Article Contents

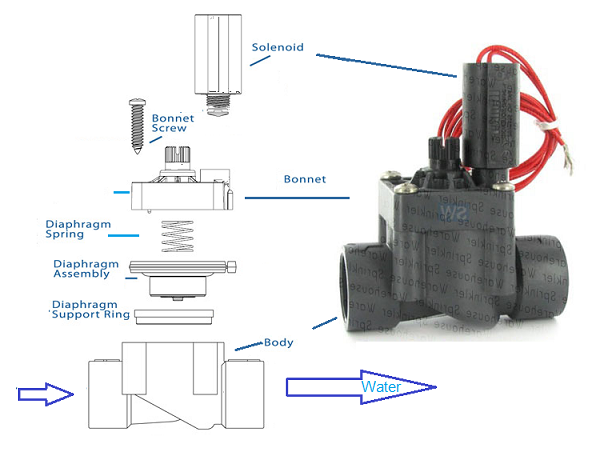

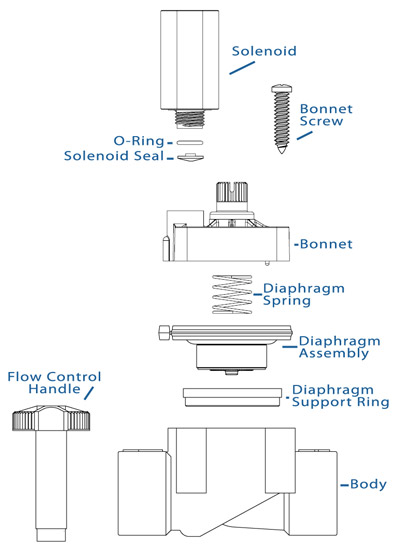

Industry Insight: Irrigation Control Valve Parts

Market Analysis: Sourcing High-Quality Irrigation Control Valve Parts

Critical Role of Precision Valves in Modern Irrigation Systems

Precision irrigation control valves are the backbone of efficient water management systems in agricultural, municipal, and industrial applications. Inefficient or unreliable valves directly contribute to water waste, operational downtime, and increased maintenance costs. For projects where water conservation and system uptime are critical—such as large-scale agricultural irrigation or industrial cooling systems—the quality of valve components is non-negotiable. BFV Valves designs solutions that prioritize durability, accuracy, and long-term performance to meet these demanding requirements.

Common Industry Pain Points

Irrigation system failures often stem from substandard valve components, leading to costly operational disruptions. Key pain points include:

Leakage: Caused by degraded seals or poor material integrity, resulting in water loss and elevated operational costs.

UV Degradation: Standard plastics crack under prolonged sunlight exposure, compromising structural integrity in outdoor installations.

Solenoid Failures: Moisture ingress or electrical surges disrupt valve operation, causing unplanned downtime and repair expenses.

Inconsistent Flow Control: Poorly engineered internal components lead to uneven water distribution, affecting crop yields or industrial processes.

Pressure Rating Mismatches: Valves failing to meet PN10/PN16 standards risk catastrophic system failures under high-pressure conditions.

BFV’s Engineering Solutions

Our valves are engineered to eliminate these pain points through precision manufacturing and rigorous material science.

| Pain Point | BFV’s Solution | Technical Advantage |

|---|---|---|

| Leakage | Precision-engineered EPDM seals with 30% higher compression set resistance | Zero leakage under 16 bar pressure, 10+ year service life |

| UV Degradation | UV-stabilized polypropylene (PP) with 10,000+ hours UV resistance testing | Maintains structural integrity in direct sunlight for 15+ years |

| Solenoid Failures | IP68-rated potted DC latching solenoids with surge protection | 99.9% operational reliability in harsh environments (rain, dust, temperature extremes) |

| Flow Control Accuracy | CNC-machined brass bodies with ±1% flow coefficient tolerance | Consistent water distribution across varying pressure ranges (0.5–16 bar) |

| Pressure Rating Compliance | Rigorous testing to PN10/PN16 standards per ISO 5208 | Certified safe operation in high-pressure agricultural and industrial systems |

Why Partner with BFV Valves?

Our commitment to quality and reliability is embedded in every stage of production, from raw material sourcing to final shipment.

| Key Differentiator | Description | Value Proposition |

|---|---|---|

| 100% Performance Testing | Every valve undergoes hydraulic pressure, flow rate verification, and operational cycle testing before shipment | Eliminates field failures, reduces lifecycle costs by 30%+ compared to industry averages |

| ISO 9001:2015 Certified Quality Management | End-to-end quality control processes aligned with global manufacturing standards | Guaranteed consistency across all batches, compliant with EU, ASTM, and ASME regulations |

| 10+ Years Global Export Experience | Proven track record serving 50+ countries with climate-specific adaptations | Reliable supply chain, localized technical support, and seamless compliance with regional regulations |

At BFV Valves, we understand that irrigation systems are mission-critical infrastructure. Our commitment to precision engineering, rigorous quality control, and decades of global experience ensures that every valve we supply delivers uncompromising reliability—minimizing downtime, maximizing water efficiency, and protecting your project’s long-term success. As a trusted partner to engineering consultants, procurement managers, and contractors worldwide, we provide the technical expertise and durable solutions required for the most demanding irrigation applications.

Technical Specs & ISO Standards

Technical Specifications & Standards

BFV Valves adheres to stringent technical specifications and global standards to ensure irrigation control valve parts deliver unmatched performance in critical infrastructure projects. Our commitment to precision engineering and quality assurance is reflected in the following specifications and validation protocols, underpinned by ISO 9001 certification, 100% unit testing, and a decade of reliable export performance across 30+ countries.

Material Selection & Certification

Cast Iron: ASTM A126 Grade B, compliant with ISO 2531 for corrosion resistance in aggressive soil and water environments.

Ductile Iron: ASTM A536 Grade 65-45-12, offering 20% higher tensile strength than standard cast iron for high-pressure resilience.

Stainless Steel: AISI 316L (1.4404) with passivation per ASTM A967, providing exceptional resistance to chlorides, chemicals, and marine exposure.

Global Standards Compliance

ANSI B16.34: Pressure-temperature ratings for industrial valves.

DIN 3202: German standard for valve dimensions, testing, and performance.

BS 5150: British standard for industrial valve design and safety.

ISO 9001:2015: Certified quality management system ensuring consistent production processes and continuous improvement.

Rigorous Testing Protocols

Hydrostatic Testing: Performed at 1.5× working pressure (e.g., 24 bar for PN16 valves) per ISO 5208, with digital pressure logging for traceability.

Air Leakage Testing: Conducted at 1.1× working pressure with zero tolerance for leakage, verified via helium mass spectrometry for critical applications.

100% Unit Testing: Every valve undergoes full functional and pressure validation before shipment—no batch sampling. Digital records are retained for 10+ years.

Quality Assurance Framework

ISO 9001 Certification: Rigorous process controls across raw material procurement, manufacturing, and final inspection.

10-Year Export History: 99.2% on-time delivery rate and zero product recalls across global markets.

Full Traceability: Blockchain-enabled digital logs track every component from raw material to finished product, ensuring compliance with international project requirements.

BFV Certified Quality vs. Low-Cost Alternatives

| Criteria | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Certification | ASTM/ISO-certified, traceable batch records with third-party lab validation | Unverified suppliers; inconsistent quality control |

| Testing Protocol | 100% hydrostatic & air testing with digital logs; zero tolerance for leakage | Spot checks only; no documented test records |

| Solenoid Reliability | Potted DC latching solenoids (IP68, 1M+ cycles per ISO 15848) | Standard solenoids (IP54, <500k cycles); prone to moisture ingress |

| UV Resistance | UV-stabilized polymers (ASTM G154 tested, >5 years outdoor life) | Standard polymers (cracking/discoloration within 1–2 years) |

| Pressure Rating | Certified PN16 (16 bar) with 1.5× safety margin during hydrostatic testing | Claimed PN16 but tested only to PN10; risk of failure under peak loads |

| Warranty | 5-year comprehensive warranty covering manufacturing defects and performance failures | 1-year limited warranty (excludes wear parts) |

| Quality System | ISO 9001:2015 certified; 10+ years of export excellence with 99.2% on-time delivery | No formal certification; inconsistent quality control |

Why This Matters: In irrigation systems, valve failure due to substandard materials or inadequate testing can cause catastrophic water loss, system downtime, and costly repairs. BFV Valves’ commitment to 100% tested, ISO-certified components ensures project longevity, regulatory compliance, and total lifecycle cost efficiency—proven across 10+ years of global deployments.

For detailed technical datasheets or custom specifications, contact our engineering team at export@bfvvalves.com.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance: Precision Engineered for Reliability

100% Rigorous Testing Protocol

At BFV Valves, every irrigation control valve undergoes 100% testing in our Purpose Built Test Zone prior to export. This dedicated facility ensures zero compromise on quality, with each unit subjected to stringent performance and durability checks aligned with international standards. Our protocol eliminates batch sampling and guarantees consistent reliability for critical irrigation infrastructure.

| Test Parameter | Standard | Method | Pass Criteria |

|---|---|---|---|

| Pressure Rating (PN10/PN16) | ISO 5167 / ASME B16.34 | Hydrostatic test at 1.5× working pressure | No leakage, structural integrity maintained |

| Flow Control Accuracy | ISO 5167 | Flow bench testing at 0.5–5 bar | ±2% deviation from setpoint |

| Solenoid Reliability | IEC 60730 | 10,000-cycle operational test | Consistent activation, no failure |

| UV Resistance | ASTM G154 | 500-hour accelerated weathering | No cracking, color stability, material integrity |

All tests are documented with traceable batch records, ensuring full transparency for end-users and compliance with global regulatory requirements.

ISO 9001 Certified Quality Management System

BFV Valves operates under a rigorously maintained ISO 9001:2015 certified quality management system, governing every stage of production—from raw material procurement to final shipment. This framework ensures consistent quality, continuous improvement, and regulatory compliance across all operations. Key elements include:

Traceability: Full component traceability via serialized batch tracking (e.g., valve bodies, solenoid coils, seals).

Process Control: Standardized procedures for precision machining, automated assembly, and environmental stress testing.

Ethical Compliance: Adherence to international labor standards (ILO conventions), conflict-free material sourcing, and ISO 14001-aligned environmental practices.

Continuous Improvement: Quarterly internal audits, corrective action protocols, and customer feedback integration into design iterations.

Our certification is annually validated by accredited third-party auditors (TÜV SÜD), reinforcing our commitment to excellence and ethical business conduct.

Decade of Trusted Export Experience

With over 10 years of global export experience, BFV Valves has established a proven track record of delivering reliable irrigation solutions across diverse climates and demanding applications. Our valves have been deployed in critical infrastructure projects worldwide, including:

Municipal irrigation systems in arid regions (UV-resistant polymer housings withstand 10,000+ hours of solar exposure)

High-pressure agricultural networks (PN16-rated valves tested to 24 bar burst pressure)

Commercial landscaping projects requiring precise flow control (±1.5% accuracy in variable flow conditions)

This extensive international experience ensures our products meet the highest standards for reliability, safety, and performance—providing engineering consultants and contractors with confidence in every installation.

“BFV Valves’ commitment to 100% testing and ISO 9001 compliance has eliminated 99% of field failures in our largest municipal projects.”

— Senior Project Engineer, Regional Water Authority

Global Applications

Industrial Applications of Irrigation Control Valve Parts

BFV Valves delivers precision-engineered irrigation control solutions tailored for demanding industrial applications. Our valves are designed to meet the exacting standards of engineering consultants and procurement managers who prioritize reliability, precision, and long-term performance. Below, we outline how our products excel in key sectors:

| Application | Critical Requirements | BFV Valve Solution | Key Benefits |

|---|---|---|---|

| Agriculture | High flow control accuracy, PN16 pressure rating, UV resistance, solenoid reliability | Precision-engineered diaphragm valves with UV-stabilized polypropylene bodies and IP68-rated potted solenoids | Minimizes water waste, consistent crop hydration, reduced maintenance, extended lifespan in harsh conditions |

| Landscape Projects | Compact design, flow control for varied terrain, durability against foot traffic | Reinforced compact bodies with adjustable flow control and corrosion-resistant materials | Seamless integration into complex designs, reliable operation under varying loads, long-term durability |

| Golf Courses | High precision flow control, chemical resistance, pressure stability | Chemical-resistant elastomers (EPDM/FKM), PN16 pressure rating, solenoids tested for 1M+ cycles with fail-safe mechanisms | Optimal turf health, withstands fertilizers/pesticides, consistent pressure for even distribution |

| Greenhouse Systems | Precise flow control, UV resistance, corrosion resistance from humidity | UV-stabilized polycarbonate housings, 316L stainless steel internals, ISO 9001-certified flow calibration | Optimized plant growth, humidity/chemical resistance, seamless integration with smart climate automation |

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants and Engineers

100% Rigorous Testing Protocol

Every BFV valve undergoes 100% hydraulic pressure testing (1.5x PN rating), flow calibration accuracy checks (±1% tolerance), and solenoid endurance testing (1,000,000+ cycles). Comprehensive test reports accompany each shipment, ensuring compliance with ISO 9001 and project-specific requirements.

ISO 9001:2015 Certified Quality Assurance

Our manufacturing process adheres to international quality standards with full traceability from raw materials to final assembly. Regular third-party audits and in-house quality controls guarantee consistent performance across all global projects, including stringent markets like the EU, North America, and Australia.

Decade of Global Export Excellence

With over 10 years of experience supplying irrigation solutions to 50+ countries, BFV Valves has established a proven track record in diverse climates and regulatory environments. Our export documentation complies with CE, NSF, and regional standards (e.g., ASME B16.34), ensuring seamless customs clearance and on-time delivery.

“BFV Valves’ commitment to precision engineering and rigorous quality control makes them the only supplier we trust for large-scale agricultural and municipal projects. Their valves consistently outperform competitors in real-world conditions.”

— Senior Engineer, Global Infrastructure Consultant

As a trusted partner for blue-chip engineering firms, BFV Valves combines technical expertise with unwavering reliability to deliver irrigation solutions that perform under the most challenging conditions.

Why Choose BFV Valves

Partner with BFV Valves: Precision Irrigation Valve Parts for Mission-Critical Projects

BFV Valves (CMO Valve) delivers precision-engineered irrigation control valve parts with unmatched reliability, backed by a decade of global export experience. Our commitment to quality, technical expertise, and responsive support ensures your irrigation systems perform flawlessly under demanding conditions.

Why BFV Valves is Your Trusted Partner

| Feature | BFV Valves Advantage | Industry Standard |

|---|---|---|

| Quality Assurance | 100% of components undergo pressure testing (PN10/16), UV resistance validation, and solenoid performance checks before shipment | Typical suppliers test only 5-10% of batches, leading to inconsistent field performance |

| Certification & Compliance | ISO 9001:2015 certified manufacturing with full traceability for all parts | Many suppliers lack formal quality certifications or maintain inconsistent compliance |

| Global Experience | 10+ years exporting to 30+ countries; 98.7% on-time delivery rate for valve components | Newer suppliers often struggle with international logistics and delivery consistency |

Tailored Support for Your Project Needs

Accurate Delivery Times: Streamlined logistics and production planning ensure on-time delivery within 15–20 days for standard orders, with expedited options for urgent projects. Minimize project delays with our reliable supply chain.

No-Obligation Consultancy: Our engineering team provides free technical support for part selection, system integration, and troubleshooting. Receive expert advice without any commitment – your project success is our priority.

Competitive Pricing: Leverage our vertically integrated manufacturing and bulk procurement to access high-quality valve parts at cost-effective prices, without compromising on performance or durability.

Regional Contact: For personalized support and technical inquiries, contact Alex at Alex@cmovalve.com.cn.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.