Introduction: Navigating the Global Market for irrigation system blowout valve

In the realm of irrigation systems, the importance of sourcing the right blowout valve cannot be overstated. These crucial components play a vital role in protecting irrigation infrastructure from freeze damage, particularly in regions where temperatures plummet. However, international B2B buyers often face challenges in identifying suitable blowout valves tailored to their specific needs, such as climate adaptability, material durability, and compatibility with existing systems. This guide provides a comprehensive overview of the global market for irrigation system blowout valves, detailing various types, applications, and critical considerations for effective supplier vetting.

Throughout this guide, we delve into the nuances of blowout valve selection, offering insights into cost structures and best practices for maintenance and installation. By addressing key factors such as pressure ratings, materials used (like PVC or polyethylene), and installation methods (manual drain versus blowout), we empower B2B buyers from diverse regions—whether in Africa, South America, the Middle East, or Europe—to make informed purchasing decisions.

Our aim is to equip you with the knowledge necessary to navigate the complexities of sourcing irrigation system blowout valves effectively. By understanding the market landscape and recognizing the specific needs of your irrigation systems, you can enhance operational efficiency, mitigate risks, and ultimately ensure the longevity of your infrastructure.

Understanding irrigation system blowout valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Drain Valve | Requires manual operation to drain water; installed at low points. | Small-scale irrigation systems; residential. | Pros: Low cost, simple maintenance. Cons: Labor-intensive, potential for residual water. |

| Automatic Drain Valve | Automatically drains water when pressure drops; self-activating. | Commercial systems; large-scale applications. | Pros: Reduces labor, minimizes freeze risk. Cons: Higher initial cost, potential mechanical failures. |

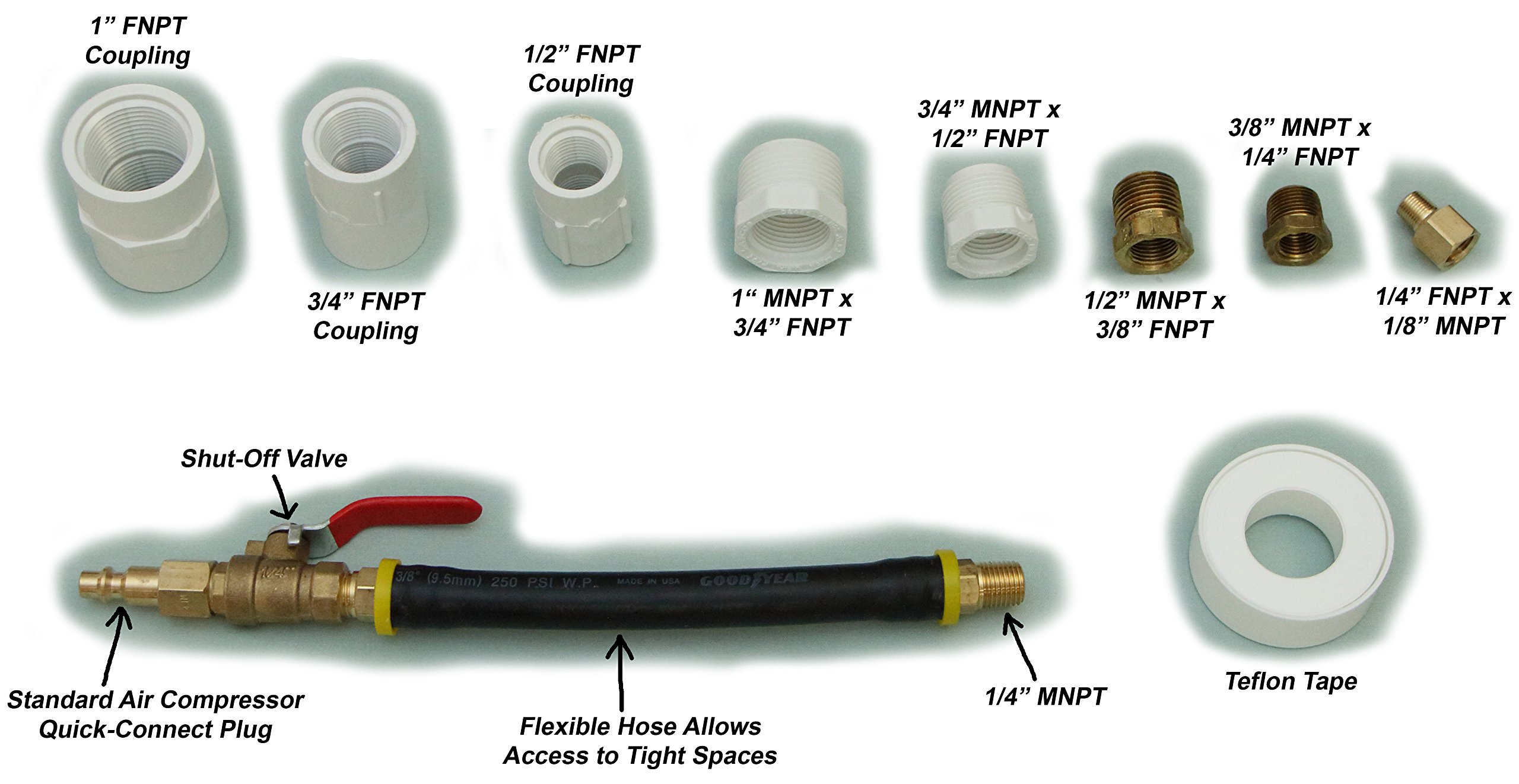

| Blowout Valve | Designed specifically for air blowout; connects to air compressor. | Winterization of irrigation systems. | Pros: Effective for winterization, prevents pipe damage. Cons: Requires air compressor, safety precautions needed. |

| Backflow Prevention Valve | Prevents contamination of water supply; often part of blowout system. | Any irrigation system requiring backflow protection. | Pros: Ensures compliance with regulations, protects water quality. Cons: Can be complex to install, may require maintenance. |

| Pressure Relief Valve | Releases excess pressure to prevent pipe damage. | High-pressure irrigation systems. | Pros: Protects system integrity, enhances safety. Cons: May require regular checks, can be costly to replace. |

What are the characteristics of a Manual Drain Valve in irrigation systems?

Manual drain valves are designed for straightforward operation, requiring users to manually open the valve to allow water to drain from the system. Typically installed at the lowest points of the irrigation network, these valves are prevalent in smaller systems, such as residential setups. While they are cost-effective and easy to maintain, the manual operation can be labor-intensive, and there’s a risk of residual water being left in the system, which could lead to freeze damage in colder climates.

How does an Automatic Drain Valve work and where is it used?

Automatic drain valves are engineered to activate when the system’s pressure drops, allowing water to drain without manual intervention. This feature makes them ideal for larger, commercial irrigation systems where efficiency is critical. By reducing the need for manual winterization, these valves help mitigate the risk of freeze damage. However, they come at a higher initial cost and may involve mechanical components that could fail if not properly maintained.

What is the purpose of a Blowout Valve in irrigation systems?

Blowout valves are specifically designed for winterization processes, allowing for the efficient removal of water from irrigation systems using compressed air. These valves connect directly to air compressors and are essential in regions prone to freezing temperatures. While blowout valves effectively prevent pipe damage during winter, they require the use of an air compressor and necessitate safety precautions during operation to protect against potential injuries from compressed air.

Why are Backflow Prevention Valves important in irrigation systems?

Backflow prevention valves are crucial for maintaining water quality in irrigation systems by preventing contaminants from entering the water supply. Often integrated into blowout systems, these valves ensure compliance with local regulations regarding backflow prevention. Although they provide significant benefits in terms of safety and regulatory compliance, their installation can be complex, and they may require ongoing maintenance to ensure optimal performance.

How do Pressure Relief Valves enhance irrigation system safety?

Pressure relief valves are designed to release excess pressure within irrigation systems, protecting pipes and components from damage due to overpressure conditions. They are particularly important in high-pressure systems where the risk of pipe failure is heightened. While these valves enhance safety and system integrity, they may require regular checks and maintenance, and their replacement can be costly, making them a critical consideration for B2B buyers focusing on high-performance irrigation solutions.

Key Industrial Applications of irrigation system blowout valve

| Industry/Sector | Specific Application of Irrigation System Blowout Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Winterization of irrigation systems | Prevents pipe damage from freezing, ensuring longevity of systems | Compatibility with existing systems and climate-specific designs |

| Landscaping and Turf Care | Seasonal system maintenance | Reduces repair costs and downtime during off-seasons | Durability and ease of installation in various environmental conditions |

| Golf Course Management | Efficient water management during winter months | Maintains optimal turf health while preventing equipment damage | Sourcing from reputable manufacturers with proven track records |

| Municipal Water Management | System blowout for public irrigation systems | Ensures compliance with safety regulations and reduces liability | Adherence to local regulations and standards for public safety |

| Commercial Horticulture | Protecting high-value crops from winter damage | Minimizes crop loss and enhances yield consistency | Availability of specialized valves designed for sensitive crops |

How is the Irrigation System Blowout Valve Utilized in Agriculture?

In the agricultural sector, irrigation system blowout valves are crucial for winterizing irrigation systems before the frost sets in. These valves allow for the safe expulsion of water from the pipes, preventing freeze-related damage that could compromise the integrity of the system. For B2B buyers in regions like South America and Africa, it’s essential to consider compatibility with local irrigation setups and the climate conditions prevalent in their areas. Ensuring that the valves are designed for specific temperatures can greatly enhance the longevity of irrigation systems.

What Role Does the Blowout Valve Play in Landscaping and Turf Care?

Landscaping and turf care professionals utilize irrigation system blowout valves to maintain the health of lawns and gardens during cold months. By removing residual water, these valves prevent costly repairs due to burst pipes. Buyers in Europe and the Middle East should prioritize sourcing valves that are easy to install and operate, as well as those that can withstand varying weather conditions. This not only improves operational efficiency but also minimizes the risk of service interruptions during peak landscaping seasons.

Why is the Blowout Valve Important for Golf Course Management?

For golf course management, the irrigation system blowout valve is vital for maintaining turf quality throughout the winter. This application ensures that water is effectively removed from the irrigation lines, preventing damage that could lead to costly repairs and compromised playing conditions. Buyers should seek valves that provide reliable performance and are specifically engineered for high-traffic areas. Additionally, sourcing from suppliers with a strong reputation in the golf industry can provide peace of mind regarding product quality.

How Does Municipal Water Management Benefit from Blowout Valves?

Municipal water management agencies rely on irrigation system blowout valves for the seasonal maintenance of public irrigation systems. These valves play a critical role in ensuring compliance with safety regulations by preventing water retention that could lead to system failures or hazards. B2B buyers in this sector should focus on sourcing valves that meet local regulatory standards, ensuring that they are robust and reliable enough to handle the demands of public infrastructure.

What is the Application of Blowout Valves in Commercial Horticulture?

In commercial horticulture, irrigation system blowout valves are essential for protecting high-value crops from winter damage. By effectively removing water from irrigation systems, these valves help minimize the risk of crop loss due to freezing temperatures. Buyers in regions such as Africa and South America should consider sourcing specialized valves that cater to the unique needs of sensitive plants. Ensuring that these valves are designed to handle the specific water pressures and flow rates required for horticulture is crucial for maximizing yield and profitability.

3 Common User Pain Points for ‘irrigation system blowout valve’ & Their Solutions

Scenario 1: Inadequate Winterization Procedures Lead to System Failures

The Problem: Many B2B buyers in regions prone to freezing temperatures struggle with the proper winterization of their irrigation systems. Without effective winterization, residual water can freeze, leading to cracked pipes and damaged components, which result in costly repairs and downtime. This issue is particularly pressing for agricultural businesses and landscaping companies that rely on their irrigation systems to maintain operations through the seasons. The complexity of blowout procedures, coupled with the potential for human error, can exacerbate these challenges.

The Solution: To ensure thorough winterization and prevent damage, it is essential for buyers to understand the correct blowout procedures for their specific irrigation systems. First, buyers should source high-quality blowout valves that are compatible with their existing infrastructure. Next, they should invest in a reliable air compressor with the appropriate CFM rating—generally calculated based on the largest zone’s GPM divided by 7.5. This will ensure adequate pressure without exceeding the safe limits for PVC or polyethylene pipes.

Buyers should also consider hiring qualified professionals to perform the blowout, particularly in complex systems where the risk of damaging components is high. If opting for DIY, detailed instructional guides or training sessions should be provided to staff. Additionally, implementing a checklist for winterization procedures can help ensure that no step is overlooked, from shutting off the main water supply to opening the correct valves during the blowout.

Scenario 2: Safety Risks During Blowout Operations

The Problem: Safety is a significant concern when performing blowout operations. Compressed air can cause severe injuries, including eye damage from flying debris, if proper precautions are not taken. This risk is particularly pronounced in environments where multiple team members are involved, as miscommunication can lead to accidents. B2B buyers often find it challenging to balance the need for effective irrigation system maintenance with the imperative of ensuring worker safety.

The Solution: To mitigate safety risks, buyers should prioritize training and safety protocols. This includes mandating the use of ANSI-approved safety goggles for all personnel involved in the blowout process. Additionally, creating a detailed safety manual that outlines specific procedures—such as wearing protective gear, ensuring that the area is clear of obstructions, and establishing communication protocols—can greatly reduce the likelihood of accidents.

Moreover, buyers should invest in blowout valves that include safety features, such as pressure relief mechanisms, to prevent excessive pressure build-up. Regular safety drills and refresher training sessions can also help reinforce safe practices among the team. By fostering a culture of safety and ensuring that all team members are aware of potential hazards, businesses can conduct blowout operations with greater confidence.

Scenario 3: Inconsistent Performance of Blowout Valves

The Problem: B2B buyers often encounter issues with inconsistent performance of blowout valves, leading to incomplete blowouts and potential damage to irrigation systems. Factors such as low-quality components, improper installation, or lack of maintenance can contribute to this inconsistency. This issue can result in significant downtime during critical operational periods, affecting overall productivity and profitability.

The Solution: To combat performance issues, buyers should prioritize the selection of high-quality blowout valves from reputable manufacturers. Conducting thorough research and reading reviews can help identify products known for their reliability. Additionally, buyers should ensure that the valves are installed correctly and maintained regularly to prevent blockages and other performance issues.

Implementing a routine maintenance schedule that includes inspections of the blowout valves, checking for signs of wear or damage, and ensuring that they are functioning correctly can help catch problems early. Furthermore, providing training for staff on the proper use and maintenance of these valves will enhance their longevity and performance. By taking a proactive approach to valve management, B2B buyers can minimize disruptions and ensure their irrigation systems operate smoothly throughout the year.

Strategic Material Selection Guide for irrigation system blowout valve

What Are the Common Materials for Irrigation System Blowout Valves?

When selecting materials for irrigation system blowout valves, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. Here, we analyze four common materials: brass, PVC, stainless steel, and polyethylene. Each material has unique characteristics that can affect performance and suitability for various applications, particularly in diverse global markets.

How Does Brass Perform in Irrigation System Applications?

Brass is a popular choice for irrigation system blowout valves due to its excellent corrosion resistance and strength. It typically has a high-temperature rating, making it suitable for various climates. Brass valves can withstand pressures up to 300 psi, making them ideal for high-pressure systems.

Pros: Brass is highly durable and resistant to rust and corrosion, which is essential for longevity in irrigation systems. It also has a relatively low manufacturing complexity, allowing for efficient production.

Cons: The primary drawback of brass is its cost, which is higher than plastic alternatives. Additionally, brass can be susceptible to dezincification in certain water conditions, potentially compromising its integrity.

Impact on Application: Brass is compatible with a wide range of media, including potable water, making it suitable for various irrigation applications. However, in regions with aggressive water chemistry, this could pose a risk.

Considerations for International Buyers: Compliance with standards such as ASTM B283 for brass fittings is crucial. Buyers from regions like Africa and South America should also consider local regulations regarding metal usage in water systems.

What Advantages Does PVC Offer for Blowout Valves?

PVC (Polyvinyl Chloride) is another common material used in irrigation blowout valves. It is lightweight, resistant to corrosion, and can handle pressures up to 150 psi.

Pros: PVC is cost-effective, making it an attractive option for large-scale irrigation projects. Its resistance to chemical corrosion is beneficial in various agricultural applications.

Cons: PVC has a lower temperature tolerance compared to metals, which may limit its use in hot climates. Additionally, it can become brittle over time when exposed to UV radiation unless treated.

Impact on Application: PVC is suitable for non-potable water applications and is widely used in agricultural irrigation. However, it may not be suitable for areas with extreme temperature fluctuations.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM D1784 for PVC materials. In regions like the Middle East, where UV exposure is high, UV-resistant PVC products are recommended.

How Does Stainless Steel Compare in Performance?

Stainless steel is known for its exceptional strength and corrosion resistance, making it suitable for high-pressure irrigation systems. It can typically handle pressures exceeding 300 psi.

Pros: Stainless steel valves are durable and can withstand harsh environmental conditions. They are also resistant to corrosion and scaling, ensuring a long service life.

Cons: The primary disadvantage of stainless steel is its higher cost compared to other materials. Additionally, manufacturing stainless steel components can be more complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with various media, including potable water, making it suitable for both agricultural and landscape irrigation systems.

Considerations for International Buyers: Compliance with standards like ASTM A312 for stainless steel pipes is essential. Buyers in Europe may also need to consider the European Union’s REACH regulations regarding materials.

What Role Does Polyethylene Play in Blowout Valve Applications?

Polyethylene is a flexible and lightweight plastic commonly used in irrigation systems. It is resistant to corrosion and can handle pressures up to 100 psi.

Pros: Polyethylene is cost-effective and easy to install, making it ideal for DIY projects. Its flexibility allows it to expand under pressure, reducing the risk of cracking in freezing conditions.

Cons: The main limitation of polyethylene is its lower temperature and pressure ratings compared to metals. It can also degrade when exposed to UV light unless treated.

Impact on Application: Polyethylene is suitable for non-potable water applications and is often used in drip irrigation systems. However, its lower pressure rating may limit its use in high-pressure systems.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM D2239 for polyethylene pipes. In regions with high UV exposure, UV-resistant polyethylene products are advisable.

Summary Table of Material Selection for Irrigation System Blowout Valves

| Material | Typical Use Case for irrigation system blowout valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-pressure irrigation systems | Excellent corrosion resistance | Higher cost, potential dezincification | High |

| PVC | Non-potable water applications | Cost-effective and lightweight | Lower temperature tolerance, UV brittleness | Low |

| Stainless Steel | Potable water and high-pressure systems | Exceptional strength and corrosion resistance | Higher cost, complex manufacturing | High |

| Polyethylene | Drip irrigation systems | Flexible and easy to install | Lower pressure rating, UV degradation | Low |

This strategic material selection guide provides a comprehensive overview of the key materials used in irrigation system blowout valves, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation system blowout valve

What Are the Main Stages in the Manufacturing Process of Irrigation System Blowout Valves?

The manufacturing process of irrigation system blowout valves involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensure the final product meets the necessary performance and durability standards.

Material Preparation

The first step in manufacturing blowout valves is the selection and preparation of materials. Common materials include brass, PVC, and polyethylene, each chosen for their resistance to corrosion, pressure, and temperature fluctuations. Quality assurance begins here, as the raw materials must undergo Incoming Quality Control (IQC) checks to ensure they meet specific standards. Suppliers often provide material certificates that detail the chemical composition and mechanical properties, which can be verified by B2B buyers.

How Are Blowout Valves Formed?

Forming processes vary depending on the material used. For brass valves, processes such as forging or machining are common, while PVC and polyethylene valves may be produced through injection molding. These techniques require precision to maintain the valve’s integrity and functionality. Throughout this stage, In-Process Quality Control (IPQC) measures are implemented, including dimensional checks and pressure tests to ensure compliance with design specifications.

What Does the Assembly Process Involve for Blowout Valves?

The assembly of irrigation blowout valves is where various components are brought together to create the final product. This stage typically includes fitting the valve body, seals, and other internal parts. Ensuring a proper seal is crucial for preventing leaks, which can lead to system failures. Quality checks during assembly involve visual inspections and functional tests to confirm that each valve operates smoothly and adheres to the required specifications.

What Finishing Techniques Are Used in Blowout Valve Manufacturing?

Finishing processes enhance the aesthetic and functional characteristics of blowout valves. Techniques such as coating, polishing, or plating are employed to increase resistance to environmental factors and improve the product’s longevity. After finishing, Final Quality Control (FQC) checks are conducted, which often include pressure testing to ensure that the valve can withstand operational stresses without failure.

Which International Standards Apply to Blowout Valve Manufacturing?

For B2B buyers, understanding the relevant international standards is vital. The ISO 9001 standard is commonly adopted in manufacturing environments to ensure consistent quality management systems are in place. Additionally, industry-specific certifications such as the CE mark for compliance with European safety standards and API standards for petroleum and natural gas products may apply. Buyers should verify that suppliers possess these certifications and understand their implications for product quality and safety.

How Can B2B Buyers Ensure Quality Control in Blowout Valve Manufacturing?

Quality Control (QC) is a continuous process throughout the manufacturing stages. B2B buyers should look for the following QC checkpoints:

- Incoming Quality Control (IQC): This involves the inspection of raw materials upon arrival.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing and inspections of the final product before shipment.

Common testing methods include pressure testing, visual inspections, and functional testing, which help ensure that each valve meets the required specifications.

What Are the Best Practices for Verifying Supplier Quality Control?

To verify a supplier’s quality control processes, B2B buyers should consider conducting audits and requesting quality assurance reports. Third-party inspections can also be beneficial, providing an unbiased assessment of the manufacturing process and product quality. Buyers can ask for documentation that outlines the supplier’s QC protocols, including details on their compliance with international standards and any industry-specific certifications.

What Are the QC and Certification Nuances for International Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential. Different regions may have varying regulations and standards that affect product certifications. Buyers should familiarize themselves with local compliance requirements and ensure that their suppliers are compliant with both local and international regulations.

Additionally, language barriers and differences in manufacturing practices can complicate the verification process. Establishing clear communication channels with suppliers and utilizing local representatives who understand the regional market can help mitigate these challenges.

Conclusion: The Importance of Quality Assurance in Blowout Valve Manufacturing

In conclusion, the manufacturing processes and quality assurance protocols for irrigation system blowout valves are critical to ensuring product reliability and performance. By understanding each stage of manufacturing and the applicable quality control measures, B2B buyers can make informed decisions when selecting suppliers. Prioritizing quality assurance not only enhances operational efficiency but also contributes to the longevity and effectiveness of irrigation systems in various climates and conditions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation system blowout valve’

Introduction

This practical sourcing guide aims to assist B2B buyers in procuring irrigation system blowout valves, essential components for winterizing irrigation systems in regions prone to freezing temperatures. Proper sourcing ensures reliability, safety, and efficiency in irrigation management, which is critical for maintaining agricultural productivity and landscape aesthetics.

Step 1: Define Your Technical Specifications

Before approaching suppliers, clearly outline the technical requirements for your blowout valves. This includes understanding the type of irrigation system you have and the specific features needed, such as pressure ratings, compatibility with existing pipes, and valve materials (e.g., brass or PVC). Detailed specifications prevent misunderstandings and ensure you acquire the right product for your operational needs.

Step 2: Research Supplier Experience and Reputation

Investigate potential suppliers’ experience in the irrigation industry. Look for established companies with a proven track record of providing blowout valves that meet international standards. A reputable supplier should have experience in your specific geographical region, as local conditions can affect product performance.

- Check Reviews and Testimonials: Look for customer feedback on platforms like industry forums or trade publications to gauge reliability and service quality.

- Request Case Studies: Ask for examples of previous projects similar to yours, showcasing their expertise and problem-solving capabilities.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you consider have relevant certifications that comply with international standards. Certifications such as ISO 9001 indicate a commitment to quality management systems, which is essential for the manufacturing of durable and reliable irrigation components.

- Verify Compliance with Local Regulations: Depending on your region, specific certifications may be necessary to ensure compliance with local agricultural regulations.

Step 4: Analyze Pricing and Terms of Sale

Request detailed quotes from multiple suppliers, but don’t focus solely on the lowest price. Consider the total cost of ownership, which includes shipping, warranties, and potential maintenance costs.

- Negotiate Terms: Discuss payment terms, bulk purchase discounts, and return policies. A flexible supplier may offer better long-term value, especially for larger projects.

Step 5: Assess After-Sales Support and Warranty Options

Confirm the level of after-sales support that suppliers provide. Quality customer service is crucial for resolving issues quickly and efficiently.

- Inquire About Warranties: A robust warranty policy indicates the supplier’s confidence in their product quality. Ensure the terms of the warranty meet your operational needs, covering potential defects and failures.

Step 6: Visit Supplier Facilities if Possible

If feasible, arrange a visit to the supplier’s manufacturing facility. This allows you to assess their production processes, quality control measures, and overall operational capabilities firsthand.

- Observe Equipment and Processes: Pay attention to the technology used and the cleanliness of the facility, which can reflect the quality of the products manufactured.

Step 7: Finalize the Order with Clear Specifications

Once you have selected a supplier, finalize the order with a comprehensive written agreement that specifies all details, including quantities, delivery timelines, and any agreed-upon modifications. This document will serve as a reference point and help prevent disputes.

By following this checklist, B2B buyers can confidently source irrigation system blowout valves that meet their technical needs and ensure the longevity and efficiency of their irrigation systems.

Comprehensive Cost and Pricing Analysis for irrigation system blowout valve Sourcing

When sourcing irrigation system blowout valves, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. The following analysis outlines the cost components, price influencers, and valuable buyer tips to optimize purchasing decisions.

What Are the Key Cost Components in Sourcing Blowout Valves?

Materials: The primary cost driver for blowout valves is the material used in their construction. Common materials include brass, PVC, and polyethylene. Brass valves, known for their durability and resistance to corrosion, generally command higher prices than plastic options. The choice of material impacts not only the upfront cost but also the long-term maintenance and replacement costs.

Labor: Labor costs are significant, especially for manufacturers in regions with higher wage standards. In contrast, sourcing from countries with lower labor costs can provide savings. However, it’s essential to consider the trade-off between cost and quality, as lower labor costs may sometimes correlate with inferior craftsmanship.

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Overhead can vary widely based on the location of the manufacturer. Countries with advanced manufacturing technologies may have higher overhead but also offer increased efficiency and quality assurance.

Tooling: The initial investment in tooling for the production of blowout valves can be substantial, particularly for custom designs. Buyers should be aware that tooling costs may be amortized over larger production runs, potentially lowering per-unit costs for bulk orders.

Quality Control (QC): Effective QC processes ensure product reliability and compliance with international standards. The costs associated with QC can influence the final pricing of blowout valves, particularly for suppliers who prioritize rigorous testing and certification.

Logistics: Shipping and transportation costs can significantly affect the total cost of ownership, especially for international transactions. Factors such as distance, shipping mode, and Incoterms (International Commercial Terms) play a critical role in determining logistics expenses.

Margin: Suppliers typically apply a margin to cover their costs and ensure profitability. Understanding the margin expectations of suppliers can provide leverage during negotiations.

How Do Price Influencers Affect Sourcing Decisions?

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes can lead to significant discounts. Buyers should negotiate MOQs with suppliers to align with their operational needs while maximizing cost efficiency.

Specifications and Customization: Custom-designed valves or those with specific features may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses during the sourcing process.

Material Quality and Certifications: Higher quality materials and certifications (such as ISO or NSF) can increase costs but are essential for ensuring product longevity and compliance with safety standards. Buyers should evaluate the long-term benefits of investing in certified products.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge higher prices but offer better service and product assurance. Conducting thorough research on potential suppliers is critical.

Incoterms: Understanding the implications of different Incoterms is essential for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect pricing and risk allocation, impacting the overall cost structure.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

Negotiation: Always approach negotiations with a clear understanding of your budget and requirements. Leverage competitive quotes from multiple suppliers to enhance your bargaining position.

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the TCO, which includes maintenance, operational efficiency, and potential replacement costs. This holistic view can lead to more informed purchasing decisions.

Pricing Nuances for International Buyers: When sourcing from regions like Africa, South America, the Middle East, and Europe, be mindful of currency fluctuations, trade tariffs, and import duties that can influence overall costs. Establishing long-term relationships with suppliers may provide stability and better pricing over time.

In conclusion, a comprehensive understanding of the cost components, price influencers, and effective negotiation strategies can empower international B2B buyers to make informed decisions when sourcing irrigation system blowout valves. Always keep in mind that indicative prices can vary widely based on market conditions, supplier relationships, and specific project requirements.

Alternatives Analysis: Comparing irrigation system blowout valve With Other Solutions

Introduction to Alternative Solutions for Irrigation System Winterization

When considering the best methods for winterizing irrigation systems, particularly in regions susceptible to freezing temperatures, the irrigation system blowout valve is one popular option. However, there are alternative solutions that may better suit specific needs and conditions. This section compares the blowout valve with other viable methods, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Irrigation System Blowout Valve | Manual Drain Method | Freeze-Proof Irrigation Systems |

|---|---|---|---|

| Performance | Highly effective at removing water, reducing freeze risk. | Can leave residual water, less effective. | Prevents freezing without draining. |

| Cost | Moderate initial cost; may require professional installation. | Low cost; requires minimal equipment. | Higher initial investment, but saves on maintenance. |

| Ease of Implementation | Requires equipment (air compressor) and knowledge of system. | Simple; can be done by anyone with basic understanding. | Complex installation; requires specialized knowledge. |

| Maintenance | Minimal; primarily involves checking equipment. | Low; periodic checks needed for valves. | Requires regular checks to ensure integrity. |

| Best Use Case | Ideal for systems with significant water volume and risk of freeze. | Suitable for small systems or less critical applications. | Best for high-value landscapes needing constant irrigation. |

Detailed Breakdown of Alternative Solutions

What is the Manual Drain Method and its Advantages?

The manual drain method involves physically draining water from the irrigation system through manually operated valves. This approach is cost-effective and straightforward, making it accessible for smaller systems or less critical applications. However, its main drawback is the potential for residual water to remain in the system, which can still lead to freeze damage. This method is best suited for smaller installations where the risk of freeze is lower or when budget constraints are a primary concern.

How Do Freeze-Proof Irrigation Systems Function and What are Their Benefits?

Freeze-proof irrigation systems are designed to prevent water from freezing in the first place, eliminating the need for winterization methods like blowouts or manual draining. These systems typically involve specialized components that remain functional during cold months. While they represent a higher upfront investment, they can save costs in the long run by minimizing maintenance and potential damage. However, installation requires specialized knowledge and can be complex, making it less suitable for all users.

Conclusion: How to Choose the Right Solution for Your Irrigation Needs

When selecting the appropriate method for winterizing an irrigation system, B2B buyers should carefully consider their specific operational requirements, budget constraints, and the environmental conditions of their regions. The irrigation system blowout valve offers a robust solution for larger systems at risk of freezing, while the manual drain method may suffice for smaller installations. Conversely, freeze-proof systems, despite their higher initial costs and complexity, provide long-term benefits for high-value landscapes. By evaluating these factors, buyers can make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for irrigation system blowout valve

What Are the Key Technical Properties of Irrigation System Blowout Valves?

When evaluating irrigation system blowout valves, understanding their technical properties is crucial for ensuring efficiency and longevity in agricultural or landscaping applications. Here are some essential specifications to consider:

Material Grade

The material grade of a blowout valve typically ranges from PVC to brass or stainless steel. Each material has its own corrosion resistance and durability characteristics, which are vital in varying climates. For instance, brass valves are preferred in colder regions due to their ability to withstand freezing conditions without cracking. Selecting the right material can significantly affect the valve’s lifespan and performance.Pressure Rating

This specification indicates the maximum pressure the valve can safely handle, commonly measured in psi (pounds per square inch). For blowout valves, a pressure rating of 50 psi for polyethylene pipes and 80 psi for PVC pipes is standard. Understanding pressure ratings is essential for preventing system failures and ensuring that the valve operates within safe limits, especially during the blowout process.Flow Rate (GPM)

The flow rate, measured in gallons per minute (GPM), determines how quickly water can pass through the valve. A blowout valve should ideally match the flow rate of the irrigation system to ensure efficient water removal during winterization. Selecting a valve with the appropriate flow rate minimizes the risk of air pressure buildup, which can lead to pipe damage.Temperature Tolerance

This property indicates the range of temperatures the valve can withstand without compromising its integrity. Valves need to operate effectively in both high and low temperatures, especially in regions experiencing extreme weather. Ensuring the blowout valve has a suitable temperature tolerance is critical for maintaining system reliability.Connection Type

Blowout valves come with various connection types, such as threaded, slip, or flanged. The connection type must be compatible with the existing irrigation system to ensure a secure and leak-proof installation. Understanding connection types facilitates smoother procurement and installation processes.Size and Dimensions

The physical size of the valve impacts its fit within the irrigation system and its ability to handle water flow. Blowout valves are available in various sizes, so it is vital to match the dimensions with the existing piping to ensure optimal performance and prevent leaks.

What Are Common Trade Terms Related to Irrigation System Blowout Valves?

Familiarity with industry terminology can streamline communication and enhance the purchasing process for B2B buyers. Here are some common terms:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality products that meet specific industry standards.MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, particularly for businesses looking to purchase blowout valves in bulk.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price quote on specific products. This is a critical step in the procurement process, allowing buyers to compare prices and terms before making a purchase decision.Incoterms

Short for International Commercial Terms, Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding Incoterms is vital for B2B buyers to manage shipping costs, risks, and delivery timelines effectively.Lead Time

Lead time refers to the time taken from placing an order to its delivery. Knowing the lead time helps businesses plan their operations and manage inventory levels more effectively, especially when preparing for seasonal changes.Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition and performance of the product. Understanding warranty terms is crucial for B2B buyers, as it impacts long-term maintenance costs and product reliability.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions, ensuring the efficient operation of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation system blowout valve Sector

What Are the Current Market Dynamics and Key Trends in the Irrigation System Blowout Valve Sector?

The irrigation system blowout valve market is experiencing significant growth, driven by several global factors. Increasing agricultural demands, especially in regions like Africa and South America, are pushing for efficient water management systems. As climate change intensifies water scarcity, countries are investing in advanced irrigation technologies to optimize water use. This shift is particularly evident in emerging markets where traditional farming practices are being augmented with modern solutions to enhance yield and sustainability.

International B2B buyers are also witnessing a surge in technology-driven sourcing trends. The integration of IoT (Internet of Things) in irrigation systems allows for real-time monitoring and automation, leading to more efficient blowout valve operations. Manufacturers are increasingly adopting smart technologies, providing buyers with innovative solutions that enhance system reliability and reduce maintenance costs. Furthermore, the trend towards digital procurement platforms is making it easier for international buyers to source high-quality blowout valves from reputable suppliers, streamlining the purchasing process.

As the market matures, buyers should be aware of the importance of selecting suppliers who can offer not just competitive pricing but also robust after-sales support and expertise in local regulations. Understanding regional compliance standards, especially in Europe and the Middle East, can significantly impact procurement strategies.

How Are Sustainability and Ethical Sourcing Transforming the Irrigation System Blowout Valve Industry?

Sustainability and ethical sourcing have become paramount considerations for B2B buyers in the irrigation system blowout valve sector. The environmental impact of irrigation systems is under scrutiny, prompting companies to seek products that minimize ecological footprints. Manufacturers are now focusing on developing blowout valves using recycled materials and environmentally friendly manufacturing processes. This shift not only addresses environmental concerns but also aligns with the growing consumer demand for sustainable practices.

Moreover, ethical supply chains are essential for maintaining brand integrity and consumer trust. Buyers are increasingly prioritizing suppliers who adhere to ethical labor practices and fair trade principles. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications provide assurance of a supplier’s commitment to sustainability. These credentials can help buyers differentiate between suppliers and make informed decisions that support their sustainability goals.

As global regulations tighten around environmental standards, B2B buyers must stay informed about the sourcing trends that promote sustainability. By selecting blowout valves that incorporate sustainable practices, companies can enhance their operational efficiency while contributing positively to the environment.

What Has Been the Evolution and History of Irrigation System Blowout Valves?

The evolution of irrigation system blowout valves can be traced back to the growing need for efficient water management in agriculture. Initially, basic manual drain valves were used, but the advent of automated systems in the late 20th century revolutionized irrigation practices. The introduction of blowout valves allowed for the safe removal of water from irrigation systems, preventing freeze damage in colder climates.

As technology advanced, blowout valves evolved to incorporate features that enhance performance, such as pressure regulation and automated controls. This evolution has been crucial in improving the reliability and efficiency of irrigation systems, particularly in regions with diverse climatic challenges. The development of smart irrigation technologies has further refined the functionality of blowout valves, ensuring that they meet the demands of modern agriculture while supporting sustainable practices.

In summary, the irrigation system blowout valve sector is shaped by emerging trends in technology, sustainability, and the evolving needs of international B2B buyers. Understanding these dynamics is essential for making informed procurement decisions that align with both operational efficiency and environmental stewardship.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation system blowout valve

1. How do I winterize my irrigation system effectively?

To winterize your irrigation system, first, shut off the main water supply. Then, use an air compressor to blow out water from the system to prevent freeze damage. Attach the compressor to the system’s mainline, ensuring the pressure remains below 50 psi for polyethylene pipes and 80 psi for PVC pipes. Activate each zone sequentially, starting from the furthest point, until no water is expelled. Finally, ensure all valves are closed after the process and check that any backflow devices are properly drained to prevent water accumulation.2. What is the best blowout valve for irrigation systems?

The best blowout valve for irrigation systems depends on your specific needs and the system’s configuration. Look for valves made from durable materials such as brass or high-grade PVC, which can withstand pressure and temperature fluctuations. Consider valves with easy-access ports for compressor attachment and those designed for quick opening and closing to facilitate efficient blowout processes. Consulting with manufacturers or suppliers for specific recommendations based on your geographical climate and irrigation setup can also provide valuable insights.3. What are the key considerations when sourcing blowout valves internationally?

When sourcing blowout valves internationally, consider factors such as compliance with local regulations and standards, material quality, and supplier reliability. Ensure the supplier can provide certifications and quality assurance documentation. Evaluate shipping logistics, including costs and delivery times, especially for remote areas. Additionally, consider the supplier’s ability to support after-sales service and technical assistance, as well as their experience in your specific region to understand any unique requirements.4. How can I verify the credibility of a supplier for blowout valves?

To verify a supplier’s credibility, conduct thorough due diligence by checking their business licenses, certifications, and industry reputation. Look for online reviews, ratings, and testimonials from previous customers. Engage directly with the supplier through communication to assess their responsiveness and expertise. It may also be beneficial to request references or case studies of previous projects to gauge their reliability and product quality. Consider visiting their facility if possible or using third-party inspection services.5. What customization options are available for blowout valves?

Many suppliers offer customization options for blowout valves, including size, material, and pressure ratings. Customization may also extend to specific fittings or features tailored to your irrigation system’s design. Discuss your project requirements with the supplier to explore available options and ensure the product meets your operational needs. This customization can be crucial for optimizing system performance and longevity, especially in diverse climates.6. What are the typical minimum order quantities (MOQs) for blowout valves?

Minimum order quantities (MOQs) for blowout valves can vary significantly among suppliers, ranging from a few units to several hundred, depending on the manufacturer’s production capabilities and inventory policies. For international buyers, MOQs may also be influenced by shipping considerations and local market demand. It is advisable to negotiate with suppliers to find a mutually beneficial agreement, especially if you are a smaller buyer or looking to trial products before committing to larger orders.7. What payment terms should I expect when purchasing blowout valves?

Payment terms for purchasing blowout valves can differ widely based on the supplier and your negotiation. Common arrangements include upfront payments, deposits with the balance due upon shipment, or net terms allowing payment within a specified period after delivery. Consider using secure payment methods, such as letters of credit or escrow services, to protect your transaction. Always clarify payment terms in the purchase agreement to avoid misunderstandings and ensure compliance with international trade regulations.8. How do I manage logistics and shipping for international orders of blowout valves?

Managing logistics and shipping for international orders requires careful planning. Start by selecting a reliable freight forwarder experienced in handling industrial equipment. Discuss shipping methods, such as air freight for speed or ocean freight for cost-effectiveness, based on your timeline and budget. Ensure that all customs documentation is prepared accurately to avoid delays. Consider potential tariffs or duties in your budgeting process, and track your shipment to monitor its progress and address any issues promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Irrigation System Blowout Valve Manufacturers & Suppliers List

1. Reddit – Sprinkler System Winterization Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user is attempting to blow out their sprinkler system for winterization without a blowout port, using a home air compressor. They mention that last year a professional used a different method by connecting directly to a sprinkler head. The user is facing issues with air escaping from the line instead of effectively blowing out the water. Comments suggest that a standard home air compressor may…

2. The Spruce – Essential Air Compressor Tools

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Equipment / Tools Needed: 1. Air compressor (producing 30 to 50 cubic feet per minute (cfm) at pressures of 40 to 80 pounds per square inch (PSI)) 2. Air compressor water blow out adapter 3. Bucket 4. Channel lock pliers

3. Winterizing Sprinkler Systems – Key Valve Considerations

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: The text discusses the process of winterizing a sprinkler system, specifically focusing on the valves involved. Key points include: 1. Main shutoff valve should be closed before blowing out the system. 2. The left valve (likely the main shutoff) should remain open during the blowout. 3. The four small stubs at the bottom are likely ball valves that may need to be drained or left open to prevent fr…

4. DIY Chatroom – Plumbing Essentials

Domain: diychatroom.com

Registered: 2003 (22 years)

Introduction: Backflow preventer, test cock, compressor hose, ball valve, hose bib, 1″ vertical copper pipe.

5. RME – Sprinkler Blowout System

Domain: rme4x4.com

Registered: 2007 (18 years)

Introduction: Sprinkler blowout system, air compressor, backflow preventer, valve for air fitting, 1/4 NPT air fitting, garden valve, rubber tip air nozzle.

6. The Lawn Forum – Essential Irrigation Components

Domain: thelawnforum.com

Registered: 2017 (8 years)

Introduction: 1. Tee Fitting: Options discussed include a standard tee fitting, compression tee, and slip tee. 2. Backflow Preventer: Model referenced is a Watts Double Check Valve Assembly (850 series). 3. Valve Box: Mentioned for installation after the backflow. 4. Pipe Threads: 3/4″ male pipe threads mentioned for the port. 5. Reducer: 3/4″ to 1″ reducer discussed. 6. Hose Bib: Suggested installation of hose…

7. Lawnsite – Backflow Prevention Solutions

Domain: lawnsite.com

Registered: 2000 (25 years)

Introduction: backflow preventor, pressure vacuum breaker, air compressor, sprinkler zones, ball valves, test c-ock valves, Double Check Valve Assembly (DCVA), Atmospheric vacuum breaker (AVB), Spill-resistant pressure vacuum breaker (SVB), Reduced pressure principle backflow prevention assembly (RP)

8. Hunter Irrigation – Winterization Guide

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: The text discusses the winterization of irrigation systems, emphasizing the importance of removing water to prevent freeze damage. It details two methods: the blowout method, which requires an air compressor with specific CFM ratings and safety precautions, and the manual drain method, which is only applicable if manual drain valves are present. Key points include the need for professional assista…

9. Terry Love – Pressure Vacuum Breaker & Febco 765 Solutions

Domain: terrylove.com

Registered: 1996 (29 years)

Introduction: Pressure Vacuum Breaker Backflow Preventer, Febco 765 Freeze Protection Manual, Febco 765 Maintenance Manual, Sharkbite fittings, C x C x F tee, hose Bib with a vacuum breaker.

Strategic Sourcing Conclusion and Outlook for irrigation system blowout valve

How Can Strategic Sourcing Enhance Your Irrigation System Blowout Valve Procurement?

In summary, strategic sourcing for irrigation system blowout valves is essential for optimizing performance and reducing operational risks, especially in regions prone to freezing temperatures. By selecting high-quality valves and components, buyers can ensure effective winterization processes, safeguarding their irrigation systems from costly damage.

International buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers that offer robust product support, technical expertise, and reliable delivery. Collaborating with manufacturers who understand local climate conditions and installation practices can further enhance the efficiency of your irrigation systems.

Looking ahead, the demand for advanced irrigation solutions will only grow as global agricultural practices evolve. Buyers are encouraged to leverage strategic sourcing to identify innovative technologies and sustainable practices that can improve yield while minimizing water waste. By engaging with reputable suppliers and staying informed about industry trends, businesses can position themselves for success in the competitive irrigation market.

Take the next step—evaluate your current sourcing strategies and explore new partnerships that can elevate your irrigation systems to the next level of efficiency and reliability.