Introduction: Navigating the Global Market for leaky irrigation valve

In today’s competitive agricultural landscape, sourcing high-quality leaky irrigation valves is crucial for businesses aiming to enhance water efficiency and reduce operational costs. Leaky irrigation valves can significantly impact the performance of irrigation systems, leading to wasted resources and increased expenses. This guide aims to equip international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, with the essential insights needed to make informed purchasing decisions.

Throughout this comprehensive guide, we will explore various types of leaky irrigation valves, their applications across different agricultural settings, and strategies for effective supplier vetting. We will also delve into cost considerations and maintenance practices that can extend the lifespan of these critical components. By understanding the nuances of leaky irrigation valves, buyers can optimize their irrigation systems and ensure sustainable water management.

Our goal is to empower businesses with actionable knowledge that fosters better procurement strategies, enhances operational efficiency, and ultimately contributes to more sustainable agricultural practices. Whether you’re looking to upgrade existing systems or invest in new technology, this guide serves as your roadmap to navigating the global market for leaky irrigation valves, helping you secure the best solutions tailored to your unique needs.

Understanding leaky irrigation valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solenoid Valve | Electrically operated, precise control | Commercial irrigation systems | Pros: High precision, automation-friendly. Cons: Requires electrical setup and may need more maintenance. |

| Manual Valve | Operated by hand, simple design | Small-scale agricultural applications | Pros: Low cost, easy to operate. Cons: Labor-intensive, less efficient for large systems. |

| Pressure Vacuum Breaker | Prevents backflow, protects water supply | Municipal water systems, large farms | Pros: Essential for safety, prevents contamination. Cons: More complex installation, higher initial cost. |

| Ball Valve | Quick on/off operation, durable | Industrial irrigation and water supply | Pros: Reliable performance, minimal leakage. Cons: Limited flow regulation capabilities. |

| Butterfly Valve | Compact design, suitable for larger pipelines | Large irrigation networks | Pros: Space-saving, efficient flow control. Cons: May require more frequent maintenance if not properly installed. |

What Are the Key Characteristics of Solenoid Valves for Irrigation Systems?

Solenoid valves are electrically operated devices that allow for precise control over water flow in irrigation systems. Their ability to automate watering schedules makes them ideal for large commercial irrigation setups. B2B buyers should consider the compatibility of solenoid valves with existing systems and the availability of electrical infrastructure, as these factors can influence installation and operational costs.

How Do Manual Valves Compare in Simplicity and Cost?

Manual valves feature a straightforward, hand-operated mechanism that makes them easy to use and cost-effective. They are particularly suited for small-scale agricultural applications where automation is not feasible or necessary. Buyers should weigh the lower initial investment against the potential for increased labor costs, as manual operation can be more time-consuming for larger operations.

Why Are Pressure Vacuum Breakers Important in Irrigation?

Pressure vacuum breakers are critical for preventing backflow and protecting the water supply from contamination. They are commonly used in municipal water systems and large agricultural operations. B2B purchasers should evaluate the installation requirements and maintenance needs, as these valves can be more complex and costly to implement, but they provide essential safety features.

What Advantages Do Ball Valves Offer for Industrial Applications?

Ball valves are known for their quick on/off operation and durability, making them a reliable choice for industrial irrigation and water supply systems. Their design minimizes leakage, which is a significant advantage in applications where water conservation is paramount. Buyers should consider the valve’s flow capacity and compatibility with existing systems to ensure optimal performance.

How Do Butterfly Valves Enhance Flow Control in Large Systems?

Butterfly valves are designed to be compact and are particularly effective for managing flow in larger irrigation networks. Their efficient design allows for significant space savings while providing effective flow regulation. B2B buyers must consider installation requirements and the frequency of maintenance, as improper installation can lead to operational issues over time.

Key Industrial Applications of leaky irrigation valve

| Industry/Sector | Specific Application of leaky irrigation valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Precision farming systems to manage water resources | Reduces water wastage, optimizes crop yield | Quality of materials, compatibility with existing systems |

| Landscaping & Horticulture | Automated landscape irrigation systems | Enhances aesthetic appeal while minimizing water costs | Durability, ease of installation, and maintenance requirements |

| Municipal Water Management | Urban irrigation systems for public parks and gardens | Conserves water and reduces operational costs | Compliance with local regulations, reliability, and efficiency |

| Golf Courses | Irrigation systems for maintaining greens and fairways | Ensures optimal playing conditions while managing water use | Performance under varying conditions, service support |

| Industrial Facilities | Irrigation systems for cooling and dust suppression | Improves operational efficiency and reduces environmental impact | Customization options, reliability, and maintenance services |

How Is a Leaky Irrigation Valve Used in Agriculture?

In agriculture, leaky irrigation valves are critical components in precision farming systems. These valves help manage water distribution effectively, ensuring crops receive adequate hydration while minimizing waste. By detecting and addressing leaks promptly, farmers can significantly reduce water consumption, optimize crop yields, and lower operational costs. International buyers from regions like Africa and South America should consider sourcing durable, high-quality valves that can withstand varying environmental conditions and integrate seamlessly with existing irrigation setups.

What Role Do Leaky Irrigation Valves Play in Landscaping & Horticulture?

In landscaping and horticulture, leaky irrigation valves are employed in automated systems to maintain gardens, lawns, and other green spaces. These valves help control water flow, ensuring that plants receive the right amount of moisture without oversaturation. This is particularly important for maintaining aesthetic appeal while reducing overall water costs. Buyers in Europe and the Middle East should prioritize valves that offer ease of installation and low maintenance, as well as compatibility with smart irrigation technologies.

How Do Leaky Irrigation Valves Benefit Municipal Water Management?

Municipal water management utilizes leaky irrigation valves in urban irrigation systems for parks and public gardens. These valves help conserve water by efficiently regulating flow and quickly addressing leaks, which can lead to significant cost savings for municipalities. For international buyers, especially in developing regions, sourcing valves that comply with local regulations and ensure reliability is crucial. This will not only enhance public green spaces but also promote sustainable water management practices.

Why Are Leaky Irrigation Valves Important for Golf Courses?

Golf courses rely on leaky irrigation valves to maintain optimal playing conditions on greens and fairways. These valves ensure consistent water delivery, which is essential for turf health and playability. By addressing leaks, golf course management can prevent water wastage and reduce costs associated with water usage. Buyers in regions like Brazil and Vietnam should focus on valves that perform well under various weather conditions and provide robust service support to ensure uninterrupted operations.

How Do Industrial Facilities Utilize Leaky Irrigation Valves?

In industrial facilities, leaky irrigation valves are integral to systems designed for cooling processes and dust suppression. By managing water flow efficiently, these valves contribute to improved operational efficiency and reduced environmental impact. Businesses in sectors such as manufacturing should seek valves that offer customization options and high reliability. This ensures that the irrigation systems can be tailored to specific operational needs while minimizing maintenance downtime and costs.

3 Common User Pain Points for ‘leaky irrigation valve’ & Their Solutions

Scenario 1: Excessive Water Waste and Rising Costs

The Problem: B2B buyers managing large agricultural or landscaping operations often face the challenge of water waste due to leaky irrigation valves. In regions where water scarcity is a concern, such as parts of Africa and the Middle East, the financial implications are significant. A leaking valve can lead to thousands of gallons of water wasted monthly, impacting both operational costs and sustainability efforts. Additionally, the increased water usage can result in higher utility bills, straining budgets and affecting profitability.

The Solution: To address water waste, it’s essential to implement regular maintenance schedules that include inspecting and testing irrigation valves. Buyers should consider investing in smart irrigation technology that can detect leaks in real-time and automatically shut off water flow when leaks are detected. Additionally, sourcing high-quality, durable valves designed to withstand harsh environmental conditions can prevent leaks from developing in the first place. Collaborating with reliable suppliers who offer warranties and after-sales support can also ensure that any issues are addressed promptly, minimizing downtime and conserving water resources.

Scenario 2: Compromised Crop Health and Yield

The Problem: For agricultural businesses, a leaky irrigation valve can severely compromise crop health. Excess moisture from leaks can lead to waterlogged soil, which in turn can drown roots, create an environment for fungal diseases, and promote pest infestations. This scenario is particularly critical in regions like South America, where agriculture is a primary economic driver, and crop yield directly impacts food supply and profitability.

The Solution: Buyers should focus on implementing a comprehensive irrigation system that includes moisture sensors. These sensors can provide valuable data about soil moisture levels, allowing for timely adjustments to irrigation schedules and helping to identify potential leaks before they cause significant damage. Furthermore, when sourcing irrigation valves, opting for those with built-in pressure regulation can help mitigate the risk of leaks due to pressure fluctuations. Regular training for maintenance staff on how to recognize signs of leaks and conduct repairs promptly will further safeguard crop health and enhance yields.

Scenario 3: Operational Disruptions and Downtime

The Problem: For businesses that rely on irrigation systems for daily operations—such as nurseries or golf courses—a leaky valve can lead to operational disruptions. When a valve fails, it often requires immediate attention, which can result in downtime and lost revenue. This is especially pressing in regions like Europe, where seasonal changes demand that irrigation systems function optimally during peak growth periods.

The Solution: To minimize downtime caused by leaky valves, buyers should adopt a proactive maintenance strategy that includes routine inspections and an inventory of essential spare parts. Establishing relationships with local suppliers who can provide rapid replacement parts can significantly reduce the time taken to resolve issues. Additionally, considering the installation of easy-to-access above-ground valve boxes can simplify maintenance procedures. Training staff to conduct regular system checks and empowering them to make minor repairs can also lead to quicker resolutions, ensuring that operations run smoothly without significant interruptions.

Strategic Material Selection Guide for leaky irrigation valve

What Are the Key Materials for Leaky Irrigation Valves?

When selecting materials for leaky irrigation valves, it is essential to consider factors such as durability, resistance to environmental conditions, and compatibility with the media being transported. Below are analyses of four common materials used in the manufacturing of irrigation valves.

1. PVC (Polyvinyl Chloride)

Key Properties: PVC is known for its excellent chemical resistance, lightweight nature, and low cost. It can withstand temperatures up to 60°C (140°F) and pressures typically up to 10 bar (145 psi).

Pros & Cons: PVC is highly durable and resistant to corrosion, making it suitable for various irrigation applications. However, it can become brittle over time when exposed to UV light, which may lead to cracks and leaks. Additionally, while PVC is cost-effective, it may not be suitable for high-pressure applications.

Impact on Application: PVC is compatible with a wide range of media, including water and fertilizers, but is not suitable for high-temperature fluids.

Considerations for International Buyers: Compliance with local standards such as ASTM D1785 is crucial. In regions like Africa and South America, where UV exposure can be intense, buyers should consider UV-resistant coatings.

2. Brass

Key Properties: Brass offers excellent strength, corrosion resistance, and can handle high temperatures (up to 200°C or 392°F) and pressures (up to 20 bar or 290 psi).

Pros & Cons: The main advantage of brass is its durability and longevity, making it ideal for long-term applications. However, it is more expensive than plastic alternatives and can be susceptible to dezincification in certain water conditions.

Impact on Application: Brass valves are suitable for potable water applications, but buyers need to ensure the brass is lead-free to comply with health regulations.

Considerations for International Buyers: Compliance with standards such as EN 12165 is vital for European buyers. In regions like the Middle East, where water quality may vary, selecting high-quality brass can mitigate corrosion issues.

3. Stainless Steel

Key Properties: Stainless steel is renowned for its exceptional strength, corrosion resistance, and ability to withstand high temperatures (up to 300°C or 572°F) and pressures (up to 25 bar or 362 psi).

Pros & Cons: Its primary advantage is its durability and resistance to rust and corrosion. However, stainless steel is more expensive than both PVC and brass, and its manufacturing process can be complex.

Impact on Application: Stainless steel is compatible with a wide range of media, including aggressive chemicals, making it suitable for various irrigation applications.

Considerations for International Buyers: Buyers should be aware of different grades of stainless steel, such as 304 and 316, which have varying corrosion resistance levels. Compliance with standards like ASTM A312 is essential, especially for buyers in Europe and North America.

4. Polypropylene

Key Properties: Polypropylene has good chemical resistance and can handle temperatures up to 100°C (212°F) and pressures around 10 bar (145 psi).

Pros & Cons: It is lightweight and cost-effective, making it a popular choice for irrigation systems. However, its lower temperature tolerance compared to other materials may limit its application in hotter climates.

Impact on Application: Polypropylene is suitable for non-potable water applications and is resistant to many chemicals, making it versatile.

Considerations for International Buyers: Buyers should ensure compliance with local standards like ASTM D4101. In regions with extreme temperatures, such as parts of Africa and the Middle East, the temperature limitations of polypropylene should be considered.

Summary Table

| Material | Typical Use Case for leaky irrigation valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Standard irrigation systems | Cost-effective and lightweight | Brittle under UV exposure | Low |

| Brass | Potable water applications | Durable and long-lasting | More expensive, dezincification risk | High |

| Stainless Steel | High-pressure and chemical applications | Exceptional strength and corrosion resistance | Expensive, complex manufacturing | High |

| Polypropylene | Non-potable water applications | Lightweight and versatile | Limited temperature tolerance | Med |

This guide provides a comprehensive overview of material selection for leaky irrigation valves, aiding international B2B buyers in making informed decisions based on their specific needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for leaky irrigation valve

What Are the Key Stages in the Manufacturing Process of Leaky Irrigation Valves?

The manufacturing process of leaky irrigation valves involves several critical stages designed to ensure product durability and functionality. Understanding these stages can help B2B buyers identify quality suppliers.

1. Material Preparation: What Materials Are Used for Manufacturing Irrigation Valves?

The first step in manufacturing leaky irrigation valves is selecting the appropriate materials. Common materials include high-density polyethylene (HDPE), brass, and various types of rubber for seals and O-rings. These materials are chosen for their resistance to corrosion, wear, and water pressure.

After material selection, suppliers prepare the raw materials through processes such as cutting, molding, or extrusion. For example, brass components are often machined to precise specifications, while rubber seals are typically produced through injection molding. Ensuring that the materials meet industry standards is crucial for the longevity and reliability of the valves.

2. Forming: How Are Irrigation Valves Shaped and Assembled?

The forming stage involves shaping the prepared materials into the components of the valve. This may include stamping, casting, or machining operations. For example, the valve body may be forged or cast, while internal components such as springs and seals are manufactured separately.

Once the components are formed, they undergo initial assembly. At this stage, manufacturers often employ techniques like automated assembly lines or manual assembly, depending on the complexity of the valve design. Each component must fit perfectly to ensure that the valve operates efficiently and prevents leaks.

3. Assembly: What Are the Key Steps in Assembling Irrigation Valves?

During the assembly phase, all the individual components are put together. This typically includes installing the O-rings, springs, and the valve actuator. Quality control is critical at this stage; manufacturers often use fixtures and jigs to ensure that each assembly meets specified tolerances.

The assembly process may also involve pressure testing to confirm that the valve can withstand the required operational pressures without leaking. This testing helps to identify any assembly errors before the product reaches the market.

4. Finishing: How Is the Final Product Prepared for Distribution?

The finishing stage includes surface treatments, coatings, and inspections. Manufacturers may apply protective coatings to prevent corrosion, particularly for metal components.

Finishing also involves detailed inspections to ensure that the valves meet aesthetic and functional standards. This can include visual inspections, dimensional checks, and functional tests. After finishing, the valves are packaged for distribution, often with detailed documentation to assist B2B buyers in understanding product specifications and quality assurance measures.

What Quality Assurance Standards Should B2B Buyers Look for in Irrigation Valves?

Quality assurance is a fundamental aspect of manufacturing leaky irrigation valves. Buyers should familiarize themselves with international and industry-specific standards to ensure that they are sourcing high-quality products.

1. International Standards: What Are the Key Quality Certifications?

One of the most recognized international standards is ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer has established processes for consistent quality and customer satisfaction.

Additionally, industry-specific certifications such as CE marking for products sold in Europe and API standards for components used in oil and gas applications may also apply. These certifications signal that the products meet specific safety and quality standards.

2. What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are essential for maintaining the integrity of the manufacturing process. Common checkpoints include:

Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet specified quality standards before production begins.

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process itself, ensuring that each stage adheres to quality standards.

Final Quality Control (FQC): Before the products are shipped, they undergo comprehensive testing to ensure they function as intended. This may include pressure testing, leak testing, and dimensional checks.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is crucial to ensuring product reliability. Here are several strategies to consider:

1. Conducting Audits: What Should Be Included in Supplier Audits?

One effective method is to conduct supplier audits. This can involve on-site visits to evaluate manufacturing practices, quality control processes, and compliance with international standards. During audits, buyers should focus on:

- Reviewing documentation of quality control processes.

- Inspecting equipment and production lines.

- Interviewing key personnel to understand their quality assurance practices.

2. Requesting Quality Reports: What Information Should Quality Reports Provide?

Buyers should request detailed quality reports from suppliers. These reports should include:

- Test results for various quality control checkpoints.

- Records of any non-conformances and how they were addressed.

- Certification documents that demonstrate compliance with industry standards.

3. Utilizing Third-Party Inspection Services: How Can Third-Party Inspections Enhance Quality Assurance?

Employing third-party inspection services can further enhance confidence in supplier quality. These independent inspectors can provide unbiased assessments of manufacturing processes and product quality. This is particularly important for international buyers, as it helps mitigate risks associated with cross-border sourcing.

What Are the Unique Quality Control Challenges for International B2B Buyers?

International buyers often face unique challenges when it comes to quality control. Language barriers, different regulatory environments, and varying cultural attitudes towards quality can complicate the sourcing process.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of these nuances. It may be beneficial to engage local representatives or consultants who understand the regional market and can facilitate communication with suppliers. Additionally, establishing clear quality expectations and maintaining open lines of communication can help ensure that both parties are aligned on quality standards.

Conclusion: Ensuring Quality in the Sourcing of Irrigation Valves

For B2B buyers, understanding the manufacturing processes and quality assurance measures for leaky irrigation valves is essential for making informed purchasing decisions. By focusing on the key stages of manufacturing, familiarizing themselves with relevant quality standards, and implementing robust verification strategies, buyers can significantly enhance their sourcing outcomes. This not only ensures product reliability but also fosters long-term relationships with reputable suppliers in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leaky irrigation valve’

To assist international B2B buyers in effectively sourcing solutions for leaky irrigation valves, this guide provides a practical checklist. This checklist will enable you to make informed decisions when procuring valves that meet your operational needs and standards.

Step 1: Identify Your Specific Requirements

Begin by defining the technical specifications needed for your irrigation system. Consider factors such as the type of valve, flow rate, pressure requirements, and the environmental conditions in your region. This step is crucial as it sets the foundation for all subsequent procurement decisions.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers who specialize in irrigation components. Look for suppliers with a proven track record and positive customer reviews. Pay attention to their experience in your target market, particularly in regions like Africa, South America, the Middle East, and Europe, where environmental conditions may vary.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that your chosen suppliers hold relevant certifications and comply with international quality standards. Certifications like ISO 9001 demonstrate a commitment to quality management, while other industry-specific certifications may indicate compliance with local regulations. This ensures that you are sourcing products that meet safety and quality benchmarks.

Step 4: Request Detailed Product Information

Ask suppliers for comprehensive product specifications, including materials used, warranty details, and maintenance requirements. Understanding the lifecycle and durability of the irrigation valves is essential to ensure long-term performance and reliability. Consider requesting samples to assess the quality firsthand.

Step 5: Assess Pricing and Payment Terms

Obtain detailed pricing from multiple suppliers to compare costs effectively. Pay attention to the total cost of ownership, including shipping and potential import duties. Additionally, review payment terms, ensuring they align with your budgeting and cash flow requirements. Favor suppliers who offer flexible payment options or discounts for bulk purchases.

Step 6: Inquire About After-Sales Support

Evaluate the level of after-sales support offered by suppliers. This includes availability for technical assistance, warranty claims, and replacement parts. Reliable after-sales support can significantly reduce downtime and operational disruptions, making it an essential factor in your sourcing decision.

Step 7: Establish Communication Channels

Finally, ensure that you have clear communication channels established with your chosen suppliers. Effective communication is vital for addressing any issues that may arise during the procurement process or afterward. Confirm the preferred methods of contact and response times to streamline your interactions.

By following this checklist, B2B buyers can effectively navigate the sourcing process for leaky irrigation valves, ensuring that they select the best products and suppliers for their needs.

Comprehensive Cost and Pricing Analysis for leaky irrigation valve Sourcing

What Are the Key Cost Components for Leaky Irrigation Valve Sourcing?

When sourcing leaky irrigation valves, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

Materials: The choice of materials significantly impacts costs. Common materials for valves include brass, PVC, and various grades of rubber for seals and O-rings. Higher-quality materials, like corrosion-resistant alloys, may incur a higher upfront cost but can lead to lower maintenance expenses over time.

Labor: Labor costs encompass the wages for workers involved in the manufacturing process, including assembly and quality control. In regions with higher labor costs, such as Europe, the overall price of valves may be elevated compared to areas with lower labor expenses, like parts of Africa or South America.

Manufacturing Overhead: This includes indirect costs associated with production, such as facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, which is reflected in the pricing.

Tooling: The initial investment in tooling for valve production is a significant factor. Customization options may require specialized molds, which can lead to higher costs, particularly for low-volume orders.

Quality Control (QC): Ensuring the reliability of irrigation valves necessitates rigorous quality checks. The costs associated with QC processes are crucial for maintaining product standards, especially for buyers in regions with strict compliance regulations.

Logistics: Transporting valves from the manufacturer to the buyer involves shipping costs, which vary based on the distance, mode of transport, and Incoterms. International shipments may incur additional customs duties and taxes, impacting total costs.

Margin: Suppliers typically add a profit margin to cover their expenses and provide returns. This margin can fluctuate based on market demand, competition, and supplier reputation.

What Influences the Pricing of Leaky Irrigation Valves?

Several factors can influence the pricing of leaky irrigation valves, including:

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Buyers should consider bulk purchasing to benefit from economies of scale.

Specifications and Customization: Custom valves designed to meet specific agricultural needs may have higher costs due to the complexity of production and the need for specialized materials.

Materials and Quality Certifications: Valves made from high-grade materials with certifications (like ISO or CE) may command higher prices. Buyers should weigh the long-term benefits of investing in quality against initial costs.

Supplier Factors: The reputation, reliability, and location of suppliers can impact pricing. Sourcing from established manufacturers may lead to higher costs but can also ensure better quality and service.

Incoterms: Understanding Incoterms is essential for international buyers. They dictate the responsibilities of buyers and sellers during transportation and can affect pricing due to differences in shipping costs and insurance.

How Can Buyers Optimize Costs When Sourcing Leaky Irrigation Valves?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-effectiveness:

Negotiate: Engage suppliers in discussions about pricing, especially for larger orders. Many suppliers are open to negotiations, particularly if they foresee a long-term partnership.

Consider Total Cost of Ownership (TCO): While initial prices are important, consider long-term costs such as maintenance, replacement, and potential water savings. Investing in higher-quality valves may reduce TCO significantly.

Research Local Suppliers: Exploring local suppliers can minimize shipping costs and lead times. Additionally, local manufacturers may better understand regional needs and regulations.

Stay Informed on Market Trends: Keeping abreast of market conditions and pricing trends can provide leverage during negotiations. Awareness of seasonal demand fluctuations can also help in timing purchases.

Conclusion

Understanding the comprehensive cost structure and pricing influences of leaky irrigation valves is essential for B2B buyers aiming to optimize their sourcing strategies. By focusing on cost components, price influencers, and strategic purchasing tips, buyers can make informed decisions that align with their operational needs and budget constraints. Remember to consider the long-term implications of your purchases to ensure sustainable and cost-effective irrigation solutions.

Alternatives Analysis: Comparing leaky irrigation valve With Other Solutions

Introduction to Alternative Solutions for Irrigation Systems

When managing irrigation systems, particularly in regions with varying water availability and economic constraints, finding effective solutions is crucial. While leaky irrigation valves present significant challenges, several alternative technologies and methods can offer viable options. Understanding these alternatives allows B2B buyers to make informed decisions that align with their operational needs and budget constraints.

Comparison Table of Irrigation Solutions

| Comparison Aspect | Leaky Irrigation Valve | Smart Irrigation Controllers | Drip Irrigation Systems |

|---|---|---|---|

| Performance | Moderate; prone to leaks affecting efficiency | High; optimizes water usage based on real-time data | High; delivers water directly to roots, minimizing waste |

| Cost | Low initial cost; potential high long-term costs due to leaks | Moderate; includes installation and ongoing service fees | Moderate to high; initial setup can be costly but saves water |

| Ease of Implementation | Relatively easy; requires basic plumbing skills | Requires professional installation; may involve complex setup | More complex; requires design and installation planning |

| Maintenance | High; frequent repairs needed due to wear and leaks | Low; minimal upkeep once installed | Moderate; occasional cleaning and component replacement needed |

| Best Use Case | Small to medium gardens with occasional leaks | Large agricultural fields needing precise water management | Arid regions or gardens where water conservation is critical |

Detailed Breakdown of Alternatives

Smart Irrigation Controllers

Smart irrigation controllers utilize weather data and soil moisture levels to optimize watering schedules. These systems can significantly enhance water efficiency by ensuring that plants receive the right amount of water at the right time. While the initial investment may be moderate, the potential for water savings and improved plant health can justify the cost. However, these systems often require professional installation and may involve a learning curve for users unfamiliar with technology.

Drip Irrigation Systems

Drip irrigation systems deliver water directly to the roots of plants through a network of tubing and emitters. This method is highly efficient, minimizing evaporation and runoff, making it ideal for regions facing water scarcity. While the upfront costs can be higher compared to traditional irrigation methods, the long-term savings on water bills and improved crop yield can provide substantial returns on investment. However, these systems require careful planning and installation, which may pose challenges for some users.

Conclusion: Choosing the Right Irrigation Solution

Selecting the appropriate irrigation solution involves evaluating the specific requirements of your operation, including budget, water availability, and maintenance capabilities. While leaky irrigation valves may offer a low-cost entry point, the potential for increased costs due to leaks and inefficiencies can outweigh initial savings. Alternatives like smart irrigation controllers and drip irrigation systems provide advanced solutions that enhance water management and conservation. B2B buyers should consider their long-term goals and operational context to choose the best solution that aligns with their needs.

Essential Technical Properties and Trade Terminology for leaky irrigation valve

What Are the Key Technical Properties of a Leaky Irrigation Valve?

When assessing a leaky irrigation valve, understanding its technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

Material Grade

The material used in the construction of irrigation valves typically ranges from PVC and CPVC to brass and stainless steel. The choice of material affects durability, resistance to corrosion, and overall lifespan. For instance, brass valves may offer better resilience in high-pressure systems, while PVC valves are lighter and cost-effective for residential applications. Selecting the right material ensures that the valve can withstand local environmental conditions, which is essential for B2B buyers operating in diverse climates.Pressure Rating

This specification indicates the maximum pressure the valve can handle, usually measured in pounds per square inch (PSI). A valve with a higher pressure rating is essential for systems that require significant water flow or operate under high pressure. Understanding pressure ratings helps buyers match valves with their irrigation systems, ensuring optimal performance and preventing leaks that could lead to operational failures.Flow Rate

Measured in gallons per minute (GPM) or liters per minute (LPM), the flow rate is a critical property that influences how effectively an irrigation system can distribute water. Buyers should evaluate the flow rate in relation to their specific irrigation needs. A valve with an inadequate flow rate can lead to uneven watering and increased water waste, impacting both efficiency and cost.Tolerance Levels

Tolerance refers to the acceptable deviation in the valve’s dimensions and performance specifications. In the context of irrigation valves, tighter tolerances typically lead to better sealing capabilities and reduced chances of leaks. B2B buyers must consider tolerance levels when selecting valves to ensure compatibility with existing systems and to minimize maintenance costs.Sealing Mechanism

The type of sealing mechanism used in a valve can significantly impact its performance. Common sealing types include O-rings and gaskets. Understanding the sealing mechanism is vital for buyers, as it directly affects the valve’s ability to prevent leaks. Selecting valves with reliable sealing mechanisms can lead to reduced maintenance and longer operational lifespans.

What Are Common Trade Terms Associated with Leaky Irrigation Valves?

Understanding industry jargon is essential for B2B buyers to navigate procurement processes effectively. Here are some common terms related to leaky irrigation valves:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are then marketed by another manufacturer. In the context of irrigation valves, OEM parts are often synonymous with quality and compatibility. Buyers should look for OEM products to ensure that they are receiving reliable and tested components.MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers who need to manage inventory effectively. Understanding MOQ helps in negotiating better pricing and managing procurement budgets, especially in regions with fluctuating demand.RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Utilizing RFQs enables B2B buyers to compare different vendors, ensuring they receive competitive pricing and favorable terms for irrigation valves.Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms is crucial for B2B buyers, especially in international transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transport.Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled, from the moment it is placed until it is delivered. Understanding lead times is critical for B2B buyers to plan their irrigation system installations and maintenance schedules effectively.Warranty Period

This term denotes the timeframe during which a manufacturer will repair or replace a defective product. Knowing the warranty period is vital for buyers as it provides insight into the manufacturer’s confidence in their product and can influence long-term maintenance costs.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions that enhance the efficiency and reliability of their irrigation systems, ultimately leading to better resource management and cost savings.

Navigating Market Dynamics and Sourcing Trends in the leaky irrigation valve Sector

What Are the Current Market Dynamics and Key Trends in the Leaky Irrigation Valve Sector?

The global market for leaky irrigation valves is influenced by several key drivers, including water scarcity, rising agricultural demands, and technological advancements in irrigation management. In regions like Africa and South America, where agriculture is a primary economic driver, efficient water management systems are critical. The integration of smart irrigation technologies, such as IoT-enabled sensors and automated control systems, is becoming increasingly popular. These innovations not only help in identifying leaks but also optimize water usage, making them essential tools for international B2B buyers looking to enhance efficiency.

Additionally, as environmental regulations become stricter, there is a noticeable shift towards sourcing valves made from sustainable materials. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability and environmental responsibility. The trend towards digitalization in supply chain management is also gaining traction, allowing buyers to track their orders in real-time and ensure timely deliveries. This is particularly relevant for buyers in Europe and the Middle East, where supply chain transparency is becoming a competitive advantage.

The demand for high-quality leaky irrigation valves that can withstand various climatic conditions is rising. Buyers are now looking for robust products that not only meet their current needs but are also adaptable to future challenges, such as climate change and water conservation initiatives.

How Is Sustainability and Ethical Sourcing Shaping the Leaky Irrigation Valve Market?

Sustainability is at the forefront of the leaky irrigation valve sector, driven by growing awareness of environmental impacts. The irrigation industry is a significant contributor to water wastage, with small leaks leading to substantial losses over time. B2B buyers are increasingly seeking valves designed to minimize leaks and conserve water, reinforcing the need for innovation in product design.

Ethical sourcing is also gaining importance as buyers recognize the value of transparent supply chains. This includes ensuring that materials used in leaky irrigation valves are sourced responsibly and that manufacturers adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance a supplier’s credibility, making it an attractive option for international buyers.

Moreover, the use of recycled materials and eco-friendly manufacturing processes is becoming a selling point. Buyers are more likely to choose suppliers that prioritize ‘green’ certifications, as these practices not only reduce environmental footprints but also align with global sustainability goals. This trend is particularly pronounced in regions like Europe, where consumers and businesses are more inclined to support sustainable practices.

What Is the Evolution and Historical Context of the Leaky Irrigation Valve Sector?

The leaky irrigation valve sector has evolved significantly over the decades, driven by advancements in irrigation technology and changing agricultural practices. Initially, traditional valves were rudimentary, often leading to inefficiencies and water wastage. As awareness of environmental issues grew, so did the need for more efficient irrigation solutions.

In the late 20th century, the introduction of automated and pressure-regulating valves marked a turning point, allowing for better control over water flow and reduced leakage. The shift towards smart irrigation technologies in the 21st century has further transformed the landscape. Today, modern leaky irrigation valves are equipped with sensors that can detect leaks in real-time, providing invaluable data for maintenance and operational efficiency.

This evolution is crucial for B2B buyers as it highlights the importance of investing in cutting-edge technology to stay competitive in the market. Understanding the historical context of these innovations can help buyers make informed decisions about sourcing and investing in products that will offer long-term benefits in efficiency and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of leaky irrigation valve

How do I identify signs of a leaking irrigation valve?

Identifying a leaking irrigation valve is crucial for maintaining system efficiency. Common signs include unusually wet areas in your landscape, increased water bills despite normal usage, and water pooling around the valve. Additionally, if the water pressure appears low or if the water does not turn off completely, these could indicate a valve leak. Regular inspection of your irrigation system can help catch these issues early and prevent costly water waste.What is the best way to repair a leaking irrigation valve?

The repair process depends on the type of leak. For minor leaks, replacing worn O-rings or seals can often resolve the issue. If the valve is visibly damaged, it may need to be replaced entirely. Begin by shutting off the water supply, then inspect the valve for cracks or deterioration. If you’re unsure, consulting a professional irrigation technician can provide insight and ensure proper repairs.What are the common causes of leaks in irrigation valves?

Leaks in irrigation valves can stem from several factors, including wear and tear, improper installation, or physical damage from environmental conditions. Over time, components like O-rings can degrade, leading to leaks. Additionally, sediment buildup or blockages can cause pressure fluctuations, further exacerbating the problem. Regular maintenance and inspections can help identify potential issues before they lead to significant leaks.How can I find a reliable supplier for irrigation valves?

When sourcing irrigation valves, look for suppliers with a strong reputation in the industry, positive customer reviews, and proven experience in your specific region. Consider attending trade shows or industry conferences to network with potential suppliers. Verify their certifications and quality control processes to ensure they meet international standards. Request samples to assess product quality before making bulk purchases.What is the minimum order quantity (MOQ) for irrigation valves?

Minimum order quantities can vary significantly among suppliers. Some may require a MOQ of several hundred units, while others might offer lower quantities for smaller businesses. It’s essential to communicate your needs upfront and negotiate terms that suit your purchasing capacity. If you are uncertain, consider reaching out to multiple suppliers to compare MOQs and find a suitable partner.What payment terms should I expect when sourcing irrigation valves internationally?

Payment terms can differ widely based on the supplier and your relationship with them. Common arrangements include upfront payments, letter of credit, or payment upon delivery. For new suppliers, consider negotiating terms that protect your interests, such as partial payments before shipment and the balance upon receipt. Always confirm the currency and payment method to avoid any unforeseen charges.How do I ensure quality assurance for the irrigation valves I purchase?

Quality assurance is crucial for maintaining system integrity. Before placing an order, inquire about the supplier’s quality control processes, including testing methods and certifications. Request documentation of compliance with international standards, such as ISO certifications. Additionally, consider implementing a pre-shipment inspection to verify that the products meet your specifications before they leave the supplier’s facility.What logistics considerations should I keep in mind when importing irrigation valves?

When importing irrigation valves, consider shipping methods, customs regulations, and potential tariffs that may apply. Work with logistics partners experienced in international shipping to navigate these complexities. Ensure you have all necessary import documentation prepared in advance to avoid delays. Additionally, factor in lead times for production and shipping to align with your project schedules, especially in regions with less predictable logistics environments.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Leaky Irrigation Valve Manufacturers & Suppliers List

1. Reddit – Sprinkler Valve Issues

Domain: reddit.com

Registered: 2005 (20 years)

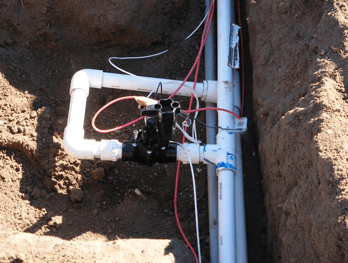

Introduction: Leaking sprinkler valve, replaced by two different landscape irrigation technicians, first replacing the top of the valve and then the entire assembly. Leak stops when the main sprinkler valve is shut off. Previous leaks in underground sprinkler pipes noted. Possible issues include excessive pressure in the system.

2. DIY – O-Ring Bag #6 Union

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: #39 O-Ring Bag, Part Number: 9D0035753B, size: #6 Union O-Ring, price: 59 cents.

3. Hunter – HCV Check Valves

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: The text discusses issues related to valves weeping or leaking when the valve is off. It identifies two main causes: 1) Low Head Drainage, where water drains from the lateral piping out of the sprinkler, which can be resolved by installing check valves (such as the HCV) on sprinklers and lateral lines. 2) Water leaking through the zone valve due to debris obstructing the valve’s diaphragm, which r…

4. Rachio – Irrigation Solutions

Domain: community.rachio.com

Registered: 2013 (12 years)

Introduction: Weathermatic master valve, Hunter valves on 5 zones, Flume flow monitor, ultrasonic/magnetic non-invasive flow meter.

5. Irrigreen – Smart Sprinkler Head

Domain: irrigreen.com

Registered: 2013 (12 years)

Introduction: Labor Day Sale: 20% off with code LABORDAY20. Ends tonight. Contact: (952) 222-4900. Irrigreen Smart Sprinkler Head: Features CableLock for easy connection. Replacement instructions for both Irrigreen and non-Irrigreen heads provided. Tools needed: shovel, trowel, tin snips, tubing cutter, pipe cutter, Teflon tape, compression couplings. DIY instructions for fixing leaks in valve boxes, sprinkler …

6. Sprinkler Warehouse – Key Rotors with Check Valves

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: 1. Rain Bird 1804 SAM with built-in check valve. 2. Hunter Adjustable Arc CV Rotor with built-in check valve. 3. Toro Rotor with Check Valve 1 in. | T7P-02. 4. Irritrol Rotor 5 in. | 550R.

7. This Old House – Sprinkler System Repair Tools

Domain: thisoldhouse.com

Registered: 1998 (27 years)

Introduction: Tools and materials needed for sprinkler system repair include: garden trowel, Phillips screwdriver, pliers, bucket, replacement valve diaphragms, waterproof wire connectors, clean stones or gravel, and dry rags.

8. WaterWeld – Flex Seal

9. Austex Sprinklers – Sprinkler Valve Repair

Domain: austexsprinklers.com

Registered: 2011 (14 years)

Introduction: Austex Sprinklers offers professional sprinkler repair services, specifically addressing issues related to leaking sprinkler valves. Common causes of leaks include low-head drainage and valve seal breaks. Signs of a sprinkler valve leak include increased water bills, pools of water around sprinkler heads, visible damage to pipes and valves, low water pressure, and dry areas in the lawn. The compan…

Strategic Sourcing Conclusion and Outlook for leaky irrigation valve

What Are the Key Takeaways for B2B Buyers Regarding Leaky Irrigation Valves?

In summary, the implications of leaky irrigation valves extend beyond mere water loss; they can impact operational efficiency, increase water bills, and lead to potential damage in landscaping. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding the signs of leaks—such as unusually wet areas, increased water bills, and low pressure—is crucial. Strategic sourcing of high-quality valves and components is vital for ensuring long-term sustainability and performance of irrigation systems.

How Can Strategic Sourcing Enhance Your Irrigation Solutions?

Investing in robust irrigation systems that prioritize quality components will significantly reduce maintenance costs and enhance overall efficiency. By establishing relationships with reputable suppliers and manufacturers, businesses can secure reliable products that withstand the rigors of varied climates and usage demands.

What’s Next for International Buyers in the Irrigation Sector?

As global awareness of water conservation grows, the demand for efficient irrigation solutions will continue to rise. Now is the time for B2B buyers to act—evaluate your current suppliers, explore innovative technologies, and consider the long-term benefits of strategic sourcing. By prioritizing quality and sustainability, you position your business for success in a competitive market, ensuring your irrigation systems operate flawlessly and responsibly.