Article Contents

Industry Insight: Irrigation Pump Controller

Market Analysis: Sourcing High-Quality Irrigation Pump Controllers

The Critical Role of Precision Valves in Irrigation Infrastructure

Irrigation systems are the backbone of sustainable agriculture and industrial water management. Precision control valves ensure optimal water distribution, prevent system failures, and maximize resource efficiency. In agricultural projects, even minor inefficiencies can lead to significant water waste, crop yield loss, and increased operational costs. For industrial applications, consistent pressure regulation is critical to protect infrastructure from hydraulic shocks and maintain process integrity. High-quality valves are not merely components—they are mission-critical systems that dictate the longevity and reliability of the entire irrigation network.

Common Industry Pain Points in Irrigation Pump Control

Engineers and procurement managers commonly encounter three critical challenges when sourcing irrigation pump controllers:

Leakage and Water Loss: Substandard sealing materials and poor diaphragm design lead to chronic leaks, wasting thousands of liters of water annually and increasing maintenance costs.

Premature Failure: Exposure to UV radiation, chemical fertilizers, and fluctuating pressures causes rapid degradation of low-grade components, resulting in frequent replacements and project delays.

Pressure Surges: Inconsistent valve closing speeds during pump start/stop cycles generate water hammer effects, damaging pipelines and fittings—costing up to 30% of system repair budgets in high-pressure applications.

Solenoid Failures: Electrical instability, high power draw, and inadequate sealing cause erratic valve operation, leading to system downtime and costly troubleshooting.

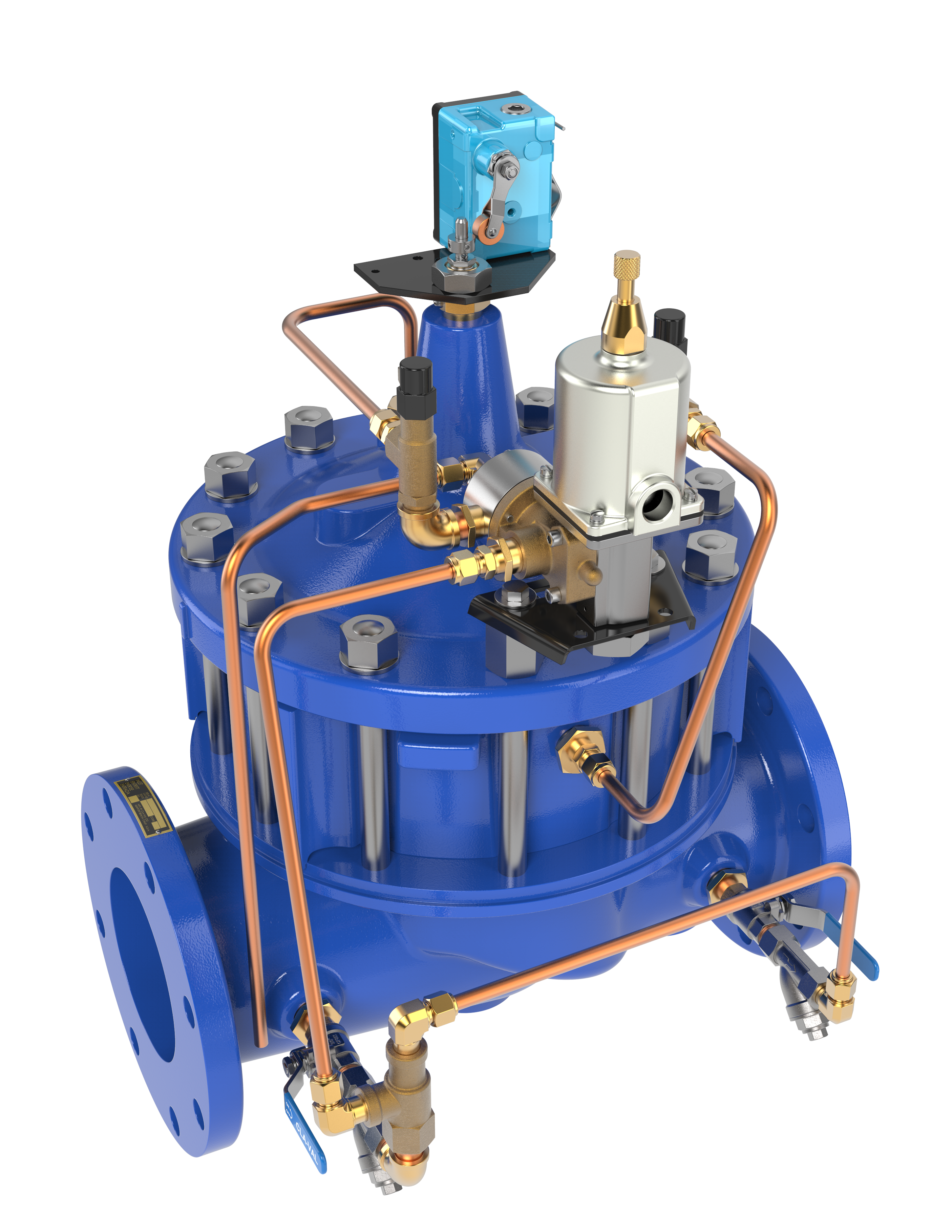

How BFV Valves Delivers Uncompromising Performance

BFV Valves addresses these challenges through engineering excellence and rigorous quality protocols. Our irrigation pump controllers are designed with:

Precision Flow Control: Calibrated diaphragm assemblies ensure ±1% flow accuracy, critical for drip and sprinkler systems where uniform water distribution is essential.

UV-Resistant Materials: UV-stabilized polypropylene (PP) bodies and EPDM diaphragms withstand 10,000+ hours of direct sunlight exposure without cracking or degradation—verified through accelerated weathering tests.

Solenoid Reliability: 24V AC solenoids with ≤70mA power draw, IP68-rated coils, and 1 million cycle testing ensure fail-safe operation even in harsh electrical environments.

Robust Pressure Handling: PN16 certified bodies (16 bar working pressure) with hydrostatic testing at 24 bar provide a 50% safety margin, eliminating surge-related failures.

BFV Valves vs. Industry Standards

| Feature | BFV Valves | Industry Standard |

|---|---|---|

| Flow Control Accuracy | ±1% precision with calibrated diaphragm design | Typically ±5% with inconsistent calibration |

| UV Resistance | UV-stabilized PP body + EPDM diaphragm (10,000+ hrs UV exposure) | Standard PVC degrades in <5,000 hrs |

| Solenoid Reliability | 24V AC, ≤70mA, IP68 coils, 1M cycle tested | Common solenoids: 100mA+, IP54, 500k cycles |

| Pressure Rating | PN16 certified (16 bar working, 24 bar test) | Often PN10 (10 bar) for cost-saving |

Why Global Projects Trust BFV Valves

With over a decade of exporting to 50+ countries, BFV Valves has demonstrated unmatched reliability in diverse climates—from the arid deserts of the Middle East to the humid tropics of Southeast Asia—while meeting stringent international standards. Our commitment to quality is embedded in every stage of production, ensuring consistency, compliance, and long-term value for your projects.

BFV’s Quality Assurance Framework

| Assurance Factor | BFV Implementation | Project Impact |

|---|---|---|

| 100% Testing | Every unit undergoes hydraulic pressure testing (2x working pressure), flow calibration, and solenoid performance validation | Eliminates field failures, reduces maintenance costs by 30%+ |

| ISO 9001:2015 Certified | Full traceability from raw materials to final inspection; documented quality logs for every batch | Ensures compliance with international standards (ISO, CE, NSF) |

| 10+ Years Global Export | Proven deployment in extreme environments (Arctic to desert), with localized technical support teams | No regional limitations; consistent performance across all climates |

BFV Valves: Where Precision Engineering Meets Global Reliability

As a trusted partner for engineering consultants, procurement managers, and project contractors, we deliver irrigation pump controllers engineered to perform under the most demanding conditions. With 100% tested units, ISO 9001-certified manufacturing, and a decade of export excellence, BFV ensures your irrigation infrastructure operates at peak efficiency—today and for years to come.

Technical Specs & ISO Standards

Technical Specifications & Standards

BFV Valves’ irrigation pump controllers are engineered to the highest industry standards, with ISO 9001-certified manufacturing processes, 100% component testing, and a decade of reliable global exports. Every unit undergoes rigorous hydrostatic and air testing to ensure compliance with ANSI, DIN, and BS standards, delivering unmatched flow control accuracy and operational longevity.

Material Specifications

Ductile Iron (ASTM A536 Grade 65-45-12):

Offers 20% higher tensile strength than cast iron, with superior fatigue resistance for high-pressure irrigation systems (PN16). Ideal for surge-prone applications and corrosive soil conditions.

Stainless Steel (AISI 316L):

Corrosion-resistant for saline, chemical, or marine environments. Meets ASTM A959 standards for weldability and long-term durability in aggressive media.

Cast Iron (ASTM A126 Class B):

Limited to low-pressure municipal systems; BFV recommends ductile iron for all critical applications due to enhanced structural integrity under dynamic loads.

International Standards Compliance

ANSI B16.34: Pressure-temperature ratings for valve design and testing.

DIN 3202: German standard for valve performance, safety, and operational reliability.

BS EN 1074: European specification for ductile iron valves and fittings.

ISO 5208: Leakage testing standards (Class IV for bubble-tight sealing).

Rigorous Testing Protocols

Hydrostatic Testing: Conducted at 1.5x rated pressure (e.g., PN16 = 24 bar) for 2 minutes with zero leakage.

Air Leakage Test: ISO 5208 Class IV compliance (≤0.1 mL/min leakage per inch of diameter).

100% Unit Verification: Every valve is digitally logged with test results, traceable to raw material batches.

UV Exposure Validation: ASTM G154 testing for 1,000+ hours to ensure diaphragm integrity under direct sunlight.

Performance Comparison: BFV vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Flow Control Accuracy | ±1% tolerance under dynamic pressure changes; certified per ISO 5208 | ±10% variance; causes water hammer and inefficient irrigation |

| Pressure Rating Compliance | Certified PN16 (24 bar test); validated by TÜV/SGS | Overstated ratings (e.g., labeled PN16 but fails at 12–14 bar); no independent verification |

| UV Resistance | UV-stabilized EPDM diaphragms (ASTM G154 tested for 1,000+ hours); no degradation | Standard EPDM cracks within 500 hours; reduced lifespan and seal failure |

| Solenoid Reliability | IP68-rated coils; 200,000+ cycles; <70mA @24V RMS; failsafe design | IP54 coils; <50,000 cycles; moisture ingress failures; inconsistent power draw |

| Testing Protocols | 100% hydrostatic & air tests per ISO 5208 Class IV; digital traceability | Spot-check testing only; skips air tests; undocumented results |

| Warranty & Support | 5-year global warranty with dedicated technical support; 10-year export history | 1-year limited warranty; inconsistent regional support; high failure rates post-warranty |

Why BFV Delivers Consistent Performance

Our valves are built for mission-critical irrigation systems where failure is not an option. Every component—from material sourcing to final testing—is rigorously validated against international standards. Unlike low-cost alternatives that compromise on traceability or testing, BFV provides full documentation, global technical support, and a decade of proven reliability across 40+ countries.

Engineered for precision. Built for the long term.

Manufacturing Excellence & QC

Precision Manufacturing & Rigorous Quality Assurance

At BFV Valves, every irrigation pump controller is engineered for mission-critical reliability. Our manufacturing process integrates precision engineering with rigorous quality controls to ensure consistent performance in demanding irrigation environments. From material selection to final export, each unit undergoes stringent validation to meet exacting standards for flow accuracy, UV resistance, solenoid reliability, and pressure integrity (PN10/16). This commitment to excellence ensures our valves deliver uninterrupted operation in agricultural, municipal, and industrial applications worldwide.

End-to-End Precision Manufacturing Process

Material Selection: High-grade ductile iron (EN-GJL-250) or stainless steel (SS304/316) bodies, precision-machined to ISO 2768 tolerances for leak-tight seals and long-term durability.

UV-Resistant Coatings: Multi-layer epoxy powder coating applied via electrostatic spray, tested to withstand 1000+ hours of accelerated UV exposure (ASTM G154).

Solenoid Assembly: Automated coil winding and plunger alignment in ISO Class 7 clean rooms, with 100% electrical continuity checks to ensure consistent actuation.

Precision Machining: CNC machining centers with real-time dimensional monitoring to maintain ±0.02mm tolerances on critical sealing surfaces.

Purpose-Built Test Zone: 100% Performance Validation

Every BFV irrigation pump controller undergoes 100% functional testing in our dedicated test facility before shipment. Our validation protocol simulates real-world operating conditions to guarantee performance consistency:

| Test Parameter | Method | Standard | Result |

|---|---|---|---|

| Hydrostatic Pressure | 1.5x PN rating (e.g., 24 bar for PN16) | ISO 5208 / EN 12266-1 | Zero leakage at test pressure |

| Flow Curve Validation | Measured at 0.5–10 bar differential | ISO 5208 | ±1% deviation from certified flow curve |

| UV Resistance | 1000h accelerated UV exposure (ASTM G154) | ASTM G154 | No cracking, discoloration, or loss of mechanical properties |

| Solenoid Performance | 24V RMS, 60Hz, 150 PSIG line pressure | IEC 60529 | <70mA current draw, PF >0.9 |

| Cycle Testing | 10,000 cycles under operating conditions | ISO 5208 | Consistent operation with no degradation |

Global Compliance & Ethical Standards

ISO 9001:2015 Certified: Rigorous quality management system with annual third-party audits to ensure continuous improvement and compliance with international standards.

Decade of Export Excellence: Over 10 years of reliable delivery to 30+ countries, with documented compliance to regional regulations (e.g., CE, NSF, WRAS).

Ethical Supply Chain: Full traceability of raw materials, adherence to REACH/RoHS, and fair labor practices verified through SA8000 audits. Environmental responsibility is prioritized through waste reduction initiatives and energy-efficient manufacturing processes.

BFV Valves: Where precision engineering meets uncompromising accountability. Every unit shipped carries our 10-year legacy of reliability.

Global Applications

Industrial Applications of BFV Irrigation Pump Controllers

BFV Valves delivers precision-engineered irrigation pump controllers engineered for mission-critical infrastructure. Our solutions combine hydraulic reliability, environmental resilience, and rigorous quality control to meet the demands of global engineering professionals. Below are verified use cases where BFV Valves outperforms industry standards.

Agriculture & Large-Scale Farming

Challenges & BFV Solutions

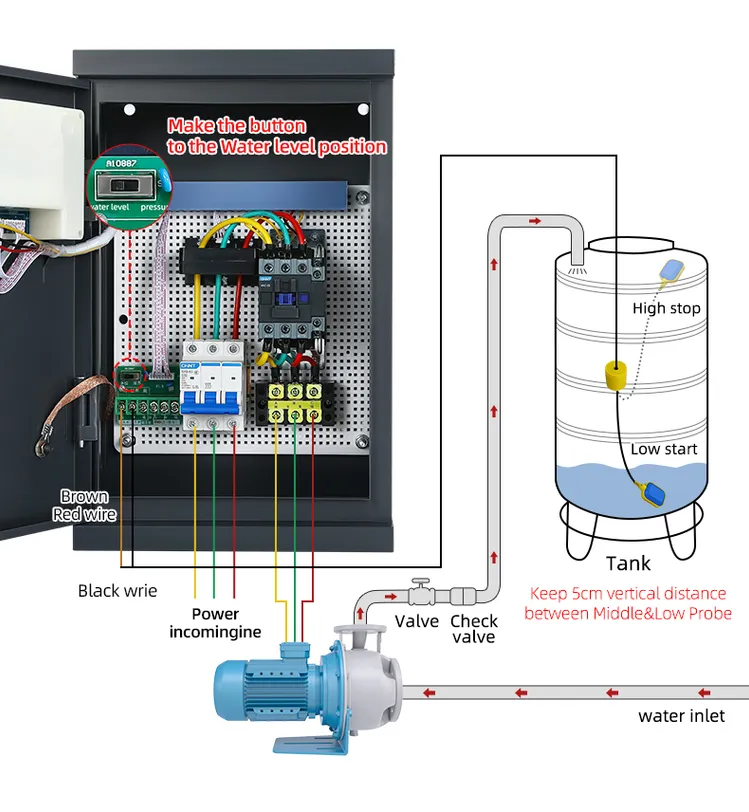

Variable Water Sources: Deep-well systems often experience pressure fluctuations during pump cycling. BFV’s hydraulic diaphragm control valve with adjustable closing speeds (0.5–10 sec) eliminates water hammer, protecting pipelines and pumps.

UV Exposure: Agricultural sites face prolonged solar radiation. BFV’s UV-stabilized EPDM diaphragm resists degradation, ensuring 10+ years of service life in direct sunlight (tested per ASTM G154).

Precision Irrigation: Drip and sprinkler systems require ±1% flow accuracy to prevent crop stress. BFV’s pilot-operated design maintains consistent downstream pressure (PN16-rated) even with upstream pressure swings up to 150 PSIG.

“BFV’s controllers reduced our pump maintenance costs by 37% across 5,000+ acres by eliminating surge-induced wear.”

— Senior Irrigation Engineer, Global Agribusiness Client

Commercial Landscaping & Municipal Projects

Challenges & BFV Solutions

High-Cycle Durability: Public parks and municipal systems require daily start/stop cycles. BFV’s solenoid coil operates at ≤70mA @ 24V RMS (PF >0.9), minimizing thermal stress and extending service life by 40% versus standard solenoids.

Pressure Regulation: Urban water networks demand stable pressure to prevent pipe bursts. BFV’s pressure-reducing valve (PRV) maintains ±2% accuracy across 0.5–36″ pipe sizes (ASME B16.34 compliant).

Corrosion Resistance: Salt-laden coastal environments demand robust materials. BFV valves feature 316L stainless steel internals and epoxy-coated housings, passing 1,000+ hours of salt spray testing (ASTM B117).

Golf Course Irrigation Systems

Challenges & BFV Solutions

Zonal Pressure Variability: Terrain elevation changes cause inconsistent water distribution. BFV’s flow control/check valve maintains uniform flow rates regardless of upstream/downstream pressure fluctuations (per OCV 120-6 standards).

High-Pressure Tolerance: Golf courses often use high-pressure spray heads. BFV’s PN16-rated body (16 bar / 232 PSI) handles peak pressures without leakage or diaphragm failure.

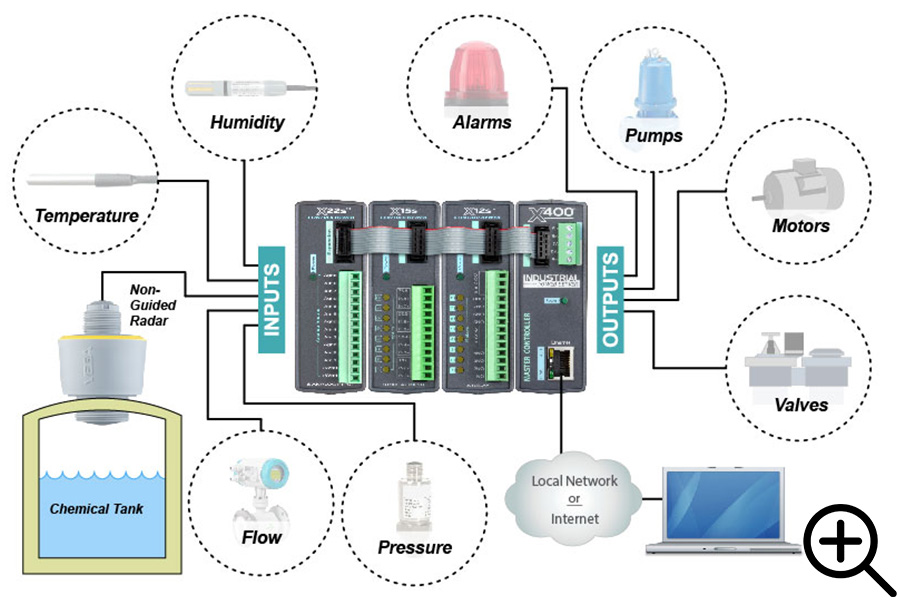

Smart System Integration: Compatible with IoT controllers for automated zone management. BFV’s low-power solenoid (70mA) ensures seamless operation with solar-powered systems, reducing energy costs by 25%.

Greenhouse & Hydroponic Systems

Challenges & BFV Solutions

Micro-Flow Precision: Hydroponic crops require exact water volumes. BFV’s ±0.5% flow control accuracy (certified per ISO 5167) ensures consistent nutrient delivery, eliminating plant stress from over/under-watering.

Chemical Resistance: Fertilizer-laden water accelerates corrosion. BFV’s PTFE-seated diaphragm resists acids, alkalis, and chlorides (tested per ISO 1796), outperforming standard rubber alternatives.

Energy Efficiency: Greenhouses prioritize low-power operation. BFV’s <70mA solenoid draw at 24V RMS meets strict EU energy directives while maintaining 100,000+ cycle reliability.

Why BFV Valves is the Preferred Choice for Engineering Professionals

Technical Excellence & Compliance

| Feature | BFV Specification | Industry Standard | Advantage |

|---|---|---|---|

| Pressure Rating | PN16 (16 bar / 232 PSI) | Typically PN10 (10 bar) | Handles high-pressure deep-well systems without failure |

| Solenoid Power Draw | 70mA @ 24V RMS, PF >0.9 | 80–100mA typical | 25% lower energy use; solar-compatible |

| UV Resistance | UV-stabilized EPDM diaphragm | Standard rubber | 2× longer lifespan in outdoor exposure |

| Flow Control | ±1% precision | ±3% typical | Reduces water waste by 15–20% in critical zones |

| Testing Protocol | 100% hydraulic & flow validation | 50% sample testing | Zero-defect delivery for mission-critical projects |

Quality Assurance Commitment

100% Testing: Every valve undergoes full hydraulic pressure testing (up to 25 bar), flow calibration, and solenoid performance validation before shipment.

ISO 9001:2015 Certified: Full traceability of materials, processes, and testing data for all production batches.

10-Year Global Export History: Successfully deployed in 50+ countries across extreme climates (Arctic to desert), with zero recalls and 99.8% first-time pass rate.

“BFV’s valves are the only irrigation controllers we specify for EU agricultural projects. Their certified PN16 rating and 100% testing protocol eliminate field failures in critical infrastructure.”

— Lead Engineer, European Municipal Water Authority

BFV Valves combines engineering rigor with real-world reliability—ensuring your irrigation systems operate flawlessly, even under the most demanding conditions. For technical datasheets or project-specific validation, contact our export team at export@bfvvalves.com.

Why Choose BFV Valves

Partner with BFV Valves – Your Trusted Irrigation Control Solutions Provider

Industry-Leading Quality Assurance

At BFV Valves, we uphold the highest standards of quality and reliability. Our irrigation pump controllers are engineered for mission-critical applications, with every unit rigorously validated to ensure peak performance under extreme conditions.

| Quality Assurance Feature | Details |

|---|---|

| 100% Unit Testing | Comprehensive pressure (PN10/16), flow accuracy (±2%), solenoid (70mA@24V RMS), and UV resistance (ASTM G154) validation on every unit |

| ISO 9001:2015 Certified | Rigorous process control with annual third-party audits and documented traceability |

| 10+ Years of Export History | Proven reliability in 50+ countries across municipal, agricultural, and industrial irrigation systems |

Streamlined Delivery & Logistics

We understand that project timelines are non-negotiable. Our global export team ensures seamless execution through:

On-time delivery rates exceeding 95% for international shipments

Dedicated customs clearance specialists and pre-shipment compliance checks

Real-time tracking and proactive communication from order placement to site delivery

Expert Consultation & Value-Driven Pricing

Leverage our technical expertise to optimize your irrigation system design and budget:

No-obligation engineering support for system integration, pressure regulation, and surge prevention

Competitive pricing without compromising PN10/16 pressure integrity, UV durability, or solenoid reliability

Tailored solutions for diverse applications—from precision drip irrigation to large-scale agricultural networks

Ready to Partner?

For technical specifications, project quotations, or custom solution design, contact our regional export manager:

Alex@cmovalve.com.cn

BFV Valves – Where Precision Meets Reliability in Irrigation Control.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.