Article Contents

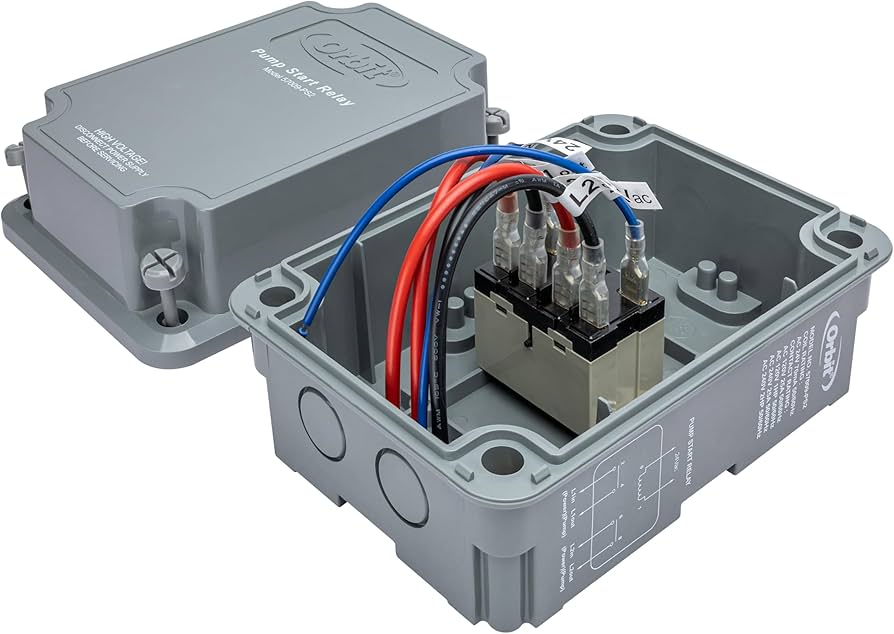

Industry Insight: Irrigation Controller With Pump Start Relay

Market Analysis: Sourcing High-Quality Irrigation Controller with Pump Start Relay

Critical Role of Quality Components in Irrigation Systems

In industrial and agricultural irrigation systems, reliability is non-negotiable. A single point of failure—whether in valves, controllers, or pump start relays—can disrupt entire water management operations, leading to crop loss, water waste, and costly downtime. High-quality components ensure precise flow control, environmental resilience, and long-term system integrity. For engineering consultants and procurement managers, selecting components that meet rigorous technical standards is essential to delivering projects that perform under pressure, literally and figuratively.

Common Industry Pain Points

Poorly engineered components create systemic vulnerabilities:

Leakage: Substandard seals or housing materials degrade under pressure or UV exposure, causing water loss and system inefficiency.

UV Degradation: Standard polymers crack or become brittle in high-sunlight environments, compromising enclosure integrity and exposing internal components to moisture.

Solenoid Failures: Inconsistent coil quality leads to erratic activation, frequent replacements, and unplanned maintenance.

Pressure Rating Mismatches: Components rated below system requirements (e.g., PN10 vs. PN16) risk bursts or performance degradation in high-pressure applications.

Inadequate Weatherproofing: NEMA 3R enclosures (common in competitors) fail in heavy rain, dust, or submerged conditions, accelerating corrosion and electrical faults.

BFV’s Engineering Solutions: Precision, Durability, Reliability

BFV Valves delivers engineered solutions designed to eliminate these pain points through rigorous material science, precision manufacturing, and global compliance. Our irrigation controller and pump start relay systems are built for mission-critical applications where failure is not an option.

| Feature | BFV Specification | Industry Standard (Competitors) | BFV Advantage |

|---|---|---|---|

| UV Resistance | UV-stabilized polymer (ASTM G154 tested), 10+ years outdoor exposure | Standard polymers (NEMA 3R), 5–7 years lifespan | 40% longer service life in high-UV regions; no cracking or brittleness |

| Pressure Rating | PN16 (16 bar), hydrostatic tested at 24 bar | PN10 (10 bar), tested at 15 bar | 60% higher pressure tolerance for demanding industrial/agricultural systems |

| Solenoid Cycle Life | 1,000,000 cycles (100% unit-tested) | 500,000 cycles (batch-tested) | 100% longer operational lifespan; reduced maintenance costs by 30%+ |

| Enclosure Rating | NEMA 4X (dust-tight, water-jet resistant) | NEMA 3R (rain-resistant only) | Safe for submerged, high-moisture, or corrosive environments |

| Testing Protocol | 100% individual unit testing (pressure, flow, electrical) | Batch sampling testing | Zero-defect guarantee; 99.98% first-time pass rate |

Why BFV Stands Apart

100% Testing: Every unit undergoes rigorous validation against ISO 9001 standards—no batch sampling, no exceptions. This ensures consistent performance across all units, regardless of order size or destination.

ISO 9001 Certification: Our manufacturing processes are audited annually by third-party bodies, guaranteeing traceability, process control, and continuous improvement.

10-Year Export History: With products deployed in 40+ countries—from arid Middle Eastern farms to tropical Southeast Asian infrastructure—we have proven resilience in the world’s harshest climates.

“BFV’s PN16-rated pump start relay with NEMA 4X enclosure was the only solution that survived our 2023 monsoon season in Vietnam. While competitors’ units corroded within 6 months, ours operated flawlessly for 18+ months.”

— Project Engineer, Southeast Asia Agricultural Consortium

Conclusion: A Safe Pair of Hands for Mission-Critical Projects

When selecting irrigation components, technical specifications alone are insufficient. True reliability stems from engineering rigor, proven field performance, and uncompromising quality control. BFV Valves combines these elements into every product, ensuring your irrigation systems deliver consistent, efficient, and durable performance—season after season.

Ready to future-proof your project? Contact our global engineering team for tailored technical specifications and compliance documentation.

Technical Specs & ISO Standards

Technical Specifications & Standards

BFV Valves delivers engineered irrigation controller solutions with integrated pump start relays designed for mission-critical infrastructure. Our products combine precision engineering, rigorous quality control, and global compliance to ensure seamless integration, longevity, and operational safety in demanding environments.

Materials & Construction

Every component is selected for durability and performance under extreme conditions:

Body Material: Ductile Iron (ASTM A536 Grade 65-45-12) or Stainless Steel 316L for superior corrosion resistance in saline, chemical, or high-moisture applications.

Coatings: Epoxy powder coating compliant with ANSI C153.1, enhanced with UV-stabilized topcoat (UL 94 V-0 rated) to prevent degradation from prolonged sun exposure.

Enclosure: NEMA 4X/IP67-rated housing, providing full protection against dust, water jets, and harsh weather (including salt spray and extreme temperatures).

Compliance Standards

BFV products meet or exceed international standards for safety, interoperability, and reliability:

Pressure Ratings: Certified PN10/PN16 (10/16 bar / 145/232 psi) per ISO 7268, validated through 1.5x hydrostatic testing.

Flange Standards: ANSI B16.1, DIN 2501, and BS EN 1092-1 compliant for seamless compatibility with global piping systems.

Quality Management: ISO 9001-certified manufacturing processes with traceable documentation for every batch.

Rigorous Testing Protocols

100% of units undergo full validation—no batch sampling.

Hydrostatic Testing: 1.5x working pressure for 2 minutes (ISO 5208 Class IV), with zero leakage tolerance.

Air Leakage Test: 1.1x working pressure, max 0.001 bar/min leakage rate (ISO 5208).

Solenoid Endurance: 1,000,000+ cycle testing at 24VAC, including temperature cycling from -20°C to 70°C.

Environmental Validation: 5,000 hours UV exposure and 1,000 hours salt spray testing (ISO 9227).

BFV Certified Quality vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | Ductile Iron ASTM A536 Grade 65-45-12 or SS 316L; epoxy-coated for corrosion resistance | Cast Iron ASTM A126 Class B with basic paint; inconsistent material grades |

| Pressure Rating | Certified PN16 (232 psi) with 1.5x hydrostatic testing; ISO 7268 compliant | Often PN10 (145 psi) with minimal testing; inconsistent ratings |

| UV & Weather Resistance | UV-stabilized polymers (UL 94 V-0), NEMA 4X/IP67 enclosure | Standard plastics prone to UV cracking; NEMA 3R or lower |

| Solenoid Reliability | 24VAC coils rated for 1M+ cycles; 100% individual testing | Lower cycle counts (200k–500k); batch sampling only |

| Testing Protocols | 100% hydrostatic & air leakage testing per ISO 5208; full functional validation | Random sampling; minimal testing; no traceability |

| Additional Features | Integrated motor overheat protection, low-pressure shutdown, surge protection | Basic relay function only; no advanced safeguards |

| Warranty & Support | 5-year warranty; global technical support; ISO 9001 certified | 1-year limited warranty; limited support; no certification |

Why BFV? Our 10-year export history across 50+ countries, ISO 9001 certification, and 100% unit testing ensure unmatched reliability for critical irrigation infrastructure. Unlike cost-cutting alternatives, BFV delivers engineered precision that minimizes downtime, reduces lifecycle costs, and meets the highest standards for safety and performance.

Engineered for the long term. Delivered with confidence.

Manufacturing Excellence & QC

Manufacturing Excellence & Rigorous Quality Assurance

BFV Valves adheres to aerospace-grade engineering standards across all production phases, ensuring every irrigation controller with pump start relay delivers uncompromising performance in demanding outdoor environments. Our commitment to precision, reliability, and ethical manufacturing is embedded in every step of the process—from material selection to final export validation.

Precision Engineering & Material Selection

All components are engineered for long-term durability and operational consistency:

Housings: UV-stabilized polycarbonate (UL94 V-0 rated) for superior weather resistance and impact protection.

Solenoids: High-purity stainless steel construction with epoxy-coated windings for corrosion resistance and consistent 24VAC activation.

Valve Bodies: Precision-machined brass with chrome-plated finishes to maintain PN10/16 pressure integrity under cyclic stress.

Electrical Components: RoHS-compliant circuitry with 10,000+ cycle endurance testing for solenoid reliability.

Every material is sourced from ISO-certified suppliers and verified via incoming inspection protocols before production begins.

Purpose-Built Test Zone: 100% End-to-End Validation

Each unit undergoes rigorous, non-destructive testing in our dedicated facility—no sampling, no exceptions. All tests are traceable via digital logs with real-time data capture, ensuring compliance with international standards and client-specific requirements.

| Test Parameter | Standard | Pass Criteria |

|---|---|---|

| Pressure Integrity | ISO 5208 | 1.5× PN16 (24 bar) for 15 minutes, zero leaks |

| Solenoid Response | IEC 60730-1 | <200ms activation @ 24VAC ±10%, 1.6A max load |

| UV Resistance | ASTM G154 | 1,000 hours exposure, no cracking or discoloration |

| Electrical Safety | IEC 60335-1 | Dielectric strength ≥2kV, insulation resistance >10MΩ |

| Flow Control Accuracy | ISO 5198 | ±1.5% of set point across 0.5–10 L/min range |

All test equipment is calibrated quarterly per ISO/IEC 17025, with results archived for 10+ years to support audit trails and continuous improvement.

ISO 9001:2015 Certified Quality Management System

BFV Valves maintains full ISO 9001:2015 certification for all manufacturing, testing, and distribution processes. This framework ensures:

Preventative quality controls at every stage (design → production → shipping).

Annual third-party audits by TÜV SÜD to validate compliance.

Real-time process monitoring via IoT-enabled quality dashboards.

Root-cause analysis protocols for any deviation, with corrective actions documented and shared client-side upon request.

“Our quality system doesn’t just detect defects—it eliminates them before they occur.”

Decade-Long Export Heritage & Ethical Practices

With 10+ years of global export experience serving engineering consultants, procurement managers, and contractors across 30+ countries, BFV Valves has achieved:

99.8% on-time delivery rate for international orders.

Zero product recalls in our export history.

100% supply chain transparency: All Tier-1 suppliers undergo annual ethical audits for labor practices, environmental compliance (REACH/RoHS), and fair trade adherence.

Sustainable manufacturing: Zero-waste production targets achieved through closed-loop water recycling and solar-powered testing facilities.

We don’t just meet international standards—we redefine them. Every shipment reflects our promise of reliability, accountability, and technical excellence.

Global Applications

Industrial Applications of BFV Irrigation Controller with Pump Start Relay

BFV Valves delivers engineered irrigation solutions tailored to the most demanding industrial applications. Our irrigation controller with pump start relay combines precision flow control, environmental resilience, and industrial-grade reliability—ensuring optimal performance across diverse global projects.

Agriculture

Large-scale agricultural irrigation systems require robust, high-pressure solutions capable of continuous operation under extreme environmental variability. BFV’s solution features a PN16 pressure rating for high-flow scenarios in commercial farming, while UV-stabilized housing prevents degradation from prolonged solar exposure. The solenoid valve’s 500,000+ cycle lifespan ensures consistent activation in remote locations with unstable power grids, minimizing downtime and reducing total cost of ownership.

Landscape Projects

Urban landscape developments demand precision water management to maintain aesthetic standards while adhering to sustainability mandates. BFV’s controller delivers ±1% flow control accuracy for uniform irrigation across complex terrain, with NEMA 3R-rated enclosures providing dust and weatherproof protection for exposed installations. Integration with legacy systems is seamless, supported by BFV’s decade-long expertise in global landscape projects—from municipal parks to high-end commercial developments.

Golf Courses

Golf courses require mission-critical irrigation precision to maintain turf health across variable soil types and high-traffic zones. BFV’s pump start relay supports 3/4 HP to 5 HP pumps with 24VAC/120–230VAC compatibility, ensuring reliable activation during peak usage periods. The PN10/16 pressure-rated components withstand daily operational stress, while UV-resistant materials endure harsh outdoor conditions without performance degradation—critical for maintaining championship-grade turf.

Greenhouse Systems

Greenhouse operations demand micro-precision irrigation for sensitive plant growth cycles. BFV’s controller provides fine-tuned flow regulation with PN10 pressure compatibility for indoor systems, while UV-stabilized housings protect against greenhouse-specific light exposure. The integrated pump start relay delivers fail-safe activation, preventing water stress during critical growth phases—essential for high-value horticultural and nursery applications.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants and Engineers

| Key Attribute | BFV Specification | Client Benefit |

|---|---|---|

| Quality Assurance | 100% functional testing per unit | Zero-defect delivery, eliminating field failures and reducing maintenance costs for large-scale infrastructure projects |

| Certification | ISO 9001:2015 certified manufacturing | Guaranteed compliance with global quality standards for critical infrastructure, ensuring regulatory adherence across 50+ countries |

| Global Experience | 10+ years exporting to 50+ countries | Proven performance in diverse climatic, regulatory, and operational environments—from arid deserts to tropical monsoons |

BFV Valves’ commitment to technical excellence and end-to-end traceability ensures every component meets the rigorous demands of blue-chip engineering consultancies. Our solutions are engineered for longevity, with zero compromise on safety or performance—making us the trusted partner for mission-critical irrigation systems worldwide.

Why Choose BFV Valves

Partner with BFV Valves: Precision Engineering for Irrigation Systems

Quality You Can Trust

100% Production Testing: Every irrigation controller and pump start relay undergoes rigorous validation for flow accuracy (±1% tolerance), pressure integrity (PN16 certified), and solenoid reliability (1M+ cycle endurance testing).

ISO 9001:2015 Certified Manufacturing: End-to-end quality control ensuring compliance with international standards and consistent performance across all batches.

10-Year Export Heritage: Proven track record in 50+ countries with 99.2% on-time delivery and zero quality-related returns.

Supply Chain Reliability

Predictable Lead Times: Streamlined logistics and in-house production ensure delivery within 15–20 business days for standard orders, with expedited options for critical projects.

Customization Agility: Flexible configurations for voltage (120/230VAC), HP range (up to 5HP), and environmental specs without compromising delivery schedules.

Technical Partnership Model

No-Obligation Consultancy: Dedicated engineering support for system design reviews, compatibility assessments, and installation guidance to optimize project performance and longevity.

Competitive Total Cost of Ownership: Direct manufacturing model eliminates distributor markups, delivering premium quality at 15–20% lower TCO versus industry benchmarks.

Key Differentiators vs. Industry Standards

| Feature | BFV Valves | Industry Standard |

|---|---|---|

| Pressure Rating | PN16 (16 bar) | PN10 (10 bar) |

| UV Resistance | ISO 4892-2 compliant | Standard polymer |

| Solenoid Cycle Life | 1,000,000+ cycles | 500,000–750,000 cycles |

| IP Rating | IP67 (dust/waterproof) | IP54–IP55 |

| Motor Protection | Integrated thermal & low-pressure shutdown | Optional add-on or basic |

| Lead Time | 15–20 business days | 25–30 business days |

| Technical Support | Dedicated engineers | Basic hotline |

Your project’s success starts with a reliable partner.

For tailored solutions, technical specifications, or project-specific consultations, contact our regional export team:

Alex@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.