Introduction: Navigating the Global Market for irrigation drain valve

In the ever-evolving landscape of agricultural technology, sourcing the right irrigation drain valve is critical for optimizing water management and safeguarding irrigation systems against freeze damage. As businesses in regions like Africa, South America, the Middle East, and Europe (including Germany and Vietnam) strive to enhance their irrigation infrastructure, understanding the nuances of these essential components becomes paramount. This comprehensive guide delves into the various types of irrigation drain valves available on the market, their specific applications across different climates, and the factors influencing their cost and performance.

B2B buyers will benefit from insights into supplier vetting processes, ensuring that they select reliable partners capable of meeting their unique needs. With a focus on actionable intelligence, this guide empowers decision-makers to navigate the complexities of the global market, equipping them with the knowledge to make informed purchasing decisions. By addressing key challenges such as product compatibility, installation ease, and long-term maintenance considerations, we aim to enhance the efficiency and sustainability of irrigation practices worldwide. Whether you are looking to upgrade existing systems or implement new solutions, this guide serves as an invaluable resource for optimizing irrigation management through effective sourcing of drain valves.

Understanding irrigation drain valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Drain Valves | Opens automatically when water pressure drops; prevents freezing and damage to lines. | Agricultural irrigation, landscaping | Pros: Easy installation, prevents freeze damage. Cons: May drain water unnecessarily in warm climates. |

| Manual Drain Valves | Requires manual operation to open and close; simple design and less expensive. | Smaller irrigation systems, residential | Pros: Cost-effective, straightforward operation. Cons: Labor-intensive; prone to human error. |

| Anti-Siphon Drain Valves | Prevents backflow of contaminated water; often used in potable water systems. | Urban landscaping, golf courses | Pros: Ensures water quality, compliant with regulations. Cons: Higher initial cost, complex installation. |

| Pressure-Activated Drain Valves | Operates based on water pressure; closes when water is on and opens when off. | Commercial irrigation, large farms | Pros: Efficient operation, minimizes water wastage. Cons: Requires precise pressure management. |

| Lateral Line Drain Valves | Installed at the lowest points of the irrigation system to facilitate drainage. | Drip irrigation systems | Pros: Prevents water pooling, easy to integrate. Cons: Limited to specific system designs. |

What Are the Key Features of Automatic Drain Valves for B2B Buyers?

Automatic drain valves are designed to open when water pressure drops, allowing residual water to drain out. This feature is crucial in preventing freeze damage, particularly in regions with colder climates. B2B buyers in agricultural and landscaping sectors often prefer these valves for their ease of installation and maintenance. While they effectively protect irrigation systems, businesses should consider the potential for unnecessary drainage in warmer climates, which could lead to water wastage.

How Do Manual Drain Valves Fit into B2B Irrigation Solutions?

Manual drain valves are a cost-effective option for smaller irrigation systems or residential applications. Their straightforward design allows for easy operation; however, they require manual intervention to drain the system. This can be a disadvantage in larger operations where labor efficiency is critical. Buyers should weigh the lower initial costs against the increased labor requirements when considering manual options.

What Advantages Do Anti-Siphon Drain Valves Offer for Urban Applications?

Anti-siphon drain valves are essential for preventing the backflow of contaminated water, making them suitable for urban landscaping and golf courses. These valves comply with health regulations, ensuring that irrigation systems do not compromise water quality. While they offer significant advantages, such as regulatory compliance, their higher initial costs and complex installation processes may deter some buyers.

Why Choose Pressure-Activated Drain Valves for Larger Irrigation Systems?

Pressure-activated drain valves are ideal for commercial irrigation setups and large farms. They operate efficiently by responding to changes in water pressure, reducing water wastage when the system is not in use. However, they require precise pressure management, which may necessitate additional training for staff. Buyers should consider the operational efficiency against the need for proper system management.

How Do Lateral Line Drain Valves Enhance Drip Irrigation Systems?

Lateral line drain valves are specifically designed for installation at the lowest points of irrigation systems, facilitating effective drainage. They are particularly beneficial in drip irrigation setups, where water pooling can lead to system inefficiencies. While they are easy to integrate, buyers must ensure compatibility with their existing irrigation designs to maximize benefits.

Key Industrial Applications of irrigation drain valve

| Industry/Sector | Specific Application of Irrigation Drain Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop Irrigation Systems | Prevents water logging and crop damage, enhancing yield | Durability against soil corrosion, local climate compatibility |

| Landscaping & Horticulture | Sprinkler Systems for Parks and Gardens | Protects irrigation infrastructure from freeze damage, ensuring consistent watering | Easy installation, compatibility with various sprinkler systems |

| Golf Course Management | Irrigation for Fairways and Greens | Reduces maintenance costs by preventing water wastage and erosion | High pressure tolerance, reliability in varying climates |

| Municipal Water Management | Urban Green Spaces and Sports Facilities | Maintains healthy vegetation while conserving water resources | Compliance with local regulations, ease of integration with existing systems |

| Industrial Agriculture | Large-scale Farming Operations | Enhances water management efficiency, reducing operational costs | Sourcing from reliable suppliers, bulk purchasing options |

How Are Irrigation Drain Valves Used in Agriculture?

In agricultural applications, irrigation drain valves are critical for managing water flow in crop irrigation systems. They prevent water from accumulating in the lines, mitigating the risk of water logging, which can lead to root rot and reduced crop yields. Buyers in regions with varying climates, such as Africa and South America, should prioritize valves that can withstand local soil conditions and potential corrosive elements.

What Role Do Irrigation Drain Valves Play in Landscaping and Horticulture?

In landscaping and horticulture, irrigation drain valves are utilized to protect sprinkler systems, particularly in parks and gardens. These valves automatically release water when the system is off, preventing freeze damage in colder climates and ensuring efficient watering practices. Buyers should consider the ease of installation and compatibility with existing systems to optimize performance and reduce maintenance.

Why Are Irrigation Drain Valves Important for Golf Course Management?

Golf course management relies heavily on effective irrigation systems to maintain the health of fairways and greens. Irrigation drain valves are essential for preventing water wastage and erosion, thus reducing maintenance costs. International buyers, especially from Europe, should focus on valves that offer high pressure tolerance and reliability, given the diverse weather conditions experienced in different regions.

How Do Municipal Water Management Systems Benefit from Irrigation Drain Valves?

Municipal water management systems utilize irrigation drain valves to maintain urban green spaces and sports facilities. These valves ensure that water resources are used efficiently while supporting the growth of healthy vegetation. When sourcing these valves, municipalities should ensure compliance with local regulations and consider ease of integration with existing irrigation infrastructure to maximize efficiency.

What Advantages Do Irrigation Drain Valves Provide for Industrial Agriculture?

In industrial agriculture, where large-scale farming operations are common, irrigation drain valves enhance water management efficiency. By facilitating proper drainage, they reduce operational costs associated with over-irrigation and help maintain optimal soil conditions. Buyers should seek reliable suppliers offering bulk purchasing options to ensure consistent supply and support for large-scale projects.

3 Common User Pain Points for ‘irrigation drain valve’ & Their Solutions

Scenario 1: Managing Seasonal Freeze Risks in Colder Climates

The Problem: B2B buyers in colder regions often face the challenge of ensuring their irrigation systems are protected against freeze damage. Water left in pipes can freeze during the winter months, leading to burst pipes and costly repairs when the system is restarted in spring. This risk is particularly significant for agricultural businesses and landscape contractors who rely on effective irrigation throughout the growing season. Understanding how to prevent such damage is crucial for maintaining operational efficiency and minimizing repair costs.

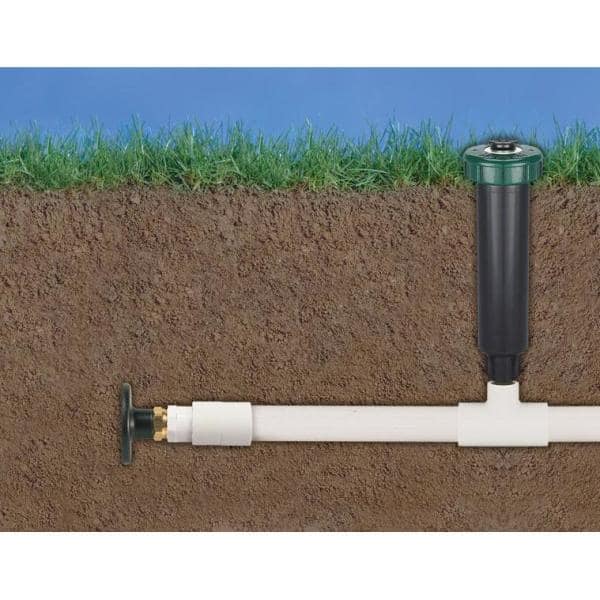

The Solution: To mitigate the risk of freeze damage, it is essential to implement automatic drain valves in your irrigation systems. These valves function by allowing water to drain from the pipes when the system is turned off, preventing any residual water from freezing. When sourcing these valves, ensure they are compatible with your existing irrigation components, and select models that have a proven track record in harsh weather conditions. Installation should be performed at the low points of your irrigation lines to optimize drainage. Additionally, consider conducting regular maintenance checks on these valves before the onset of winter to ensure they are functioning correctly and can effectively protect your system.

Scenario 2: Overwatering and Erosion from Dripping Sprinkler Heads

The Problem: In regions with variable terrain or uneven landscapes, B2B buyers often encounter issues with overwatering due to sprinkler heads that continue to drip after the system shuts off. This can lead to soil erosion, water wastage, and uneven watering, which negatively impacts crop yields or landscape aesthetics. The challenge lies in finding a solution that effectively addresses the issue without requiring extensive system redesigns.

The Solution: Installing automatic drain valves can significantly reduce the occurrence of post-operation drips from sprinkler heads. These valves work by draining residual water from the lines after the system is turned off, ensuring that no excess water remains to flow out of the heads. When selecting automatic drain valves, prioritize models that are designed for your specific irrigation system type and ensure they are correctly installed at the end of lateral lines. Furthermore, educate your team on the importance of checking these valves regularly to prevent blockages that could impede their operation. By implementing this solution, businesses can minimize water wastage and protect their landscapes from erosion.

Scenario 3: Complications in System Retrofits and Upgrades

The Problem: As irrigation technology evolves, many B2B buyers face the challenge of retrofitting existing systems with modern components, including irrigation drain valves. Integrating new valves into older systems can lead to compatibility issues and may require extensive modifications, resulting in increased costs and downtime. This is especially challenging for businesses operating in fast-paced agricultural environments or those providing services to clients with tight schedules.

The Solution: When retrofitting existing irrigation systems, it is crucial to conduct a thorough assessment of current infrastructure before selecting new drain valves. Focus on choosing universal models that can be easily adapted to various pipe sizes and configurations. Work with suppliers who offer technical support and installation guidance to ensure compatibility. Furthermore, consider engaging an experienced irrigation specialist to assist with the retrofit process, minimizing potential setbacks and ensuring a seamless integration. By taking these steps, businesses can efficiently upgrade their systems without incurring significant costs or operational disruptions.

Strategic Material Selection Guide for irrigation drain valve

What Are the Key Materials Used for Irrigation Drain Valves?

When selecting materials for irrigation drain valves, it is essential to consider factors such as durability, cost, and compatibility with various environmental conditions. Here, we analyze four common materials used in the manufacturing of irrigation drain valves: brass, plastic (PVC), stainless steel, and aluminum. Each material has unique properties that can significantly influence the performance and longevity of the valves.

How Does Brass Perform in Irrigation Drain Valves?

Brass is a popular choice for irrigation drain valves due to its excellent durability and resistance to corrosion. It typically has a high-temperature rating, making it suitable for various climates. Brass valves can withstand pressures of up to 150 psi, making them ideal for high-pressure irrigation systems.

Pros: Brass is highly durable and resistant to rust, which is crucial for longevity in irrigation applications. It also has a relatively low manufacturing complexity, allowing for easier production and installation.

Cons: However, brass can be more expensive than other materials, which may be a consideration for budget-conscious buyers. Additionally, brass may not be suitable for acidic or alkaline water, which could lead to corrosion over time.

Impact on Application: Brass valves are compatible with a wide range of media, including water and fertilizers, making them versatile for different irrigation systems.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, especially in regions like Europe and the Middle East, where quality regulations are stringent.

What Are the Advantages of Plastic (PVC) in Irrigation Drain Valves?

Plastic, particularly PVC, is another common material used in irrigation drain valves. PVC is lightweight and resistant to corrosion, making it suitable for various applications, especially in regions with high humidity or saline conditions. It can typically handle pressures up to 100 psi.

Pros: The primary advantage of PVC is its cost-effectiveness. It is significantly cheaper than brass and stainless steel, making it an attractive option for large-scale irrigation projects.

Cons: On the downside, PVC has a lower temperature rating and can become brittle in extreme cold. It is also less durable than metals, leading to potential failures in high-pressure situations.

Impact on Application: PVC is compatible with water and many fertilizers, but it should not be used with certain solvents or oils, which can degrade the material.

Considerations for International Buyers: Buyers in Africa and South America should ensure that PVC products meet local standards, as there may be variations in quality and specifications.

How Does Stainless Steel Compare for Irrigation Drain Valves?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a premium choice for irrigation drain valves. It can withstand extreme temperatures and pressures, often rated for up to 300 psi.

Pros: The durability of stainless steel ensures a long lifespan, even in harsh environments. Its resistance to rust and corrosion makes it suitable for various media, including saline water.

Cons: However, stainless steel is one of the most expensive materials, which may deter some buyers. Additionally, its manufacturing complexity can lead to higher production costs.

Impact on Application: Stainless steel valves are ideal for applications involving aggressive chemicals or extreme temperatures, making them suitable for specialized irrigation systems.

Considerations for International Buyers: Compliance with international standards is crucial, especially in Europe, where regulations on material quality are strict. Buyers should verify certifications to ensure product reliability.

What Role Does Aluminum Play in Irrigation Drain Valves?

Aluminum is a lightweight and corrosion-resistant material that is increasingly used in irrigation drain valves. It typically has a pressure rating of around 150 psi, making it suitable for various irrigation applications.

Pros: The primary advantage of aluminum is its lightweight nature, which simplifies installation and reduces shipping costs. It is also relatively affordable compared to brass and stainless steel.

Cons: However, aluminum can corrode in certain environments, especially when exposed to alkaline water. Its strength is also less than that of stainless steel, which may limit its use in high-pressure systems.

Impact on Application: Aluminum valves are suitable for applications where weight is a concern, but their use should be carefully evaluated in corrosive environments.

Considerations for International Buyers: Buyers should ensure that aluminum products meet local standards and consider the environmental conditions in their region to prevent premature failure.

Summary Table of Material Selection for Irrigation Drain Valves

| Material | Typical Use Case for irrigation drain valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-pressure irrigation systems | Durable and corrosion-resistant | Higher cost; not suitable for acidic water | Medium |

| Plastic (PVC) | General irrigation applications | Cost-effective and lightweight | Lower durability; brittle in cold | Low |

| Stainless Steel | Specialized irrigation systems | Exceptional strength and longevity | High cost; complex manufacturing | High |

| Aluminum | Lightweight applications | Lightweight and affordable | Prone to corrosion in alkaline conditions | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to choose the right irrigation drain valve for their specific needs. Understanding the properties, advantages, and limitations of each material can help in making informed purchasing decisions that align with local regulations and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation drain valve

What Are the Key Stages in the Manufacturing Process of Irrigation Drain Valves?

The manufacturing process of irrigation drain valves involves several critical stages that ensure the final product meets performance and quality standards. Here’s a breakdown of these stages:

Material Preparation: What Materials Are Used in Irrigation Drain Valves?

The first step in manufacturing irrigation drain valves is the selection and preparation of materials. Common materials include brass, plastic, and various alloys, each chosen for their durability, resistance to corrosion, and suitability for different environmental conditions. Manufacturers often source materials from certified suppliers to ensure compliance with industry standards. This stage also includes cutting materials to size and performing initial inspections to verify their quality.

Forming: How Are Irrigation Drain Valves Shaped?

After material preparation, the forming process begins. Techniques such as injection molding for plastic components or machining for metal parts are commonly used. In injection molding, heated plastic is injected into molds to create specific valve shapes, ensuring precision and uniformity. For metal parts, processes like CNC machining or die casting shape the materials into the desired configurations. This stage is crucial as it directly affects the valve’s functionality and compatibility within the irrigation system.

Assembly: What Is Involved in Assembling Irrigation Drain Valves?

Once the individual components are formed, they are assembled into complete irrigation drain valves. This process may involve manual assembly or automated systems, depending on the manufacturer’s capabilities. Key components, such as seals, springs, and filters, are integrated during this stage. Proper assembly is vital to ensure that the valves function correctly, especially under varying pressure conditions. Manufacturers often employ jigs and fixtures to maintain consistency and accuracy during assembly.

Finishing: What Finishing Techniques Are Used for Quality Control?

The finishing stage involves surface treatments that enhance the durability and aesthetics of the irrigation drain valves. Techniques such as anodizing for aluminum parts, galvanization for corrosion resistance, or painting may be applied. This stage not only improves the product’s appearance but also its longevity and performance in harsh environments. Additionally, finishing processes are often followed by inspections to ensure that all surfaces meet quality standards.

What Quality Assurance Measures Are Essential for Irrigation Drain Valves?

Quality assurance (QA) is paramount in the manufacturing of irrigation drain valves, ensuring that products meet international standards and customer expectations.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are crucial for manufacturers of irrigation drain valves. This standard outlines requirements for a quality management system (QMS), emphasizing continuous improvement and customer satisfaction. Other relevant certifications may include CE marking for European markets and API standards for products used in oil and gas applications. Manufacturers should provide documentation proving compliance with these standards, which can be a critical factor for B2B buyers.

What Are the Key Quality Control Checkpoints?

Quality control in the manufacturing process typically includes several checkpoints:

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon receipt to ensure they meet specified quality criteria. Any materials that do not meet standards are rejected.

In-Process Quality Control (IPQC): During the manufacturing process, random samples of products are tested at various stages. This helps identify defects early in the production cycle, allowing for immediate corrective actions.

Final Quality Control (FQC): Before the irrigation drain valves are packaged and shipped, a final inspection is conducted. This includes functional testing, pressure testing, and visual inspections to ensure the products meet all specifications.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods for irrigation drain valves include:

Functional Testing: Ensures that the valve operates correctly under simulated real-world conditions. This may involve cycling the valve open and closed multiple times to assess performance.

Pressure Testing: Verifies that the valve can withstand the required pressure levels without leaking or failing. This is particularly important for valves that will be used in high-pressure irrigation systems.

Corrosion Resistance Testing: Especially critical for valves made from metals, this testing determines how well the product can withstand exposure to various environmental factors.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This may include reviewing their QMS documentation, production methods, and compliance with international standards.

Quality Reports: Requesting quality reports or certificates from suppliers can help buyers assess product quality. These documents should detail the results of various testing methods and inspections conducted during the manufacturing process.

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of verification. These independent entities can assess the manufacturing processes and product quality to ensure compliance with industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

Regional Regulations: Different regions may have varying regulations regarding product standards and certifications. Buyers should familiarize themselves with local laws and ensure that suppliers comply with these regulations.

Cultural Considerations: Understanding cultural differences in business practices can enhance communication and foster better relationships with suppliers. This can lead to improved collaboration on quality assurance initiatives.

Supply Chain Transparency: International buyers should seek suppliers who offer transparency in their supply chain practices. This includes clear documentation of sourcing, manufacturing, and quality control processes.

By understanding the manufacturing processes and quality assurance measures associated with irrigation drain valves, B2B buyers can make informed decisions, ensuring they procure reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation drain valve’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure irrigation drain valves. As these components play a crucial role in protecting irrigation systems from freezing and ensuring efficient drainage, a thoughtful sourcing process is essential. By following this step-by-step checklist, you can make informed purchasing decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Understanding the technical requirements for your irrigation drain valves is the first step in the procurement process. Consider factors such as the size, material (brass vs. plastic), pressure ratings, and compatibility with existing systems. Clearly defined specifications will help you avoid purchasing unsuitable products, saving time and costs in the long run.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who specialize in irrigation drain valves. Look for companies with a strong reputation in the industry, positive customer reviews, and relevant experience in your geographical region. Supplier reliability is critical to ensure that you receive quality products and support.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Pay attention to:

– Certification and Compliance: Ensure that suppliers meet international standards and local regulations.

– Customer Support: Look for suppliers that offer robust customer service, including installation guidance and after-sales support.

Step 4: Assess Product Quality and Performance

Quality assurance is vital when sourcing irrigation drain valves. Inquire about the materials used and the manufacturing process. Request samples, if possible, to assess the durability and functionality of the valves. Consider the following:

– Pressure Ratings: Ensure the valves can withstand the operational pressures of your irrigation system.

– Warranty and Returns Policy: A solid warranty can provide peace of mind regarding product longevity and performance.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Be cautious of prices that seem too low, as they may indicate inferior quality. Look for:

– Bulk Discounts: Many suppliers offer discounts for larger orders, which can significantly reduce your overall costs.

– Shipping and Handling Fees: Understand the total cost of acquisition, including any additional fees for shipping, customs, or taxes.

Step 6: Place a Trial Order

Before making a large commitment, consider placing a trial order. This allows you to evaluate the product’s performance in real-world conditions without a significant upfront investment. Monitor the functionality of the valves and any impact on your irrigation system to ensure they meet your expectations.

Step 7: Establish a Long-term Relationship

Once you have identified a reliable supplier and confirmed the quality of their products, work on establishing a long-term relationship. A strong partnership can lead to better pricing, priority service, and access to new products. Regular communication and feedback will help both parties grow and improve over time.

By following this checklist, B2B buyers can navigate the sourcing process for irrigation drain valves effectively, ensuring they make well-informed decisions that meet their specific operational needs.

Comprehensive Cost and Pricing Analysis for irrigation drain valve Sourcing

What Are the Key Cost Components in Sourcing Irrigation Drain Valves?

When sourcing irrigation drain valves, understanding the cost structure is essential for effective budget management and pricing negotiations. The primary cost components include:

Materials: The choice of materials—such as brass, plastic, or ABS—significantly impacts the cost. High-quality materials may command higher prices but offer better durability and performance, which can justify the investment.

Labor: Labor costs encompass the wages paid to workers involved in manufacturing the valves. This varies by region; for instance, labor may be less expensive in certain South American countries compared to Europe.

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with the production facility. Efficient manufacturing processes can help minimize these costs.

Tooling: Tooling costs involve the initial investment in molds and machinery needed for production. Custom designs or specifications may require additional tooling, raising initial costs.

Quality Control (QC): Implementing rigorous QC processes ensures that the valves meet industry standards. While this adds to the cost, it helps prevent costly recalls and enhances brand reputation.

Logistics: Shipping and transportation costs are critical, especially for international buyers. Factors such as distance, mode of transport, and fuel prices will influence the overall logistics cost.

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s market positioning and competitive strategy.

What Influences the Pricing of Irrigation Drain Valves?

Several factors affect the pricing of irrigation drain valves, particularly for B2B buyers:

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders due to economies of scale. Understanding the MOQ can help buyers negotiate better terms.

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO standards) may increase the price but can enhance reliability and lifespan.

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge a premium for their proven quality and service.

Incoterms: The chosen Incoterms (International Commercial Terms) influence logistics costs and risk distribution. Understanding these terms is crucial for international transactions.

What Are the Best Practices for Negotiating Prices in International B2B Transactions?

For buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to substantial cost savings. Here are some actionable tips:

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, replacement, and potential downtime. A lower upfront cost may not always be the most economical choice.

Leverage Bulk Buying: If possible, consolidate orders to meet MOQs. This can lead to lower per-unit costs and improved bargaining power with suppliers.

Research Market Prices: Conduct thorough market research to understand the typical pricing for similar products. This knowledge can provide leverage during negotiations.

Build Relationships: Establishing a good relationship with suppliers can lead to better pricing and terms. Regular communication and loyalty can yield benefits over time.

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, tariffs, and regulations. Buyers should be mindful of these factors when negotiating prices.

Conclusion

Sourcing irrigation drain valves involves navigating a complex landscape of costs and pricing influencers. By understanding the components that affect pricing and employing strategic negotiation techniques, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that indicative prices may vary based on market conditions and specific supplier terms, so continuous evaluation and strategic sourcing are key to achieving the best outcomes.

Alternatives Analysis: Comparing irrigation drain valve With Other Solutions

When evaluating irrigation solutions, it’s essential to consider various technologies that can achieve similar goals as an irrigation drain valve. Each option presents unique benefits and challenges, making the decision process vital for optimizing irrigation systems. Below is a comparative analysis of the irrigation drain valve against two viable alternatives: manual drain valves and automated irrigation control systems.

| Comparison Aspect | Irrigation Drain Valve | Manual Drain Valve | Automated Irrigation Control System |

|---|---|---|---|

| Performance | Effective at preventing freeze damage by draining water automatically. | Requires manual operation, which can lead to human error and potential damage if forgotten. | Can optimize water usage and reduce overwatering, but relies on proper programming and sensor accuracy. |

| Cost | Moderate initial investment, typically around $5 to $50 per unit. | Generally lower upfront cost, but may lead to higher long-term costs due to potential damages. | Higher initial investment, ranging from hundreds to thousands of dollars depending on system complexity. |

| Ease of Implementation | Easy to install in existing systems, with minimal disruption. | Installation can vary; may require additional fittings or alterations. | More complex installation, often requiring professional setup and ongoing adjustments. |

| Maintenance | Low maintenance; minimal parts prone to wear. | Moderate maintenance required to ensure operability and prevent clogs. | Maintenance can be high, needing regular updates and checks on sensors and software. |

| Best Use Case | Ideal for climates prone to freezing or where drainage is critical. | Suitable for smaller systems where manual oversight is feasible. | Best for large-scale operations needing precise control over water delivery. |

What are the Pros and Cons of Manual Drain Valves?

Manual drain valves are simpler mechanisms that allow users to drain water from their irrigation systems by hand. The primary advantage is their lower cost and straightforward design, which can be less prone to mechanical failure. However, the reliance on human action introduces a significant risk of oversight, especially in larger systems. If operators forget to open the valve, they may face costly damage from freezing or overwatering.

How Does an Automated Irrigation Control System Compare?

Automated irrigation control systems represent the pinnacle of irrigation technology, utilizing sensors and software to optimize water delivery based on real-time data. The primary benefit is efficiency; these systems can significantly reduce water waste and improve crop health by providing precise irrigation. However, the complexity and cost of installation can be prohibitive for smaller operations. Additionally, they require ongoing maintenance and may be susceptible to software glitches or sensor failures.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate irrigation solution, B2B buyers should consider their specific operational needs and environmental conditions. For those in colder climates or with complex irrigation requirements, an irrigation drain valve may offer the best balance of performance and cost. Conversely, smaller operations might benefit from manual valves, while larger agricultural enterprises may find that the investment in automated systems pays off in water conservation and crop yield improvements. Ultimately, the right choice hinges on weighing initial costs against long-term benefits and operational efficiencies.

Essential Technical Properties and Trade Terminology for irrigation drain valve

What Are the Key Technical Properties of an Irrigation Drain Valve?

When selecting an irrigation drain valve, understanding its technical specifications is crucial for ensuring reliability and efficiency in agricultural applications. Here are some essential properties to consider:

Material Composition

The materials used in the construction of an irrigation drain valve significantly affect its durability and performance. Common materials include brass, plastic, and ABS. Brass offers corrosion resistance and strength, making it suitable for high-pressure systems, while plastic options are lightweight and cost-effective for lower-pressure applications. Selecting the appropriate material based on the specific environment (e.g., temperature extremes, exposure to chemicals) is vital for longevity.Pressure Ratings

Each valve comes with a specified pressure rating, typically measured in psi (pounds per square inch). This rating indicates the maximum pressure the valve can handle without failing. For example, a valve with a rating of 5 psi might be suitable for standard irrigation systems, while higher ratings are necessary for more demanding applications. Understanding pressure requirements is essential for system compatibility and to prevent costly leaks or failures.Flow Rate

The flow rate, often expressed in gallons per minute (GPM), determines how quickly water can exit the system through the valve. This specification is crucial for ensuring that the irrigation system operates efficiently and meets the watering needs of crops. A valve with an inadequate flow rate can lead to poor irrigation performance and may require additional valves or modifications to the system.Size and Compatibility

Irrigation drain valves come in various sizes, typically measured in inches for pipe diameter. Common sizes include ½ inch and ¾ inch. It’s important to choose a valve that matches the existing piping system to ensure a proper fit and optimal performance. Compatibility with other components, such as fittings and connectors, also plays a significant role in installation and functionality.Opening and Closing Mechanism

The mechanism by which the valve opens and closes is critical for its operation. Most automatic drain valves utilize a pressure-activated seal that remains closed while the system is pressurized and opens when the pressure drops. This design prevents water from remaining in the pipes, mitigating the risk of freeze damage in colder climates. Understanding how the mechanism works can help in selecting the right valve for specific operational needs.

What Are Common Trade Terms Related to Irrigation Drain Valves?

In the B2B landscape, familiarity with industry terminology can streamline communications and negotiations. Here are some essential terms:

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of irrigation drain valves, understanding OEM partnerships can help buyers identify reliable suppliers and quality assurance processes.MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for buyers to understand, as it impacts purchasing decisions and inventory management. Negotiating favorable MOQs can optimize costs, particularly for large-scale agricultural operations.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For irrigation drain valves, submitting an RFQ can help buyers compare prices, delivery times, and terms from multiple suppliers, leading to more informed purchasing decisions.Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping responsibilities, insurance, and risk management, particularly when sourcing products from different countries.Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times for irrigation drain valves is crucial for planning and scheduling, especially in agricultural seasons where timely irrigation is vital for crop success.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring the effective and efficient operation of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation drain valve Sector

What Are the Key Market Trends Influencing the Irrigation Drain Valve Sector?

The irrigation drain valve sector is witnessing significant transformation driven by global demand for efficient water management solutions. Key trends include the rise of smart irrigation technologies, which integrate IoT devices to optimize water usage and minimize waste. This is particularly crucial for regions facing water scarcity, such as parts of Africa and the Middle East, where innovative solutions can enhance agricultural productivity while conserving vital resources. Additionally, the increasing adoption of automated systems reflects a broader trend towards precision agriculture, where data-driven insights help in decision-making and resource allocation.

Emerging sourcing trends indicate a shift towards suppliers that offer comprehensive solutions, including installation and maintenance services. International buyers are increasingly looking for manufacturers that provide robust customer support and quick turnaround times for shipping, especially in regions like South America and Europe. The competitive landscape is also being shaped by the need for customization, as businesses seek valves tailored to specific irrigation systems and environmental conditions. This trend highlights the importance of developing partnerships with suppliers who can provide technical expertise and local market insights.

How Are Sustainability and Ethical Sourcing Shaping the Irrigation Drain Valve Market?

Sustainability is becoming a cornerstone of the irrigation drain valve market, with buyers prioritizing products that minimize environmental impact. The production process for drain valves often involves materials that are recyclable and durable, reducing the need for frequent replacements. Ethical sourcing practices are also gaining traction, as companies are increasingly held accountable for their supply chain transparency. This is particularly relevant in regions like Europe, where regulatory frameworks emphasize corporate social responsibility and environmental stewardship.

Green certifications and the use of eco-friendly materials are critical considerations for B2B buyers. Products that meet recognized sustainability standards not only appeal to environmentally conscious customers but can also enhance brand reputation. For instance, valves made from recycled plastics or those that comply with international environmental regulations can provide a competitive edge. As more businesses commit to reducing their carbon footprint, suppliers who align with these values are likely to see increased demand.

What Is the Historical Context of Irrigation Drain Valves in B2B Markets?

The evolution of irrigation drain valves can be traced back to the early 20th century when the need for effective drainage solutions in agriculture became evident. Initially, these valves were simple mechanical devices designed to prevent water accumulation in irrigation systems, which could lead to crop damage. Over the decades, advancements in material science and engineering have led to the development of more sophisticated automatic drain valves that not only enhance efficiency but also protect irrigation systems from damage due to freezing temperatures.

Today, the historical context of irrigation drain valves is characterized by a transition towards automation and smart technology integration. This evolution reflects broader trends in agricultural technology, where efficiency, sustainability, and ease of use are paramount. As the sector continues to innovate, understanding this history can help B2B buyers appreciate the advancements in product offerings and the importance of selecting reliable suppliers who are aligned with these ongoing trends.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation drain valve

How do I solve issues with water accumulation in my irrigation system?

Water accumulation in irrigation systems can lead to overwatering and potential damage. To mitigate this, consider installing automatic drain valves at the lowest points of your system. These valves open when water pressure drops, allowing residual water to drain out, thus preventing accumulation. When sourcing these valves, ensure they are compatible with your existing system’s specifications and materials, and select a reliable supplier who understands the environmental challenges specific to your region.What is the best automatic drain valve for protecting against freeze damage?

The best automatic drain valves for freeze protection are those that utilize pressure-activated seals, ensuring they remain closed during operation and open when the system shuts down. Look for models made from durable materials like brass or high-quality plastic, which can withstand harsh conditions. Additionally, verify that the valve size matches your piping system, and check for customer reviews or case studies that demonstrate the valve’s effectiveness in similar climates.How can I ensure the quality of irrigation drain valves when sourcing internationally?

To ensure quality, conduct thorough supplier vetting by checking for certifications, customer reviews, and compliance with international standards. Request samples of the irrigation drain valves to evaluate their construction and performance firsthand. It’s also advisable to visit the manufacturing facility if possible or engage a third-party inspection service to assess quality before shipment. Establishing clear communication with the supplier about quality expectations and specifications will further safeguard your investment.What are the typical minimum order quantities (MOQs) for irrigation drain valves?

Minimum order quantities for irrigation drain valves can vary significantly based on the supplier and the materials used. Typically, MOQs range from 50 to 100 units, but some manufacturers may offer lower quantities for first-time buyers or trial orders. When negotiating, inquire about the possibility of reducing MOQs for specific designs or materials that suit your needs. Additionally, consider collaborating with other buyers in your region to meet MOQ requirements collectively.What payment terms should I expect when sourcing irrigation drain valves internationally?

Payment terms in international B2B transactions often include options such as advance payment, letter of credit, or payment on delivery. A common arrangement is a 30% deposit upfront with the balance due before shipping. Discussing payment terms openly with your supplier is crucial to ensure clarity and protect both parties’ interests. Always choose secure payment methods to minimize risks associated with international trade.What logistics considerations should I keep in mind for importing irrigation drain valves?

Logistics considerations include understanding shipping options, customs regulations, and delivery timelines. Determine whether air freight or sea freight is more suitable based on urgency and cost-effectiveness. Ensure that your supplier can provide the necessary documentation for customs clearance. It’s also wise to work with a reliable freight forwarder familiar with your destination country’s import regulations to streamline the process and avoid delays.Can I customize the specifications of irrigation drain valves for my project needs?

Many manufacturers offer customization options for irrigation drain valves, including size, material, and specific design features. When discussing customization, provide detailed specifications and any relevant standards your project requires. Be prepared for potential changes in pricing and lead times associated with custom orders. Building a good relationship with your supplier can facilitate smoother negotiations and better outcomes for custom solutions.What are common challenges faced in international sourcing of irrigation drain valves, and how can I overcome them?

Common challenges include language barriers, cultural differences, and variations in product standards. To overcome these, engage in clear and continuous communication with your supplier, possibly utilizing professional translation services if necessary. Familiarize yourself with local regulations that may affect product specifications and compliance. Additionally, consider working with local agents or consultants who understand the market dynamics and can bridge gaps between you and your supplier effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Irrigation Drain Valve Manufacturers & Suppliers List

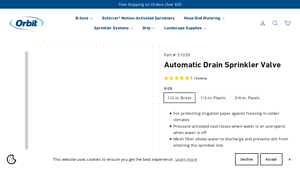

1. Orbit – Automatic Drain Sprinkler Valve

Domain: orbitonline.com

Registered: 1999 (26 years)

Introduction: Product Name: Automatic Drain Sprinkler Valve

Part #: 51039

Available Sizes: 1/2-in. Brass, 1/2-in. Plastic, 3/4-in. Plastic

Key Features:

– Protects irrigation pipes against freezing in colder climates

– Pressure-activated seal closes when water is on and opens when water is off

– Mesh filter allows water to discharge and prevents dirt from entering the sprinkler line

– ABS construction with thre…

2. Reddit – Automatic Drain Valves

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Automatic drain valves are designed to be held closed by pressure when the irrigation system is running and drain water when the pressure drops. They are considered appealing for winterization in cold climates, specifically in climate zone 6 where freezing occurs. Users express concerns about their effectiveness, potential water wastage during the active season, and the need for proper installatio…

3. Rainbird – 16AFDVC1 Filtered Drain Valve

Domain: store.rainbird.com

Registered: 1995 (30 years)

Introduction: {“model”:”16AFDVC1″,”type”:”Filtered Drain Valve”,”connection”:”1/2 in. MPT”,”special_price”:”$3.99″,”list_price”:”$5.83″,”features”:[“Unique two-stage screening process prevents grit from siphoning back into pipes”,”Protects against freezing by automatically draining pipes when water is turned off”,”Eliminates need for gravel drain”],”sku”:”B40511″,”availability”:”In stock”}

4. Pioneer Underground – Sprinkler System Winterization

Domain: pioneerunderground.net

Registered: 2010 (15 years)

Introduction: Pioneer Underground Lawn Sprinklers provides reliable sprinkler system blowout and winterization solutions in Omaha. They offer both commercial and residential sprinkler system services, helping clients avoid system failures due to frozen pipes. Their team understands local climate patterns and uses proven freeze protection techniques to prepare lawn irrigation for winter. They provide free estima…

5. The Lawn Forum – Automatic Drainage Valves

Domain: thelawnforum.com

Registered: 2017 (8 years)

Introduction: Automatic valves that intentionally leak when there is no pressure in the pipe; designed for irrigation systems to drain water and prevent freezing in Northern climates; installation involves sloping each zone to a low point with a V shape; low point approximately 4 feet underground; encased in a valve box with gravel and soil.

6. Irrigation Solutions – Essential Components

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Irrigation valves, double check backflow preventer, ports labeled A, C, D, E, isolation valve, drain valves, sprinkler zones, air compressor for winterizing.

Strategic Sourcing Conclusion and Outlook for irrigation drain valve

As the demand for efficient irrigation systems continues to rise globally, the strategic sourcing of irrigation drain valves emerges as a critical focus for B2B buyers. Key insights highlight the importance of selecting high-quality valves that not only prevent freeze damage but also enhance the overall efficiency of irrigation systems. Investing in automatic drain valves can significantly mitigate risks associated with water retention, which often leads to costly repairs and system inefficiencies.

In regions such as Africa, South America, the Middle East, and Europe, where climate variability can affect agricultural productivity, the right sourcing strategies are essential. Buyers should prioritize suppliers that offer robust products, transparent pricing, and reliable shipping options. Additionally, considering the ease of installation can lead to reduced labor costs, making these products even more appealing.

Looking ahead, the integration of advanced technology in irrigation systems promises to revolutionize water management practices. International buyers are encouraged to stay informed about emerging trends and innovations in the irrigation sector. By strategically sourcing high-quality irrigation drain valves, you can enhance operational efficiency and contribute to sustainable agricultural practices. Engage with suppliers today to secure the best solutions for your irrigation needs.