Introduction: Navigating the Global Market for stainless steel electric butterfly valve for agricultural irrigation

In the ever-evolving landscape of agricultural irrigation, sourcing reliable stainless steel electric butterfly valves poses a significant challenge for international B2B buyers. These critical components facilitate efficient water management, yet selecting the right valve can be daunting due to varying specifications, applications, and supplier capabilities. This comprehensive guide delves into the diverse types of stainless steel electric butterfly valves, their specific applications in agricultural settings, and essential criteria for vetting suppliers effectively.

By exploring the intricacies of valve functionality, including torque ranges, pressure specifications, and material compatibility, this guide empowers buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Germany—to make informed purchasing decisions. Understanding cost implications and best practices for maintenance further enhances the buyer’s ability to optimize their irrigation systems while ensuring long-term sustainability and performance.

Equipped with actionable insights and expert recommendations, this guide not only simplifies the sourcing process but also provides a strategic framework for establishing robust supplier relationships. As the demand for efficient agricultural practices continues to rise, investing in the right stainless steel electric butterfly valves will be pivotal in driving productivity and operational excellence.

Understanding stainless steel electric butterfly valve for agricultural irrigation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Electric Butterfly Valve | Offers on/off control with a 90-degree rotation. | General agricultural irrigation systems | Pros: Simple operation, cost-effective. Cons: Limited modulation capabilities. |

| Modulating Electric Butterfly Valve | Allows for variable flow control with adjustable opening. | Precision irrigation systems | Pros: Enhanced control, energy-efficient. Cons: Higher initial cost. |

| Intelligent Electric Butterfly Valve | Features integrated sensors and smart control systems. | Advanced agricultural automation | Pros: Real-time monitoring, remote control. Cons: Complex installation and maintenance. |

| Wafer Type Electric Butterfly Valve | Compact design with easy installation between flanges. | Space-constrained irrigation setups | Pros: Space-saving, lightweight. Cons: May require specific flanges. |

| High-Pressure Electric Butterfly Valve | Designed for high-pressure applications up to 2.0 MPa. | Heavy-duty agricultural applications | Pros: Durable under pressure, reliable. Cons: Higher cost and weight. |

What Are the Key Characteristics of Standard Electric Butterfly Valves?

Standard electric butterfly valves are designed for straightforward on/off control, making them ideal for general agricultural irrigation applications. They typically feature a 90-degree rotation and are available in various sizes, accommodating a range of flow requirements. Buyers should consider their simplicity and cost-effectiveness, although they lack the ability to modulate flow, limiting their use in more complex irrigation systems.

How Do Modulating Electric Butterfly Valves Enhance Irrigation Efficiency?

Modulating electric butterfly valves are tailored for applications requiring precise flow control. By allowing users to adjust the opening of the valve, they enable more efficient water use in precision irrigation systems. This adaptability can lead to significant water savings and improved crop yields. While they offer substantial advantages in control and efficiency, the initial investment is higher than that of standard models, making them a consideration for budget-conscious buyers.

What Makes Intelligent Electric Butterfly Valves Suitable for Automation?

Intelligent electric butterfly valves come equipped with advanced features such as integrated sensors and smart control systems. These valves facilitate real-time monitoring and remote operation, making them particularly suited for advanced agricultural automation. While they provide unmatched operational efficiency and data collection capabilities, buyers must account for the complexity of installation and potential maintenance challenges, which can increase overall costs.

Why Choose Wafer Type Electric Butterfly Valves for Space-Constrained Areas?

Wafer type electric butterfly valves are characterized by their compact design, allowing them to fit seamlessly between flanges in tight spaces. This makes them a practical choice for irrigation setups where space is limited. Their lightweight nature simplifies installation; however, buyers should ensure compatibility with specific flange types, as this can impact overall system integration.

When Are High-Pressure Electric Butterfly Valves Necessary?

High-pressure electric butterfly valves are engineered to handle demanding applications, withstanding pressures up to 2.0 MPa. They are essential in heavy-duty agricultural environments where durability and reliability are paramount. While they offer exceptional performance under pressure, buyers should weigh the benefits against their higher cost and weight, which may affect installation logistics.

Key Industrial Applications of stainless steel electric butterfly valve for agricultural irrigation

| Industry/Sector | Specific Application of stainless steel electric butterfly valve for agricultural irrigation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems for crop fields | Enhances efficiency and reduces labor costs | Compatibility with existing systems, torque requirements |

| Water Management | Flow control in water treatment facilities for irrigation | Ensures optimal water quality and supply | Pressure ratings, sealing materials, and maintenance needs |

| Greenhouse Operations | Nutrient delivery systems in hydroponic setups | Precise control of nutrient flow | Size compatibility, voltage options, and automation features |

| Desalination Plants | Integration into seawater desalination processes | Supports sustainable water sourcing | Corrosion resistance, pressure handling, and certification |

| Municipal Irrigation | Management of municipal water supply systems | Reliable water distribution for urban areas | Compliance with local regulations, durability, and service life |

How is the Stainless Steel Electric Butterfly Valve Used in Agriculture?

In the agricultural sector, stainless steel electric butterfly valves are pivotal for automated irrigation systems. These valves facilitate precise control over water flow, ensuring that crops receive optimal irrigation without manual intervention. This automation not only enhances operational efficiency but also significantly reduces labor costs, making it a valuable investment for farmers in regions like Africa and South America, where labor costs can be high. Buyers should consider compatibility with existing irrigation infrastructure and the torque requirements necessary for effective operation.

What Role Do These Valves Play in Water Management?

In water treatment facilities, stainless steel electric butterfly valves are essential for managing flow rates and ensuring the quality of water supplied for irrigation. They help in maintaining consistent water pressure and can be easily integrated into existing control systems. This is particularly important in regions facing water scarcity, as it allows for better resource management. When sourcing these valves, businesses should prioritize pressure ratings and the type of sealing materials used, as these factors will influence the valve’s performance and longevity.

How Are They Beneficial for Greenhouse Operations?

In greenhouse operations, stainless steel electric butterfly valves are used in nutrient delivery systems for hydroponics. These valves allow for precise control of nutrient flow, which is critical for plant health and yield. The ability to automate this process minimizes waste and optimizes resource use, directly impacting profitability. Buyers should focus on size compatibility with existing systems and voltage options, as well as the availability of automation features that can enhance system performance.

What Is Their Application in Desalination Plants?

Stainless steel electric butterfly valves are also integrated into seawater desalination processes, where they play a crucial role in controlling the flow of seawater and treated water. Their corrosion-resistant properties make them ideal for such harsh environments, ensuring reliability and longevity. For businesses in the Middle East, where water scarcity is a pressing issue, sourcing valves that can handle high pressure and comply with industry certifications is essential for successful operation.

How Do They Support Municipal Irrigation?

In municipal irrigation systems, these valves are vital for managing water supply efficiently. They ensure that urban areas receive a reliable water distribution, which is crucial for both residential and agricultural needs. The durability and compliance with local regulations are key considerations for municipalities in Europe and other regions. By focusing on these aspects, municipal buyers can ensure that they invest in solutions that enhance the sustainability and reliability of their water supply systems.

3 Common User Pain Points for ‘stainless steel electric butterfly valve for agricultural irrigation’ & Their Solutions

Scenario 1: Difficulty in Maintaining System Integrity During Operation

The Problem: B2B buyers often face challenges with the integrity of irrigation systems when using stainless steel electric butterfly valves. These valves, while effective, can suffer from issues like leakage or failure due to improper sealing, particularly in high-pressure applications or environments with fluctuating temperatures. Such failures can lead to significant downtime, increased maintenance costs, and, most critically, can affect crop yields if irrigation is interrupted.

The Solution: To ensure the integrity of stainless steel electric butterfly valves, buyers should prioritize sourcing high-quality valves that meet or exceed industry standards for pressure and temperature ratings. It’s essential to consider factors such as the sealing materials used in the valve. Opt for valves with PTFE or EPDM seals, which provide better resistance to temperature fluctuations and chemical exposure. Additionally, regular maintenance checks should be established to inspect the valve for wear and tear, ensuring that seals remain intact and the valve operates smoothly. Implementing predictive maintenance through monitoring systems can help detect early signs of failure, allowing for proactive replacement or repair before significant issues arise.

Scenario 2: Complexity in Automation Integration

The Problem: Many agricultural operations are moving towards automation to increase efficiency and reduce labor costs. However, integrating stainless steel electric butterfly valves into existing systems can be complex and daunting for buyers. Issues may arise from compatibility with different control systems, leading to operational inefficiencies and potential system failures if not addressed correctly.

The Solution: Buyers should focus on selecting stainless steel electric butterfly valves that offer flexible control options, such as MODBUS or PROFIBUS communication protocols, ensuring compatibility with existing automation systems. Collaborating with suppliers who provide comprehensive technical support can facilitate smoother integration. Furthermore, it is advisable to conduct thorough compatibility testing in a controlled environment before full-scale implementation. This allows buyers to troubleshoot any potential integration issues early on, minimizing disruption to operations.

Scenario 3: Inadequate Knowledge of Sizing and Specifications

The Problem: A common pain point for B2B buyers is the lack of knowledge regarding the proper sizing and specifications of stainless steel electric butterfly valves for their specific agricultural applications. Incorrect sizing can lead to inefficient flow control, increased energy consumption, and ultimately higher operational costs.

The Solution: To avoid these pitfalls, buyers should engage in a detailed assessment of their irrigation system’s requirements before purchasing valves. This includes calculating the flow rate, pressure drops, and the specific media being transported. Consulting with valve manufacturers or technical experts can provide valuable insights into selecting the right valve size and specifications tailored to the operation’s unique needs. Additionally, utilizing resources such as flow charts and valve sizing calculators can aid in making informed decisions. Ensuring that the selected valves have adjustable features can also provide the flexibility needed to accommodate future changes in system demands.

Strategic Material Selection Guide for stainless steel electric butterfly valve for agricultural irrigation

When selecting materials for stainless steel electric butterfly valves used in agricultural irrigation, it is crucial to consider the specific properties, advantages, and limitations of each material. This selection directly influences the valve’s performance, longevity, and suitability for various applications. Below is an analysis of four common materials used in the manufacturing of these valves.

What are the Key Properties of Stainless Steel in Electric Butterfly Valves?

1. Stainless Steel 304

Stainless Steel 304 is a widely used material known for its excellent corrosion resistance and good mechanical properties. It can handle temperatures up to 870°C (1600°F) and pressures typically around 1.0 to 1.6 MPa. Its resistance to a variety of chemicals makes it suitable for applications involving water, oil, and air.

- Pros: High corrosion resistance, good weldability, and formability. It is also relatively cost-effective compared to other stainless steel grades.

- Cons: While it performs well in many environments, it may not be suitable for highly corrosive substances like chlorides, which can lead to pitting.

- Impact on Application: Ideal for general agricultural irrigation and water treatment applications, but care should be taken in environments with aggressive chemicals.

- Considerations for International Buyers: Compliance with standards such as ASTM A240 is essential. Buyers in regions like Europe may prefer materials that meet DIN standards.

2. Stainless Steel 316

Stainless Steel 316 offers enhanced corrosion resistance, particularly against chlorides and marine environments. It can withstand similar temperature and pressure ratings as 304, making it a versatile option for various applications.

- Pros: Superior corrosion resistance, particularly in saline and chemical environments. It also provides good strength and toughness at elevated temperatures.

- Cons: Higher cost compared to 304 due to the addition of molybdenum, which can increase manufacturing complexity.

- Impact on Application: Best suited for agricultural applications near coastal areas or where chemical exposure is a concern.

- Considerations for International Buyers: Compliance with ASTM A240 and JIS G4303 is crucial. Buyers in Africa and South America may find the initial investment worthwhile due to the material’s longevity.

3. Ductile Iron with Stainless Steel Coating

Ductile iron valves coated with stainless steel provide a balance between strength and corrosion resistance. This combination allows for high-pressure applications while maintaining resistance to rust and wear.

- Pros: Excellent mechanical strength and shock resistance. The stainless steel coating enhances corrosion resistance, making it suitable for various media.

- Cons: The coating process can add to manufacturing time and costs. If the coating is damaged, the underlying iron may corrode.

- Impact on Application: Suitable for high-pressure irrigation systems where durability is crucial.

- Considerations for International Buyers: Ensure the coating meets relevant standards for durability. Buyers in the Middle East may prioritize this material for its robustness in harsh climates.

4. PVC-Lined Stainless Steel

This hybrid material combines the structural integrity of stainless steel with the chemical resistance of PVC lining. It is particularly useful in applications where the valve is exposed to aggressive chemicals.

- Pros: Excellent chemical resistance and lower weight compared to full metal valves. The PVC lining can also reduce noise and vibration.

- Cons: Limited temperature resistance compared to all-metal options. The PVC can degrade under UV exposure if not properly shielded.

- Impact on Application: Ideal for irrigation systems using fertilizers or other chemicals, where corrosion is a primary concern.

- Considerations for International Buyers: Check compliance with relevant agricultural standards. Buyers in Europe may favor this option for its versatility and lower maintenance needs.

Summary Table of Material Comparisons

| Material | Typical Use Case for stainless steel electric butterfly valve for agricultural irrigation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel 304 | General irrigation and water treatment applications | High corrosion resistance | Not suitable for highly corrosive substances | Medium |

| Stainless Steel 316 | Agricultural applications near coastal areas or chemical exposure | Superior corrosion resistance | Higher cost than 304 | High |

| Ductile Iron with Coating | High-pressure irrigation systems | Excellent mechanical strength | Coating damage can lead to corrosion | Medium |

| PVC-Lined Stainless Steel | Irrigation systems using aggressive chemicals | Excellent chemical resistance | Limited temperature resistance | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in stainless steel electric butterfly valves for agricultural irrigation. Understanding these factors will help in making informed purchasing decisions tailored to specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel electric butterfly valve for agricultural irrigation

What Are the Main Stages in the Manufacturing Process of Stainless Steel Electric Butterfly Valves?

The manufacturing process of stainless steel electric butterfly valves involves several crucial stages, each designed to ensure the final product meets the rigorous demands of agricultural irrigation applications. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation

The first stage is material preparation, where high-grade stainless steel is selected for its corrosion resistance and durability. Suppliers typically source materials compliant with international standards such as ASTM A182 or A351, ensuring the components can withstand harsh environmental conditions. This selection process includes rigorous inspection of raw materials for impurities or defects, which can compromise performance.

Forming

In the forming stage, the prepared stainless steel is shaped into the desired components of the butterfly valve. This often involves processes such as casting, forging, or machining. Advanced techniques like CNC machining are frequently employed to achieve precise dimensions and tolerances. The valve disc, body, and other components are formed to meet specific design standards, ensuring optimal flow control and sealing capabilities.

Assembly

Once the individual components are formed, they proceed to the assembly stage. Here, skilled technicians or automated systems fit together the valve body, disc, stem, and actuator. This stage is critical as it determines the valve’s operational efficiency. Tight tolerances are essential, as improper assembly can lead to leaks or mechanical failure. The assembly process may also involve the installation of seals made from materials like PTFE or EPDM to enhance sealing performance.

Finishing

The final stage, finishing, involves surface treatments to enhance durability and aesthetics. Processes such as polishing, passivation, and coating are applied to improve corrosion resistance and reduce friction. This stage may also include the installation of actuators, which are tested for functionality and compatibility with the valve components. Proper finishing not only extends the product’s lifespan but also ensures compliance with industry regulations.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is paramount in the manufacturing of stainless steel electric butterfly valves. International standards and industry-specific certifications play a vital role in ensuring product reliability and safety.

What Are the Relevant International Standards?

Buyers should look for suppliers that adhere to ISO 9001, which establishes a framework for quality management systems. Compliance with this standard indicates that the manufacturer has processes in place to consistently provide products that meet customer and regulatory requirements. Additionally, certifications such as CE mark and API standards are crucial for ensuring the valves are suitable for use in various applications, including agricultural irrigation.

What Are the Key QC Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure product integrity. Common checkpoints include:

Incoming Quality Control (IQC): This step verifies the quality of raw materials before they enter the production process. Inspections may include material certifications and dimensional checks.

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections assess critical parameters such as dimensions, tolerances, and assembly quality. This ensures that any defects are identified and rectified promptly.

Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted. This includes functional testing of the valves to ensure they meet performance specifications, as well as visual inspections for surface defects.

What Testing Methods Are Commonly Used for Stainless Steel Electric Butterfly Valves?

Testing methods are vital to ensuring that the valves perform reliably under operational conditions. Common methods include:

Hydrostatic Testing: This method assesses the valve’s ability to withstand pressure by filling it with water and applying pressure beyond its rated capacity.

Functional Testing: The valve is operated through its full range of motion to ensure that it opens and closes smoothly and that the actuator responds correctly.

Leak Testing: This involves pressurizing the valve and checking for leaks at joints and seals, ensuring that the valve maintains its integrity.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, buyers should consider several verification methods:

Supplier Audits

Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can include evaluating their adherence to international standards, inspecting their facilities, and assessing their equipment and technology.

Requesting Quality Reports

Buyers should request quality assurance reports that detail the QC measures taken during production. These reports can include results from testing methods, as well as records of any non-conformities and corrective actions taken.

Utilizing Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can perform audits and inspections at various stages of the manufacturing process, ensuring compliance with industry standards.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must navigate various QC and certification nuances. Different regions may have specific regulations or certification requirements that suppliers must meet. For instance, the CE marking is essential for products sold in Europe, while compliance with local standards may be necessary in African markets.

Understanding these regional differences is crucial for buyers to ensure that the products they import are compliant and safe for use in their respective applications. Additionally, buyers should be aware of the potential for language barriers or differences in business practices that may affect communication and contract negotiations.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for stainless steel electric butterfly valves is essential for B2B buyers. By focusing on these elements, buyers can make informed decisions, ensuring they source reliable and compliant products for agricultural irrigation applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel electric butterfly valve for agricultural irrigation’

In the competitive landscape of agricultural irrigation, sourcing the right stainless steel electric butterfly valve is crucial for ensuring efficiency and reliability in your operations. This guide will help international B2B buyers navigate the procurement process by providing a structured checklist to streamline decision-making.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the stainless steel electric butterfly valve. Consider factors such as size, pressure range, and compatibility with the media being transported (water, oil, etc.). Defining these specifications early on will help narrow down options and ensure that the selected valves meet operational needs.

- Size Range: Common sizes include 2 inches to 24 inches; ensure the valve fits your existing piping.

- Pressure Ratings: Look for valves that can handle the required pressure, typically between 1.0MPa to 2.0MPa for irrigation applications.

Step 2: Identify Suitable Materials

The material of the valve is critical, especially for agricultural applications where exposure to various elements is common. Stainless steel is favored for its durability and resistance to corrosion.

- Material Quality: Ensure the stainless steel used (e.g., SS304) is suitable for your environment.

- Sealing Materials: Verify that the seals (PTFE, NBR, EPDM) can withstand the operational conditions.

Step 3: Evaluate Potential Suppliers

It’s vital to conduct thorough research on potential suppliers. Look for established companies with a proven track record in manufacturing electric butterfly valves.

- Request Documentation: Ask for product catalogs, certifications, and compliance with industry standards (ISO, DIN).

- Customer References: Seek testimonials or case studies from previous clients in agriculture to gauge reliability and service quality.

Step 4: Check for Automation Compatibility

As irrigation systems become more automated, ensuring that the valve can integrate with existing control systems is crucial.

- Actuator Types: Determine whether you need an ON/OFF actuator, modulating type, or intelligent actuator with feedback capabilities.

- Control Signals: Ensure compatibility with your control system (e.g., 4-20mA, MODBUS).

Step 5: Assess After-Sales Support and Warranty

Robust after-sales support can save you time and money in the long run. Confirm the level of service provided by the supplier post-purchase.

- Warranty Terms: Understand the warranty coverage for the valves and the actuator.

- Technical Support: Ensure that the supplier offers assistance for installation and maintenance.

Step 6: Compare Pricing and Payment Terms

Once you have a shortlist of suppliers, compare their pricing structures and payment terms.

- Total Cost of Ownership: Look beyond the initial price to consider long-term costs, including maintenance and potential downtime.

- Payment Flexibility: Evaluate the payment options offered, especially for large orders.

Step 7: Finalize Your Purchase and Logistics

After selecting a supplier, confirm your order and arrange for shipping and delivery.

- Shipping Arrangements: Discuss logistics to ensure timely delivery, especially if you’re operating in remote regions.

- Customs and Duties: Be aware of any import regulations or duties applicable in your country.

By following this checklist, B2B buyers can make informed decisions when procuring stainless steel electric butterfly valves for agricultural irrigation, ensuring they choose the right products and partners for their operational needs.

Comprehensive Cost and Pricing Analysis for stainless steel electric butterfly valve for agricultural irrigation Sourcing

What Are the Key Cost Components for Stainless Steel Electric Butterfly Valves?

When sourcing stainless steel electric butterfly valves for agricultural irrigation, understanding the cost structure is crucial. The primary components influencing the total cost include:

Materials: The quality of stainless steel, often specified as SS304 or SS316, directly impacts the cost. Higher grades or specialized coatings for corrosion resistance can significantly increase material expenses.

Labor: Labor costs vary by region. In countries with a skilled workforce, such as Germany, labor may be more expensive than in emerging markets like Nigeria or Brazil. Skilled labor is essential for assembly, ensuring that the valve functions properly.

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. Manufacturers in regions with high operational costs may pass these expenses onto buyers.

Tooling: Specialized tooling for valve production can be a significant upfront cost. If a supplier has invested in advanced manufacturing technology, this may reflect in the pricing structure.

Quality Control (QC): Investing in rigorous QC processes ensures product reliability and compliance with international standards. Suppliers that adhere to certifications like ISO or API may charge higher prices due to their commitment to quality.

Logistics: Transportation costs can vary widely based on the distance from the manufacturer to the buyer, as well as the chosen shipping method. For international buyers, understanding Incoterms (like FOB, CIF) is essential to anticipate additional shipping charges.

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand and competition.

How Do Price Influencers Impact Sourcing Decisions?

Several factors can influence the pricing of stainless steel electric butterfly valves:

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, which can significantly reduce the per-unit cost. Understanding a supplier’s MOQ can help in planning purchases effectively.

Specifications and Customization: Custom features, such as specific torque requirements or unique actuator types, can increase costs. Buyers should assess whether customization is necessary or if off-the-shelf products meet their needs.

Quality and Certifications: Valves with higher quality standards and certifications may come at a premium. Buyers should evaluate whether these certifications are essential for their application to justify the additional cost.

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers with a track record of quality may charge more but can provide peace of mind.

What Buyer Tips Can Enhance Cost-Efficiency?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negotiation: Engage in discussions with suppliers to negotiate pricing. Suppliers may be willing to adjust their prices based on your commitment to larger orders or long-term contracts.

Total Cost of Ownership (TCO): Consider not just the purchase price but the entire lifecycle cost, including maintenance, energy consumption, and potential downtime. Investing in higher-quality valves may reduce long-term operational costs.

Understanding Pricing Nuances: Be aware of regional pricing differences. For instance, European suppliers may offer higher-quality products with better certifications, while suppliers in emerging markets may provide more competitive pricing.

What Should Be Considered in Pricing?

While indicative prices for stainless steel electric butterfly valves can range widely (e.g., $200 to $2,000 per unit depending on specifications), buyers should approach pricing with caution. Factors like market fluctuations, economic conditions, and supplier changes can all affect prices.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and strategic buyer tips can significantly enhance sourcing decisions for stainless steel electric butterfly valves in agricultural irrigation applications. Buyers should conduct thorough market research and supplier evaluations to ensure they achieve the best possible value for their investments.

Alternatives Analysis: Comparing stainless steel electric butterfly valve for agricultural irrigation With Other Solutions

Introduction to Alternative Solutions for Agricultural Irrigation Valves

In agricultural irrigation systems, selecting the right valve technology is crucial for ensuring efficient water management and operational effectiveness. While stainless steel electric butterfly valves are popular for their durability and automation capabilities, several alternative solutions may also meet the specific needs of different irrigation setups. This analysis compares stainless steel electric butterfly valves with other viable options, helping international B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Stainless Steel Electric Butterfly Valve For Agricultural Irrigation | Pneumatic Actuated Valve | Manual Gate Valve |

|---|---|---|---|

| Performance | High flow control, quick actuation, suitable for various media | Fast response, ideal for high-pressure applications | Reliable but slower operation, limited to on/off control |

| Cost | Moderate initial investment, lower long-term operational costs | Generally lower upfront cost, higher maintenance expenses | Low initial cost, higher labor costs for operation |

| Ease of Implementation | Requires electrical setup, easy to integrate with automation systems | Can be easier to install with pneumatic systems | Simple installation, requires manual operation training |

| Maintenance | Low maintenance; periodic checks needed for electrical components | Moderate; pneumatic system components may need regular servicing | Low maintenance; mechanical wear over time may require replacement |

| Best Use Case | Ideal for automated, precise irrigation control in diverse conditions | Suitable for high-demand applications with rapid cycling | Best for small-scale operations or where manual control is preferred |

Detailed Breakdown of Alternatives

Pneumatic Actuated Valve

Pneumatic actuated valves are driven by compressed air, making them suitable for applications requiring rapid operation and high flow rates. These valves offer a fast response time and can handle high-pressure conditions effectively. However, they can incur higher maintenance costs due to the need for regular servicing of pneumatic components. The initial investment is generally lower than electric options, but operational costs may rise depending on air supply management. These valves are well-suited for environments where speed and pressure control are paramount.

Manual Gate Valve

Manual gate valves are a traditional choice for irrigation systems, primarily used for on/off flow control. They are characterized by their simplicity and cost-effectiveness, making them an attractive option for smaller operations or those with limited budgets. However, they require manual operation, which can be labor-intensive and inefficient in larger systems. While maintenance is minimal, mechanical wear may necessitate eventual replacement. Manual gate valves are best suited for situations where automation is not a priority, and operators can manage flow manually.

Conclusion: How to Choose the Right Valve for Your Agricultural Irrigation Needs

When selecting a valve for agricultural irrigation, B2B buyers must consider multiple factors, including performance requirements, budget constraints, and the desired level of automation. Stainless steel electric butterfly valves offer a balance of durability, efficiency, and automation, making them ideal for modern irrigation systems. However, alternatives like pneumatic actuated valves and manual gate valves may be more appropriate depending on specific operational needs and cost considerations. Ultimately, the right choice will depend on the unique requirements of the irrigation system and the long-term goals of the agricultural operation.

Essential Technical Properties and Trade Terminology for stainless steel electric butterfly valve for agricultural irrigation

What Are the Key Technical Properties of Stainless Steel Electric Butterfly Valves for Agricultural Irrigation?

Understanding the technical properties of stainless steel electric butterfly valves is crucial for international B2B buyers in agricultural irrigation. Here are essential specifications that can impact performance, durability, and suitability for various applications.

1. Material Grade

The most common material used for stainless steel electric butterfly valves is 304 or 316 stainless steel. The choice between these grades depends on the application environment; for instance, 316 stainless steel offers superior corrosion resistance, making it ideal for saline or aggressive media. Selecting the appropriate material grade ensures longevity and reduces maintenance costs, which is vital for agricultural operations that rely on uninterrupted water supply.

2. Pressure Rating

Pressure rating indicates the maximum pressure the valve can handle, typically measured in MPa (megapascals) or bar. Most agricultural applications require valves with pressure ratings ranging from 1.0 to 2.0 MPa. Understanding pressure ratings is essential for ensuring that the valve can withstand the operational demands of irrigation systems, preventing failures that could lead to costly downtime.

3. Torque Range

The torque range of the electric actuator determines how much force is required to operate the valve. In the case of stainless steel electric butterfly valves, torque can range from 50Nm to 4000Nm. Knowing the torque requirements helps buyers select the right actuator type, ensuring efficient operation and minimizing energy consumption, which is particularly important for large-scale agricultural operations.

4. Size Range

Valves are available in various sizes, typically from 2 inches to 24 inches. The size of the valve should match the diameter of the piping system to maintain proper flow rates and pressure. Selecting the correct size is critical for optimizing irrigation efficiency, as improperly sized valves can lead to pressure drops and inefficient water distribution.

5. End Connection Types

Common end connection types include wafer, lug, and flange connections. The choice of end connection affects how the valve integrates with existing piping systems. Understanding these options is essential for buyers to ensure compatibility with their infrastructure, which can significantly reduce installation costs and time.

6. Operating Temperature Range

The operating temperature range specifies the temperatures within which the valve can function effectively. It is crucial to select valves that can withstand the temperature variations typical in agricultural settings, especially when dealing with heated water or chemicals. This knowledge helps buyers avoid premature valve failure and ensures reliable performance.

What Are Common Trade Terms Related to Stainless Steel Electric Butterfly Valves?

Understanding trade terminology is vital for effective communication and negotiation in B2B transactions. Here are several commonly used terms in the industry.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of stainless steel electric butterfly valves, OEMs often provide custom solutions tailored to specific agricultural needs. Knowing about OEM partnerships can help buyers identify reliable suppliers who can meet unique specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers, as it affects inventory management and cost. For smaller agricultural operations, negotiating a lower MOQ can be beneficial to manage cash flow while ensuring access to necessary components.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. For agricultural businesses looking to purchase stainless steel electric butterfly valves, submitting an RFQ can facilitate better pricing and terms, helping to ensure they get the best value for their investments.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers in agriculture, as it helps clarify costs and responsibilities during the procurement process.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In agriculture, where timely irrigation is critical, understanding lead times helps buyers plan their operations effectively and avoid disruptions.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when selecting stainless steel electric butterfly valves for agricultural irrigation, ensuring optimal performance and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the stainless steel electric butterfly valve for agricultural irrigation Sector

What are the Current Market Trends for Stainless Steel Electric Butterfly Valves in Agricultural Irrigation?

The stainless steel electric butterfly valve market is witnessing robust growth, driven by increasing demands for efficient water management and sustainable agricultural practices globally. Key drivers include the rising adoption of precision irrigation systems, which enhance water use efficiency and crop yield. As countries in Africa, South America, the Middle East, and Europe prioritize food security and sustainable agricultural practices, the need for reliable and efficient flow control solutions like electric butterfly valves has surged.

Emerging technologies are transforming sourcing trends in this sector. Automation and IoT integration are increasingly common, allowing for remote monitoring and control, which enhances operational efficiency. Moreover, the trend towards modular valve systems is gaining traction, enabling easier upgrades and maintenance. International buyers, particularly from regions like Nigeria and Germany, are also showing a preference for suppliers that offer comprehensive after-sales support, including installation and maintenance services.

Another significant trend is the emphasis on customization. Different agricultural applications require specific valve configurations, such as size, pressure ratings, and material specifications. Suppliers are now focusing on offering tailored solutions to meet the diverse needs of their clients, thereby increasing their competitive edge in the global market.

How is Sustainability Influencing the Sourcing of Stainless Steel Electric Butterfly Valves?

Sustainability is becoming a cornerstone of sourcing strategies for stainless steel electric butterfly valves in the agricultural irrigation sector. The environmental impact of valve manufacturing and operation is under scrutiny, leading to a demand for eco-friendly practices. Buyers are increasingly seeking valves made from recyclable materials and those that contribute to energy savings in operations.

Ethical sourcing is crucial, as stakeholders aim to ensure that their supply chains adhere to environmental standards and promote social responsibility. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications are becoming critical in the supplier selection process. Companies that can demonstrate compliance with these standards are more likely to attract international buyers looking for sustainable solutions.

Furthermore, the use of advanced materials, such as corrosion-resistant stainless steel, not only extends the lifecycle of the valves but also reduces the frequency of replacements, thereby minimizing waste. This aligns with the growing global focus on circular economy principles, where the emphasis is on longevity and recyclability.

What is the Historical Context of Stainless Steel Electric Butterfly Valves in Agricultural Applications?

The evolution of stainless steel electric butterfly valves can be traced back to the early developments in valve technology, which aimed to improve control over fluid dynamics in various applications, including agriculture. Initially, manual valves dominated the market, but the advent of electric actuators in the late 20th century revolutionized the industry by enhancing automation and operational efficiency.

As agricultural practices evolved, particularly with the introduction of modern irrigation techniques, the demand for reliable and efficient control systems increased. Stainless steel emerged as the material of choice due to its durability, resistance to corrosion, and ability to withstand harsh environmental conditions. This material not only provided longevity but also ensured that the valves could operate effectively in diverse agricultural settings.

Today, the integration of advanced technologies such as IoT and automation in stainless steel electric butterfly valves reflects a significant leap from their historical counterparts. This evolution underscores the importance of continuous innovation in meeting the growing demands of the agricultural sector, ensuring that international buyers have access to cutting-edge solutions that contribute to sustainable agricultural practices.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel electric butterfly valve for agricultural irrigation

How do I determine the right size of stainless steel electric butterfly valve for my agricultural irrigation system?

To choose the correct size of a stainless steel electric butterfly valve, consider the flow rate, pressure, and the specific requirements of your irrigation system. Typically, valve sizes range from 2 to 24 inches. You should consult with the system design specifications or a technical expert to calculate the necessary valve diameter that ensures optimal flow without causing excessive pressure drops. Additionally, ensure that the valve’s size aligns with the piping dimensions and the overall system layout.What is the best material for stainless steel electric butterfly valves used in agricultural irrigation?

The most suitable material for stainless steel electric butterfly valves in agricultural irrigation is 304 or 316 stainless steel. These materials offer excellent corrosion resistance, durability, and strength, making them ideal for handling various media such as water, oil, and air. For environments with higher salinity or corrosive elements, 316 stainless steel may be preferred due to its enhanced resistance to pitting and crevice corrosion. Always verify that the valve material complies with local regulations and agricultural standards.How can I ensure the quality of stainless steel electric butterfly valves when sourcing from international suppliers?

To ensure quality when sourcing from international suppliers, conduct thorough research on potential vendors. Check for certifications like ISO 9001, which indicates adherence to quality management standards. Request product samples and technical documentation to assess the specifications and performance. Additionally, consider visiting the manufacturing facility if feasible, or utilize third-party inspection services to verify product quality before shipping. Building relationships with reputable suppliers can also lead to better quality assurance practices.What customization options are available for stainless steel electric butterfly valves?

Customization options for stainless steel electric butterfly valves typically include various actuator types (on/off, modulating, intelligent), size adjustments, and specific connection types (wafer, lug, flange). You may also request custom torque ranges, voltage options, and additional features like manual overrides or feedback systems. Discuss your specific requirements with the supplier to explore available modifications that suit your irrigation system’s needs.What are the minimum order quantities (MOQs) when purchasing stainless steel electric butterfly valves?

Minimum order quantities can vary significantly by supplier and product type. Generally, MOQs for stainless steel electric butterfly valves can range from 10 to 100 units. It’s essential to communicate directly with your supplier to understand their specific MOQ policies, as some manufacturers may offer flexibility, especially for repeat customers or larger contracts. Consider discussing options for mixed orders if you require different sizes or models.What payment terms are typically offered by international suppliers of stainless steel electric butterfly valves?

Payment terms for international suppliers often include options like advance payment, letters of credit, or payment upon delivery. Standard practices may require a deposit (usually 30-50%) before production, with the balance due before shipment. Always negotiate terms that fit your cash flow and risk tolerance. Ensure that payment methods are secure and consider using escrow services for added protection against fraud in international transactions.How should I manage logistics and shipping for stainless steel electric butterfly valves?

Managing logistics for international shipping of stainless steel electric butterfly valves involves careful planning. Confirm the supplier’s shipping capabilities and choose a reliable freight forwarder familiar with customs regulations in your country. Discuss shipping methods, such as air freight for faster delivery or sea freight for cost-effectiveness. Ensure all necessary documentation, including invoices, packing lists, and certificates of origin, is prepared to facilitate smooth customs clearance.What quality assurance measures should I expect from suppliers of stainless steel electric butterfly valves?

Reputable suppliers should implement comprehensive quality assurance measures, including material inspections, dimensional checks, and functional testing before shipment. Expect documentation of these processes, such as test reports and compliance certificates. Additionally, inquire about their warranty policies and after-sales support to address potential issues post-purchase. A strong QA process not only ensures product reliability but also enhances your confidence in the supplier’s capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Stainless Steel Electric Butterfly Valve For Agricultural Irrigation Manufacturers & Suppliers List

1. Valveman – Electric Butterfly Valves

Domain: valveman.com

Registered: 2009 (16 years)

Introduction: Electric butterfly valves provide automated flow control solutions for HVAC, water treatment, chemical, and industrial systems. They feature a compact design and reliable electric actuation, allowing for precise on/off or modulating control. Available in a broad range of body styles, materials, and voltage options, these valves are built for performance and can be easily integrated into control sy…

2. D971X – Electric Butterfly Valve 220V

Domain: aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, D971X – Electric Butterfly Valve 220V, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Morrill Industries – Agricultural Filtration Equipment

Domain: morrillinc.com

Registered: 2003 (22 years)

Introduction: Morrill Industries, Inc. manufactures and supplies a variety of agricultural equipment including:

– Filtration Equipment: Manual, Automatic, and Cartridge Filters for irrigation, cooling towers, fish protection, industrial processing, leach mining, municipal water supply, and wastewater applications. Materials include Carbon Steel, Stainless Steel (304 and 316 grades), with various coatings and f…

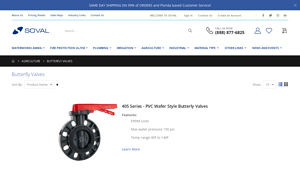

4. Soval – PVC Wafer Butterfly Valves

Domain: soval.com

Registered: 1997 (28 years)

Introduction: [{‘series’: ‘405 Series’, ‘type’: ‘PVC Wafer Style Butterfly Valve’, ‘features’: [‘EPDM Liner’, ‘Max water pressure 150 psi’, ‘Temp range 40F to 140F’]}, {‘series’: ‘585 Series’, ‘type’: ‘PVC Wafer Butterfly Valve’, ‘description’: ‘The only PVC butterfly valves needed for flow control projects including irrigation, plumbing, utilities.’}, {‘series’: ‘840 Series’, ‘type’: ‘Cast Iron Wafer Style But…

5. POV – Wafer Style Butterfly Valves

Domain: povbutterflyvalve.com

Registered: 2018 (7 years)

Introduction: Wafer style butterfly valves are flow control devices characterized by a disc mounted on a rotating shaft. They are designed to block or allow the passage of fluids or gases with minimal resistance. The ‘wafer’ design means the valve body is sandwiched between two pipe flanges, making it compact and cost-effective. These valves are durable, easy to install, and efficient, suitable for HVAC systems…

Strategic Sourcing Conclusion and Outlook for stainless steel electric butterfly valve for agricultural irrigation

In conclusion, strategic sourcing of stainless steel electric butterfly valves for agricultural irrigation is pivotal for enhancing operational efficiency and ensuring sustainable water management. By prioritizing quality, durability, and cost-effectiveness, businesses can secure reliable supply chains that meet the rigorous demands of agricultural applications. The versatility of these valves, capable of handling various media while providing excellent sealing performance, positions them as essential components in modern irrigation systems.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should leverage the insights gained from this guide to make informed purchasing decisions. Establishing partnerships with reputable manufacturers can lead to improved productivity and reduced downtime, vital for meeting the increasing agricultural output demands.

As the global market continues to evolve, investing in high-quality stainless steel electric butterfly valves will be crucial for agricultural stakeholders aiming to optimize their irrigation systems. Embrace this opportunity to advance your operations and contribute to sustainable agricultural practices. Connect with suppliers today to explore innovative solutions tailored to your specific needs.