Introduction: Navigating the Global Market for how to replace solenoid irrigation valve

In today’s rapidly evolving global market, understanding how to effectively replace a solenoid irrigation valve is critical for maintaining efficient water management systems. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, sourcing the right replacement components can be a daunting task. Common challenges include identifying suitable valve types, navigating diverse applications, and ensuring compliance with local standards—all while managing costs and supplier relationships.

This comprehensive guide serves as a vital resource for decision-makers involved in irrigation system maintenance and upgrades. It offers detailed insights into various solenoid valve types, their specific applications, and essential installation techniques. Additionally, the guide outlines key considerations for vetting suppliers, evaluating product quality, and understanding pricing structures. By empowering buyers with actionable knowledge, this guide enables informed purchasing decisions that not only enhance operational efficiency but also contribute to sustainable water usage practices.

As you navigate the complexities of the irrigation market, this guide will help you overcome common obstacles, ensuring that your procurement process is both streamlined and effective. Whether you are in Vietnam, Brazil, or anywhere in between, the insights provided here will facilitate a more strategic approach to sourcing solenoid irrigation valves, ultimately leading to improved system performance and customer satisfaction.

Understanding how to replace solenoid irrigation valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bolt-Down Valves | Secured with bolts, offering a robust seal | Commercial landscaping, agricultural use | Pros: Durable; Cons: Time-consuming to install. |

| Jar-Top Valves | Easy access for maintenance; top-opening design | Residential gardens, small farms | Pros: Quick repairs; Cons: Less durable under pressure. |

| Electric Solenoid Valves | Operated by electrical signals; various voltages | Automated irrigation systems | Pros: Efficient; Cons: Requires electrical knowledge for installation. |

| Manual Control Valves | Operated manually without electrical components | Small-scale irrigation, DIY projects | Pros: Simple operation; Cons: Labor-intensive. |

| Pressure Regulating Valves | Maintains consistent water pressure | High-pressure irrigation systems | Pros: Prevents system damage; Cons: Higher initial cost. |

What Are Bolt-Down Valves and When Should They Be Used?

Bolt-down valves are characterized by their secure fastening mechanism, which involves bolts that ensure a tight seal. These valves are particularly suitable for commercial landscaping projects and agricultural applications where durability is crucial. When purchasing, consider the valve’s material and pressure ratings, as these will influence its longevity and performance in demanding environments. While they offer exceptional durability, the installation process can be more time-consuming compared to other valve types.

How Do Jar-Top Valves Enhance Maintenance Efficiency?

Jar-top valves feature a design that allows easy access to internal components for maintenance and repairs. This type of valve is ideal for residential gardens and small farms, where quick fixes can save time and labor costs. Buyers should evaluate the compatibility of jar-top valves with existing systems and their overall durability, especially in variable weather conditions. While they provide convenience, they may not withstand high-pressure scenarios as effectively as bolt-down alternatives.

What Advantages Do Electric Solenoid Valves Offer for Automated Irrigation?

Electric solenoid valves are controlled by electrical signals, making them suitable for automated irrigation systems. These valves can be programmed for precise water distribution, optimizing resource use. B2B buyers should consider the voltage specifications and compatibility with existing systems when selecting electric solenoid valves. Although they enhance efficiency and convenience, proper electrical knowledge is essential for installation and maintenance, which could pose a challenge for some operators.

Why Choose Manual Control Valves for Small-Scale Applications?

Manual control valves operate without electrical components, making them straightforward to use and maintain. They are well-suited for small-scale irrigation systems or DIY projects where simplicity is key. Buyers should assess the labor requirements, as manual operation can be more labor-intensive than automated systems. While these valves are easy to install, they may not be suitable for larger operations that require automated solutions.

How Do Pressure Regulating Valves Protect Irrigation Systems?

Pressure regulating valves are designed to maintain consistent water pressure across irrigation systems, preventing potential damage from high pressure. These valves are particularly valuable in high-pressure irrigation setups, such as those found in commercial agriculture. When purchasing, buyers should consider the pressure settings and flow rates to ensure compatibility with their systems. Although they represent a higher initial investment, the long-term savings from reduced damage and maintenance can be significant.

Key Industrial Applications of how to replace solenoid irrigation valve

| Industry/Sector | Specific Application of how to replace solenoid irrigation valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Replacing solenoid valves in large-scale irrigation systems | Enhances water efficiency, reduces crop loss due to over/under watering | Compatibility with existing systems, voltage and pressure ratings |

| Landscaping Services | Maintenance of irrigation systems for commercial properties | Ensures optimal water distribution, prolongs system lifespan | Availability of replacement parts, ease of installation |

| Golf Course Management | Upkeep of irrigation systems for greens and fairways | Maintains aesthetic quality and health of turf | Durability against weather conditions, brand reputation |

| Municipal Water Management | Replacement in public park irrigation systems | Promotes sustainable water usage and community beautification | Compliance with local regulations, reliability of suppliers |

| Greenhouse Operations | Maintenance of automated irrigation systems | Supports consistent plant growth and minimizes labor costs | Precision in flow rate specifications, adaptability to system changes |

How is Replacing Solenoid Irrigation Valves Applied in Agriculture?

In the agriculture sector, replacing solenoid valves in extensive irrigation systems is crucial for optimizing water usage. These valves control water flow to various zones, ensuring crops receive adequate hydration. Efficient management minimizes crop losses due to overwatering or drought, enhancing yield quality. For international buyers, sourcing valves that match existing systems in terms of voltage and pressure ratings is essential, ensuring compatibility and reducing installation time.

What Role Does Solenoid Valve Replacement Play in Landscaping Services?

Landscaping services heavily rely on well-maintained irrigation systems to ensure commercial properties remain attractive. Replacing faulty solenoid valves helps maintain optimal water distribution, preventing dry patches and promoting lush greenery. This maintenance practice not only elevates property aesthetics but also extends the lifespan of the irrigation system. Buyers should consider the availability of replacement parts and the ease of installation to streamline the maintenance process.

How Do Golf Course Management Teams Benefit from Solenoid Valve Replacement?

Golf course management teams prioritize the upkeep of irrigation systems to maintain the health and appearance of greens and fairways. Regular replacement of solenoid valves ensures a consistent water supply, crucial for turf health and playability. This practice also helps in managing water resources effectively, contributing to sustainability efforts. Buyers should focus on the durability of valves against various weather conditions and the reputation of brands for reliable performance.

Why is Solenoid Valve Replacement Important for Municipal Water Management?

Municipal water management teams often oversee irrigation systems in public parks, where maintaining aesthetic quality is vital. Replacing solenoid valves ensures efficient water distribution, promoting sustainable usage and enhancing community spaces. Compliance with local regulations regarding water management is a significant consideration for procurement teams. Reliability of suppliers and the quality of components are paramount to ensure long-term performance.

How is Solenoid Valve Replacement Critical for Greenhouse Operations?

In greenhouse operations, maintaining automated irrigation systems is essential for consistent plant growth. Replacing solenoid valves ensures that water flow is precise, reducing labor costs associated with manual watering. This automation supports optimal growing conditions, which is crucial for crop yield and quality. International buyers should prioritize sourcing valves that meet specific flow rate requirements and can adapt to changing system configurations, ensuring seamless integration into existing setups.

3 Common User Pain Points for ‘how to replace solenoid irrigation valve’ & Their Solutions

Scenario 1: Inconsistent Water Flow Across Irrigation Zones

The Problem:

Many B2B buyers in agriculture or landscaping face the challenge of inconsistent water flow across different irrigation zones due to faulty solenoid valves. This inconsistency can result in overwatering some areas while leaving others dry, leading to crop damage or uneven landscape growth. Buyers often struggle with identifying whether the issue lies with the solenoid itself, the wiring, or the valve assembly, making troubleshooting a complex process that consumes valuable time and resources.

The Solution:

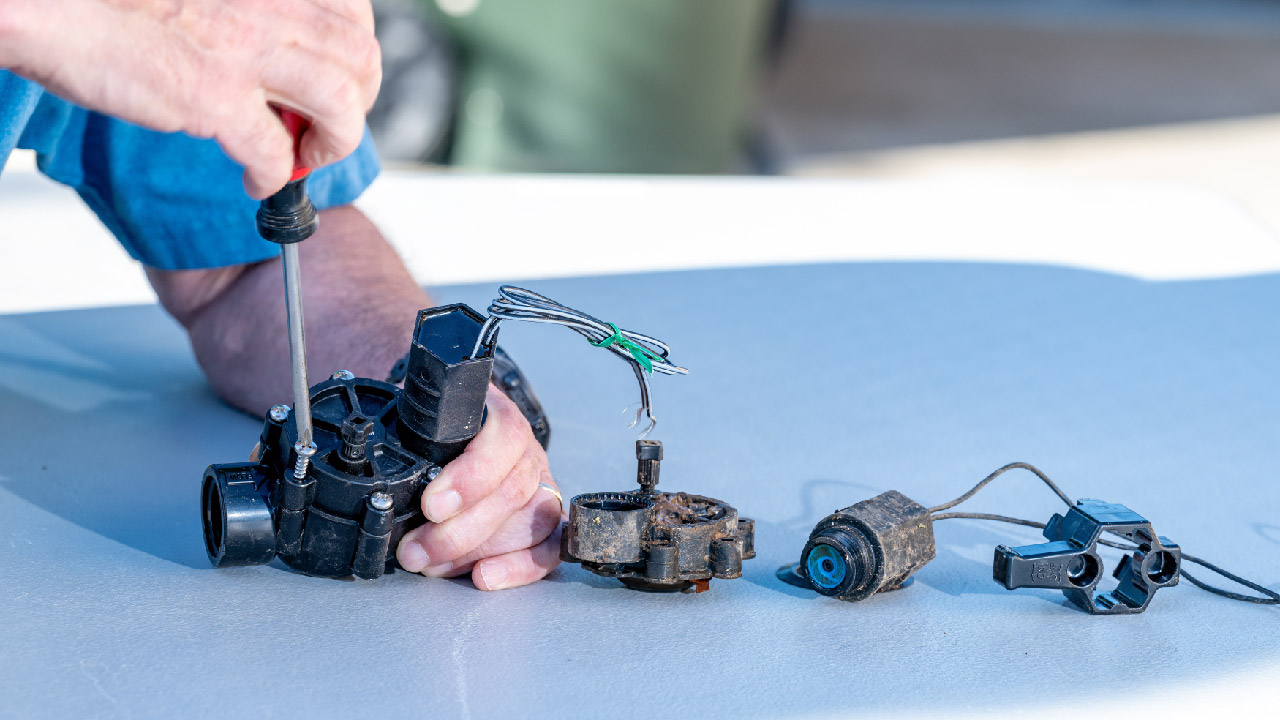

To address this issue effectively, buyers should first conduct a thorough diagnostic check of the irrigation system. Start by manually testing each valve to see which zones are affected. If a specific valve shows signs of malfunction, carefully inspect the solenoid for dirt or debris that may be obstructing its function. If cleaning does not resolve the issue, it may be time to replace the solenoid. When sourcing a new solenoid, ensure compatibility with the existing irrigation system by checking voltage requirements, pressure ratings, and flow specifications. It’s also advisable to consult the manufacturer’s guidelines for the specific valve model to avoid mismatches that could exacerbate the problem.

Scenario 2: Difficulty in Properly Wiring the New Solenoid

The Problem:

Another common pain point arises when buyers attempt to replace solenoid valves and encounter issues with wiring. Poorly connected or corroded wires can lead to malfunctioning solenoids, causing frustration and further delays in restoring the irrigation system. Buyers often lack clear guidance on how to securely connect the wiring, especially in regions where weather conditions may affect the durability of these connections.

The Solution:

To facilitate a successful wiring process, buyers should gather the necessary tools, including wire strippers, weatherproof connectors, and electrical tape. Begin by ensuring that the power to the irrigation system is completely turned off before starting any work. When disconnecting the old solenoid, note the wiring configuration or take a photo for reference. After installing the new solenoid, strip the wires back about half an inch and connect them using weatherproof wire connectors to prevent corrosion. For added security, wrap the connections with electrical tape and consider using a weatherproof junction box if the wiring is exposed to the elements. This proactive approach will minimize future wiring issues and ensure reliable operation.

Scenario 3: Selecting the Right Replacement Solenoid for Different Conditions

The Problem:

In diverse climates, selecting the right replacement solenoid valve can be a significant pain point for international B2B buyers, particularly those operating in varying environmental conditions such as high humidity, extreme temperatures, or dusty areas. Buyers may feel overwhelmed by the multitude of options available and are often unsure which features to prioritize for their specific irrigation needs.

The Solution:

To navigate this selection process effectively, buyers should conduct a needs assessment based on the specific conditions of their irrigation systems. Factors to consider include the solenoid’s operating voltage, pressure rating, and resistance to environmental challenges such as corrosion or temperature fluctuations. For example, a solenoid with a higher pressure rating may be necessary in areas with fluctuating water pressure, while a valve designed with robust materials can withstand harsh weather. Collaborating with reputable suppliers who understand local conditions can also provide valuable insights into the best solenoid options available. Buyers should request product samples when possible, enabling them to assess the quality and compatibility with their existing systems before making a bulk purchase. This strategic approach will ultimately enhance the longevity and performance of the irrigation system, ensuring efficient water management tailored to specific environmental needs.

Strategic Material Selection Guide for how to replace solenoid irrigation valve

What Are the Key Materials for Replacing Solenoid Irrigation Valves?

When considering the replacement of solenoid irrigation valves, the choice of materials is crucial for ensuring long-term performance and reliability. Below, we analyze four common materials used in solenoid valves, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Brass

Key Properties:

Brass is known for its excellent corrosion resistance and ability to withstand high pressures and temperatures. It typically has a pressure rating of up to 600 PSI and can operate effectively in temperatures ranging from -40°F to 200°F.

Pros & Cons:

Brass valves are durable and have a long lifespan, making them suitable for various irrigation applications. However, they tend to be more expensive than plastic alternatives, and their manufacturing process can be complex due to the need for precise machining.

Impact on Application:

Brass is compatible with a wide range of media, including water and various fertilizers, making it ideal for agricultural irrigation systems.

Considerations for International Buyers:

Brass is often compliant with international standards such as ASTM and DIN. However, buyers in regions with high humidity or saline environments, like parts of Africa and the Middle East, should consider additional protective coatings to prevent corrosion.

2. PVC (Polyvinyl Chloride)

Key Properties:

PVC is lightweight, resistant to corrosion, and has a pressure rating of around 150 PSI. It operates effectively in temperatures up to 140°F.

Pros & Cons:

PVC valves are cost-effective and easy to install, making them popular for small-scale irrigation systems. However, they are not as durable as metal options and may become brittle over time, particularly in extreme temperatures.

Impact on Application:

PVC is suitable for freshwater applications but is not recommended for hot water or aggressive chemicals, limiting its use in certain agricultural practices.

Considerations for International Buyers:

PVC products must meet local standards, which can vary significantly. Buyers should ensure compliance with regulations in their respective countries, such as JIS in Japan or EN standards in Europe.

3. Stainless Steel

Key Properties:

Stainless steel offers exceptional corrosion resistance and can withstand high temperatures and pressures, typically rated up to 1500 PSI and effective in temperatures up to 400°F.

Pros & Cons:

Stainless steel valves are highly durable and suitable for a wide range of applications, including those involving aggressive chemicals. However, they are among the more expensive options, and their manufacturing requires specialized techniques.

Impact on Application:

Ideal for industrial applications, stainless steel valves are compatible with a variety of media, including saline and acidic solutions, making them versatile for diverse irrigation needs.

Considerations for International Buyers:

Stainless steel products often comply with international standards such as ASTM and ISO. Buyers should verify the grade of stainless steel, as different grades offer varying levels of corrosion resistance and cost.

4. Nylon

Key Properties:

Nylon is a lightweight, flexible material that provides good chemical resistance. It typically has a pressure rating of about 100 PSI and can operate in temperatures up to 180°F.

Pros & Cons:

Nylon valves are cost-effective and easy to handle, making them suitable for low-pressure applications. However, they may not be suitable for high-temperature or high-pressure environments, limiting their use in more demanding applications.

Impact on Application:

Nylon is compatible with water and some fertilizers but can degrade when exposed to UV light, making it less suitable for outdoor applications without protective measures.

Considerations for International Buyers:

Nylon products should meet relevant standards, such as ASTM. Buyers in regions with high UV exposure, like parts of South America and Africa, should consider additional protective coatings or alternatives.

Summary Table

| Material | Typical Use Case for how to replace solenoid irrigation valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Agricultural irrigation systems | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| PVC | Small-scale irrigation systems | Cost-effective and easy to install | Less durable, may become brittle | Low |

| Stainless Steel | Industrial irrigation applications | Exceptional corrosion resistance | High cost and specialized manufacturing required | High |

| Nylon | Low-pressure irrigation systems | Lightweight and cost-effective | Limited pressure and temperature capabilities | Med |

This analysis provides international B2B buyers with a clear understanding of material options for solenoid irrigation valves, enabling informed decisions that align with their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how to replace solenoid irrigation valve

What Are the Main Stages in the Manufacturing Process for Solenoid Irrigation Valves?

The manufacturing of solenoid irrigation valves involves several critical stages, each crucial for producing a reliable and efficient product. Understanding these stages helps B2B buyers assess the quality and reliability of the valves they are purchasing.

Material Preparation: What Raw Materials Are Used?

The process begins with selecting high-quality raw materials, typically including brass, PVC, or stainless steel for the valve body, and durable plastics for the solenoid and diaphragm components. The choice of materials is vital, as they must withstand various environmental conditions, such as pressure fluctuations, moisture, and temperature changes. Suppliers often implement stringent sourcing protocols to ensure that all materials meet relevant international standards.

How Is the Forming Process Conducted?

Once the materials are prepared, they undergo various forming processes. For metal components, techniques such as casting, machining, and stamping are commonly employed. This phase ensures precise dimensions and compatibility with other valve parts. For plastic components, injection molding is frequently used, allowing for complex shapes and reliable performance under pressure.

What Techniques Are Used in the Assembly Phase?

The assembly phase is where the individual parts come together to form the complete solenoid valve. This process can be manual or automated, depending on the scale of production. Key techniques include:

- Mechanical Assembly: Components like the solenoid, diaphragm, and valve body are assembled using screws or clips, ensuring secure fittings.

- Electrical Assembly: The solenoid coil is wound and fitted into the valve, requiring careful attention to avoid shorts and ensure proper electrical conductivity.

- Quality Checks: Each assembly line typically includes checkpoints to catch defects early in the process, reducing waste and ensuring quality.

What Finishing Techniques Are Applied?

The finishing stage adds protective coatings and final touches to the valves. Common techniques include:

- Surface Treatment: Processes such as anodizing or galvanizing are used for metal components to enhance corrosion resistance.

- Quality Coating: Plastics may receive UV-resistant coatings to extend lifespan, especially in regions with intense sunlight.

How Does Quality Control Ensure the Reliability of Solenoid Irrigation Valves?

Quality control (QC) is paramount in the manufacturing of solenoid irrigation valves. B2B buyers must be aware of the standards and checkpoints involved to ensure they are sourcing high-quality products.

What Are the Relevant International Standards?

Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with these standards indicates that a manufacturer has established processes to ensure consistent product quality. Additionally, industry-specific certifications like CE marking for European markets or API standards for components used in oil and gas applications can further validate product reliability.

What Are the Key QC Checkpoints Throughout the Manufacturing Process?

Quality control typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials before they enter the production process, ensuring that only high-quality inputs are used.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, inspections are conducted to monitor the production process and identify defects early.

- Final Quality Control (FQC): Before products leave the facility, a thorough inspection is performed. This includes functional testing of the solenoid valve to ensure it operates under specified conditions.

What Common Testing Methods Are Used to Ensure Product Integrity?

Manufacturers employ a range of testing methods to verify the functionality and durability of solenoid irrigation valves:

- Pressure Testing: Valves are subjected to high-pressure conditions to ensure they can withstand operational stresses without leaking.

- Electrical Testing: The solenoid coil is tested for resistance and functionality, ensuring reliable operation when activated.

- Durability Testing: Components may undergo environmental tests simulating extreme conditions to assess their long-term performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are several strategies:

- Supplier Audits: Conducting onsite audits allows buyers to assess a supplier’s QMS and production processes directly. This hands-on approach can reveal adherence to standards and highlight areas for improvement.

- Requesting Quality Reports: Buyers should request documentation that outlines QC processes, including any certifications and test results for specific products.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes, ensuring that products meet the required specifications before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various certification requirements based on their local regulations and standards. Understanding these nuances can facilitate smoother transactions and ensure compliance:

- Regional Standards: Different regions may have specific standards that a product must meet. Buyers should be familiar with these requirements to avoid compliance issues.

- Documentation and Traceability: Ensuring that the supplier can provide complete documentation, including certificates of compliance and traceability for materials, is crucial for quality assurance.

- Logistics and Supply Chain Considerations: Buyers should consider how the supplier’s QC processes align with their logistics and supply chain management to minimize risks associated with shipping and storage.

By understanding the manufacturing processes and quality assurance practices of solenoid irrigation valves, B2B buyers can make informed purchasing decisions, ensuring they invest in reliable and efficient irrigation solutions that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to replace solenoid irrigation valve’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure components for replacing solenoid irrigation valves. Understanding the nuances of this process is crucial, as it impacts the efficiency and longevity of irrigation systems. This step-by-step approach will help you navigate the procurement process effectively, ensuring that you secure the right products and services.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is fundamental to sourcing the correct solenoid irrigation valve. Consider factors such as voltage, pressure rating, and flow rate requirements specific to your irrigation system. This clarity will help you communicate effectively with suppliers and ensure compatibility with existing infrastructure.

- Voltage requirements: Ensure that the solenoid matches the electrical specifications of your system.

- Pressure and flow rate: Confirm that the valve can handle the necessary water pressure and flow for optimal performance.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to gauge their reliability and product offerings. Look for suppliers with a strong reputation in the irrigation sector, particularly those with experience in your geographical area. This step is vital to avoid costly mistakes and ensure a smooth procurement process.

- Supplier reviews: Check online reviews and testimonials from other B2B buyers in similar markets.

- Industry presence: Evaluate their presence in the irrigation industry through trade shows and publications.

Step 3: Evaluate Product Quality and Certifications

Before finalizing any purchase, assess the quality of the solenoid valves and any certifications they possess. High-quality components are crucial for minimizing maintenance costs and ensuring operational efficiency. Look for industry-standard certifications that indicate compliance with safety and performance regulations.

- ISO certifications: Check if the products are manufactured under ISO-certified processes.

- Warranty and support: Ensure that the supplier offers a warranty and reliable customer support.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that outline the costs, terms, and delivery schedules. This transparency allows for better comparisons and helps avoid unexpected expenses down the line. Pay attention to the total cost of ownership, including shipping and installation, if applicable.

- Breakdown of costs: Ensure the quote includes a clear breakdown of all charges.

- Lead times: Confirm the expected lead times for delivery to align with your project timelines.

Step 5: Verify Supplier Capabilities

It’s essential to assess the capabilities of your chosen supplier to ensure they can meet your specific needs. Inquire about their inventory levels, production capacity, and ability to handle custom orders if necessary. This verification mitigates risks associated with supply chain disruptions.

- Stock availability: Ensure the supplier has sufficient stock for your immediate needs.

- Customization options: Discuss options for custom specifications if standard products do not meet your requirements.

Step 6: Finalize the Purchase Agreement

Once you’ve selected a supplier, finalize the purchase agreement. This document should clearly outline all agreed-upon terms, including payment schedules, delivery timelines, and return policies. A well-structured agreement protects both parties and establishes clear expectations.

- Payment terms: Discuss and agree on payment methods and timelines.

- Return policy: Ensure you understand the return and exchange policy in case the product does not meet expectations.

Step 7: Plan for Installation and Maintenance

After procurement, develop a plan for the installation and ongoing maintenance of the new solenoid valves. Proper installation is critical for optimal performance, and regular maintenance can extend the life of the components. Consider training options for your staff to ensure they are equipped to handle these tasks effectively.

- Installation guidelines: Provide clear instructions or hire professionals for installation.

- Maintenance schedule: Create a maintenance schedule to monitor the performance and longevity of the valves.

By following these steps, B2B buyers can ensure a successful procurement process for solenoid irrigation valves, leading to enhanced efficiency and reliability in their irrigation systems.

Comprehensive Cost and Pricing Analysis for how to replace solenoid irrigation valve Sourcing

What Are the Key Cost Components for Replacing Solenoid Irrigation Valves?

When considering the replacement of solenoid irrigation valves, several cost components come into play, which can significantly affect the overall expenditure for international B2B buyers. The primary components include:

Materials: The cost of the solenoid valve itself is often the most substantial part of the budget. Factors such as the valve’s specifications, including pressure ratings and materials (plastic vs. brass), will influence pricing. A high-quality valve typically ranges from $10 to $50, depending on these specifications.

Labor: Labor costs can vary based on region and the complexity of the installation. In many countries, skilled technicians may charge hourly rates ranging from $20 to $100. For larger projects or installations involving multiple valves, this cost can escalate quickly.

Manufacturing Overhead: This includes costs related to production facilities, equipment, and utilities. Depending on the manufacturer’s location and operational efficiency, this can add an additional 10-30% to the base cost of the valves.

Tooling: If special tools are required for installation or replacement, this should also be factored into the cost. This could range from $50 to several hundred dollars, depending on the tools needed.

Quality Control (QC): Ensuring that the valves meet industry standards involves QC processes. This can add approximately 5-10% to the cost of the valve, particularly if certifications are required.

Logistics: Shipping and handling costs can vary significantly based on distance, shipping method, and the urgency of delivery. Buyers should consider Incoterms and associated costs, which can range from 5% to 20% of the total order value, especially when dealing with international suppliers.

Margin: Suppliers typically mark up prices to cover their costs and generate profit, which can add an additional 15-25% to the final price.

How Do Price Influencers Impact the Cost of Solenoid Valve Replacement?

Several factors influence the pricing of solenoid irrigation valves:

Volume/MOQ: Larger orders often qualify for discounts due to economies of scale. Understanding the minimum order quantities (MOQ) can help buyers negotiate better terms.

Specifications and Customization: Custom valves tailored to specific irrigation systems may come at a premium. Buyers should evaluate the necessity of such customizations against standard options.

Quality and Certifications: Valves that meet international quality standards or certifications, such as ISO or CE, may be priced higher but offer better reliability and performance, impacting the Total Cost of Ownership (TCO).

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Well-established suppliers might charge more, but they often provide better warranties and customer service.

Incoterms: The chosen Incoterm can significantly affect total costs. For example, choosing FOB (Free On Board) may lead to lower initial costs but could incur additional fees once the goods reach the destination port.

What Negotiation and Cost-Efficiency Tips Should B2B Buyers Consider?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings. Here are some actionable tips:

Leverage Volume Discounts: If you anticipate needing multiple valves over time, negotiating bulk pricing with suppliers can yield substantial savings.

Evaluate Total Cost of Ownership: Look beyond the initial purchase price. Consider factors like maintenance costs, warranty terms, and energy efficiency to assess the long-term value of the valve.

Research Supplier Backgrounds: Investigate potential suppliers for reliability and previous customer feedback. This can help ensure you are investing in quality products.

Understand Pricing Nuances: Familiarize yourself with regional pricing dynamics and currency fluctuations that may affect costs. Consider locking in prices when favorable exchange rates are available.

Explore Local Suppliers: Depending on your location, sourcing from local manufacturers may reduce logistics costs and lead times, enhancing overall cost-efficiency.

Disclaimer on Pricing

Prices for solenoid irrigation valves and associated services can vary widely based on numerous factors, including market conditions and supplier negotiations. The figures mentioned in this analysis are indicative and should be validated with current market research and supplier quotes.

Alternatives Analysis: Comparing how to replace solenoid irrigation valve With Other Solutions

Exploring Alternatives for Replacing Solenoid Irrigation Valves

When considering the replacement of solenoid irrigation valves, it’s essential to evaluate various alternatives that may provide similar functionality or address specific operational challenges. The choice of solution can significantly impact performance, costs, and maintenance requirements, particularly for businesses operating in diverse environments such as Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | How To Replace Solenoid Irrigation Valve | Smart Irrigation Systems | Manual Valve Control Systems |

|---|---|---|---|

| Performance | Reliable control of water flow | Automated adjustments based on weather | Manual adjustments required |

| Cost | Moderate (parts and labor) | Higher initial investment, potential savings over time | Low initial cost, ongoing labor costs |

| Ease of Implementation | Relatively simple DIY process | Requires technical knowledge for setup | Easy to implement but labor-intensive |

| Maintenance | Regular inspections needed | Low maintenance; software updates required | High maintenance; regular manual checks |

| Best Use Case | Standard agricultural or landscaping applications | Large-scale operations needing efficiency | Small farms or gardens where manual labor is feasible |

What Are the Benefits and Drawbacks of Smart Irrigation Systems?

Smart irrigation systems leverage technology to optimize water usage by automatically adjusting based on real-time environmental conditions. These systems utilize sensors and weather data to operate more efficiently. The primary advantage is their ability to conserve water and reduce operational costs in the long run. However, the initial investment can be substantial, and implementation may require technical expertise to set up and maintain the system effectively. For businesses focused on sustainability and cost reduction, this option can yield significant long-term benefits.

How Do Manual Valve Control Systems Compare?

Manual valve control systems offer a straightforward alternative where operators physically adjust water flow through valves. This method is cost-effective, especially for small operations with limited irrigation needs. However, it demands significant labor and time, which can become inefficient as the scale of operation increases. Maintenance is also a concern, as frequent manual checks are required to ensure proper functioning. This solution works best for smaller farms or gardens where hands-on management is feasible and labor costs are not prohibitive.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When evaluating the best solution for replacing solenoid irrigation valves, B2B buyers should consider their specific operational needs, budget constraints, and long-term goals. For organizations seeking efficiency and sustainability, smart irrigation systems may provide a compelling advantage despite their higher initial costs. Conversely, businesses with limited budgets or smaller operations might find manual valve control systems more practical. Ultimately, the choice will depend on the balance between upfront investments, ongoing maintenance, and the desired level of automation in irrigation management. By carefully analyzing these aspects, buyers can make informed decisions that align with their operational objectives and resource availability.

Essential Technical Properties and Trade Terminology for how to replace solenoid irrigation valve

What Are the Key Technical Properties for Replacing a Solenoid Irrigation Valve?

When replacing a solenoid irrigation valve, understanding the critical technical properties is essential for ensuring compatibility and optimal performance. Here are some key specifications to consider:

Material Grade

The material used in solenoid valves typically includes high-grade plastics or brass, which resist corrosion and wear. For B2B buyers, selecting valves made from durable materials is crucial to minimize maintenance costs and extend the lifespan of the irrigation system, especially in harsh environments common in regions like Africa and South America.Operating Voltage

Solenoid valves operate on specific voltages, commonly 12V or 24V. It is important to match the replacement valve’s voltage with the existing system to avoid electrical failures. Understanding the operating voltage can help buyers ensure that the valve integrates seamlessly with their existing infrastructure, reducing downtime and operational disruptions.Flow Rate

The flow rate, measured in gallons per minute (GPM), indicates how much water the valve can handle. Selecting a valve with an appropriate flow rate is vital for efficient irrigation, as it affects water distribution across different zones. Buyers should evaluate their irrigation needs to choose a valve that supports the required flow rates for their specific applications.Pressure Rating

The pressure rating of a valve indicates the maximum pressure it can withstand without failure. This is particularly important in regions with high water pressure, as exceeding the pressure limits can lead to leaks or system failures. Buyers should assess their irrigation system’s pressure conditions to ensure they select a valve that meets or exceeds these specifications.Compatibility with Existing Systems

Compatibility with existing systems is crucial, especially regarding threading and design. Buyers should verify that the replacement solenoid valve matches the dimensions and connection types of their current setup. Ensuring compatibility minimizes installation challenges and enhances system efficiency.

What Are the Common Trade Terms Associated with Solenoid Valve Replacement?

Understanding trade terminology is essential for effective communication and decision-making in B2B transactions. Here are some common terms relevant to solenoid valve replacement:

OEM (Original Equipment Manufacturer)

OEM refers to products made by the original manufacturer of the equipment. In the context of solenoid valves, sourcing OEM parts ensures that the replacement valve meets the same quality and performance standards as the original. This is important for maintaining system integrity and reliability.MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ is critical for budgeting and inventory management. It allows businesses to plan purchases based on their operational needs and cash flow considerations.RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Submitting an RFQ for solenoid valves enables buyers to compare costs and terms from different suppliers, facilitating better purchasing decisions.Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms helps B2B buyers understand their obligations regarding shipping costs, risks, and delivery timelines when importing solenoid valves from international suppliers.Warranty Terms

Warranty terms outline the conditions under which a product is guaranteed against defects and failures. Knowing the warranty terms for solenoid valves can protect buyers from potential losses due to faulty products, ensuring they receive adequate support and service post-purchase.Lead Time

Lead time refers to the amount of time it takes for an order to be processed and delivered. Understanding lead times is essential for B2B buyers to manage their project schedules effectively and avoid delays in irrigation system maintenance or upgrades.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when replacing solenoid irrigation valves, leading to enhanced system performance and reduced operational costs.

Navigating Market Dynamics and Sourcing Trends in the how to replace solenoid irrigation valve Sector

What Are the Current Market Dynamics and Key Trends in the Solenoid Irrigation Valve Sector?

The global market for irrigation systems, particularly solenoid valves, is influenced by several critical drivers, including increasing agricultural demands, water conservation efforts, and technological advancements. Regions such as Africa, South America, the Middle East, and Europe are experiencing a surge in agricultural activities, leading to a higher demand for efficient irrigation solutions. B2B buyers are increasingly looking for systems that integrate smart technology, enabling automated and remote management of irrigation, which enhances efficiency and reduces labor costs.

Emerging trends include the adoption of IoT-enabled irrigation systems that facilitate real-time monitoring and adjustments. This not only optimizes water usage but also helps in preventing issues such as overwatering or crop damage due to equipment failures. Additionally, the rise of precision agriculture is pushing buyers to seek out solenoid valves that can withstand varying environmental conditions, ensuring reliability across diverse applications.

Furthermore, the market is witnessing a shift towards modular components that allow for easier upgrades and replacements, appealing to buyers who prioritize long-term investment in their irrigation systems. As international trade continues to grow, buyers are also focusing on sourcing from manufacturers who can guarantee quality and timely delivery, especially in regions with less established supply chains.

How Does Sustainability and Ethical Sourcing Impact the Solenoid Irrigation Valve Market?

Sustainability is becoming a cornerstone of the B2B purchasing process, particularly in the agricultural sector. The environmental impact of irrigation systems, including the use of materials and energy consumption, is under scrutiny. Buyers are increasingly motivated to source solenoid valves that are made from sustainable materials and are designed for energy efficiency. This aligns with global efforts to reduce carbon footprints and promote responsible resource management.

Ethical sourcing practices are also gaining traction. Buyers are encouraged to engage with manufacturers who adhere to environmentally friendly practices and provide transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and products labeled with eco-friendly certifications not only enhance credibility but also provide assurance to buyers that their investments contribute positively to the environment.

Moreover, as climate change continues to impact agricultural productivity, the demand for durable and resilient irrigation components that can withstand extreme weather conditions is on the rise. This has led to innovations in solenoid valve design, focusing on longevity and reduced maintenance needs, which ultimately supports sustainability goals.

What Is the Evolution of Solenoid Irrigation Valve Technology?

The solenoid irrigation valve has evolved significantly over the past few decades, driven by advancements in technology and increasing agricultural demands. Originally, solenoid valves were simple mechanical devices designed to control water flow in irrigation systems. However, as precision agriculture gained prominence, the need for more sophisticated and reliable valves became apparent.

Modern solenoid valves now incorporate advanced features such as built-in flow sensors and connectivity options for integration with smart irrigation systems. This evolution has not only enhanced operational efficiency but also improved the ability to monitor and manage water resources effectively. As a result, buyers today have access to a wide range of options tailored to meet the specific needs of their agricultural practices, ensuring that they can achieve optimal results while promoting sustainability.

In conclusion, understanding these market dynamics, sustainability considerations, and the technological evolution of solenoid irrigation valves is crucial for B2B buyers looking to make informed purchasing decisions in today’s competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of how to replace solenoid irrigation valve

How do I solve common solenoid valve issues?

Common issues with solenoid valves include failure to open or close, leaks, or erratic operation. Start by inspecting the wiring for any loose connections or corrosion. Check the voltage supplied to the solenoid, as incorrect voltage can lead to operational failures. If debris is present, clean the valve and its components thoroughly. If problems persist after these checks, it may be time to replace the solenoid or the entire valve unit. Regular maintenance can prevent these issues, so consider implementing a routine inspection schedule.What is the best solenoid valve for my irrigation system?

The best solenoid valve for your irrigation system depends on your specific requirements, including the water pressure, flow rate, and the nature of the irrigation layout. Look for valves that are compatible with your existing system’s specifications. Consider durability and resistance to environmental factors, especially if operating in regions with extreme temperatures or high sediment levels. Consulting with suppliers about their most reliable and efficient valve options can help you make an informed choice.What are the key factors to consider when sourcing solenoid valves?

When sourcing solenoid valves, prioritize factors such as compatibility with your existing system, operating voltage, and pressure range. Additionally, assess the supplier’s reputation for quality and reliability, as well as their compliance with international standards. It’s also important to evaluate the warranty and support services offered by the supplier. Requesting samples or technical specifications can help ensure that the valves meet your operational needs before committing to a bulk purchase.How can I vet suppliers for solenoid valves?

To vet suppliers for solenoid valves, start by researching their market presence and customer reviews. Request references from other businesses in your industry to gauge their reliability and service quality. Evaluate their certifications and adherence to international standards, which can indicate product quality. Additionally, consider visiting their manufacturing facility if feasible, to assess their production capabilities and quality control processes. Establishing a strong communication channel can also provide insights into their customer support and responsiveness.What are the minimum order quantities (MOQ) for solenoid valves?

Minimum order quantities (MOQ) for solenoid valves can vary significantly between suppliers and depend on the valve type and specifications. Some suppliers may offer flexible MOQs, especially for established customers or bulk orders. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your purchasing strategy. Understanding the cost implications of different MOQs can also help you manage your budget more effectively.What payment terms should I expect when purchasing solenoid valves?

Payment terms for purchasing solenoid valves can vary based on the supplier and your relationship with them. Common terms include upfront payments, partial payments upon order confirmation, or net payment terms after delivery. Always clarify the payment options available, and consider discussing discounts for early payments or bulk purchases. Ensure that the payment terms are documented clearly in the purchase agreement to avoid any misunderstandings later.How can I ensure quality assurance (QA) for my solenoid valve orders?

To ensure quality assurance (QA) for solenoid valve orders, request detailed specifications and certifications from your suppliers. Implement a quality control process that includes inspecting products upon arrival and testing their functionality. Consider setting up a third-party inspection service, especially for larger orders, to verify compliance with your quality standards. Establishing a clear return policy for defective items can also help mitigate risks associated with poor-quality products.What logistics considerations should I be aware of when importing solenoid valves?

When importing solenoid valves, logistics considerations include shipping costs, delivery timelines, and customs regulations specific to your region. Research the best shipping methods that balance cost and speed, and consider working with logistics providers experienced in international trade. Be aware of any tariffs or import duties that may apply, and ensure proper documentation is prepared for customs clearance. Planning for potential delays in transit can help you maintain your project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 How To Replace Solenoid Irrigation Valve Manufacturers & Suppliers List

1. Sprinkler Warehouse – Irrigation Valve Solenoid Replacement Guide

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

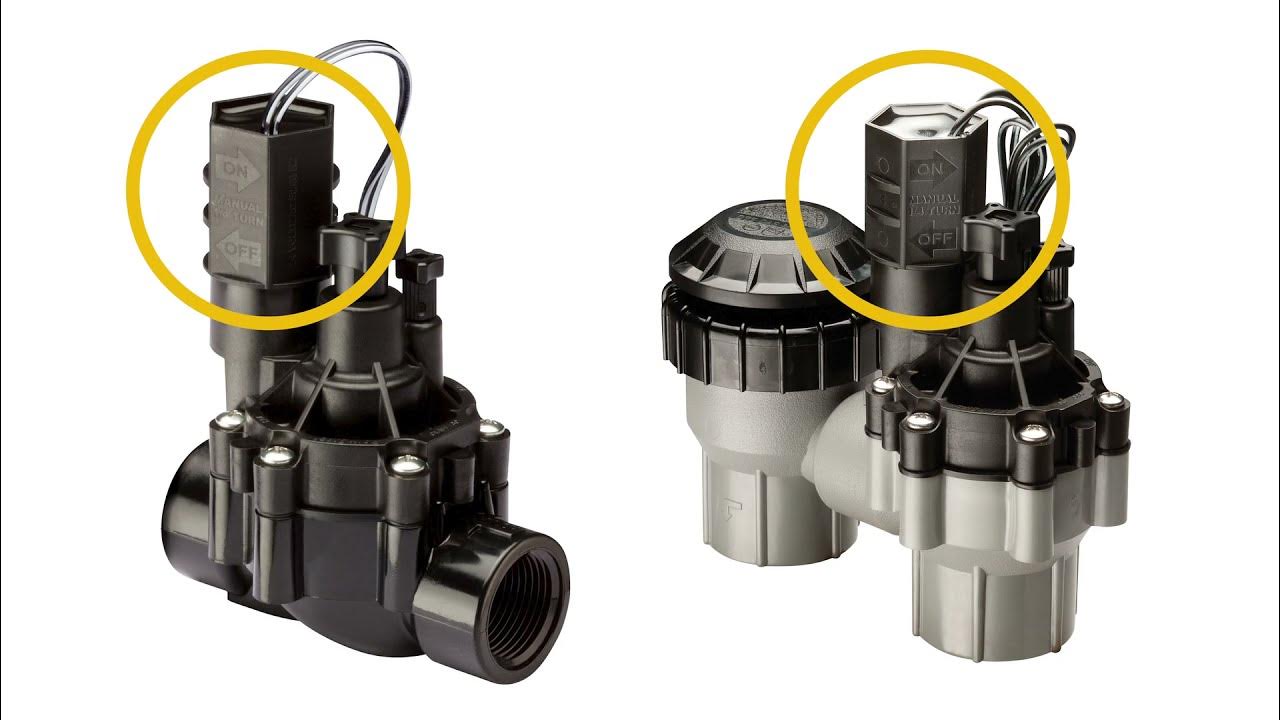

Introduction: The article discusses how to replace an irrigation valve solenoid, highlighting key components such as the diaphragm, solenoid, and valve body. It mentions two types of valves: anti-siphon and in-line, and explains the process of either replacing just the top (guts) or the entire valve unit. It emphasizes the importance of using the same brand and model for replacement parts, cleaning clogged area…

2. Lawnsite – Replacement Solenoids for Nelson Valves

Domain: lawnsite.com

Registered: 2000 (25 years)

Introduction: Replacement solenoid options for old Nelson valve; Irritrol solenoid recommended; Standard 3/4 x 20 thread solenoid; Diaphragm assemblies available under Signature name after Nelson sold turf irrigation division.

3. Irritrol – 2400 Solenoid Replacement

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Irritrol 2400 solenoid; replacement solenoid available for less than $15; installation requires no special tools; solenoid twists off for easy replacement; available at local sprinkler supply stores or Home Depot.

4. JustAnswer – Solenoid Replacement Guide

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: This company, JustAnswer – Solenoid Replacement Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Irrigation Tutorials – Solenoid Valve

Domain: irrigationtutorials.com

Registered: 2001 (24 years)

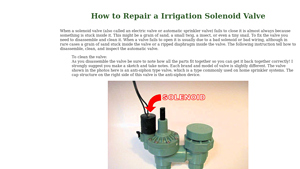

Introduction: Product: Irrigation Solenoid Valve (also known as electric valve or automatic sprinkler valve)\nKey Features: 1. Commonly used in home sprinkler systems. 2. Anti-siphon type valve design. 3. Requires disassembly for cleaning and inspection. 4. Solenoid removal is counter-clockwise; watch for spring-loaded plunger. 5. Diaphragm and seat gasket must be checked for cracks or damage. 6. Valve seat sho…

6. Illustrarch – Replacement Solenoid Valve

Domain: illustrarch.com

Registered: 2018 (7 years)

Introduction: Replacement solenoid valve, operating voltage, pressure range, flow rate, compatibility with existing irrigation system components, wire nuts or waterproof connectors, durable gloves, eye protection.

7. Irrigreen – Sprinkler Solenoid Valve

Domain: irrigreen.com

Registered: 2013 (12 years)

Introduction: A sprinkler solenoid valve is a crucial component of a sprinkler system that controls water flow. It receives electrical signals from sprinkler controllers to manage water pressure and flow. Common signs of a bad solenoid include constant water flow, water leaks, low water pressure, and clicking noises. Testing involves checking voltage with a multimeter, inspecting for physical damage, and ensuri…

Strategic Sourcing Conclusion and Outlook for how to replace solenoid irrigation valve

In summary, the process of replacing a solenoid irrigation valve is not only essential for maintaining the efficiency of irrigation systems but also represents a significant opportunity for international B2B buyers to streamline operations and reduce costs. By understanding the intricacies of solenoid valve functionality, including the importance of selecting the right components and ensuring proper installation, businesses can enhance their irrigation systems’ performance and longevity.

Strategic sourcing plays a crucial role in this process. By partnering with reliable suppliers who offer high-quality valves and components tailored to specific regional needs, companies can mitigate risks associated with valve failure, such as overwatering or dry spots. This proactive approach not only ensures a seamless replacement process but also fosters long-term relationships with vendors who understand the local market dynamics.

As we look to the future, it is imperative for B2B buyers across Africa, South America, the Middle East, and Europe to embrace innovative sourcing strategies. Investing in quality components and establishing strong supplier connections will not only improve irrigation efficiency but also contribute to sustainable agricultural practices. Take the next step in optimizing your irrigation systems—evaluate your sourcing options today and position your business for success in a competitive landscape.