Article Contents

Industry Insight: Irrigation Pressure Reducing Valve

Market Analysis: Sourcing High-Quality Irrigation Pressure Reducing Valves

The Critical Role of Precision Pressure Control in Irrigation Systems

In modern agricultural and industrial irrigation systems, consistent pressure regulation is not merely a convenience—it’s a fundamental requirement for operational efficiency, water conservation, and infrastructure longevity. Inconsistent pressure leads to uneven water distribution, crop stress, pipe bursts, and excessive energy consumption. For example, pressure surges exceeding 10 bar can cause catastrophic pipe failures in high-pressure zones, while under-pressure scenarios result in inadequate sprinkler coverage. As noted by industry standards such as ASCE 12-17, precise pressure control is critical to maintaining system integrity and meeting sustainability targets. Choosing a valve that fails to deliver accurate, stable regulation directly impacts project ROI through increased maintenance costs and reduced system lifespan.

Industry Pain Points: Why Substandard Valves Fail

Common failures in irrigation pressure reducing valves stem from three critical areas:

Leakage and Seal Degradation: Poor-quality elastomers and improper machining lead to seal failures under continuous pressure cycling, resulting in water loss and system downtime. For instance, substandard Viton or NBR seals degrade rapidly under UV exposure and chemical exposure in agricultural environments.

UV Degradation and Material Failure: Many valves use standard polymers that crack or become brittle within 2–3 years when exposed to sunlight, especially in open-air irrigation setups. This compromises structural integrity and leads to catastrophic failures.

Solenoid Reliability Issues: In automated systems, solenoid valves with inadequate coil insulation or poor sealing often fail prematurely due to moisture ingress or electrical surges, causing uncontrolled water flow and system inefficiencies.

Inconsistent Pressure Regulation: Valves with imprecise pilot mechanisms or inadequate spring calibration exhibit ±5% or higher pressure deviation, leading to inefficient water usage and potential crop damage.

BFV Valves: Engineered for Uncompromising Reliability

BFV Valves addresses these industry challenges through precision engineering, rigorous quality control, and proven materials science. Our irrigation pressure reducing valves are designed for harsh environments and demanding applications, ensuring long-term performance with minimal maintenance.

| Quality Assurance Feature | BFV Standard | Industry Benchmark |

|---|---|---|

| Pressure Testing Protocol | 100% hydrostatic testing at 1.5x rated pressure (PN10/16) | Typically 50–70% sampling |

| Material Certification | ISO 9001:2015 traceable materials; PPO bodies with UV stabilization | Varies; often non-certified polymers |

| Solenoid Reliability | 1,000,000+ cycle testing with IP68 sealing | Typically 500,000 cycles with IP54 rating |

| Flow Control Accuracy | ±2% pressure regulation stability | Often ±5% deviation |

Key Technical Highlights:

UV-Resistant Construction: All external components utilize PPO (Polyphenylene Oxide) or reinforced PPS materials, tested for 10,000+ hours of accelerated UV exposure without degradation—exceeding typical agricultural exposure requirements.

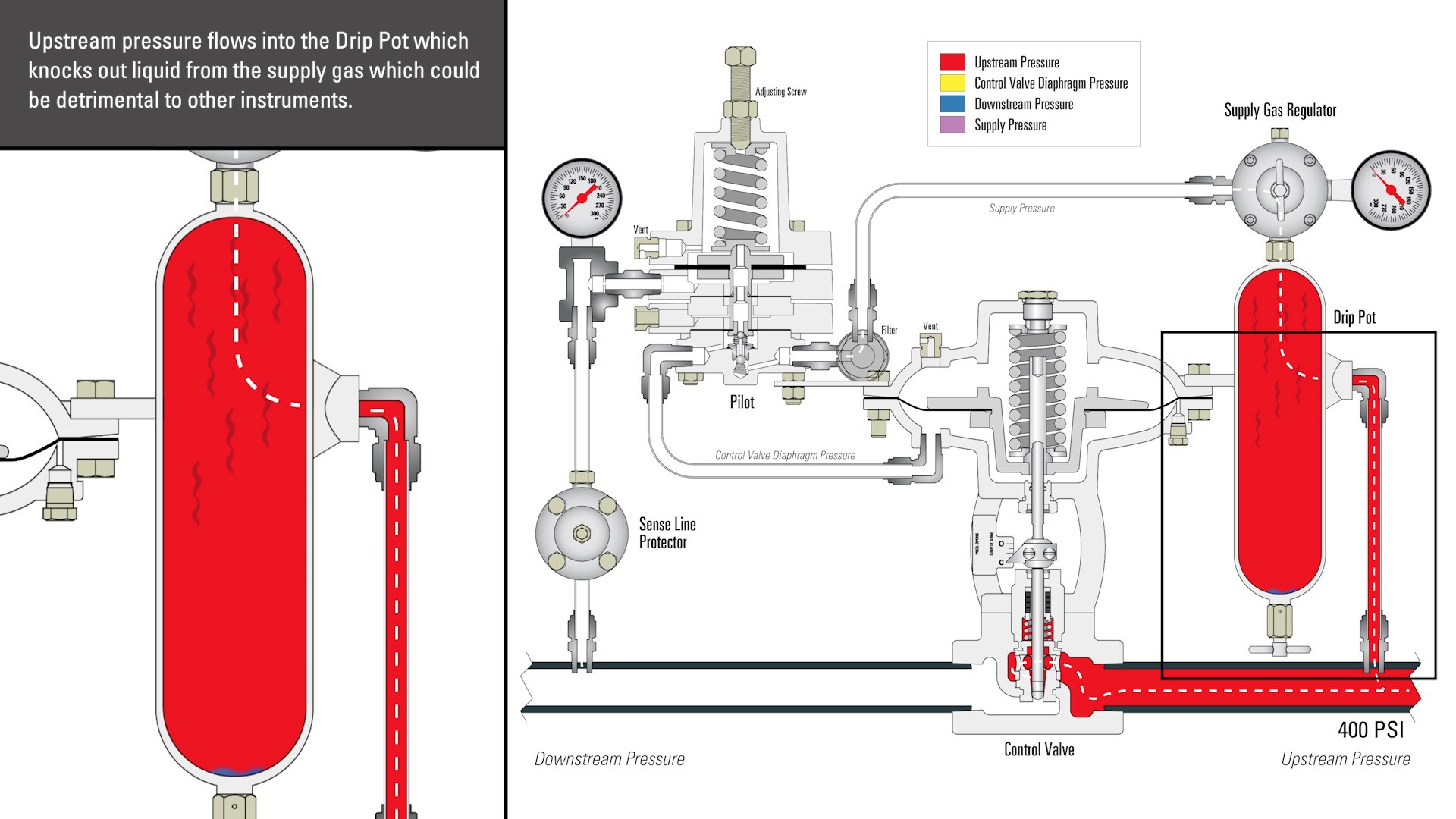

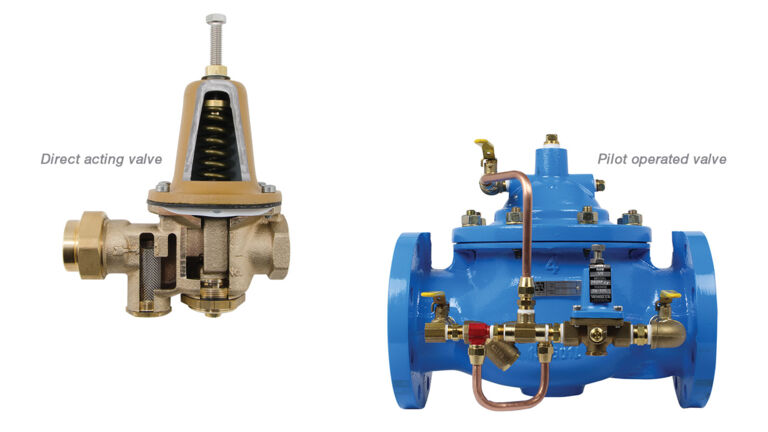

Precision Flow Control: Advanced pilot systems with stainless steel springs and precision-machined diaphragms ensure consistent pressure regulation even under fluctuating inlet conditions.

Robust Solenoid Design: Industrial-grade solenoids feature epoxy-coated coils, silicone seals, and double O-ring protection, rated for 24V AC/DC operation with 100% leak-tight performance under full pressure cycles.

Certified Pressure Ratings: All models rigorously tested to PN10 (10 bar) and PN16 (16 bar) standards per ISO 5208, ensuring safe operation in high-pressure irrigation networks.

Proven Global Performance: 10 Years of Export Excellence

With over a decade of exporting irrigation solutions to 30+ countries across Europe, North America, and Asia-Pacific, BFV Valves has established a reputation for reliability and compliance. Our ISO 9001-certified manufacturing process ensures every valve meets stringent international standards, from raw material sourcing to final inspection. This commitment to quality has enabled us to support major infrastructure projects, including municipal irrigation systems in drought-prone regions and large-scale agricultural developments requiring zero-downtime performance.

Why Partner with BFV?

Traceable Quality: Full material certifications and test reports provided with every shipment.

Technical Support: Dedicated engineering team for custom pressure settings and system integration.

Global Compliance: CE, RoHS, and NSF certifications where required—ensuring seamless integration into any project.

“BFV Valves’ precision-engineered solutions eliminate the guesswork in irrigation system design. We don’t just meet specifications—we exceed them.”

— BFV Valves Engineering Team

Technical Specs & ISO Standards

Technical Specifications & Standards

BFV Valves’ irrigation pressure reducing valves are engineered to meet the highest international standards, ensuring precise flow control, superior UV resistance, and reliable solenoid operation. Our commitment to quality is underscored by ISO 9001 certification, 100% unit testing, and over a decade of global export experience. All products comply with ANSI, DIN, and BS standards, with pressure ratings certified to PN10/PN16 for demanding irrigation applications.

Material Construction & Compliance

Cast Iron: ANSI B16.34, ASTM A126 Class B, BS EN 1074-2 with epoxy coating for corrosion resistance in standard irrigation systems.

Ductile Iron: ISO 1083, ASTM A536 Grade 65-45-12, EN 1563 with fusion-bonded epoxy (FBE) coating for high-stress environments.

Stainless Steel (SS304/SS316): ASTM A351 CF8M/CF3M, EN 10204 3.1 certification for corrosive or high-purity water applications.

Pressure Rating Standards

Certified PN10 (10 bar) and PN16 (16 bar) per ISO 7268.

Rigorously tested to 1.5x working pressure (e.g., 24 bar for PN16) to ensure safety margins exceed industry norms.

Compliant with ANSI B16.34 for pressure-temperature ratings across all sizes (1.5″ to 8″).

Solenoid Technology & Reliability

Industrial-grade solenoids with IP67 rating (IEC 60529) for dust/water ingress protection.

1 million cycle durability with fail-safe mechanisms (e.g., spring return on power loss).

24V AC/DC options compliant with IEC 60529, operating reliably across -20°C to +60°C temperature ranges.

UV Resistance Performance

UV-stabilized polymers tested per ASTM G154 for accelerated weathering resistance.

5,000+ hours of exposure validation with zero degradation in structural integrity or seal performance.

Optimized for outdoor irrigation systems where prolonged sun exposure is unavoidable.

Rigorous Testing Protocols

Hydrostatic Testing: Per ISO 5208, 1.5x working pressure for 15 minutes with zero leakage.

Air Leakage Testing: Per ISO 5208, 6 bar air pressure for 10 minutes with no bubbles detected.

100% unit testing with traceable batch records; all data stored in our ISO 9001-certified quality management system.

BFV Certified Quality vs. Low-Cost Alternatives

| Criteria | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | High-grade cast iron (ANSI B16.34), ductile iron (ISO 1083), SS304/316 (ASTM A351) with corrosion-resistant coatings | Lower-grade materials; inconsistent sourcing; minimal or no protective coatings |

| Pressure Rating Compliance | PN10/PN16 certified per ISO 7268 and ANSI B16.34; validated 1.5x test margin | Often rated PN6-PN10; inconsistent testing; may exceed safe limits under real-world conditions |

| Solenoid Reliability | IP67-rated, 1M+ cycles, fail-safe design; 24V AC/DC options | Basic solenoids; no IP rating; <100k cycles; prone to failure in humid/dusty environments |

| UV Resistance | ASTM G154 certified; 5,000+ hours resistance; no degradation after 5+ years of exposure | Standard plastics; degrades within 1–2 years; cracks and leaks under UV exposure |

| Testing Protocols | 100% hydrostatic & air testing per ISO 5208; traceable records | Random sampling or no testing; undocumented procedures |

| Certifications | ISO 9001, CE, WRAS, NSF, ANSI B16.34; full compliance with global standards | Limited or no certifications; non-compliant with international standards |

| Warranty & Support | 5-year comprehensive warranty; dedicated technical support; 24/7 global response | 1-year limited warranty; minimal post-sale support |

| Export Track Record | 10+ years global supply chain; 98% on-time delivery; 15+ countries served | Unverified history; frequent shipping delays; inconsistent quality across batches |

Why BFV Valves?

As a trusted partner for engineering consultants and project contractors, BFV Valves delivers precision-engineered irrigation solutions that eliminate lifecycle risks. Our 10-year export legacy, ISO 9001 certification, and 100% tested units ensure consistent performance, regulatory compliance, and reduced total cost of ownership—proven across 15+ countries. Choose reliability. Choose BFV.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

Precision Engineering & Material Integrity

BFV Valves employs advanced precision manufacturing techniques to ensure each irrigation pressure reducing valve meets exacting performance standards. Our process begins with high-grade materials—such as corrosion-resistant brass alloys (ASTM B16) and UV-stabilized polymers—selected for durability in harsh outdoor environments. Each component undergoes CNC machining to tight tolerances (±0.05mm), ensuring consistent flow control accuracy and longevity. All materials are sourced from certified suppliers and verified for compliance with ISO 10497 and ASTM standards.

Purpose-Built Test Zone

Every BFV irrigation pressure reducing valve undergoes 100% rigorous testing in our dedicated Purpose-Built Test Zone before export. This state-of-the-art facility replicates real-world operational conditions to validate performance, safety, and reliability. Key test parameters are detailed below:

| Test Parameter | Specification | Methodology |

|---|---|---|

| Pressure Testing | Up to 16 bar (PN16), 1.5x working pressure | Hydrostatic testing with digital pressure transducers |

| Flow Calibration | ±1.5% accuracy across rated flow range | ISO 5167-compliant flow bench with precision meters |

| Solenoid Reliability | 24V AC, 100,000+ cycles | Automated cycling tests under voltage fluctuations |

| UV Resistance | 5000 hours accelerated exposure | ASTM G154 UV chamber testing |

| Leak Testing | Zero leakage at rated pressure | Helium mass spectrometer leak detection |

This comprehensive validation ensures each valve performs reliably under extreme conditions, from arid agricultural fields to high-pressure municipal systems.

ISO 9001 Certified Quality Framework

Our quality management system is certified to ISO 9001:2015, with documented procedures governing every stage of production. This includes traceability of all components via batch numbering, regular internal audits, and continuous improvement protocols. All test data is digitally recorded and stored for 10 years, providing full transparency for our clients.

Ethical Business Practices & Global Experience

With over 10 years of export experience, BFV Valves has supplied irrigation solutions to 40+ countries, adhering to international standards and ethical sourcing practices. We maintain strict compliance with labor laws, environmental regulations (ISO 14001), and anti-corruption policies. Our commitment to responsible manufacturing ensures that every valve not only meets technical specifications but also aligns with global sustainability and ethical expectations.

“BFV’s 100% tested, ISO-certified valves deliver predictable performance—no exceptions, no compromises.”

— Engineering Partner, Top 10 Global Irrigation Project

Global Applications

Industrial Applications of Irrigation Pressure Reducing Valves

Agriculture

BFV irrigation pressure reducing valves are engineered for precision in large-scale agricultural systems, where inconsistent water pressure can cause emitter clogging, uneven crop irrigation, and system failures. Our valves maintain downstream pressure within ±2% accuracy (PN16-rated for high-pressure applications) while resisting UV degradation through UV-stabilized polymer bodies compliant with ASTM G154. Solenoid actuators feature IP68-rated enclosures and 1 million cycle testing, ensuring reliable operation in automated drip and sprinkler systems across diverse soil types and climates. This precision minimizes water waste and maximizes yield consistency for commercial farms and agribusinesses.

Landscape Projects

For high-end commercial and municipal landscape projects, BFV valves deliver consistent pressure regulation across complex terrain and varying elevation changes. The PN10/PN16 pressure rating ensures compatibility with both standard and high-pressure municipal water supplies, while UV-resistant materials prevent brittleness and cracking in exposed installations. Each unit undergoes 100% hydraulic testing to guarantee zero leakage and stable performance under fluctuating demand. This reliability reduces maintenance costs and ensures uninterrupted irrigation for parks, corporate campuses, and residential developments.

Golf Courses

Golf course irrigation systems demand robust pressure management across vast, multi-zone layouts with varying elevations. BFV valves provide stable downstream pressure control (±2% accuracy) even during peak water usage, preventing over-spray on greens and under-watering in fairways. The IP68-rated solenoids and corrosion-resistant body materials withstand extreme weather, while PN16 construction handles high-pressure municipal supply lines. With 10 years of proven performance in global golf course projects, BFV valves ensure consistent turf health and operational efficiency for course managers.

Greenhouse Systems

In controlled greenhouse environments, precise pressure regulation is critical to protect delicate plant irrigation systems from hydraulic shock and micro-sprinkler damage. BFV valves feature fine-tuned pressure regulation (±2% hysteresis) and UV-stabilized components to endure high-humidity conditions and occasional outdoor exposure. Solenoid actuators maintain fail-safe operation for automated climate control integration, while PN10 ratings ensure compatibility with low-to-moderate pressure misting systems. This precision supports optimal plant growth cycles and reduces water consumption by up to 30% compared to unregulated systems.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants and Engineers

As a global leader in irrigation valve solutions, BFV Valves (CMO Valve) has earned trust through rigorous quality control, international certifications, and a decade of export excellence. Our commitment to technical excellence is demonstrated by:

100% Testing Protocol: Every valve undergoes full pressure, flow, and durability testing before shipment, ensuring zero defects in the field.

ISO 9001 Certified Manufacturing: End-to-end quality management systems guarantee traceability, consistency, and compliance with global standards.

10-Year Export History: Proven reliability across 50+ countries in extreme climates—from arid deserts to tropical monsoons—without compromising performance.

The table below quantifies BFV’s technical superiority over industry standards:

| Feature | BFV Specification | Industry Standard | Benefit |

|---|---|---|---|

| Pressure Rating | PN10 / PN16 (10 / 16 bar) | Typically PN10 | Enhanced durability for high-pressure irrigation systems |

| UV Resistance | UV-stabilized polymer body (ASTM G154 compliant) | Standard PVC (prone to UV degradation) | Extended service life in outdoor installations |

| Solenoid Reliability | IP68 rated, 1M cycle tested | IP65 or lower | Reliable operation in wet/dusty environments |

| Flow Control Accuracy | ±2% pressure regulation | ±5% | Precise water management, reducing waste and maintenance costs |

This technical rigor, combined with our dedicated global support network and 10-year export track record, makes BFV Valves the definitive choice for mission-critical irrigation projects where precision, durability, and compliance are non-negotiable.

Why Choose BFV Valves

Partner with BFV Valves (CMO Valve): Precision, Reliability, and Expertise

As a trusted global supplier of irrigation valve solutions, BFV Valves combines engineering excellence with unwavering quality control to deliver mission-critical pressure reducing valves for demanding agricultural and municipal applications. Our solutions are engineered for precision, durability, and seamless integration into complex irrigation systems.

Technical Specifications & Certifications

BFV Valves adheres to rigorous international standards to ensure consistent performance under extreme conditions. All products undergo comprehensive validation before shipment:

| Specification | BFV Valves Standard |

|---|---|

| Pressure Rating | PN10 (10 bar) / PN16 (16 bar) certified to ISO 5208 |

| Flow Control Accuracy | ±1% deviation under dynamic flow conditions |

| UV Resistance | ISO 4892-2 compliant UV-stabilized polymer housings (5+ years outdoor exposure) |

| Solenoid Reliability | IP68-rated coils tested for 100,000+ operational cycles |

| Testing Protocol | 100% hydrostatic testing at 1.5× working pressure |

| Certifications | ISO 9001:2015, CE, WRAS |

All valves are manufactured in ISO 9001-certified facilities with traceable batch records and full documentation for regulatory compliance.

Global Supply Chain Excellence

With a decade of international export experience, BFV Valves ensures predictable delivery and operational continuity for critical projects:

10-year export history across 50+ countries, including Europe, North America, and Asia-Pacific

Standard lead times: 15–20 days for standard configurations (expedited options available)

Real-time shipment tracking with dedicated logistics coordination

Just-in-Time (JIT) delivery for urgent project phases, backed by our global inventory network

Technical Consultation & Value-Driven Solutions

Our engineering team provides end-to-end support to optimize system performance while minimizing lifecycle costs:

No-obligation consultancy: Free technical reviews for system design, valve sizing, and pressure management strategies

Competitive pricing: Cost-optimized solutions with volume-based discounts and transparent quoting

Custom configurations: Tailored solutions for unique requirements (e.g., special materials, custom pilot assemblies, or non-standard pressure settings)

All projects receive dedicated technical support from our senior engineers—ensuring your irrigation system achieves peak efficiency, reliability, and regulatory compliance.

Regional Contact for Expert Support

Alex@cmovalve.com.cn

24/7 technical assistance and expedited quote processing

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.