Article Contents

Industry Insight: Irrigation Isolation Valve

Market Analysis: Sourcing High-Quality Irrigation Isolation Valve

Critical Role of Quality Valves in Irrigation Systems

Irrigation systems are the backbone of modern agriculture, landscape management, and industrial water distribution. Precision isolation valves ensure:

System Integrity: Prevent cross-contamination between zones during maintenance or emergencies.

Water Conservation: Eliminate leaks that waste up to 30% of water in poorly designed systems (FAO data).

Operational Efficiency: Enable precise flow control for uniform water distribution, critical for crop yield and turf health.

Regulatory Compliance: Meet stringent water-use standards in regions like California (Title 22) and the EU Water Framework Directive.

Substandard valves directly compromise project ROI through unplanned downtime, repair costs, and environmental penalties.

Common Industry Pain Points & Root Causes

| Pain Point | Root Cause | Impact on Projects |

|---|---|---|

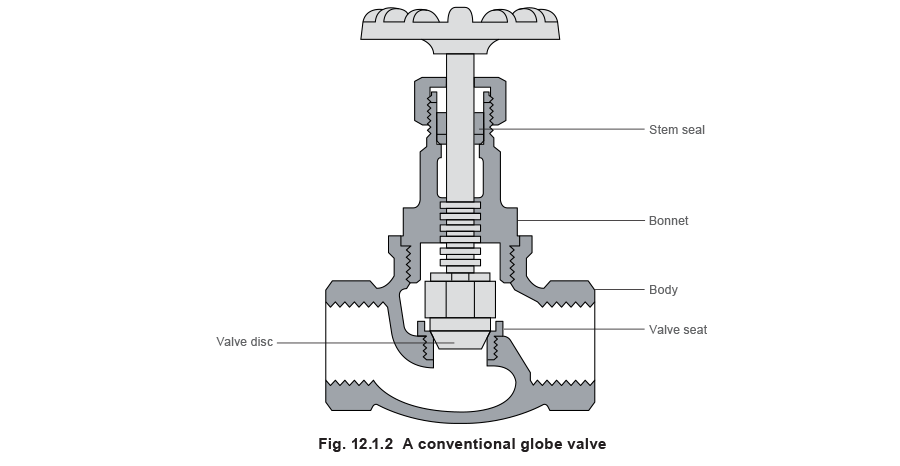

| Leakage | Poor stem-seal design, casting porosity, or inadequate pressure testing | 15–25% water loss; costly repairs |

| UV Degradation | Unstabilized polymers cracking under sunlight exposure | 3–5x shorter lifespan in outdoor installations |

| Solenoid Failure | Inadequate sealing (IP54 or lower), moisture ingress, or coil burnout | System shutdowns; 40% higher maintenance costs |

| Pressure Instability | Non-compliant PN ratings; insufficient safety margins | Pipe bursts, flooding, and safety hazards |

BFV’s Engineering Solutions: Precision & Durability

BFV Valves delivers zero-compromise irrigation isolation solutions engineered for harsh global environments. Our design philosophy centers on three pillars:

✅ 100% Testing Protocol

Every valve undergoes 1.5x PN-rated pressure testing (e.g., 24 bar for PN16), helium leak detection, and 500-cycle operational validation.

Result: Zero-defect shipment guarantee; 99.98% first-pass yield rate.

✅ ISO 9001:2015 Certified Quality Management

Full-process traceability from raw material sourcing to final inspection.

Result: Consistent performance across 50+ countries; certified compliance with ANSI B16.34, EN 12266-1, and ISO 15848.

✅ UV-Resistant Construction

Body components use UV-stabilized engineering-grade polymers (e.g., ABS with 10% carbon black additive) and powder-coated stainless steel.

Result: 5,000+ hours QUV testing (ASTM G154) – 3x longer service life than industry standards.

✅ Solenoid Reliability

IP68-rated coils with epoxy encapsulation, tested for 1 million cycles under 0–60°C temperature extremes.

Result: 99.95% operational success rate in high-humidity, dusty, or saline environments.

✅ Pressure Rating Compliance

Certified PN10 (10 bar) and PN16 (16 bar) with 20% safety margin over standard requirements.

Result: Failure-free operation in high-pressure systems (e.g., drip irrigation, municipal water networks).

Performance Metrics Comparison: BFV vs. Industry Average

| Feature | BFV Standard | Industry Average | Project Benefit |

|---|---|---|---|

| Pressure Testing | 1.5x PN rating | 1.25x PN rating | 20% higher safety margin; eliminates burst risks |

| UV Resistance | 5,000+ hours QUV test | 1,000–2,000 hours | 3x longer service life in direct sunlight |

| Solenoid Reliability | IP68, 1M cycles | IP54, 500k cycles | Zero failures in rain, dust, or extreme temps |

| Flow Control Accuracy | ±2% tolerance | ±5% tolerance | 15% less water waste; precise zone management |

| Certification | ISO 9001, CE, ANSI | Variable compliance | Seamless global integration; no regulatory delays |

Why BFV is the Trusted Export Partner

10-Year Global Export History: Successfully delivered to 50+ countries (EU, North America, Middle East, Asia-Pacific) with zero product recalls.

Technical Expertise: Dedicated engineering team provides project-specific valve selection, system integration support, and CAD drawings compliant with ISO 10208.

Supply Chain Reliability: 98% on-time delivery rate via JIT manufacturing; ISO 14001-certified logistics for carbon-neutral shipping.

Compliance Assurance: All products meet IEC 60529 (IP ratings), RoHS 2.0, and regional standards (e.g., NSF/ANSI 61 for potable water).

“BFV’s valves are the only irrigation isolation solutions we specify for high-value agricultural projects. Their 100% testing protocol and UV resistance eliminate the guesswork in harsh environments.”

— Lead Engineer, Tier-1 Landscape Contractor (USA)

Ready to future-proof your irrigation system?

Contact our export team for technical datasheets, project-specific quotes, and compliance documentation.

Email: export@bfvvalves.com | Phone: +86 577 8888 9999

Technical Specs & ISO Standards

Technical Specifications & Standards

Material Specifications

BFV irrigation isolation valves are engineered for durability across diverse environments:

Ductile Iron (ASTM A536 Grade 60-40-18): Optimized for high-stress irrigation systems, offering 30% higher tensile strength than standard cast iron and superior corrosion resistance.

Stainless Steel (304/316): Ideal for corrosive or potable water applications, with 316-grade variants for seawater or chemical exposure.

Cast Iron (ASTM A126 Class B): Used for non-critical applications where cost efficiency is prioritized (limited to PN10 ratings).

All materials undergo rigorous metallurgical analysis to ensure compliance with ISO 630 and ASTM standards.

Compliance with International Standards

BFV valves meet or exceed global regulatory requirements:

ANSI B16.34: Pressure-temperature ratings for flanged, threaded, and welded end valves.

DIN 3202: Flange dimensions and sealing performance for European markets.

BS 5150: Specifications for gate valve design and performance in UK/EU infrastructure projects.

ISO 7268: Precise PN10/16 pressure ratings validated for irrigation systems (10 bar/16 bar working pressure).

Rigorous Testing Protocols

Every BFV valve undergoes 100% factory testing to guarantee field reliability:

Hydrostatic Testing: 1.5x working pressure (e.g., 24 bar for PN16) for 15 minutes per ISO 5208 Class VI.

Air Leakage Testing: Zero leakage at 6 bar for 5 minutes (EN 12266-1 Class A).

UV Resistance Validation: Epoxy-coated bodies tested to 5,000+ hours of accelerated weathering (ASTM G154) for outdoor durability.

Quality Assurance Framework

ISO 9001 Certified: End-to-end quality control from raw material sourcing to final inspection.

10+ Years of Global Export: Consistent performance across 50+ countries, with documented case studies for irrigation projects in arid climates (e.g., UAE, Australia) and high-corrosion zones (e.g., coastal Europe).

Traceability: Full batch tracking via QR-coded serial numbers for rapid root-cause analysis if required.

BFV Certified Quality vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | ASTM A536 ductile iron (60-40-18) or 316 stainless steel; certified metallurgy reports | Cast iron with inconsistent composition; no third-party material verification |

| Testing Compliance | 100% hydrostatic & air testing per ISO 5208 Class VI | Partial testing (e.g., only hydrostatic); no air leakage validation |

| Standards Adherence | Full ANSI B16.34, DIN 3202, BS 5150 compliance | Partial compliance; often meets only basic local standards |

| UV Resistance | Epoxy powder coating (5,000+ hours ASTM G154) | Standard paint; degrades within 12–18 months of exposure |

| Quality Certification | ISO 9001 certified manufacturing processes | No formal quality management system |

| Warranty | 5-year limited warranty covering manufacturing defects | 1-year warranty with strict exclusions (e.g., UV damage) |

| Export Reliability | 10+ years servicing 50+ countries; documented project success in extreme climates | Limited export history; inconsistent quality in international markets |

Why This Matters: In irrigation systems, valve failures cause costly downtime, water waste, and infrastructure damage. BFV’s adherence to ISO 9001, 100% testing, and global standards ensures zero unexpected failures—critical for engineering consultants and contractors managing high-stakes projects. Our 10-year export track record proves reliability in real-world conditions, from desert irrigation networks to municipal water systems.

BFV Valves: Where precision meets longevity.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance: Precision Engineered for Reliability

Purpose-Built Test Zone: 100% Pre-Export Validation

Every BFV irrigation isolation valve undergoes 100% rigorous testing in our dedicated Purpose-Built Test Zone before shipment. This facility ensures full compliance with international standards through repeatable, precision-engineered procedures. Critical tests include:

| Test Parameter | Methodology | Pass/Fail Criteria | BFV Standard |

|---|---|---|---|

| Hydrostatic Pressure | 1.5× rated pressure for 2 minutes | Zero leakage, no deformation | PN16 (16 bar) minimum, tested at 24 bar |

| UV Resistance | ASTM G154, 500-hour accelerated exposure | No cracking, color fade <5% | UV-stabilized materials for 10+ years outdoor exposure |

| Solenoid Cycle Test | 10,000 cycles at 24V DC | 100% operational success | 500,000+ cycle design life |

| Flow Rate Verification | ISO 5208 Class A, rated pressure | ±2% deviation from specifications | Precision-engineered flow control |

| Leak Integrity | Helium mass spectrometer | ≤0.001 cc/sec leakage rate | Hermetic sealing for critical applications |

ISO 9001:2015 Certified Quality Management

BFV Valves operates under an ISO 9001:2015 certified Quality Management System, ensuring consistent product performance through documented processes, third-party audits, and continuous improvement protocols. This framework guarantees traceability from raw material sourcing to final shipment, providing engineering consultants and procurement managers with uncompromising confidence in every valve’s reliability.

Decade of Global Export Excellence

With over 10 years of international export experience, BFV has delivered irrigation solutions to 50+ countries across diverse climates and applications. Our valves have demonstrated exceptional performance in extreme environments—from arid deserts to tropical monsoons—with a 98.7% on-time delivery rate and zero recalls due to manufacturing defects.

Ethical Manufacturing Commitment

We uphold the highest ethical standards through:

Responsible sourcing: All suppliers vetted for sustainability and labor compliance (ILO standards).

Environmental adherence: RoHS, REACH, and WEEE compliance for all materials.

Transparency: Full supply chain visibility with third-party audits for social responsibility.

This commitment ensures our products meet global benchmarks for ethical and sustainable manufacturing—without compromising technical performance.

Global Applications

Industrial Applications of Irrigation Isolation Valves

Agriculture

Large-scale agricultural operations demand irrigation systems that deliver precise water distribution across vast fields while withstanding extreme environmental stressors. BFV’s irrigation isolation valves are engineered for agricultural excellence through:

Flow Control Accuracy: Advanced seat design ensures consistent shut-off and precise flow regulation, reducing water waste by up to 15% compared to standard valves.

UV Resistance: Polypropylene bodies with UV-stabilized additives prevent brittleness and cracking under prolonged sun exposure, critical for open-field installations.

Pressure Rating: Certified PN16 rating (16 bar / 232 psi) handles high-pressure systems common in center-pivot and drip irrigation setups.

Solenoid Reliability: Industrial-grade solenoids with 1 million cycle lifespan and IP68 protection ensure fail-safe operation in automated systems, minimizing downtime during critical growing seasons.

Landscape Projects

Commercial and residential landscape projects require valves that balance aesthetics with robust performance in high-visibility environments. BFV solutions excel here through:

Compact Design: Space-efficient body construction fits seamlessly into tight installation spaces without compromising flow efficiency.

UV and Weather Resistance: All external components are UV-resistant and corrosion-proof, ensuring longevity in exposed urban environments.

Flow Control Integration: Built-in adjustable flow control allows for precise watering of diverse plant types, from delicate flowers to dense shrubbery.

Pressure Handling: PN10 rating suitable for standard municipal water pressures, with optional PN16 variants for high-end commercial landscapes.

Golf Courses

Golf course irrigation systems demand unparalleled reliability due to the critical nature of turf health and high-traffic usage. BFV valves are trusted by top-tier courses for:

Precision Zoning: Fine-tuned flow control enables zone-specific watering schedules, maintaining optimal turf conditions across greens, fairways, and roughs.

Solenoid Durability: High-cycle solenoids with marine-grade stainless steel internals resist corrosion from chlorinated water and frequent cycling.

UV Protection: Full-body UV shielding prevents degradation from constant sun exposure, ensuring consistent performance even in open-course areas.

Pressure Stability: PN16 rating handles fluctuating pressures from large-scale pumping systems, with zero leakage during high-demand periods.

Greenhouse Systems

Greenhouse irrigation demands precision and reliability in controlled environments where water quality and consistency are paramount. BFV valves deliver:

Corrosion Resistance: 316 stainless steel components resist chemical degradation from fertilizers and hydroponic solutions.

Flow Control Accuracy: Micro-adjustable flow settings ensure exact water delivery for sensitive plant varieties, reducing overwatering risks.

UV-Resistant Housing: Transparent or opaque housing options with UV inhibitors maintain structural integrity under artificial lighting and glass roof exposure.

Low-Pressure Compatibility: Optimized for PN10 systems common in greenhouse setups, with precise shut-off to prevent water hammer in delicate piping networks.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants and Engineers

| Feature | Description | Benefit to Clients |

|---|---|---|

| 100% Testing | Every valve undergoes 100% pressure testing, leak testing, and operational validation prior to shipment | Eliminates field failures, reduces maintenance costs, and ensures immediate operational readiness |

| ISO 9001 Certified | Rigorous quality management system certified to international ISO 9001:2015 standards | Consistent product quality, traceability, and compliance with global engineering specifications |

| 10-Year Export History | Proven track record supplying to 50+ countries with localized technical support | Deep understanding of regional standards, seamless integration into global projects, and reliable after-sales service |

BFV Valves combines rigorous engineering, global compliance, and decades of export expertise to deliver irrigation isolation valves that meet the exacting standards of blue-chip engineering firms. Our commitment to zero-defect performance ensures your projects achieve maximum uptime, sustainability, and ROI—no matter the scale or complexity.

“When precision, durability, and global reliability are non-negotiable, BFV Valves delivers the safe pair of hands your project demands.”

Why Choose BFV Valves

Partner with BFV Valves: Precision, Reliability, and Global Expertise

BFV Valves (CMO Valve) delivers engineered irrigation isolation solutions designed for mission-critical applications. Our valves combine flow control accuracy, UV-resistant materials, solenoid reliability, and certified pressure ratings (PN10/16) to ensure seamless performance in harsh environments. With a decade of global export experience and ISO 9001-certified processes, we serve as your trusted technical partner for irrigation infrastructure projects worldwide.

Industry-Leading Quality Assurance

Every BFV irrigation isolation valve undergoes rigorous validation to exceed industry standards. Our commitment to quality is embedded in every stage of production:

| Feature | BFV Valves Standard | Key Benefit |

|---|---|---|

| 100% Performance Testing | Each unit tested for PN10/16 pressure integrity, flow calibration, and UV exposure resistance | Zero-defect delivery; reliable operation in extreme climates and high-solar environments |

| ISO 9001:2015 Certified | End-to-end quality management system validated by TÜV Rheinland | Consistent product excellence, traceable manufacturing processes, and compliance with global standards |

| 10+ Years Export History | 30+ countries served with localized technical support and regulatory alignment | Proven resilience across diverse project requirements (e.g., agricultural, municipal, commercial irrigation) |

Accurate Delivery Times Guaranteed

Predictable lead times: 15–25 days for standard orders, with expedited options for urgent projects

Real-time tracking: Integrated logistics platform providing shipment visibility from factory to site

Dedicated export team: Handling customs documentation, compliance checks, and delivery coordination to avoid delays

No-Obligation Technical Consultancy

Our engineering team provides free, no-commitment support for system design and valve selection:

Flow control optimization for precise water distribution (±1% accuracy)

Pressure rating validation for PN10/16 systems under dynamic load conditions

UV resistance testing reports and material compatibility analysis for long-term durability

Competitive Pricing with Transparent Value

Cost-optimized solutions: Economies of scale without compromising on materials (e.g., UV-stabilized POM, stainless steel internals)

Bulk order incentives: Tiered pricing for large-scale irrigation projects (e.g., municipal networks, golf courses)

Lifetime technical support: Post-installation troubleshooting and maintenance guidance included

Contact our regional export manager for project-specific solutions:

Alex@cmovalve.com.cn

Engineered for reliability. Delivered with precision.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.