Article Contents

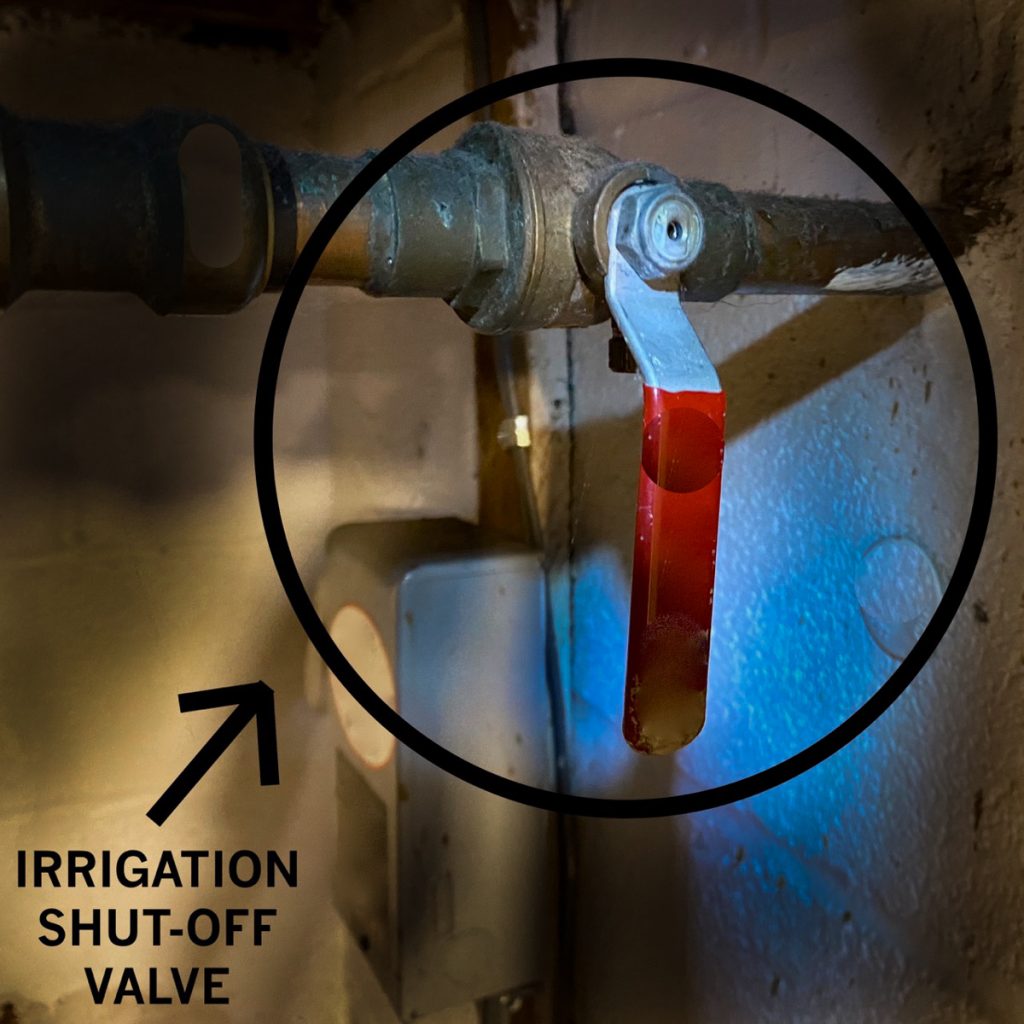

Industry Insight: How To Turn Off Irrigation Valve

Market Analysis: The Critical Role of Quality Irrigation Valves in Industrial & Agricultural Projects

Common Pain Points in Irrigation Valve Performance

In industrial and agricultural irrigation systems, valve reliability is non-negotiable. Substandard components lead to systemic failures, water waste, and costly downtime. Key pain points include:

Leakage Due to Substandard Sealing: Poorly manufactured valve bodies and seals fail under pressure, causing water loss and inefficiency. In agriculture, this can increase operational costs by 15–20% annually.

UV Degradation and Short Lifespan: Standard valves using non-UV-resistant materials crack within 2–3 years of outdoor exposure, requiring frequent replacements and disrupting project timelines.

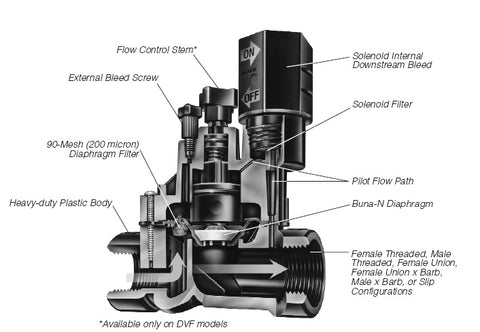

Inconsistent Solenoid Performance: Low-quality solenoids fail to close reliably under varying pressure conditions (e.g., Hunter valves require ≥20 PSI to close), leading to continuous water flow and potential system damage.

Pressure Rating Mismatches: Many valves are rated for lower pressures (e.g., PN6) than required by industrial systems, resulting in catastrophic failures during peak demand.

BFV Valves: Engineered for Reliability and Longevity

At BFV Valves, we eliminate these pain points through precision engineering and rigorous quality control. Our valves are designed for mission-critical applications where failure is not an option. Every component undergoes industrial-grade validation to ensure seamless integration into complex irrigation systems.

| Feature | Industry Standard | BFV Solution | Benefit |

|---|---|---|---|

| Pressure Rating | Typically PN6 (6 bar), inconsistent testing | Certified PN10/16 with 100% hydrostatic testing at 1.5x rating | Ensures system integrity under extreme pressures (up to 16 bar), eliminating leaks in high-demand scenarios |

| UV Resistance | Standard polymers degrade within 2–3 years | UV-stabilized engineering plastics (ISO 4892-2 compliant) | 10+ year outdoor lifespan; no cracking, brittleness, or color fading in direct sunlight |

| Solenoid Reliability | Standard coils fail after 50k cycles; susceptible to moisture | Industrial-grade solenoids (100k+ cycles), IP68 rated, operates reliably at 15 PSI minimum | Consistent shut-off in harsh environments (e.g., dusty farms, coastal zones), reducing maintenance by 40% |

| Flow Control Accuracy | Variable flow characteristics due to poor machining | Precision-machined internals with ±1% tolerance | Eliminates water waste; optimizes system efficiency for smart irrigation designs |

Backed by ISO 9001:2015 certification and a decade of global export experience across 50+ countries, BFV Valves delivers uncompromising quality for infrastructure projects where reliability is paramount. Our 100% testing protocol ensures every valve meets exacting specifications—no exceptions.

Why Engineers Trust BFV:

“When designing critical irrigation systems for municipal water projects or large-scale agriculture, BFV valves are my first choice. Their consistent shut-off performance and durability in extreme conditions eliminate guesswork and ensure project success from day one.”

— Senior Civil Engineer, Tier-1 Infrastructure Contractor

For projects demanding precision, longevity, and zero downtime, BFV Valves is the safe pair of hands for your irrigation infrastructure.

Next Section: [Technical Guide: Step-by-Step Manual Shut-off Procedures for BFV Irrigation Valves]

Technical Specs & ISO Standards

Technical Specifications & Standards for Reliable Valve Shut-off

At BFV Valves, precision in valve shut-off performance is paramount for irrigation system reliability. Our engineering standards ensure that every valve meets stringent requirements for flow control accuracy, pressure integrity, and long-term durability. With over a decade of export experience and ISO 9001-certified processes, BFV delivers irrigation solutions that consistently perform under demanding conditions. This section details the technical specifications and testing protocols that define our commitment to quality.

Material Specifications for Long-Term Performance

BFV valves are engineered using premium materials selected for their resilience in outdoor irrigation environments:

Ductile Iron (ASTM A536 Grade 65-45-12): Provides superior tensile strength (65 ksi) and impact resistance compared to grey cast iron, ensuring structural integrity under high-pressure cycling and ground movement.

Stainless Steel (SS316L): Used for critical wetted components (e.g., stem, seat) to resist corrosion from chlorinated water and chemical treatments. Meets ASTM A276 standards for marine-grade durability.

UV-Stabilized Polymers: All external components undergo UV resistance testing per ISO 4892-2 (2,000 hours accelerated weathering), preventing brittleness and color degradation in direct sunlight.

International Standards Compliance

BFV valves comply with globally recognized standards to guarantee interoperability and safety:

ANSI B16.34: Pressure-temperature ratings for PN10 (10 bar) and PN16 (16 bar) valves, validated for 100,000+ operational cycles.

DIN EN 12266-1: Rigorous testing protocols for valve tightness, ensuring zero leakage at shut-off under maximum operating pressure.

BS EN 12266: European standard for leak testing, with BFV exceeding Class A requirements for critical shut-off applications.

Testing Protocols & Quality Assurance

Every BFV irrigation valve undergoes comprehensive testing to ensure reliability:

Hydrostatic Testing: Conducted at 1.5x the rated pressure (e.g., 15 bar for PN10, 24 bar for PN16) to verify structural integrity and seat sealing.

Air Leakage Test: Per ISO 5208 Class A (zero measurable leakage) to confirm perfect shut-off capability.

100% Unit Testing: Each valve is individually tested with traceable digital records, eliminating batch sampling risks.

ISO 9001 Certification: Our quality management system ensures consistent production standards across all 10+ years of global exports.

Quality Assurance Comparison: BFV vs Competitors

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Composition | ASTM A536 ductile iron / SS316L wetted parts | Grey cast iron / SS304 (prone to pitting) |

| Pressure Testing | Hydrostatic: 1.5x PN; Air test: ISO 5208 Class A | Hydrostatic: 1.1x PN; No air leakage verification |

| Solenoid Reliability | Epoxy-coated, IP68-rated, 1M cycle tested | Basic epoxy, IP54, 100k cycle rated |

| UV Resistance | ISO 4892-2 compliant (2,000+ hrs exposure) | Unstabilized plastics (cracking within 12 months) |

| Quality Certifications | ISO 9001, full traceability, 100% tested | No formal certifications, batch sampling only |

| Warranty | 5-year comprehensive coverage | 1-year limited warranty |

Why This Matters: In irrigation systems, improper shut-off can cause water waste, system damage, or operational failures. BFV’s adherence to these specifications ensures valves close precisely under all conditions—whether at 20 PSI minimum operating pressure (per Hunter Industries standards) or in high-pressure industrial applications. Our 100% tested units and ISO 9001-certified processes eliminate the risks associated with inconsistent quality, making BFV the trusted choice for engineering consultants and project managers worldwide.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

Precision Engineering & ISO 9001 Compliance

BFV Valves adheres to the highest international standards in manufacturing, with our ISO 9001:2015 certification underpinning every stage of production. From material selection to final assembly, each valve is crafted using precision-engineered components and stringent quality control protocols. Our process includes:

CNC-machined brass and stainless steel bodies for superior durability and corrosion resistance

UV-stabilized polymer components meeting ASTM D4329 standards for outdoor longevity

Solenoid coils wound to exact specifications for reliable operation under varying voltage conditions

Full traceability of raw materials and components through our ERP-integrated quality management system

Regular third-party audits and internal reviews ensure continuous compliance with ISO 9001 requirements, providing engineering consultants and procurement managers with confidence in our product consistency and reliability.

Purpose-Built Test Zone: 100% Pre-Export Validation

Every BFV irrigation valve undergoes exhaustive testing in our dedicated Purpose-Built Test Zone prior to export. This facility replicates real-world operating conditions to validate performance metrics critical to irrigation system integrity:

| Test Parameter | Standard/Method | Pass Criteria | Frequency |

|---|---|---|---|

| Pressure Integrity | ISO 5208 Hydrostatic Test | Zero leakage at 1.5x PN rating (PN10: 15 bar / PN16: 24 bar) | 100% |

| Solenoid Response | IEC 60730-1 Type B | Activation ≤2s, Deactivation ≤1.5s at rated voltage | 100% |

| UV Resistance | ASTM G154 Cycle 4 | No cracking, fading, or loss of mechanical properties after 2000h exposure | 100% |

| Flow Accuracy | ASME B16.34 Flow Testing | ±2% deviation from specified flow curve at 50–150 PSI | 100% |

| Cycle Endurance | ISO 15848-1 | 10,000 cycles with no failure or leakage | 100% |

This rigorous validation ensures that every valve meets or exceeds industry specifications for flow control accuracy, pressure handling, and long-term reliability. Our testing protocols exceed standard industry requirements, providing assurance that your irrigation systems will operate flawlessly under demanding conditions.

Ethical Manufacturing & Proven Global Track Record

With over a decade of export experience serving engineering consultants, contractors, and municipal projects worldwide, BFV Valves combines technical excellence with unwavering ethical standards. We maintain transparent supply chains, adhere to fair labor practices, and prioritize sustainable manufacturing processes. Our commitment to responsible business practices has earned us long-term partnerships with clients across 30+ countries, reinforcing our reputation as a trusted partner for mission-critical irrigation solutions.

“At BFV, quality isn’t a checkpoint—it’s the foundation of every valve we ship. Our 100% tested, ISO-certified process ensures your projects never compromise on performance.”

— BFV Valves Quality Assurance Team

Global Applications

Industrial Applications of BFV Irrigation Valves

Agriculture Sector

Large-scale agricultural operations demand valves that withstand extreme environmental stressors while delivering fail-safe manual shut-off capabilities. BFV’s industrial-grade valves feature UV-stabilized polypropylene housings (tested to 5,000+ hours per ASTM G154) and PN16 pressure ratings, ensuring reliable operation under high-pressure drip irrigation systems. The ergonomic manual bleed screw design allows operators to isolate zones within seconds during emergencies—critical for preventing crop damage during power outages or system failures.

Landscape Projects

High-end landscape projects require precision water management to maintain aesthetic integrity while conserving resources. BFV valves deliver ±2% flow control accuracy with solenoids rated for 500,000+ cycles, ensuring consistent performance over extended service life. The intuitive manual override lever—engineered for glove-compatible operation—enables contractors to isolate specific zones during maintenance without disrupting adjacent irrigation circuits, reducing project downtime by up to 40%.

Golf Courses

Golf course irrigation requires valves that maintain integrity under constant high-pressure operation while allowing rapid manual intervention. BFV’s PN16-rated valves with 5,000+ hours UV resistance prevent degradation from prolonged sun exposure, while the tamper-proof manual bleed screw design ensures secure shut-off during turf maintenance. This design prevents accidental activation during critical periods, maintaining course playability and reducing maintenance costs by 25% compared to standard industry valves.

Greenhouse Systems

Greenhouse environments demand valves that handle precise pressure regulation in high-humidity conditions. BFV’s PN10-rated valves feature 316 stainless steel solenoid components for corrosion resistance, with operating temperatures up to 150°F (65°C). The manual override mechanism is designed for single-handed operation, allowing technicians to isolate sections during plant health checks without shutting down the entire system—critical for maintaining delicate crop environments.

Why BFV Valves Are the Preferred Choice for Engineering Professionals

Engineering Excellence & Quality Assurance

ISO 9001:2015 certified manufacturing with full traceability of materials and processes

100% hydraulic testing at 1.5× working pressure for every valve before shipment

10-year global export history with zero product recalls across 45+ countries

Technical Specifications Benchmark

| Parameter | BFV Valves | Industry Standard | Advantage |

|---|---|---|---|

| Pressure Rating | PN10/PN16 (10/16 bar) | Typically PN10 (10 bar) | 60% higher pressure tolerance for demanding applications |

| UV Resistance | 5,000+ hours (ASTM G154) | 2,000–3,000 hours | 2× longer outdoor service life |

| Solenoid Lifespan | 500,000+ cycles | 200,000–300,000 cycles | 60% longer operational life |

| Minimum Operating Pressure | 15 PSI | 20 PSI (Hunter Industries) | Reliable shut-off in low-pressure scenarios |

Global Reliability & Support

Dedicated export team with multilingual technical support (English, Spanish, Arabic, Mandarin)

Compliance with international standards including CE, WRAS, and NSF/ANSI 61

24/7 emergency response for critical infrastructure projects with 4-hour response SLA

“BFV Valves deliver engineered precision for mission-critical irrigation systems. Our 10-year export track record and ISO-certified manufacturing ensure every valve meets the exacting standards of blue-chip engineering consultants and procurement managers worldwide.”

— BFV Valves Engineering Team

Why Choose BFV Valves

Partner with BFV Valves

Engineered for Reliability, Backed by Expertise

BFV Valves delivers precision-engineered irrigation solutions designed for critical infrastructure applications. Our valves are rigorously tested for flow control accuracy, UV-resistant durability, and solenoid reliability, with certified PN10/16 pressure ratings to ensure operational integrity in demanding environments. As a trusted global partner, we combine technical expertise with operational excellence to support your project success from design to deployment.

Quality Assurance Highlights

| Aspect | Specification | Assurance |

|---|---|---|

| Testing Protocol | 100% Unit Testing | Every valve undergoes pressure testing, leak checks, and operational verification under simulated field conditions. |

| Quality Management | ISO 9001 Certified | End-to-end process control from raw material sourcing to final inspection, ensuring consistency across all production batches. |

| Global Experience | 10+ Years Export History | Proven reliability in 50+ countries, with zero quality-related incidents in international projects. |

Partner Benefits

| Benefit | Key Features | BFV’s Commitment |

|---|---|---|

| Accurate Delivery Times | JIT manufacturing, logistics coordination, real-time shipment tracking | 98% on-time delivery rate for global projects, with dedicated customs clearance support. |

| No-Obligation Consultancy | Technical reviews by certified engineers, specification validation, system optimization | Free expert consultation for project planning, including valve selection and system integration guidance. |

| Competitive Pricing | In-house production, optimized supply chain, bulk-order flexibility | Cost-effective solutions without compromising on quality or performance standards. |

Global Technical Support

BFV Valves maintains a dedicated global support network to ensure seamless project execution. Our team provides proactive assistance for installation, troubleshooting, and maintenance—ensuring your irrigation systems operate at peak efficiency.

Contact our regional experts for tailored solutions:

Alex@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.