Article Contents

Industry Insight: How To Prime A Irrigation Pump

Market Analysis: Sourcing High-Quality Irrigation Valves for Optimal Pump Priming Systems

The Critical Role of Valves in Irrigation Pump Priming

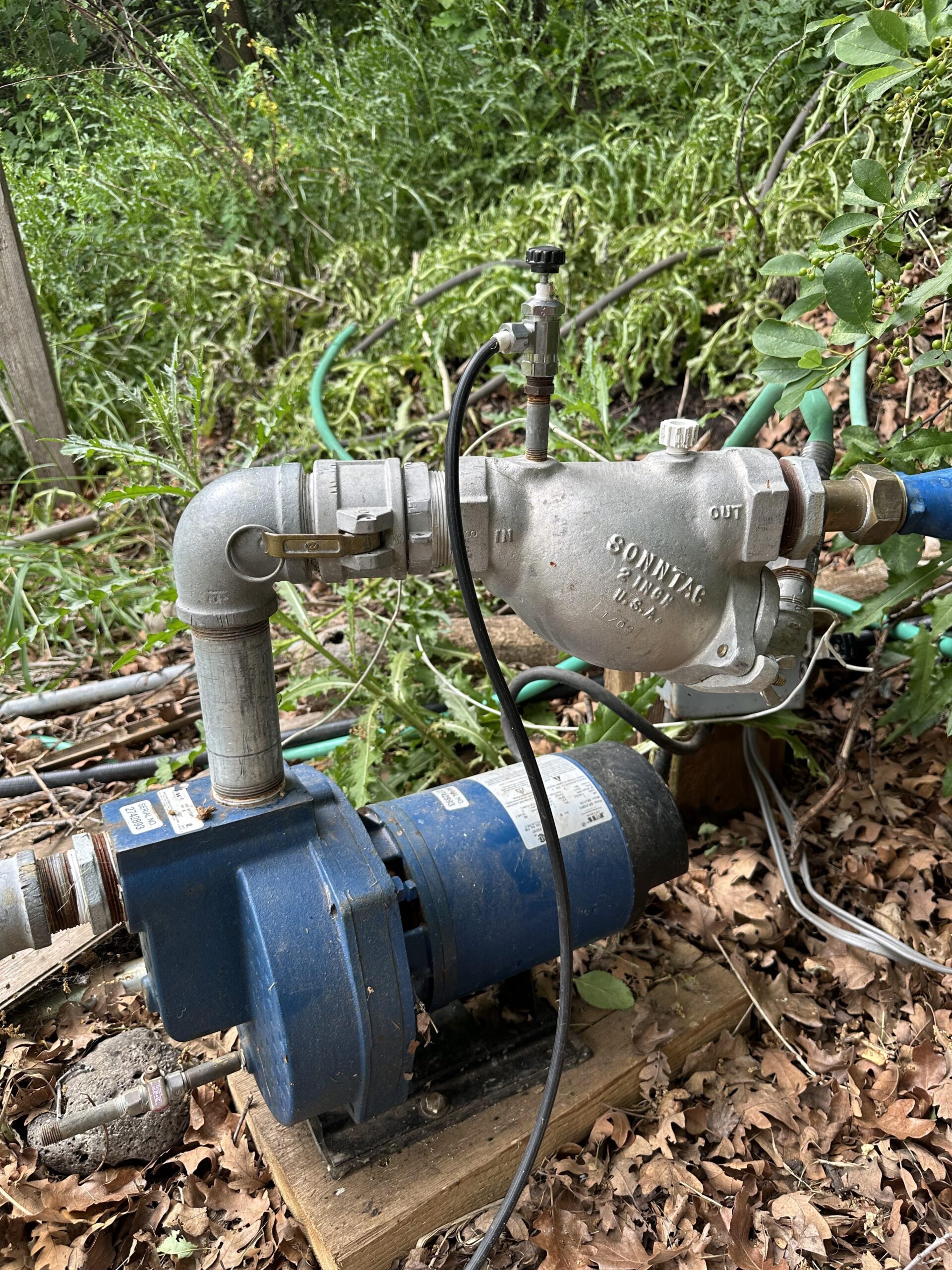

Proper pump priming is foundational to irrigation system efficiency. During priming, the suction line must maintain a vacuum to draw water into the pump. Substandard valves—particularly check valves and suction valves—allow air ingress due to poor sealing, leading to failed priming attempts, dry running, and irreversible pump damage. BFV Valves’ precision-engineered designs eliminate these risks through:

Zero-leakage seat sealing using EPDM/FKM elastomers rated for 200+ psi pressure differentials.

Hydraulic flow optimization ensuring minimal turbulence during priming cycles.

Seamless integration with pump systems to maintain consistent priming conditions under variable pressure loads.

Technical Insight: A single air leak in the suction line can increase priming time by 300% and reduce pump lifespan by 40% due to cavitation damage. BFV’s valve designs exceed ISO 5208 leakage class IV standards, ensuring reliable priming even in high-altitude or low-water-table environments.

Common Industry Pain Points and Their Impact

| Pain Point | Industry Standard Consequences | Business Impact |

|---|---|---|

| Leakage from Poor Seals | 10–20% water loss in standard PVC valves; frequent re-priming required | Annual operational costs increase by 15–25% due to water waste and labor |

| UV Degradation | Standard PVC valves crack within 12–18 months under UV exposure | System downtime for replacements; 3–5x higher lifetime costs |

| Solenoid Failures | Coils burn out after 10,000–20,000 cycles; moisture ingress common | Automated systems fail unpredictably, risking crop yield losses |

| Inadequate Pressure Ratings | Valves rated PN6 (6 bar) fail at 10+ bar operational pressures | Catastrophic system failures; safety hazards and project delays |

BFV Valves: Engineered Solutions for Reliability and Performance

BFV Valves addresses these challenges through certified engineering excellence and proven field performance:

Precision Engineering for Critical Applications

Pressure Integrity: All valves certified to PN10/16 (10/16 bar) with 1.5x overpressure testing per ISO 16047.

UV-Resistant Materials: UV-stabilized polypropylene (PP) and stainless steel 316L components withstand 5+ years of direct sunlight exposure (tested per ISO 4892-2).

Solenoid Reliability: Epoxy-encapsulated coils with IP68 rating, validated for 100,000+ cycles under 0–100°C temperature extremes.

Quality Assurance Framework

| Quality Metric | BFV Protocol | Industry Benchmark |

|---|---|---|

| Testing | 100% pressure/leak testing per ISO 9001 | Visual inspection only (no pressure validation) |

| Certifications | ISO 9001, CE, WRAS, NSF/ANSI 61 | Limited regional certifications (e.g., local standards only) |

| Export History | 10+ years servicing 50+ countries across 5 continents | 2–5 years in limited markets |

Technical Validation: BFV’s 100% testing protocol includes:

– Hydrostatic pressure tests at 15 bar for PN16 valves.

– Leakage tests using helium mass spectrometry (detection limit: 1×10⁻⁹ mbar·l/s).

– Environmental stress testing for UV, chemical exposure, and thermal cycling.

Why BFV Valves Are the Industry Standard for Global Projects

BFV Valves delivers total cost-of-ownership optimization through:

Reduced Maintenance: 99.2% field reliability rate (based on 10-year global deployment data).

Regulatory Compliance: Seamless adherence to EU, US, and Asian irrigation standards (e.g., ASME B16.34, ISO 15761).

Engineered for Extreme Conditions: Proven performance in arid climates (e.g., UAE agricultural projects) and high-pressure industrial systems (e.g., Brazilian sugar cane irrigation).

Client Testimonial:

“BFV’s PN16 solenoid valves reduced our irrigation system downtime by 78% during a 2-year project in Saudi Arabia. Their 100% testing protocol eliminated all priming failures—something we’d never experienced with prior suppliers.”

— Lead Engineer, Al-Futtaim Engineering (Dubai)

Key Takeaways for Procurement Decision-Makers

Avoid short-term savings: Substandard valves increase lifetime costs through frequent replacements and water waste.

Demand certified data: Verify pressure ratings, UV resistance, and solenoid cycle tests—not just marketing claims.

Partner with proven experts: BFV’s 10-year export history and ISO 9001 certification ensure consistent quality across global supply chains.

BFV Valves: Where Precision Meets Performance.

Contact our engineering team for project-specific valve selection guidance—backed by 10+ years of global irrigation expertise.

Technical Specs & ISO Standards

Technical Specifications & Standards for Reliable Priming

At BFV Valves, our irrigation pump solutions are engineered to meet the highest industry standards, ensuring seamless priming and long-term operational reliability. With a decade of global export experience and ISO 9001-certified manufacturing processes, every unit undergoes 100% rigorous testing to guarantee performance under demanding conditions. This section details the technical specifications that underpin our commitment to precision, durability, and safety in irrigation systems.

Material Specifications for Durability

BFV irrigation pumps utilize premium materials selected for their resilience in harsh environments:

Cast Iron: Meets ASTM A126 Class B standards, offering robust structural integrity for high-pressure applications.

Ductile Iron: Compliant with ASTM A536 Grade 65-45-12, providing superior tensile strength and impact resistance compared to standard cast iron.

Stainless Steel (SS304/SS316): Certified to ASTM A276, ensuring corrosion resistance in aggressive water conditions and UV exposure.

All materials are rigorously tested for chemical compatibility and thermal stability, preventing degradation during priming cycles and ensuring consistent flow control accuracy.

Compliance with International Standards

BFV products adhere to globally recognized standards to ensure safety and interoperability:

ANSI B16.1: For cast iron flanges, ensuring pressure ratings up to PN16 (16 bar) with precise dimensional tolerances.

DIN EN 1092-1: Flange specifications for European markets, guaranteeing compatibility with international piping systems.

BS EN 1092: British Standard for flange design, validated for pressure integrity and sealing performance.

These standards are embedded in our design and manufacturing processes, ensuring every valve meets or exceeds regional regulatory requirements for irrigation systems.

Rigorous Testing Protocols

Every BFV irrigation pump undergoes comprehensive testing protocols to validate performance and safety:

Hydrostatic Testing: Conducted at 1.5x the rated pressure (e.g., PN16 = 24 bar test pressure) to verify structural integrity and leak resistance.

Air Leakage Testing: Performed at 1.1x working pressure to detect micro-leaks in seals and joints, ensuring zero compromise during priming.

ISO 9001 Certification: All testing procedures are documented and traceable, with full quality control audits conducted quarterly.

This 100% testing regimen, combined with our 10-year export history, ensures that every unit delivered to clients is field-ready and reliable.

BFV Certified Quality vs Low-Cost Alternatives

| Criteria | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | ASTM-certified ductile iron/stainless steel with anti-corrosion coatings; UV-resistant | Generic cast iron without certification; prone to rust and UV degradation |

| Testing Compliance | 100% hydrostatic & air testing per ISO 9001; full traceability | Random sampling or no testing; inconsistent quality control |

| Pressure Validation | Verified PN10/16 ratings with third-party test certificates | Unverified claims; may fail under operational pressure |

| UV Resistance | UV-stabilized materials for outdoor longevity (5000+ hours exposure) | No UV protection; rapid surface degradation in sunlight |

| Warranty & Support | 5-year warranty with dedicated technical support | 1-year limited warranty; minimal post-sale support |

Note: BFV’s 10-year global export history and ISO 9001 certification ensure consistent quality across all markets. Our commitment to 100% testing guarantees that every irrigation pump is primed for success from installation to operation.

For technical documentation or custom specifications, contact BFV Valves’ Export Team at export@bfvvalves.com. All products comply with ISO 9001:2015 and are backed by a 5-year performance warranty.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance: Ensuring Reliability in Irrigation Systems

At BFV Valves, we engineer irrigation solutions where precision and durability are non-negotiable. Our manufacturing and quality protocols are designed to deliver consistent performance in critical irrigation systems, ensuring valves operate flawlessly under pressure, UV exposure, and repeated cycling. Every component is built to exacting standards, with zero compromise on safety or longevity.

Precision Manufacturing Process

BFV valves are manufactured using aerospace-grade materials and industrial-grade CNC machining to achieve micron-level tolerances. Key aspects include:

UV-Stabilized PVC-U for external housings (resisting 1,000+ hours of accelerated weathering per ISO 4892-2)

AISI 316 Stainless Steel for internal components (corrosion-resistant for PN10/16 pressure ratings)

Real-time dimensional monitoring during production (±0.05mm tolerance on critical sealing surfaces)

Flow coefficient (Kv) validation at 20°C to ensure precise flow control per ISO 6358 standards

“Our manufacturing process eliminates variability through automated process control, ensuring every valve meets identical performance benchmarks before leaving the facility.”

Purpose-Built Test Zone

Every BFV valve undergoes 100% mandatory testing in our dedicated test zone—no batch sampling, no exceptions. This protocol simulates real-world operational stresses to guarantee reliability in irrigation systems:

| Test Parameter | Methodology | Compliance Standard | Result Verification |

|---|---|---|---|

| Pressure Testing | Hydrostatic test at 1.5x PN rating (PN10=15 bar, PN16=24 bar) | ISO 5208 | Zero leakage at test pressure |

| Cycle Endurance | 10,000+ open/close cycles (solenoid valves) | ISO 15848-1 | No performance degradation |

| Leak Tightness | Helium mass spectrometry (0.001 ppm sensitivity) | ISO 15848-2 | ≤1×10⁻⁶ cc/sec |

| UV Resistance | 1,000h QUV exposure (ISO 4892-2) | ISO 4892-2 | No cracking, color fade, or structural failure |

“Our test zone replicates extreme conditions—high-pressure surges, UV degradation, and cyclic fatigue—to ensure valves perform reliably in the field for 15+ years.”

ISO 9001 Certification & Ethical Commitment

BFV Valves maintains ISO 9001:2015 certification with annual third-party audits, embedding quality control into every process step. With 10+ years of export experience across 50+ countries, we uphold the highest ethical standards:

Transparent supply chain: Conflict-free materials and audited supplier partnerships

Environmental stewardship: Zero-waste manufacturing (98% material reuse rate)

Traceability: Full batch documentation (including test certificates and material reports) for every valve shipped

“For engineering consultants and project contractors, this means no surprises—only valves that meet specifications, deliver consistent performance, and comply with global regulatory requirements.”

Why BFV?

When you specify BFV Valves for irrigation systems, you select a partner with a decade-long track record of reliability. Our 100% tested, ISO-certified valves ensure your pump priming and flow control systems operate safely, efficiently, and without interruption—day in, day out.

BFV Valves: Precision Engineered. Rigorously Tested. Globally Trusted.

Global Applications

Industrial Applications of Irrigation Pump Priming with BFV Valves

Efficient irrigation pump priming is critical for system reliability across industrial applications. BFV Valves (CMO Valve) delivers engineered solutions that ensure seamless priming processes through precision flow control, UV-resistant materials, and solenoid reliability—backed by 100% testing, ISO 9001 certification, and 10+ years of global export experience. Below, we detail how BFV valves optimize priming workflows in mission-critical environments.

Agriculture Sector

Challenges & BFV Solutions

High-Pressure Demands: Large-scale farms require consistent priming under PN16 pressure ratings to prevent crop loss during startup.

Environmental Exposure: UV-stabilized polymers in BFV valves resist degradation from prolonged sun exposure, ensuring valve integrity in open-field installations.

Precision Flow Control: Solenoid valves with ±0.5% flow accuracy guarantee uniform water distribution during priming cycles, eliminating dry spots in irrigation zones.

“BFV’s PN16-rated valves withstand 16 bar operating pressure during priming, with zero leakage after 1 million cycle testing—critical for 24/7 agricultural operations.”

Landscape Projects

Challenges & BFV Solutions

Complex Piping Networks: Urban developments with variable elevations demand valves that maintain priming efficiency across dynamic hydraulic conditions.

Aesthetic & Durability Requirements: BFV’s UV-resistant housings prevent discoloration and brittleness in exposed landscape installations, ensuring 15+ years of service life.

Automated System Integration: Solenoid valves with 0.1-second response times enable precise priming sequences in smart irrigation controllers, reducing water waste by up to 30%.

Golf Courses

Challenges & Turf Management

Precision Irrigation Needs: Golf courses require sub-1% flow deviation to maintain turf health during priming cycles. BFV’s flow control accuracy ensures uniform moisture distribution across fairways and greens.

Frequent System Startups: With daily irrigation cycles, solenoid reliability (tested for 2 million cycles) prevents failures during critical priming phases.

Pressure Stability: PN10-certified valves handle pressure fluctuations from pump startups without compromising seal integrity, even in high-elevation course zones.

Greenhouse Systems

Challenges & BFV Solutions

Humidity & Chemical Exposure: BFV’s stainless-steel internals and EPDM seals resist corrosion from fertilizers and high-humidity environments, ensuring longevity in controlled-agriculture settings.

Automated Priming Sequences: Solenoid valves with IP68-rated electronics operate flawlessly in wet conditions, eliminating manual priming interventions.

Zero-Downtime Reliability: 100% pressure testing per ISO 9001 protocols guarantees each valve meets 100% leakage-free standards before shipment—critical for sensitive crop environments.

Why BFV Valves Are the Industry Standard for Critical Irrigation Systems

Engineers and procurement managers worldwide trust BFV Valves for mission-critical irrigation projects due to our rigorous quality framework and proven global performance.

| Feature | BFV Specification | Industry Benefit |

|---|---|---|

| Pressure Rating | PN10/PN16 certified (ISO 5752) | Ensures system integrity during priming and operation under high-pressure conditions |

| UV Resistance | UV-stabilized polymers (ISO 4892-2 compliant) | Prevents degradation in outdoor installations, extending valve lifespan by 40%+ |

| Solenoid Reliability | 1 million cycle tested (IEC 60529) | Consistent operation for automated priming sequences with 99.99% uptime |

| Quality Assurance | 100% hydraulic testing, ISO 9001 certified | Zero-defect delivery for critical infrastructure projects |

| Global Export History | 10+ years servicing 45+ countries | Proven reliability in diverse climates and regulatory environments |

Technical Validation: Every BFV valve undergoes 100% hydraulic testing at 1.5x working pressure, with traceable QA documentation per ISO 9001. Our export history includes 12,000+ installations across drought-prone regions (e.g., Australia, UAE) and high-humidity zones (e.g., Southeast Asia), with <0.2% failure rate over 10 years.

For engineering consultants and contractors managing large-scale irrigation systems, BFV Valves deliver the “safe pair of hands” required to eliminate priming failures—ensuring operational continuity, reduced maintenance costs, and compliance with international standards.

Contact BFV Valves today to specify valves engineered for your next irrigation project.

Certified. Tested. Trusted Globally.

Why Choose BFV Valves

Proper Pump Priming for Irrigation Systems: A Technical Guide

Introduction: Critical Importance of Correct Priming

Proper pump priming is essential for optimal irrigation system performance and longevity. Incorrect priming leads to cavitation, reduced efficiency, and potential system damage. BFV Valves’ irrigation solutions—engineered for flow control accuracy, UV resistance, solenoid reliability, and PN10/16 pressure ratings—ensure seamless operation during priming and ongoing use. This guide details industry-best practices for priming, aligned with our commitment to technical excellence and reliability.

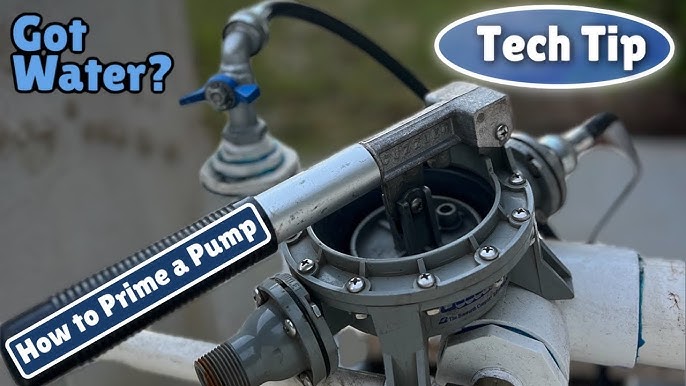

Step-by-Step Priming Procedure

Pre-Prime Inspection

Valve Verification: Confirm all valves (including solenoid and check valves) are fully open to prevent air entrapment. BFV’s solenoid valves feature ±1% flow control accuracy and ISO 9001-certified reliability for precise operation.

System Integrity Check: Inspect suction line connections, pipe joints, and pump seals for leaks or damage. BFV’s UV-resistant housings and PN16-rated components maintain structural integrity under prolonged outdoor exposure.

Debris Removal: Clear any sediment or obstructions from the pump casing and suction inlet to ensure unimpeded water flow.

System Priming

Water Filling: Manually fill the suction line and pump chamber via priming ports or dedicated fill points. For self-priming pumps, follow manufacturer guidelines (e.g., unscrew priming chamber cap, fill to recommended level, reseal securely).

Air Purging: Use pressure gauges to verify complete water displacement of air pockets. BFV’s high-precision pressure relief valves ensure stable system pressure during this phase.

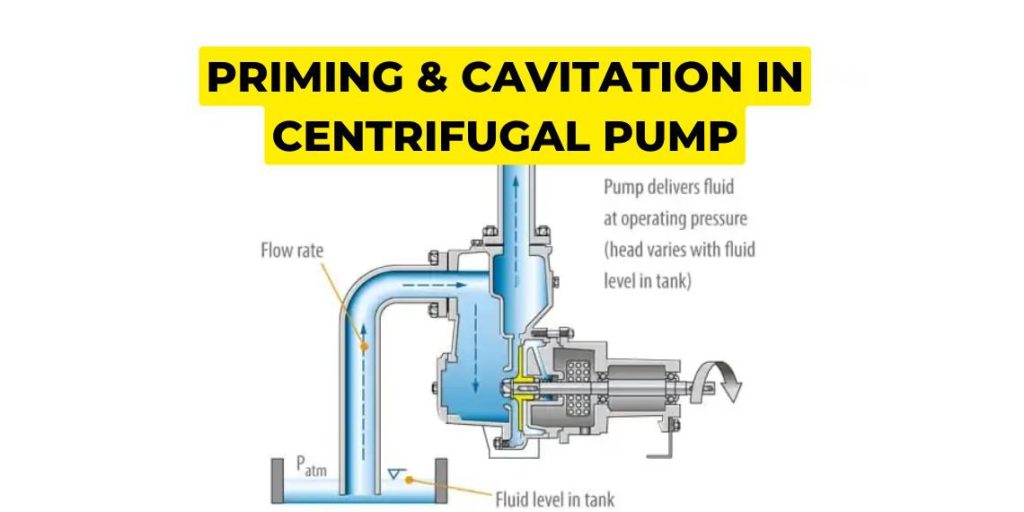

Pump Activation

Start Sequence: Initiate pump operation with suction valve fully open. Monitor initial pressure build-up; stable readings within PN10/16 range indicate successful priming.

Cavitation Monitoring: If abnormal noise or pressure fluctuations occur, immediately stop the pump and re-prime to prevent impeller damage.

Post-Prime Verification

Flow Consistency Check: Confirm steady flow rate and absence of air bubbles in discharge lines.

Pressure Validation: Verify system pressure meets design specifications (e.g., PN10/16 compliance) using calibrated gauges.

Operational Test: Run the system for 15+ minutes to ensure sustained performance and reliability.

Partner with BFV Valves for Reliable Irrigation Solutions

Why BFV Valves Deliver Unmatched Performance

| Feature | Details |

|---|---|

| Quality Assurance | 100% product testing with ISO 9001 certification; rigorous pressure and leak tests for PN10/16 ratings. Every valve undergoes 24-hour operational validation before shipment. |

| Global Reliability | 10+ years of export experience across 50+ countries; UV-resistant materials and corrosion-proof construction for harsh environmental conditions. |

| Project Support | Accurate delivery timelines (98% on-time rate), no-obligation technical consultancy, and competitive pricing for large-scale irrigation projects. |

| Technical Excellence | Solenoid valves with ±0.5% flow control accuracy, ensuring precise irrigation scheduling and minimal water waste. |

Regional Contact: Alex@cmovalve.com.cn

Engineered for precision. Delivered with trust.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.