Introduction: Navigating the Global Market for irrigation shutoff valve

In an era of increasingly complex agricultural practices and stringent water management regulations, sourcing the right irrigation shutoff valve is a pivotal challenge for international B2B buyers. These valves play a crucial role in optimizing irrigation efficiency and ensuring sustainable water usage, a necessity for businesses across Africa, South America, the Middle East, and Europe. This comprehensive guide delves into various types of irrigation shutoff valves, their diverse applications, and best practices for supplier vetting and cost analysis.

With a focus on practical insights, this resource empowers buyers to make informed purchasing decisions that align with their operational needs and regional regulations. Whether you’re a distributor in Nigeria seeking reliable suppliers or a project manager in Germany looking to enhance irrigation systems, this guide addresses your specific concerns. By examining critical factors such as valve material, functionality, and compatibility with existing systems, we aim to equip you with the knowledge necessary to navigate the global market effectively.

Ultimately, this guide serves as a strategic tool, enabling businesses to not only meet their irrigation needs but also to contribute to broader sustainability goals within their respective regions. As you explore the intricacies of irrigation shutoff valves, you will gain the confidence to enhance your procurement processes and drive operational success.

Understanding irrigation shutoff valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Anti-Siphon Valve | Prevents backflow, typically includes a vacuum breaker | Residential and light commercial irrigation | Pros: Prevents contamination; easy installation. Cons: May require more maintenance than inline valves. |

| Inline Valve | Direct flow control, available in various sizes and materials | Commercial agriculture, municipal systems | Pros: Versatile; can handle high pressure. Cons: Installation can be complex; may require additional fittings. |

| Quick Coupling Valve | Allows for easy connection/disconnection of hoses and systems | Temporary irrigation setups, sports fields | Pros: Quick setup; reusable. Cons: Not suitable for permanent installations; may leak if not properly secured. |

| Globe Valve | Designed for throttling flow, typically used for precision control | Golf courses, high-value landscapes | Pros: Excellent flow control; durable. Cons: Higher cost; can be bulky. |

| Angle Valve | Features a bent design for space-saving installation | Tight spaces, residential applications | Pros: Space-efficient; effective flow direction. Cons: Limited to specific configurations; may not be as robust as other types. |

What Are the Characteristics of Anti-Siphon Valves and Their Applications?

Anti-siphon valves are designed to prevent backflow in irrigation systems, ensuring that contaminated water does not return to the main supply. They typically incorporate a vacuum breaker, making them ideal for residential and light commercial applications. Buyers should consider the maintenance requirements, as these valves may need regular checks to ensure proper functioning. Their ease of installation makes them a popular choice for B2B buyers looking for reliable solutions in smaller-scale projects.

How Do Inline Valves Benefit Commercial and Municipal Systems?

Inline valves are characterized by their direct flow control capabilities and are available in a variety of sizes and materials. They are commonly used in commercial agriculture and municipal irrigation systems due to their ability to handle high pressures. For B2B buyers, the versatility of inline valves offers significant advantages, but they may require complex installation procedures. Consideration of the specific system requirements and compatibility with existing infrastructure is crucial for optimal performance.

What Makes Quick Coupling Valves Ideal for Temporary Setups?

Quick coupling valves are designed for easy connection and disconnection of irrigation hoses, making them particularly useful in temporary setups such as sports fields or seasonal agricultural applications. Their reusable nature allows for quick changes in configuration, which is beneficial for B2B buyers in dynamic environments. However, they may not be suitable for permanent installations, and potential leakage if not secured properly should be taken into account.

Why Are Globe Valves Preferred for Precision Flow Control?

Globe valves are favored for their ability to throttle flow, making them suitable for applications requiring precise water management, such as golf courses and high-value landscapes. Their durability and effective flow control justify their higher cost, making them a solid investment for B2B buyers focused on long-term performance. However, the bulkiness of globe valves and their installation complexity may be a drawback for some applications.

How Do Angle Valves Optimize Space in Irrigation Systems?

Angle valves feature a bent design that allows for space-efficient installations, making them ideal for tight spaces in residential applications. They effectively direct flow while conserving space, which is a significant advantage for B2B buyers working in constrained environments. However, their specialized design may limit their use to specific configurations, and they may not be as robust as other valve types, which should be considered during the purchasing process.

Key Industrial Applications of irrigation shutoff valve

| Industry/Sector | Specific Application of irrigation shutoff valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Efficient water management in crop irrigation systems | Reduces water wastage, optimizes crop yield | Durability, compatibility with local soil and climate conditions, compliance with agricultural regulations. |

| Landscaping & Parks | Automated irrigation systems for public parks | Ensures consistent watering, enhances aesthetic appeal | Weather resistance, ease of installation, and maintenance requirements. |

| Golf Courses | Control of water supply in turf management systems | Maintains high-quality greens, reduces operational costs | Robustness against heavy use, ability to handle reclaimed water, and integration with existing systems. |

| Municipal Water Supply | Regulation of water flow in urban irrigation networks | Improves resource management, minimizes overflow risks | Compliance with local water regulations, reliability under varying pressure conditions, and ease of access for repairs. |

| Horticulture | Specialized irrigation for greenhouses and nurseries | Enhances plant growth, conserves water resources | Customization options for flow rates, material compatibility with specific plants, and automation capabilities. |

How is the Irrigation Shutoff Valve Used in Agriculture?

In the agriculture sector, irrigation shutoff valves are integral to managing water resources efficiently. They are used to control the flow of water to various crop fields, allowing farmers to optimize irrigation schedules based on weather conditions and soil moisture levels. This not only conserves water but also maximizes crop yield by ensuring that plants receive the appropriate amount of water. For international buyers, particularly in regions like Africa and South America, sourcing valves that are durable and compatible with local climates is crucial to withstand varying conditions and regulatory standards.

What Role Do Irrigation Shutoff Valves Play in Landscaping & Parks?

Irrigation shutoff valves are essential for automated irrigation systems in public parks and landscaped areas. They facilitate the consistent watering of plants and lawns, ensuring that these green spaces remain healthy and visually appealing. By automating the watering process, municipalities can significantly reduce labor costs and water wastage. Buyers in Europe, such as in Germany, should consider valves that offer weather resistance and ease of maintenance, particularly in regions with fluctuating climates.

How Do Golf Courses Benefit from Using Irrigation Shutoff Valves?

In golf course management, irrigation shutoff valves are critical for maintaining the quality of turf and greens. These valves allow for precise control over water distribution, ensuring that all areas receive adequate moisture without overwatering. This not only preserves the aesthetic quality of the course but also reduces operational costs associated with water usage. Buyers from the Middle East, where water scarcity is a concern, should prioritize sourcing robust valves that can handle reclaimed water and integrate seamlessly with existing irrigation systems.

What Advantages Do Municipal Water Supply Systems Gain from Shutoff Valves?

Municipal water supply systems utilize irrigation shutoff valves to regulate water flow in urban irrigation networks. These valves help manage resources effectively, minimizing the risk of overflow and ensuring that water is distributed evenly across public green spaces. For international buyers, particularly in developing regions, it is essential to source valves that comply with local water regulations and can withstand varying pressure conditions, ensuring reliable performance over time.

How Are Irrigation Shutoff Valves Customized for Horticulture?

In horticulture, irrigation shutoff valves are tailored for specialized applications such as greenhouses and nurseries. They play a pivotal role in enhancing plant growth by allowing for precise control over water delivery based on specific plant needs. Buyers should look for options that allow customization of flow rates and are compatible with the materials used in their irrigation systems. Additionally, automation features can significantly improve efficiency, making these valves a critical investment for horticultural businesses across diverse markets.

3 Common User Pain Points for ‘irrigation shutoff valve’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Irrigation Shutoff Valves

The Problem: B2B buyers often face significant challenges when it comes to sourcing high-quality irrigation shutoff valves. This is especially prevalent in regions such as Africa and South America, where inconsistent supply chains and a lack of reliable local manufacturers can lead to delays and subpar products. Poor-quality valves may result in leaks, system failures, and increased maintenance costs, which can severely disrupt agricultural operations or landscape management.

The Solution: To overcome these sourcing challenges, buyers should prioritize establishing relationships with reputable suppliers who have a proven track record in the irrigation industry. Conducting thorough market research is essential; look for suppliers that specialize in irrigation systems and have positive reviews from other B2B clients. Additionally, consider engaging in trade shows or industry conferences to meet manufacturers and distributors in person. When selecting a supplier, assess their quality assurance practices and inquire about certifications that ensure compliance with international standards. Forming long-term partnerships with trusted suppliers can lead to better pricing, consistent quality, and reliable service, ultimately enhancing operational efficiency.

Scenario 2: Managing Valve Compatibility in Diverse Systems

The Problem: Another common pain point for B2B buyers is the compatibility of irrigation shutoff valves with existing systems. Many agricultural and commercial operations utilize a mix of equipment and systems, leading to concerns about whether new valves will integrate seamlessly with older components. Incompatibility can lead to operational inefficiencies, additional costs for retrofitting, and potential downtime during installation.

The Solution: To address compatibility issues, buyers should conduct a thorough audit of their existing irrigation systems before purchasing new shutoff valves. This includes documenting the specifications of current valves, such as size, thread type, and material. Buyers should consult with system engineers or irrigation specialists to ensure that any new valves meet the required technical standards. When purchasing, opt for valves that are designed for flexibility and compatibility with various systems. Many manufacturers provide detailed specifications and compatibility guides; leveraging these resources can streamline the selection process. Consider also investing in adjustable valves or those with universal fittings to mitigate future compatibility issues.

Scenario 3: Ensuring Efficient Maintenance and Operation of Shutoff Valves

The Problem: Regular maintenance of irrigation shutoff valves is often overlooked, leading to increased wear and tear, inefficiencies, and unexpected failures. For B2B buyers managing large-scale irrigation systems, the cost of downtime due to valve malfunctions can be substantial. Additionally, many buyers may lack the technical knowledge to perform proper maintenance or may not have access to replacement parts, which exacerbates the problem.

The Solution: To ensure efficient maintenance, buyers should implement a proactive maintenance schedule tailored to their specific irrigation systems. This includes routine inspections of shutoff valves to check for leaks, wear, and proper operation. Buyers should also invest in training for their maintenance staff, focusing on best practices for valve care and troubleshooting common issues. Establishing a partnership with a reliable supplier for replacement parts can streamline the process of repairing or replacing faulty components. Additionally, utilizing smart irrigation technologies that include monitoring systems can provide real-time data on valve performance, allowing for timely interventions before problems escalate. By adopting these strategies, B2B buyers can enhance the longevity and efficiency of their irrigation systems, ultimately leading to cost savings and improved productivity.

Strategic Material Selection Guide for irrigation shutoff valve

When selecting materials for irrigation shutoff valves, it is essential to consider the properties, advantages, and limitations of each material type. This analysis will focus on four common materials: plastic, brass, stainless steel, and ductile iron. Each material presents unique characteristics that can significantly impact performance, durability, and suitability for specific applications.

What Are the Key Properties of Plastic Irrigation Shutoff Valves?

Plastic valves, typically made from PVC or ABS, are lightweight and corrosion-resistant, making them suitable for various irrigation systems. They generally have a temperature rating of up to 140°F (60°C) and can handle moderate pressure levels, usually around 150 psi.

Pros: Plastic valves are cost-effective and easy to install, making them ideal for residential and light commercial applications. They are resistant to rust and corrosion, which is particularly beneficial in humid or chemically aggressive environments.

Cons: However, plastic valves may not withstand extreme temperatures or high pressure as well as metal options. They can also be less durable over time, especially when exposed to UV light without protective coatings.

Impact on Application: Plastic valves are compatible with water and most irrigation chemicals but may not be suitable for high-pressure systems or applications involving abrasive materials.

How Do Brass Irrigation Shutoff Valves Perform?

Brass valves are known for their strength and durability, making them suitable for heavy-duty applications, such as municipal systems and golf courses. They typically have a higher temperature and pressure rating, often exceeding 200°F (93°C) and 300 psi.

Pros: The primary advantage of brass is its robustness and resistance to corrosion, especially in outdoor environments. Brass valves also have excellent sealing capabilities, ensuring minimal leakage.

Cons: The main drawback is the higher cost compared to plastic valves. Additionally, brass can be susceptible to dezincification, where zinc leaches out, weakening the material.

Impact on Application: Brass valves are compatible with a wide range of media, including potable water. However, compliance with local regulations regarding lead content is crucial, particularly in Europe and North America.

What Are the Benefits of Stainless Steel Irrigation Shutoff Valves?

Stainless steel valves are highly resistant to corrosion and can handle extreme temperatures and pressures, making them suitable for industrial applications. They can operate effectively in environments ranging from -40°F to 400°F (-40°C to 204°C) and can withstand pressures up to 600 psi.

Pros: The durability and longevity of stainless steel make it an excellent choice for high-performance applications. They require minimal maintenance and can handle aggressive chemicals without degrading.

Cons: The primary disadvantage is the cost, as stainless steel valves are significantly more expensive than plastic or brass options. Additionally, they can be heavier, which may complicate installation.

Impact on Application: Stainless steel valves are ideal for applications involving corrosive media, but buyers must ensure compliance with international standards, such as ASTM or DIN, particularly in regions with stringent regulations.

Why Choose Ductile Iron for Irrigation Shutoff Valves?

Ductile iron valves are robust and designed for high-pressure applications, often used in municipal water systems. They can withstand temperatures up to 250°F (121°C) and pressures exceeding 400 psi.

Pros: The strength and durability of ductile iron make it suitable for heavy-duty applications. They are resistant to impact and can handle significant stress, making them ideal for high-traffic areas.

Cons: However, ductile iron valves are prone to corrosion if not properly coated, which can increase maintenance costs. They are also heavier, making installation more labor-intensive.

Impact on Application: Ductile iron valves are compatible with most water types but may require protective coatings for long-term outdoor use. Compliance with local and international standards is essential for ensuring safety and performance.

Summary Table of Material Selection for Irrigation Shutoff Valves

| Material | Typical Use Case for irrigation shutoff valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Residential and light commercial applications | Lightweight, cost-effective, corrosion-resistant | Limited pressure and temperature ratings | Low |

| Brass | Municipal systems, golf courses | High durability, excellent sealing | Higher cost, potential dezincification | Medium |

| Stainless Steel | Industrial applications | Corrosion-resistant, handles extreme conditions | High cost, heavier | High |

| Ductile Iron | High-pressure municipal systems | Strong, impact-resistant | Prone to corrosion without coatings | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in diverse international markets, enabling informed decisions based on specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation shutoff valve

What Are the Key Stages in the Manufacturing Process of Irrigation Shutoff Valves?

The manufacturing process of irrigation shutoff valves involves several key stages, each critical for ensuring the quality and reliability of the final product.

Material Preparation

The first step in the manufacturing process is material preparation. Common materials used for irrigation shutoff valves include high-density polyethylene (HDPE), PVC, and brass. These materials are selected for their durability, resistance to corrosion, and ability to withstand various environmental conditions. The raw materials undergo rigorous quality checks to ensure they meet specific standards before they are processed further.

Forming Techniques: How Are Valves Shaped?

The forming stage involves shaping the prepared materials into the desired valve components. This can be achieved through various techniques such as injection molding for plastic valves and machining for metal valves. Injection molding is particularly effective for producing complex shapes with high precision, which is essential for the internal mechanisms of the valves. For brass and other metal valves, processes like casting and CNC machining are employed to create the valve bodies, ensuring tight tolerances that are crucial for performance.

Assembly: What Is Involved in the Assembly Process?

Following forming, the components are assembled. This stage typically involves the installation of internal parts such as diaphragms, solenoids, and seals. Automated assembly lines are often utilized to enhance efficiency and consistency, although some components may require manual assembly to ensure precision. Each valve is assembled in a clean environment to prevent contamination, which could affect performance.

Finishing: How Is the Final Product Prepared for Distribution?

The finishing stage includes surface treatments such as coating or painting to enhance resistance to environmental factors and improve aesthetics. Additionally, valves undergo a final inspection and testing to ensure they meet performance specifications. This may include pressure testing to confirm that the valves can handle the operational pressures they will face in the field.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance is critical in the manufacturing of irrigation shutoff valves to ensure that they meet international standards and customer expectations.

Which International Standards Apply to Irrigation Shutoff Valves?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 assures buyers that the manufacturer has established processes for continuous improvement and customer satisfaction. Additionally, specific certifications like CE marking in Europe or API standards for oil and gas applications may apply, depending on the intended use of the valves.

What Are the Key QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to verify that they meet specified requirements.

In-Process Quality Control (IPQC): During production, regular inspections are conducted to ensure that the manufacturing processes are producing components that conform to quality standards. This includes monitoring critical parameters such as temperature, pressure, and dimensions.

Final Quality Control (FQC): After assembly and finishing, the valves undergo a final inspection. This may include functional testing, leak testing, and dimensional checks to ensure the product meets quality standards before it is shipped.

What Testing Methods Are Commonly Used for Irrigation Shutoff Valves?

To verify the functionality and reliability of irrigation shutoff valves, various testing methods are employed:

Pressure Testing: Valves are subjected to pressure tests to ensure they can withstand operational pressures without leaking.

Flow Rate Testing: This assesses the valve’s performance by measuring the flow rate at different pressure levels, ensuring it meets the specifications.

Durability Testing: Valves are tested under extreme conditions to simulate long-term usage, which helps identify potential failure points.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital for ensuring product reliability.

What Steps Can Buyers Take to Conduct Supplier Audits?

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturer’s processes, quality control measures, and overall operational efficiency. This can include reviewing documentation related to certifications, process controls, and testing methodologies.

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline the results of various tests performed on the valves. These reports can provide insight into the consistency and reliability of the products.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and the quality of the final products. This can be particularly beneficial for buyers who are unfamiliar with local suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must also consider the regulatory environments in their respective regions. For instance, compliance with local regulations regarding materials and environmental standards may differ significantly from those in the supplier’s country. Buyers should familiarize themselves with these regulations to ensure that the products they import are compliant and safe for use in their markets.

In summary, understanding the manufacturing processes and quality assurance measures for irrigation shutoff valves is essential for B2B buyers. By focusing on key stages of production, adhering to international standards, and implementing thorough quality control checks, manufacturers can ensure they deliver reliable, high-quality products that meet the specific needs of diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation shutoff valve’

To assist B2B buyers in procuring irrigation shutoff valves effectively, this practical sourcing guide outlines essential steps to ensure a successful procurement process. By following this checklist, buyers can make informed decisions that meet their operational needs and align with industry standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements of the irrigation shutoff valve. Consider factors such as size, pressure rating, material (plastic or metal), and flow control features. Specificity in your requirements helps to narrow down potential suppliers and ensures that the products meet your operational standards.

- Size and Configuration: Determine the inlet and outlet sizes, as well as whether the valve will be used in a residential or commercial application.

- Material Selection: Assess whether plastic or metal valves are more suitable based on the environment and intended usage.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in irrigation shutoff valves. Look for companies that have a proven track record in the industry and can meet your specific needs.

- Supplier Reputation: Explore online reviews, testimonials, and case studies to gauge the reliability of potential suppliers.

- Product Range: Ensure they offer a diverse selection of valves to match your specifications, including anti-siphon and inline options.

Step 3: Evaluate Supplier Certifications

Verify that your chosen suppliers possess relevant certifications and comply with industry standards. Certifications can indicate a supplier’s commitment to quality and safety.

- ISO Certification: Look for suppliers with ISO 9001 certification, as this reflects adherence to quality management systems.

- Local Regulations: Ensure compliance with local regulations in your target markets, especially for international purchases.

Step 4: Request Samples for Testing

Before making bulk purchases, request samples of the irrigation shutoff valves. Testing samples allows you to assess the product’s quality, functionality, and compatibility with your existing systems.

- Functional Testing: Evaluate how the valve operates under various pressure conditions.

- Material Assessment: Inspect the material for durability and resistance to environmental factors.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to finalize pricing, payment terms, and delivery schedules. Effective negotiation can lead to cost savings and better contract terms.

- Volume Discounts: Inquire about discounts for bulk orders or long-term contracts.

- Payment Flexibility: Discuss payment options that align with your budget cycles.

Step 6: Confirm Shipping and Delivery Logistics

Ensure that the supplier can meet your logistical requirements for shipping and delivery. Timely delivery is critical for maintaining project timelines.

- Lead Times: Confirm the expected lead times for production and shipping.

- Shipping Methods: Discuss available shipping options and their associated costs.

Step 7: Establish a Communication Plan

Maintain open lines of communication with your supplier throughout the procurement process. A solid communication plan can prevent misunderstandings and facilitate timely updates.

- Regular Updates: Schedule regular check-ins to monitor the progress of your order.

- Issue Resolution: Establish a protocol for addressing any potential issues that may arise during fulfillment.

By adhering to this checklist, B2B buyers can ensure a systematic and efficient procurement process for irrigation shutoff valves, ultimately leading to successful project outcomes.

Comprehensive Cost and Pricing Analysis for irrigation shutoff valve Sourcing

Understanding the cost structure and pricing dynamics of irrigation shutoff valves is essential for international B2B buyers seeking to optimize their procurement strategies. This analysis delves into the cost components, price influencers, and practical buyer tips tailored for stakeholders in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Irrigation Shutoff Valves?

The cost structure of irrigation shutoff valves consists of several components:

Materials: The choice of materials significantly impacts cost. Plastic valves are generally less expensive than metal ones, with prices reflecting the durability and application suitability. For instance, plastic valves may range from $17 to $38, while brass valves can exceed $200.

Labor: Labor costs vary based on geographical location and manufacturing practices. In regions with lower labor costs, such as parts of Africa and South America, manufacturers may offer competitive pricing.

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can reduce overhead, contributing to lower product prices.

Tooling: Initial tooling costs for custom valve designs can be substantial. For standard designs, these costs are amortized over larger production volumes, reducing the per-unit cost.

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Valves that meet international certifications may command higher prices due to the added assurance of quality.

Logistics: Shipping and handling costs can vary significantly based on the distance and method of transport. International buyers should factor in logistics as a critical component of the total cost.

Margin: Supplier profit margins can vary based on competition, market demand, and the unique value proposition offered.

How Do Price Influencers Affect Irrigation Shutoff Valve Pricing?

Several factors can influence the pricing of irrigation shutoff valves:

Volume/MOQ: Larger orders typically attract volume discounts. Buyers should negotiate minimum order quantities (MOQs) to achieve better pricing.

Specifications and Customization: Custom valves designed for specific applications may incur additional costs. Buyers should weigh the benefits of customization against the increased price.

Materials and Quality Certifications: High-quality materials and certifications such as ISO or CE can increase costs but provide long-term reliability, which may reduce maintenance expenses.

Supplier Factors: The reputation and reliability of the supplier play a crucial role. Established suppliers may charge a premium for their products, backed by superior service and warranty options.

Incoterms: Understanding Incoterms is vital for international transactions. They dictate who bears the responsibility for shipping, insurance, and tariffs, affecting the overall price.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

B2B buyers can employ several strategies to enhance cost efficiency when sourcing irrigation shutoff valves:

Negotiation Tactics: Approach suppliers with clear expectations and be prepared to negotiate on price, terms, and delivery timelines. Building a relationship can also lead to better pricing.

Understanding Total Cost of Ownership (TCO): Evaluate the TCO, including initial purchase price, installation, maintenance, and potential downtime. Opting for a slightly more expensive, high-quality valve may result in lower long-term costs.

Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local economic conditions, demand, and supply chain factors. Buyers should conduct thorough market research to understand local pricing trends.

Requesting Sample Products: Before committing to large orders, request samples to assess quality and suitability. This helps mitigate risks associated with bulk purchases.

In conclusion, navigating the cost and pricing landscape for irrigation shutoff valves requires a strategic approach that considers various components and influencers. By leveraging insights into cost structures and employing effective negotiation strategies, international B2B buyers can make informed purchasing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing irrigation shutoff valve With Other Solutions

Exploring Alternatives to Irrigation Shutoff Valves for Efficient Water Management

In the realm of irrigation systems, selecting the right water management solution is crucial for optimizing efficiency and sustainability. While irrigation shutoff valves play a vital role in controlling water flow, several alternative solutions can also achieve similar objectives. Understanding the strengths and weaknesses of these alternatives is essential for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Irrigation Shutoff Valve | Drip Irrigation System | Smart Irrigation Controllers |

|---|---|---|---|

| Performance | High flow control; reliable | Efficient water delivery; reduces waste | Adaptive watering based on real-time data |

| Cost | Moderate initial investment; low ongoing costs | Higher initial setup costs; long-term savings | Variable costs based on technology used |

| Ease of Implementation | Relatively simple installation | Requires planning and design; more complex | Installation can be straightforward, but setup may require expertise |

| Maintenance | Low maintenance; occasional checks needed | Low maintenance; filter cleaning may be required | Requires regular software updates; potential sensor maintenance |

| Best Use Case | Traditional fields, residential lawns | Gardens, orchards, and greenhouses | Large-scale farms or landscapes with variable conditions |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Drip Irrigation Systems?

Drip irrigation systems provide a targeted approach to delivering water directly to plant roots, minimizing evaporation and runoff. The efficiency of drip systems significantly reduces water waste, making them ideal for arid regions. However, the initial installation costs can be higher compared to irrigation shutoff valves, and the systems require careful planning and design to ensure optimal layout and functionality. Additionally, while maintenance is generally low, filters may need periodic cleaning to prevent clogging.

How Do Smart Irrigation Controllers Enhance Water Management?

Smart irrigation controllers utilize real-time data from weather forecasts and soil moisture sensors to optimize watering schedules automatically. This adaptive technology can significantly reduce water usage and improve crop health. While the initial investment can vary widely based on the technology chosen, the long-term savings on water bills and improved plant health can justify the costs. However, these systems may require regular software updates and occasional sensor maintenance, which could complicate the maintenance process compared to traditional shutoff valves.

Conclusion: How to Choose the Right Solution for Your Irrigation Needs

When selecting the most suitable irrigation solution, B2B buyers should consider their specific operational context, including budget constraints, geographical challenges, and the scale of their irrigation needs. Irrigation shutoff valves offer a reliable and straightforward solution for controlling water flow, particularly in traditional irrigation setups. In contrast, drip irrigation systems and smart controllers provide advanced efficiencies that can lead to significant water savings but may require more complex implementation and maintenance efforts. Ultimately, the choice hinges on balancing initial investment with long-term operational efficiency, making it essential for buyers to conduct a thorough needs assessment before deciding on the optimal solution for their irrigation systems.

Essential Technical Properties and Trade Terminology for irrigation shutoff valve

What Are the Key Technical Properties of Irrigation Shutoff Valves?

When selecting irrigation shutoff valves, understanding their technical properties is crucial for ensuring efficient and reliable irrigation systems. Here are some essential specifications to consider:

Material Grade

– Definition: This refers to the type of material used to manufacture the valve, such as PVC, brass, or stainless steel.

– Importance: The material affects durability, resistance to corrosion, and suitability for different environmental conditions. For instance, PVC is lightweight and cost-effective for residential use, while brass is preferred for heavy-duty applications in commercial settings.Pressure Rating

– Definition: This indicates the maximum pressure the valve can handle, typically measured in pounds per square inch (PSI).

– Importance: Understanding the pressure rating is vital for preventing valve failures in high-pressure systems, which can lead to leaks or system downtime. Selecting a valve with an appropriate pressure rating ensures long-term reliability.Flow Rate

– Definition: The flow rate is the volume of water that can pass through the valve in a given time, usually measured in gallons per minute (GPM).

– Importance: Matching the flow rate to the system’s requirements is essential for maintaining adequate water distribution across the irrigation network. An incorrect flow rate can result in either under- or over-watering.Size and Connection Type

– Definition: Valves come in various sizes, typically defined by their diameter (e.g., 1 inch, 2 inches) and can have different connection types like threaded, slip, or barbed.

– Importance: The size and connection type must align with existing piping to ensure a proper fit and avoid leaks. Accurate sizing also affects installation efficiency and system performance.Diaphragm Type

– Definition: The diaphragm is a critical component that opens and closes the valve. Types include rubber, plastic, or metal.

– Importance: Different diaphragm materials affect the valve’s responsiveness and longevity. For instance, rubber diaphragms are often more flexible but may wear faster in harsh conditions compared to metal.Actuation Method

– Definition: This refers to how the valve is operated, which can be manual, electric, or hydraulic.

– Importance: The actuation method impacts ease of use and automation capabilities. Electric valves, for example, can be integrated with smart irrigation systems, enhancing efficiency and control.

What Are Common Trade Terminology Terms Related to Irrigation Shutoff Valves?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms:

OEM (Original Equipment Manufacturer)

– Explanation: Refers to companies that produce parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers evaluate product quality and warranty options.MOQ (Minimum Order Quantity)

– Explanation: This is the smallest number of units that a supplier is willing to sell.

– Relevance: Knowing the MOQ is crucial for budgeting and inventory management, particularly for small-scale operations or new entrants in the market.RFQ (Request for Quotation)

– Explanation: A document that a buyer sends to suppliers to request pricing and terms for specific products.

– Relevance: Submitting RFQs helps buyers compare costs and negotiate better deals based on detailed specifications.Incoterms (International Commercial Terms)

– Explanation: These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Understanding Incoterms is essential for managing shipping costs and risks, especially for international buyers in regions like Africa and South America.Lead Time

– Explanation: The time it takes from placing an order to receiving the goods.

– Relevance: Knowing the lead time helps businesses plan their projects effectively, ensuring timely availability of irrigation components.Warranty Period

– Explanation: The duration during which a product is guaranteed against defects or failures.

– Relevance: A clear understanding of warranty terms can protect buyers from unexpected costs and provides assurance regarding product reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance the performance and efficiency of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation shutoff valve Sector

What Are the Key Market Dynamics and Trends in the Irrigation Shutoff Valve Sector?

The global irrigation shutoff valve market is being driven by several factors, including the increasing demand for efficient water management solutions, especially in regions susceptible to drought, such as parts of Africa and the Middle East. As urbanization accelerates, there is a growing need for advanced irrigation systems that optimize water usage and reduce waste. This trend is particularly evident in agricultural sectors that prioritize sustainable practices, which has led to an uptick in smart irrigation technologies.

Emerging technologies such as IoT (Internet of Things) are revolutionizing the industry by enabling real-time monitoring and control of irrigation systems. This not only enhances operational efficiency but also supports data-driven decision-making for international B2B buyers. Additionally, the rise of automation in agriculture is compelling manufacturers to innovate, leading to the development of more durable and reliable valves designed to withstand harsh environmental conditions.

Furthermore, sourcing trends indicate a shift towards localized manufacturing and procurement strategies to minimize supply chain disruptions, especially in light of recent global events. Buyers in Europe, Africa, and South America are increasingly looking for suppliers who can provide quick turnaround times and high-quality products tailored to local market needs. This evolving landscape emphasizes the importance of agility and responsiveness among suppliers in the irrigation shutoff valve sector.

How Can Sustainability and Ethical Sourcing Impact the Irrigation Shutoff Valve Market?

Sustainability is becoming a central pillar in the irrigation shutoff valve market. As environmental concerns gain traction, B2B buyers are increasingly prioritizing products that reflect a commitment to sustainable practices. The production and use of irrigation shutoff valves can significantly impact water conservation efforts, making it imperative for suppliers to adopt environmentally friendly materials and manufacturing processes.

Ethical sourcing also plays a crucial role, as buyers are now scrutinizing supply chains for transparency and ethical labor practices. This includes sourcing materials from suppliers who adhere to environmental regulations and labor standards. Green certifications, such as those from the Forest Stewardship Council (FSC) or other recognized environmental bodies, can enhance the credibility of products and attract buyers who are focused on sustainability.

For manufacturers, investing in eco-friendly materials, such as recycled plastics and non-toxic coatings, not only reduces environmental impact but also aligns with the growing consumer demand for sustainable products. By showcasing a commitment to ethical practices and sustainable sourcing, suppliers can differentiate themselves in a competitive market and appeal to conscious B2B buyers across various regions.

What Is the Historical Context of Irrigation Shutoff Valves in B2B Markets?

The evolution of irrigation shutoff valves can be traced back to traditional farming practices, where manual systems were predominantly used. Early valves were basic, often made from metal, and relied heavily on human intervention for operation. As agricultural technology progressed, so did the design and functionality of these valves, leading to the introduction of automated and electrically operated systems.

In the latter half of the 20th century, with the advent of plastic materials, manufacturers began producing lightweight and corrosion-resistant valves, which significantly improved their durability and application in diverse environments. The focus shifted towards efficiency and reliability, paving the way for modern innovations such as smart valves integrated with sensors and IoT capabilities.

Today, the irrigation shutoff valve market is characterized by a blend of traditional practices and cutting-edge technology, providing B2B buyers with a range of options that cater to both conventional and advanced irrigation systems. Understanding this historical context is essential for buyers looking to make informed purchasing decisions that align with current market trends and future advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation shutoff valve

How do I choose the right irrigation shutoff valve for my system?

Choosing the right irrigation shutoff valve depends on several factors, including the type of irrigation system you have, the water pressure, and the specific application (residential vs. commercial). For residential systems, plastic valves are often sufficient, while metal valves are recommended for commercial and heavy-duty applications. Consider flow control features and whether you need anti-siphon capabilities. It’s also crucial to match the valve size with your piping to ensure optimal performance.What types of irrigation shutoff valves are available?

Irrigation shutoff valves come in various types, including globe, angle, and anti-siphon valves. Globe valves are generally used for flow regulation, while angle valves are suitable for applications requiring directional changes. Anti-siphon valves are essential for preventing backflow in systems connected to potable water. Selecting the right type will depend on your system’s configuration and intended use.What is the minimum order quantity (MOQ) for irrigation shutoff valves?

Minimum order quantities can vary significantly between suppliers. Typically, manufacturers may require an MOQ ranging from 50 to 500 units, depending on the valve type and customization options. For international buyers, it’s advisable to discuss your needs directly with suppliers to negotiate terms that align with your purchasing strategy, especially if you are entering new markets or testing demand.How can I verify the quality of irrigation shutoff valves from suppliers?

To ensure quality, request product samples before placing a large order. Additionally, inquire about certifications that meet international standards, such as ISO 9001. It’s beneficial to check supplier reviews and testimonials from other B2B buyers. Establishing a quality assurance process, including inspections during production and pre-shipment, can also help mitigate risks associated with subpar products.What are common payment terms for international B2B transactions?

Payment terms can vary widely, but common options include letters of credit, advance payments, and payment upon delivery. Many suppliers offer a 30% deposit with the balance due before shipping. It’s essential to negotiate terms that protect both parties and consider using escrow services for high-value transactions to ensure security throughout the payment process.How do I handle shipping and logistics for irrigation shutoff valves?

When managing shipping, consider working with freight forwarders who specialize in international logistics. Determine whether you need air or sea freight based on urgency and cost. Discuss customs clearance procedures with your supplier to ensure all necessary documentation is in order. It’s wise to factor in lead times for production and shipping to avoid delays in your irrigation projects.Can I customize irrigation shutoff valves to meet specific requirements?

Yes, many manufacturers offer customization options for irrigation shutoff valves. This can include specific sizes, materials, and features tailored to your unique irrigation system needs. Be sure to communicate your requirements clearly during the initial discussions with suppliers, as this can affect pricing and lead times. Custom solutions can enhance system efficiency and longevity.What are the best practices for maintaining irrigation shutoff valves?

Regular maintenance is key to ensuring the longevity and efficiency of your irrigation shutoff valves. Check for leaks, corrosion, and blockages at least once a season. Clean the valves periodically to prevent dirt accumulation, and replace any worn-out components promptly. Implementing a routine inspection schedule will help you identify issues early, minimizing downtime and maintenance costs in the long run.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Irrigation Shutoff Valve Manufacturers & Suppliers List

1. Rain Bird – 075ASVF Anti-Siphon Irrigation Valve

Domain: store.rainbird.com

Registered: 1995 (30 years)

Introduction: Rain Bird offers a variety of sprinkler valves including anti-siphon, inline, and quick-coupling options. Key products include: 075ASVF – 3/4 in. Plastic Residential Anti-Siphon Irrigation Valve with Flow Control ($28.38), 100ASVF – 1 in. Plastic Residential Anti-Siphon Irrigation Valve with Flow Control ($30.87), 100DV – 1 in. DV Series Inline Plastic Residential Irrigation Valve ($26.36), 100DVA…

2. Sprinkler Supply Store – Automatic Irrigation Valves

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: Sprinkler valves are automatic irrigation valves that can be either globe or angle (straight or bent) and utilize a diaphragm and an electric solenoid to open and close. They are generally made of plastic for residential and most commercial applications, while metal is used for heavy-duty sites such as golf courses and municipal pumping stations.

3. Irrigation Global – AMV Automatic Water Flow Meter

Domain: irrigationglobal.com

Registered: 2009 (16 years)

Introduction: This company, Irrigation Global – AMV Automatic Water Flow Meter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Reddit – Irrigation Control Valve

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Irrigation Control Valve, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. DripWorks – Drip Irrigation Fittings

Domain: dripworks.com

Registered: 1998 (27 years)

Introduction: Drip Irrigation – Fittings – PVC – Ball Valves. Guaranteed Lowest Price with excellent customer service. Available sizes: 1/2″, 3/4″, 1″, up to 2″. Constructed of schedule 40 PVC or brass. Options include threaded or slip valves and three-way valves. Ideal for creating a manual shutoff in irrigation systems for emergency situations, routine maintenance, repair, or renovation. Featured products inc…

6. DIG – Shut-Off Valves for Drip Irrigation

Domain: digcorp.com

Registered: 1996 (29 years)

Introduction: DIG offers a variety of shut-off valves for drip irrigation systems, including manual and automatic options. These valves are designed to control water flow effectively, ensuring optimal irrigation for gardens, flowerbeds, and other plant areas. The shut-off valves are compatible with various drip irrigation components and can be easily integrated into existing systems. They are constructed for du…

7. Angi – Irrigation Shut-Off Valve

Domain: angi.com

Registered: 1996 (29 years)

Introduction: The irrigation shut-off valve is typically located near the corners of the house or main building, just downstream of the backflow preventer. It can be above-ground, found inside the home (garage, utility closet, basement) or outside in a protective box near the water source. Below-ground valves are usually buried in a valve box with a green lid, often near the water meter or well. The shut-off va…

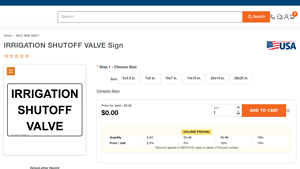

8. ComplianceSigns – Irrigation Shutoff Valve Sign

Domain: compliancesigns.com

Registered: 2005 (20 years)

Introduction: {“SKU”:”NHE-50471″,”Product Name”:”Irrigation Shutoff Valve Sign”,”Sizes Available”:[“5×3.5 in”,”7×5 in”,”10×7 in”,”14×10 in”,”20×14 in”,”28×20 in”],”Price”:”$0.00″,”Volume Pricing”:{“3-24 units”:”2.5% discount”,”25-49 units”:”5% discount”,”50-99 units”:”10% discount”,”100+ units”:”15% discount”},”Construction”:”Printed”,”Mounting Option”:”Surface Mount”,”Wording”:”IRRIGATION SHUTOFF VALVE”,”Descr…

Strategic Sourcing Conclusion and Outlook for irrigation shutoff valve

How Can Strategic Sourcing Enhance Your Procurement of Irrigation Shutoff Valves?

In conclusion, strategic sourcing of irrigation shutoff valves is paramount for optimizing operational efficiency and cost-effectiveness in your irrigation systems. By carefully evaluating supplier options across different regions, particularly in Africa, South America, the Middle East, and Europe, businesses can ensure they select high-quality products that meet their specific needs. Key takeaways include prioritizing suppliers that offer a range of valve types, materials, and configurations to cater to diverse irrigation applications, from residential setups to large-scale agricultural projects.

Moreover, leveraging local suppliers can significantly reduce lead times and shipping costs, while also fostering partnerships that enhance supply chain resilience. As the demand for sustainable and efficient irrigation solutions grows, the importance of investing in reliable shutoff valves cannot be overstated.

Looking ahead, it is crucial for international B2B buyers to stay informed about advancements in valve technology and sustainability practices. Engaging with suppliers who innovate in this space will not only secure a competitive edge but also contribute to responsible water management practices. Take the next step in your procurement strategy by exploring the diverse options available and forging partnerships that will drive your business forward.