Introduction: Navigating the Global Market for how to install a irrigation valve

Navigating the complexities of how to install an irrigation valve can be a daunting task for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With diverse climates and varying agricultural practices, finding the right irrigation solutions tailored to specific needs is essential. This guide serves as a comprehensive resource, detailing the different types of irrigation valves, their applications in various landscapes, and key considerations when sourcing these critical components.

Understanding the intricacies of installation—from selecting the appropriate valve type to ensuring compliance with local regulations—can significantly impact the effectiveness of irrigation systems. This guide empowers B2B buyers by offering insights into supplier vetting, cost analysis, and best practices for installation, helping them make informed purchasing decisions. By addressing common challenges, such as the need for reliable water management solutions and the importance of durable materials, this guide positions buyers to optimize their irrigation systems effectively.

With actionable advice and expert recommendations, readers will gain a clearer perspective on the global market for irrigation valves, enabling them to navigate their purchasing journey with confidence. Whether you are in the agricultural sector or involved in landscaping projects, this guide will equip you with the knowledge needed to enhance your irrigation systems and achieve sustainable results.

Understanding how to install a irrigation valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| In-Line Valves | Installed below ground, no backflow prevention | Large-scale agricultural irrigation systems | Pros: Discreet installation; less risk of damage. Cons: Requires more complex installation and maintenance. |

| Anti-Siphon Valves | Built-in backflow prevention, must be above ground | Residential and small commercial landscapes | Pros: Simple installation; prevents contamination. Cons: Aesthetic concerns; limited to certain applications. |

| Electric Control Valves | Operated electronically, often paired with timers | Automated irrigation systems in parks/gardens | Pros: Precision control; reduces labor. Cons: Dependence on electricity; potential for electronic failure. |

| Manual Control Valves | Operated manually, often with a lever or knob | Small farms and gardens | Pros: Low cost; easy to operate. Cons: Labor-intensive; less efficient for large areas. |

| Solenoid Valves | Uses electric solenoid for operation, quick response | Commercial irrigation systems | Pros: Fast activation; effective for large areas. Cons: Vulnerable to power outages; higher initial investment. |

What Are In-Line Valves and When Should B2B Buyers Consider Them?

In-line valves are typically installed below ground and do not include backflow prevention mechanisms. They are ideal for large-scale agricultural applications where aesthetics and damage from external elements are concerns. B2B buyers should consider these valves for extensive irrigation setups where seamless integration with existing systems is crucial. However, the complexity of installation and maintenance can be a drawback, requiring skilled labor for effective management.

How Do Anti-Siphon Valves Function in Irrigation Systems?

Anti-siphon valves feature built-in backflow prevention and must be installed above ground. They are particularly useful for residential and small commercial landscapes where preventing water contamination is paramount. Buyers should consider these valves for their ease of installation and effectiveness in safeguarding water supplies. However, their visibility can be a disadvantage in certain aesthetic-focused applications.

What Advantages Do Electric Control Valves Offer for B2B Irrigation Solutions?

Electric control valves are operated electronically and are often used in conjunction with irrigation timers. These valves are particularly beneficial for automated irrigation systems in parks and gardens, allowing for precision control of water distribution. While they significantly reduce labor costs and enhance operational efficiency, buyers must consider the dependency on electricity and the potential for electronic failures that could disrupt operations.

Why Choose Manual Control Valves for Smaller Irrigation Needs?

Manual control valves are straightforward, operated by hand via levers or knobs, making them a cost-effective solution for small farms and gardens. They are easy to operate and maintain, which can be appealing for businesses with limited irrigation needs. However, their labor-intensive nature and inefficiency for larger areas may deter buyers looking for scalable solutions.

How Do Solenoid Valves Enhance Commercial Irrigation Systems?

Solenoid valves utilize electric solenoids to control water flow, providing rapid activation for irrigation systems. They are well-suited for commercial applications, where large areas require efficient watering. The quick response time is a significant advantage, but B2B buyers should be aware of their vulnerability to power outages and the higher initial investment compared to manual systems.

Key Industrial Applications of how to install a irrigation valve

| Industry/Sector | Specific Application of how to install a irrigation valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Installing irrigation valves in crop fields | Enhanced water efficiency and crop yield | Compatibility with local water supply systems |

| Landscaping & Gardening | Setting up valves for residential and commercial landscapes | Improved aesthetics and water management | Availability of durable materials for local climates |

| Horticulture | Using valves in greenhouse irrigation systems | Precise water control for optimal growth | Adherence to regional agricultural standards |

| Golf Course Management | Installing valves for automated irrigation systems | Cost savings through reduced water usage | Quality of components to withstand heavy use |

| Municipal Water Systems | Implementing valves in public park irrigation systems | Efficient resource management for municipalities | Compliance with local regulations and standards |

How is ‘how to install an irrigation valve’ utilized in Agriculture?

In the agriculture sector, installing irrigation valves is crucial for optimizing water usage in crop fields. By effectively managing water flow, farmers can significantly enhance crop yields while minimizing wastage. Buyers in this sector must consider the compatibility of valves with local water supply systems and the specific irrigation needs of various crops, particularly in regions with variable climates, such as Africa and South America.

What are the implications for Landscaping & Gardening?

In landscaping and gardening, the installation of irrigation valves plays a pivotal role in maintaining the health and appearance of both residential and commercial properties. Properly installed valves allow for efficient water management, ensuring that plants receive the right amount of water without excessive runoff. Buyers should prioritize sourcing durable materials that can withstand local environmental conditions, especially in areas with extreme weather patterns.

How does Horticulture benefit from proper valve installation?

Horticulture relies heavily on controlled irrigation systems, where the installation of valves is essential for greenhouses. These valves enable precise water control, which is vital for the growth of delicate plants and flowers. For international buyers, particularly in Europe and the Middle East, it is critical to adhere to regional agricultural standards and practices to ensure compliance and maximize crop quality.

Why is valve installation important for Golf Course Management?

In golf course management, installing irrigation valves is integral to maintaining lush greens and fairways. Automated irrigation systems that utilize these valves can lead to significant cost savings through reduced water usage and labor. Buyers need to focus on the quality of components to ensure they can withstand the heavy use typical of golf courses, especially in regions where water conservation is a priority.

What role do valves play in Municipal Water Systems?

For municipal water systems, the installation of irrigation valves in public parks and recreational areas is essential for efficient resource management. These systems help municipalities manage water consumption effectively, ensuring that public spaces remain green and inviting. Key considerations for sourcing valves include compliance with local regulations and standards to avoid any legal issues while promoting sustainable water use in community spaces.

3 Common User Pain Points for ‘how to install a irrigation valve’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Components for Irrigation Valves

The Problem: Many B2B buyers encounter challenges when sourcing the right components compatible with their irrigation systems. This is particularly prevalent in regions where availability of specific brands and models varies significantly. For instance, a buyer in South America might purchase valves only to find that the associated fittings or adapters available locally do not match, leading to delays and additional costs in their irrigation projects.

The Solution: To mitigate this issue, buyers should conduct thorough research before making purchases. Creating a detailed inventory of required components, including specific valve models, fittings, and adapters, can streamline the procurement process. Engaging with suppliers who offer comprehensive product lines and ensuring they understand local standards and compatibility issues is crucial. Additionally, leveraging online platforms that provide real-time inventory updates can help buyers identify and source compatible products efficiently. Establishing relationships with local distributors can also ensure access to a range of components that meet international standards while accommodating local requirements.

Scenario 2: Installation Errors Due to Lack of Technical Knowledge

The Problem: A common pain point is the installation of irrigation valves without adequate technical knowledge, which can lead to significant errors. For example, buyers may misinterpret the valve orientation or fail to understand the necessity of backflow prevention devices. Such mistakes can result in system malfunctions, increased maintenance costs, and even damage to the irrigation infrastructure, particularly in regions with varying soil and climate conditions.

The Solution: To address this challenge, it’s essential for buyers to invest in comprehensive training for their installation teams. This can be achieved through workshops conducted by manufacturers or local experts who specialize in irrigation systems. Providing detailed, illustrated installation manuals that outline best practices can also be beneficial. Furthermore, utilizing video tutorials or virtual training sessions can enhance understanding and ensure that all team members are well-versed in installation techniques. Implementing a mentorship program where experienced technicians guide newer staff can also lead to better installation outcomes and increased confidence in handling complex installations.

Scenario 3: Inadequate Planning Leading to Accessibility Issues

The Problem: Many buyers overlook the importance of planning valve placement, which can create accessibility issues for maintenance and repairs. For instance, if the valve box is installed in an inconvenient location, it can hinder timely inspections or emergency repairs, leading to system downtime. This is especially critical for businesses that rely on irrigation for agricultural purposes, where every minute of downtime can result in financial losses.

The Solution: To circumvent this issue, buyers should prioritize the design phase of their irrigation systems. This includes strategically placing valve manifolds in easily accessible locations while considering the layout of the landscape. Conducting a site survey before installation can help identify optimal locations that balance accessibility and functionality. Additionally, incorporating a maintenance plan that includes regular checks of all components can ensure that any potential accessibility issues are addressed promptly. Engaging with landscape architects or irrigation specialists during the planning stage can provide valuable insights into effective valve placement and system design, ultimately leading to a more efficient and reliable irrigation system.

Strategic Material Selection Guide for how to install a irrigation valve

What Are the Best Materials for Installing Irrigation Valves?

When selecting materials for installing irrigation valves, it is crucial to consider their properties, advantages, disadvantages, and their suitability for specific applications. Here, we analyze four common materials used in the installation of irrigation valves: PVC, brass, stainless steel, and polyethylene. Each material has distinct characteristics that can influence performance, cost, and compliance with international standards.

How Does PVC Perform in Irrigation Valve Installations?

Key Properties: PVC (Polyvinyl Chloride) is known for its excellent chemical resistance, lightweight nature, and ease of installation. It typically operates effectively at temperatures up to 60°C and is suitable for low-pressure applications.

Pros & Cons: PVC is cost-effective and easy to handle, making it a popular choice for many irrigation systems. However, it can become brittle over time, especially when exposed to UV rays, leading to potential failures in outdoor applications. Its lower pressure rating compared to metals limits its use in high-pressure systems.

Impact on Application: PVC is compatible with a wide range of irrigation media, including water and some fertilizers. However, it is not suitable for hot water applications or for systems requiring high-pressure ratings.

Considerations for International Buyers: PVC standards vary globally, with common standards including ASTM in the USA and DIN in Europe. Buyers should ensure compliance with local regulations regarding material use, especially in regions with stringent environmental policies.

What Are the Advantages of Brass in Irrigation Valve Installations?

Key Properties: Brass offers excellent corrosion resistance and can handle high temperatures and pressures, making it suitable for various irrigation applications. It typically operates effectively at temperatures up to 120°C and has a high-pressure rating.

Pros & Cons: The durability of brass makes it ideal for long-term installations, particularly in harsh environments. However, it is more expensive than PVC and may require more complex manufacturing processes, which can increase overall project costs.

Impact on Application: Brass is compatible with most irrigation media, including potable water, and is often preferred in systems requiring high durability and reliability.

Considerations for International Buyers: Brass fittings must comply with specific standards such as ASTM and JIS. In regions like Europe, buyers should also consider lead-free options due to health regulations.

Why Choose Stainless Steel for Irrigation Valve Installations?

Key Properties: Stainless steel is highly resistant to corrosion and can withstand extreme temperatures and pressures, making it suitable for demanding environments. It operates effectively at temperatures exceeding 150°C and is ideal for high-pressure systems.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to rust and corrosion. However, it is the most expensive option among the materials discussed and may require specialized tools for installation.

Impact on Application: Stainless steel is compatible with a wide range of media, including aggressive chemicals and saline solutions, making it ideal for agricultural applications in coastal areas.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider the availability of stainless steel in their region, as it may be less common in some markets.

When Is Polyethylene the Best Choice for Irrigation Valve Installations?

Key Properties: Polyethylene (PE) is flexible, lightweight, and resistant to various chemicals, making it suitable for irrigation systems. It can handle temperatures up to 60°C and is often used in low-pressure applications.

Pros & Cons: The flexibility of polyethylene allows for easier installation and adaptation to various landscapes. However, it is less durable than metals and can be prone to damage from UV exposure and physical impacts.

Impact on Application: Polyethylene is compatible with water and many fertilizers, making it suitable for agricultural irrigation. However, its low-pressure rating limits its use in high-pressure systems.

Considerations for International Buyers: Polyethylene materials must comply with local standards, such as ASTM and ISO. Buyers should also consider the availability of high-density polyethylene (HDPE) for more demanding applications.

Summary Table of Material Selection for Irrigation Valve Installation

| Material | Typical Use Case for how to install a irrigation valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Residential irrigation systems | Cost-effective and easy to install | Brittle over time, lower pressure | Low |

| Brass | Commercial and high-pressure systems | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | Med |

| Stainless Steel | Industrial and high-temperature applications | Long-lasting and corrosion-resistant | Most expensive and requires special tools | High |

| Polyethylene | Agricultural irrigation systems | Flexible and lightweight | Less durable, UV exposure vulnerability | Low |

This analysis provides a comprehensive overview of materials used in irrigation valve installations, helping international B2B buyers make informed decisions based on their specific requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to install a irrigation valve

What Are the Main Stages of Manufacturing Irrigation Valves?

The manufacturing process for irrigation valves involves several key stages that ensure the final product meets the required standards of quality and functionality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used in Irrigation Valve Production?

The first step in the manufacturing process is the preparation of materials. Common materials for irrigation valves include brass, PVC, and high-density polyethylene (HDPE). These materials are chosen for their durability, resistance to corrosion, and ability to withstand various environmental conditions.

During material preparation, suppliers typically conduct a thorough analysis of raw materials to ensure they meet industry specifications. This includes testing for chemical composition, tensile strength, and resistance to temperature fluctuations. Buyers should verify that suppliers source materials from reputable manufacturers, as the quality of materials directly impacts the longevity and performance of the valves.

How Are Irrigation Valves Formed and Shaped?

Once materials are prepared, the next stage involves forming the components of the irrigation valves. This can be achieved through various techniques, including:

- Casting: For metal valves, casting is a common method where molten metal is poured into molds to create the desired shapes.

- Injection Molding: For plastic components, this technique involves injecting molten plastic into a mold, allowing for high precision and complex geometries.

- Machining: This involves cutting, drilling, and milling processes to achieve the final dimensions of valve components.

Each technique has its own set of advantages, and the choice often depends on the type of valve being manufactured and the specific requirements of the irrigation system.

What Is the Assembly Process for Irrigation Valves?

Following the forming stage, the assembly of the irrigation valves takes place. This process may involve several steps, including:

- Component Assembly: Individual parts such as the valve body, diaphragm, and solenoid are assembled. This may require precise alignment to ensure optimal functionality.

- Sealing: O-rings and other sealing components are installed to prevent leaks. Quality seals are crucial, especially in high-pressure systems.

- Final Assembly: The entire valve is assembled, ensuring that all components are securely fastened and properly aligned.

B2B buyers should inquire about the assembly processes used by suppliers, as automated assembly lines can enhance consistency and reduce the risk of human error.

What Finishing Techniques Are Employed in Irrigation Valve Manufacturing?

Finishing processes are critical for enhancing the durability and aesthetic appeal of irrigation valves. Common finishing techniques include:

- Surface Treatment: Processes such as anodizing or powder coating can provide additional protection against corrosion and wear.

- Quality Inspection: Each valve undergoes a visual and functional inspection to identify any defects or inconsistencies.

Buyers should look for suppliers that adhere to best practices in finishing to ensure that the valves will perform reliably in the field.

How Is Quality Assurance Implemented in Irrigation Valve Manufacturing?

Quality assurance (QA) is an essential component of the manufacturing process for irrigation valves. It ensures that the final products meet the required specifications and are safe for use.

What International Standards Govern Irrigation Valve Quality?

Several international standards can guide B2B buyers in assessing the quality of irrigation valves. The ISO 9001 standard focuses on quality management systems and is widely recognized across various industries. Suppliers adhering to this standard demonstrate their commitment to continuous improvement and customer satisfaction.

Additionally, industry-specific certifications such as CE marking (for compliance with European standards) and API standards (for valves used in oil and gas) provide further assurance of product quality.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is typically implemented at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to detect any issues early in the process.

- Final Quality Control (FQC): Before products are shipped, a comprehensive inspection is performed to ensure they meet all specifications and performance criteria.

B2B buyers should ask suppliers about their QC protocols to ensure that they maintain high-quality standards throughout the production process.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure the reliability of irrigation valves, B2B buyers should take proactive steps to verify the quality control measures of their suppliers. Here are some strategies:

What Documentation Should Buyers Request from Suppliers?

Buyers should request documentation related to quality control processes, including:

- Quality Management System (QMS) Certifications: Evidence of ISO 9001 or other relevant certifications.

- Test Reports: Documentation of testing results, including material tests and performance evaluations.

- Inspection Reports: Records of inspections conducted at various manufacturing stages.

How Can Buyers Conduct Supplier Audits?

Conducting supplier audits can provide valuable insights into a supplier’s manufacturing processes and quality control practices. Buyers can evaluate:

- Manufacturing Facilities: Assess the cleanliness, organization, and technology used in the manufacturing process.

- Employee Training: Ensure that staff are adequately trained in quality control procedures.

- Compliance with Standards: Verify that the supplier adheres to international and industry-specific standards.

What Testing Methods Are Commonly Used in Quality Assurance?

Quality assurance in the manufacturing of irrigation valves includes several testing methods to ensure product reliability:

- Pressure Testing: Valves are tested under pressure to ensure they can withstand operational conditions without leaking.

- Flow Testing: This assesses the flow rate and efficiency of the valve, ensuring it meets performance specifications.

- Durability Testing: Valves may undergo accelerated aging tests to evaluate their longevity under various environmental conditions.

These testing methods are crucial for ensuring that the valves will perform effectively in real-world applications.

What Are the Specific QC Considerations for International B2B Buyers?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, there are additional QC considerations to keep in mind:

- Regulatory Compliance: Different regions may have specific regulations governing irrigation systems. Buyers should ensure that their suppliers comply with local laws and standards.

- Cultural Differences: Understanding cultural nuances in business practices can enhance communication and collaboration with suppliers.

- Logistical Challenges: Buyers should be aware of potential logistical issues that may arise during shipping and customs clearance, which can impact delivery timelines and product integrity.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions and establish reliable partnerships with suppliers of irrigation valves.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to install a irrigation valve’

Introduction

This practical sourcing guide provides B2B buyers with a systematic approach to procuring the necessary components and understanding the installation process for irrigation valves. Whether you’re operating in Africa, South America, the Middle East, or Europe, following these steps will ensure you make informed decisions while sourcing and installing irrigation systems effectively.

1. Define Your Technical Specifications

Understanding the technical requirements of your irrigation system is crucial. This includes the type of valve (e.g., in-line or anti-siphon), flow rate, pressure rating, and material compatibility. A clear specification will help streamline the sourcing process and ensure the selected products meet your operational needs.

2. Research Local Regulations and Standards

Before proceeding with procurement, familiarize yourself with local regulations regarding irrigation systems. Compliance with these regulations can prevent costly fines and ensure safe operation. Consult local building codes and agricultural guidelines to ensure your system meets all legal requirements.

3. Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, product specifications, and references from buyers in similar industries or regions. Look for suppliers that have a strong reputation and proven experience in the irrigation sector.

- Check Certifications: Ensure suppliers have relevant certifications that affirm their compliance with international quality standards.

- Assess Product Availability: Confirm that suppliers can meet your demand in terms of product variety and quantities.

4. Request Samples and Product Demos

Before finalizing your order, request samples or product demonstrations. This allows you to assess the quality and functionality of the irrigation valves firsthand. Pay attention to the materials used, ease of installation, and overall design to ensure they align with your specifications.

5. Evaluate Pricing and Payment Terms

Compare pricing from different suppliers to ensure you are getting a competitive rate. Additionally, evaluate payment terms, including credit options and discounts for bulk purchases. Understanding the total cost of ownership, including installation and maintenance, will help you make a more informed decision.

6. Plan for Installation Logistics

Consider the logistics of installing the irrigation valves, including the necessary tools and labor. Determine whether you will handle the installation in-house or hire a professional service. Proper planning can reduce downtime and ensure a smoother installation process.

- Identify Required Tools: Make a checklist of tools needed for installation, such as wrenches, Teflon tape, and waterproof wire connectors.

- Schedule Installation: Coordinate installation timelines with your team or contractor to ensure availability and minimize disruptions.

7. Implement a Testing and Maintenance Plan

Once the irrigation system is installed, develop a testing and maintenance plan to ensure optimal performance. Regular checks will help identify potential issues early, prolonging the lifespan of the valves and the overall system.

- Establish a Maintenance Schedule: Set regular intervals for checking valve functionality and system integrity.

- Train Staff: Ensure that your team is trained in basic troubleshooting and maintenance procedures to handle minor issues independently.

By following these steps, B2B buyers can effectively navigate the process of sourcing and installing irrigation valves, ensuring a successful and compliant irrigation system tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for how to install a irrigation valve Sourcing

What Are the Key Cost Components for Installing an Irrigation Valve?

When considering the installation of an irrigation valve, several cost components must be evaluated to understand the overall expenditure. Key components include:

Materials: This encompasses the cost of the irrigation valve itself, piping, fittings, backflow prevention devices, and other necessary components such as shut-off valves and connectors. Prices can vary significantly based on material quality—brass and PVC are common, but brass offers better durability, particularly in harsh environments.

Labor: Labor costs can vary widely depending on the complexity of the installation and local wage rates. For example, hiring a skilled technician may be more expensive but can ensure the installation is performed correctly, reducing future maintenance costs.

Manufacturing Overhead: This includes costs associated with production, such as utilities, rent, and salaries of production staff. Understanding a supplier’s overhead can provide insights into their pricing strategy.

Tooling: If specialized tools are required for installation (e.g., soldering kits for copper pipes), these costs should be factored into the overall budget.

Quality Control (QC): Implementing quality control measures can add to the initial cost but is crucial for ensuring long-lasting, reliable irrigation systems. Investing in quality can prevent costly repairs and replacements down the line.

Logistics: Shipping and handling costs are vital, particularly when sourcing materials internationally. These costs can fluctuate based on distance, shipping methods, and current freight rates.

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding typical margins in your region can aid in evaluating pricing offers.

What Influences Pricing for Irrigation Valve Installation?

Several factors can influence pricing, particularly for international B2B buyers:

Volume/MOQ: Purchasing in bulk often leads to significant discounts. Understanding minimum order quantities (MOQ) can help buyers negotiate better prices.

Specifications and Customization: Custom or specialized valves may incur additional costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

Material Quality and Certifications: Higher-quality materials often come with a premium price. However, certifications can also add to costs. Buyers should weigh these factors against the expected lifespan and efficiency of the product.

Supplier Factors: The reputation, reliability, and location of suppliers can impact pricing. Established suppliers may offer better warranty terms and support, justifying a higher price.

Incoterms: Familiarity with international commercial terms (Incoterms) is essential for understanding responsibilities related to shipping, customs clearance, and delivery. These terms can significantly affect the total landed cost of goods.

What Are the Best Buyer Tips for Cost-Efficiency in Irrigation Valve Installation?

Negotiation: Always seek to negotiate pricing, especially for large orders. Many suppliers may have room for discounts that can significantly lower overall costs.

Total Cost of Ownership (TCO): Evaluate the TCO rather than just upfront costs. Consider long-term maintenance, energy efficiency, and replacement costs when choosing materials and suppliers.

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of exchange rates, import duties, and taxes that can affect the final cost. Understanding local market conditions and pricing trends can also provide leverage during negotiations.

Research and Compare Suppliers: Take the time to research multiple suppliers and compare their offerings. This can uncover better pricing options and ensure you select a supplier that meets your quality and service expectations.

Plan for Future Scalability: When installing irrigation systems, consider future needs and scalability. Investing slightly more in a modular system can save costs if expansion is anticipated.

Disclaimer on Indicative Prices

Prices for irrigation valves and associated installation costs can vary widely based on geographic location, supplier, and market conditions. This analysis provides a framework for understanding potential costs and pricing influences but should not be construed as definitive pricing. Always consult with local suppliers for the most accurate and relevant pricing information.

Alternatives Analysis: Comparing how to install a irrigation valve With Other Solutions

Introduction to Alternatives for Installing Irrigation Valves

When considering the installation of irrigation systems, various methods and technologies can achieve similar outcomes. While traditional irrigation valve installation is a popular approach, alternative solutions may offer different benefits, such as reduced labor, lower costs, or enhanced efficiency. This section explores how to install an irrigation valve in comparison to other viable solutions, helping B2B buyers make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | How To Install An Irrigation Valve | Smart Irrigation Controllers | Drip Irrigation Systems |

|---|---|---|---|

| Performance | Reliable control of water flow; requires manual setup | Automated adjustments based on weather data | Highly efficient water usage, reduces waste |

| Cost | Moderate initial investment; ongoing maintenance costs | Higher upfront cost; potential long-term savings | Variable costs based on system design and scale |

| Ease of Implementation | Requires plumbing knowledge; labor-intensive | Generally user-friendly; minimal installation required | Can be complex; needs careful planning and setup |

| Maintenance | Regular checks for leaks; moderate upkeep | Low maintenance; software updates needed | Requires regular monitoring and occasional component replacements |

| Best Use Case | Ideal for standard landscaping and lawn areas | Best for large-scale or variable environments (e.g., farms) | Excellent for gardens and areas with varying water needs |

Detailed Breakdown of Alternatives

Smart Irrigation Controllers

Smart irrigation controllers utilize advanced technology to automate the watering process based on real-time weather data and soil moisture levels. These systems can significantly reduce water consumption and ensure optimal plant health. However, the initial investment can be higher compared to traditional irrigation valves, which may deter some buyers. Nonetheless, the efficiency and potential long-term savings on water bills make this solution appealing for large-scale agricultural operations or commercial properties.

Drip Irrigation Systems

Drip irrigation is a method that delivers water directly to the roots of plants, minimizing evaporation and runoff. This solution is highly efficient and can be tailored to meet the specific needs of different plants. However, it requires careful planning and setup, which can be more complex than installing traditional irrigation valves. Additionally, while the initial costs may vary based on design and scale, the long-term benefits in water savings and improved plant health often justify the investment. Drip systems are particularly well-suited for gardens, greenhouses, and areas with varied plant requirements.

Conclusion: Choosing the Right Solution for Your Needs

When selecting an irrigation solution, B2B buyers should carefully consider their specific requirements, including the scale of the operation, budget constraints, and maintenance capabilities. Traditional irrigation valve installation offers reliability and control but may require more labor and expertise. In contrast, smart irrigation controllers and drip irrigation systems provide automation and efficiency, potentially reducing water usage and operational costs. By evaluating the performance, cost, ease of implementation, maintenance, and best use cases of each option, buyers can make informed decisions that align with their business goals and environmental considerations.

Essential Technical Properties and Trade Terminology for how to install a irrigation valve

What Are the Essential Technical Properties for Installing an Irrigation Valve?

When installing an irrigation valve, understanding the technical properties is crucial for ensuring efficiency, durability, and compliance with local regulations. Here are some critical specifications that B2B buyers should consider:

Material Grade

Irrigation valves are typically made from materials such as brass, PVC, or high-density polyethylene (HDPE). The material grade affects durability, resistance to corrosion, and overall lifespan. For example, brass valves are preferred for their strength and resistance to rust, making them suitable for various environments. Choosing the right material ensures a longer service life, reducing the need for frequent replacements and maintenance.Pressure Rating

Each valve is designed to operate at a specific pressure range, often measured in pounds per square inch (PSI). Understanding the pressure rating is essential to prevent leaks or failures. For B2B buyers, selecting a valve with an appropriate pressure rating ensures compatibility with the existing irrigation system, preventing costly damages and operational downtime.Flow Rate

The flow rate, usually measured in gallons per minute (GPM), indicates how much water can pass through the valve. Selecting a valve with the correct flow rate is critical for achieving optimal irrigation coverage. A mismatch can lead to inadequate watering or wastage, impacting crop yield and resource efficiency.Temperature Tolerance

Irrigation valves must withstand varying temperatures, particularly in regions with extreme climates. Temperature tolerance indicates the range of temperatures the valve can endure without deforming or failing. This property is vital for ensuring reliable operation and longevity, particularly in agricultural settings where conditions can fluctuate.Connection Type

The type of connection (e.g., threaded, slip, or flanged) determines how the valve integrates with the irrigation system. Understanding the connection type is essential for ensuring a proper fit and preventing leaks. For B2B buyers, specifying the right connection type can streamline installation processes and reduce labor costs.

What Trade Terminology Should B2B Buyers Know When Installing Irrigation Valves?

Familiarity with industry terminology can facilitate smoother transactions and communications. Here are some common terms relevant to irrigation valve installation:

OEM (Original Equipment Manufacturer)

An OEM produces parts or components that are used in another company’s end product. In the irrigation industry, purchasing from an OEM ensures that buyers receive high-quality, compatible components designed specifically for their systems.MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it can impact inventory management and cost-effectiveness when procuring irrigation valves for large projects.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For irrigation valve installations, submitting RFQs to multiple suppliers can help buyers compare costs and make informed purchasing decisions.Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Knowing the applicable Incoterms can help B2B buyers understand shipping costs, risks, and responsibilities associated with importing irrigation valves.Valve Manifold

A valve manifold is a system of valves that manage the flow of water to different areas of an irrigation system. Understanding how to correctly install and configure a valve manifold is crucial for efficient water distribution in agricultural and landscaping applications.Backflow Prevention

Backflow prevention is a mechanism that prevents contaminated water from flowing back into the clean water supply. This is a critical component in irrigation systems to comply with health regulations and ensure water quality. Understanding the importance of backflow prevention can help buyers select the right components for their systems.

By grasping these essential properties and terms, B2B buyers can make informed decisions that enhance the efficiency and reliability of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the how to install a irrigation valve Sector

What Are the Global Drivers and Key Trends Influencing the Irrigation Valve Installation Market?

The global irrigation valve installation market is driven by several key factors, including the increasing need for efficient water management systems, especially in regions facing water scarcity. In Africa and the Middle East, the demand for sustainable agricultural practices is pushing the adoption of advanced irrigation technologies. This trend is mirrored in South America, where agriculture plays a vital role in the economy, and in Europe, where stringent regulations on water usage are prompting the adoption of efficient irrigation solutions.

Emerging technologies such as smart irrigation systems, which leverage IoT (Internet of Things) for real-time monitoring and control, are reshaping the market landscape. B2B buyers are increasingly seeking systems that integrate automated valves with moisture sensors and weather forecasts to optimize water usage. Furthermore, the rise of e-commerce platforms facilitates easier access to a broader range of products and suppliers, enhancing competition and providing buyers with more options.

As international B2B buyers navigate this market, they should pay attention to local regulations and standards that may impact installation practices and product selection. Understanding regional variations in climate and agricultural practices is also crucial for making informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Impacting the Irrigation Valve Market?

Sustainability has become a cornerstone of the irrigation valve market, with a growing emphasis on reducing environmental impact. B2B buyers are increasingly prioritizing suppliers that adopt sustainable practices, such as utilizing recyclable materials and minimizing waste in their manufacturing processes. The importance of ethical supply chains cannot be overstated, as buyers look for transparency regarding the sourcing of materials and labor conditions in production facilities.

Certifications such as ISO 14001 for environmental management and the Rainforest Alliance certification for sustainable agricultural practices are becoming essential for suppliers looking to attract international buyers. Additionally, products that incorporate ‘green’ materials—such as valves made from recycled plastics or metals—are gaining traction. These certifications not only enhance the credibility of suppliers but also align with the values of socially responsible businesses.

As B2B buyers focus on sustainability, they can enhance their brand reputation and customer loyalty by aligning their procurement strategies with eco-friendly practices, thereby contributing to a more sustainable future for the agricultural sector.

What Is the Historical Context of Irrigation Valve Technology Development?

The evolution of irrigation valve technology can be traced back to the early 20th century when the need for efficient water distribution systems became paramount in agriculture. Initially, manual valves were the norm, requiring significant labor and oversight. Over the decades, technological advancements have led to the development of automatic and remote-controlled valves, significantly improving efficiency and ease of use.

The introduction of plastic materials in the 1960s revolutionized the industry by offering lightweight, durable, and cost-effective alternatives to traditional metal valves. This shift not only reduced installation and maintenance costs but also broadened access to irrigation systems for smallholder farmers, particularly in developing regions.

Today, the integration of digital technology and smart systems represents the latest phase in this evolution, enabling precision agriculture and more sustainable water management practices. As these technologies continue to advance, B2B buyers are presented with opportunities to invest in cutting-edge solutions that can enhance agricultural productivity and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of how to install a irrigation valve

1. How do I solve common installation issues with irrigation valves?

Common installation issues include leaks at connections, improper valve orientation, and inadequate pressure. To address leaks, ensure that Teflon tape or paste is used correctly on threaded connections, and tighten fittings appropriately. For valve orientation, confirm that the water flow direction matches the arrow on the valve body. If pressure is insufficient, check for blockages in the system or verify that the valve is compatible with your water supply specifications. Consulting local regulations and best practices can also prevent installation complications.2. What is the best type of irrigation valve for my project?

The best type of irrigation valve depends on your specific needs. For most applications, in-line valves are preferred for their durability and ease of installation, especially in areas with heavy foot traffic. Anti-siphon valves are ideal for preventing backflow and should be used in elevated installations. Consider the size of your irrigation system, the type of plants being watered, and local regulations when selecting valves. It’s advisable to consult with suppliers for recommendations based on your unique requirements.3. How do I ensure compliance with international trade regulations when sourcing irrigation valves?

To ensure compliance with international trade regulations, familiarize yourself with the import/export laws of your country and the country of origin of the irrigation valves. This includes understanding tariffs, customs duties, and any specific certifications required for irrigation equipment. Engage with a trade compliance expert or legal advisor who specializes in international trade to navigate these regulations effectively. Additionally, verify that suppliers provide necessary documentation, such as safety and quality certifications, to facilitate smooth customs clearance.4. What are the key factors to consider when vetting suppliers for irrigation valves?

When vetting suppliers for irrigation valves, consider their industry experience, product quality, and reliability. Check for certifications such as ISO 9001, which indicates a commitment to quality management. Request references from previous clients to gauge their satisfaction levels. Assess the supplier’s production capacity, lead times, and ability to customize products according to your needs. Lastly, ensure they have robust after-sales support and warranty policies to address any potential issues post-purchase.5. What is the minimum order quantity (MOQ) for irrigation valves, and how does it vary by supplier?

Minimum order quantities (MOQ) for irrigation valves can vary widely among suppliers, typically ranging from 50 to 500 units. Factors influencing MOQ include the supplier’s production capabilities, inventory levels, and the specific type of valve being ordered. It’s advisable to discuss your project needs directly with suppliers to negotiate MOQs, especially if you require a smaller batch for testing or pilot projects. Some suppliers may offer flexibility on MOQs for repeat orders or long-term contracts.6. What payment terms should I expect when purchasing irrigation valves internationally?

Payment terms for international purchases of irrigation valves typically include options such as advance payment, letters of credit, or payment upon delivery. It’s common for suppliers to request a deposit (often 30-50%) upfront, with the balance due upon shipment or delivery. Negotiate terms that suit your cash flow while ensuring the supplier feels secure in the transaction. Always confirm currency exchange rates and potential transaction fees, especially when dealing with international suppliers.7. How can I ensure quality assurance (QA) for irrigation valves sourced from suppliers?

To ensure quality assurance (QA) for irrigation valves, establish clear quality criteria with your suppliers before placing orders. Request samples for testing prior to bulk purchases to evaluate performance and durability. Implement regular inspections during production and upon arrival at your facility. Consider third-party quality control services to conduct audits and checks on suppliers’ manufacturing processes. Establish a feedback loop with your suppliers to address quality concerns promptly and maintain high standards.8. What logistics considerations should I keep in mind when importing irrigation valves?

When importing irrigation valves, consider logistics factors such as shipping methods, lead times, and customs clearance. Choose a reliable freight forwarder experienced in handling agricultural equipment to ensure timely delivery. Factor in potential delays due to customs inspections, especially in regions with stringent import regulations. Additionally, assess warehousing needs upon arrival and determine whether your supply chain can accommodate just-in-time inventory to optimize costs and reduce storage requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 How To Install A Irrigation Valve Manufacturers & Suppliers List

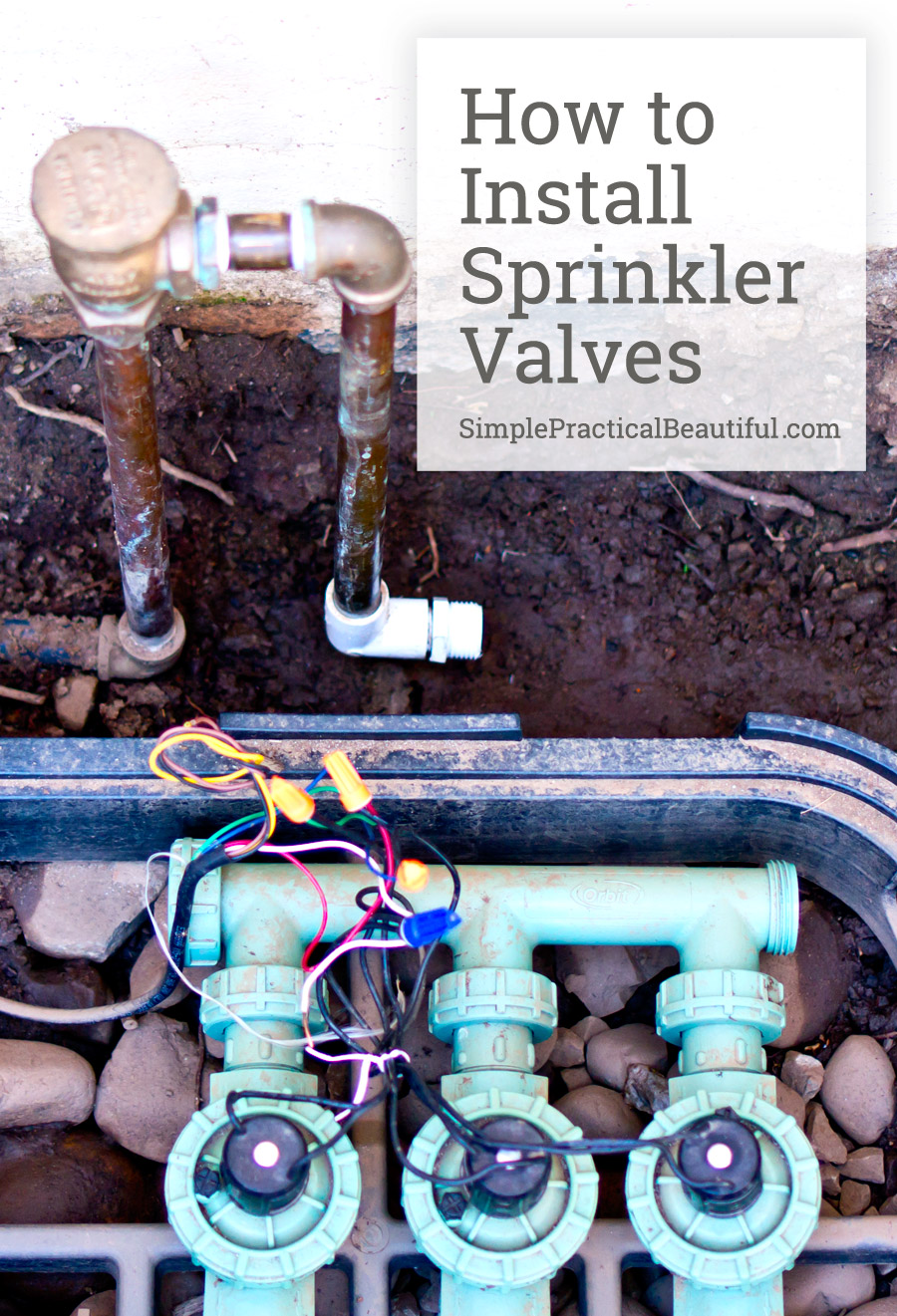

1. Simple Practical Beautiful – Water Supply Solutions

Domain: simplepracticalbeautiful.com

Registered: 2015 (10 years)

Introduction: 1. Water Supply Connection: Utilized a hose bib as the water supply, replaced an elbow joint with a T connection for water flow. 2. Shut-off Valve: Added a shut-off valve with a yellow handle to control water flow without shutting off the entire house. 3. Backflow Prevention Device: Required to prevent contamination of the water supply, installed above the sprinkler valves. 4. Sprinkler Valves: Ch…

2. Lawn Genie – Sprinkler Valve

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Lawn Genie sprinkler valve, Rain Bird valve, PTFE tape, RectorSeal T plus 2, 3/4 inch size, anti-siphon feature, no O-ring on female side.

3. Sprinkler Warehouse – Anti-Siphon & In-Line Valves

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Anti-Siphon Valve: Backflow prevention valve, must be installed above ground, check local building codes. In-Line Valve: Installed below ground in a protective valve box, requires gravel at the bottom, ensure valve box is level with the ground. Valve Inlet Size: 3/4″ for under 10 GPM, 1″ for above 10 GPM. Recommended to group valves into manifolds based on use or location. Include extra connection…

4. Rainbird – Sprinkler System Installation

Domain: rainbird.com

Registered: 1995 (30 years)

Introduction: Sprinkler system installation involves several key components and steps: 1. **Sprinkler Locations**: Place stakes or flags at each sprinkler location as per the layout. 2. **Trenching**: Dig trenches 6 to 12 inches deep, marking sprinkler locations. Use water pressure to run pipes under walkways. 3. **Water Supply Connection**: Ensure proper connections as per local codes. 4. **Valve Manifold Asse…

5. Rain Bird – 100DVFSS Valve

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Valves: Rain Bird 100DVFSS – 1 in. Slip x Slip ‘Street’ elbows (one end is male, other end is female); Supplies: Solvent glue, Hacksaw (preferably with an extending blade), Irrigation wire nuts (or house wiring nuts with hot melt glue), Optional: 1in to 3/4in reducing bushings if you have 1in supply and 3/4 sprinkler lines.

6. The Spruce – Sprinkler Valve Replacement Guide

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Working Time: 1 hr, 30 mins; Total Time: 1 – 2 hrs; Skill Level: Intermediate; Estimated Cost: $20 to $40; Yield: Replace one sprinkler valve; Common symptoms of a faulty valve: Valve leaks, Poor water flow, Heads that don’t work; Equipment/Tools needed: Reciprocating saw, PVC pipe cutter or hacksaw, Utility knife or sandpaper, Tongue-and-groove pliers; Materials needed: New sprinkler valve, PVC M…

7. Making Manzanita – Sprinkler Solutions

Domain: makingmanzanita.com

Registered: 2017 (8 years)

Introduction: Timer & Sprinkler Wire, Sprinkler Valve, Manifold, Tubing (Schedule 40 PVC), Swing Pipe, Backflow Preventer, Sprinkler Heads

8. Pinterest – Sprinkler Valve Installation Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Sprinkler valve installation DIY, Sprinkler valve parts diagram, Champion Irrigation Valve Repair Kit, Irrigation system DIY, Lawn sprinkler system.

9. WikiHow – Sprinkler Head Types

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: 1. Gear-driven rotor sprinkler head: Covers wide areas, adjustable spray distance of 8–65 feet (2.4–19.8 m). 2. Shrub heads or bubblers: Emit low-level stream of water, cover about 3 square feet (0.28 m²), work only on flat ground. 3. Fixed pop-up heads: Spray water in a half-circle, suitable for areas adjacent to buildings, spray distance of about 10 feet (3.0 m).

Strategic Sourcing Conclusion and Outlook for how to install a irrigation valve

What Are the Key Takeaways for Installing an Irrigation Valve?

In conclusion, successfully installing an irrigation valve hinges on meticulous planning, adherence to local regulations, and sourcing quality materials. B2B buyers should prioritize strategic sourcing to ensure they acquire durable, high-performance components that meet their specific irrigation needs. Considerations such as valve placement, water supply connections, and backflow prevention are critical to achieving an efficient and reliable irrigation system.

How Can Strategic Sourcing Benefit Your Irrigation Projects?

Investing in quality irrigation valves and related components not only enhances system longevity but also minimizes maintenance costs in the long run. International buyers, particularly from Africa, South America, the Middle East, and Europe, should engage with reputable suppliers who can provide tailored solutions and support.

What’s Next for Your Irrigation Solutions?

As global demand for sustainable agricultural practices grows, the importance of efficient irrigation systems cannot be overstated. Embrace innovative technologies and solutions in your procurement strategy to remain competitive. Take action now—evaluate your current irrigation setup and consider how strategic sourcing can elevate your operations to meet future challenges.