Introduction: Navigating the Global Market for cascade pump and irrigation bend oregon

In the complex landscape of sourcing cascade pumps and irrigation solutions from Bend, Oregon, international buyers face the challenge of ensuring quality and reliability while navigating diverse market options. This guide is designed to assist B2B buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Vietnam and Nigeria—in making informed decisions when investing in essential water management systems.

We delve into the various types of cascade pumps and irrigation systems available, their specific applications in both residential and agricultural settings, and the key factors that influence pricing. Additionally, our guide provides insights into supplier vetting processes, ensuring that buyers can identify reputable partners who meet their operational needs. By offering comprehensive information on installation, maintenance, and repair services, this resource empowers businesses to enhance their water management capabilities effectively.

In an era where reliable water systems are critical for both agricultural productivity and residential comfort, understanding the intricacies of the market is vital. This guide equips international buyers with actionable insights, enabling them to navigate the global market confidently and optimize their procurement strategies in the ever-evolving landscape of water management solutions.

Understanding cascade pump and irrigation bend oregon Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centrifugal Pumps | High flow rate, efficient for large volumes | Agricultural irrigation, industrial use | Pros: High efficiency; Cons: Requires regular maintenance. |

| Submersible Pumps | Operates underwater, compact design | Residential water systems, wells | Pros: Space-saving; Cons: Limited to specific depths. |

| Well Pumps | Designed for deep water extraction | Agricultural, municipal water supply | Pros: Effective for deep wells; Cons: Installation complexity. |

| Drip Irrigation Systems | Delivers water directly to plant roots | Agriculture, landscaping | Pros: Water-efficient; Cons: Initial setup cost. |

| Pivot Irrigation Systems | Automated, rotates around a pivot point | Large-scale farming | Pros: Covers large areas; Cons: High initial investment. |

What Are the Key Characteristics of Centrifugal Pumps for B2B Buyers?

Centrifugal pumps are renowned for their ability to handle large volumes of water efficiently, making them ideal for agricultural irrigation and industrial applications. These pumps utilize rotational energy to move fluid, which allows for high flow rates. When considering a centrifugal pump, B2B buyers should evaluate the pump’s material, capacity, and energy consumption, as these factors can significantly impact operational costs and efficiency.

Why Choose Submersible Pumps for Specific Applications?

Submersible pumps are designed to operate underwater, making them suitable for residential water systems and wells. Their compact design allows for easy installation in tight spaces. Buyers should consider the pump’s depth rating and power requirements when purchasing, as these factors will determine its suitability for specific applications. Additionally, submersible pumps tend to require less maintenance due to their protective casing.

How Do Well Pumps Serve Agricultural and Municipal Needs?

Well pumps are specifically engineered for deep water extraction, making them essential for agricultural and municipal water supply systems. Their design allows for efficient operation in deeper wells, providing a reliable water source. Buyers should assess the well’s depth and the pump’s capacity to ensure compatibility. While well pumps can be complex to install, they are crucial for operations that rely on groundwater.

What Are the Benefits of Drip Irrigation Systems for Water Efficiency?

Drip irrigation systems are designed to deliver water directly to the root zone of plants, significantly improving water efficiency. This method is particularly advantageous in agriculture and landscaping, where water conservation is critical. B2B buyers should consider the initial setup costs and the system’s scalability for future expansion. The benefits of reduced water waste and improved crop yield often outweigh the initial investment.

Why Consider Pivot Irrigation Systems for Large-Scale Farming?

Pivot irrigation systems offer automated watering solutions that rotate around a central pivot point, making them ideal for large-scale farming operations. These systems can cover extensive areas, ensuring uniform water distribution. Buyers should evaluate the system’s size, automation features, and maintenance requirements. Although the initial investment can be high, the efficiency and labor savings provided by pivot systems can lead to long-term cost benefits.

Key Industrial Applications of cascade pump and irrigation bend oregon

| Industry/Sector | Specific Application of cascade pump and irrigation bend oregon | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Agricultural irrigation systems using centrifugal pumps | Enhanced crop yield through efficient water distribution | Compatibility with local water sources and soil types |

| Water Supply & Management | Residential water systems and well pumps | Reliable access to potable water for communities | Local regulations on water sourcing and system installation |

| Construction | Pumping systems for dewatering construction sites | Minimized project delays and enhanced safety | Durable equipment that can withstand harsh conditions |

| Energy | Pumping solutions for geothermal energy systems | Increased energy efficiency and reduced operational costs | Compliance with energy regulations and efficiency standards |

| Environmental Services | Wastewater management and treatment systems | Improved public health and environmental protection | Adherence to local environmental regulations and standards |

How is Cascade Pump & Irrigation Used in Agriculture and What Problems Does it Solve?

In the agricultural sector, cascade pumps and irrigation systems are vital for managing water resources effectively. These systems facilitate precise water distribution across fields, leading to improved crop yields and resource conservation. For international buyers, particularly in regions like Africa and South America, it’s crucial to consider the compatibility of these systems with local soil types and water availability. Additionally, understanding local agricultural practices can help in selecting the most suitable pump systems for specific crops.

What Role Does Cascade Pump & Irrigation Play in Water Supply and Management?

For residential water systems, cascade pump solutions ensure consistent access to clean drinking water. This is particularly important in areas where water scarcity is an issue. Buyers from the Middle East and Europe should focus on the regulatory landscape regarding water sourcing and system installation. Ensuring compliance with local water management policies can prevent legal complications and enhance community trust in the solutions provided.

How Do Cascade Pump Systems Benefit the Construction Industry?

In the construction sector, cascade pumps are essential for dewatering applications, especially in areas prone to flooding or high groundwater levels. These systems help maintain dry conditions on-site, which is critical for safety and efficiency. Buyers should prioritize sourcing durable equipment capable of withstanding harsh construction environments, as well as understanding the logistical aspects of transporting and installing these systems in remote areas.

How Can Cascade Pump Solutions Enhance Energy Efficiency?

The energy sector benefits from cascade pumping solutions, particularly in geothermal energy applications. These pumps help circulate fluids within geothermal systems, enhancing energy extraction efficiency. International buyers should pay close attention to compliance with energy regulations and standards to ensure that the pumps contribute to overall system efficiency and sustainability. This can significantly reduce operational costs and improve return on investment.

Why is Cascade Pump & Irrigation Important for Environmental Services?

In environmental services, cascade pump systems are crucial for wastewater management and treatment. They help in transporting and treating wastewater effectively, thereby protecting public health and the environment. Buyers should be aware of local environmental regulations and standards to ensure that the systems they implement meet or exceed compliance requirements. This is particularly relevant for international buyers in regions facing environmental challenges.

3 Common User Pain Points for ‘cascade pump and irrigation bend oregon’ & Their Solutions

Scenario 1: Inconsistent Water Supply Disrupting Operations

The Problem: B2B buyers, particularly those in agriculture or commercial sectors, often face challenges with inconsistent water supply from pumps. This can be due to equipment failures, inadequate pump specifications, or poor installation practices. In regions like Bend, Oregon, where water management is crucial for irrigation, any disruption can lead to significant losses in crop yield or operational inefficiencies. For instance, a farmer might find their irrigation system failing to deliver adequate water during peak growing seasons, impacting not only productivity but also revenue.

The Solution: To mitigate this issue, B2B buyers should engage with local experts, such as Cascade Pump & Irrigation Services, to conduct a thorough assessment of their current systems. It is vital to specify the correct pump type and size based on the specific needs of the application, whether for agricultural irrigation or commercial use. Buyers should also consider implementing regular maintenance schedules to prevent unexpected failures. Cascade’s full-service approach, including design, installation, and repair, can ensure that systems are not only installed correctly but also optimized for performance. Additionally, investing in advanced monitoring systems can provide real-time data on water supply and pump performance, allowing for proactive adjustments before issues arise.

Scenario 2: Lack of Technical Support for Emergency Situations

The Problem: Many B2B buyers experience anxiety over the lack of timely technical support during emergencies, such as a pump failure or a water shortage. In agricultural settings, the inability to quickly resolve these issues can lead to crop damage, while in commercial enterprises, it can result in operational downtime and financial losses. For instance, a factory that relies on a consistent water supply may face production halts due to a malfunctioning pump, leading to costly delays.

The Solution: Establishing a relationship with a reliable local service provider, like Cascade Pump & Irrigation Services, can alleviate this pain point. Buyers should inquire about the availability of emergency services and response times before making a commitment. Cascade offers on-call technicians who can respond promptly to emergencies, which is critical in high-stakes situations. Moreover, buyers should consider creating a service agreement that includes regular system checks and emergency support provisions. This proactive approach not only minimizes downtime but also ensures that any potential issues are addressed before they escalate into emergencies.

Scenario 3: Navigating Complex Regulatory Compliance

The Problem: B2B buyers in sectors reliant on water usage must navigate a complex web of local regulations and compliance requirements, which can be overwhelming. In regions like Bend, Oregon, where water resources are carefully managed, understanding the legalities around water extraction, pump installation, and irrigation practices is crucial. For instance, a commercial developer might be uncertain about the permits needed for a new irrigation system, risking non-compliance and potential fines.

The Solution: To successfully navigate these regulatory challenges, it is essential for buyers to collaborate with experienced professionals who understand local laws. Cascade Pump & Irrigation Services not only provides installation and maintenance but also offers consultation on compliance issues. Engaging with these experts can help buyers understand the necessary permits and regulations for their specific projects. Additionally, leveraging Cascade’s extensive knowledge can streamline the permitting process, ensuring that all installations meet regulatory standards from the outset. This proactive stance not only mitigates the risk of fines but also fosters a sustainable approach to water management in their operations.

Strategic Material Selection Guide for cascade pump and irrigation bend oregon

What Are the Key Materials Used in Cascade Pump and Irrigation Systems?

When selecting materials for cascade pump and irrigation systems in Bend, Oregon, it’s essential to consider their properties and suitability for specific applications. The following analysis covers four common materials: stainless steel, PVC, cast iron, and polyethylene. Each material has unique characteristics that impact performance, durability, and cost, especially for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

How Does Stainless Steel Perform in Cascade Pump and Irrigation Systems?

Stainless steel is renowned for its exceptional corrosion resistance and high strength, making it an ideal choice for applications involving water and various chemicals. Its temperature and pressure ratings are generally high, allowing it to withstand demanding environments.

Pros: Stainless steel is highly durable and can last for years with minimal maintenance. It is also resistant to rust and scaling, which is crucial for maintaining water quality.

Cons: The primary drawback is its cost, as stainless steel is more expensive than other materials. Additionally, manufacturing complexities can arise during fabrication, which may increase lead times.

Impact on Application: This material is compatible with a wide range of media, including potable water and agricultural chemicals, making it versatile for both residential and commercial systems.

Considerations for International Buyers: Compliance with standards such as ASTM and ISO is critical. Buyers should ensure that the stainless steel used meets local regulations regarding water quality and safety.

What Are the Advantages of Using PVC in Cascade Pump and Irrigation Systems?

Polyvinyl chloride (PVC) is a popular choice for irrigation systems due to its lightweight nature and ease of installation. It has good chemical resistance and can handle moderate pressure levels.

Pros: PVC is cost-effective and easy to work with, which reduces installation time and labor costs. Its resistance to corrosion makes it suitable for various water types.

Cons: However, PVC has limitations in terms of temperature tolerance; it can become brittle in extreme cold and may deform under high heat.

Impact on Application: PVC is suitable for non-potable water systems and is often used in agricultural irrigation applications. Its compatibility with various fertilizers and chemicals is a plus.

Considerations for International Buyers: Buyers should check for compliance with local regulations and standards, such as DIN and JIS, to ensure the material’s suitability for specific applications.

How Does Cast Iron Compare in Cascade Pump and Irrigation Applications?

Cast iron is traditionally used in pump manufacturing due to its strength and ability to handle high pressures. It is particularly favored for heavy-duty applications.

Pros: The durability of cast iron is unmatched, providing a long service life with proper maintenance. It also has excellent vibration dampening properties, which can enhance pump performance.

Cons: On the downside, cast iron is heavy and can be more challenging to install. It is also susceptible to corrosion if not properly coated or maintained.

Impact on Application: Cast iron is ideal for high-pressure applications, making it suitable for industrial pumping systems. However, its compatibility with certain corrosive media may be limited.

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially for buyers in regions with stringent industrial regulations. Proper coatings may be necessary to ensure longevity in corrosive environments.

What Role Does Polyethylene Play in Cascade Pump and Irrigation Systems?

Polyethylene is a flexible plastic often used in irrigation tubing and fittings. It offers excellent chemical resistance and is lightweight, making it easy to handle.

Pros: The flexibility of polyethylene allows for easy installation and adaptation to different layouts. It is also resistant to UV light, which is beneficial for outdoor applications.

Cons: However, polyethylene is not suitable for high-pressure applications and can be vulnerable to punctures and abrasions.

Impact on Application: It is commonly used for drip irrigation systems and other low-pressure applications. Its compatibility with various fertilizers and pesticides makes it a practical choice for agricultural use.

Considerations for International Buyers: Buyers should ensure that the polyethylene materials conform to local standards and regulations, particularly in terms of environmental safety and chemical compatibility.

Summary of Material Selection for Cascade Pump and Irrigation Systems

| Material | Typical Use Case for cascade pump and irrigation bend oregon | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure water systems, potable water applications | Exceptional corrosion resistance | Higher cost and manufacturing complexity | High |

| PVC | Agricultural irrigation, non-potable water systems | Cost-effective and easy installation | Limited temperature tolerance | Low |

| Cast Iron | Heavy-duty industrial pumping systems | High durability and pressure handling | Heavy and susceptible to corrosion | Medium |

| Polyethylene | Drip irrigation, low-pressure applications | Flexible and UV resistant | Not suitable for high-pressure applications | Low |

This guide provides a comprehensive overview of material options for cascade pump and irrigation systems, aiding international B2B buyers in making informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cascade pump and irrigation bend oregon

What Are the Key Stages in the Manufacturing Process of Cascade Pumps and Irrigation Systems?

The manufacturing process of cascade pumps and irrigation systems involves several critical stages, each designed to ensure the efficiency, reliability, and longevity of the final product.

Material Preparation: The first stage involves selecting high-quality materials, such as stainless steel, cast iron, or engineered plastics, depending on the specific application of the pump or irrigation system. Materials are inspected for compliance with industry standards and specifications, ensuring they meet necessary mechanical properties and corrosion resistance.

Forming: In this phase, the prepared materials are subjected to various forming techniques. Common methods include casting for pump housings and machining for precision components like impellers and shafts. Advanced forming techniques, such as CNC machining, are employed to achieve high tolerances and complex geometries, which are essential for optimal pump performance.

Assembly: The assembly stage brings together all the components, including the motor, pump casing, and electrical parts. Skilled technicians utilize both manual and automated processes to ensure that each assembly is completed accurately. This stage often includes the installation of seals and gaskets to prevent leaks and ensure operational efficiency.

Finishing: Finally, the products undergo finishing processes such as surface treatments, painting, and protective coatings to enhance durability and aesthetic appeal. This stage also includes final adjustments and calibrations to ensure that the pumps and irrigation systems operate at their specified performance levels.

How is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is integral to ensuring that cascade pumps and irrigation systems meet both customer expectations and regulatory standards.

International Standards and Certifications: Many manufacturers adhere to international standards like ISO 9001, which outlines criteria for a quality management system. Additionally, industry-specific certifications such as CE marking for European markets and API (American Petroleum Institute) standards for pumps used in petroleum applications are vital for ensuring compliance and safety.

Quality Control Checkpoints: The manufacturing process includes several critical quality control (QC) checkpoints:

– Incoming Quality Control (IQC): At this stage, raw materials and components are inspected for quality before they enter the manufacturing process. This may involve testing material properties and verifying supplier certifications.

– In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the manufacturing process. This includes checking dimensions, tolerances, and assembly techniques.

– Final Quality Control (FQC): Before shipping, the completed products undergo rigorous testing to ensure they function correctly under operating conditions. Tests may include performance assessments, pressure tests, and leak tests.Common Testing Methods: Various testing methods are employed to validate product quality. These may include:

– Hydraulic Testing: Ensures that the pumps can handle the specified pressure and flow rates.

– Electrical Testing: Verifies that electrical components function correctly and safely.

– Durability Testing: Simulates long-term operation to assess wear and tear on components.

How Can B2B Buyers Verify Quality Control Practices of Suppliers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial for ensuring product reliability and compliance. Here are actionable steps to consider:

Supplier Audits: Conducting on-site audits can provide insight into the manufacturing processes and quality control measures in place. Audits should assess compliance with international standards and the effectiveness of the supplier’s quality management system.

Requesting Quality Reports: Buyers should ask for detailed quality assurance reports that outline the testing methodologies used, results obtained, and any corrective actions taken. Regular reporting is a good indicator of a supplier’s commitment to quality.

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These inspections often include detailed reports that can help buyers make informed decisions.

What Nuances Should International Buyers Consider Regarding Quality Control?

When navigating the complexities of international procurement, particularly for cascade pumps and irrigation systems, buyers must be aware of several nuances related to quality control:

Regional Standards Variability: Different regions may have varying standards and regulations. For instance, the CE marking is essential for products sold in the European Union, while compliance with local standards in Africa or South America may differ. Understanding these nuances is vital for ensuring compliance and market acceptance.

Cultural Differences in Quality Expectations: Quality perceptions can vary significantly across cultures. Buyers should engage with suppliers to understand their quality philosophies and practices, ensuring alignment with the buyer’s expectations.

Logistical Considerations: Quality control doesn’t stop at manufacturing. It is essential to consider the entire supply chain, including transportation and storage conditions, which can impact product quality. Ensuring that suppliers adhere to quality practices throughout the supply chain is crucial for international transactions.

By understanding the manufacturing processes, quality assurance protocols, and verification methods, international B2B buyers can make informed decisions when sourcing cascade pumps and irrigation systems from Bend, Oregon. This knowledge will not only enhance procurement strategies but also foster strong partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cascade pump and irrigation bend oregon’

This guide aims to provide a practical checklist for international B2B buyers seeking to procure cascade pump and irrigation systems from Bend, Oregon. As the demand for efficient water management systems continues to rise across various sectors, understanding the procurement process can significantly enhance your purchasing experience. Follow these steps to ensure a successful sourcing journey.

1. Define Your Technical Specifications

Begin by outlining the specific requirements for your irrigation or pumping system. Consider factors such as the size of your operation, the type of crops or applications, and the water source available.

– Performance Requirements: Specify flow rates, pressure levels, and any other performance metrics essential to your operations.

– System Type: Decide whether you need residential, commercial, or agricultural systems, as this will influence supplier selection.

2. Research Potential Suppliers

Conduct thorough research to identify suppliers in Bend, Oregon, that specialize in cascade pumps and irrigation systems. Look for companies with a solid reputation and experience in your specific industry.

– Industry Experience: Prioritize suppliers with a track record in your sector, whether it be agriculture, landscaping, or commercial irrigation.

– Customer Reviews: Check platforms like Yelp or the Better Business Bureau for customer feedback and ratings to gauge service quality.

3. Evaluate Supplier Certifications

Ensure that potential suppliers hold the necessary licenses and certifications to operate in the irrigation and pumping sector. This step is crucial for compliance and quality assurance.

– Licensing Verification: Confirm that the supplier is licensed as a general and electrical contractor, as required by local regulations.

– Certifications: Look for certifications that reflect industry standards and best practices, such as ISO or other relevant quality management certifications.

4. Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals. This will allow you to compare pricing, delivery timelines, and service offerings.

– Quote Breakdown: Ensure proposals provide a clear breakdown of costs, including equipment, installation, and maintenance services.

– Service Level Agreements (SLAs): Check for SLAs that outline the supplier’s responsibilities in terms of service quality and response times for emergencies.

5. Assess After-Sales Support

Evaluate the after-sales support offered by potential suppliers. Reliable after-sales service is essential for maintaining operational efficiency in irrigation systems.

– Maintenance Services: Inquire about the availability of ongoing maintenance and repair services, as well as the response time for emergencies.

– Technical Support: Confirm that the supplier offers robust technical support, including troubleshooting assistance and access to spare parts.

6. Visit Supplier Facilities (If Possible)

If feasible, arrange a visit to the supplier’s facilities in Bend. This can provide invaluable insights into their operations, inventory, and overall professionalism.

– Factory Tour: Observe the production process and the quality of materials used in their products.

– Meet the Team: Interacting with the team can help you assess their expertise and commitment to customer service.

7. Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, engage in negotiations to finalize the terms of the agreement. This is your opportunity to secure the best possible deal.

– Payment Terms: Discuss payment options, including deposits, milestones, and final payments.

– Delivery and Installation: Clearly outline delivery schedules and installation responsibilities to avoid any misunderstandings.

By following this checklist, international B2B buyers can effectively navigate the procurement process for cascade pump and irrigation systems in Bend, Oregon, ensuring they select a reliable supplier that meets their specific needs.

Comprehensive Cost and Pricing Analysis for cascade pump and irrigation bend oregon Sourcing

What Are the Key Cost Components in Sourcing Cascade Pumps and Irrigation Systems?

When considering the sourcing of cascade pumps and irrigation systems from Bend, Oregon, it’s essential to understand the various cost components that contribute to the overall pricing structure. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The quality and type of materials used in pumps and irrigation systems significantly influence costs. High-grade materials that ensure durability and efficiency may come at a premium but can reduce long-term maintenance costs.

Labor: Labor costs can vary depending on local wage standards in Bend. Skilled labor may command higher wages but is crucial for ensuring quality installations and repairs.

Manufacturing Overhead: This includes all indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient management of these costs can lead to more competitive pricing.

Tooling: The cost of specialized tools and equipment necessary for manufacturing and maintenance also factors into the overall pricing structure.

Quality Control: Investing in rigorous QC processes can increase initial costs but ultimately saves money by reducing defects and ensuring product reliability.

Logistics: Transportation costs to deliver products to international buyers can vary widely based on distance, shipping methods, and tariffs.

Margin: Suppliers typically add a profit margin to cover their operational costs and risk, which can fluctuate based on market demand and competitive landscape.

How Do Price Influencers Affect Cascade Pump and Irrigation System Costs?

Several factors can influence the pricing of cascade pumps and irrigation systems, particularly for international buyers. Understanding these influencers can help you make informed purchasing decisions.

Volume/MOQ: Purchasing in bulk can often lead to significant discounts. Buyers should negotiate minimum order quantities (MOQs) to maximize cost savings.

Specifications and Customization: Customized solutions tailored to specific agricultural or residential needs may incur additional costs. Clearly defining specifications upfront can help manage expectations and budget.

Materials Quality and Certifications: Products that meet international standards and certifications may carry higher prices but can ensure compliance and reliability, especially for international buyers.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more but can also offer better service and warranties.

Incoterms: The choice of Incoterms will affect logistics and shipping costs. Buyers should be aware of who bears responsibility for shipping, insurance, and tariffs to accurately assess total costs.

What Buyer Tips Can Help in Negotiating Prices for Cascade Pumps and Irrigation Systems?

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider specific strategies to ensure cost-effective purchasing of cascade pumps and irrigation systems.

Negotiation: Don’t hesitate to negotiate prices, especially if purchasing in bulk. Establish a good rapport with suppliers, as this can often lead to better deals and terms.

Cost Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also installation, maintenance, and operational costs over the product’s lifespan.

Pricing Nuances: Be aware that pricing can vary based on geopolitical factors, currency fluctuations, and local economic conditions. Staying informed about these elements can provide leverage during negotiations.

Research and Compare: Conduct thorough research and compare multiple suppliers. Understanding the market landscape can help you identify fair pricing and quality benchmarks.

Disclaimer on Indicative Prices

It’s important to note that prices for cascade pumps and irrigation systems can vary widely based on the aforementioned factors. Always seek detailed quotes from suppliers to get accurate pricing tailored to your specific requirements.

Alternatives Analysis: Comparing cascade pump and irrigation bend oregon With Other Solutions

Exploring Alternatives to Cascade Pump and Irrigation Services in Bend, Oregon

In the realm of irrigation and pumping solutions, businesses often seek alternatives that can provide similar benefits while catering to diverse operational needs. Cascade Pump and Irrigation Services in Bend, Oregon, offers a range of specialized services and products for residential, commercial, and agricultural applications. However, understanding other viable options can empower B2B buyers to make informed decisions that align with their specific requirements.

Comparison Table

| Comparison Aspect | Cascade Pump And Irrigation Bend Oregon | Drip Irrigation Systems | Subsurface Irrigation Systems |

|---|---|---|---|

| Performance | High efficiency for diverse applications | Excellent water efficiency; minimal evaporation | Consistent moisture delivery; efficient water use |

| Cost | Moderate initial investment; ongoing maintenance costs | Lower initial cost; cost-effective over time | Higher initial cost; savings on water over time |

| Ease of Implementation | Requires professional installation and expertise | Generally easier to install; DIY options available | Requires professional installation; site-specific design |

| Maintenance | Regular maintenance needed; parts availability | Low maintenance; occasional filter cleaning | Low maintenance; infrequent checks needed |

| Best Use Case | Ideal for large-scale and complex irrigation needs | Best for small to medium gardens or farms | Suitable for crops requiring steady moisture; works well in arid climates |

Detailed Breakdown of Alternatives

Drip Irrigation Systems

Drip irrigation is a method that delivers water directly to the roots of plants through a network of tubing and emitters. This system is particularly favored for its water efficiency, significantly reducing evaporation and runoff. The initial costs are generally lower than traditional systems, making it an attractive option for smaller agricultural operations or garden setups. However, while installation can be simple, achieving optimal performance may require careful planning to avoid clogging and ensure even distribution.

Subsurface Irrigation Systems

Subsurface irrigation involves burying a network of pipes below the soil surface, allowing water to seep directly into the root zone. This method is highly efficient, especially in arid regions, as it minimizes evaporation and surface runoff. While the upfront investment can be substantial due to the need for professional installation and tailored designs, the long-term savings on water usage can offset these costs. This system is particularly beneficial for crops that thrive on consistent moisture levels, but it requires careful management to avoid potential issues with soil salinity and system clogging.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right irrigation and pumping solution is crucial for ensuring operational efficiency and sustainability. B2B buyers should consider factors such as the specific agricultural needs, budget constraints, and long-term maintenance requirements. Cascade Pump and Irrigation Services provides a robust option for businesses with complex irrigation needs, while alternatives like drip and subsurface irrigation systems may offer cost-effective solutions for smaller operations. Evaluating these aspects will help businesses make informed decisions that align with their goals and environmental conditions.

Essential Technical Properties and Trade Terminology for cascade pump and irrigation bend oregon

What Are the Key Technical Properties of Cascade Pump and Irrigation Systems?

Understanding the essential technical properties of cascade pumps and irrigation systems is crucial for B2B buyers, especially when making informed purchasing decisions. Below are some critical specifications that buyers should consider:

Material Grade

The material used in the construction of pumps and irrigation systems greatly affects durability and performance. Common materials include stainless steel, cast iron, and thermoplastics. Each material has unique characteristics, such as resistance to corrosion or pressure, making it vital for buyers to choose based on the specific environmental conditions of their application.Flow Rate

Measured in gallons per minute (GPM) or liters per second (L/s), the flow rate indicates how much water a pump can deliver over a given period. This specification is crucial for determining whether a pump can meet the demands of agricultural or residential water systems. A higher flow rate generally signifies better efficiency but can also lead to increased energy consumption.Head Pressure

This refers to the height to which a pump can raise water, typically measured in feet or meters. Understanding head pressure is essential for ensuring that the irrigation system can distribute water effectively across the desired area. Insufficient head pressure may lead to inadequate irrigation coverage.Power Consumption

The energy requirements of a pump, often expressed in horsepower (HP) or kilowatts (kW), are important for calculating operational costs. Buyers should consider the trade-off between initial investment and long-term energy savings when selecting pumps. Efficient pumps can significantly reduce operational costs, especially for large-scale agricultural applications.Tolerance

Tolerance refers to the allowable deviation from specified dimensions in pump components. High tolerance levels ensure precise fitting and optimal performance. For B2B buyers, understanding tolerances can prevent costly installation issues and ensure that components function correctly together.

Which Trade Terms Should B2B Buyers Understand in the Cascade Pump and Irrigation Industry?

Familiarity with industry-specific terminology can empower B2B buyers to navigate contracts, negotiations, and product specifications more effectively. Here are some common trade terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing pumps or components, buyers should consider whether they are purchasing OEM parts, as these often guarantee compatibility and quality.MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for budgeting and inventory planning. Buyers should assess their needs against the MOQ to avoid overcommitting resources.RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. Including detailed specifications in an RFQ helps ensure that the quotes received are accurate and relevant. This process can streamline purchasing decisions and facilitate cost comparisons.Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers manage logistics more effectively, especially when sourcing products from overseas suppliers.Lead Time

This term refers to the time between placing an order and receiving the product. Understanding lead times is essential for planning and scheduling installation or project timelines. Buyers should inquire about lead times when negotiating contracts to avoid disruptions in their operations.Warranty and Service Agreements

These terms outline the terms of repair, replacement, and maintenance services provided by the manufacturer or supplier. Knowing the details of warranty coverage can protect buyers against potential defects and ensure long-term reliability of their systems.

By grasping these essential properties and terms, B2B buyers in Africa, South America, the Middle East, and Europe can make more informed decisions regarding cascade pumps and irrigation systems, ensuring they meet their operational needs efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the cascade pump and irrigation bend oregon Sector

What are the Key Market Dynamics and Trends in the Cascade Pump and Irrigation Sector?

The cascade pump and irrigation sector is currently experiencing a transformative phase driven by technological advancements and a growing emphasis on sustainability. Global demand for efficient water management systems is escalating, particularly in regions facing water scarcity, such as parts of Africa and the Middle East. B2B buyers are increasingly seeking innovative solutions that integrate automation and smart technologies, allowing for real-time monitoring and optimization of water usage. This trend is particularly relevant for agricultural sectors in South America and Europe, where precision irrigation systems are becoming essential for enhancing crop yields while conserving water.

In addition, the rise of e-commerce platforms is reshaping how international buyers source equipment and services. Buyers from regions like Nigeria and Vietnam are leveraging online marketplaces to connect with suppliers in Bend, Oregon, thus streamlining procurement processes. Moreover, the ongoing global push towards digitalization is enhancing supply chain transparency, enabling buyers to track their purchases more effectively. As competition intensifies, companies that invest in robust digital strategies will likely gain a significant advantage in securing B2B partnerships.

How is Sustainability Influencing Sourcing Decisions in the Cascade Pump and Irrigation Sector?

Sustainability has become a cornerstone of sourcing strategies in the cascade pump and irrigation sector. International buyers are increasingly aware of the environmental impacts of their procurement choices and are prioritizing suppliers that demonstrate commitment to sustainable practices. This includes the use of energy-efficient pumps, recyclable materials, and eco-friendly manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers from regions such as Europe and South America are demanding transparency in sourcing, encouraging suppliers to adopt certifications that verify sustainable practices. Certifications such as ISO 14001 for environmental management systems and WaterSense for water-efficient products are becoming prerequisites for many procurement decisions. As a result, suppliers in Bend, Oregon, are adapting their offerings to meet these criteria, creating a market environment that rewards sustainable innovation.

What is the Historical Context of the Cascade Pump and Irrigation Sector in Bend, Oregon?

The cascade pump and irrigation sector in Bend, Oregon, has evolved significantly since its inception in the early 1990s. Initially focused on basic irrigation solutions, the industry has grown to encompass a wide range of services, including advanced pumping systems and integrated water management solutions. Over the past three decades, the region has established itself as a hub for innovative irrigation technology, thanks in part to the increasing demand for efficient agricultural practices.

This evolution has been marked by the introduction of cutting-edge technologies, such as solar-powered pumps and automated irrigation systems, which have transformed traditional practices. As the sector continues to adapt to global trends, including climate change and water conservation efforts, it remains well-positioned to meet the needs of international B2B buyers seeking reliable and sustainable solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of cascade pump and irrigation bend oregon

How do I solve issues with my irrigation system?

To address problems with your irrigation system, first identify the specific issue, such as low water pressure or uneven distribution. Contact a specialized service like Cascade Pump & Irrigation in Bend, Oregon, for expert troubleshooting. Their team can assist with diagnosing the issue on-site and recommend repairs or modifications. Regular maintenance and timely intervention can prevent larger issues, ensuring your irrigation system operates efficiently.What is the best type of pump for agricultural irrigation?

The best type of pump for agricultural irrigation largely depends on your specific needs, including the size of your operation and the source of your water. Centrifugal pumps are commonly used for their efficiency and ability to handle large volumes of water. For deeper wells, submersible pumps are ideal. Consulting with a local expert like Cascade Pump & Irrigation can provide tailored recommendations based on your unique agricultural requirements.What should I consider when sourcing irrigation equipment internationally?

When sourcing irrigation equipment internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. Verify the supplier’s experience and reputation by checking references and reviews. Additionally, assess the logistics involved, including shipping times and costs, and ensure that the equipment meets your specific agricultural needs.What are common payment terms for B2B transactions in the irrigation sector?

Common payment terms in B2B transactions for irrigation equipment often include net 30 or net 60 days, meaning payment is due within 30 or 60 days after the invoice date. Some suppliers may require a deposit upfront, especially for custom orders. Always clarify payment terms before finalizing your order, and consider using secure payment methods to protect your investment.How can I ensure quality assurance (QA) for imported irrigation products?

To ensure quality assurance for imported irrigation products, request certifications and compliance documents from the supplier. Implement a quality control process, including inspecting products upon arrival. Establish a clear communication channel with your supplier to address any concerns promptly. Consider working with third-party inspection services to verify product quality before shipment.What is the minimum order quantity (MOQ) for irrigation equipment?

The minimum order quantity (MOQ) for irrigation equipment can vary significantly by supplier and product type. Some suppliers may have an MOQ as low as one unit for standard items, while custom or specialized equipment may require larger orders. Discuss your needs with the supplier to understand their MOQ policies and explore options for smaller orders if necessary.What logistical considerations should I keep in mind when importing from the U.S.?

When importing irrigation equipment from the U.S., consider shipping methods, customs duties, and potential tariffs. Work with a reliable freight forwarder who understands the intricacies of international shipping. Additionally, be aware of the documentation required for customs clearance, including bills of lading and commercial invoices, to avoid delays in receiving your products.How do I vet suppliers for irrigation equipment effectively?

To effectively vet suppliers for irrigation equipment, start by researching their background, years in business, and customer reviews. Request references from previous clients and follow up to gauge satisfaction levels. Verify their certifications and licenses relevant to your industry. Additionally, consider conducting site visits or virtual meetings to assess their operations and product quality firsthand.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Cascade Pump And Irrigation Bend Oregon Manufacturers & Suppliers List

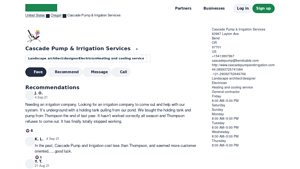

1. Cascade Pump & Irrigation Services – Water Heaters & Pumping Systems

Domain: nextdoor.com

Registered: 2004 (21 years)

Introduction: Cascade Pump & Irrigation Services, LLC provides Residential Water Heaters, Commercial Water Heaters, Industrial Water Heaters, Pumping Systems, and Electrical Systems to the Bend, OR area.

2. Cascade Pump & Irrigation Services – Electrical & Irrigation Solutions

Domain: buildzoom.com

Registered: 2011 (14 years)

Introduction: Cascade Pump & Irrigation Services LLC offers a range of services including electrical work related to irrigation systems and pumps. They hold multiple licenses, including an Electrical license, and have a BuildZoom score of 108, placing them in the top 5% of contractors in Oregon. Their typical project sizes range from under $5,000 to over $250,000, with an average permit value of approximately $…

3. Cascade Pump & Irrigation Services – Water Heaters & Pumping Systems

Domain: local.yahoo.com

Registered: 1995 (30 years)

Introduction: Cascade Pump & Irrigation Services, LLC provides Residential Water Heaters, Commercial Water Heaters, Industrial Water Heaters, Pumping Systems, and Electrical Systems to the Bend, OR area.

Strategic Sourcing Conclusion and Outlook for cascade pump and irrigation bend oregon

What Are the Key Insights for Strategic Sourcing in Cascade Pump and Irrigation Services?

In summary, Cascade Pump and Irrigation Services in Bend, Oregon, stands out as a premier provider for international B2B buyers seeking reliable water and irrigation solutions. Their extensive expertise in design, installation, and maintenance of both residential and commercial systems positions them as a trustworthy partner. Notably, their emphasis on prompt service delivery, particularly for emergency situations, enhances their value proposition.

Strategic sourcing from Cascade ensures that buyers can leverage high-quality products and services tailored to diverse agricultural needs. With a robust parts inventory and a dedicated team of experts, organizations can optimize their irrigation systems for efficiency and sustainability. As global demand for reliable water management solutions continues to rise, engaging with Cascade Pump and Irrigation Services offers a strategic advantage.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should consider forging partnerships with Cascade. By doing so, they can access innovative solutions that cater to their unique challenges and ensure long-term success in their water management initiatives. Explore opportunities to collaborate with Cascade Pump and Irrigation Services today and elevate your operational capabilities.