Introduction: Navigating the Global Market for severe service knife gate valve

In today’s global marketplace, sourcing a reliable severe service knife gate valve can be a daunting challenge for international B2B buyers. These valves are essential in industries ranging from mining and oil and gas to chemical processing and wastewater management, where they must withstand extreme pressures, abrasive materials, and demanding operational conditions. The complexity of selecting the right valve—considering factors such as application-specific requirements, supplier reliability, and cost-effectiveness—can significantly impact operational efficiency and overall project success.

This comprehensive guide aims to demystify the intricate world of severe service knife gate valves. It covers various types of valves, their specific applications, and critical performance features that distinguish high-quality products from subpar options. Additionally, the guide provides actionable insights on supplier vetting processes, ensuring that buyers can confidently engage with manufacturers that meet international standards.

By equipping B2B buyers from regions like Africa, South America, the Middle East, and Europe—including emerging markets such as Brazil and Nigeria—with the knowledge they need, this guide empowers them to make informed purchasing decisions. Whether you are looking for bi-directional zero-leakage solutions or valves designed for high-density slurry lines, our insights will help you navigate the complexities of the global valve market and secure the right products for your operational needs.

Understanding severe service knife gate valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Guided Shear Gate Valve | Features a shearing tip and internal gate guides for cutting through tough media. | Mining, Chemical Processing, Pulp & Paper | Pros: High durability and performance in severe conditions. Cons: Initial cost can be higher than standard valves. |

| Rigid One-Piece Body Valve | Constructed from a single piece to withstand high pressures and abrasive slurries. | Oil Sands, Steel, Waste Water | Pros: Reduced risk of leakage and maintenance. Cons: Limited flexibility in installation. |

| Bi-Directional Zero Leakage Valve | Engineered for complete isolation with no leakage in both directions. | Power Generation, Municipal Services | Pros: Effective for critical applications requiring reliability. Cons: May require specialized maintenance. |

| Hard-Faced Gate Valve | Incorporates hard-facing materials to enhance wear resistance in abrasive environments. | Mining, Chemical Processing | Pros: Extended service life in harsh conditions. Cons: Heavier design may complicate installation. |

| Adjustable Packing Gland Valve | Allows for easy adjustments to packing to maintain performance over time. | Pulp & Paper, Biofuels Production | Pros: Simplifies maintenance and ensures long-term performance. Cons: Requires periodic adjustments for optimal performance. |

What are the Key Characteristics of Guided Shear Gate Valves?

Guided Shear Gate Valves are specifically designed for severe service applications where media may include solids, fibers, and slurries. The shearing tip and internal guides enable these valves to effectively cut through challenging materials, ensuring minimal wear and tear. Buyers should consider their operational environment and the specific media being handled, as these valves excel in high-pressure and high-density applications, making them ideal for industries such as mining and chemical processing.

How Do Rigid One-Piece Body Valves Perform in Harsh Environments?

Rigid One-Piece Body Valves are built to endure extreme conditions, featuring a robust construction that minimizes the risk of leakage. This design is particularly beneficial in industries like oil sands and steel, where abrasive slurries are common. B2B buyers should weigh the advantages of reduced maintenance needs against the installation constraints, as these valves may have limitations in terms of flexibility and adaptability in certain setups.

Why Choose Bi-Directional Zero Leakage Valves for Critical Applications?

Bi-Directional Zero Leakage Valves are engineered for applications that demand complete isolation without any leakage, making them suitable for power generation and municipal services. Their robust construction ensures reliability in critical systems. Buyers must consider the total cost of ownership, as these valves may require specialized maintenance to uphold their performance, but the investment can lead to significant long-term savings through reduced downtime.

What Benefits Do Hard-Faced Gate Valves Offer in Abrasive Conditions?

Hard-Faced Gate Valves are designed with materials that enhance their resistance to wear, making them an excellent choice for industries dealing with abrasive materials, such as mining and chemical processing. The durability of these valves often results in lower replacement costs over time. However, buyers should be aware that their heavier design may complicate installation and require more robust support structures.

How Do Adjustable Packing Gland Valves Enhance Maintenance?

Adjustable Packing Gland Valves allow users to make easy adjustments to the packing, ensuring optimal performance and longevity. This feature is particularly advantageous in industries like pulp and paper and biofuels, where maintenance can be challenging. Buyers should consider the ease of maintenance these valves provide, balanced against the need for periodic adjustments to maintain their effectiveness in sealing and operation.

Key Industrial Applications of severe service knife gate valve

| Industry/Sector | Specific Application of Severe Service Knife Gate Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Isolation in tailings slurry lines | Prevents leakage and maintains operational efficiency | High-pressure ratings, resistance to abrasive materials |

| Oil and Gas | Flow control in high-pressure pipelines | Enhances safety and reliability in harsh environments | Compliance with industry standards, corrosion resistance |

| Chemical Processing | Isolation of corrosive and viscous media | Ensures zero-leakage and prolongs equipment life | Material compatibility, sealing technology, maintenance ease |

| Pulp and Paper | Control of fibrous slurries in processing | Reduces downtime and maintenance costs | Durable materials, ease of cleaning, effective sealing |

| Waste Water Management | Control of sludge and waste materials | Improves environmental compliance and reduces spills | Bi-directional shutoff capability, robust design, low maintenance |

How is the Severe Service Knife Gate Valve Used in Mining Applications?

In the mining industry, severe service knife gate valves are essential for isolating tailings slurry lines. These valves are designed to handle high-pressure and abrasive materials, ensuring zero leakage during operations. By utilizing a robust design that includes a hard-faced gate and a rigid body, these valves minimize downtime and maintenance costs, which is crucial in maintaining operational efficiency. International buyers should prioritize sourcing valves that meet high pressure and temperature ratings to withstand the demanding conditions of mining operations.

What Role Do Severe Service Knife Gate Valves Play in Oil and Gas?

In the oil and gas sector, severe service knife gate valves are employed for flow control in high-pressure pipelines. Their ability to provide bi-directional, zero-leakage performance is vital for ensuring safety and operational reliability in harsh environments. These valves must comply with stringent industry standards and be resistant to corrosion and erosion. Buyers from regions like Africa and South America should consider the valve’s material properties and certifications to ensure they meet local regulations and environmental conditions.

Why Are Severe Service Knife Gate Valves Important in Chemical Processing?

In chemical processing, severe service knife gate valves are used to isolate corrosive and viscous media. Their design allows for effective sealing and minimizes leakage, which is critical for safety and compliance with environmental regulations. Buyers should focus on valves made from materials compatible with the specific chemicals handled in their processes. Additionally, the ease of maintenance and the longevity of the valve can significantly impact operational costs, making these factors essential considerations in the sourcing process.

How Do Severe Service Knife Gate Valves Benefit the Pulp and Paper Industry?

Severe service knife gate valves are crucial in the pulp and paper industry for controlling fibrous slurries during processing. Their robust design helps to reduce downtime caused by maintenance and cleaning, thus enhancing productivity. Buyers should look for valves that offer effective sealing capabilities and are made from durable materials to withstand the abrasive nature of pulp slurries. Additionally, sourcing valves that facilitate easy cleaning can further enhance operational efficiency.

What Advantages Do Severe Service Knife Gate Valves Provide in Waste Water Management?

In waste water management, severe service knife gate valves are vital for controlling sludge and waste materials. Their ability to provide bi-directional shutoff ensures environmental compliance by preventing spills and leaks. Buyers should consider the valve’s design features that enhance its robustness and reliability in handling challenging waste materials. Key sourcing considerations include the valve’s resistance to wear and tear, ease of maintenance, and the ability to operate effectively in varying pressure conditions.

3 Common User Pain Points for ‘severe service knife gate valve’ & Their Solutions

Scenario 1: Struggling with Valve Leakage in High-Pressure Systems

The Problem: One of the most significant challenges faced by B2B buyers in industries such as mining and chemical processing is valve leakage, especially in high-pressure environments. When severe service knife gate valves fail to contain the media, it can lead to costly downtime, environmental hazards, and safety risks. Buyers may find that standard valves do not provide the necessary sealing capabilities, resulting in a loss of productivity and increased maintenance costs.

The Solution: To mitigate leakage issues, buyers should prioritize sourcing severe service knife gate valves that feature advanced sealing technologies, such as patented gate edge seal systems and robust packing materials. For instance, valves designed with a heavy cross-section elastomer seat can significantly enhance sealing performance under extreme conditions. It’s also crucial to ensure that the selected valves meet industry standards such as MSS SP-135 or ASME B16.34, which guarantee their reliability in severe applications. Regular maintenance, including monitoring the condition of seals and packing, will further enhance valve longevity and performance, ultimately reducing the risk of leakage.

Scenario 2: Difficulty in Handling Abrasive Media

The Problem: In applications dealing with abrasive slurries, such as those found in wastewater treatment or mining, B2B buyers often encounter rapid wear and tear on valves. This scenario leads to frequent replacements and maintenance, which not only disrupts operations but also escalates costs. Buyers may feel overwhelmed by the challenge of selecting a valve that can withstand such harsh conditions without incurring excessive wear.

The Solution: Buyers should opt for severe service knife gate valves that feature hard-faced gates and integral wear rings. These design elements significantly reduce wear and extend the service life of the valve, making them ideal for abrasive applications. Additionally, considering valves with a full round port design can minimize pressure drops and improve flow efficiency, which is particularly beneficial in slurry handling. It’s advisable to consult with manufacturers about the specific abrasive media characteristics to ensure the correct materials and coatings are chosen for the valve construction, thus optimizing performance and durability.

Scenario 3: Challenges in Installation and Maintenance

The Problem: Many B2B buyers find that the installation and ongoing maintenance of severe service knife gate valves are cumbersome and time-consuming. This issue often arises from the complexity of the valve design, which may require specialized tools or knowledge that is not readily available within their operational teams. As a result, companies may experience extended downtimes and increased labor costs.

The Solution: To streamline installation and maintenance processes, buyers should look for valves that are designed for ease of service. Features such as repairable designs that allow for quick replacement of parts with standard tools can significantly reduce downtime. Additionally, choosing valves with dynamically self-adjusting seals and accessible maintenance points will facilitate easier upkeep. Training sessions offered by manufacturers can also equip operational teams with the necessary skills to handle installations and repairs effectively. Prioritizing user-friendly design and comprehensive support from suppliers will lead to smoother operations and minimized disruption in service.

Strategic Material Selection Guide for severe service knife gate valve

What Are the Key Materials for Severe Service Knife Gate Valves?

When selecting materials for severe service knife gate valves, it is crucial to consider the specific operating conditions and media compatibility. Here, we analyze four common materials used in the construction of these valves, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and good temperature tolerance, typically rated up to 400°F (204°C) and pressures up to ASME Class 1500. Its resistance to oxidation and scaling makes it suitable for harsh environments.

Pros & Cons:

The primary advantage of stainless steel is its durability and ability to withstand corrosive media, making it ideal for applications in chemical processing and wastewater treatment. However, it can be more expensive than other materials and may require specialized manufacturing processes, increasing lead times.

Impact on Application:

Stainless steel is compatible with a wide range of media, including acidic and alkaline solutions. However, it may not perform well in environments with high chloride concentrations, which can lead to pitting corrosion.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A312 for pipes and ASTM A276 for bars. In regions like Europe and South America, adherence to EN standards is also essential.

2. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and excellent wear resistance, with temperature ratings typically up to 300°F (149°C) and pressure ratings up to ASME Class 300. It is often coated or lined to enhance corrosion resistance.

Pros & Cons:

The cost-effectiveness of carbon steel makes it a popular choice for many applications. However, its susceptibility to corrosion can limit its use in certain environments without protective coatings, which may complicate maintenance.

Impact on Application:

Carbon steel is suitable for handling water, slurries, and some oils but is not recommended for highly corrosive media. Its performance can significantly degrade in acidic or saline environments.

Considerations for International Buyers:

Compliance with standards like ASTM A106 for seamless carbon steel pipes is crucial. Buyers from Africa and the Middle East should also consider local regulations regarding material use in industrial applications.

3. Alloy Steel

Key Properties:

Alloy steel combines carbon steel with other elements like chromium, molybdenum, or nickel to improve strength, toughness, and corrosion resistance. It can handle higher temperatures and pressures, often rated above ASME Class 300.

Pros & Cons:

The enhanced properties of alloy steel make it suitable for severe service applications, particularly in mining and oil and gas sectors. However, it can be more expensive and complex to manufacture due to the need for specific alloy compositions.

Impact on Application:

Alloy steel excels in high-pressure environments and is compatible with abrasive slurries and high-temperature fluids. However, it may require specific surface treatments to prevent corrosion in aggressive media.

Considerations for International Buyers:

Buyers should verify compliance with both ASTM and local standards. In regions like Europe, adherence to EN 10025 for structural steels is vital.

4. Plastic and Composite Materials

Key Properties:

Advanced plastics and composites offer excellent chemical resistance and lightweight properties, with temperature ratings generally below 200°F (93°C). They are often used in applications where corrosion is a primary concern.

Pros & Cons:

The main advantage is their resistance to corrosive media and lower weight compared to metals, which can reduce installation costs. However, they may not withstand high pressures and temperatures as effectively as metals, limiting their application scope.

Impact on Application:

These materials are ideal for handling aggressive chemicals and slurries but may not be suitable for high-pressure systems. Their use in mining and heavy industrial applications is limited.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards, such as ASTM D638 for tensile properties of plastics. In regions like South America, local regulations regarding plastic use in industrial applications should be reviewed.

Summary Table

| Material | Typical Use Case for Severe Service Knife Gate Valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, wastewater treatment | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Carbon Steel | Water and slurry handling | Cost-effective, high strength | Susceptible to corrosion | Low |

| Alloy Steel | Mining, oil and gas | Enhanced strength and toughness | Higher cost, complex manufacturing | Medium |

| Plastic and Composite | Aggressive chemical handling | Lightweight, excellent chemical resistance | Limited pressure and temperature ratings | Medium |

This material selection guide provides critical insights for international B2B buyers, helping them make informed decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for severe service knife gate valve

What Are the Main Stages of Manufacturing Severe Service Knife Gate Valves?

Manufacturing severe service knife gate valves involves several critical stages that ensure the final product meets the stringent demands of various industries such as mining, oil and gas, and chemical processing. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-quality materials. Common materials include carbon steel, stainless steel, and special alloys designed to withstand harsh environments and abrasive materials. Each material undergoes rigorous testing to verify its properties before being cut into specific dimensions. This stage may also involve heat treatment to enhance the material’s strength and durability.

Forming

Once the materials are prepared, they are subjected to forming processes such as machining, casting, or forging. Machining is particularly critical for achieving precise dimensions and surface finishes. Advanced CNC (Computer Numerical Control) machines are often utilized to ensure consistency and accuracy. For cast valves, the molten metal is poured into molds to create the desired shape, followed by cooling and solidification.

Assembly

The assembly stage involves integrating various components, including the body, gate, packing, and actuator. Each valve is designed to facilitate easy assembly, allowing for efficient production. During this phase, attention is paid to the alignment of parts to prevent leakage and ensure optimal performance. Specialized tools are often used to secure components, ensuring that the assembly process maintains the integrity of the valve.

Finishing

The finishing process enhances the valve’s surface quality and prepares it for use in demanding environments. This may include surface treatments such as painting, coating, or polishing to increase corrosion resistance and improve aesthetic appeal. Quality checks are performed at this stage to ensure that the valve meets industry standards and specifications.

How Is Quality Assurance Implemented in Manufacturing Severe Service Knife Gate Valves?

Quality assurance (QA) is a cornerstone of the manufacturing process for severe service knife gate valves. Ensuring that each valve meets international and industry-specific standards is vital for reliability and performance.

What International Standards Guide Quality Assurance?

Manufacturers typically adhere to various international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking for European markets and API (American Petroleum Institute) standards are crucial for valves used in oil and gas applications.

What Are the Key QC Checkpoints During Manufacturing?

Quality control (QC) checkpoints are implemented throughout the manufacturing process. These checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards and requirements.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages. This includes dimensional checks and material properties assessments at various points in the production line.

- Final Quality Control (FQC): Once the assembly is complete, a thorough inspection is conducted to verify that the valve meets all design specifications and performance criteria.

What Common Testing Methods Are Used for Severe Service Knife Gate Valves?

Testing is a critical part of the quality assurance process for severe service knife gate valves. Various methods are employed to ensure that the valves perform reliably under extreme conditions.

Hydrostatic Testing

This method checks for leaks and verifies that the valve can withstand high-pressure conditions. The valve is filled with water and subjected to pressure that exceeds its operational limits. Any signs of leakage indicate a failure in the valve’s integrity.

Functional Testing

Functional tests assess the valve’s operational performance, ensuring that it opens and closes smoothly without obstruction. This test is crucial for confirming that the valve can handle the specific media it is designed for, including abrasive slurries and high-density fluids.

Non-Destructive Testing (NDT)

Techniques such as ultrasonic testing and magnetic particle inspection are used to detect internal flaws without damaging the valve. NDT is particularly important for ensuring the reliability of critical components, especially in high-risk applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of potential suppliers is essential. Here are actionable steps to ensure that you partner with reliable manufacturers:

Conduct Supplier Audits

Request to conduct on-site audits of the manufacturing facilities. This will allow you to evaluate their quality management systems, production processes, and adherence to international standards.

Review Quality Assurance Documentation

Ask suppliers for their quality assurance documentation, including certifications, test reports, and quality control procedures. This information can provide insights into their commitment to maintaining high standards.

Engage Third-Party Inspectors

Consider hiring third-party inspection services to evaluate the valves before shipment. These independent assessments can offer an unbiased view of the product quality and compliance with specifications.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of specific nuances in quality control when sourcing severe service knife gate valves. Different regions may have varying standards and regulations that impact valve performance and acceptance.

Understanding Regional Standards

Buyers should familiarize themselves with the local standards in their markets. For instance, valves intended for the European market must comply with CE marking requirements, while those for the U.S. may need to meet API standards. Understanding these distinctions is crucial for ensuring regulatory compliance.

Language and Communication Barriers

Language differences can lead to misinterpretations of quality specifications. It is advisable to establish clear communication channels and, if necessary, employ translators or local representatives to facilitate understanding.

Cultural Differences in Business Practices

Cultural nuances may influence business negotiations and expectations. Being aware of these differences can enhance cooperation and foster better relationships with suppliers, ultimately leading to improved quality outcomes.

In conclusion, the manufacturing processes and quality assurance measures for severe service knife gate valves are vital for ensuring reliability and performance in demanding applications. By understanding these processes and actively verifying supplier quality, international B2B buyers can make informed purchasing decisions that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘severe service knife gate valve’

In the competitive landscape of industrial procurement, sourcing a severe service knife gate valve requires careful consideration and strategic planning. This guide provides a practical checklist to help international B2B buyers navigate the complexities of selecting the right valve for their specific applications.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. Consider factors such as pressure and temperature ratings, material compatibility, and size specifications. This ensures that the valve can withstand the operational conditions it will face, which is crucial for performance and longevity.

- Pressure and Temperature Ratings: Ensure the valve meets the ASME or MSS standards relevant to your industry.

- Material Compatibility: Assess whether the valve materials can handle the media being processed, especially in corrosive or abrasive environments.

Step 2: Identify the Application Requirements

Different applications have unique demands. Analyze the specific conditions under which the valve will operate, including the type of media (liquids, slurries, solids) and the environment (temperature, pressure, and potential for erosion). This step is vital to ensure the valve’s design is suitable for its intended use.

- Media Characteristics: Determine if the valve will need to handle solid particles, corrosive substances, or high-viscosity materials.

- Environmental Conditions: Consider factors like temperature fluctuations and exposure to harsh chemicals.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they have the necessary expertise and a solid track record. Request detailed company profiles, case studies, and references from clients in similar industries. This step mitigates risks and builds confidence in your procurement decision.

- Reputation and Experience: Look for suppliers with extensive experience in severe service applications.

- Customer Reviews and Testimonials: Seek feedback from past clients to gauge reliability and service quality.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your selected suppliers hold relevant certifications, such as ISO 9001 or API compliance. This step is crucial for ensuring that the valves meet industry standards and regulatory requirements, which can affect both safety and performance.

- Quality Management Systems: Check for compliance with international quality standards.

- Industry-Specific Certifications: Validate that the supplier meets specific industry requirements (e.g., MSS SP-135).

Step 5: Assess Actuation Options and Features

Evaluate the actuation options available with the valve. Different actuation methods (manual, pneumatic, electric) can impact operational efficiency and maintenance needs. Understanding these options helps tailor the valve to your operational requirements.

- Customization Options: Look for suppliers that offer tailored actuation solutions based on your operational needs.

- Maintenance Considerations: Choose designs that simplify maintenance and reduce downtime.

Step 6: Request and Compare Quotes

Once you have narrowed down your options, request detailed quotes from your shortlisted suppliers. Compare not just the price but also the terms of service, warranty conditions, and delivery timelines. This thorough analysis ensures you receive the best value for your investment.

- Total Cost of Ownership: Consider long-term costs, including maintenance and operational efficiency, rather than just the upfront price.

- Delivery and Support: Evaluate the supplier’s ability to meet your timelines and provide ongoing support.

Step 7: Conduct a Final Review Before Purchase

Before finalizing your purchase, conduct a comprehensive review of all gathered information. Ensure that the selected valve aligns with your defined specifications, application needs, and supplier reliability. This last step is critical to avoid costly mistakes and ensure that the valve will perform as expected.

- Cross-Verification: Double-check technical specifications against supplier offerings.

- Risk Assessment: Identify any potential risks associated with your choice and develop contingency plans if necessary.

By following this practical checklist, you can make informed decisions when sourcing severe service knife gate valves, ultimately enhancing operational efficiency and ensuring reliability in your processes.

Comprehensive Cost and Pricing Analysis for severe service knife gate valve Sourcing

What Are the Key Cost Components for Severe Service Knife Gate Valves?

When sourcing severe service knife gate valves, it is crucial to understand the various cost components that contribute to the overall price. These components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials represent a significant portion of the cost, with high-quality metals and elastomers required to ensure durability and performance in harsh environments. The choice of materials directly impacts the valve’s resistance to abrasion, corrosion, and high-pressure conditions, which are critical for applications in industries such as mining, oil and gas, and chemical processing.

Labor costs encompass the skilled workforce needed for manufacturing, assembly, and quality assurance. Given the technical nature of severe service valves, skilled labor is essential for achieving the precision required in production.

Manufacturing overhead includes expenses related to factory operations, such as utilities, equipment maintenance, and indirect labor. These costs can vary depending on the manufacturing location and operational efficiency.

Tooling costs refer to the initial investment in specialized tools and machinery required for valve production. High-quality tooling can enhance efficiency and reduce waste during the manufacturing process.

Quality control is vital for ensuring that the valves meet stringent industry standards, such as API and ASME certifications. QC processes can add to the overall cost but are necessary to avoid costly failures and downtime.

Logistics costs involve shipping, handling, and storage. For international buyers, understanding Incoterms is essential, as they define the responsibilities of buyers and sellers regarding shipping and risk management.

Margins vary by supplier and can be influenced by market demand, competition, and the supplier’s operational costs. Premium suppliers may charge higher margins due to their reputation for quality and service.

How Do Price Influencers Impact Sourcing Decisions for Severe Service Knife Gate Valves?

Several factors can influence the pricing of severe service knife gate valves, including volume or minimum order quantity (MOQ), specifications and customization, material selection, quality certifications, supplier reputation, and Incoterms.

Volume/MOQ plays a significant role in pricing; higher quantities often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs with suppliers to optimize their purchasing strategy.

Specifications and customization can substantially affect price. Custom features tailored to specific applications may incur additional costs, but they can enhance performance and longevity, thus providing better value in the long run.

Material choices also influence pricing. For instance, valves made from exotic alloys or advanced composites may cost more but offer superior performance in extreme conditions.

Quality certifications are a crucial consideration for B2B buyers. Valves that meet or exceed industry standards often command higher prices due to the assurance of reliability and compliance with safety regulations.

Supplier factors, such as reputation, service quality, and technical support, can also impact pricing. Established suppliers may charge a premium, but they often provide better after-sales support and product warranties.

Incoterms dictate the division of costs and responsibilities between buyers and sellers, impacting the total landed cost of the valves. Buyers should be aware of the implications of different Incoterms when negotiating contracts.

What Are the Best Practices for Negotiating Prices and Ensuring Cost-Efficiency?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings. Here are some tips:

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQs, allowing for better pricing negotiations.

Understand Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, operation, and potential downtime. Opting for higher-quality valves may result in lower TCO.

Research Market Prices: Conduct market research to benchmark prices and understand the competitive landscape. This information can empower negotiations with suppliers.

Prioritize Specifications: Clearly outline your needs and specifications to avoid unnecessary costs associated with features that may not be essential for your application.

Build Relationships with Suppliers: Establishing long-term relationships can lead to better terms, discounts, and favorable service agreements.

Be Aware of Pricing Nuances: Understand regional pricing variations, as local economic conditions, import duties, and currency fluctuations can affect costs.

Conclusion

In summary, a comprehensive understanding of the cost structure, price influencers, and effective negotiation strategies is essential for B2B buyers looking to source severe service knife gate valves. By considering these factors, buyers can make informed decisions that align with their operational needs and financial objectives.

Alternatives Analysis: Comparing severe service knife gate valve With Other Solutions

Understanding the Alternatives to Severe Service Knife Gate Valves

In industries where fluid control is critical, choosing the right valve can significantly impact operational efficiency and cost. While the severe service knife gate valve is a robust choice for handling challenging media, it’s important to consider alternative solutions that may offer different benefits. This analysis compares the severe service knife gate valve against two viable alternatives: the ball valve and the butterfly valve.

Comparison Table

| Comparison Aspect | Severe Service Knife Gate Valve | Ball Valve | Butterfly Valve |

|---|---|---|---|

| Performance | Bi-directional, zero leakage; excellent for abrasive and viscous media | Quick shut-off; good for liquids and gases | Suitable for large volumes; offers tight sealing |

| Cost | Higher initial investment; lower total cost of ownership due to durability | Generally lower cost; may require more frequent replacement | Moderate cost; economical for large-scale applications |

| Ease of Implementation | Requires careful installation; may need specialized tools | Simple installation; widely used | Easy to install; lightweight design |

| Maintenance | Low maintenance due to durable design; parts are replaceable | Moderate; may need regular replacements | Low maintenance; fewer parts to service |

| Best Use Case | Mining, power generation, wastewater treatment | Oil and gas, water treatment | HVAC systems, large-scale water systems |

Analyzing the Alternatives

Ball Valve

Ball valves are known for their ability to provide a tight seal and quick on/off control. They perform exceptionally well in applications involving liquids and gases, making them suitable for many industries, including oil and gas. While they often come at a lower initial cost, they may not handle abrasive or viscous media as effectively as severe service knife gate valves. Additionally, they may require more frequent replacements, leading to higher long-term costs.

Butterfly Valve

Butterfly valves are another alternative, particularly favored in applications requiring the control of large volumes of fluid. They are lightweight, easy to install, and offer a relatively low cost compared to knife gate valves. However, while they provide good sealing capabilities, they may not perform as effectively in high-pressure or abrasive environments. Their maintenance is minimal, but they may not offer the same level of durability and reliability as severe service knife gate valves in severe service conditions.

Making the Right Choice for Your Needs

When selecting a valve for your operations, it’s essential to evaluate the specific requirements of your application. Consider the type of media being handled, the operating pressure and temperature, as well as maintenance capabilities. While severe service knife gate valves excel in harsh conditions and provide long-lasting performance, alternatives like ball and butterfly valves might be more appropriate for less demanding environments or where cost is a primary concern. Ultimately, understanding the strengths and weaknesses of each option will help you make an informed decision that aligns with your operational goals and budget.

Essential Technical Properties and Trade Terminology for severe service knife gate valve

What Are the Key Technical Properties of Severe Service Knife Gate Valves?

When selecting severe service knife gate valves, understanding their technical properties is crucial for ensuring optimal performance in demanding environments. Here are some critical specifications that buyers should be aware of:

Material Grade

The material grade of a knife gate valve is vital for its durability and resistance to corrosion and wear. Common materials include stainless steel, carbon steel, and specialized alloys. Selecting the right material is essential for applications involving aggressive fluids or abrasive solids, as it directly impacts the valve’s lifespan and reliability in severe service conditions.Pressure Rating

Pressure ratings, often defined by standards such as ASME Class 150 or Class 300, indicate the maximum pressure the valve can withstand. This is crucial in industries like oil and gas or mining, where high-pressure systems are commonplace. Choosing a valve with the appropriate pressure rating ensures safety and prevents failures that could lead to costly downtime or catastrophic incidents.Temperature Rating

The temperature rating defines the maximum operating temperature of the valve. Severe service applications often involve extreme temperatures, making this specification critical. For instance, valves rated for high temperatures can maintain performance without warping or degrading, thereby ensuring longevity and reliability in operations such as chemical processing or power generation.Shutoff Capability

The shutoff capability refers to the valve’s ability to provide a leak-tight seal when closed. This is particularly important in applications where containment of hazardous materials is necessary. Valves with resilient seat designs or advanced sealing technologies can achieve zero-leakage performance, which is essential for compliance with environmental regulations and preventing operational losses.Size Range

The size range of a knife gate valve is determined by its diameter and can vary from small to large configurations (e.g., 3-60 inches). Selecting the correct size is vital for ensuring compatibility with existing pipeline systems and achieving optimal flow characteristics. Proper sizing can prevent issues related to pressure drop and flow turbulence.

What Are Common Trade Terms Related to Severe Service Knife Gate Valves?

Understanding trade terminology is equally important for effective communication and negotiation in the B2B space. Here are some common terms related to severe service knife gate valves:

OEM (Original Equipment Manufacturer)

An OEM produces components that are used in another company’s end products. In the context of knife gate valves, OEMs provide specialized valves that meet specific industry standards. Understanding the OEM’s reputation and certification can guide buyers in selecting reliable products.MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant in B2B transactions, where suppliers may set MOQs to ensure profitability. Buyers need to be aware of MOQs to plan their inventory and avoid overstocking or understocking situations.RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific products or services. This process helps buyers compare prices and specifications from multiple suppliers, enabling informed decision-making. It is a critical step in the procurement process for severe service knife gate valves.Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is crucial for international buyers importing knife gate valves. Familiarity with Incoterms can help avoid misunderstandings and disputes.Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In industries with tight deadlines, such as mining and chemical processing, understanding lead times is critical for project planning and avoiding costly delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their severe service knife gate valve selections meet their operational needs while aligning with industry standards.

Navigating Market Dynamics and Sourcing Trends in the severe service knife gate valve Sector

What Are the Current Market Dynamics and Key Trends in the Severe Service Knife Gate Valve Sector?

The global market for severe service knife gate valves is witnessing significant growth, driven by the increasing demand from industries such as oil and gas, mining, chemical processing, and wastewater management. Key trends influencing this sector include the rising focus on zero-leakage technology, which is becoming a standard requirement for applications involving abrasive and high-density slurries. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing valves that meet stringent specifications such as API, ASME, and MSS standards.

Emerging technologies, such as advanced materials and automated actuation systems, are reshaping sourcing strategies. Manufacturers are incorporating smart technologies that enable remote monitoring and predictive maintenance, enhancing operational efficiency and reducing downtime. For buyers in markets like Brazil and Nigeria, understanding local regulations and specifications is crucial, as these can vary significantly and impact procurement decisions. Additionally, the trend toward consolidation in the valve manufacturing sector is leading to fewer but more robust suppliers, making it essential for buyers to establish strong relationships with key manufacturers who can provide tailored solutions.

How Important Is Sustainability and Ethical Sourcing in the Severe Service Knife Gate Valve Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the severe service knife gate valve market. The environmental impact of valve manufacturing and operation cannot be overlooked, especially in industries that deal with hazardous materials or large-scale waste management. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, including the use of recyclable materials and energy-efficient production processes.

Certifications such as ISO 14001 for environmental management and the use of ‘green’ materials can serve as indicators of a supplier’s commitment to sustainability. Moreover, ethical supply chains are essential to mitigate risks associated with environmental regulations and corporate social responsibility. Buyers are encouraged to engage with suppliers who not only meet performance specifications but also align with their values regarding environmental stewardship and social responsibility. This alignment can enhance brand reputation and customer loyalty in an increasingly eco-conscious market.

What Is the Brief Evolution and History of Severe Service Knife Gate Valves?

The evolution of severe service knife gate valves can be traced back to the early 20th century when traditional gate valves were adapted for more demanding applications. Over the decades, advancements in materials science and engineering have led to the development of specialized designs that can handle extreme pressures and abrasive conditions. The introduction of features like bi-directional sealing and guided shear gate designs has significantly improved the performance and reliability of these valves.

Today, severe service knife gate valves are engineered to meet rigorous industry standards and are used across various sectors, including mining, chemical processing, and wastewater treatment. As industries continue to evolve, these valves are being designed to not only withstand harsh environments but also to incorporate smart technologies that enhance operational efficiency and maintenance practices. This ongoing innovation positions severe service knife gate valves as critical components in modern industrial applications, catering to the specific needs of B2B buyers across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of severe service knife gate valve

How do I choose the right severe service knife gate valve for my application?

Choosing the right severe service knife gate valve involves assessing the specific requirements of your application, including the type of media being handled, pressure and temperature conditions, and the need for bi-directional sealing. Evaluate the valve’s construction materials to ensure compatibility with corrosive or abrasive substances. Consult manufacturers’ specifications and consider factors such as actuation options and maintenance ease. Collaborating with suppliers who understand your industry can provide insights tailored to your needs, enhancing operational efficiency.What are the key features to look for in severe service knife gate valves?

When sourcing severe service knife gate valves, prioritize features such as a bi-directional zero-leakage design, robust construction for high-pressure applications, and the ability to handle abrasive slurries. Look for specialized designs like guided shear gates, which improve cutting through solid media. Additionally, consider the valve’s packing system, which should offer superior sealing capabilities and ease of maintenance. Certifications such as ASME and MSS standards are also crucial indicators of quality and reliability.What is the average lead time for ordering severe service knife gate valves?

Lead times for severe service knife gate valves can vary significantly based on the manufacturer, customization requirements, and order volume. Typically, standard valves may take 4 to 6 weeks for delivery, while customized solutions can extend this timeframe to 8 weeks or more. It’s advisable to discuss lead times with suppliers early in the procurement process to ensure alignment with your project schedules and avoid potential delays.What are the typical minimum order quantities (MOQs) for severe service knife gate valves?

Minimum order quantities (MOQs) for severe service knife gate valves vary by supplier and can depend on factors such as the valve size and customization options. Generally, MOQs can range from 5 to 50 units for standard valves. For specialized or custom valves, suppliers may have higher MOQs due to production costs. Always confirm MOQs with potential suppliers to align with your purchasing strategy and budget.How can I ensure the quality of severe service knife gate valves when sourcing internationally?

To ensure quality when sourcing severe service knife gate valves internationally, conduct thorough supplier vetting. Verify certifications such as ISO, ASME, or MSS, and request product samples for testing. It’s beneficial to review customer testimonials and case studies that demonstrate the supplier’s experience in your specific industry. Additionally, consider engaging third-party inspection services to evaluate products before shipment, ensuring they meet your specifications and quality standards.What payment terms are typically offered for international purchases of severe service knife gate valves?

Payment terms for international purchases of severe service knife gate valves vary by supplier but typically include options such as advance payment, letter of credit, or payment upon delivery. It’s crucial to clarify terms upfront to avoid misunderstandings. Many suppliers may also offer flexible terms for larger orders or established customers. Discussing payment terms during initial negotiations can help build a strong relationship and ensure smoother transactions.What logistics considerations should I keep in mind when importing severe service knife gate valves?

When importing severe service knife gate valves, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling industrial equipment to navigate potential challenges. Ensure that all documentation, including invoices and shipping manifests, complies with international trade regulations. It’s also wise to anticipate potential tariffs or duties applicable to your region, which can impact overall costs.How do I address maintenance and serviceability for severe service knife gate valves?

To ensure long-term performance of severe service knife gate valves, establish a maintenance schedule based on manufacturer recommendations. Regular inspections for wear and tear, particularly on seals and packing, are essential. Opt for valves designed for easy servicing with replaceable parts that can be handled using standard tools. Training your maintenance team on best practices will also enhance the reliability and lifespan of the valves, minimizing downtime in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Severe Service Knife Gate Valve Manufacturers & Suppliers List

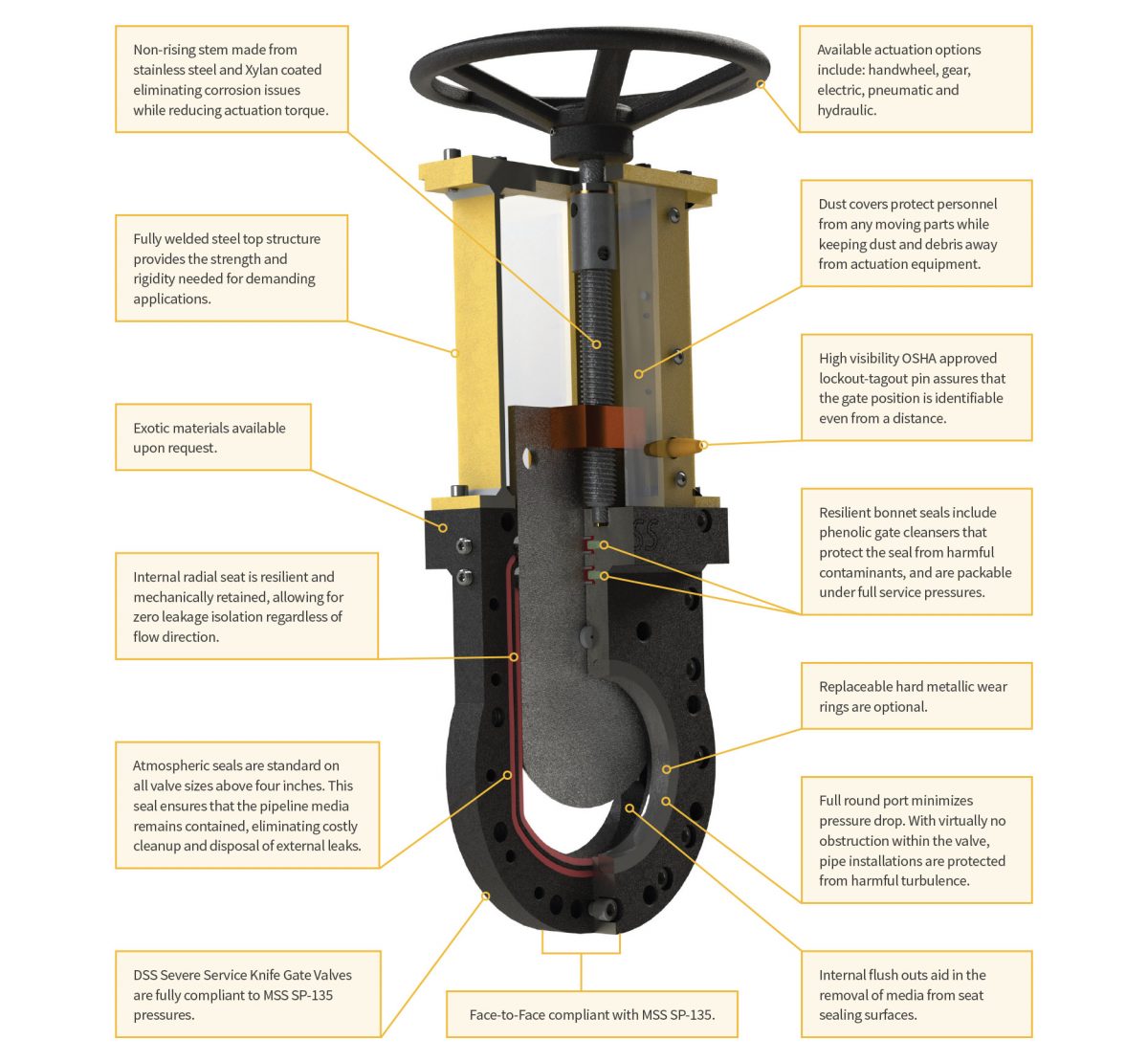

1. DSS Valves – Severe Service Knife Gate Valve

Domain: dssvalves.com

Registered: 2016 (9 years)

Introduction: Product Name: Severe Service Knife Gate Valve (SSKGV)\nKey Features: 1. Bidirectional zero-leakage design exceeding API, ASME, and MSS specifications up to ASME Class 1500/PN 250 (3750 psig/250 barg). 2. Guided Shear Gate design with a shearing tip and internal gate guides for cutting through all media including solids, scale, fiber, and paste. 3. Designed to perform in harsh conditions, overcomin…

2. Emerson – True Bi-Directional Valve

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – True Bi-Directional Valve, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. DeZURIK – Severe Service Knife Gate Valve

Domain: shop.dwprouty.com

Registered: 1997 (28 years)

Introduction: {“Brand”:”DeZURIK”,”Product Name”:”Severe Service Knife Gate Valve (KSV)”,”Description”:”Designed to withstand high pressures and abrasive slurries, suitable for mining, steel, power, chemical, municipal sludge, bio-fuels production, and paper industries.”,”Features”:”Rigid one-piece body, 100% diameter port, hard-faced gate, rotatable seat rings, ideal for high-pressure, high-density slurry lines…

4. Special Alloy Fabricators – Knife Gate Valves

Domain: oreaclevalves.com

Registered: 2021 (4 years)

Introduction: Knife Gate Valves engineered and manufactured in Canada by Special Alloy Fabricators. Features include unique seat designs, unibody fabrication, and high-performance materials for durability and long service life in abrasive slurry applications. Key specifications include: unibody design for a single heavy-duty component, full port geometry matching pipe I.D., extreme wear resistance with abrasion…

5. Dual Valves – DSSWSV Knife Gate Valve

Domain: dualvalves.com

Registered: 2002 (23 years)

Introduction: Dual Severe Service Wafer Sleeve Knife Gate Valve (DSSWSV) is designed for full on/off applications. Key features include:

– Operation at 25 Bar/365 Psi

– Superior isolation with a one-piece metal covered rubber or urethane sleeve (replaceable)

– No metal parts in contact with flowing slurry

– Bubble tight shut off

– External epoxy or powder coated

– Easily adapted to fit most actuators

– L…

6. Wey Valve – W Series Knife Gate Valves

Domain: weyvalve.com

Registered: 1997 (28 years)

Introduction: W Series Knife Gate Valves

– Nominal Sizes: 2 – 56 inch

– Materials: Stainless steel, Carbon steel, Cast tin-bronze, Cast aluminum-bronze

– Pressure Rating: 0 – 740 psi

– Flange Drilling: ANSI Class 150, ANSI Class 300, MSS-SP135 Class 150 short, MSS-SP135 Class 150 long, MSS-SP135 Class 300 short, MSS-SP135 Class 300 long

– Features: Robust universal bonnet compatible with various actuator types,…

Strategic Sourcing Conclusion and Outlook for severe service knife gate valve

In the competitive landscape of severe service knife gate valves, strategic sourcing emerges as a pivotal strategy for international B2B buyers. By prioritizing suppliers with proven reliability and advanced engineering capabilities, companies can mitigate risks associated with high-pressure applications and abrasive media. Key differentiators such as zero-leakage designs, robust materials, and customizable actuation options are essential in ensuring optimal performance across various industries, including mining, oil and gas, and chemical processing.

Investing in high-quality severe service knife gate valves not only enhances operational efficiency but also contributes to long-term cost savings through reduced maintenance and downtime. As markets in Africa, South America, the Middle East, and Europe continue to evolve, understanding regional demands and supplier capabilities will be crucial.

Looking ahead, B2B buyers are encouraged to leverage insights from this guide to refine their sourcing strategies. By aligning with reputable manufacturers and exploring innovative solutions, organizations can secure a competitive edge in their respective markets. Embrace the opportunity to enhance your operational resilience by sourcing the right severe service knife gate valves tailored to your specific needs.