Introduction: Navigating the Global Market for solar water pump irrigation system

In an era where water scarcity poses significant challenges to agricultural productivity, sourcing an effective solar water pump irrigation system can be a game-changer for businesses operating in resource-limited regions. With the increasing demand for sustainable and cost-effective irrigation solutions, international B2B buyers from Africa, South America, the Middle East, and Europe are seeking reliable systems that not only reduce operational costs but also enhance water accessibility. This comprehensive guide delves into the diverse types of solar water pump irrigation systems available on the market, their various applications, and critical factors to consider when selecting a supplier.

Navigating this complex landscape involves understanding the technical specifications, such as flow rates and power requirements, as well as evaluating supplier credibility and pricing structures. By outlining key considerations, including installation processes, maintenance needs, and potential financial incentives, this guide empowers buyers to make informed purchasing decisions tailored to their specific agricultural needs. Whether you are in Vietnam looking to optimize rice irrigation or in Saudi Arabia aiming to sustain livestock operations, our insights will help you identify the right solar water pump solutions that align with your operational goals and environmental commitments. Embrace the potential of solar technology to transform your irrigation practices and secure a sustainable future for your agricultural endeavors.

Understanding solar water pump irrigation system Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Submersible Solar Pumps | Operates underwater; high head capacity | Agricultural irrigation, livestock | Pros: Effective in deep installations; reliable water supply. Cons: Higher initial cost; installation complexity. |

| Surface Solar Pumps | Positioned above water source; lower head | Irrigation for shallow water sources | Pros: Easier installation; lower cost. Cons: Limited to shallow applications; less efficient in high-demand scenarios. |

| Hybrid Solar Pumps | Combines solar and grid power; versatile | Year-round irrigation, commercial use | Pros: Reliable during cloudy weather; flexible energy sourcing. Cons: Higher upfront cost; dependency on grid availability. |

| DC Solar Pumps | Direct current operation; energy-efficient | Small-scale farms, remote locations | Pros: Low energy consumption; ideal for off-grid systems. Cons: Limited power output; may require battery backup for consistent performance. |

| Solar Water Pump Kits | All-in-one solutions with necessary components | Residential and small agricultural use | Pros: Simplified purchasing; comprehensive solution. Cons: Limited customization; may not meet specific needs of larger operations. |

What are the Characteristics of Submersible Solar Pumps?

Submersible solar pumps are designed to operate underwater, making them ideal for deep installations such as wells. They typically have high head capacities, allowing them to pump water from significant depths efficiently. B2B buyers should consider the specific depth and flow rate requirements of their applications, as well as the installation complexity, which can be higher than surface pumps. The durability and reliability of these pumps make them suitable for agricultural irrigation and livestock watering, especially in remote areas.

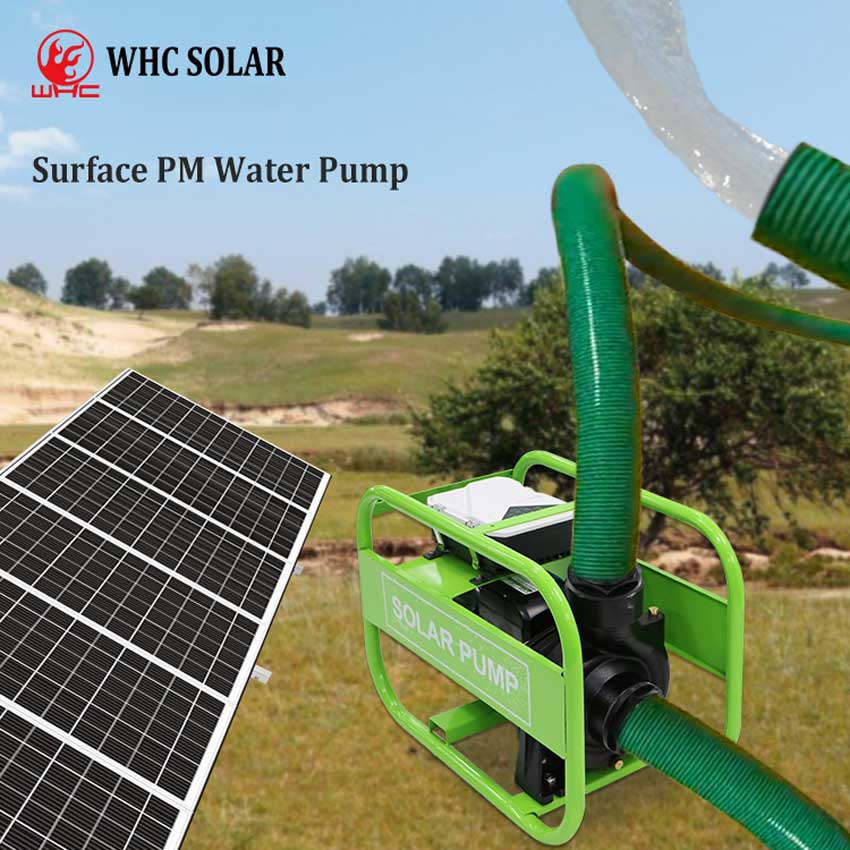

How Do Surface Solar Pumps Function?

Surface solar pumps are installed above the water source, making them a cost-effective option for shallow water applications. They are easier to install and maintain compared to submersible models, which can be advantageous for B2B buyers with limited technical expertise. However, their efficiency diminishes in high-demand scenarios, and they may not be suitable for deeper water sources. Buyers should evaluate their specific needs, including water depth and volume, before opting for surface pumps.

What Benefits Do Hybrid Solar Pumps Offer?

Hybrid solar pumps combine solar energy with traditional grid power, providing flexibility for year-round use. They are particularly beneficial for commercial applications where consistent water supply is critical, even during cloudy days. B2B buyers should weigh the higher initial investment against the reliability and versatility offered by these systems. Understanding the energy requirements and potential for grid dependency is crucial for making informed purchasing decisions.

Why Choose DC Solar Pumps for Small-Scale Applications?

DC solar pumps operate on direct current, making them energy-efficient and particularly suited for small-scale farms and remote locations. They consume less power and can be integrated with battery systems for off-grid applications. However, potential buyers should consider the limited power output, which may necessitate a battery backup for consistent operation. Assessing the scale of water needs and energy consumption will guide buyers in selecting the right system.

What Should Buyers Know About Solar Water Pump Kits?

Solar water pump kits provide a comprehensive solution, including all necessary components for installation. They are particularly appealing to residential users and small agricultural operations due to their simplicity and ease of use. However, these kits may lack customization options, which could be a disadvantage for larger operations with specific requirements. B2B buyers should evaluate their water needs and consider whether a kit will meet their operational demands effectively.

Key Industrial Applications of solar water pump irrigation system

| Industry/Sector | Specific Application of solar water pump irrigation system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Drip irrigation for crops | Reduces water usage, increases crop yield, and lowers energy costs | Sizing, pump type, solar panel compatibility, and local climate |

| Livestock Farming | Water supply for livestock and feeding systems | Ensures consistent water availability, enhancing livestock health | Pump depth, flow rate, and durability in various environments |

| Horticulture | Irrigation for greenhouses and nurseries | Optimizes plant growth, minimizes labor costs | Pump capacity, energy efficiency, and automation options |

| Aquaculture | Water management in fish farming | Maintains optimal water levels, improving fish health and yield | Pump size, water quality considerations, and maintenance support |

| Rural Community Development | Community water supply systems | Provides reliable access to water, improving quality of life | Installation support, local regulations, and scalability options |

How is Solar Water Pump Irrigation Used in Agriculture?

In agriculture, solar water pump irrigation systems are primarily utilized for drip irrigation, which delivers water directly to the plant roots. This method reduces water wastage and enhances crop yields, making it particularly beneficial in regions facing water scarcity, such as parts of Africa and the Middle East. Buyers in this sector must consider the pump size and type, ensuring compatibility with solar panels based on local sunlight availability. Additionally, understanding the specific water requirements of different crops is crucial for optimizing irrigation efficiency.

What are the Benefits of Solar Water Pumps in Livestock Farming?

For livestock farming, solar water pumps provide a sustainable solution for ensuring a consistent water supply for animals. These systems can be installed in remote areas where access to electricity is limited, thereby enhancing livestock health and productivity. Key considerations for international buyers include the depth of the water source and the required flow rate, which will vary depending on herd size and livestock type. Durability is also vital, as the systems must withstand harsh environmental conditions.

How Do Solar Water Pumps Support Horticulture?

In horticulture, solar water pumps are essential for irrigating greenhouses and nurseries. These systems help maintain optimal moisture levels, which is critical for plant growth and health. By reducing labor costs associated with manual watering, businesses can increase their operational efficiency. Buyers should evaluate pump capacity and energy efficiency, as well as consider options for automation to further streamline their irrigation processes.

What Role Do Solar Pumps Play in Aquaculture?

Aquaculture relies on effective water management to maintain the health of fish populations. Solar water pump irrigation systems facilitate this by ensuring optimal water levels and quality, which are crucial for fish growth and survival. When sourcing these systems, businesses should focus on the size of the pump and its ability to handle specific water quality requirements, such as salinity levels. Additionally, maintenance support is a key consideration to ensure long-term operational efficiency.

How Can Solar Water Pumps Benefit Rural Community Development?

In rural community development, solar water pump irrigation systems serve as reliable water supply solutions, significantly improving the quality of life for residents. These systems can provide clean drinking water and support agricultural activities, promoting economic growth. For international buyers, it is essential to consider installation support and local regulations that may affect the deployment of these systems. Scalability options are also important, as community needs may evolve over time.

3 Common User Pain Points for ‘solar water pump irrigation system’ & Their Solutions

Scenario 1: Navigating Inconsistent Water Supply for Agriculture

The Problem: Many agricultural businesses in remote areas face the challenge of inconsistent water supply, which can severely impact crop yields. Traditional irrigation systems often rely on electric power, making them unreliable in regions with unstable electricity or no access to the grid. This inconsistency can lead to drought stress on crops, ultimately affecting harvest quality and profitability.

The Solution: To combat this issue, B2B buyers should invest in solar water pump irrigation systems designed specifically for agricultural applications. These systems utilize solar energy to provide a reliable water supply without dependence on the electrical grid. When sourcing these systems, it is crucial to assess the specific water requirements of the crops, including the volume needed and the delivery pressure. Buyers should engage with manufacturers that offer customizable solutions, ensuring the pump size and solar array are tailored to the specific needs of the agricultural operation. Additionally, opting for systems with integrated storage tanks can help buffer against periods of low sunlight, ensuring that water is available even during cloudy days.

Scenario 2: Overcoming High Initial Investment Concerns

The Problem: While solar water pumps present a sustainable long-term solution, the initial investment can be a barrier for many businesses, especially in developing regions. B2B buyers often hesitate to make large upfront expenditures without guaranteed returns, leading them to stick with less efficient, traditional irrigation methods that incur ongoing operational costs.

The Solution: To mitigate concerns about high initial investments, potential buyers should conduct a comprehensive cost-benefit analysis that outlines the total cost of ownership over the lifespan of the solar water pump system. This analysis should include projected savings from reduced electricity costs, maintenance expenses, and potential increases in crop yields due to consistent watering. Buyers can also explore financing options or government incentives that promote renewable energy adoption. Engaging with suppliers who offer leasing or pay-as-you-go models can further ease financial constraints, allowing businesses to transition to solar without the burden of upfront costs.

Scenario 3: Ensuring System Longevity and Reliability

The Problem: Users of solar water pump irrigation systems often express concerns about the longevity and reliability of these systems, particularly in harsh environmental conditions. Factors such as extreme temperatures, dust, and moisture can affect pump performance and durability, leading to unexpected failures and costly repairs.

The Solution: To enhance the longevity and reliability of solar water pump systems, B2B buyers should prioritize sourcing high-quality equipment that is specifically designed for the local climate. It is advisable to select pumps that come with robust warranties and are made from corrosion-resistant materials. Additionally, regular maintenance is critical; establishing a proactive maintenance schedule can prevent small issues from escalating into major problems. Buyers should also consider investing in monitoring technology that provides real-time data on pump performance and alerts users to any potential issues before they lead to system failure. Collaborating with suppliers who offer technical support and maintenance services can also help ensure that the irrigation system operates efficiently throughout its lifespan.

Strategic Material Selection Guide for solar water pump irrigation system

What Are the Key Materials Used in Solar Water Pump Irrigation Systems?

When selecting materials for solar water pump irrigation systems, it is crucial to consider their properties, advantages, disadvantages, and specific applications. This analysis focuses on four common materials: stainless steel, thermoplastics, aluminum, and cast iron. Each material presents unique characteristics that can significantly influence the performance and longevity of solar water pumps.

How Does Stainless Steel Perform in Solar Water Pump Applications?

Stainless steel is renowned for its excellent corrosion resistance and high strength, making it a popular choice for components exposed to water and varying environmental conditions. With a high-temperature rating, stainless steel can withstand extreme conditions without deforming.

Pros: Its durability ensures a long lifespan, reducing the need for frequent replacements. Stainless steel is also relatively easy to clean and maintain, which is crucial for systems that may deal with sediment-laden water.

Cons: The primary drawback is its cost, which tends to be higher than other materials. Manufacturing complexity can also be an issue, as stainless steel components often require specialized welding and machining.

Impact on Application: Stainless steel is compatible with a wide range of media, including potable water, making it suitable for agricultural and residential applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A312 for pipes and fittings. In regions like Africa and the Middle East, where water quality can vary, selecting high-grade stainless steel can mitigate corrosion risks.

What Role Do Thermoplastics Play in Solar Water Pump Systems?

Thermoplastics, such as PVC and polyethylene, are increasingly used in solar water pump systems due to their lightweight nature and resistance to corrosion. They are ideal for applications that require flexibility and ease of installation.

Pros: Thermoplastics are cost-effective and easy to manufacture, which allows for rapid production and installation. Their resistance to chemicals and UV light makes them suitable for outdoor applications.

Cons: However, thermoplastics can be less durable than metals, especially under high-pressure conditions. They may also be prone to deformation at elevated temperatures.

Impact on Application: Thermoplastics are best suited for low-pressure applications, such as surface water pumping and irrigation systems where flexibility is beneficial.

Considerations for International Buyers: Compliance with standards like ASTM D1785 for PVC pipes is essential. In regions like South America, where UV exposure is high, selecting UV-stabilized thermoplastics is crucial.

How Does Aluminum Compare in Solar Water Pump Systems?

Aluminum is lightweight and has excellent corrosion resistance, making it a viable option for solar water pump components, especially in portable systems.

Pros: Its lightweight nature simplifies installation and reduces shipping costs. Aluminum also offers good thermal conductivity, which can be advantageous in heat dissipation applications.

Cons: The main limitation is its lower strength compared to stainless steel, which may restrict its use in high-pressure applications. Additionally, aluminum can be more expensive than thermoplastics.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as mobile irrigation systems.

Considerations for International Buyers: Buyers should check compliance with international standards like ASTM B221 for aluminum extrusions. In regions with high humidity, ensuring proper coatings to prevent oxidation is essential.

What Are the Advantages of Using Cast Iron in Solar Water Pump Systems?

Cast iron is known for its strength and durability, making it a traditional choice for pump housings and components.

Pros: Its robustness allows it to handle high pressures and heavy-duty applications. Cast iron also has excellent wear resistance, making it suitable for abrasive water conditions.

Cons: The primary disadvantage is its weight, which can complicate installation and transportation. Cast iron is also more susceptible to corrosion if not properly coated.

Impact on Application: Cast iron is ideal for high-pressure applications and environments where durability is paramount.

Considerations for International Buyers: Compliance with standards such as ASTM A48 for gray cast iron is important. In regions with varying water quality, ensuring proper protective coatings can extend the lifespan of cast iron components.

Summary Table of Material Selection for Solar Water Pump Irrigation Systems

| Material | Typical Use Case for solar water pump irrigation system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure applications, potable water systems | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Thermoplastics | Surface water pumping, low-pressure irrigation | Cost-effective, lightweight | Less durable under high pressure | Low |

| Aluminum | Portable irrigation systems | Lightweight, good thermal conductivity | Lower strength than stainless steel | Medium |

| Cast Iron | Heavy-duty applications, high-pressure systems | High strength, wear resistance | Heavy, susceptible to corrosion | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on specific applications, regional requirements, and material properties.

In-depth Look: Manufacturing Processes and Quality Assurance for solar water pump irrigation system

What Are the Main Stages in the Manufacturing Process of Solar Water Pump Irrigation Systems?

The manufacturing process for solar water pump irrigation systems involves several critical stages, each designed to ensure the final product meets rigorous performance and reliability standards. Understanding these stages is essential for B2B buyers looking to source high-quality systems.

1. Material Preparation

The first step in the manufacturing process is material preparation. This involves sourcing high-grade materials, including corrosion-resistant metals, durable plastics, and advanced photovoltaic (PV) cells. Suppliers often conduct thorough evaluations of raw materials to ensure they meet predefined specifications, which may include tensile strength, thermal stability, and resistance to environmental factors.

2. Forming Techniques

Once materials are ready, the forming stage begins. Various techniques are employed depending on the components being produced. For instance, stamping and molding are commonly used to create the housings and structural parts of pumps. Advanced technologies like CNC machining may be utilized for precision parts, ensuring that every component fits perfectly. This stage is crucial as it directly affects the performance and longevity of the pump systems.

3. Assembly of Components

After forming, the next phase is assembly. This involves integrating various components, such as the pump motor, PV panels, control systems, and piping. Automation plays a significant role here, with robotic systems ensuring consistent assembly quality. Skilled technicians oversee the process to manage any manual interventions required for complex integrations.

4. Finishing Processes

The final stage of manufacturing is finishing, where components are coated or treated to enhance durability and resistance to the elements. This may involve applying protective coatings, such as epoxy or powder finishes, that guard against corrosion and UV damage. It is also common to conduct functional tests at this stage to verify the operational integrity of the assembled units.

How Is Quality Assurance Implemented in Solar Water Pump Manufacturing?

Quality assurance (QA) is integral to the manufacturing of solar water pump systems. It ensures that products meet both international standards and specific industry requirements, thereby reducing the risk of failure in the field.

Relevant International Standards for Quality Control

Many manufacturers adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system (QMS). Compliance with ISO 9001 assures B2B buyers that the manufacturer has established processes to enhance customer satisfaction and continually improve product quality. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are vital for ensuring safety and performance, especially in regions with stringent regulations.

What Are the Key Quality Control Checkpoints?

Quality control is typically structured around several key checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards before production begins.

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor the quality of components as they are being produced. This includes dimensional checks and functionality tests.

Final Quality Control (FQC): Once assembly is complete, the entire system undergoes rigorous testing to validate its performance against predefined criteria. This may include pressure tests, flow rate assessments, and operational checks under simulated conditions.

What Testing Methods Are Commonly Used for Quality Assurance?

Several testing methods are employed to ensure the reliability and efficiency of solar water pump systems. Common practices include:

Functional Testing: Evaluates the operational performance of the pump, ensuring it meets flow rate and pressure specifications.

Environmental Testing: Assesses the system’s resilience against temperature variations, humidity, and UV exposure, which are critical for long-term outdoor use.

Durability Testing: Simulates extended use to identify potential points of failure and ensure the product can withstand the rigors of daily operation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are actionable steps buyers can take:

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes, quality control measures, and adherence to international standards.

Quality Control Reports: Requesting documentation of QC processes and results can provide insights into the supplier’s operational effectiveness and commitment to quality.

Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of the supplier’s capabilities and product quality, ensuring that the products meet required standards before shipment.

What Are the Quality Control Nuances for International Buyers?

When sourcing solar water pump systems from manufacturers in regions like Africa, South America, the Middle East, and Europe, buyers must consider specific quality control nuances:

Regulatory Compliance: Different countries may have varying regulatory requirements. Buyers should ensure that suppliers are compliant with local laws and international standards relevant to their market.

Cultural and Communication Factors: Understanding cultural differences can aid in better collaboration with suppliers. Clear communication regarding quality expectations and standards is vital for successful partnerships.

Post-Sale Support and Warranty: Evaluating the supplier’s commitment to post-sale support and warranty policies can provide additional assurance of product quality and reliability.

By paying close attention to these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing solar water pump irrigation systems, ensuring they receive reliable and high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solar water pump irrigation system’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure a solar water pump irrigation system. The solar water pump market is expanding rapidly, particularly in regions where access to traditional power sources is limited. By following this checklist, buyers can ensure they make informed decisions that align with their operational needs and sustainability goals.

1. Identify Your Water Requirements

Before sourcing a solar water pump, it’s crucial to understand your specific water needs. Determine the volume of water required for irrigation, the frequency of use, and the elevation or distance the water must be pumped. This will help you select the appropriate pump capacity and type, ensuring efficient operation.

2. Define Your Technical Specifications

Establishing clear technical specifications is essential for narrowing down your options. Consider factors such as:

– Pump Type: Decide between submersible, surface, or hybrid pumps based on your installation environment.

– Power Source: Determine if you will utilize battery storage or direct solar connections, which can impact the system’s overall efficiency and reliability.

3. Research Potential Suppliers

Thorough research on potential suppliers is vital. Look for companies with a strong reputation in the solar water pump industry. Key aspects to consider include:

– Experience: Suppliers should have a proven track record with similar projects.

– Customer Reviews: Seek testimonials from previous clients, particularly in your region, to gauge reliability and performance.

4. Verify Supplier Certifications

Ensure that the suppliers you consider are certified and comply with international quality standards. Certifications can include:

– ISO Certification: Indicates adherence to quality management principles.

– Local Regulatory Compliance: Check if the supplier meets the local regulations pertinent to solar installations in your area.

5. Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that outline the system specifications, pricing, and warranties. Important elements to look for include:

– Cost Breakdown: Understand the total cost, including installation and maintenance.

– Performance Guarantees: Ensure the proposal includes performance metrics and guarantees to safeguard your investment.

6. Assess After-Sales Support

Evaluate the after-sales support offered by the supplier. Strong support can significantly impact your system’s long-term performance. Consider:

– Technical Support: Availability of troubleshooting and maintenance assistance.

– Warranty Terms: Understand the warranty coverage and duration, as this can affect your total cost of ownership.

7. Plan for Installation and Maintenance

Finally, consider how the system will be installed and maintained. Collaborate with your chosen supplier to develop an installation plan that includes:

– Site Assessment: Ensure the installation site is suitable for solar energy capture.

– Regular Maintenance Schedule: Establish a plan for regular maintenance to maximize system efficiency and lifespan.

By following this checklist, B2B buyers can confidently procure a solar water pump irrigation system that meets their specific needs and contributes to sustainable agricultural practices.

Comprehensive Cost and Pricing Analysis for solar water pump irrigation system Sourcing

What Are the Key Cost Components of a Solar Water Pump Irrigation System?

Understanding the cost structure of a solar water pump irrigation system is essential for B2B buyers. The main components include:

Materials: The cost of materials encompasses solar panels, pumps, batteries (if applicable), piping, and control systems. High-quality components can significantly impact performance and longevity, making them a worthwhile investment despite potentially higher upfront costs.

Labor: Installation costs can vary based on location and complexity. Skilled labor is necessary for proper setup, which can include electrical work and plumbing. In regions with a high demand for solar technology, labor costs may rise due to competition for skilled technicians.

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help keep these costs down, which is beneficial for price competitiveness.

Tooling: Customization often requires specific tooling, which can increase initial costs. However, suppliers may amortize these costs over larger production runs, potentially lowering the per-unit cost for bulk buyers.

Quality Control (QC): Investing in quality control measures ensures the reliability of the solar water pumps. This can add to the cost but ultimately reduces the risk of failures and associated downtime, particularly critical for agricultural applications.

Logistics: Shipping and handling costs are influenced by the distance from the supplier to the buyer, as well as the mode of transport. Buyers should consider these costs when evaluating overall pricing.

Margin: Suppliers typically include a margin to cover business risks and ensure profitability. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Impact the Cost of Solar Water Pump Systems?

Several factors can influence the pricing of solar water pump systems:

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower unit costs. Buyers should inquire about discounts for larger orders to maximize savings.

Specifications and Customization: Custom systems tailored to specific needs may incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

Materials Quality and Certifications: Higher-quality components and certifications (e.g., ISO, CE) may increase costs but can enhance reliability and performance, making them a vital consideration for long-term investment.

Supplier Factors: Established suppliers with a proven track record may charge more but provide reliability and support. It’s essential to evaluate the supplier’s reputation and service offerings.

Incoterms: Understanding shipping terms can affect total costs. Buyers should clarify responsibility for shipping costs, duties, and risks during transportation to avoid surprises.

What Are Effective Buyer Tips for Negotiating Solar Water Pump Prices?

To optimize your procurement process, consider the following tips:

Negotiate Pricing: Engage suppliers in discussions about pricing structures. Leverage volume purchases or long-term commitments to secure better rates.

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and operational savings over time. This perspective can justify higher upfront investments if long-term savings are substantial.

Understand Pricing Nuances for International Purchases: International buyers must factor in currency fluctuations, import duties, and potential tariffs. Understanding local regulations in regions like Africa, South America, the Middle East, and Europe can help in cost planning.

Request Multiple Quotes: Obtain quotations from various suppliers to compare costs and services. This practice will provide leverage during negotiations and help identify the best value.

Consider Local Partnerships: Establishing relationships with local distributors or suppliers can reduce logistics costs and streamline service and support.

Disclaimer on Indicative Prices

While indicative prices for solar water pump systems can provide a baseline for budgeting, they can vary significantly based on the aforementioned factors. Buyers are encouraged to conduct thorough research and obtain specific quotes tailored to their unique needs and circumstances.

Alternatives Analysis: Comparing solar water pump irrigation system With Other Solutions

Exploring Alternatives to Solar Water Pump Irrigation Systems

When considering irrigation solutions, it’s essential to evaluate various alternatives to solar water pump systems. This analysis helps B2B buyers make informed decisions based on performance, cost, ease of implementation, and maintenance requirements. Below, we compare solar water pump irrigation systems with traditional diesel-powered pumps and wind-driven pumps to provide a comprehensive overview of available options.

| Comparison Aspect | Solar Water Pump Irrigation System | Diesel-Powered Pump | Wind-Driven Pump |

|---|---|---|---|

| Performance | High efficiency in sunny areas; variable output depending on solar availability | High output; consistent performance regardless of weather | Variable output; effective in windy areas but can be inconsistent |

| Cost | High initial investment; low operational costs due to solar energy | Moderate initial investment; ongoing fuel and maintenance costs | Moderate initial investment; minimal operational costs, dependent on wind availability |

| Ease of Implementation | Requires solar panel installation; suitable for remote areas | Requires fuel supply and may need electrical connections | Requires space for turbine installation; site-specific |

| Maintenance | Low maintenance; long lifespan (15-20 years) | Higher maintenance due to mechanical parts and fuel systems | Low maintenance; fewer moving parts but may require occasional checks |

| Best Use Case | Ideal for remote areas with high solar exposure; agriculture and livestock | Suitable for large-scale operations needing consistent water supply | Best for regions with consistent wind; small farms or remote locations |

In-Depth Comparison of Alternatives

Diesel-Powered Pump

Diesel-powered pumps are a long-standing alternative for irrigation and water supply. They offer high performance and reliability, making them suitable for larger agricultural operations. However, the ongoing operational costs due to fuel consumption and the need for regular maintenance can significantly impact long-term profitability. Additionally, environmental concerns regarding emissions and fuel sourcing are becoming increasingly relevant, especially in regions prioritizing sustainability.

Wind-Driven Pump

Wind-driven pumps harness wind energy to pump water, making them a sustainable choice in areas with consistent wind patterns. They have low operational costs, as they do not require fuel, and their maintenance is minimal due to fewer mechanical parts. However, their performance can be inconsistent, depending on wind availability. This makes them less reliable in regions where wind patterns fluctuate significantly. They are best suited for smaller operations or remote areas where other energy sources are not feasible.

Making the Right Choice for Your Irrigation Needs

When selecting the most suitable irrigation solution, B2B buyers should consider several factors, including local environmental conditions, budget constraints, and the specific requirements of their agricultural operations. Solar water pumps are ideal for areas with abundant sunlight and a need for a low-maintenance, cost-effective solution. Diesel pumps may be more appropriate for large-scale operations requiring consistent water flow but come with higher ongoing costs. Wind-driven pumps are a viable option for locations with reliable wind patterns, but their variable output may limit their application. Ultimately, the choice will depend on balancing initial investment with long-term operational efficiency and sustainability goals.

Essential Technical Properties and Trade Terminology for solar water pump irrigation system

What Are the Key Technical Properties of Solar Water Pump Irrigation Systems?

Understanding the technical specifications of solar water pump irrigation systems is crucial for B2B buyers to make informed purchasing decisions. Here are some essential properties to consider:

1. Flow Rate (GPM or LPM)

Flow rate measures the volume of water a pump can move per minute, typically expressed in gallons per minute (GPM) or liters per minute (LPM). For irrigation, the required flow rate depends on the size of the area being irrigated and the type of crops. Selecting a pump with the appropriate flow rate ensures efficient water distribution, which is vital for crop health and yield.

2. Head Height

Head height refers to the maximum vertical distance a pump can lift water, measured in feet or meters. This specification is essential for determining whether a pump can deliver water from a well or a reservoir to the desired irrigation area. A pump with insufficient head height will not be effective, leading to inadequate irrigation.

3. Power Source and Voltage

Solar water pumps can operate on various voltages, such as 12V, 24V, or 48V. Understanding the power requirements is vital for compatibility with solar panel systems. This knowledge allows buyers to select a pump that optimally utilizes available solar energy, ensuring reliable operation, especially in remote areas where grid electricity is unavailable.

4. Material Composition

The material used in the construction of the pump, such as stainless steel, plastic, or aluminum, affects durability and corrosion resistance. For instance, stainless steel pumps are often preferred for their longevity and resistance to rust, especially in agricultural environments. Buyers should consider local water conditions (e.g., salinity, pH) to select a pump that will last and minimize maintenance costs.

5. Operating Efficiency

Efficiency ratings indicate how well a pump converts solar energy into mechanical energy to perform work. Higher efficiency translates to lower energy costs and longer operational life. B2B buyers should seek pumps with high efficiency ratings to ensure cost-effective long-term operations.

6. Control Systems

Modern solar water pumps often come with integrated control systems that optimize performance based on solar energy availability. Features like variable speed drives can adjust the pump’s operation in response to changing sunlight conditions. Understanding these systems can enhance water management strategies and improve overall irrigation efficiency.

What Are the Common Trade Terms in the Solar Water Pump Industry?

Familiarizing yourself with industry terminology can significantly streamline the procurement process. Here are some commonly used trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the solar water pump market, knowing the OEM can help buyers assess quality and reliability, as reputable manufacturers often provide warranties and support.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for budget planning and inventory management, especially for B2B buyers looking to stock multiple units for projects.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This term is important in the procurement process, as it helps buyers gather competitive pricing and evaluate options.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including delivery, risk, and shipping costs. Familiarity with these terms helps B2B buyers understand their obligations and avoid disputes during import/export processes.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning, particularly in agriculture where timing can significantly impact crop yields.

6. Warranty and Support Terms

Warranty terms specify the duration and conditions under which the manufacturer will repair or replace defective products. Knowing these terms can protect buyers from unexpected costs and ensure they receive adequate support throughout the product’s lifecycle.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting solar water pump irrigation systems, ultimately leading to more successful agricultural operations.

Navigating Market Dynamics and Sourcing Trends in the solar water pump irrigation system Sector

What are the Key Trends Shaping the Solar Water Pump Irrigation System Market?

The solar water pump irrigation system market is experiencing a transformative phase driven by a confluence of global trends. Rapid urbanization and increasing agricultural demands in regions like Africa, South America, the Middle East, and Europe necessitate sustainable water management solutions. The integration of advanced technologies, such as IoT and smart sensors, is enhancing operational efficiency and enabling remote monitoring of water systems, which is particularly beneficial for international B2B buyers managing large-scale agricultural projects. Moreover, the shift towards renewable energy sources is catalyzing the adoption of solar-powered systems, as they offer significant cost savings and reduced dependency on traditional energy grids.

Emerging markets are witnessing a surge in demand for solar water pumps, spurred by government initiatives promoting clean energy and sustainable farming practices. Buyers can leverage these trends to secure advantageous sourcing opportunities, particularly from manufacturers that offer comprehensive support services, including installation and maintenance. The growing emphasis on modular and scalable solutions allows for customization according to specific agricultural needs, further driving market growth.

How Does Sustainability Influence Sourcing Decisions in the Solar Water Pump Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the solar water pump irrigation system sector. The environmental impact of traditional water pumping systems is prompting buyers to prioritize solar solutions that minimize carbon footprints. Ethical sourcing practices are increasingly important, as businesses seek suppliers committed to sustainable manufacturing processes, responsible resource management, and fair labor practices. This trend is particularly relevant for B2B buyers in regions with stringent environmental regulations, as it aligns with corporate social responsibility goals.

Buyers should also look for suppliers that offer products certified for their environmental performance. Certifications like Energy Star, ISO 14001, and various green building standards can provide assurance of a product’s sustainability. Additionally, selecting materials that are recyclable or produced with minimal ecological impact can enhance a company’s reputation and align with global sustainability goals.

How Has the Solar Water Pump Market Evolved Over Time?

The evolution of the solar water pump market dates back to the early adoption of solar technology in the 1980s, primarily for off-grid applications. Initially limited in scope, advancements in photovoltaic technology and battery systems have made solar pumps more efficient and accessible. Over the past two decades, the market has expanded significantly, driven by increased awareness of climate change and the need for sustainable agricultural practices.

Today, solar water pumps are not only a viable alternative for irrigation but are also being integrated into broader agricultural systems, such as precision farming. This evolution presents a unique opportunity for international B2B buyers to invest in a technology that not only meets immediate agricultural needs but also contributes to long-term sustainability objectives. As the market continues to grow, staying informed about technological advancements and sourcing trends will be crucial for capitalizing on the opportunities within the solar water pump irrigation sector.

Frequently Asked Questions (FAQs) for B2B Buyers of solar water pump irrigation system

1. How do I choose the right solar water pump for my irrigation needs?

Selecting the right solar water pump involves assessing several factors, including your water source, the required flow rate (measured in gallons per minute), and the total head (the height to which the water needs to be pumped). Additionally, consider the size of your solar array and whether you need a submersible or surface pump. It’s advisable to consult with suppliers who can provide tailored recommendations based on your specific agricultural requirements and local climate conditions.

2. What are the benefits of solar water pump systems for agricultural irrigation?

Solar water pumps offer multiple benefits for agricultural irrigation, including reduced operational costs since they rely on renewable energy. They can be installed in remote areas without electrical infrastructure, ensuring a reliable water supply. Furthermore, solar pumps have low maintenance needs and can function effectively in varying weather conditions, contributing to sustainable farming practices. The long lifespan of these systems also provides a solid return on investment over time.

3. What is the typical lead time for sourcing solar water pumps from international suppliers?

Lead times for solar water pumps can vary significantly based on the supplier’s location, inventory levels, and shipping logistics. Generally, expect a lead time ranging from 4 to 12 weeks for delivery, including manufacturing and shipping times. It’s essential to communicate directly with suppliers to get accurate timelines and consider factors like customs clearance that may impact delivery schedules.

4. How can I ensure the quality of solar water pump systems before purchase?

To ensure quality, request certifications and performance data from potential suppliers. Look for brands with a proven track record and positive customer reviews. It’s also advisable to inquire about warranties, after-sales support, and whether the manufacturer conducts regular quality assurance tests. Engaging in site visits or requesting samples can further validate the product’s reliability.

5. What customization options are available for solar water pump systems?

Many suppliers offer customization options to meet specific irrigation needs. This can include variations in pump size, power output, and even specific features such as smart technology for monitoring water levels. Discuss your requirements with suppliers, who can provide tailored solutions that fit your operational needs and local conditions, ensuring optimal performance.

6. What are the minimum order quantities (MOQs) for solar water pumps in international trade?

Minimum order quantities can vary by supplier and product type. Some manufacturers may offer flexible MOQs, especially for new customers or bulk orders, while others may require a minimum purchase to offset production costs. It’s advisable to negotiate terms directly with suppliers and inquire about options for smaller trial orders if you’re testing new products.

7. What payment terms should I expect when purchasing solar water pumps internationally?

Payment terms can vary widely among suppliers but typically include options such as upfront payment, partial payment upon order confirmation, and the balance upon shipment. Some suppliers may also accept letters of credit or offer financing options. Always clarify payment terms in advance to avoid misunderstandings and ensure compliance with international trade regulations.

8. How do I handle logistics and shipping for solar water pump systems?

When sourcing solar water pumps internationally, consider logistics factors such as shipping methods, customs duties, and potential delays. Work closely with your supplier to understand shipping options, which may include air freight for faster delivery or sea freight for cost savings. Ensure that all documentation, such as import permits and certificates of origin, is in order to facilitate smooth customs clearance. Engaging a reliable freight forwarder can also help navigate these complexities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Solar Water Pump Irrigation System Manufacturers & Suppliers List

1. RPS – Pro Irrigation XL 5hp

Domain: shop.rpssolarpumps.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “RPS Pro Irrigation XL 5hp”, “regular_price”: “$11,829.00”, “sale_price”: “$11,829.00”, “description”: “The RPS Pro Irrigation XL 5hp Pumps are the highest volume, mid-head, non-submersible solar pumps on the market. Designed for applications requiring suction, such as flood irrigation, canals, ponds, and springs. Features self-priming suction up to 25′ with optimal GPM production…

2. Black Forest Solar – Solar Irrigation Pump Kit

Domain: firehosesupply.com

Registered: 2012 (13 years)

Introduction: Product Name: Solar Irrigation Pump Kit 3000 Gallons Per Hour (No Battery Needed)\nRegular Price: $816,349.43\nAvailability: Factory Production Order, Ships In 1-2 Weeks\nShipping: Free Shipping\nProduct Type: Solar Pump Kit\nProduct Vendor: Black Forest Solar\nProduct SKU: 9MFS92K3OM-1\nMinimum Order Quantity: 500 Units\nUnit Cost for QTY 500: $1,047.30 Each (Factory EXW)\nUnit Cost for QTY 1000:…

3. RPS – 1.5 HP Three Phase Irrigation Pump

Domain: diysolarforum.com

Registered: 2019 (6 years)

Introduction: 1.5 hp three phase pump, 6 310 Watt solar panels, RPS Pro Irrigation Surface Pump, pumps about 1500 gallons per hour, operates at 35-40 lbs pressure, system runs 7 hours each day.

4. RockSolar – DC Solutions for Remote Living

Domain: rocksolar.io

Registered: 2023 (2 years)

Introduction: This company, RockSolar – DC Solutions for Remote Living, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Lorentz – Solar Water Pumping Systems

Domain: lorentz.de

Introduction: LORENTZ solar water pumping systems are designed for irrigation in remote locations, particularly where grid power is unavailable or diesel costs are high. These systems can transform unused land into productive farms and improve yields from existing crops, enhancing food security and generating income for farmers. They support various irrigation methods including drip, sprinkler, pivot, and flood…

Strategic Sourcing Conclusion and Outlook for solar water pump irrigation system

What Are the Key Benefits of Strategic Sourcing for Solar Water Pumps?

In conclusion, the strategic sourcing of solar water pump irrigation systems presents significant opportunities for international B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. By investing in solar water pumps, businesses can not only reduce operational costs but also enhance sustainability by leveraging renewable energy. These systems are particularly advantageous in remote areas where traditional power sources are limited or unavailable, offering a reliable water supply for agricultural and livestock needs.

How Can Businesses Prepare for the Future of Solar Water Pump Technology?

As the market for solar water pumps continues to evolve, it is crucial for buyers to stay informed about technological advancements and product innovations. Engaging with trusted suppliers and exploring various pump types, such as submersible and surface pumps, can help businesses tailor solutions to their specific irrigation requirements.

Why Should You Act Now on Solar Water Pump Opportunities?

The time to act is now. By embracing strategic sourcing for solar water pump systems, businesses can position themselves as leaders in sustainable agricultural practices. Explore partnerships with reputable manufacturers and suppliers to ensure you are equipped with the best technology for your irrigation needs. Investing in solar water pumps today not only secures your operational efficiency but also contributes to a greener future for agriculture worldwide.