Here’s a straightforward breakdown of how a knife gate valve works — without burying you in unnecessary jargon:

1. Basic Principle

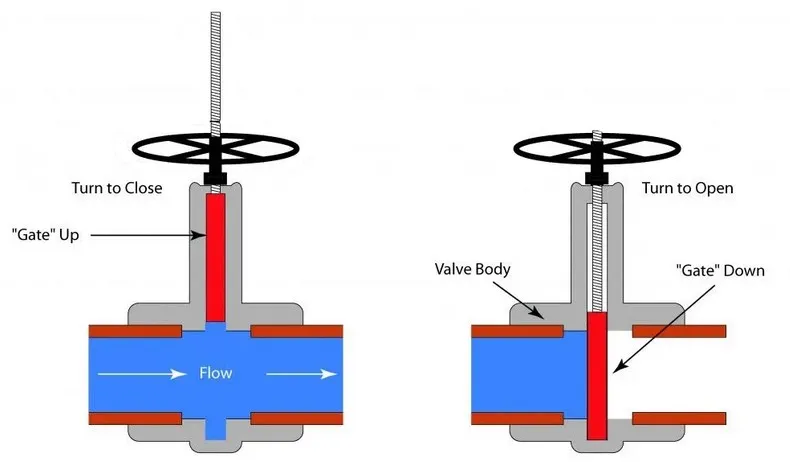

A knife gate valve controls the flow of fluid by sliding a flat, sharp-edged blade (the “knife”) up and down through the path of the fluid.

Open position: The blade is lifted out of the flow path, allowing fluid to pass through freely.

Closed position: The blade lowers into the seat, blocking the passage completely.

2. Step-by-Step Operation

Handle or Actuator Moves the Stem

The operator turns a handwheel, pulls a lever, or the actuator (pneumatic, electric, or hydraulic) moves the stem up or down.

Stem Lifts or Lowers the Knife Blade

In rising-stem designs, the stem physically lifts the blade.

In non-rising-stem designs, the stem rotates in place to move the blade.

Knife Cuts Through Media

The thin, sharpened edge pushes aside solids and cuts through fibrous or sticky materials (slurry, pulp, wastewater).

This prevents clogging and ensures the gate can reach the bottom to seal.

Sealing Against the Seat

When fully lowered, the blade presses into a resilient or metal seat, creating a seal.

Depending on design, the seal may be bi-directional (both flow directions) or uni-directional (one direction only).

Flow Resumes or Stops

Lifting the blade opens the passage, and lowering it closes the passage — all in a straight-line, low-torque motion.

3. Why It Works Well for Slurries

The knife edge scrapes away scale, fibers, or solids every time it moves.

The open body design allows material to pass without excessive buildup.

Low-pressure drop when fully open makes it energy efficient for pumping thick fluids.

4. Limitations

Not ideal for high-pressure applications.

Not designed for frequent throttling — better for on/off control.

Seal wear is faster in very abrasive services, so maintenance is key.

Visual Summary

Imagine the valve like a guillotine:

Blade up → flow path is clear.

Blade down → flow path is blocked.

But unlike a guillotine, the knife gate valve is built to do this repeatedly without jamming, even when dealing with gritty, sticky, or chunky media.