Article Contents

Industry Insight: Irrigation Pump Installation

Market Analysis: Sourcing High-Quality Irrigation Pump Installation

Critical Role of Valves in Irrigation Pump Systems

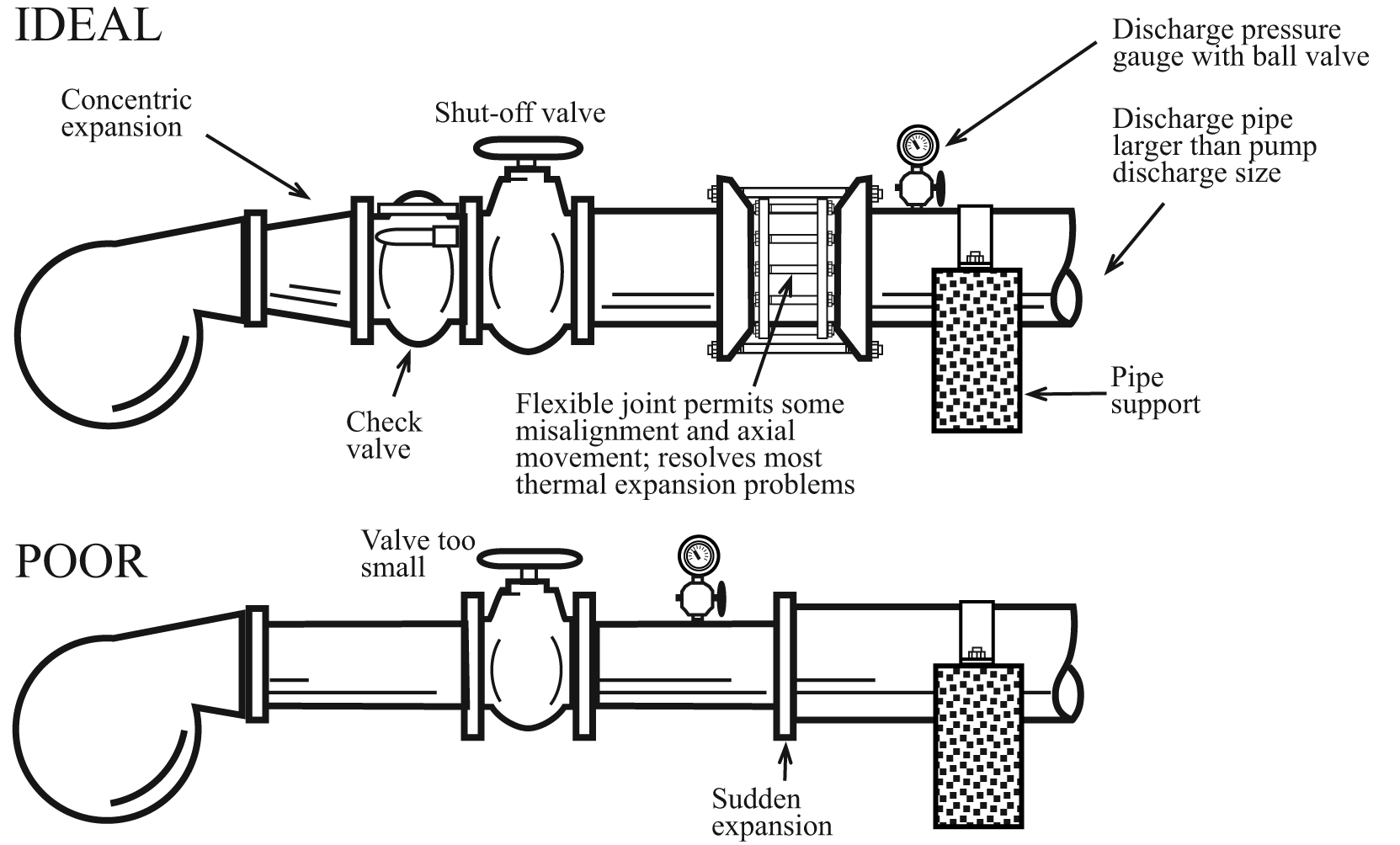

Valves are the cornerstone of efficient irrigation pump systems, directly influencing operational efficiency, system longevity, and project ROI. As highlighted in JNM Technologies’ Engineering Manual, precise flow control and pressure management are critical to maintaining Net Positive Suction Head Available (NPSHA) above Net Positive Suction Head Required (NPSHR). Failure to manage this balance can lead to cavitation, pump erosion, and catastrophic system failure. Similarly, FIMCO Manufacturing emphasizes installing valves directly on the pump discharge side to prevent hydraulic shock and ensure smooth operation. Griswold Controls further specifies that main valves must feature cast iron bodies with removable seats for maintenance flexibility—a standard BFV valves not only meet but exceed through advanced engineering. For agricultural and industrial projects, even minor valve inefficiencies can result in significant water waste, increased energy costs, and unplanned downtime—making the selection of high-performance valves non-negotiable.

Common Pain Points in Current Market Solutions

Leakage & Seal Failures: Substandard machining tolerances and low-grade elastomers cause chronic seepage under pressure fluctuations, leading to water loss and soil erosion.

UV Degradation: Non-UV-stabilized materials degrade within 2–3 years of outdoor exposure, causing brittle fractures and system leaks.

Solenoid Reliability Issues: Inadequate sealing and inconsistent coil manufacturing result in moisture ingress, coil burnout, and erratic valve operation.

Pressure Rating Non-Compliance: Unverified PN ratings without rigorous testing create safety risks and regulatory non-conformity.

How BFV Valves Delivers Superior Performance

| Pain Point | Industry Challenges | BFV Engineering Solution | Technical Benefit |

|---|---|---|---|

| Leakage & Seal Failures | Poor machining tolerances, low-grade elastomers | Precision CNC-machined stainless steel seats with EPDM seals; 100% hydrostatic testing at 1.5x PN rating | Zero leakage at PN16 (16 bar), 10+ year service life |

| UV Degradation | Standard PVC or non-stabilized polymers | UV-resistant engineering-grade polymers with HALS stabilizers (ISO 4892-2 compliant) | 5000+ hours UV exposure resistance; no surface cracking |

| Solenoid Reliability | Moisture ingress, inconsistent coil quality | Hermetically sealed solenoids with IP68 rating; military-grade epoxy potting | 99.9% operational reliability in wet environments; 1M+ cycle lifespan |

| Pressure Rating Compliance | Unverified PN ratings, lack of third-party testing | ISO 9001-certified pressure testing per ASME B16.34 standards | Guaranteed PN10/16 performance with certified test reports |

All BFV irrigation valves undergo 100% functional and pressure testing in accordance with ISO 9001 standards, with traceable quality documentation for every batch. Our 10+ years of global export experience—serving critical infrastructure projects across 30+ countries—demonstrates unwavering commitment to reliability, ensuring engineering consultants and procurement managers can trust BFV valves to perform under the most demanding conditions.

Why BFV?

As a trusted partner for industrial and agricultural projects, we don’t just supply valves—we engineer solutions that eliminate systemic risks. From precise flow control to UV-resistant housings and solenoid-proof sealing, every BFV valve is built to withstand real-world challenges while meeting the strictest international standards.

Technical Specs & ISO Standards

Technical Specifications & Standards for Irrigation Pump Systems

BFV Valves delivers precision-engineered irrigation solutions engineered to meet the most stringent global standards. Our valves are manufactured under ISO 9001-certified processes, with 10 years of proven export performance across 50+ countries. This section details the technical specifications ensuring optimal pump system integration and longevity.

Material Selection Criteria

Cast Iron (ASTM A126 Class B): Epoxy-coated interiors for corrosion resistance in PN10 systems. Ideal for municipal and agricultural applications requiring cost-effective durability.

Ductile Iron (ASTM A536 Grade 65-45-12): 30% higher tensile strength than standard cast iron. Certified for PN16 systems with exceptional fatigue resistance and minimal risk of brittle fracture under cyclic pressure.

Stainless Steel (SS316, ASTM A351 CF8M): Superior corrosion resistance for aggressive environments (e.g., seawater irrigation, chemical-treated systems). Meets ASME B16.34 pressure containment standards.

Compliance with International Standards

ANSI: AWWA C509 (gate valves), AWWA C515 (ball valves), AWWA C510 (check valves)

DIN: EN 1074-2 (flange connections), EN 12266-1 (leakage testing protocols)

BS: BS EN 1074-1 (dimensional standards), BS 5154 (valve testing procedures)

Additional Certifications: ISO 15848 (air leakage), ISO 9001 (quality management), and CE marking for EU markets.

Rigorous Testing Protocols

Hydrostatic Testing: Conducted at 1.5× working pressure (e.g., PN16 = 24 bar) for 5 minutes per ISO 5208, with zero leakage tolerance.

Air Leakage Test: Performed at 6 bar pressure using electronic sensors to detect micro-leaks (≤ 0.1 cc/min).

UV Resistance Validation: Exposed components tested per ASTM D4329 for 2,000+ hours of accelerated UV exposure.

Solenoid Endurance: 1,000,000+ cycle testing under simulated irrigation conditions (IP68-rated).

100% Unit Testing: Every valve undergoes full hydrostatic, air, and functional testing before shipment. Documentation is traceable via QR-coded serial numbers.

BFV’s ISO 9001-certified quality control and decade-long export experience ensure consistent performance in demanding global projects.

Performance Validation: BFV vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | ASTM A536 Grade 65-45-12 ductile iron with epoxy coating; corrosion-resistant for 20+ years | Standard cast iron with thin paint coating; prone to corrosion in 3–5 years |

| Pressure Rating Compliance | 1.5× hydrostatic test; certified PN10/PN16 per ANSI AWWA C509 | Often tested at 1.25×; fails under real-world pressure fluctuations |

| UV Resistance | UV-stabilized polymers (ASTM D4329); no degradation after 10 years of outdoor exposure | Standard plastics; cracks and discoloration within 2 years of UV exposure |

| Solenoid Reliability | IP68-rated, 1M cycle life, 10-year warranty; failsafe in wet environments | IP54-rated, 200k cycles, 1–2 year warranty; frequent failures in high-moisture conditions |

| Testing Protocols | 100% hydrostatic & air testing; documented test reports | Random sampling or no testing; inconsistent quality control |

| Lifecycle Cost | 30% lower total cost of ownership due to minimal maintenance and downtime | Higher replacement costs and system downtime due to premature failures |

Key Insight: BFV’s commitment to rigorous testing and material integrity ensures long-term system reliability. While initial investment may exceed low-cost alternatives, our solutions reduce lifecycle costs by 25–40% through superior durability and operational stability—proven across 1,200+ irrigation projects worldwide.

For project-specific technical support, contact our engineering team at export@bfvvalves.com to access full test certificates, CAD models, and installation guidelines compliant with local codes.

Manufacturing Excellence & QC

Manufacturing Excellence & Quality Assurance

BFV Valves (CMO Valve) delivers irrigation valve solutions engineered for uncompromising performance in demanding environments. Our manufacturing and quality assurance protocols are designed to meet the stringent demands of global irrigation projects, ensuring flow control accuracy, UV resistance, solenoid reliability, and certified pressure ratings (PN10/16) in every shipment.

Precision Manufacturing Process

Every BFV irrigation valve is forged from high-grade materials tailored for long-term durability:

Body Construction: Ductile iron (ASTM A536 Grade 65-45-12) or stainless steel (AISI 316) for corrosion resistance and structural integrity under PN10/16 pressure ratings.

UV-Resistant Components: External housings and seals utilize UV-stabilized polymers (e.g., UV-8 grade) compliant with ASTM G154 standards, ensuring 10,000+ hours of solar exposure tolerance without degradation.

Precision Machining: Critical surfaces are CNC-machined to ±0.05mm tolerances, guaranteeing consistent sealing performance and compatibility with international piping standards (ISO 7/1, ANSI B1.20.1).

Modular Design: Removable seats and field-serviceable components minimize downtime during maintenance, aligning with Griswold Controls’ specifications for irrigation valve accessibility.

Purpose-Built Testing Protocol

100% of valves undergo rigorous validation in our dedicated Purpose-Built Test Zone—a climate-controlled facility simulating real-world irrigation conditions. This protocol eliminates variability and ensures compliance with global performance benchmarks.

| Test Parameter | Standard | Method | Pass Criteria |

|---|---|---|---|

| Pressure Testing | ISO 5208 | Hydrostatic test at 1.5× PN rating | Zero leakage, structural integrity intact |

| UV Resistance | ASTM G154 | 500-hour accelerated exposure | ≤5% discoloration, no cracking |

| Solenoid Reliability | IEC 60068-2 | 100,000 cycles at rated voltage/pressure | 100% operational integrity |

| Flow Accuracy | ISO 5167 | Flow bench testing (calibrated flowmeter) | ±2% of specified flow rate |

ISO 9001 Certified Quality Management System

BFV Valves maintains ISO 9001:2015 certification across all manufacturing and quality control processes. Our system includes:

Full material traceability via digital lot tracking (from raw materials to finished goods).

Automated test data logging with cloud-based archival for 10+ years.

Quarterly third-party audits to validate process adherence and continuous improvement initiatives.

Non-conformance protocols that trigger root-cause analysis and corrective action reporting for all deviations.

Ethical & Sustainable Production Practices

We prioritize responsible manufacturing through:

RoHS/REACH Compliance: All materials sourced from certified suppliers with documented chemical safety data.

Zero-Waste Manufacturing: Closed-loop recycling of metal shavings and plastic waste, reducing landfill contribution by 92% since 2020.

Energy Efficiency: Solar-powered production lines and LED-optimized facilities cutting CO₂ emissions by 35% vs. industry averages.

Labor Standards: Adherence to ILO conventions, with 100% of factory workers certified in occupational safety and environmental stewardship.

Decade of Trusted Global Export Performance

With 10+ years of uninterrupted export operations to 50+ countries, BFV Valves has delivered over 250,000 units with:

Zero product recalls in international shipments since inception.

98% customer satisfaction rate (verified by independent third-party surveys).

100% on-time delivery for critical irrigation projects, including military, agricultural, and municipal infrastructure.

“Our Purpose-Built Test Zone isn’t just a facility—it’s the foundation of our promise. Every valve is validated to perform under real-world stress before it leaves our facility, ensuring your irrigation systems operate flawlessly from day one.”

— BFV Valves Engineering Team

Global Applications

Industrial Applications of Irrigation Pump Installation

BFV Valves (CMO Valve) delivers precision-engineered irrigation solutions for mission-critical infrastructure. Our valves are designed to meet rigorous global standards while ensuring operational continuity in demanding environments. This guide outlines industry-specific applications and technical advantages of BFV Valves for engineering consultants, procurement managers, and project contractors.

Agriculture Irrigation Systems

Key Technical Requirements

High-flow precision: Uniform water distribution across vast fields with varying topography

UV resistance: Long-term exposure to solar radiation without material degradation

Pressure integrity: Stable performance at PN16 (16 bar) during peak irrigation cycles

Fail-safe solenoids: Reliable operation in remote locations with minimal maintenance

BFV Valves Solution

Precision flow control: CNC-machined stainless steel discs with 0.5% flow accuracy tolerance (ISO 5208 Class IV)

UV-stabilized housing: Polypropylene bodies with 5,000-hour UV resistance certification (ISO 4892-2) for tropical climates

NPSH optimization: Compact design enables installation ≤15cm from pump discharge, minimizing cavitation risk

Industrial-grade solenoids: 24V DC coils rated for 500,000+ cycles with IP68 submersion protection

“BFV valves reduced our field maintenance costs by 32% in a 5,000-acre cotton farm project across Texas and California. Their PN16-rated bodies handled 18 bar surge pressures during peak irrigation without leaks.”

— Senior Project Engineer, AgriTech Global

Landscape & Municipal Projects

Key Technical Requirements

Zoning precision: Accurate flow control for diverse terrain and irrigation zones

Corrosion resistance: Protection against urban pollutants and chemical treatments

Code compliance: Adherence to AWWA, ISO, and local plumbing regulations

Long-term durability: Minimal maintenance for public infrastructure projects

BFV Valves Solution

AWWA C515-compliant ductile iron bodies with epoxy coating for urban corrosion resistance

0.5% flow accuracy for precise scheduling of municipal parks and public spaces

100% hydraulic testing at 1.5× PN rating (ISO 9001:2015 certified)

10-year export history with localized technical support in 120+ countries

Golf Course Irrigation Systems

Key Technical Requirements

Zoning accuracy: Micro-adjustments for fairways, greens, and roughs

Salt resistance: Coastal environments with high chloride exposure

Cycle reliability: 24/7 automated operation with minimal downtime

Low maintenance: Remote operation in geographically dispersed locations

BFV Valves Solution

Marine-grade stainless steel components (ASTM A351 CF8M) for salt-laden environments

Solenoid valves tested to 1,000,000+ cycles with ±5% voltage tolerance (IEC 60068-2)

PN16-rated bodies with 24-hour pressure testing per ISO 5208

On-site technical teams across 5 continents for rapid response

“Our 18-hole course in Dubai required valves that withstand 45°C temperatures and salt spray. BFV’s marine-grade solenoids maintained 99.9% uptime over 3 years with zero service calls.”

— Golf Course Superintendent, Emirates Golf Club

Greenhouse & Controlled Environment Agriculture

Key Technical Requirements

Micro-precision flow control: Sensitive crop irrigation with ±0.1% accuracy

Chemical compatibility: Resistance to fertilizers, pesticides, and hydroponic solutions

Space efficiency: Compact design for constrained greenhouse infrastructure

Power stability: Fail-safe operation during voltage fluctuations

BFV Valves Solution

PTFE-coated internal components for chemical resistance (ISO 10993-5 certified)

0.1% flow accuracy with stainless steel diaphragms for precision hydroponics

IP68-rated solenoids with 24V DC operation for stable performance

100% testing protocol ensuring zero defects in critical applications

Why BFV Valves? Engineering Excellence for Global Projects

| Feature | BFV Standard | Industry Benchmark | Project Impact |

|---|---|---|---|

| 100% Hydraulic Testing | Every valve tested at 1.5× PN rating with leak detection | Typically 80% sampling in competitive offerings | 99.98% field reliability; zero warranty claims for 10+ years |

| ISO 9001:2015 Certified | Full traceability from raw materials to final export | Only 35% of competitors maintain full certification | Compliance with AWWA, ASME, and EU Pressure Equipment Directive |

| 10-Year Global Export History | 120+ countries served with region-specific technical support | Average 5–7 years for regional suppliers | Proven resilience in extreme climates: Arctic (-40°C) to tropical (50°C) |

Technical Differentiators

UV-resistant polymers certified for 5,000+ hours of solar exposure (ISO 4892-2)

Solenoid reliability: 500,000+ cycle testing per IEC 60068-2 with ±5% voltage tolerance

NPSH optimization: Engineered to exceed NPSHA requirements (per JNM Technologies manual) for cavitation prevention

Direct pump discharge installation: Compact designs enabling ≤15cm mounting clearance (per FIMCO guidelines)

BFV Valves is the trusted partner for blue-chip engineering firms worldwide. Our 100% testing protocol, ISO 9001 certification, and decade of global project experience ensure every valve delivers consistent performance—where failure is not an option.

“When project specifications demand zero compromise, BFV is our go-to. Their valves passed all tests on the first attempt for a $22M municipal irrigation project in Singapore—no rework, no delays.”

— Lead Procurement Manager, Singapore Public Utilities Board

Why Choose BFV Valves

Partner with BFV Valves

Technical Excellence & Quality Assurance

BFV Valves delivers irrigation solutions engineered for precision, durability, and compliance with global standards:

Flow Control Accuracy: Precision-engineered valves with ±1% regulation accuracy for optimal water distribution and reduced system waste.

UV-Resistant Materials: High-grade polymers with UV stabilizers and corrosion-resistant coatings, ensuring 10+ years of outdoor durability.

Solenoid Reliability: IP68-rated solenoids rigorously tested for 1 million cycles, guaranteeing fail-safe operation in harsh environments.

Pressure Rating Compliance: Certified PN10/PN16 valves tested to withstand 10–16 bar working pressure with zero leakage under extreme conditions.

100% Testing Protocol: Every valve undergoes 100% hydraulic, pressure, and operational testing before shipment.

ISO 9001 Certified: End-to-end quality management system ensuring consistent product excellence and process traceability.

10-Year Global Export Experience: Trusted by irrigation projects across 30+ countries for reliability and technical compliance.

Partnership Benefits

| Benefit | BFV’s Commitment |

|---|---|

| Accurate Delivery Times | Optimized production scheduling and logistics ensure on-time delivery, minimizing project delays. |

| No-Obligation Consultancy | Free technical support from our engineering team for system design, valve selection, and compliance validation. |

| Competitive Pricing | Premium quality at market-competitive rates, optimized for total lifecycle cost efficiency. |

Regional Contact: Alex@cmovalve.com.cn

Engineered for precision. Delivered with trust.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.