Introduction: Navigating the Global Market for diaphragm irrigation valve

In today’s competitive agricultural landscape, sourcing reliable diaphragm irrigation valves can be a daunting challenge for international B2B buyers. These essential components play a pivotal role in efficient irrigation systems, directly impacting crop yields and water conservation efforts. Understanding the diverse types of diaphragm irrigation valves, their specific applications, and the nuances of supplier vetting is crucial for making informed purchasing decisions. This guide offers a comprehensive overview that addresses these key considerations, enabling buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Saudi Arabia—to navigate the complexities of the global market.

Throughout this guide, we will delve into various types of diaphragm valves, exploring their functionalities and applications in different agricultural settings. Additionally, we will provide insights into cost analysis and best practices for supplier selection, ensuring that buyers can identify trustworthy manufacturers and distributors. By equipping B2B buyers with the knowledge and tools necessary to make educated decisions, this guide empowers them to enhance their irrigation systems, optimize resource allocation, and ultimately achieve greater operational efficiency. Whether you are looking to upgrade existing systems or implement new solutions, understanding the diaphragm irrigation valve market is essential for success in today’s evolving agricultural environment.

Understanding diaphragm irrigation valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Globe Valve Diaphragm | Compact design, suitable for high-pressure systems | Commercial irrigation, landscape design | Pros: Efficient flow control; Cons: Limited flow capacity compared to angle valves. |

| Angle Valve Diaphragm | Angled design for space-saving installation | Agricultural irrigation, industrial use | Pros: Versatile installation; Cons: Slightly more complex maintenance. |

| Anti-Siphon Diaphragm | Built-in protection against backflow | Residential irrigation, golf courses | Pros: Prevents contamination; Cons: May require additional components for installation. |

| Electric Diaphragm Valve | Automated operation via solenoids | Automated irrigation systems, large farms | Pros: Enhances efficiency; Cons: Higher upfront cost and potential for electrical issues. |

| Manual Diaphragm Valve | Operated manually, simple design | Small-scale irrigation, DIY projects | Pros: Cost-effective; Cons: Labor-intensive operation compared to electric valves. |

What are the characteristics and suitability of Globe Valve Diaphragms?

Globe valve diaphragms are designed for applications requiring precise control over water flow. Their compact design makes them suitable for high-pressure systems, often found in commercial irrigation setups and landscape designs. B2B buyers should consider the efficiency of flow control, which can be advantageous in maintaining water distribution. However, they may experience limitations in flow capacity when compared to angle valves, making them less ideal for larger-scale agricultural applications.

How do Angle Valve Diaphragms stand out in irrigation?

Angle valve diaphragms feature a unique angled design that allows for more flexible installation options, particularly in tight spaces. They are commonly used in agricultural irrigation and industrial settings where adaptability is crucial. When purchasing, B2B buyers should assess the installation complexity versus the benefit of versatile application. While angle valves provide significant space-saving advantages, they may require more intricate maintenance compared to simpler designs.

Why choose Anti-Siphon Diaphragm Valves for your projects?

Anti-siphon diaphragm valves are engineered to prevent backflow, thereby protecting water sources from contamination. They are particularly beneficial in residential irrigation systems and golf courses, where water quality is paramount. Buyers should weigh the benefits of built-in backflow protection against the potential need for additional installation components. While they provide essential safety features, the complexity of installation can be a consideration for less experienced buyers.

What are the advantages of Electric Diaphragm Valves?

Electric diaphragm valves offer automated operation through solenoids, making them ideal for large-scale automated irrigation systems and farming operations. Their ability to enhance efficiency is a significant advantage for businesses looking to optimize water usage. However, B2B buyers should be aware of the higher upfront costs and the potential for electrical issues that may arise over time. Assessing the return on investment in terms of labor savings and efficiency is crucial.

When should you consider Manual Diaphragm Valves?

Manual diaphragm valves are straightforward in design and operation, making them a cost-effective choice for small-scale irrigation and DIY projects. Their simplicity appeals to buyers looking for budget-friendly options. However, the labor-intensive nature of manual operation can be a drawback in larger applications. B2B buyers should consider their specific irrigation needs and whether the trade-off between cost and labor is acceptable for their operations.

Key Industrial Applications of diaphragm irrigation valve

| Industry/Sector | Specific Application of diaphragm irrigation valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems for crops | Enhances water efficiency and crop yield | Compatibility with existing systems, durability, and serviceability |

| Horticulture | Greenhouse irrigation | Provides precise control over water distribution | Size and flow rate specifications, resistance to chemicals |

| Landscape Management | Commercial landscaping irrigation | Reduces water wastage and maintenance costs | Availability of replacement parts, ease of installation |

| Municipal Water Supply | Public park irrigation systems | Ensures sustainable water management | Compliance with local regulations, reliability under varying pressures |

| Industrial Facilities | Cooling systems in manufacturing | Maintains optimal temperatures and operational efficiency | Robustness against industrial conditions, technical support availability |

How is the Diaphragm Irrigation Valve Used in Agriculture?

In agriculture, diaphragm irrigation valves are integral to automated irrigation systems, allowing for the controlled delivery of water to crops. These valves enable farmers to optimize water usage, which is crucial in regions prone to drought, such as parts of Africa and the Middle East. By automating irrigation, farmers can significantly increase crop yields while reducing labor costs. International buyers should consider the compatibility of these valves with existing irrigation systems and their durability in harsh environmental conditions.

What Role Does the Diaphragm Irrigation Valve Play in Horticulture?

In horticulture, diaphragm irrigation valves facilitate precise water management in greenhouses, ensuring that plants receive the optimal amount of moisture. This precision is vital for maintaining plant health and maximizing growth rates. Buyers in this sector should focus on the size and flow rate specifications to match their greenhouse requirements, as well as the valve’s resistance to various chemicals used in horticultural practices.

How Does the Diaphragm Irrigation Valve Benefit Landscape Management?

For commercial landscaping, diaphragm irrigation valves are essential for maintaining lush, healthy environments in parks and public spaces. These valves help reduce water wastage by allowing for scheduled irrigation, thus optimizing resource use and lowering maintenance costs. Buyers should ensure that the valves they source come with readily available replacement parts and are easy to install, facilitating quick repairs and minimizing downtime.

What is the Importance of Diaphragm Irrigation Valves in Municipal Water Supply?

Municipalities utilize diaphragm irrigation valves in public park irrigation systems to ensure efficient and sustainable water management. These valves help cities manage water resources effectively, especially in regions with fluctuating water availability. When sourcing these valves, municipalities must consider compliance with local regulations and the reliability of the valves under varying pressure conditions, ensuring they can withstand the demands of public use.

How are Diaphragm Irrigation Valves Used in Industrial Facilities?

In industrial settings, diaphragm irrigation valves are often part of cooling systems that maintain optimal temperatures during manufacturing processes. These valves ensure a steady flow of water, which is critical for operational efficiency. When sourcing valves for this application, businesses should prioritize robustness against industrial conditions and the availability of technical support to address any operational issues that may arise.

3 Common User Pain Points for ‘diaphragm irrigation valve’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Replacement Parts

The Problem: Many B2B buyers in the irrigation sector encounter challenges when sourcing reliable replacement parts for diaphragm irrigation valves. This issue is particularly pronounced in regions like Africa and South America, where supply chains can be inconsistent. Buyers often receive low-quality or incompatible parts that lead to system inefficiencies or further breakdowns. This not only affects operational efficiency but can also result in significant downtime, which is costly in agricultural settings where timely irrigation is crucial.

The Solution: To address this challenge, buyers should establish relationships with reputable suppliers who specialize in irrigation components. It’s essential to verify that these suppliers offer genuine parts compatible with specific valve models. Consider using a multi-supplier strategy to mitigate risks associated with single-source dependency. Furthermore, buyers can request detailed product specifications and certifications to ensure quality. Engaging in bulk purchasing can also provide cost advantages while ensuring a steady supply of high-quality components. Regular maintenance schedules should be implemented, allowing for timely replacement of diaphragms before they fail, thus minimizing operational disruptions.

Scenario 2: Understanding Technical Specifications and Compatibility

The Problem: B2B buyers often struggle with the technical specifications and compatibility of diaphragm irrigation valves. Misunderstanding the required dimensions, materials, and pressure ratings can lead to poor performance, resulting in water wastage or insufficient irrigation coverage. This is especially critical for businesses in arid regions where water management is paramount. The complexity of valve systems can leave buyers feeling overwhelmed and unsure of how to make informed purchasing decisions.

The Solution: To overcome this barrier, buyers should invest time in understanding the specific requirements of their irrigation systems. This can be achieved through comprehensive training sessions provided by manufacturers or attending industry workshops. Buyers should familiarize themselves with the common technical terminology and specifications that impact performance. Additionally, using online resources and calculators to determine the appropriate valve size and type based on flow rates and pressure can be incredibly beneficial. Collaboration with irrigation consultants can also provide tailored solutions and recommendations, ensuring that the chosen diaphragm valves align perfectly with the operational needs.

Scenario 3: Navigating Maintenance and Repair Challenges

The Problem: Maintaining diaphragm irrigation valves can pose significant challenges for B2B buyers, especially in regions with harsh environmental conditions. Over time, components may wear out due to exposure to chemicals or abrasive particles in the water. Buyers often find themselves grappling with the decision of whether to repair or replace valves, leading to confusion and potential losses in productivity when systems fail.

The Solution: Implementing a proactive maintenance plan is key to navigating these challenges effectively. Buyers should schedule regular inspections and cleaning of diaphragm valves to identify wear and tear early on. Establishing a routine maintenance checklist that includes checking for leaks, ensuring proper alignment, and testing for responsiveness can help in identifying potential issues before they escalate. Additionally, investing in diaphragm repair kits can be a cost-effective solution, allowing for quick fixes without the need for complete replacements. Training maintenance staff on best practices for handling and repairing diaphragm valves will empower them to manage these systems more effectively, ultimately enhancing operational reliability and reducing long-term costs.

Strategic Material Selection Guide for diaphragm irrigation valve

When selecting materials for diaphragm irrigation valves, several factors must be considered to ensure optimal performance and compatibility with various irrigation systems. The choice of material directly affects the valve’s durability, cost, and suitability for specific applications. Below, we analyze four common materials used in diaphragm irrigation valves, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Rubber for Diaphragm Irrigation Valves?

Rubber is one of the most commonly used materials for diaphragm construction due to its flexibility and resilience. It typically has a temperature rating of -40°F to 180°F and can withstand moderate pressure levels. Rubber exhibits excellent corrosion resistance against water and mild chemicals, making it suitable for various irrigation applications.

Pros: Rubber diaphragms are cost-effective and easy to manufacture, which contributes to lower overall valve costs. They also provide good sealing capabilities, ensuring minimal leakage.

Cons: However, rubber can degrade over time when exposed to UV light and extreme temperatures. Additionally, it may not be suitable for high-pressure applications or aggressive chemicals.

Impact on Application: Rubber is compatible with most water types, but buyers must consider its limitations in harsh chemical environments.

Considerations for International Buyers: Compliance with standards such as ASTM D2000 is essential. Buyers in regions like Africa and the Middle East should consider local climate conditions that may affect rubber durability.

How Does PVC Compare as a Material for Diaphragm Irrigation Valves?

Polyvinyl chloride (PVC) is another popular choice for diaphragm materials. It has a temperature rating of up to 140°F and offers excellent resistance to corrosion and chemical exposure, particularly in agricultural settings.

Pros: PVC is lightweight, durable, and relatively inexpensive, making it a preferred choice for many irrigation systems. Its resistance to environmental factors enhances its longevity.

Cons: The main drawback is its limited temperature tolerance, which may restrict its use in hotter climates. Additionally, PVC can become brittle over time, especially if exposed to UV light.

Impact on Application: PVC is suitable for freshwater applications but may not be ideal for saline or highly corrosive environments.

Considerations for International Buyers: Buyers should ensure that the PVC used complies with international standards like DIN 8062. In regions like South America, where agricultural chemicals are prevalent, compatibility with specific chemicals should be verified.

What Are the Advantages of Using EPDM for Diaphragm Irrigation Valves?

Ethylene propylene diene monomer (EPDM) is a synthetic rubber known for its excellent weather resistance and flexibility. It can handle temperatures ranging from -40°F to 300°F, making it suitable for various climates.

Pros: EPDM is highly resistant to ozone, UV radiation, and extreme temperatures, providing a longer lifespan compared to traditional rubber. It also offers good chemical resistance, particularly against water and steam.

Cons: The primary disadvantage is its higher cost compared to rubber and PVC. Additionally, EPDM may not be suitable for certain petroleum-based products.

Impact on Application: EPDM is ideal for applications requiring high durability and exposure to harsh environmental conditions.

Considerations for International Buyers: Compliance with standards like ASTM D1418 is crucial. Buyers in Europe may prefer EPDM for its superior performance in diverse climates.

How Does Stainless Steel Enhance Diaphragm Irrigation Valve Performance?

Stainless steel is often used for the valve body rather than the diaphragm itself, but its role is crucial. It provides high strength and corrosion resistance, withstanding temperatures up to 1,500°F.

Pros: Stainless steel offers exceptional durability and is resistant to rust and corrosion, making it ideal for harsh environments. Its strength allows for high-pressure applications.

Cons: The main limitation is the higher cost compared to plastic materials. Additionally, stainless steel can be heavier, which may impact installation.

Impact on Application: Stainless steel is suitable for applications involving aggressive chemicals and high-pressure systems.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A240. In regions like Saudi Arabia, where high temperatures and saline environments are common, stainless steel is often preferred.

| Material | Typical Use Case for diaphragm irrigation valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General irrigation systems | Cost-effective and flexible | Degrades under UV and extreme conditions | Low |

| PVC | Freshwater irrigation | Lightweight and durable | Limited temperature tolerance | Low |

| EPDM | Harsh environmental conditions | Excellent weather resistance | Higher cost than rubber/PVC | Medium |

| Stainless Steel | High-pressure applications | Exceptional durability and corrosion resistance | Higher cost and weight | High |

This strategic material selection guide provides B2B buyers with essential insights into diaphragm materials, helping them make informed decisions that align with their operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for diaphragm irrigation valve

What Are the Key Manufacturing Processes for Diaphragm Irrigation Valves?

The manufacturing of diaphragm irrigation valves involves several critical stages that ensure the final product meets the necessary performance standards. The main stages of the manufacturing process include material preparation, forming, assembly, and finishing.

How is Material Prepared for Diaphragm Irrigation Valves?

Material preparation is the first step in the manufacturing process. High-quality materials such as rubber, plastic, and metal are selected based on their durability and resistance to environmental factors. Rubber is often used for diaphragms due to its flexibility and ability to create a watertight seal. Materials undergo rigorous testing to ensure they meet industry specifications and standards before moving to the next stage.

What Techniques Are Used in Forming Diaphragm Irrigation Valves?

Forming techniques vary depending on the material used. For plastic components, injection molding is a common method, allowing for precise shaping and minimal waste. Metal parts may be produced through stamping or machining, ensuring they are robust enough to withstand high pressure and temperature variations. During this stage, manufacturers often apply coatings to enhance corrosion resistance and improve longevity.

How Are Diaphragm Irrigation Valves Assembled?

The assembly stage is critical for ensuring that all components fit together correctly. This often involves automated processes such as robotic assembly for efficiency and consistency. Manual assembly may also be employed for more intricate components. Key parts, including the diaphragm, solenoid, and body of the valve, are carefully aligned and secured using screws or adhesives. Quality checks are conducted at this stage to identify any assembly defects.

What Finishing Processes Are Applied to Diaphragm Irrigation Valves?

Finishing processes include surface treatments, painting, or coating to enhance aesthetic appeal and functionality. These treatments help to protect against UV radiation and chemical exposure, which is vital for irrigation applications. The final product is cleaned and inspected to ensure it meets the required specifications before packaging.

What Quality Assurance Measures Are Implemented in the Manufacturing of Diaphragm Irrigation Valves?

Quality assurance (QA) is essential in the production of diaphragm irrigation valves to ensure reliability and performance. Various international standards, such as ISO 9001, guide manufacturers in implementing effective QA processes.

Which International Standards Are Relevant for Diaphragm Irrigation Valves?

ISO 9001 provides a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking and API standards may be required, especially for valves used in specific applications or regions. Compliance with these standards can significantly enhance product credibility in international markets.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the assembly and forming processes.

- Final Quality Control (FQC): Before packaging, a comprehensive inspection is performed on finished products to ensure they meet all quality standards.

Common testing methods include pressure testing, leak testing, and durability tests to evaluate the performance of the diaphragm under various conditions.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is crucial. Here are several methods to ensure that suppliers maintain high-quality standards:

What Steps Can Buyers Take to Assess Supplier Quality?

Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers can assess whether the supplier complies with relevant international standards.

Quality Reports: Requesting documentation of quality control processes and results can help buyers evaluate the supplier’s commitment to quality. This includes records of IQC, IPQC, and FQC.

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of verification. These organizations can perform independent assessments of the manufacturing process and product quality.

Certifications and Compliance: Buyers should check for certifications such as ISO 9001, CE, or API. These certifications indicate adherence to rigorous quality standards and can enhance trust in the supplier’s capabilities.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various challenges when it comes to quality assurance. Different regions may have varying regulatory requirements and standards, which can impact product compliance.

How Do Regional Differences Affect Quality Assurance?

For example, buyers from Nigeria may need to consider local regulations regarding irrigation equipment, while those in Saudi Arabia may focus on adherence to specific industry standards. Understanding these nuances is critical for ensuring that products meet local market requirements.

Moreover, language barriers and cultural differences may affect communication with suppliers. It is advisable for buyers to establish clear expectations and requirements upfront to mitigate misunderstandings.

Conclusion

Manufacturing and quality assurance processes for diaphragm irrigation valves are complex yet crucial for ensuring product reliability and performance. B2B buyers must engage with suppliers who adhere to rigorous manufacturing standards and implement effective quality control measures. By understanding the manufacturing processes and quality assurance practices, buyers can make informed decisions, ensuring that they select suppliers capable of delivering high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diaphragm irrigation valve’

Introduction

When sourcing diaphragm irrigation valves, it is essential to navigate the complexities of procurement strategically. This guide provides a clear, step-by-step checklist to ensure that B2B buyers can make informed decisions while considering quality, compatibility, and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Determine the required size, pressure rating, and material compatibility based on your irrigation system’s needs. This will help streamline the selection process and avoid costly mistakes.

- Considerations:

- Identify the valve types (e.g., globe or angle valves) suitable for your application.

- Assess the operating conditions, such as water quality and temperature ranges.

Step 2: Research Market Trends and Innovations

Stay updated on current market trends and technological advancements in diaphragm irrigation valves. Understanding the latest innovations can lead to improved efficiency and performance in your irrigation systems.

- Action Items:

- Review industry publications and attend trade shows or webinars.

- Engage with professionals on forums and networks to gather insights.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to conduct a thorough evaluation. Request company profiles, case studies, and references from buyers in similar industries or regions to ensure reliability and quality.

- Key Factors:

- Check the supplier’s experience and track record in the irrigation sector.

- Assess their customer service capabilities and after-sales support.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you are considering meet necessary industry standards and certifications. Compliance with international quality standards guarantees that the products will perform reliably.

- Important Certifications:

- Look for ISO certifications, which indicate adherence to quality management systems.

- Verify compliance with regional standards relevant to your market (e.g., CE marking in Europe).

Step 5: Request Samples for Testing

Obtaining samples of diaphragm valves is a critical step in the procurement process. Testing samples allows you to evaluate the quality, compatibility, and performance of the valves in your specific applications.

- Testing Criteria:

- Examine the physical attributes, including material quality and sealing capabilities.

- Conduct performance tests under actual operating conditions to assess durability.

Step 6: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and terms of sale. Understanding total costs, including shipping and handling, will help in making a cost-effective decision.

- Considerations:

- Look for bulk purchase discounts and warranty options.

- Analyze payment terms to ensure they align with your budget and cash flow.

Step 7: Finalize Purchase Agreements

After selecting a supplier, finalize the purchase agreement. Ensure that all terms, including delivery schedules, payment conditions, and warranties, are clearly documented.

- Key Elements:

- Confirm lead times for delivery and installation.

- Outline the process for handling defects or returns to protect your investment.

By following this structured checklist, B2B buyers can enhance their procurement process for diaphragm irrigation valves, ensuring quality, reliability, and optimal performance in their irrigation systems.

Comprehensive Cost and Pricing Analysis for diaphragm irrigation valve Sourcing

Understanding the cost structure and pricing dynamics of diaphragm irrigation valves is crucial for international B2B buyers aiming to optimize their sourcing strategies. This analysis focuses on the various components that contribute to the overall cost, the factors influencing pricing, and actionable tips for buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Diaphragm Irrigation Valves?

The cost structure for diaphragm irrigation valves typically encompasses several key components:

Materials: The quality and type of materials used, such as rubber, plastic, and metal components, significantly affect costs. High-quality, durable materials may lead to higher initial expenses but can reduce long-term maintenance costs.

Labor: Labor costs vary depending on the region of manufacture. Countries with lower labor costs can offer competitive pricing, but this may impact quality. Understanding the labor market in the sourcing country is essential.

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and general administrative expenses. Efficient manufacturing processes can help minimize overhead costs, impacting the final pricing of the valves.

Tooling: Tooling costs are incurred during the production setup phase. Custom designs or specifications may require specialized tooling, which can increase upfront costs.

Quality Control (QC): Implementing robust QC processes ensures product reliability but adds to manufacturing costs. Suppliers with stringent QC measures may charge higher prices, reflecting the added value of quality assurance.

Logistics: Shipping and handling fees are critical, especially for international buyers. Costs can vary based on shipping methods, distances, and customs duties, impacting the total landed cost.

Margin: Suppliers typically apply a markup to cover their costs and desired profit margins. Understanding the margin expectations of suppliers can aid in negotiations.

What Influences the Pricing of Diaphragm Irrigation Valves?

Several factors influence the pricing of diaphragm irrigation valves:

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to price discounts. Buyers should evaluate their needs against suppliers’ MOQs to maximize cost savings.

Specifications and Customization: Custom specifications can lead to higher costs due to the need for specialized manufacturing processes. Buyers should weigh the benefits of customization against potential price increases.

Materials and Quality Certifications: High-quality materials and compliance with international standards (such as ISO certifications) can elevate prices. However, they often result in better performance and longevity.

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers may charge a premium, but their reliability could justify the cost.

Incoterms: Understanding the implications of different Incoterms (International Commercial Terms) is essential. They dictate the responsibilities of buyers and sellers in shipping, which can affect overall costs.

What Are the Best Practices for Negotiating Prices?

B2B buyers should consider the following tips when negotiating prices for diaphragm irrigation valves:

Conduct Market Research: Familiarize yourself with market prices and trends. This knowledge empowers you during negotiations and helps you identify fair pricing.

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with a product rather than just the initial purchase price. This includes maintenance, downtime, and replacement costs.

Leverage Volume Discounts: If your purchasing needs allow, commit to larger orders to take advantage of volume discounts. Suppliers are often willing to negotiate better terms for larger quantities.

Be Open to Alternative Suppliers: Consider multiple suppliers to create competitive tension. This can lead to better pricing and terms.

Understand Regional Variances: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of regional pricing differences and logistics challenges, which can affect negotiations.

Conclusion

Navigating the cost and pricing landscape of diaphragm irrigation valves requires a strategic approach. By understanding the cost components, pricing influencers, and employing effective negotiation tactics, international B2B buyers can optimize their sourcing strategies. As market dynamics continue to evolve, staying informed and adaptable is key to achieving the best outcomes in procurement.

Alternatives Analysis: Comparing diaphragm irrigation valve With Other Solutions

When selecting irrigation solutions, it’s crucial for B2B buyers to evaluate various options to determine the most suitable technology for their specific applications. Diaphragm irrigation valves are widely recognized for their reliability and efficiency, but other alternatives may offer unique advantages depending on the operational context and requirements.

| Comparison Aspect | Diaphragm Irrigation Valve | Electric Solenoid Valve | Manual Gate Valve |

|---|---|---|---|

| Performance | High precision and control | Quick response, can be automated | Moderate control, less precise |

| Cost | Moderate initial cost | Higher initial investment | Low initial cost |

| Ease of Implementation | Requires technical setup | Easier with electrical infrastructure | Simple installation |

| Maintenance | Moderate maintenance needs | High maintenance if damaged | Low maintenance |

| Best Use Case | Precision agriculture, remote areas | Automated systems, large fields | Small-scale or temporary setups |

What Are the Pros and Cons of Electric Solenoid Valves Compared to Diaphragm Irrigation Valves?

Electric solenoid valves offer rapid response times and can be easily integrated into automated irrigation systems. This makes them ideal for large agricultural operations where timely watering is critical. However, their reliance on electricity can pose challenges in regions with unreliable power supply, and they may require more maintenance due to potential electrical failures or solenoid malfunctions.

How Do Manual Gate Valves Compare to Diaphragm Irrigation Valves in Terms of Usability?

Manual gate valves are straightforward and cost-effective solutions for irrigation, particularly in smaller operations or temporary setups. They do not require electrical components, making them less susceptible to power-related issues. However, their lack of precision and manual operation can lead to inefficiencies in water usage, especially in larger or more complex irrigation systems.

Conclusion: How Should B2B Buyers Choose the Right Irrigation Solution?

When choosing the right irrigation solution, B2B buyers should consider their specific operational needs, including the scale of their agricultural activities, access to power, and the level of precision required. Diaphragm valves excel in scenarios where precise control is paramount, while electric solenoid valves are beneficial for those looking to automate their systems. Conversely, manual gate valves serve well in simpler setups where cost and ease of use are prioritized. Ultimately, a thorough analysis of these factors will lead to an informed decision that maximizes efficiency and return on investment.

Essential Technical Properties and Trade Terminology for diaphragm irrigation valve

What Are the Key Technical Properties of Diaphragm Irrigation Valves?

Diaphragm irrigation valves are critical components in irrigation systems, and understanding their technical properties can help B2B buyers make informed decisions. Here are some essential specifications:

Material Composition:

The materials used in diaphragm valves, typically thermoplastics, elastomers, or metals, affect durability and resistance to chemicals and UV exposure. For instance, high-grade PVC or nylon is preferred for its lightweight and corrosion-resistant properties. Choosing the right material is crucial for ensuring longevity and minimizing maintenance costs in harsh environmental conditions.Pressure Rating:

This specification indicates the maximum pressure the valve can handle, often measured in psi (pounds per square inch). A higher pressure rating is vital for applications requiring robust performance, especially in regions with variable water supply pressures. Understanding pressure ratings helps buyers select valves that can withstand operational demands without risk of failure.Flow Rate:

Measured in gallons per minute (GPM), the flow rate defines how much water can pass through the valve within a specific timeframe. It is essential for determining the efficiency of the irrigation system. Buyers should align flow rates with their irrigation needs to ensure optimal water distribution and avoid wastage.Diaphragm Thickness and Design:

The thickness of the diaphragm impacts its flexibility and durability. A thicker diaphragm often provides better resistance to wear and tear, which is essential for systems operating under high-frequency cycling. Additionally, the design—whether flat, molded, or reinforced—can affect performance and compatibility with different valve types.Operating Temperature Range:

This property indicates the range of temperatures within which the valve can effectively function. For regions with extreme temperatures, selecting a valve with a suitable operating temperature range is crucial to prevent malfunction and ensure reliability.

Which Trade Terms Are Commonly Used in the Diaphragm Valve Industry?

Understanding industry jargon can significantly enhance communication between buyers and suppliers. Here are some common trade terms:

OEM (Original Equipment Manufacturer):

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, sourcing from OEMs can ensure compatibility and quality assurance for replacement parts in their irrigation systems.MOQ (Minimum Order Quantity):

This term defines the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively, particularly in regions where demand may fluctuate.RFQ (Request for Quotation):

A formal process where buyers solicit price quotes from suppliers for specific products. Crafting a detailed RFQ can help ensure that suppliers provide accurate pricing and specifications, facilitating better procurement decisions.Incoterms (International Commercial Terms):

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), helps buyers clarify shipping responsibilities and costs.Lead Time:

This refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for planning and scheduling, especially in regions with seasonal irrigation needs.Warranty Terms:

This encompasses the conditions under which a supplier will repair or replace defective products. Knowing warranty terms is essential for buyers to evaluate the risk associated with product performance and longevity.

By grasping these technical properties and trade terms, B2B buyers can navigate the diaphragm irrigation valve market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the diaphragm irrigation valve Sector

What Are the Current Market Dynamics and Key Trends in the Diaphragm Irrigation Valve Sector?

The diaphragm irrigation valve market is undergoing significant transformation, driven by various global factors. The increasing demand for efficient water management systems amid rising agricultural needs is a primary driver. As countries in Africa, South America, and the Middle East face water scarcity, investment in advanced irrigation technology is becoming essential. This trend is further accentuated by the push for precision agriculture, where diaphragm valves play a crucial role in optimizing water usage.

Emerging B2B technology trends include the integration of smart irrigation systems. These systems leverage IoT (Internet of Things) and AI (Artificial Intelligence) to provide real-time data and analytics, enhancing decision-making processes for international buyers. Additionally, the growing importance of remote monitoring and automated systems is reshaping sourcing strategies, pushing buyers to seek suppliers that offer these innovative solutions.

Market dynamics are also influenced by regional factors. For example, in Europe, regulatory frameworks promoting sustainable practices are driving the demand for eco-friendly diaphragm valves. Buyers from regions such as Nigeria and Saudi Arabia are increasingly looking for reliable suppliers who can provide not only quality products but also robust support and maintenance services. As such, understanding regional preferences and regulatory landscapes is vital for successful sourcing.

How Can Sustainability and Ethical Sourcing Impact the Diaphragm Irrigation Valve Supply Chain?

Sustainability is becoming a critical concern in the diaphragm irrigation valve sector, influencing purchasing decisions among B2B buyers. The environmental impact of manufacturing processes and materials used in valve production is under scrutiny. Buyers are increasingly seeking suppliers that demonstrate a commitment to sustainability through eco-friendly practices, such as using recyclable materials and minimizing waste.

Ethical sourcing is equally important, as companies strive to establish transparent supply chains. Buyers are encouraged to partner with manufacturers who adhere to fair labor practices and demonstrate accountability in their sourcing strategies. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainable practices.

Moreover, the adoption of ‘green’ materials in diaphragm valve production not only meets regulatory requirements but also appeals to environmentally-conscious consumers. As the global focus on sustainability intensifies, B2B buyers who prioritize ethical sourcing and sustainability will likely benefit from enhanced brand reputation and customer loyalty.

What Is the Historical Context of Diaphragm Irrigation Valve Development?

The diaphragm irrigation valve has evolved significantly since its inception, reflecting technological advancements and shifts in agricultural practices. Initially designed for basic water control, these valves have adapted to meet the demands of modern agriculture. The introduction of durable materials and innovative design features has improved their efficiency and longevity.

Historically, diaphragm valves were primarily mechanical devices, but recent developments have integrated electronic components, allowing for automated control. This evolution has made them indispensable in precision irrigation systems, particularly in regions where water conservation is critical. As the agricultural landscape continues to change, the diaphragm irrigation valve will likely undergo further innovations, aligning with the ongoing quest for efficiency and sustainability in farming practices.

In summary, understanding the dynamics of the diaphragm irrigation valve market, emphasizing sustainability and ethical sourcing, and recognizing the historical context of these products are essential for B2B buyers navigating this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of diaphragm irrigation valve

How do I solve diaphragm valve leakage issues?

To address leakage in diaphragm valves, first inspect the diaphragm for signs of wear or damage. Replacement may be necessary if the diaphragm is compromised. Ensure that the installation is secure and that there are no loose connections, as these can lead to leaks. Regular maintenance, including cleaning and periodic inspections, can prevent leaks from occurring. If issues persist, consult with the supplier for specific troubleshooting guidance or consider upgrading to a higher-quality valve designed for your application.What is the best diaphragm irrigation valve for commercial applications?

For commercial applications, the best diaphragm irrigation valves are those that offer durability and reliability under high pressure. Brands like Hunter and Toro are recognized for their robust designs and performance in demanding environments. Look for valves that are compatible with your existing irrigation system and have features such as anti-siphon capabilities or built-in filters. Consider the specific requirements of your operation, such as flow rates and pressure levels, to choose the most suitable valve.What should I consider when selecting a supplier for diaphragm irrigation valves?

When selecting a supplier, evaluate their reputation, experience in the industry, and range of products offered. Look for suppliers who provide detailed product specifications and have positive customer reviews. It’s also beneficial to assess their capacity for customization, lead times, and after-sales support. Ensure they comply with international quality standards, especially if you’re sourcing from different regions, to guarantee the reliability of the products.Are there minimum order quantities (MOQ) for diaphragm irrigation valves?

Many suppliers impose minimum order quantities (MOQ) for diaphragm irrigation valves, which can vary significantly based on the manufacturer and the specific product. It’s essential to inquire about the MOQ upfront to avoid unexpected costs. If you are a smaller business or just starting, some suppliers may offer flexibility or allow you to combine orders with other products to meet the MOQ. Always discuss your needs with the supplier to find a mutually beneficial arrangement.What payment terms are typical for international purchases of irrigation valves?

Payment terms for international purchases can vary widely but generally include options such as advance payment, letters of credit, and payment upon delivery. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) depending on your relationship and purchase history. It’s crucial to establish clear payment terms before finalizing orders to ensure smooth transactions and avoid potential disputes. Be aware of any additional fees related to currency exchange or international wire transfers.How can I ensure quality assurance (QA) for diaphragm irrigation valves?

To ensure quality assurance, request certification documents from your supplier that indicate compliance with international standards, such as ISO certifications. Consider conducting third-party inspections or audits before shipment, especially for large orders. Additionally, ask for samples before placing a bulk order to evaluate product quality firsthand. Establishing a solid relationship with your supplier can also facilitate better QA practices and prompt resolution of any issues that arise.What are the logistics considerations when importing diaphragm irrigation valves?

When importing diaphragm irrigation valves, consider factors such as shipping methods, transit times, and customs regulations in your country. It’s essential to work with a logistics provider familiar with international trade to navigate these complexities effectively. Ensure you understand the import duties and taxes applicable to your products to budget accurately. Timely communication with your supplier regarding shipping schedules can help avoid delays and ensure a smooth delivery process.Can diaphragm irrigation valves be customized for specific applications?

Yes, many manufacturers offer customization options for diaphragm irrigation valves to meet specific application needs. Customizations may include size, material, and additional features such as solenoid integration or specialized coatings for corrosion resistance. When discussing your requirements with suppliers, provide detailed information about your application to help them recommend the best customization options. Be prepared for potential lead times associated with custom orders, as these may vary based on the complexity of the modifications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Diaphragm Irrigation Valve Manufacturers & Suppliers List

1. Irritrol – 100232-H Diaphragm Assembly

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: Valve Diaphragms available from various brands including Irritrol, Hunter, Toro, and Weathermatic. Key products include:

1. Irritrol – 100232-H – Diaphragm Assembly for 204/205 Valves, Original Price: $22.04, Current Price: $12.40, In Stock: 44

2. Hunter – 332100 – PGV/SRV 1″ Diaphragm Assembly, Original Price: $16.39, Current Price: $9.22, In Stock: 320

3. Irritrol – 100236 – Replacement Diaphra…

2. Orbit – Replacement Solenoids and Diaphragms

Domain: orbitonline.com

Registered: 1999 (26 years)

Introduction: Replacement Underground Solenoids and Diaphrams for sprinkler systems. Key components include a diaphragm (rubber seal) and a solenoid (metal rod, spring, electromagnet). Common issues include faulty solenoids, damaged diaphragms, or damaged valve bodies. Easy for homeowners to replace. Available products include Sprinkler Valve Repair Kits & Diaphragms starting from $5.69 and 24V Solenoids starti…

3. Reddit – Diaphragm and Valve Replacement Costs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Cost of a new diaphragm is $10. Cost of a new valve is $25. Replacement is recommended if the diaphragm is leaking, and it’s suggested to replace the entire valve if the existing body is in good condition.

4. Rain Bird – Diaphragm Repair Kit

Domain: store.rainbird.com

Registered: 1995 (30 years)

Introduction: Diaphragm Repair Kit for Rain Bird DV, DVF and ASVF Valves. Special Price: $14.64, List Price: $19.52. In stock. SKU: 21074603. Kit includes a new black rubber diaphragm assembly with preinstalled diaphragm filter, 1 new solenoid filter, 6 screws, and a spare diaphragm spring.

5. DIG – Replacement Diaphragm for Automated Valves

Domain: dripworks.com

Registered: 1998 (27 years)

Introduction: Replacement diaphragm for 3/4″ and 1″ DIG automated valves (discontinued). Compatible with 2-wire, 9 volt DIG valves (discontinued) and older 3-wire, 18 volt DIG valves (discontinued). SKU: TGALVDIASM, UPC: Not provided, MPN: 03-025. Price: $13.95.

6. Hunter Irrigation – Essential Tools Guide

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: Tools Required: 5/16 socket (recommended), Philips Screwdriver

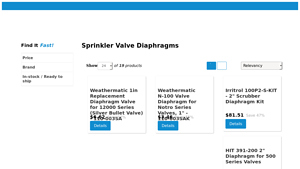

7. PlumbersStock – Sprinkler Valve Diaphragms

Domain: plumbersstock.com

Registered: 2007 (18 years)

Introduction: Sprinkler Valve Diaphragms are essential components for controlling sprinkler systems. They function as membrane valves that regulate water flow through the inlet and outlet pipes of a sprinkler valve. The diaphragm is activated by a solenoid, which creates pressure to open or close the diaphragm, ensuring proper water flow. A malfunctioning diaphragm can lead to excessive water flow or no water f…

Strategic Sourcing Conclusion and Outlook for diaphragm irrigation valve

As the global demand for efficient irrigation solutions continues to rise, diaphragm irrigation valves stand out as a critical component for sustainable agricultural practices. Key takeaways for international B2B buyers include the importance of selecting high-quality, reliable valves that ensure optimal performance, particularly in diverse climates found in regions such as Africa, South America, the Middle East, and Europe. Strategic sourcing not only reduces costs but also mitigates risks associated with supply chain disruptions, ensuring that agricultural operations remain uninterrupted.

Investing in diaphragm valves from reputable manufacturers can lead to significant long-term savings through reduced maintenance and replacement costs. Furthermore, understanding the local market dynamics and regulatory requirements can enhance sourcing strategies, making it easier to establish fruitful partnerships with suppliers.

Looking ahead, the irrigation industry is poised for innovation, with advancements in technology and sustainability practices. B2B buyers are encouraged to stay informed about emerging trends and engage with suppliers who prioritize eco-friendly solutions. By doing so, you can position your business at the forefront of the irrigation sector, contributing to a more sustainable future while meeting the growing demands of global markets.