process and enhance communication between buyers and suppliers. Here are some key terms to be familiar with:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of irrigation pump covers, knowing whether a product is OEM can impact warranty and compatibility considerations.MOQ (Minimum Order Quantity)

This term indicates the smallest amount of product a supplier is willing to sell. Understanding MOQ is essential for budget planning, especially for smaller businesses or those looking to test new products without committing to large quantities.RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers to request pricing and other relevant information for specific products. Utilizing RFQs can help buyers compare offers and negotiate better terms.Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms is vital for clarifying shipping costs, risks, and delivery responsibilities.Lead Time

This term refers to the amount of time it takes from placing an order until the product is delivered. Knowing the lead time is crucial for planning and ensuring that irrigation systems are operational when needed.Warranty Period

The warranty period specifies the duration for which a product is guaranteed against defects. It is a critical factor for B2B buyers to consider, as it reflects the manufacturer’s confidence in the product’s durability and performance.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing covers for irrigation pumps, ensuring they meet operational needs and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the cover for irrigation pump Sector

Market Overview & Key Trends

The global market for covers for irrigation pumps is increasingly influenced by several key drivers, including the demand for efficient water management solutions and the rising importance of agricultural productivity. With climate change posing significant challenges, countries in Africa, South America, the Middle East, and Europe are prioritizing sustainable irrigation practices. This focus has led to the adoption of advanced technologies, such as IoT-enabled monitoring systems and automated irrigation controls, which require reliable and durable pump covers to protect essential equipment.

Emerging trends in sourcing reveal a shift toward e-commerce platforms and online marketplaces, enabling international B2B buyers to easily access a broader range of products and suppliers. This digital transformation is complemented by advancements in supply chain transparency, allowing buyers to evaluate supplier credentials and product quality more effectively. Moreover, the growing emphasis on local sourcing is reshaping procurement strategies, as buyers seek to reduce lead times and enhance supply chain resilience.

Furthermore, the integration of smart materials and innovative designs in pump covers is gaining traction, aligning with the market’s demand for enhanced durability and environmental performance. These developments are essential for international buyers, particularly in regions like Nigeria and Vietnam, where agricultural practices are evolving rapidly, necessitating robust solutions to protect irrigation infrastructure.

Sustainability & Ethical Sourcing in B2B

The environmental impact of irrigation practices has led to heightened awareness around sustainability in the sourcing of pump covers. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing, particularly in the use of recyclable materials and low-impact production processes. This shift not only mitigates environmental harm but also aligns with global trends towards corporate social responsibility.

Sustainable certifications, such as ISO 14001 for environmental management systems, are becoming critical in supplier evaluations. Buyers should seek manufacturers that utilize eco-friendly materials, such as recycled plastics or bio-based composites, in their pump covers. These materials not only enhance the environmental profile of products but also often provide superior durability and performance.

Additionally, transparency in the supply chain is paramount. Buyers are encouraged to engage with suppliers who can provide detailed information about their sourcing practices, including the origins of raw materials and the environmental policies in place. Such due diligence not only fosters trust but also supports the broader goal of sustainable development within the agricultural sector.

Brief Evolution/History

The evolution of covers for irrigation pumps has closely mirrored advancements in irrigation technology and agricultural practices. Initially, these covers were primarily designed for basic protection against environmental factors. However, with the advent of modern irrigation systems and the need for enhanced efficiency, the design and functionality of pump covers have evolved significantly.

Today, covers are not only protective barriers but also integral components that contribute to the overall effectiveness of irrigation systems. They are engineered to withstand extreme weather conditions, provide insulation, and integrate seamlessly with smart technology solutions. This evolution highlights the critical role that pump covers play in modern agriculture, making them a vital consideration for B2B buyers seeking to optimize their irrigation operations.

Frequently Asked Questions (FAQs) for B2B Buyers of cover for irrigation pump

How do I solve issues with irrigation pump cover durability?

To ensure the durability of your irrigation pump cover, select materials that are resistant to UV rays, moisture, and extreme temperatures. Look for high-density polyethylene (HDPE) or heavy-duty plastic options that provide robust protection against environmental factors. Regular maintenance, such as cleaning and inspecting for wear, can also extend the life of the cover. Additionally, consider investing in covers with warranties or guarantees from reputable manufacturers to ensure long-term reliability.What is the best cover for protecting irrigation pumps from environmental damage?

The best cover for protecting irrigation pumps typically features waterproof, UV-resistant materials that can withstand harsh weather conditions. For areas with heavy rainfall or extreme sunlight, look for covers with reinforced seams and ventilation to prevent moisture buildup. Custom-fit covers are also advantageous, as they provide a snug fit that minimizes exposure to the elements, ensuring optimal protection for your investment.How can I verify the credibility of a supplier for irrigation pump covers?

To verify a supplier’s credibility, start by checking their business credentials, such as registration and compliance with local regulations. Look for customer reviews and testimonials to gauge their reputation in the industry. Request references from previous clients and inquire about their experience with the supplier. Additionally, consider visiting the supplier’s facility if feasible, or request third-party audits to ensure quality assurance practices are in place.What customization options are available for irrigation pump covers?

Many suppliers offer customization options for irrigation pump covers, including size adjustments, color selection, and material choices. Some manufacturers may provide branding options, allowing you to print your company logo on the cover. It’s advisable to discuss your specific requirements with potential suppliers and request samples or mock-ups to ensure the final product meets your expectations.What are the typical minimum order quantities (MOQ) for irrigation pump covers?

Minimum order quantities (MOQ) for irrigation pump covers can vary significantly among suppliers. Generally, MOQs range from 50 to 500 units, depending on the manufacturer and the level of customization required. For smaller businesses, some suppliers may offer lower MOQs or allow for mixed orders of different products. It’s beneficial to negotiate MOQs, especially when establishing a new supplier relationship.What payment terms should I expect when purchasing irrigation pump covers internationally?

Payment terms for international purchases of irrigation pump covers can vary, but common practices include a 30% deposit upfront and the balance upon shipment or delivery. Some suppliers may offer net payment terms, allowing you to pay within a specified period after receiving the goods. Always clarify payment methods accepted (e.g., wire transfer, letter of credit) and consider using escrow services for added security in transactions.How can I ensure quality assurance for irrigation pump covers?

To ensure quality assurance, request samples before placing a bulk order to assess material quality and craftsmanship. Inquire about the supplier’s quality control processes, including testing for durability and environmental resistance. You can also consider third-party quality inspections during production or before shipment to verify that the products meet your specifications and industry standards.What logistics considerations should I keep in mind for importing irrigation pump covers?

When importing irrigation pump covers, consider shipping methods, costs, and lead times. Evaluate whether you need air freight for faster delivery or sea freight for cost-effectiveness. Be aware of customs regulations and import duties in your country, as these can impact overall costs. Partnering with a reliable freight forwarder can help navigate logistics complexities, ensuring timely delivery and compliance with international shipping standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Cover For Irrigation Pump Manufacturers & Suppliers List

1. Irrigation Outlet – Mock Rock Pump Covers

Domain: irrigationoutlet.com

Introduction: This company, Irrigation Outlet – Mock Rock Pump Covers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Pentair – Sprinkler Pump Cover

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Sprinkler Pump Cover available on eBay. Key details include: Brand options such as Pentair and Unbranded, with prices ranging from under $35 to over $75. Condition options include New (311 items) and Used (3 items). Various buying formats available including Auction and Buy It Now. Shipping options include free delivery within the United States, with estimated arrival in 2-4 days. Some listings of…

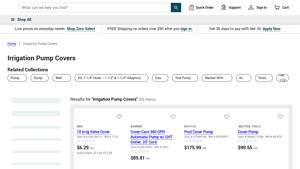

3. Zoro – Irrigation Pump Covers

Domain: zoro.com

Registered: 1995 (30 years)

Introduction: Irrigation Pump Covers available on Zoro.com include various models and prices. Key products include: 1. Nds 10 Irrig Valve Cover – Zoro # G108109121, Mfr # 111C, price: $6.29/ea (sold in multiples of 2 for $12.58). 2. Danner Cover-Care 360 GPH Automatic Pump with GHT Outlet, 25′ Cord – Zoro # G2575451, Mfr # 2531, price: $89.81/ea. 3. Eco-Flo Pool Cover Pump – Zoro # G7344198, Mfr # SUP55PC, pric…

4. Landworks Depot – Pump Cover Plastic

Domain: landworksdepot.com

Registered: 2010 (15 years)

Introduction: This company, Landworks Depot – Pump Cover Plastic, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Rain Harvesting Supplies – Camouflage Pump Cover

Domain: rainharvestingsupplies.com

Registered: 2010 (15 years)

Introduction: Pump housing, resin, Camouflage, hide pump, cover pump, pump box, fake rock, hide under rock, pump box, pump cover

Strategic Sourcing Conclusion and Outlook for cover for irrigation pump

In the competitive landscape of irrigation solutions, strategic sourcing of covers for irrigation pumps is pivotal for international buyers. By prioritizing quality, durability, and cost-effectiveness, businesses can enhance the longevity of their irrigation systems while optimizing operational efficiency. The growing demand for reliable protective solutions, particularly in regions such as Africa, South America, the Middle East, and Europe, underscores the importance of understanding local market needs and sourcing strategies.

Collaboration with reputable suppliers can yield significant advantages, including access to innovative materials and designs tailored to diverse climatic conditions. Furthermore, leveraging technology in sourcing processes can streamline procurement, ensuring timely delivery and compliance with international standards.

As the agricultural sector continues to evolve, embracing advanced sourcing practices will not only safeguard investments in irrigation infrastructure but also contribute to sustainable agricultural development. International B2B buyers are encouraged to explore partnerships that align with their operational goals and to stay informed about emerging trends in the irrigation pump cover market. By doing so, they position themselves for future success in an increasingly globalized economy, fostering resilience and adaptability in their supply chains.